Page 1

OPERATING AND MAINTENANCE INSTRUCTIONS MANUAL

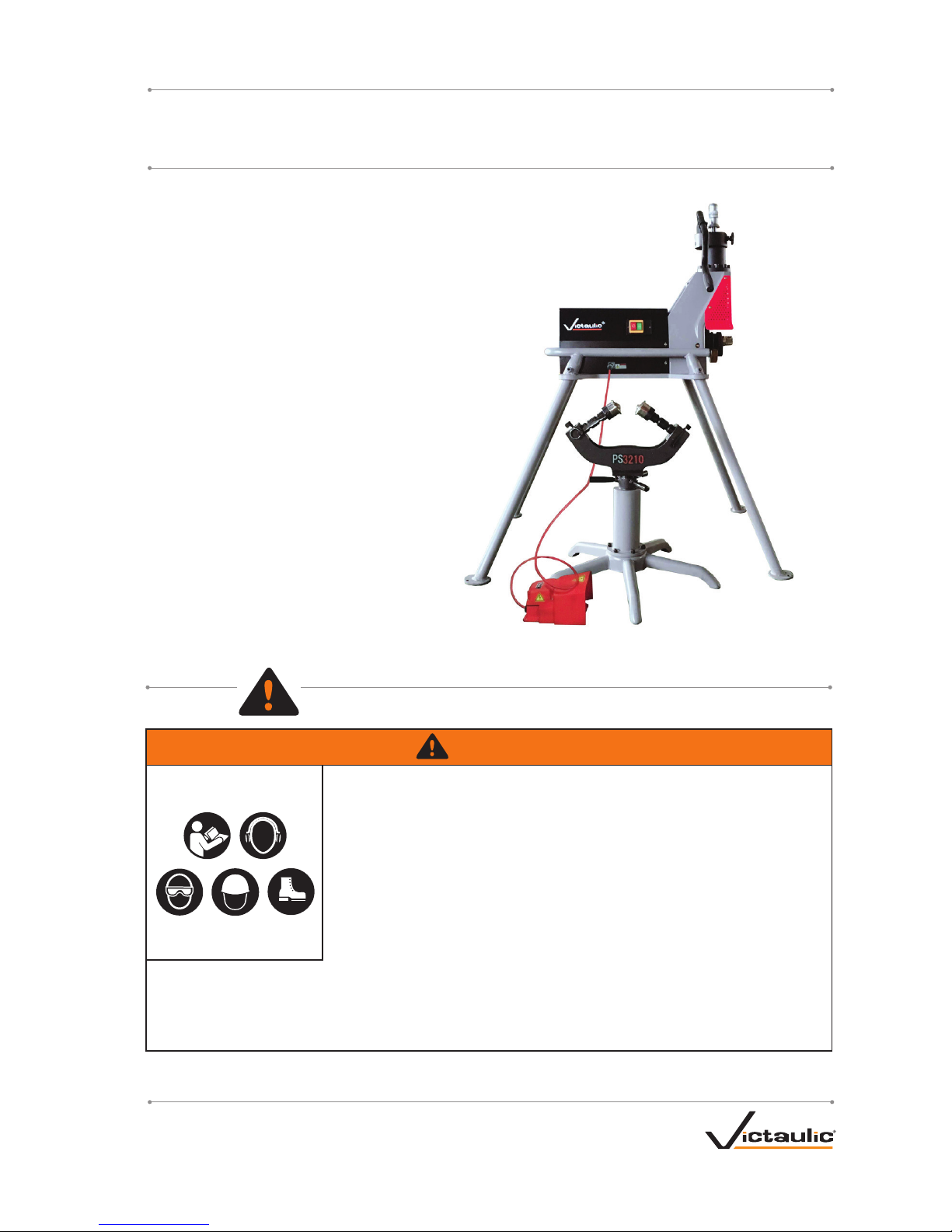

RG3210 Roll Grooving Tool

WARNING

Original Instructions

WARNING

Failure to follow instructions and warnings could result in death,

serious personal injury, property damage, and/or product damage.

