Page 1

R

The following instructions are a guide for the proper installation of Victaulic Style 441 Stainless Steel Vic-Flange Adapters. Proper installation requires pipe that is prepared and grooved

in accordance with the latest Victaulic specifications.

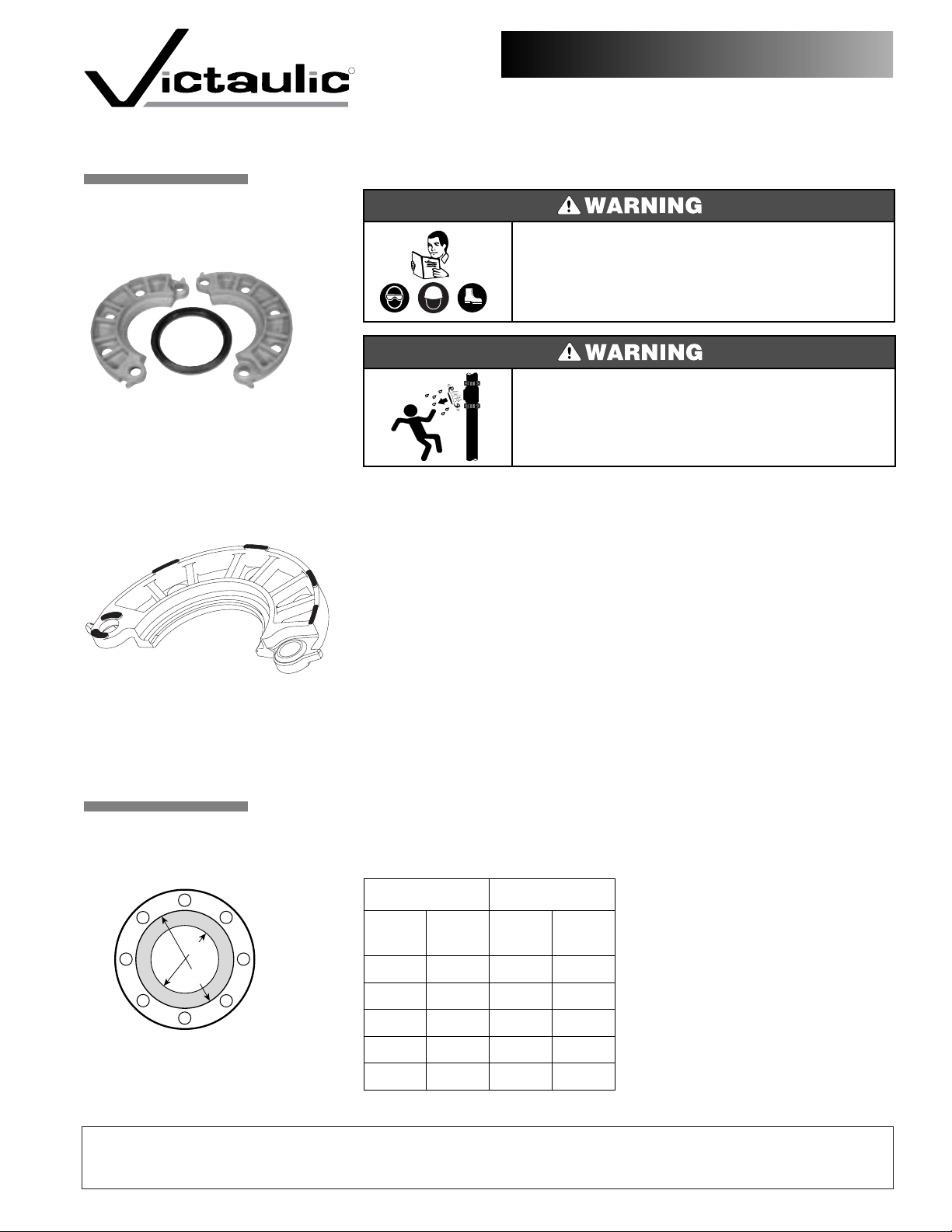

• The Style 441 is designed for use with Class 150 raised-face flanges, in accordance with

ANSI B16.5. When a Style 441 is used with a flat-faced flange, the raised projections on

the outside edge and around the mating holes of the flange adapter must be ground flush

to the body. The shaded areas on the sketch to the left identify the projections that need

to be ground flush on both segments.

• The Style 441 cannot be used, unless it mounts flush to the mating flange; therefore,

flange washers, or anything else that prevents flush mounting, cannot be used.

• The Style 441 must not be used as anchor points for tie rods across non-restrained joints.

