Page 1

I-V9INSTALLATION INSTRUCTIONS

Style V9 Victaulic® FireLock™ IGS™

Installation-Ready™ Sprinkler Coupling

I-V9_1

REV_B

IMPORTANT INFORMATION

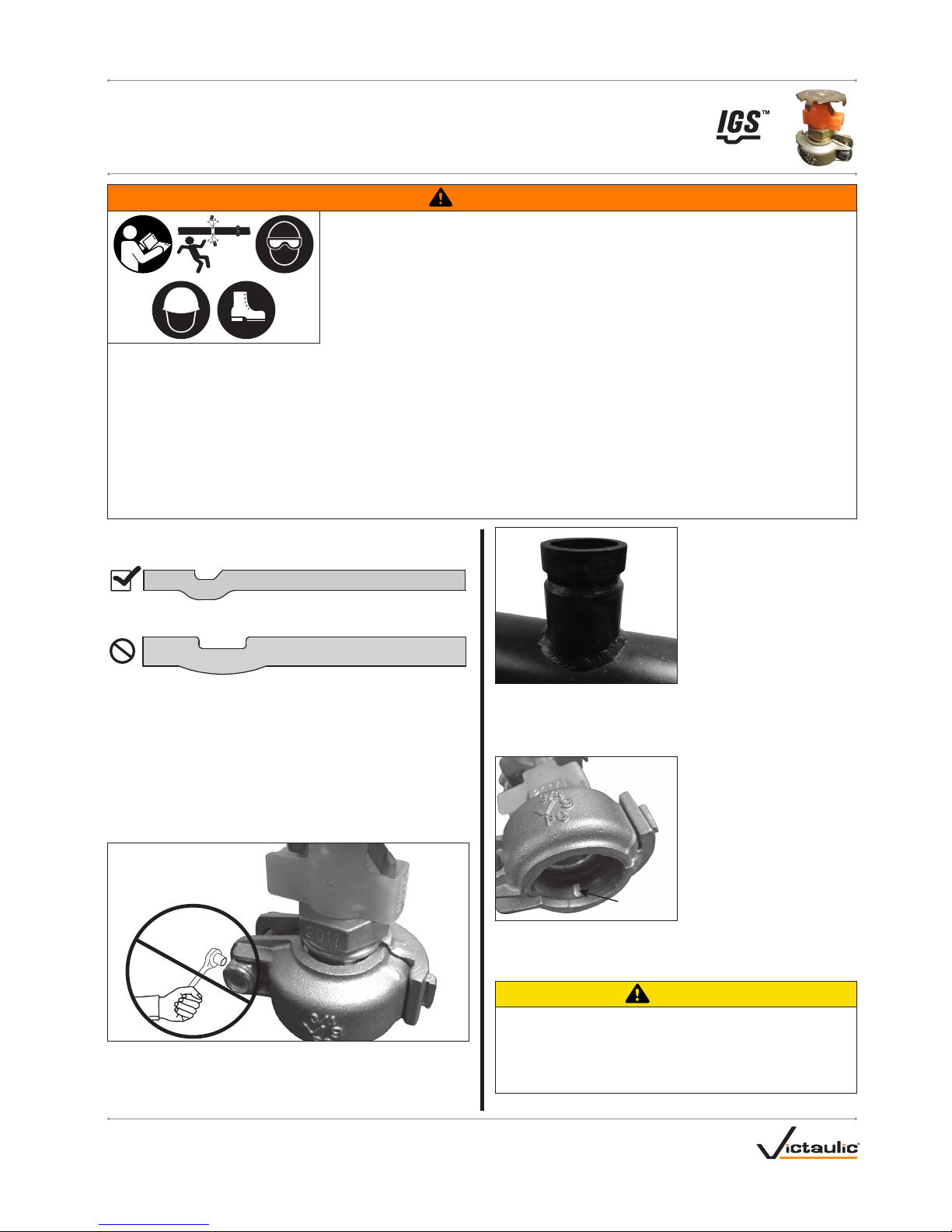

INCORRECT - Orignal Groove System (OGS) Groove Prole

CORRECT - IGS Groove Prole

The Style V9 Victaulic® FireLock™ IGS™ Installation-Ready™ Sprinkler

Coupling shall be used ONLY with sprinkler piping connections that are

prepared to Victaulic IGS proprietary groove specifications. DO NOT

attempt to install the Style V9 on sprinkler piping connections that are

prepared to any other groove specification. Refer to Victaulic publication

25.14 for the IGS groove specification, which can be downloaded at

victaulic.com.

