Victaulic Vic-300 MasterSeal 761 Series, Vic-300 MasterSeal 461 Series Installation And Maintenance Instructions Manual

Page 1

Series 761 Vic-300® MasterSeal™ Carbon Steel Butterfly Valve

Series 461 Vic-300

®

MasterSeal™ Stainless Steel Butterfly Valve

I-VIC300MSINSTALLATION AND MAINTENANCE INSTRUCTIONS

SERI ES 7 61 SERI ES 4 61

WARNING

• Read and understand all instructions before attempting to install, remove, adjust, or maintain any Victaulic piping products.

• Depressurize and drain the piping system before attempting to install, remove, adjust, or maintain any Victaulic piping products.

• Wear safety glasses, hardhat, foot protection, and hearing protection.

Failure to follow instructions and warnings could cause system failure, resulting in death or serious personal injury and property damage.

victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2014 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

REV_F

I-VIC300MS

Page 2

I-VIC300MS / Vic-300® MasterSeal™ Butterfly Valves / Installation and Maintenance Instructions

TABLE OF CONTENTS

Hazard Identification ......................................1

Butterfly Valve Components.................................2

Installation Information.....................................3

Vic-Flange® Adapter Notes .................................3

System-Related Considerations ..............................3

Prevention of Stainless Steel Product Contamination ..............3

Stem Seal Replacement for 2 - 12-inch/60.3 - 323.9-mm Valves .....4

Setting the Memory Stop Feature on 2 - 6-inch/60.3 - 168.3-mm

Valves with 10-Position Handles ...........................6

Using the Infinitely Variable Feature on 2 - 6-inch/60.3 - 168.3-mm

Valves with 10-Position Handles ...........................6

Memory Stop Feature on 8-inch/219.1-mm Valves with

Lever Lock Handles .....................................7

“A” - Setting the Memory Stop Feature on 8-inch/219.1-mm

Valves with Lever Lock Handles ............................7

“B” - Setting the Memory Stop Feature on 8-inch/219.1-mm

Valves with Lever Lock Handles ............................9

10-Position Handle Removal for 2 - 6-inch/60.3 - 168.3-mm

Valves ..............................................10

Lever Lock Handle Removal for 8-inch/219.1-mm Valves..........12

Tamper-Resistant Handle Kit Installation for 2 - 6 -inch/

60.3 - 168.3-mm Valves with 10-Position Handles ............14

Tamper-Resistant Handle Kit Installation for 8-inch/219.1-mm

Valves with Lever Lock Handles ...........................17

Telescopic Handle Kit Installation for 10 - 12-inch/

273.0 - 323.9-mm Series 761 Valves.......................19

Gear Operator Installation for 2 - 12-inch/

60.3 - 323.9-mm Valves ................................22

Adjusting and Setting the Closed Travel Limit Stops

of the Gear Operator

Adjusting and Setting the Open Travel Limit Stops

of the Gear Operator

Memory Stop Kit Installation for 2 - 12-inch/60.3 - 323.9-mm

Gear-Operated Valves ..................................25

Thermal Barrier Kit Installation for 2 - 12-inch/

60.3 - 323.9-mm Valves ................................27

Insulation Extension Kit for 2 - 8-inch/60.3 - 219.1-mm

Gear-Operated Valves ..................................28

Insulation Extension Kit Installation for 2 - 8-inch/60.3 - 219.1-mm

Gear-Operated Valves ..................................29

Insulation Extension Kit for 2 - 6-inch/6 0.3 - 168.3-mm

Valves with 10-Position Handles ..........................30

Insulation Extension Kit Installation for 2 - 6-inch/60.3 - 168.3-mm

Valves with 10-Position Handles .......................... 31

Insulation Extension Kit for 8-inch/219.1-mm Valves

with Lever Lock Handles ................................32

Insulation Extension Kit Installation for 8-inch/219.1-mm Valves

with Lever Lock Handles ................................33

...................................24

...................................24

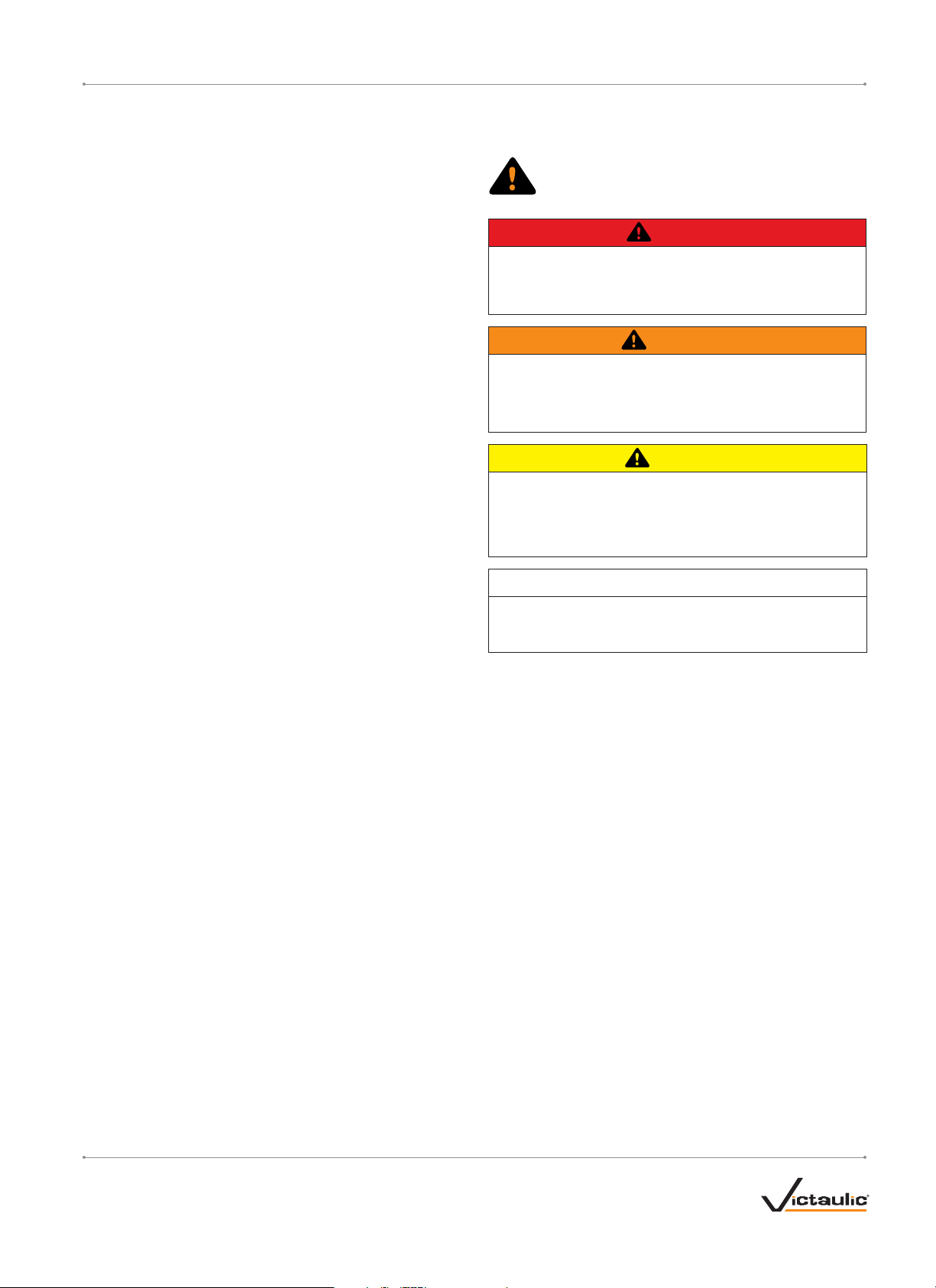

HAZARD IDENTIFICATION

Definitions for identifying the various hazard levels are

provided below. When you see this symbol, be alert to the

possibility of personal injury. Carefully read and fully

u nderstand the message that follows.

DANGER

• The use of the word “DANGER” identifies an immediate

hazard with a likelihood of death or serious personal injury

if instructions, including recommended precautions, are not

followed.

WARNING

• The use of the word “WARNING” identifies the presence

of hazards or unsafe practices that could result in death or

serious personal injury if instructions, including recommended

precautions, are not followed.

CAUTION

• The use of the word “CAUTION” identifies possible hazards or

unsafe practices that could result in personal injury and product

or property damage if instructions, including recommended

precautions, are not followed.

NOTICE

• The use of the word “NOTICE” identifies special instructions

that are important but not related to hazards.

victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2014 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

REV_F

I-VIC300MS_1

Page 3

I-VIC300MS / Vic-300® MasterSeal™ Butterfly Valves / Installation and Maintenance Instructions

