Page 1

I-VICFLEX.AQC-UINSTALLATION INSTRUCTIONS

Victaulic® VicFlex™ Style AQC-U Sprinkler Fitting

for Cleanroom Applications

I-VICFLEX.AQC-U_1

REV_B

Maximum Working Pressure:

200 psi/14 Bar/1379 kPa (FM Approval)

Maximum Ambient Temperature Rating:

225° F/107° C

Connection to Branch Line:

1 inch/25 mm NPT/BSPT

Minimum Bend Radius:

6 inch/152 mm (FM Approval)

Maximum K-Factor of Sprinkler to be Connected to the Style AQC-U:

5.6 US/80 metric

Maximum Number of 90° Bends:

Refer to the “Style AQC-U Friction Loss Data” section below

Style AQC-U Friction Loss Data

Length

inches/mm

NPT/BSPT

Sprinkler End

inches

Maximum

Number

of 90° Bends

Equivalent Length

of 1-inch /33.7-m m

Schedule 40 Pipe

feet/meters

36

½ 2

24.0

915 7. 3

48

½ 3

31.5

122 0 9.6

72

½ 4

46.6

1830 14. 2

* M+W Zander Facility Engineering GmbH is a company of the

M+W Group

‡ SBB Gorilla Grid is a product of SBB, Inc.