INSTRUCTIONS FOR THE INITIAL

INSTALLATION OF A STYLE V9

DO NOT REMOVE

NUT/BOLT FOR INITIAL

INSTALLATION

1. DO NOT DISASSEMBLE THE STYLE V9: The Style V9 is designed

so that the installer does not need to remove the bolt and nut for

installation. This facilitates installation by allowing the installer to directly

install the Style V9 onto the sprinkler piping’s grooved end.

2. CHECK GROOVED END OF

SPRINKLER PIPING: The outside

surface of the sprinkler piping,

between the groove and the end

of the sprinkler piping, shall be

generally free from indentations,

projections, weld seam anomalies,

and roll marks to ensure a leaktight seal. All oil, grease, loose

paint, dirt, and cutting particles

shall be removed.

The sprinkler piping’s outside diameter (“OD”), groove dimensions,

and maximum allowable flare diameter shall be within the tolerances

published in current Victaulic IGS specifications, publication 25.14,

which can be downloaded at victaulic.com.

Gasket Grade

Color Code Mark

3. Check the gasket to verify

that it is suitable for the intended

service. The color code identifies

the material grade. Refer to

Victaulic publication 05.01 for

the color code chart, which can

be downloaded at victaulic.com.

Refer to the "NOTICE" on the

following page for important

gasket information.

3a. If any conditions listed in the "NOTICE" are met, apply a thin coat of

a compatible lubricant, such as Victaulic Lubricant or silicone lubricant,

only to the gasket sealing lips.

CAUTION

• If any conditions listed in the "NOTICE" are met, a thin coat of a

compatible lubricant shall be applied only to the gasket sealing

lips to prevent pinching, rolling, or tearing during installation.

Failure to use a compatible lubricant may cause gasket damage,

resulting in joint leakage and property damage.

WARNING

• Read and understand all instructions before attempting to install any Victaulic products.

• Always verify that the piping system has been completely depressurized and drained immediately

prior to installation, removal, adjustment, or maintenance of any Victaulic products.

• Wear safety glasses, hardhat, and foot protection.

Failure to follow these instructions could result in death or serious personal injury and property

damage.

• The Style V9 Victaulic® FireLock™ IGS™ Installation-Ready™ Sprinkler Coupling shall be used only in fire protection systems that are

designed and installed in accordance with current, applicable National Fire Protection Association (NFPA 13, 13D, 13R, etc.) standards, or

equivalent standards, and in accordance with applicable building and fire codes. These standards and codes contain important information

regarding protection of systems from freezing temperatures, corrosion, mechanical damage, etc.

• The Style V9 shall be used only for sprinkler-piping-to-sprinker connections. DO NOT use the Style V9 for pipe-to-pipe connections.

• These installation instructions are intended for an experienced, trained installer. The installer shall understand the use of this product and

why it was specified for the particular application.

• The installer shall understand common industry safety standards and potential consequences of improper product installation.

Failure to follow installation requirements and local and national codes and standards could compromise system integrity or cause system

failure, resulting in death or serious personal injury and property damage.

Page 2

I-V9_2

REV_B

I-V9 / Style V9 Victaulic® FireLock™ IGS™ Installation-Ready™ Sprinkler Coupling / Installation Instructions

NOTICE

• Gaskets for the Style V9 are provided with

Vic-Plus

. Additional

lubrication is not required for the initial installation of wet pipe

systems that are installed at or continuously operating above

0°F/–18°C. Refer to Victaulic publication 05.03 for the

Vic-Plus

Safety Data Sheet (SDS), which can be downloaded at victaulic.

com.

Supplemental lubrication is required only if any of the following

conditions exist. Apply a thin coat of a compatible lubricant to the

gasket sealing lips, as noted in step 3a on the previous page. It

is not necessary to remove the gasket from the housings to apply

additional lubricant to the exterior surface.

• If the installation or continuous operating temperature is below

0°F/–18°C

• If the gasket has been exposed to fluids prior to installation

• If the surface of the gasket does not have a hazy appearance

• If the gasket is being installed into a dry pipe system

• If the system will be subjected to air tests prior to being filled

with water

• If the gasket was involved in a previous installation

Lubricated gaskets will not enhance sealing capabilities on

adverse sprinkler piping conditions. Sprinkler piping condition

and preparation shall conform to the requirements listed in these

product installation instructions (refer to step 2 on page 1).