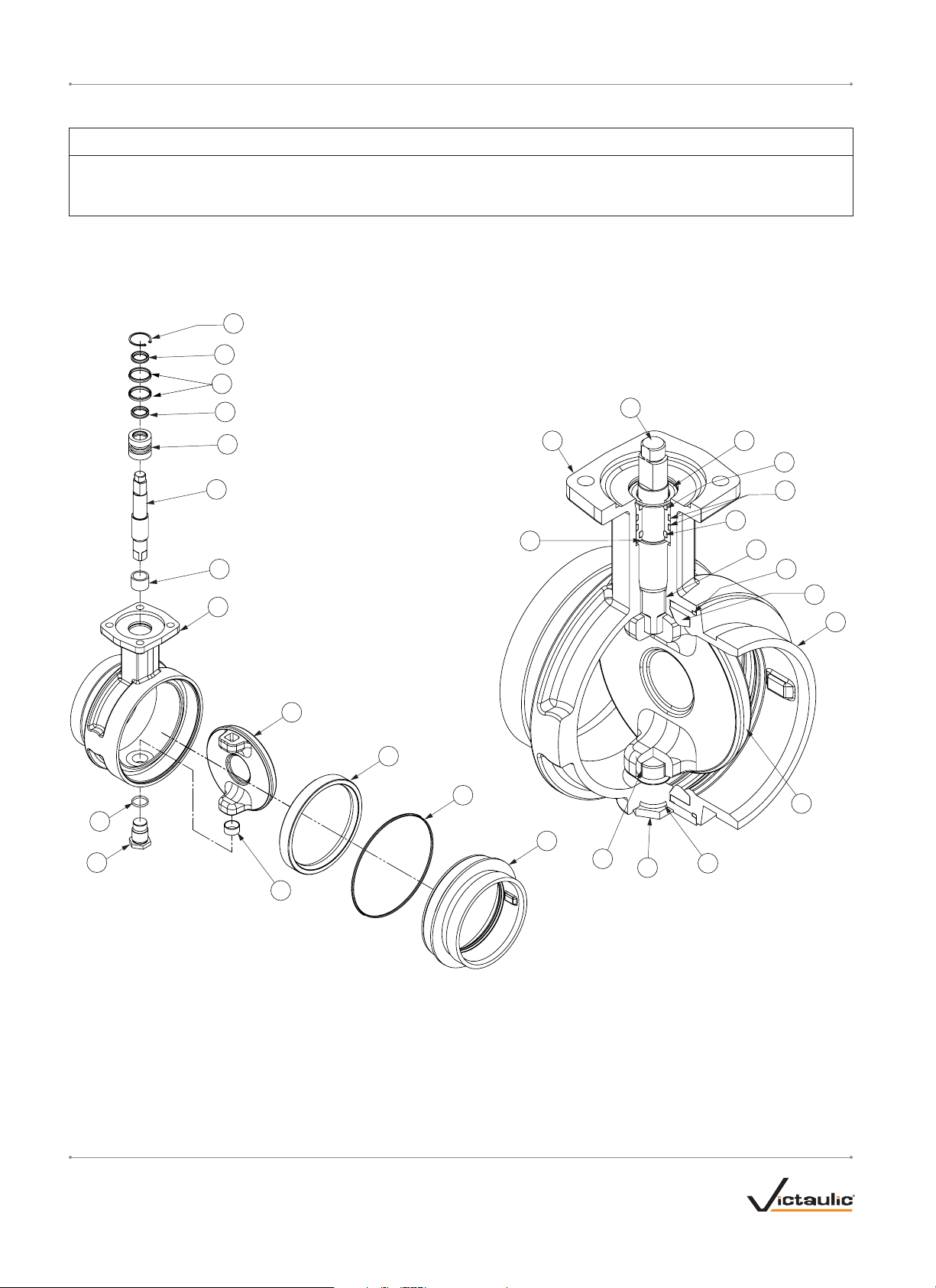

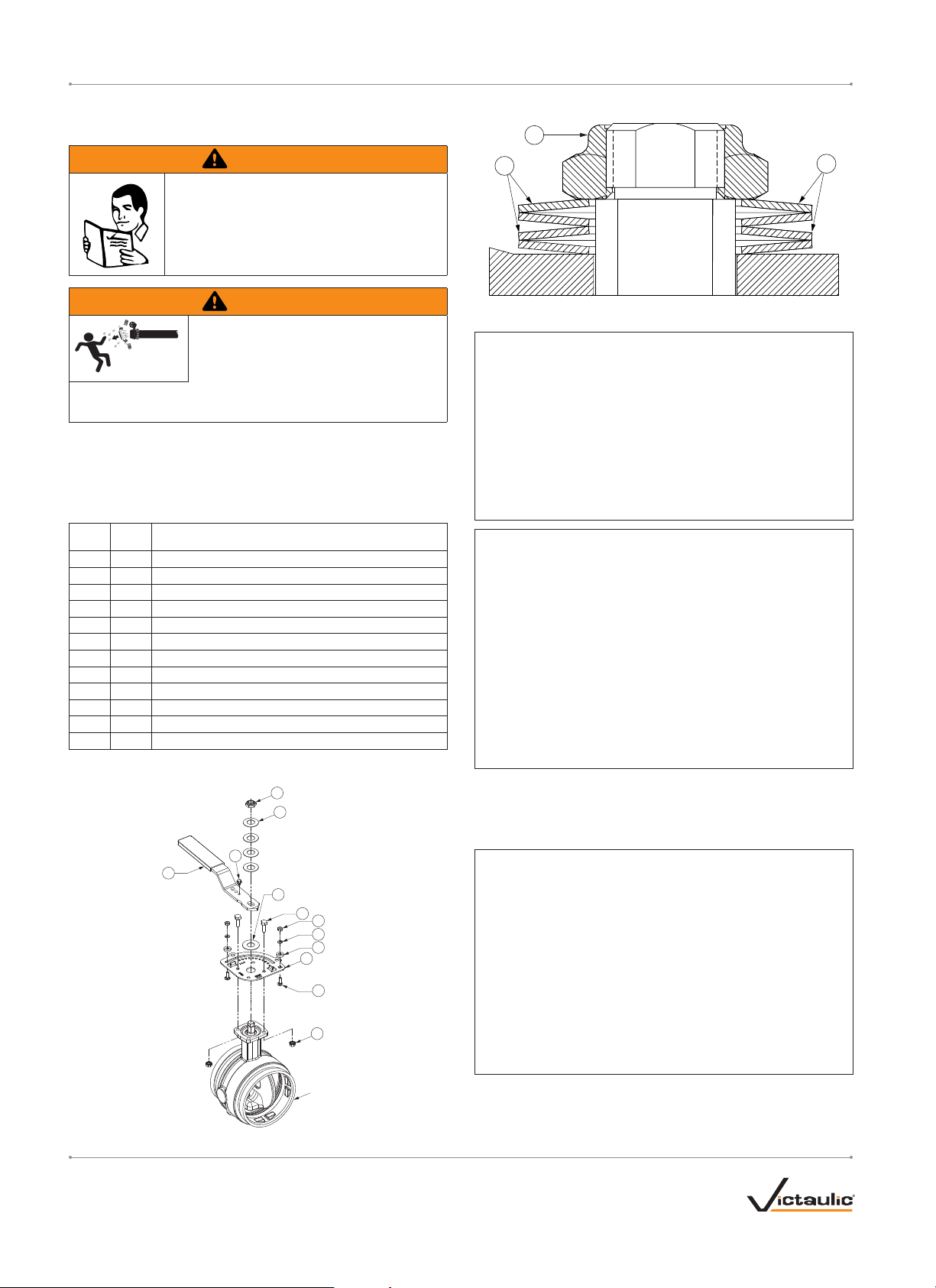

BUTTERFLY VALVE COMPONENTS

NOTICE

• Drawings and/or pictures in this manual may be exaggerated for clarity.

• The product, along with these installation and maintenance instructions, contains trademarks, copyrights, and/or patented features that are

the exclusive property of Victaulic.

Bill of Materials

Item Qty. Description Item Qty. Description

1 1 Valve Body Mounting Flange 8 1 Upper Bearing

2 1 End Face 9 1 Lower Bearing

12

13

14

13

3 1 Disc 10 1 O-Ring

4 1 Seat 11 1 Seal Cartridge

5 1 O-Ring 12 1 Retaining Ring

6 1 Stem 13 2 O-Ring

7 1 Stem Nut 14 2 O-Ring

6

10

7

11

1

12

13

6

14

13

11

8

8

5

4

1

2

3

4

5

3

2

8

7

10

9

victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2014 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

I-VIC300MS_2

REV_F

Page 4

I-VIC300MS / Vic-300® MasterSeal™ Butterfly Valves / Installation and Maintenance Instructions

INSTALLATION INFORMATION

Series 761 and 461 Butterfly Valves are designed with grooved ends

for use with Victaulic grooved pipe couplings. Refer to the instructions,

supplied with the Victaulic coupling or Vic-Flange® Adapter, and the

notes in this section for installing Series 761 or 461 Butterfly Valves into

the piping system.

DO NOT INSTALL SERIES 761 OR 461 BUTTERFLY VALVES INTO

THE SYSTEM WITH THE DISC IN THE FULLY-OPEN POSITION.

• When using Series 761 or 461 Butterfly Valves for throttling

service, Victaulic recommends positioning the disc no less than

30 degrees open. For best results, the disc should be between

30 and 70 degrees open. High pipeline velocities and/or throttling

with the disc less than 30 degrees open may result in noise,

vibration, cavitation, severe line erosion, and/or loss of control.

For details regarding throttling services, contact Victaulic.

• Victaulic recommends limiting the flow velocities for water service

to 20 feet/second (6 meters/second). When higher flow velocities

are necessary, contact Victaulic. When dealing with flow media

other than water, contact Victaulic.

• Lubricated nitrile “T” seat seals are recommended for dry or

lubricated gas services.

• When directly connecting an end cap to a Series 761 or 461

Butterfly Valve, use only an end cap with a tapped hole for

attaching a pressure relief device. If the valve is opened then

closed unknowingly while the end cap is attached, the space

between the disc and end cap will be filled and pressurized. A

sudden release of energy can occur if the end cap is removed

while the space behind it is pressurized. PRESSURE MUST

BE VENTED THROUGH THE TAP BEFORE ATTEMPTING TO

REMOVE THE CAP.

DANGER

• When directly connecting an end cap to a

butterfly valve, use only an end cap with

a tapped hole for attaching a pressure

relief device.

• Pressure must be vented through the tap

before attempting to remove the cap.

Failure to follow these instructions could

result in death or serious personal injury.

VIC-FLANGE® ADAPTER NOTES

• Style 741 Vic-Flange® Adapters can be used on all sizes of Series

761 Butterfly Valves.

• Series 761 Butterfly Valves cannot be connected directly to flanged

components with Style 743 Vic-Flange® Adapters. A No. 46 ANSI

300 groove-by-flange adapter is required for this application.

• Style 441 Stainless Steel Vic-Flange® Adapters can be used on all

sizes of Series 461 Butterfly Valves.

SYSTEM-RELATED CONSIDERATIONS

• Series 761 and 461 Butterfly Valves and connecting piping must

be supported properly to prevent the joints from being subjected to

bending loads, shear loads, or any other external loads.

• The maximum allowable corrosion allowance is 0.8inch/2 mm.

• Welding to Series 761 and 461 Butterfly Valves and couplings is

not permitted.

PREVENTION OF STAINLESS STEEL PRODUCT

CONTAMINATION

These recommendations are provided as a general guideline to help

prevent surface contamination of stainless steel products.

Handling and Storage

1. Stainless steel products should be handled only with non-

contaminating apparatus (i.e. nylon straps or apparatus protected

with a non-contaminating buffer material).