• Before operating or servicing any grooving tools, read all

instructions in this manual and all warning labels on the tool.

• Wear safety glasses, hardhat, foot protection, and hearing

protection while working around this tool.

• Save this operating and maintenance manual in a place

accessible to all operators of the tool.

If you need additional copies of any literature, or if you have questions concerning the safe

and proper operation of this tool, contact Victaulic, No.13, Tieshan Dong 2 Road,

DaLian Development Zone, Dalian, China 116630, Phone: 86-411-39213600,

E-Mail: vicap@victaulic.com

REV_E

TM-RG3210

Page 2

Page 3

TABLE OF CONTENTS

Hazard Identification ................. 4

Operator Safety Instructions ............ 4

Introduction ....................... 6

Receiving the Tool ....................6

Container Contents ...................6

Power Requirements ................. 7

Extension Cord Requirements ...........7

Tool Nomenclature................... 8

Tool Dimensions .................... 9

Tool Specifications .................. 9

Tool Setu p ........................ 9

Pre-Operation Adjustments.............10

Grooving Rolls ......................10

Preparing Pipe for Grooving ............10

Pipe Length Requirements.............10

Long Pipe Lengths...................11

Groove Diameter Stop Adjustment . . . . . . . 12

Grooving Operation ..................14

Lower Roll Removal ..................16

Upper Roll Removal..................16

Upper Roll Installation................17

Lower Roll Installation ................17

Maintenance .......................18

Hydraulic System....................18

PS3210 Pipe Stand ..................18

Replacement Parts ..................18

Troubleshooting.....................19

Explanation of Critical Roll Groove

Dimensions ..................... 20

Roll Groove Specifications for Steel Pipe .. 22

Tool Ratings for Steel Pipe............ 22

EC Declaration of Conformity .......... 23

3

REV_E

TM-RG3210 / Operating and Maintenance Instructions Manual

Page 4

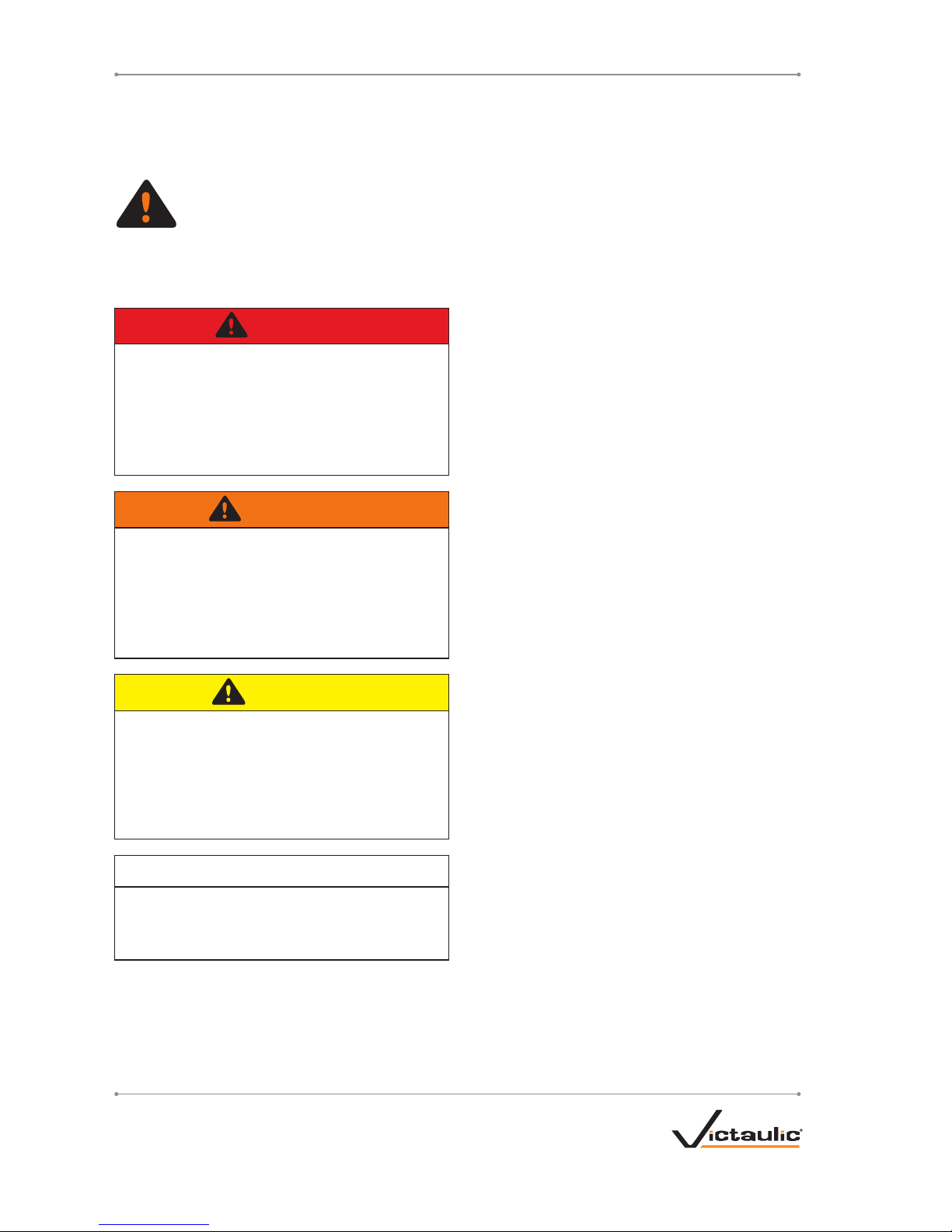

HAZARD IDENTIFICATION

Definitions for identifying the various hazard

levels are provided below.

This safety alert symbol indicates

important safety messages. When

you see this symbol, be alert to the

possibility of personal injury.

Carefully read and fully understand the message

that follows.

DANGER

• The use of the word “DANGER” always

signifies an immediate hazard with

a likelihood of severe personal injury