WARNING

• Never leave a Style V9 partially assembled.

ALWAYS TIGHTEN THE HARDWARE

IMME DIAT ELY. A partially-assembled Style

V9 poses a drop or fall hazard during

installation and a burst hazard during

testing.

• Keep hands away from the opening of the

Style V9 when attempting to install and

tighten the Style V9 onto the sprinkler

piping’s grooved end.

Failure to follow these instructions could

result in serious personal injury and property

damage.

4. ASSEMBLE JOINT: Assemble the joint by installing the Style V9 onto

the sprinkler piping's grooved end until contact with the center leg of

the gasket occurs. Rotate the sprinkler and Style V9 so that the frame

arms and bolt pads are in alignment with the sprinkler piping, as shown

above. A visual check is required to verify that the keys of the Style V9

align with the groove in the sprinkler piping.

WARNING

• The bolt shall be tightened until metal-to-metal c ontact occurs

at the bolt pads.

• DO NOT continue to tighten the bolt after the visual installation

guidelines for the Style V9 are achieved.

• DO NOT attempt to rotate the sprinkler or Style V9 after the bolt

is tightened completely.

Failure to follow these instructions could cause joint damage or

improper sprinkler operation, resulting in death or serious personal

injury and property damage.

Hex Installation Bit Provided

with Product Shipment

3⁄16-inch

(Bolt End)

¼-inch

(Drive End)

5. TIGHTEN BOLT: Using an impact wrench or standard socket wrench

with the 3/16-inch hex installation bit that is provided with the product

shipment, tighten the bolt until metal-to-metal contact occurs at the bolt

pads. DO NOT continue to tighten the bolt after metal-to-metal bolt pad

contact is achieved. Refer to the “Impact Wrench Usage Guidelines”

section. NOTE: Do not at tempt to rotate the sprinkler or Style V9 after

the bolt is tightened. If necessary, loosen the bolt before attempting to

rotate the sprinkler or Style V9, then retighten the bolt as stated earlier

in this step.

GOOD

BAD

6. Visually inspect the bolt pads at each sprinkler piping connection

to verify that metal-to-metal contact is achieved in accordance with

step 5.

Page 3

I-V9_3

REV_B

I-V9 / Style V9 Victaulic® FireLock™ IGS™ Installation-Ready™ Sprinkler Coupling / Installation Instructions

WARNING

• Sprinklers cannot operate properly with bulb protectors in place.

• Bulb protectors shall be removed from all sprinklers before the

sprinkler system is placed in service.

• DO NOT use any tools to remove bulb protectors.

Failure to remove bulb protectors from all sprinklers before the

system is placed in service will cause improper sprinkler operation,

resulting in death or serious personal injury and property damage.

7. Remove the bulb protector

from all sprinklers carefully by

hand before the sprinkler system

is placed in service. Refer to

the installation instructions for

applicable sprinkler for complete

requirements.

IMPACT WRENCH USAGE GUIDELINES

WARNING

• The bolt shall be tightened until metal-to-metal c ontact occurs

at the bolt pads.

• DO NOT continue to tighten the bolt after the visual installation

guidelines for the Style V9, described in steps 5 − 6 on page 2,

are achieved.

Failure to follow these instructions could cause joint failure,

resulting in death or serious personal injury and property damage.

Impact wrenches do not provide the installer with direct “wrench feel”

or torque to judge bolt tightness. Since some impact wrenches are

capable of high output, it is important to develop a familiarity with the

impact wrench to avoid damaging or fracturing the bolt or the coupling's

bolt pads during installation. Always choose the right size impact

wrench that has enough power, but DO NOT continue to tighten the

bolt after the visual installation guidelines for the Style V9, described

in steps 5 − 6 on page 2, are achieved. If you suspect that any

hardware has been over-tightened (as indicated by a bend or crack

in the bolt, etc.), the entire Style V9 assembly shall be replaced

imm edia tely.

If the battery is drained or if the impact wrench is under-powered, a

new battery pack or new impact wrench shall be used to ensure that

the visual installation guidelines for the Style V9, described in steps

5 − 6 on page 2, are achieved. Visual inspection of each joint is

required for verification of proper assembly.