2. If carbon steel straps are used, a buffer material must be placed

between the strap and the stainless steel product. Common noncontaminating buffer materials include wood, cardboard, paper,

canvas, and other stainless steel material.

3. Stainless steel products must be stocked on non-contaminating

racks or skids.

4. Stainless steel products must be stocked in an area separate from

iron or carbon steel products.

5. Do no climb on or stand on stainless steel products.

6. In storage areas where salt is present in the air, stainless steel

products must be covered with a plastic tarp.

Shipping

1. Stainless steel products must be shipped with new, non-

contaminating and non-damaging packing materials.

2. If markings are required directly on stainless steel products, the

marking must have a water-soluble chloride content less than 50

parts per million (ppm). The chloride content must be measured

upon drying of the marking.

3. Identification tags and connectors, if required, must be

constructed from non-contaminating materials.

4. Stainless steel products must be shipped separately from iron

or carbon steel products. If stainless steel and/or iron or carbon

steel products must be shipped together, care must be taken

to separate the dissimilar materials completely by using a noncontaminating buffer.

WARNING

• The system designer is responsible for verifying suitability of

stainless steel materials with the intended fluid media.

• The effect of chemical composition, pH level, operating

temperature, chloride level, oxygen level, and flow rate on

stainless steel materials must be evaluated to confirm system

life will be acceptable for the intended service.

Failure to follow these instructions could cause product failure,

resulting in serious personal injury and property damage.

victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2014 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

REV_F

I-VIC300MS_3

Page 5

I-VIC300MS / Vic-300® MasterSeal™ Butterfly Valves / Installation and Maintenance Instructions

STEM SEAL REPLACEMENT FOR

2 – 12-INCH/60.3 – 323.9-MM VALVES

WARNING

• Read and understand all instructions before

attempting to replace the stem seals.

Failure to follow all instructions could result in

serious personal injury and/or property damage.

WARNING

• THE PUMP MUST BE SHUT OFF to

prevent flow from passing through the

valve during the following procedures.

Failure to follow this instruction could cause product failure,

resulting in serious personal injury and/or property damage.

4. Using retaining-ring pliers or a similar device, remove the retaining

ring from around the stem assembly, as shown above. If the

retaining ring is bent from its original shape, replace it with a new,

Victaulic-supplied retaining ring.

NOTICE

• THE STEM SEAL REPLACEMENT PROCEDURE SHOULD BE

COMPLETED ONLY IF LEAKAGE IS OCCURRING FROM THE

STEM.

• Make sure the correct stem seal kit was ordered by verifying the

o-ring material.

• O-rings for all valve sizes (12 total) are included with the kit.

However, only four o-rings are required to repair one valve.

Make sure the correct size o-rings are used for the stem seal

replacement procedure. Discard any unused o-rings.

1. Removal of the handle assembly or gear operator can be

performed without removing the valve from the piping system. THE

PUMP MUST BE SHUT OFF to prevent flow from passing through

the valve during removal of the handle assembly or gear operator.

2. To remove the handle assembly: Refer to the appropriate handle

removal section in this manual.

3. To remove the gear operator: Note the current orientation of the

gear operator before proceeding with the following steps. AS A

REFERENCE FOR GEAR OPERATOR RE-INSTALLATION: Place a

mark on the gear operator, the stem, and the valve body mounting

flange with a permanent marker or paint pen.

3a. Place the valve disc in the OPEN position by turning the

handwheel of the gear operator until the pointer is pointing toward

the OPEN position.

3b. Remove the four existing hex-head screws and lock washers

that attach the gear operator to the valve body mounting flange.

NOTE: These hex-head screws and lock washers are required for

re-installation.

3c. Pull straight upward to remove the gear operator and existing drive

bushing from the valve body mounting flange. These items are

required for re-installation. DO NOT REMOVE OR ROTATE THE

STEM.

3d. Remove any debris from the valve body mounting flange.

5. Remove the stem assembly from the disc/valve body. Be careful

not to damage the flats of the drive hub during removal.

6. Remove the seal cartridge from the stem.

victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2014 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

I-VIC300MS_4

REV_F

Page 6

I-VIC300MS / Vic-300® MasterSeal™ Butterfly Valves / Installation and Maintenance Instructions

11. Install two new o-rings onto the seal cartridge, as shown above.

7. Using an o-ring pick or a similar device, remove the two internal

and two external o-rings from the seal cartridge.

8. Clean the stem and the interior and exterior surfaces of the seal

cartridge. Check the surfaces of the stem and seal cartridge for

burrs and sharp edges. File any burrs and sharp edges to prevent

o-rings from being cut during re-assembly.

9. Lubricate the seal cartridge and o-rings with Vic-Lube™ or another

compatible material, such as silicone.

CAUTION

• Use a compatible lubricant to prevent the o-rings from pinching/

tearing during installation.

Failure to follow this instruction could result in valve leakage

through the stem.

12. Insert the stem into the seal cartridge.

13. Insert the stem assembly into the valve body/disc. Make sure the

rectangular end of the disc aligns with the stem. NOTE: The seal

cartridge must seat fully in the valve body.

14. Using retaining-ring pliers or a similar device, install the retaining

ring over the stem assembly. Make sure the retaining ring fully

seats in the recess in the valve body.

15. Re-install the handle assembly or gear operator onto the valve.

10. Install two new o-rings into the seal cartridge, as shown above.

victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2014 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

REV_F

16. Operate the valve through a full-open and full-closed cycle to verify

proper operation, then place the system back into service.

I-VIC300MS_5

Page 7

I-VIC300MS / Vic-300® MasterSeal™ Butterfly Valves / Installation and Maintenance Instructions

SETTING THE MEMORY STOP FEATURE ON

2 – 6-INCH/60.3 – 168.3-MM VALVES WITH

10-POSITION HANDLES

1. Using the handle, place the valve disc in the desired “open”

position.

2. Loosen the memory stop nut, as shown above.

USING THE INFINITELY VARIABLE FEATURE ON

2 – 6-INCH/60.3 – 168.3-MM VALVES WITH

10-POSITION HANDLES

1. Remove the detent screw.

2. Remove the hex nut, lock washer, flat washer, and bolt from the

plate, as shown above.

3. Move the memory stop hardware to make contact with the side of

the 10-Position Handle, as shown above. Re-tighten the memory

stop nut to maintain the desired “open” location.

3. Install the hardware, removed in step 2, into the center hole in the

handle, as shown above.

4. To use the memory stop feature with the infinitely variable handle

option, refer to the instructions on the following page for setting the

memory stop.

victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2014 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

I-VIC300MS_6

REV_F

Page 8

I-VIC300MS / Vic-300® MasterSeal™ Butterfly Valves / Installation and Maintenance Instructions

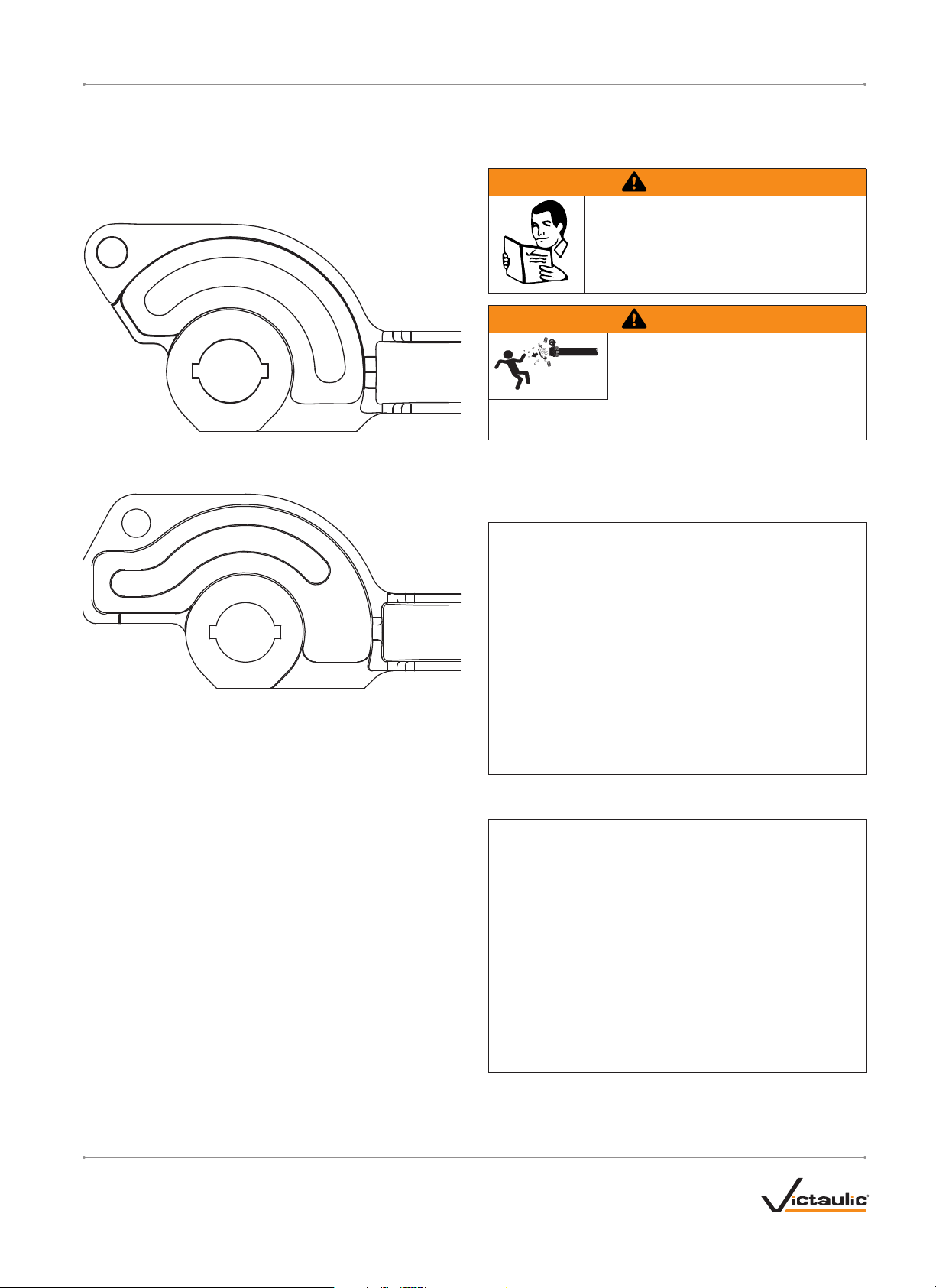

MEMORY STOP FEATURE ON 8-INCH/219.1-MM

VALVES WITH LEVER LOCK HANDLES

Determine the Lever Lock Handle design that is installed currently on

the valve.