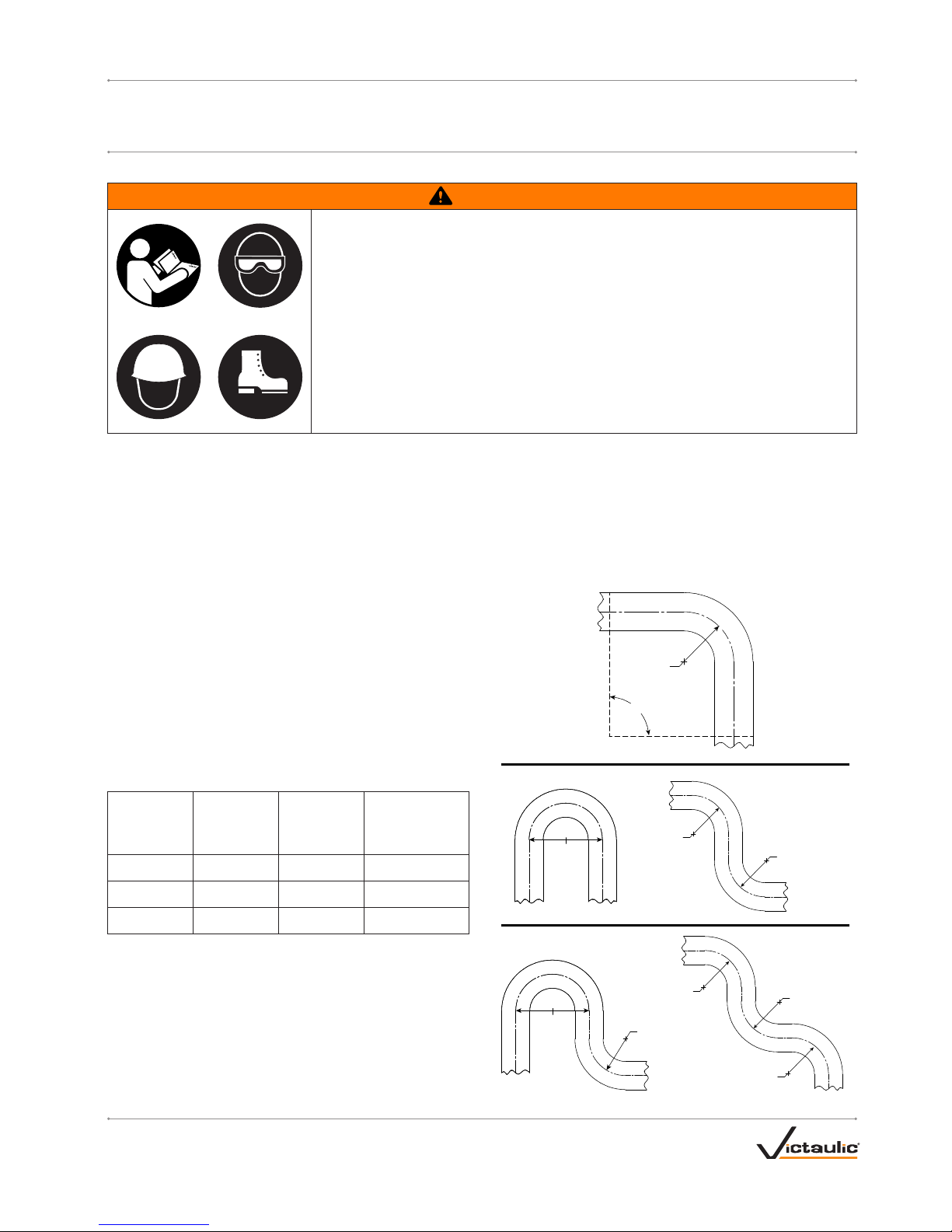

Flexible Hose Bend Characteristics:

NOTE: For out-of-plane (three-dimensional) bends, care shall be

taken to avoid imparting torque on the flexible hose.

90°

OR

OR

Minimum

Bend Radius

Minimum

Bend Radius

Minimum

Bend Radius

Minimum

Bend Radius

Minimum

Bend Radius

Minimum

Bend Radius

Minimum

Bend Radius

2X

Minimum

Bend

Radius

2X

Minimum

Bend

Radius

WARNING

• Read and understand all instructions before attempting to install any Victaulic® VicFlex™ products.

• Wear safety glasses, hardhat, and foot protection.

• These installation instructions are intended for an experienced, trained installer.

• The user shall understand the purpose of these products, c ommon industry standards for safety,

and the potential consequences of improper product installation.

• It is the system designer’s responsibility to verify suitability of stainless steel flexible hose for use

with the intended fluid media within the piping system and external environment.

• The effect of chemical composition, pH level, operating temperature, chloride level, oxygen level,

and flow rate on the stainless steel flexible hose shall be evaluated by the material specifier to

confirm system life will be acceptable for the intended service.

Failure to follow these instructions could cause improper sprinkler operation and product failure,

resulting in death or serious personal injury and property damage.

Victaulic® VicFlex™ Style AQC-U Sprinkler Fittings connect the branch line directly to the sprinkler and are FM Approved for use with the

M+W Zander Facility Engineering GmbH* and SBB Gorilla Grid‡ cleanroom ceiling systems. Other cleanroom ceilings can be evaluated on a

case-by-case basis by contacting Victaulic.

Page 2

I-VICFLEX.AQC-U_2

REV_B

I-VICFLEX.AQC-U / Victaulic® VicFlex™ Style AQC-U Sprinkler Fitting for Cleanroom Applications / Installation Instructions

IMPORTANT INSTALLATION INFORMATION

• The installer shall wear proper cleanroom attire during installation

of the Victaulic® VicFlex™ Style AQC-U. Contact the building owner

or their representative to confirm requirements for the specific

cleanroom application.

• Victaulic® VicFlex™ products shall be installed according to

current, applicable National Fire Protection Association (NFPA

13, 13D, 13R, etc.) standards or equivalent standards. Victaulic®

VicFlex™ products are intended to be installed in wet, dry, or

preaction actuated systems. Deviations from these standards or

alterations to Victaulic® VicFlex™ products or sprinklers will void

any Victaulic warranty and will impact system integrity. Installations

shall meet the provisions of the local authorit y having jurisdiction

and local codes, as applicable.

• Victaulic® VicFlex™ Style AQC-U Sprinkler Fittings shall not be

intermixed with other manufacturer’s flexible sprinkler products.

• Refer to the specific Victaulic product submittal for applications

and listing information. In addition, when installing Victaulic

FireLock® Automatic Sprinklers with Victaulic® VicFlex™

Sprinkler Fittings, refer to the I-40 Installation and Maintenance

Instructions for details on sprinkler installation requirements.

Submittals and installation instructions can be downloaded at

victaulic.com.

• Size the piping system to provide at least the minimum required

flow rate for the sprinkler system.

• Per NFPA requirements, flush the system to remove foreign

material. Continue to flush the system until water runs clear.

• DO NOT install sprinkler system piping through heating ducts.

• DO NOT connect sprinkler system piping to domestic hot water

systems.

• DO NOT install sprinklers and sprinkler fittings where they will

be exposed to temperatures that exceed the maximum ambient

temperature rating for the sprinkler and sprinkler fittings.