• The Style 441 must not be used against rubber coated surfaces or with wafer or lug-type

valves, or when the flange adapter does not mount flush with the mating flange.

• Because of the outside flange dimension, the Style 441 must not be used 90° to one

another on a standard fitting.

1.

2.

Installation Instructions

Style 441

®

Adapter

IMPORTANT

INFORMATION

Stainless Steel Vic-Flange

2 - 6" (60,3 - 168,3 mm)

• Read and understand all installation instructions before attempting to install any

Victaulic piping products.

•Wear hardhat, safety glasses, and foot protection.

Failure to follow these instructions could result in serious personal injury, property

damage, and/or product damage.

• Depressurize and drain piping systems before attempting to install, remove, or

adjust any Victaulic piping products.

Failure to follow these instructions could result in serious personal injury and/or

property damage.

ALWAYS VERIFY THAT THE GASKET IS SUITABLE FOR THE INTENDED SERVICE. Refer to publication 05.01 for complete information.

PIPE AND MATING

FACE PREPARATION

A

B

Figure 1

VICTAULIC® IS AN ISO 9001 CERTIFIED COMPANY

Victaulic Company of America

Phone: 1-800-PICK-VIC (1-800-742-5842)

Fax: 610-250-8817

e-mail:pickvic@victaulic.com

I-441

3307 Rev.B 8/02 © Copyright 2002, Victaulic ® Registered Trademark of Victaulic Printed in U.S.A Z000441000

Victaulic Company of Canada

Phone: 416-675-5575

Fax: 416-675-5565

e-mail: viccanada@victaulic.com

PIPE SIZE

Nominal

Diameter

in/

2 2.375 2.40 3.40

50 60,3 61 86

2

65 73,0 74 99

3 3.500 3.50 4.50

80 88,9 89 114

4 4.500 4.50 5.50

100 114,3 114 140

6 6.625 6.60 7.80

150 168,3 168 198

mm

¹⁄₂

Actual

Out. Dia.

in/

mm

2.875 2.90 3.90

Sealing Surface

“A” Max. “B” Max.

Victaulic Europe

Phone: 32-9-381-1500

Fax: 32-9-380-4438

e-mail: viceuro@victaulic.be

inches/

mm

the pipe end to the groove) must be

smooth and free from indentations, projections, and roll marks to provide a

leak-tight seal for the gasket. All rust,

loose scale, oil, grease, and dirt must be

removed.

ure 1) must be free from gouges, undulations, or deformities of any type for

proper sealing.