If the Lever Lock Handle looks like the graphic below, follow the

instructions designated as “A” on this page.

If the Lever Lock Handle looks like the graphic below, follow the

instructions designated as “B” on page 9.

“A” – SETTING THE MEMORY STOP FEATURE

ON 8-INCH/219.1-MM VALVES WITH LEVER

LOCK HANDLES

WARNING

• Read and understand all instructions before

attempting to remove the Lever Lock Handle

assembly.

Failure to follow all instructions could result in

serious personal injury and/or property damage.

WARNING

• THE PUMP MUST BE SHUT OFF to

prevent flow from passing through the

valve during the following procedures.

Failure to follow this instruction could cause product failure,

resulting in serious personal injury and/or property damage.

Removal of the Lever Lock Handle can be performed without removing

the valve from the piping system. THE PUMP MUST BE SHUT OFF to

prevent flow from passing through the valve during removal of the Lever

Lock Handle.

1. Remove the hex nut, lock washer, and flat washer from the hexhead screw, as shown above.

2. Loosen the set screw on the side of the handle, as shown above.

2a. Note the current orientation of the Lever Lock Handle. The handle

must be re-installed in the same orientation in later steps. Remove

the Lever Lock Handle assembly from the plate.

victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2014 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

REV_F

I-VIC300MS_7

Page 9

I-VIC300MS / Vic-300® MasterSeal™ Butterfly Valves / Installation and Maintenance Instructions

NOTICE

• The stem contains a key that is essential for re-installation of

the handle. Use care to prevent misplacement of this key.

6. Re-install the flat washer, lock washer, and hex nut onto the hexhead screw, as shown above. Tighten the hex nut until the lock

washer is compressed.

3. Loosen the hex nut of the memory stop hardware, as shown

above.

4. Move the memory stop hardware to the opposite end of the slot,

as shown above. Tighten the hex nut to prevent the hardware from

moving during re-installation of the Lever Lock Handle.

5. Re-install the Lever Lock Handle in the same orientation, as noted

in step 2a on the previous page.

7. Tighten the set screw on the side of the handle, as shown above.

8. Using the handle, place the valve disc in the desired “open”

location.

8a. Loosen the memory stop nut, as shown above, and move the

memory stop hardware to make contact with the stationary handle/

plate mounting hardware, as shown above.

8b. Tighten the memory stop nut to maintain the desired “open”

location.

victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2014 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

I-VIC300MS_8

REV_F

Page 10

I-VIC300MS / Vic-300® MasterSeal™ Butterfly Valves / Installation and Maintenance Instructions

“B” – SETTING THE MEMORY STOP FEATURE

ON 8-INCH/219.1-MM VALVES WITH LEVER

LOCK HANDLES

1. Using the handle, place the valve disc in the desired “open”

position.

2. Loosen the memory stop nut, as shown above.

3. Move the memory stop hardware to make contact with the

stationary handle/plate mounting hardware, as shown above.

3a. Tighten the memory stop nut to maintain the desired “open”

location.

victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2014 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

REV_F

I-VIC300MS_9

Page 11

I-VIC300MS / Vic-300® MasterSeal™ Butterfly Valves / Installation and Maintenance Instructions

10-POSITION HANDLE REMOVAL FOR

2 – 6-INCH/60.3 – 168.3-MM VALVES

WARNING

• Read and understand all instructions before

attempting to remove the 10-Position Handle

assembly.

Failure to follow all instructions could result in

serious personal injury and/or property damage.

WARNING

• THE PUMP MUST BE SHUT OFF to

prevent flow from passing through the

valve during the following procedures.

Failure to follow this instruction could cause product failure,

resulting in serious personal injury and/or property damage.

Removal of the 10-Position Handle can be performed without removing

the valve from the piping system. THE PUMP MUST BE SHUT OFF

to prevent flow from passing through the valve during removal of the

10-Position Handle.

10-POSITION HANDLE PARTS LIST

Item No. Q ty. Description

1 1 Handle

2 1 Plate

3 2 Hex Nut with Captive-Toothed Lock Washer (⁄ – 18 UNC)

4 2 Round-Head, Square-Neck Bolt (¼ – 20 UNC x ¾-inch Long)

5 4 Spring Washer

6 1 Hex Lock Nut

7 2 Hex Head Screw (⁄ – 18 UNC x 1-inch Long)

8 1 Flat Washer

9 2 Lock Washer (¼ inch)

10 2 Hex Nut (¼ – 20 UNC)

11 1 Detent Screw

12 2 Memor y Stop Washer

DETAIL OF SPRING WASHERS AND LOCK NUT

7

6

Exaggerated for clarity

6

10-POSITION HANDLE ASSEMBLY DRAWING

6

5

1. Remove the hex lock nut (Item 6) from the threaded portion of the

drive hub.

2. Remove the spring washers (Item 5), handle (Item 1), and flat

washer (Item 8) from the stem assembly.

11

1

8

7

10

9

12

2

4

3

Valve Body

3. Remove the hex nuts with captive-toothed lock washers (Item 3)

from the hex-head screws (Item 7) that attach the plate (Item 2) to

the valve body mounting flange.

Exaggerated for Clarity

victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2014 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

I-VIC300MS_10

REV_F

Page 12

I-VIC300MS / Vic-300® MasterSeal™ Butterfly Valves / Installation and Maintenance Instructions

4. Remove the plate (Item 2) from the valve body mounting flange.

5. The valve is now ready for conversion to a Tamper-Resistant

Handle or a Gear Operator. In addition, the “Stem Seal

Replacement” instructions can be performed, the thermal barrier

kit can be installed, or the insulation extension kit can be installed.

CAUTION

• DO NOT attempt to operate a Series 761 or 461 Butterfly Valve

without a handle or gear operator installed.

Failure to follow this instruction will cause improper valve operation

and damage to the stem.

victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2014 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

REV_F

I-VIC300MS_11

Page 13

I-VIC300MS / Vic-300® MasterSeal™ Butterfly Valves / Installation and Maintenance Instructions

LEVER LOCK HANDLE REMOVAL FOR

8-INCH/219.1-MM VALVES

WARNING

• Read and understand all instructions before

attempting to remove the Lever Lock Handle

assembly.

Failure to follow all instructions could result in

serious personal injury and/or property damage.

WARNING

• THE PUMP MUST BE SHUT OFF to

prevent flow from passing through the

valve during the following procedures.

Failure to follow this instruction could cause product failure,

resulting in serious personal injury and/or property damage.

Removal of the Lever Lock Handle can be performed without removing

the valve from the piping system. THE PUMP MUST BE SHUT OFF to

prevent flow from passing through the valve during removal of the Lever

Lock Handle.

LEVER LOCK HANDLE PARTS LIST

Item No. Q ty. Description

1 1 Lever Lock Handle Assembly

2 1 Plate

3 2 Hex Head Screw (⁄ – 18 UNC x 1-inch Long)

4 5 Lock Washer (⁄-inch)

5 5 Hex Nut (⁄ – 18 UNC)

6 1 Hex-Head Screw (⁄ – 18 UNC x 2-inches Long)

7 1 Round-Head, Square-Neck Bolt

8 2 Flat Washer (⁄ -inch Thick x ¾-inch OD x ⁄-inch ID)

9 1 Key

LEVER LOCK HANDLE ASSEMBLY DRAWING

1

8

5

7

3

4

5

Exaggerated for clarity

4

5

4

8

3

5

4

2

6

4

5

9

Valve

Body

1. Remove the hex nut (Item 5), lock washer (Item 4), and flat washer

(Item 8) from the hex-head screw (Item 6), as shown above.

victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2014 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

I-VIC300MS_12

REV_F

Page 14

I-VIC300MS / Vic-300® MasterSeal™ Butterfly Valves / Installation and Maintenance Instructions

2. Loosen the set screw on the side of the handle (Item 1), as shown

above.

2a. Remove the Lever Lock Handle assembly from the plate.

NOTICE

• The stem contains a key that is essential for re-installation of a

handle or a gear operator. Use care to prevent misplacement of

this key.

4. Remove the plate (Item 2) from the valve body mounting flange.

5. The valve is now ready for conversion to a Tamper-Resistant

Handle or a Gear Operator. In addition, the “Stem Seal

Replacement” instructions can be performed, the thermal barrier

kit can be installed, or the insulation extension kit can be installed.

CAUTION

• DO NOT attempt to operate a Series 761 or 461 Butterfly Valve

without a handle or gear operator installed.

Failure to follow this instruction will cause improper valve operation

and damage to the stem.

3. Remove the hex nuts (Item 5) and lock washers (Item 4) from the

two hex-head screws (Item 3). In addition, remove the hex nut

(Item 5) and lock washer (Item 4) from the hex-head screw (Item

6) to permit removal of the plate from the valve body mounting

flange.

victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2014 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

REV_F

I-VIC300MS_13

Page 15

I-VIC300MS / Vic-300® MasterSeal™ Butterfly Valves / Installation and Maintenance Instructions

TAMPER-RESISTANT HANDLE KIT INSTALLATION

FOR 2 – 6-INCH/60.3 – 168.3-MM VALVES WITH

10-POSITION HANDLES

WARNING

• Read and understand all instructions before

attempting to install any Victaulic accessory

kits.

Failure to follow all instructions could result in

serious personal injury and/or property damage.

WARNING

• THE PUMP MUST BE SHUT OFF to

prevent flow from passing through the

valve during the following procedures.

Failure to follow this instruction could cause product failure,

resulting in serious personal injury and/or property damage.

The tamper-resistant handle kit can be installed without removing

the valve from the piping system. THE PUMP MUST BE SHUT OFF

to prevent flow from passing through the valve during the following

procedures.