• The flexible hose shall not be bent or fluctuated up-and-down or

side-to-side when it is pressurized.

• Flexible hose and fittings have limited flexibility* and are

intended only to be installed with bends not less than their

respective minimum bend radii. DO NOT install flexible hose in

a straight configuration.

• Protect wet piping systems from freezing temperatures.

• If construction is altered, refer to applicable standards to determine

if additional sprinklers are required.

• The owner is responsible for maintaining the fire protection system

in proper operating condition.

• For minimum maintenance and inspection requirements, refer to

NFPA 25 and any other applicable NFPA standards that describe

the care and maintenance of sprinkler systems. In addition, the

authority having jurisdiction may have additional maintenance,

testing, and inspection requirements that shall be followed.

WARNING

• Relocation of Victaulic® VicFlex™ products SHALL be performed

by qualified personnel familiar with the system’s original design

criteria, sprinkler listings/ approvals, and state and local codes

(including NFPA 13 standards).

Failure to relocate this Victaulic® VicFlex™ product properly could

affect its performance during a fire, resulting in serious personal

injury and property damage.

* Reference UL 2443: Section 25.1

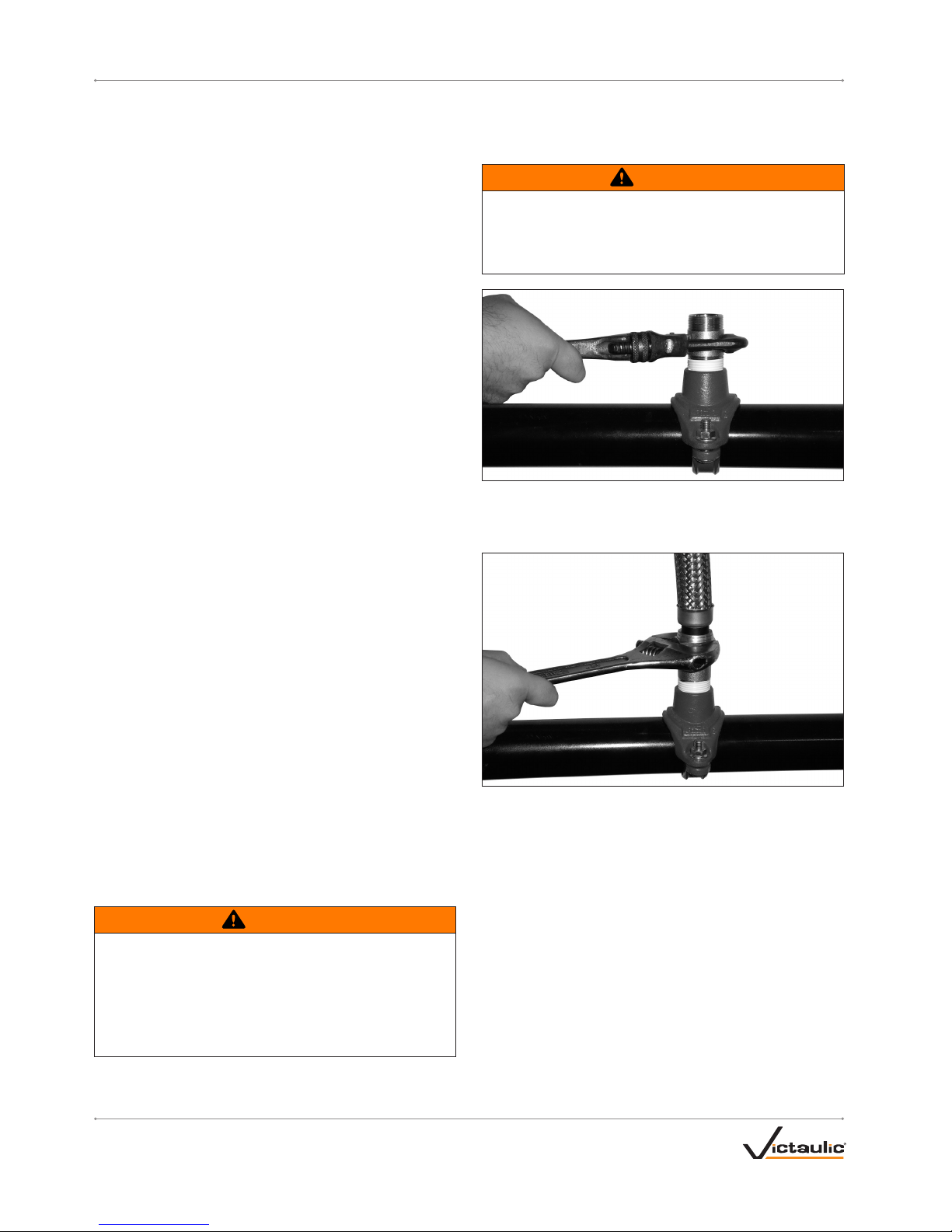

CONNECTION TO THE SPRINKLER PIPING

USING AN ADAPTER NIPPLE AND A

STYLE AQC-U SPRINKLER FITTING

WARNING

• The flexible hose shall not be bent or fluctuated up-and-down or

side-to-side when it is pressurized for test.

Failure to follow this instruction could cause improper sprinkler

operation, serious personal injury, and/or property damage.

1. Apply pipe joint compound or PTFE thread sealant tape to the

tapered threads of the adapter nipple, in accordance with the pipe

joint compound or tape manufacturer’s instructions. Using a pipe

wrench, tighten the adapter nipple into the sprinkler piping.

2. Confirm that the seal inside the nut of the Style AQC-U is in place

and is free from damage prior to installation. Connect the nut to

the adapter nipple, as shown above.

• DO NOT use pipe joint compound or PTFE thread sealant tape on

the threads of the adapter nipple. The seal inside the nut of the

Style AQC-U provides the leak-proof connection.

• Tighten the connection nut to a torque of 40 ft-lbs/54 N•m