Victaulic America Latina

Phone: 610-559-3300

Fax: 610-559-3608

e-mail: vical@victaulic.com

The outside surface of the pipe (from

The gray area of the mating face (Fig-

Victaulic Asia Pacific

Phone: 65-6235-3035

Fax: 65-6235-0535

e-mail: vicap@victaulic.com

Page 2

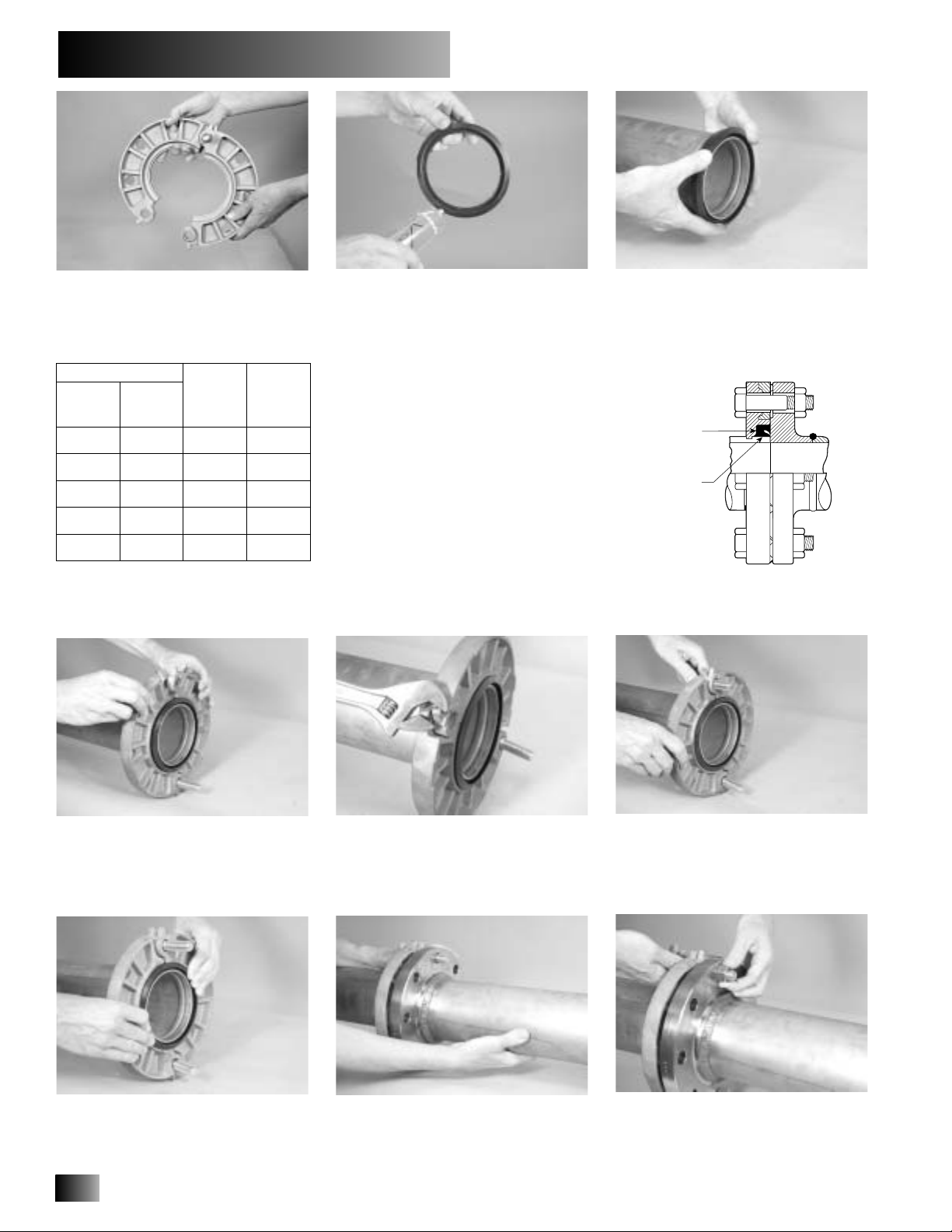

Figure 2

Gasket

Position

Gasket

Markings

3.

6.

9.

1.

4.

7.

✕

✕

✕

Installation Instructions

✕

✕

2.

5.

8.

Insert a standard bolt through a mating hole to act as a hinge, as shown

above.

BOLT REQUIREMENTS

PIPE SIZE

Nominal

Diameter

mm

in/

2 2.375

50 60,3

2

¹⁄₂

65 73,0

3 3.500

80 88,9

4 4.500

100 114,3

6 6.625

150 168,3

*Bolts are not supplied by Victaulic. When using stainless

steel bolts/nuts, consideration should be given to using

an anti-seize lubricant on the threads.

Actual

Out. Dia.

in/

2.875

mm

Number of

Bolts

Required*

4

4

4

8

8

Bolt Size

inches

⁵⁄₈

2

³⁄₄

⁵⁄₈

3

⁵⁄₈

3

⁵⁄₈

3

³⁄₄

3

¹⁄₂

Check the gasket supplied to make

sure it is suitable for the intended service. The color code identifies the gasket grade. Apply a thin coat of Victaulic

lubricant or silicone lubricant to the

gasket lips and exterior.

Install the gasket onto the pipe end.

Make sure the gasket is properly positioned, as shown in Figure 2 below.

NOTE: The markings on the outside of

the gasket must face the Style 441

flange adapter.

Place the hinged flange around the

grooved pipe end. Make sure the key

section of the flange adapter engages in

the pipe groove.

Make sure the gasket is still seated

properly in the flange adapter.

2

Closure lugs are provided to ease

installation. Clamp both lugs with a

wrench or pliers, and pull the two segments together until the bolt holes

align.

Join the mating flange with the VicFlange by aligning the two bolts with

the mating flange’s holes.

When the bolt holes are aligned,

insert a standard bolt through the other

mating hole.

Install a nut onto the two bolts.

Tighten until the nuts are finger-tight.

Page 3

Installation Instructions

10. Install the remaining standard bolts

through the Vic-Flange and the mating

flange. Install all nuts until they are

finger-tight.

11. Tighten all nuts evenly in a crossing

pattern, as with a regular flange assembly. Continue to tighten all nuts until

the standard, flange-joint torque recommendation is achieved.

This product shall be manufactured by Victaulic Company. All products to be installed in accordance with current Victaulic installation/assembly instructions.

Victaulic reserves the right to change product specifications, designs and standard equipment without notice and without incurring obligations.

3

Loading...

Loading...