CONTENTS OF TAMPER-RESISTANT HANDLE KIT

1. Place the disc in the fully-open or fully-closed position.

2. Remove the handle assembly by following the “10-Position Handle

Removal for 2 – 6-inch/60.3 – 168.3-mm Valves” section.

3. Install the plate (Item 2) over the stem assembly and onto the valve

body mounting flange. Make sure two holes in the plate align with

two holes in the valve body mounting flange. NOTE: If the plate

is installed incorrectly, it will not seat evenly on the valve body

mounting flange.

Item No. Q ty. Description

1 1 Tamper-Resistant Handle

2 1 Plate

3 2 Round-Head, Square-Neck Bolt (¼ – 20 UNC x ¾-inch Long)

4 4 Spring Washer

5 1 Tamper-Resistant Nut

6 2 Lock Washer (¼ inch)

7 2 Hex Nut (¼ – 20 UNC)

8 2 Self-Clinching Nut (⁄ – 18 UNC)

9 2 Breakaway Security Bolt (⁄ – 18 UNC x ¾-inch Long)

10 1 Detent Screw

11 1 Washer

12 2 Memor y Stop Washer

TAMPER-RESISTANT HANDLE ASSEMBLY DRAWING

5

4

7

6

12

11

10

8

2

1

Self-Clinching

Nuts (Item 8)

3

4. Apply Loctite 262* (or equivalent) to the two breakaway security

9

Valve

Body

Exaggerated for Clarity

victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2014 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

I-VIC300MS_14

bolts (Item 9). Insert a breakaway security bolt (Item 9) through

the two holes in the valve body mounting flange and into the plate

(Item 2) where the self-clinching nuts (Item 8) are pressed into the

plate (Item 2). Hand-tighten the breakaway security bolts (Item 9).

* Loctite is a registered trademark of the Henkel Corporation and 262 is a

trademark of the Henkel Corporation

REV_F

Page 16

I-VIC300MS / Vic-300® MasterSeal™ Butterfly Valves / Installation and Maintenance Instructions

5. Tighten the breakaway security bolts (Item 9) completely until the

hex portion breaks away, leaving a flush, tamper-resistant head.

6. Place the washer (Item 11) over the stem assembly.

5

4

4

8. Install the spring washers (Item 4) over the stem assembly. Make

sure the sets of spring washers are installed with the outside edges

touching, as shown in the drawing and photo above.

9. Apply Loctite 262* (or equivalent) to the tamper-resistant nut

(Item 5). Install the tamper-resistant nut (Item 5) onto the stem

7. Place the tamper-resistant handle (Item 1) onto the stem assembly.

Make sure the detent screw (Item 10) of the tamper-resistant

handle faces toward the detents of the plate, as shown above.

victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2014 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

REV_F

assembly.

* Loctite is a registered trademark of the Henkel Corporation and 262 is a

trademark of the Henkel Corporation

I-VIC300MS_15

Page 17

I-VIC300MS / Vic-300® MasterSeal™ Butterfly Valves / Installation and Maintenance Instructions

10. Using a spanner wrench, tighten the tamper-resistant nut (Item 5)

completely.

CAUTION

• DO NOT attempt to remove a tamper-resistant handle from the

valve.

Attempting to remove a tamper-resistant handle will cause damage

to the valve, resulting in leakage and property damage.

NOTE: The valve may be padlocked now in the open or shut position.

victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2014 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

I-VIC300MS_16

REV_F

Page 18

I-VIC300MS / Vic-300® MasterSeal™ Butterfly Valves / Installation and Maintenance Instructions

TAMPER-RESISTANT HANDLE KIT INSTALLATION

FOR 8-INCH/219.1-MM VALVES WITH LEVER

LOCK HANDLES

WARNING

• Read and understand all instructions before

attempting to install any Victaulic accessory

kits.

Failure to follow all instructions could result in

serious personal injury and/or property damage.

WARNING

• THE PUMP MUST BE SHUT OFF to

prevent flow from passing through the

valve during the following procedures.

Failure to follow this instruction could cause product failure,

resulting in serious personal injury and/or property damage.

The tamper-resistant handle kit can be installed without removing

the valve from the piping system. THE PUMP MUST BE SHUT OFF

to prevent flow from passing through the valve during the following

procedures.

CONTENTS OF TAMPER-RESISTANT HANDLE KIT

1. Place the disc in the fully-open or fully-closed position.

2. Remove the handle assembly by following the “Lever Lock Handle

Removal for 8-inch/219.1-mm Valves” section.

3. Install the plate (Item 2) over the stem assembly and onto the valve

body mounting flange. Make sure two holes in the plate align with

two holes in the valve body mounting flange. NOTE: If the plate

is installed incorrectly, it will not seat evenly on the valve body

mounting flange.

Item No. Q ty. Description

1 1 Tamper-Resistant Handle

2 1 Plate

3 1 Grooved Drive Pin

4 2 Tamper-Resistant Torx Screw (⁄ – 18 UNC x 1-inch Long)

5 2 Lock Washer (⁄-inch)

6 2 Tamper-Resistant Nut with Breakaway Hex (⁄ – 18 UNC)

7 1 Key

TAMPER-RESISTANT HANDLE ASSEMBLY DRAWING

1

3

4

5

6

4

2

5

7

Valve

Body

4. Insert a tamper-resistant torx screw (Item 4) through the two

holes in the plate and into the valve body mounting flange. Place

a lock washer (Item 5) onto the end of each tamper-resistant torx

screw, and thread a tamper-resistant nut (Item 6) onto the end of

each torx screw until hand tight. DO NOT tighten the torx screws

completely at this time.

6

5. Insert the key into the keyway in the stem. Place the tamperresistant handle (Item 1) onto the stem assembly. Make sure the

arm of the tamper-resistant handle faces toward the teeth of the

plate, as shown above.

Exaggerated for clarity

victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2014 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

REV_F

I-VIC300MS_17

Page 19

I-VIC300MS / Vic-300® MasterSeal™ Butterfly Valves / Installation and Maintenance Instructions

6. Insert the grooved drive pin (Item 3) into the hole in the tamperresistant handle, as shown above. Drive the pin completely into the

handle.

7. Tighten the set screw on the side of the handle (next to the hole

for the grooved drive pin), as shown above.

8. Close the valve disc to ensure the tamper-resistant handle makes

full contact with the flat portion of the plate that extends past the

teeth.

9. Using a tamper-resistant torx driver and an open-end wrench,

tighten the tamper-resistant nuts until the hex portion breaks away,

leaving a flush, tamper-resistant head.

NOTE: The valve may be padlocked in the open or shut position.

CAUTION

• DO NOT attempt to remove a tamper-resistant handle from the

valve.

Attempting to remove a tamper-resistant handle will cause damage

to the valve, resulting in leakage and property damage.

victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2014 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

I-VIC300MS_18

REV_F

Page 20

I-VIC300MS / Vic-300® MasterSeal™ Butterfly Valves / Installation and Maintenance Instructions

TELESCOPIC HANDLE KIT INSTALLATION FOR

10 – 12-INCH/273.0 – 323.9-MM SERIES 761

VALVES

WARNING

• Read and understand all instructions before

attempting to install any Victaulic accessory

kits.

Failure to follow all instructions could result in

serious personal injury and/or property damage.

WARNING

• THE PUMP MUST BE SHUT OFF to

prevent flow from passing through the

valve during the following procedures.

Failure to follow this instruction could cause product failure,

resulting in serious personal injury and/or property damage.

The telescopic handle kit can be installed without removing the Series

761 Butterfly Valve from the piping system. THE PUMP MUST BE

SHUT OFF to prevent flow from passing through the valve during the

following procedures.

CONTENTS OF TELESCOPIC HANDLE KIT

CONTENTS OF OPTIONAL MEMORY POINTER ASSEMBLY KIT

Item No. Qt y. Description

15 1 Memory Pointer

16 1

Carriage Bolt (⁄ – 16 UNC x 1 ¼-inches Long)

17 1 Wing Nut (⁄ – 16 UNC)

TELESCOPIC HANDLE ASSEMBLY DRAWING

U

H

T

S

N

P

O

S

H

T

U

7

5

Item No. Qt y. Description

1 1 Dial Plate

2 1 Telescopic Handle Assembly

2a 1 Sleeve

2b 1 Rod

2c 1 Knurled Ring

2d 1 Spring Pin

3 1 Handle Hub

4 1 Locking Lever

5 2

Socket Set Screw (⁄ – 18 UNC x 1 ½-inches Long)

6 1 Socket Set Screw (¼ – 20 UNC x ⁄ -inch Long)

7 2 Hex Nut (⁄ – 18 UNC)

8 1 Hex-Head Cap Screw (⁄ – 18 UNC x ½-inch Long)

9 1

Key (⁄-inch Square x 1 ⁄-inches Long)

10 2 Flat Washer (⁄-inch Diameter)

11 1

Flat Washer (1 ⁄-inches OD x ⁄-inch ID x 0.100-inch Thick)

12 4 Lock Washer (⁄-inch Diameter)

13 4 Hex-Head Cap Screw (⁄ – 16 UNC x 1-inch Long)

14 1 Carriage Bolt (⁄ – 16 UNC x 3-inches Long)

4

8

11

3

17

15

16

9

12

13

6

10

1

14

2a

2d

2c

2b

Exaggerated for clarity

1. Install the dial plate (Item 1) onto the valve so that the holes in the

dial plate align with the holes in the valve body mounting flange.

victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2014 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

REV_F

I-VIC300MS_19

Page 21

I-VIC300MS / Vic-300® MasterSeal™ Butterfly Valves / Installation and Maintenance Instructions

1a. Make sure the “OPEN” markings align with the valve inlet and

outlet.

2. Place one lock washer (Item 12) onto each of the four hex-head

cap screws (Item 13). Thread the hex-head cap screws up through

the valve body mounting flange and into the tapped bosses of the

dial plate.

5. Make sure the valve disc is in the “OPEN” position. Insert the

carriage bolt (Item 14) up through the bottom of the dial plate.

Place the two flat washers (Item 10) onto the carriage bolt.

5a. Align the pointer of the handle hub (Item 3) with the “OPEN”

position marking on the dial plate. Install the handle hub onto the

stem and carriage bolt, as shown above.