or death if instructions, including

recommended precautions, are not

followed.

WARNING

• The use of the word “WARNING” signifies

the presence of hazards or unsafe

practices which could result in severe

personal injury if instructions, including

recommended precautions, are not

followed.

CAUTION

• The use of the word “CAUTION”

signifies possible hazards or unsafe

practices which could result in minor

injury and product or property damage

if instructions, including recommended

precautions, are not followed.

NOTICE

• The use of the word “NOTICE” signifies

special instructions which are important

but not related to hazards.

OPERATOR SAFETY

INSTRUCTIONS

The RG3210 is designed for the sole purpose

of roll grooving pipe. These instructions must

be read and understood by each operator

PRIOR to working with the grooving tools. These

instructions describe safe operation of the tool,

including setup and maintenance. Each operator

must become familiar with the tool’s operations,

applications, and limitations. Particular care

should be given to reading and understanding

the dangers, warnings, and cautions described

throughout these operating instructions.

Use of these tools requires dexterity and

mechanical skills, as well as sound safety

habits. Although these tools are designed and

manufactured for safe, dependable operation,

it is difficult to anticipate all combinations of

circumstances that could result in an accident.

The following instructions are recommended

for safe operation of these tools. The operator

is cautioned to always practice “safety first”

during each phase of use, including set up and

maintenance. It is the responsibility of the lessee

or user of these tools to ensure that all operators

read this manual and fully understand the

operation of these tools.

Store this manual in a clean, dry area where

it is always readily available. Additional copies

of this manual are available upon request

through Victaulic, or can be downloaded at

victaulic.com.

4

REV_E

TM-RG3210 / Operating and Maintenance Instructions Manual

Page 5

DANGER

1. Avoid using the tool in potentially

dangerous environments. Do not expose

the tool to rain, and do not use the tool in

damp or wet locations. Do not use the tool

on sloped or uneven surfaces. Keep the

work area well lit. Allow sufficient space to

operate the tool properly.

2. Ground the motor to protect the operator

from electric shock. Ensure that the motor

is connected to an internally grounded

electrical source.