Perform trial assemblies with the impact wrench and check the

assemblies with a torque wrench to help determine the suitability of the

impact wrench. Using the same method, periodically check assemblies

throughout the system installation.

For safe and proper use of impact wrenches, always refer to the impact

wrench manufacturer’s operating instructions. In addition, verify that

proper impact grade hex drivers are being used for Style V9 installation.

WARNING

Failure to follow instructions for tightening hardware could result in:

• Personal injury or death

• Bolt damage or fracture

• Damaged or broken bolt pads or fractures to housings

• Joint leakage and property damage

• A negative impact on system integrity

INSTRUCTIONS FOR REASSEMBLY

OF A STYLE V9

WARNING

• Always verify that the piping system has

been completely depressurized and drained

immediately prior to installation, removal,

adjustment, or maintenance of any Victaulic

products.

• The sprinkler shall be replaced upon disassembly of a Style V9.

Verify that the replacement sprinkler is the proper model, style,

orifice size, temperature rating, and response.

Failure to follow these instructions could result in death or serious

personal injury and property damage.

1. Verify that the system is depressurized and drained completely before

attempting to disassemble a Style V9 from the sprinkler piping.

2. Loosen the hardware of the Style V9 to permit removal from the

sprinkler piping.

3. Remove the nut, bolt, and gasket from the Style V9 housings.

Inspect all components for damage or wear. If any damage or wear is

present, use a new Victaulic-supplied Style V9 assembly.

NOTE: The sprinkler shall be replaced upon disassembly of a Style V9.

Verify that the replacement sprinkler is the proper model, style, orifice

size, temperature rating, and response.

4. Check sprinkler piping ends, as described in step 2 on page 1.

CAUTION

• A thin coat of a compatible lubricant shall be used to prevent the

gasket from pinching, rolling, or tearing during reassembly.

Failure to use a compatible lubricant may cause gasket damage,

resulting in joint leakage and property damage.

5. LUBRICATE GASKET: Apply a thin coat of Victaulic Lubricant or

silicone lubricant to the gasket sealing lips and exterior. NOTE: It is

normal for the gasket surface to have a hazy white appearance after it

has been in service.

Page 4

I-V9INSTALLATION INSTRUCTIONS

Style V9 Victaulic® FireLock™ IGS™

Installation-Ready™ Sprinkler Coupling

For complete contact information, visit victaulic.com

I-V9 11351 REV B UPDATED 11/2018 Z0000V9000

VICTAULIC, FIRELOCK, IGS, AND INSTALLATION-READY ARE REGISTERED TRADEMARKS OR TRADEMARKS OF VICTAULIC COMPANY AND/OR

ITS AFFILIATED ENTITIES IN THE UNITED STATES AND/OR OTHER COUNTRIES. © 2018 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

Larger Opening

of Housings to

Larger Opening

of Gasket

6. REASSEMBLE STYLE V9: Place the lubricated gasket inside

the gasket pocket of one Style V9 housing. NOTE: For all sizes other

than the 1-inch x 1-inch/33.7-mm x 33.7-mm, verify that the larger

opening of the gasket is facing the larger opening of the housings, as

shown above. Engage the tab of the one housing with the slot of the

other housing, and close the housings around the gasket.

Head of Bolt Shall

Face Angled Feature

of Bolt Pad

7. INSTALL BOLT: Install the bolt through the housings. Verify that the

head of the bolt faces the angled feature of the bolt pad, as shown

above.

8. INSTALL NUT: Thread the bolt into the nut until the top of the nut

is flush with the end of the bolt, as shown above. Verify that the gasket

remains seated in the gasket pocket of the housings and that the nut is

engaged with the flat features of the bolt pad.

WARNING

• The sprinkler shall be replaced upon disassembly of a Style V9.

Verify that the replacement sprinkler is the proper model, style,

orifice size, temperature rating, and response.

Failure to follow this instruction could cause improper sprinkler

operation, resulting in death or serious personal injury and property

damage.

9. INSTALL NEW SPRINKLER: Insert a new sprinkler that is the proper

model, style, orifice size, temperature rating, and response into the

corresponding opening of the Style V9 housings. Rotate the sprinkler so

that the frame arms align with the bolt pads, as shown above.

10. Follow steps 4 – 7 on pages 2 – 3 of this instruction sheet to

complete the assembly.

Loading...

Loading...