6. Install the locking lever (Item 4) onto the carriage bolt, as shown

above. DO NOT tighten the locking lever completely at this time.

3. Using a wrench, tighten the four hex-head cap screws evenly until

the lock washers become flattened.

7. Secure the handle hub to the stem with the flat washer (Item 11)

and hex-head screw (Item 8), as shown above.

8. Insert the telescopic handle assembly (Item 2) into the handle

4. Install the key (Item 9) into the keyway in the stem, as shown

above.

hub. Tighten the socket set screw (Item 6) into the handle hub to

secure the telescopic handle assembly in position.

victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2014 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

I-VIC300MS_20

REV_F

Page 22

I-VIC300MS / Vic-300® MasterSeal™ Butterfly Valves / Installation and Maintenance Instructions

9. Thread a hex nut (Item 7) onto a socket set screw (Item 5). Thread

the socket set screw halfway into the travel limit boss of the dial

plate, as shown above.

10. Make sure the valve disc is in the “OPEN” position. Turn the

socket set screw until it contacts the handle hub, as shown above.

14. After placing the valve disc in the operating position, tighten the

locking lever completely to maintain the position.

OPTIONAL MEMORY POINTER INSTALLATION

1. Using the telescopic handle, move the disc to the operating

position.

2. Insert the carriage bolt (Item 16) up through the slot in the dial

plate (adjacent to the pointer of the handle hub).

2a. Install the memory pointer (Item 15) onto the carriage bolt. Make

sure the memory pointer and the pointer of the handle hub are

aligned.

2b. Thread the wing nut (Item 17) onto the carriage bolt and tighten

completely.

11. While holding the socket set screw in position, tighten the hex nut

against the travel limit boss to set the “FULL OPEN” travel stop, as

shown above.

12. For setting the “FULL SHUT” travel stop, close the valve until the

pointer aligns with the “SHUT” marking. Thread the remaining hex

nut (Item 7) onto the socket set screw (Item 5). Thread the socket

set screw halfway into the travel limit boss on the opposite side of

the dial plate.

12a. Turn the socket set screw until it contacts the handle hub.

12b. While holding the socket set screw in position, tighten the hex nut

against the travel limit boss to set the “FULL SHUT” travel stop.

13. Place the valve back into service.

victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2014 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

REV_F

3. When the memory pointer is located at the proper position, tighten

the locking lever to maintain the position.

I-VIC300MS_21

Page 23

I-VIC300MS / Vic-300® MasterSeal™ Butterfly Valves / Installation and Maintenance Instructions

GEAR OPERATOR INSTALLATION FOR

2 – 12-INCH/60.3 – 323.9-MM VALVES

WARNING

• Read and understand all instructions before

attempting to install any Victaulic accessory

kits.

Failure to follow all instructions could result in

serious personal injury and/or property damage.

WARNING

• THE PUMP MUST BE SHUT OFF to

prevent flow from passing through the

valve during the following procedures.

Failure to follow this instruction could cause product failure,

resulting in serious personal injury and/or property damage.

The gear operator can be installed without removing the valve from the

piping system. THE PUMP MUST BE SHUT OFF to prevent flow from

passing through the valve during the following procedures.

CONTENTS OF GEAR OPERATOR KIT

GEAR OPERATOR ASSEMBLY DRAWING

2

1

5

2 – 6-inch/60.3 – 168.3-mm Sizes

6

8 – 12-inch/219.1 – 323.9-mm Sizes

Exaggerated for clarity

3

4

3

NOTE: The gear operator for a 4-inch/114.3-mm valve is shown.

Therefore, Item 4 (Key) is not shown

Item No. Q ty. Description

1 1 Gear Operator

2 1 Handwheel

3 1 Drive Bushing

4 1 Key *

5 4 Lock Washer (M8)

6 4 Hex-Head Screw (M8 x 20-mm Long)

* Not applicable for 2 – 6-inch/60.3 – 168.3-mm Sizes

NOTE: For 10-inch/273.0-mm and 12-inch/323.9-mm Series 761 and

461 Butterfly Valves, the handwheel is not attached to the shaft. To

attach the handwheel to the shaft, align the holes in the handwheel with

the holes in the shaft. Drive the roll pin (provided) completely into the

handwheel and shaft.

1. Place the valve disc in the OPEN position, and turn the handwheel

of the gear operator until the pointer is pointing toward the “OPEN”

position, as shown above. NOTE: For valves currently installed in

the system, refer to the position of the stem. For 2 – 6-inch/

60.3 – 168.3-mm sizes, the flats of the stem will be parallel to

the sides of the valve when the disc is in the “OPEN” position.

For 8 – 12-inch/219.1 – 323.9-mm sizes, the key in the stem will

face toward one end of the valve when the disc is in the “OPEN”

position.

victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2014 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

I-VIC300MS_22

REV_F

Page 24

I-VIC300MS / Vic-300® MasterSeal™ Butterfly Valves / Installation and Maintenance Instructions

2. Insert the drive bushing into the gear operator, as shown above.

Place the gear operator/drive bushing assembly on top of the valve

body by aligning the four holes of the gear operator with the four

holes in the valve body.

NOTE: For 8 – 12-inch/219.1 – 323.9-mm sizes, install the key into

the keyway in the stem. Insert the drive bushing into the gear operator.

Place the gear operator/drive bushing assembly on top of the valve body

by aligning the four holes of the gear operator with the four holes in the

valve body.

3. Install a lock washer (Item 5) onto each of the four hex-head

screws (Item 6). Thread the hex-head screws up through the holes

in the valve body mounting flange and into the gear operator.

4. Using a wrench, tighten the four hex-head screws evenly until the

lock washers become flattened.

5. Turn the handle of the gear operator to ensure proper operation.

victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2014 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

REV_F

I-VIC300MS_23

Page 25

I-VIC300MS / Vic-300® MasterSeal™ Butterfly Valves / Installation and Maintenance Instructions

ADJUSTING AND SETTING THE CLOSED TRAVEL LIMIT STOPS OF

THE GEAR OPERATOR

1. Remove the dust cap from the right side of the gear operator.

2. Loosen the hex lock nut (counterclockwise) located on the right

side of the gear operator.

3. Using an allen wrench, loosen the internal set screw approximately

three turns (counterclockwise).

4. Turn the handwheel clockwise to place the disc in the closed

(shut) position. The “closed” position is reached when the pointer

on top of the gear operator reaches the “shut” marking.

ADJUSTING AND SETTING THE OPEN TRAVEL LIMIT STOPS OF

THE GEAR OPERATOR

1. Remove the dust cap from the left side of the gear operator.

2. Loosen the hex lock nut (counterclockwise) located on the left side

of the gear operator.

3. Using an allen wrench, loosen the internal set screw approximately

three turns (counterclockwise).

4. Turn the handwheel counterclockwise to place the disc in the

open position. The “open” position is reached when the position

indicator is 90º from the correctly adjusted closed position.

5. Using the allen wrench, tighten the internal set screw (clockwise)

until it contacts the internal quadrant gear.

6. Tighten the hex lock nut (clockwise).

7. Verify proper operation of the gear operator by turning the

handwheel. Repeat steps 5 and 6, if necessary.

8. Replace the dust cap.

victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2014 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

I-VIC300MS_24

5. Using the allen wrench, tighten the internal set screw (clockwise)

until it contacts the internal quadrant gear.

6. Tighten the hex lock nut (clockwise).

7. Verify proper operation of the gear operator by turning the

handwheel. Repeat steps 5 and 6, if necessary.

8. Replace the dust cap.

REV_F

Page 26

I-VIC300MS / Vic-300® MasterSeal™ Butterfly Valves / Installation and Maintenance Instructions

MEMORY STOP KIT INSTALLATION FOR

2 – 12-INCH/60.3 – 323.9-MM GEAR OPERATED

VALVES

WARNING

• Read and understand all instructions before

attempting to install any Victaulic accessory

kits.

Failure to follow all instructions could result in

serious personal injury and/or property damage.

WARNING

• THE PUMP MUST BE SHUT OFF to

prevent flow from passing through the

valve during the following procedures.

Failure to follow this instruction could cause product failure,

resulting in serious personal injury and/or property damage.

The memory stop kit can be installed without removing the valve from

the piping system. THE PUMP MUST BE SHUT OFF to prevent flow

from passing through the valve during the following procedures.

CONTENTS OF MEMORY STOP KIT

1. Pry off the plastic position-indicator cap.

2. Remove the set screw from the top of the gear operator, as shown

above.

Item No. Qty. Description

1 1 Memory Stop

2 1 Position Indicator

3 2 Drive Pin

4 1 Bolt

5 1 Flat Washer

3. Install the memory stop onto the gear operator. Make sure the

tapped hole is centered in the slot of the memory stop, as shown

above.

victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2014 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

REV_F

I-VIC300MS_25

Page 27

I-VIC300MS / Vic-300® MasterSeal™ Butterfly Valves / Installation and Maintenance Instructions

4. Install the position indicator onto the gear operator. Make sure the

holes in the memory stop align with the holes in the gear operator.

5. Insert the drive pins into the holes in the position indicator and

gear operator. Tap the drive pins into the gear operator.

7. Slide the flat, raised por tion of the memory stop toward the

position indicator until they contact.

8. Tighten the bolt completely to maintain the position of the memory

stop.

NOTE: To re-adjust the memory stop, loosen the bolt for the memory

stop. Turn the handwheel to place the disc in the desired position

(clockwise to close and counterclockwise to open). Follow steps 7 and 8

on this page.

6. Install the bolt with the flat washer into the tapped hole in the gear

operator. Do not tighten the bolt completely at this time. Turn the

handwheel to place the disc in the desired position (clockwise to

close and counterclockwise to open).

victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2014 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

I-VIC300MS_26

REV_F

Page 28

I-VIC300MS / Vic-300® MasterSeal™ Butterfly Valves / Installation and Maintenance Instructions

THERMAL BARRIER KIT INSTALLATION FOR

2 – 12-INCH/60.3 – 323.9-MM VALVES

WARNING

• Read and understand all instructions before

attempting to install any Victaulic kits.

Failure to follow all instructions could result in

serious personal injury and/or property damage.

WARNING

• THE PUMP MUST BE SHUT OFF to

prevent flow from passing through the

valve during the following procedures.