(approximately ½ to ¾ of a turn past hand-tight). NOTE: To prevent

damage to the seal, tighten the assembly by applying torque only

to the connection nut and DO NOT exceed the specified torque.

Page 3

I-VICFLEX.AQC-U_3

REV_B

I-VICFLEX.AQC-U / Victaulic® VicFlex™ Style AQC-U Sprinkler Fitting for Cleanroom Applications / Installation Instructions

ATTACHING THE STYLE AQC-U TO THE CLEANROOM CEILING GRID

* Components provided by ceiling grid manufacturer

or others.

Exploded View of

Installation Components

Ceiling Grid*

Cross Block*

Sprinkler with Bulb Protector*

T-Bolt*

Gasket

Nut*

Swivel Bracket

Nut*

T-Bolt*

Lock Washer*

Flat Washer*

Lock Washer*

Flat Washer*

Gasket

Completed

Installation

Flexible Hose

NOTICE

• If the sprinkler deflector or bulb protector appears too large to pass through the cross block location, it may be necessary to install the

sprinkler after the Style AQC-U is tightened to the ceiling grid.

1. Slide a T-Bolt (supplied with the ceiling grid) into the slot of the two opposing ceiling grid sections, as shown in the drawing above.

2. Insert the Victaulic® VicFlex™ Style AQC-U assembly into the cross block location.

3. Align the holes in the swivel bracket of the Victaulic® VicFlex™ Style AQC-U with the T-Bolts. Secure the swivel bracket to the ceiling grid by

installing a flat washer, lock washer, and nut (supplied with the ceiling grid) onto the end of each T-Bolt. To ensure a rigid connection, tighten

each nut until the lock washer is flattened completely.

4. Position the two gaskets, indicated in the drawing above, to seal the ceiling penetration.

5. Install any ceiling grid face plates, sprinkler escutcheons, elastic decorative rings or covers, etc. Use caution to prevent damage to the sprinkler

during installation of any accessories.

6. After installation is complete, test the system for leaks in accordance with NFPA guidelines.

Page 4

I-VICFLEX.AQC-UINSTALLATION INSTRUCTIONS

Victaulic® VicFlex™ Style AQC-U Sprinkler Fitting

for Cleanroom Applications

For complete contact information, visit victaulic.com

I-VICFLEX.AQC-U 9353 REV B UPDATED 06/2018 Z000AQCU00

VICTAULIC AND VICFLEX ARE REGISTERED TRADEMARKS OR TRADEMARKS OF VICTAULIC COMPANY AND/OR ITS AFFILIATED ENTITIES

IN THE UNITED STATES AND/OR OTHER COUNTRIES. © 2018 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

Loading...

Loading...