Failure to follow this instruction could cause product failure,

resulting in serious personal injury and/or property damage.

NOTICE

• The following procedures show a typical installation of the

thermal barrier kit on a gear-operated valve. When necessary,

this thermal barrier kit can also be installed onto valves

containing Lever Lock Handles, 10-Position Handles, and

Telescopic Handles.

• The thermal barrier kit contains two gaskets. One gasket c overs

2 – 8-inch/60.3 – 219.1-mm valve sizes, and the other gasket

covers 10 – 12-inch/273.0 – 323.9-mm valve sizes. Make sure

the correct gasket size is used for the corresponding valve size.

THERMAL BARRIER KIT ASSEMBLY DRAWING

Gear

Operator

Thermal

Barrier

Gasket

Stem

Removal of the gear operator can be per formed without removing

the valve from the piping system. THE PUMP MUST BE SHUT OFF

to prevent flow from passing through the valve during the following

procedures.

Note the current orientation of the gear operator before proceeding with

the following steps. As a reference for gear operator re-installation, place

a mark on the gear operator, the stem, and the valve body mounting

flange with a permanent marker or paint pen.

1. Place the valve disc in the OPEN position by turning the

handwheel of the gear operator until the pointer is pointing toward

the OPEN position.

2. Remove the four hex-head screws and lock washers that attach

the gear operator to the valve body mounting flange.

3. Pull straight upward to remove the gear operator and drive bushing

from the valve body mounting flange. DO NOT REMOVE OR

ROTATE THE STEM.

4. Remove any debris from the valve body mounting flange.

5. Place the correct size thermal barrier gasket onto the valve body

mounting flange, as shown in the sketch on this page. NOTE: The

gasket should cover the entire valve body mounting flange ( gasket

will be slightly larger than the surface area of the valve body

mounting flange).

6. BEFORE RE-INSTALLING THE GEAR OPERATOR: Refer to the

position of the stem. For 2 – 6-inch/60.3 – 168.3-mm sizes, the

flats of the stem will be parallel to the sides of the valve when the

disc is in the OPEN position. For 8 – 12-inch/219.1 – 323.9-mm

sizes, the key in the stem will face toward one end of the valve

when the disc is in the OPEN position.

7. Insert the drive bushing into the gear operator.

8. Place the gear operator/drive bushing assembly on top of the

valve body mounting flange in the same orientation as previously

installed. Align the four holes of the gear operator with the four

holes in the valve body mounting flange.

NOTE: For 8 – 12-inch/219.1 – 323.9-mm sizes, install the key into

the keyway in the stem. Insert the drive bushing into the gear operator.

Place the gear operator/drive bushing assembly on top of the valve body

by aligning the four holes of the gear operator with the four holes in the

valve body.

9. Apply a lock washer to each of the four hex-head screws. Thread

the hex-head screws up through the valve body mounting flange

and gear operator until finger-tight.

10. Tighten the four hex-head screws evenly until the lock washers are

fully compressed and metal-to-metal contact occurs between the

gear operator and the valve body mounting flange.

11. Turn the handle of the gear operator to ensure proper operation.

Valve Body

Mounting Flange

Valve

Body

Exaggerated for clarity

victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2014 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

REV_F

I-VIC300MS_27

Page 29

I-VIC300MS / Vic-300® MasterSeal™ Butterfly Valves / Installation and Maintenance Instructions

INSULATION EXTENSION KIT FOR 2 - 8-INCH/

60.3 - 219.1-MM GEAR-OPERATED VALVES

WARNING

• Read and understand all instructions before

attempting to install any Victaulic accessory

kits.

Failure to follow all instructions could result in

serious personal injury and/or property damage.

WARNING

• THE PUMP MUST BE SHUT OFF to

prevent flow from passing through the

valve during the following procedures.

Failure to follow this instruction could cause product failure,

resulting in serious personal injury and/or property damage.

Removal of the gear operator can be per formed without removing

the valve from the piping system. THE PUMP MUST BE SHUT OFF

to prevent flow from passing through the valve during the following

procedures.

Series 761 and 461 Butterfly Valves are designed to accept 2 inches/

50 mm of insulation. When more than 2 inches/50 mm of insulation

is required, the insulation extension kit should be utilized to provide

clearance for the additional insulation.

CONTENTS OF INSULATION EXTENSION KIT

FOR GEAR-OPERATED VALVES

Quantity fo r 2 - 4-inch/

60.3 - 114.3-mm

Item

No.

1 1 1 Flat Washer

2 4 2 Spring Washer

3 1 1 Stem Adapter

4 4 4 Hex-Head Bolt

5 1 1 Spacer/Insulation Extension

6 4 4 Spring-Lock Washer

7 4 4 Hex Nut

8 0 2* Key*

9 1 1 Cup-Point Set Screw

10 1 1 L-Key Hex Wrench (Not Shown)

Sizes

Quantity fo r 5 - 8-inch/

141.3 - 219.1-mm

Sizes Description

* Key is for the 8-inch/219.1-mm valve size only

Items not called out in the drawings below are existing components that

must be saved for re-installation of the gear operator assembly.

Refer to the following page for kit installation instructions.

1

2

3

9

5

4

6

7

9

5

1

2

3

8-inch/219.1-mm

Size

4

8-inch/219.1-mm

Size

6

7

2 - 4-inch/60.3 - 114.3-mm Sizes 5 - 8-inch/141.3 - 219.1-mm Sizes

8

3

8

victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2014 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

I-VIC300MS_28

REV_F

Page 30

I-VIC300MS / Vic-300® MasterSeal™ Butterfly Valves / Installation and Maintenance Instructions

INSULATION EXTENSION KIT INSTALLATION

FOR 2 – 8-INCH/60.3 – 219.1-MM

GEAR-OPERATED VALVES

WARNING

• Read and understand all instructions before

attempting to install any Victaulic accessory

kits.

Failure to follow all instructions could result in

serious personal injury and/or property damage.

Spring

Washers

Exaggerated for Clarity

9. FOR 2 - 4-INCH/60.3 - 114.3-MM VALVES ONLY: Install the four

spring washers (Item 2) onto the stem assembly. Make sure the

sets of spring washers (Item 2) are installed with the outside edges

touching, as shown in the drawing above.

Flat

Washer

WARNING

• THE PUMP MUST BE SHUT OFF to

prevent flow from passing through the

valve during the following procedures.

Failure to follow this instruction could cause product failure,

resulting in serious personal injury and/or property damage.

Removal of the gear operator can be per formed without removing

the valve from the piping system. THE PUMP MUST BE SHUT OFF

to prevent flow from passing through the valve during the following

procedures.

Note the current orientation of the gear operator before proceeding

with the following steps. AS A REFERENCE FOR GEAR OPERATOR

RE-INSTALLATION: Place a mark on the gear operator, the stem, and

the valve body mounting flange with a permanent marker or paint pen.

1. Place the valve disc in the OPEN position by turning the

handwheel of the gear operator until the pointer is pointing toward

the OPEN position.

2. Remove the four existing hex-head screws and lock washers

that attach the gear operator to the valve body mounting flange.

NOTE: These hex-head screws and lock washers are required for

re-installation.

3. Pull straight upward to remove the gear operator and existing drive

bushing from the valve body mounting flange. These items are

required for re-installation. DO NOT REMOVE OR ROTATE THE

STEM.

4. Remove any debris from the valve body mounting flange.

5. Place the stem adapter (Item 3) onto the stem. NOTE: For

8-inch/219.1-mm valves, remove the existing key from the keyway

in the stem. Install a new key (Item 8), provided in the kit, into the

keyway in the stem. Install the second key (Item 8), provided in the

kit, into the stem adapter (Item 3).

6. Using the L-key hex wrench (provided with the kit), drive the cuppoint set screw (Item 9) into the threaded hole in the stem adapter

(Item 3).

7. Place the spacer/insulation extension (Item 5) onto the valve body

mounting flange with the machined counterbore facing upward

(away from the valve). Align the four holes of the spacer/insulation

extension (Item 5) with the four holes in the valve body mounting

flange.

8. Secure the spacer/insulation extension (Item 5) to the valve body

mounting flange by using the four hex-head bolts, spring-lock

washers and hex nuts (Items 4, 6, and 7) provided in the kit.

Flat

Washer

Spring

Washers

Exaggerated for Clarity

9a. FOR 5 - 8-INCH/141.3 - 219.1-MM VALVES ONLY: Install the

two spring washers (Item 2) onto the stem assembly. Make sure

the spring washers (Item 2) are installed with the outside edges

touching, as shown in the drawing above.

10. Place the flat washer (Item 1) on top of the spring washers

(Item 2).

11. Insert the existing drive bushing into the gear operator. NOTE: For

8-inch/219.1-mm valves, make sure the existing key is installed

in the keyway in the stem. Insert the drive bushing into the gear

operator.

12. Place the gear operator assembly onto the valve body mounting

flange in the same orientation as previously installed. Insert the

four existing hex-head screws with lock washers (removed in step

2) into the holes in the spacer/insulation extension and into the

gear operator assembly.

13. Using a wrench, tighten the four hex-head screws evenly until the

lock washers become flattened.

14. Turn the handle of the gear operator to ensure proper operation.

victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2014 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

REV_F

I-VIC300MS_29

Page 31

I-VIC300MS / Vic-300® MasterSeal™ Butterfly Valves / Installation and Maintenance Instructions

INSULATION EXTENSION KIT FOR 2 - 6-INCH/

60.3 - 168.3-MM VALVES WITH 10-POSITION

HANDLES

WARNING

• Read and understand all instructions before

attempting to install any Victaulic accessory

kits.

Failure to follow all instructions could result in

serious personal injury and/or property damage.

WARNING

• THE PUMP MUST BE SHUT OFF to

prevent flow from passing through the

valve during the following procedures.

Failure to follow this instruction could cause product failure,

resulting in serious personal injury and/or property damage.

Removal of the 10-Position Handle can be performed without removing

the valve from the piping system. THE PUMP MUST BE SHUT OFF

to prevent flow from passing through the valve during the following

procedures.

Series 761 and 461 Butterfly Valves are designed to accept 2 inches/

50 mm of insulation. When more than 2 inches/50 mm of insulation

is required, the insulation extension kit should be utilized to provide

clearance for the additional insulation.

CONTENTS OF INSULATION EXTENSION KIT

FOR VALVES WITH 10-POSITION HANDLES

Item No. Quantity Description

1 1 Flat Washer

2 1 Stem Adapter

3 1 Spacer/Insulation Extension

4 4 Hex-Head Bolt

5 4 Spring-Lock Washer

6 4 Hex Nut

7 1 Cup-Point Set Screw

8 1 L-Key Hex Wrench (Not Shown)

Items not called out in the drawings below are existing components that

must be saved for re-installation of the 10-Position Handle assembly.

Refer to the following page for kit installation instructions.

1

3

7

2

4

5

6

2 - 6-inch/60.3 - 168.3-mm Sizes

victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2014 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

I-VIC300MS_30

REV_F

Page 32

I-VIC300MS / Vic-300® MasterSeal™ Butterfly Valves / Installation and Maintenance Instructions

Exaggerated for clarity

INSULATION EXTENSION KIT INSTALLATION

FOR 2 – 6-INCH/60.3 – 168.3-MM VALVES WITH

10-POSITION HANDLES

WARNING

• Read and understand all instructions before

attempting to install any Victaulic accessory

kits.

Failure to follow all instructions could result in

serious personal injury and/or property damage.

WARNING

• THE PUMP MUST BE SHUT OFF to

prevent flow from passing through the

valve during the following procedures.

Failure to follow this instruction could cause product failure,

resulting in serious personal injury and/or property damage.

Removal of the 10-Position Handle can be performed without removing

the valve from the piping system. THE PUMP MUST BE SHUT OFF

to prevent flow from passing through the valve during the following

procedures.

1. Using the handle, place the valve disc in the OPEN position.

NOTE: Using a paint stick or bright-colored marker, place a mark

on the handle plate and the valve body to aid in re-installing the

handle plate in the correct orientation.

2. Follow the “10-Position Handle Removal for 2 - 6-inch/

60.3 - 168.3-mm Valves” section in this manual to remove the

handle assembly from the valve. NOTE: All components removed

from the valve will be required for re-installation.

3. Remove any debris from the valve body mounting flange.

4. Place the stem adapter (Item 2) onto the stem.

5. Using the L-key hex wrench (provided with the kit), drive the cuppoint set screw (Item 7) into the threaded hole in the stem adapter

(Item 2).

6. Place the spacer/insulation extension (Item 3) onto the valve

body mounting flange with the machined counterbore facing

upward (away from the valve). Make sure the contoured ends of

the spacer/insulation extension (Item 3) are matched up to the

contoured ends of the valve body mounting flange, and align the

four holes.

7. Secure the spacer/insulation extension (Item 3) to the valve body

mounting flange by using the four hex-head bolts, spring-lock

washers and hex nuts (Items 4, 5, and 6) provided in the kit.

8. Place the flat washer (Item 1), provided in the kit, into the

counterbore of the spacer/insulation extension (Item 3).

9. Place the existing handle plate onto the spacer/insulation extension

(Item 3). Make sure the mark on the handle plate (made in step 1)

is aligned with the mark on the valve body (made in step 1).

10. Insert an existing hex-head screw through the holes in the existing

handle plate and into the spacer/insulation extension (Item 3).

11. Install an existing hex nut with captive-toothed lock washer onto

the existing hex-head screws.

12. Tighten the hex nuts with captive-toothed lock washer to secure

the existing handle plate to the spacer/insulation extension (Item 3).

13. Place the existing flat washer over the stem adapter (Item 2) and

onto the existing handle plate.

14. Install the existing 10-Position Handle onto the stem adapter (Item

2). Make sure the pointer of the handle is pointing to the OPEN

marking on the plate.

7

6

15. Install the existing spring washers onto the stem adapter (Item 2).

Make sure the sets of spring washers are installed with the outside

edges touching, as shown in the drawing and photo above.

15a. Install the existing lock nut onto the stem adapter (Item 2). Using a

wrench, tighten the lock nut completely to secure the 10-Position

Handle to the stem adapter (Item 2).

16. Turn the 10-Position Handle to ensure proper operation.

6

victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2014 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

REV_F

I-VIC300MS_31

Page 33

I-VIC300MS / Vic-300® MasterSeal™ Butterfly Valves / Installation and Maintenance Instructions

INSULATION EXTENSION KIT FOR 8-INCH/

219.1-MM VALVES WITH LEVER LOCK HANDLES

WARNING

• Read and understand all instructions before

attempting to install any Victaulic accessory

kits.

Failure to follow all instructions could result in

serious personal injury and/or property damage.

WARNING

• THE PUMP MUST BE SHUT OFF to

prevent flow from passing through the

valve during the following procedures.

Failure to follow this instruction could cause product failure,

resulting in serious personal injury and/or property damage.

Removal of the Lever Lock Handle can be performed without removing

the valve from the piping system. THE PUMP MUST BE SHUT OFF

to prevent flow from passing through the valve during the following

procedures.

Series 761 and 461 Butterfly Valves are designed to accept 2 inches/

50 mm of insulation. When more than 2 inches/50 mm of insulation

is required, the insulation extension kit should be utilized to provide

clearance for the additional insulation.

CONTENTS OF INSULATION EXTENSION KIT

FOR VALVES WITH LEVER LOCK HANDLES

Item No. Quantity Description

1 2 Key

2 1 Stem Adapter

3 1 Spacer/Insulation Ex tension

4 4 Hex-Head Bolt

5 4 Spring-Lock Washer

6 4 Hex Nut

Items not called out in the drawings below are existing components that

must be saved for re-installation of the Lever Lock Handle assembly.

Refer to the following page for kit installation instructions.

3

2

8-inch/219.1-mm Size

1

4

5

6

1

victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2014 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

I-VIC300MS_32

REV_F

Page 34

I-VIC300MS / Vic-300® MasterSeal™ Butterfly Valves / Installation and Maintenance Instructions

INSULATION EXTENSION KIT INSTALLATION

FOR 8-INCH/219.1-MM VALVES WITH LEVER

LOCK HANDLES

WARNING

• Read and understand all instructions before

attempting to install any Victaulic accessory

kits.

Failure to follow all instructions could result in

serious personal injury and/or property damage.

WARNING

• THE PUMP MUST BE SHUT OFF to

prevent flow from passing through the

valve during the following procedures.

Failure to follow this instruction could cause product failure,

resulting in serious personal injury and/or property damage.

Removal of the Lever Lock Handle can be performed without removing

the valve from the piping system. THE PUMP MUST BE SHUT OFF

to prevent flow from passing through the valve during the following

procedures.

1. Using the handle, place the valve disc in the OPEN position.

NOTE: Using a paint stick or bright-colored marker, place a mark

on the handle plate and the valve body to aid in re-installing the

handle plate in the correct orientation.

2. Follow the “Lever Lock Handle Removal for 8-inch/219.1-mm

Valves” section in this manual to remove the handle assembly from

the valve. NOTE: The memory stop hardware does not need to be

removed in order to remove the handle. All components removed

from the valve will be required for re-installation.

3. Remove any debris from the valve body mounting flange.

4. Remove the existing key from the keyway in the stem. Install a new

key (Item 1), provided in the kit, into the keyway in the stem.

5. Place the stem adapter (Item 2) onto the stem.

6. Place the spacer/insulation extension (Item 3) onto the valve

body mounting flange with the machined counterbore facing

upward (away from the valve). Make sure the contoured ends of

the spacer/insulation extension (Item 3) are matched up to the

contoured ends of the valve body mounting flange, and align the

four holes.

7. Secure the spacer/insulation extension (Item 3) to the valve body

mounting flange by using the four hex-head bolts, spring-lock

washers and hex nuts (Items 4, 5, and 6) provided in the kit.

8. Place the existing handle plate onto the spacer/insulation extension

(Item 3). Make sure the mark on the handle plate (made in step 1)

is aligned with the mark on the valve body (made in step 1).

Existing Memory

Stop Hardware

Existing Flat

Existing

Lever Lock

Handle

Existing Hex-Head Screws

⁄ - 18 UNC x 1-inch Long

Handle

Plate

Existing Lock

Washer and

Hex Nut

9. Insert the existing 5/16 - 18 UNC x 2-inch long hex-head screw up

through the hole in the spacer/insulation extension (Item 3) and

the hole in the existing handle plate designated in the drawing

above. Install an existing lock washer and existing hex nut onto this

hex-head screw. Using a wrench, tighten the hex nut until the lock

washer becomes flattened.

10. Install the two 5/16 - 18 UNC x 1-inch long hex-head screws into

the existing handle plate and down through the two holes in the

spacer/insulation extension (Item 3) designated in the drawing

above. Install an existing lock washer and hex nut onto these hexhead screws. Using a wrench, tighten the hex nuts until the lock

washers become flattened.

11. Install the second key (Item 1), provided in the kit, into the keyway

of the stem adapter (Item 2).

12. Install the existing Lever Lock Handle assembly onto the stem

adapter (Item 2). Make sure the pointer of the handle is pointing to

the OPEN marking on the handle plate.

{

Washer, Lock

Washer, and

{

Hex Nut

Existing Lock

Washer and

{

Hex Nut

Existing Lock

Washer and

{

Hex Nut

Existing

Hex-Head Screw

⁄ - 18 UNC x

2-inches Long

13. Tighten the set screw on the side of the Lever Lock Handle, as

shown above.

14. Install the existing flat washer, lock washer, and hex nut onto the

5/16 - 18 UNC x 2-inch long hex-head screw installed in step 9.

Using a wrench, tighten the hex nut until the lock washer becomes

flattened.

15. Turn the Lever Lock Handle to ensure proper operation.

victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2014 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

REV_F

I-VIC300MS_33

Page 35

Series 761 Vic-300® MasterSeal™ Carbon Steel Butterfly Valve

Series 461 Vic-300

®

MasterSeal™ Stainless Steel Butterfly Valve

I-VIC300MSINSTALLATION AND MAINTENANCE INSTRUCTIONS

For complete contact information, visit www.victaulic.com

I-VIC300MS 3905 REV F UPDATED 05/2014 Z000300MS0

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2014 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

I-VIC300MS

Loading...

Loading...