3. Disconnect the power cord from the

electrical source before servicing the

tool. Only authorized personnel should

perform maintenance on the tool. Always

disconnect the power cord from the

electrical source before servicing or

adjusting the tool.

4. Prevent accidental startups. Place the

power switch in the “OFF” position before

connecting the tool to an electrical source.

WARNING

1. Prevent back injury. DO NOT attempt to

lift tool components without the use of

mechanical lifting equipment.

2. Wear proper apparel. Do not wear loose

clothing, jewelry, or anything that can

become entangled in moving parts.

3. Wear protective items when working with

tools. Always wear safety glasses, hard hat,

foot protection, and hearing protection.

4. Keep hands and tools away from grooving

rolls and stabilizer wheel during the

grooving operation. Grooving rolls can

crush or cut fingers and hands.

5. Do not reach inside pipe ends during tool

operation. Pipe edges can be sharp and

can snag gloves, hands, and shirt sleeves.

Never reach across moving parts.

6. Do not over-reach. Maintain proper footing

and balance at all times.

CAUTION

1. This tool is designed ONLY for

roll grooving pipe sizes, materials, and

wall thicknesses listed in the “Tool

Ratings for Steel Pipe” section.

2. Inspect the equipment. Before using the

tool, check all moveable parts for any

obstructions. Verify that tool components

are installed and adjusted in accordance

with the “Tool Setup” section.

3. Stay alert. Do not operate the tool if you are

drowsy from medication or fatigue.

4. Keep visitors, trainees, and observers

away from the immediate work area. All

visitors should be kept a safe distance from

the equipment at all times.

5. Keep work areas clean. Keep the

work area around the tool clear of any

obstructions that could limit movement of

the operator. Clean up any spills.

6. Secure the work, machine, and

accessories. Ensure that the tool is stable.

Refer to the “Tool Setup” section.

7. Support the work. Support long pipe/tubing

lengths with a pipe stand, in accordance

with the “Long Pipe Lengths” section.

8. Do not force the tool. Do not force the tool

or accessories to perform any functions

beyond the capabilities described in these

instructions. Do not overload the tool.

9. Maintain tool with care. Keep the tool

clean at all times to ensure proper and

safe performance. Follow the instructions

for lubricating tool components.

10. Use only Victaulic replacement parts

and accessories. Use of any other parts

may result in a voided warranty, improper

operation, and hazardous situations.

11. Do not remove any labels from the tool.

Replace any damaged or worn labels.

5

REV_E

TM-RG3210 / Operating and Maintenance Instructions Manual

Page 6

INTRODUCTION

NOTICE

• Drawings and/or pictures in this manual

may be exaggerated for clarity.

• The tool, along with this operating

and maintenance instructions manual,

contains trademarks, copyrights, and/or

patented features that are the exclusive

property of Victaulic.

The RG3210 is a hydraulic-feed shop or field

tool designed to roll groove carbon steel pipe

of various diameters and wall thicknesses. The

RG3210 is a completely self-contained unit with

a motor, power cord/plug, and hydraulic pump

handle.

CAUTION

• The RG3210 should only be used for roll

grooving pipe designated in the “Tool

Ratings for Steel Pipe” section of this

manual.

Use of the tools for other purposes, or use

exceeding the pipe thickness maximums,

will overload the tools, shortening tool life

and potentially causing tool damage.

RECEIVING THE TOOL

RG3210 tools are packed individually in sturdy

containers that are designed for repeated

shipping. Save the container for return shipment

of rental tools.

Upon receipt of the tool, ensure that all

necessary parts are included. If any parts

are missing, contact Victaulic.

CONTAINER CONTENTS

Qty. Description

1

Tool with Motor and Hydraulic Pump Handle

1

Foot Switch

1

PS3210 Pipe Stand

1

Roll Set Assembly (5 Rollers)

2

Operating and Maintenance Instructions Manual

The RG3210 is supplied with grooving roll sets

for carbon steel pipe. Rolls are marked with the

pipe size and part number.

6

REV_E

TM-RG3210 / Operating and Maintenance Instructions Manual

Page 7

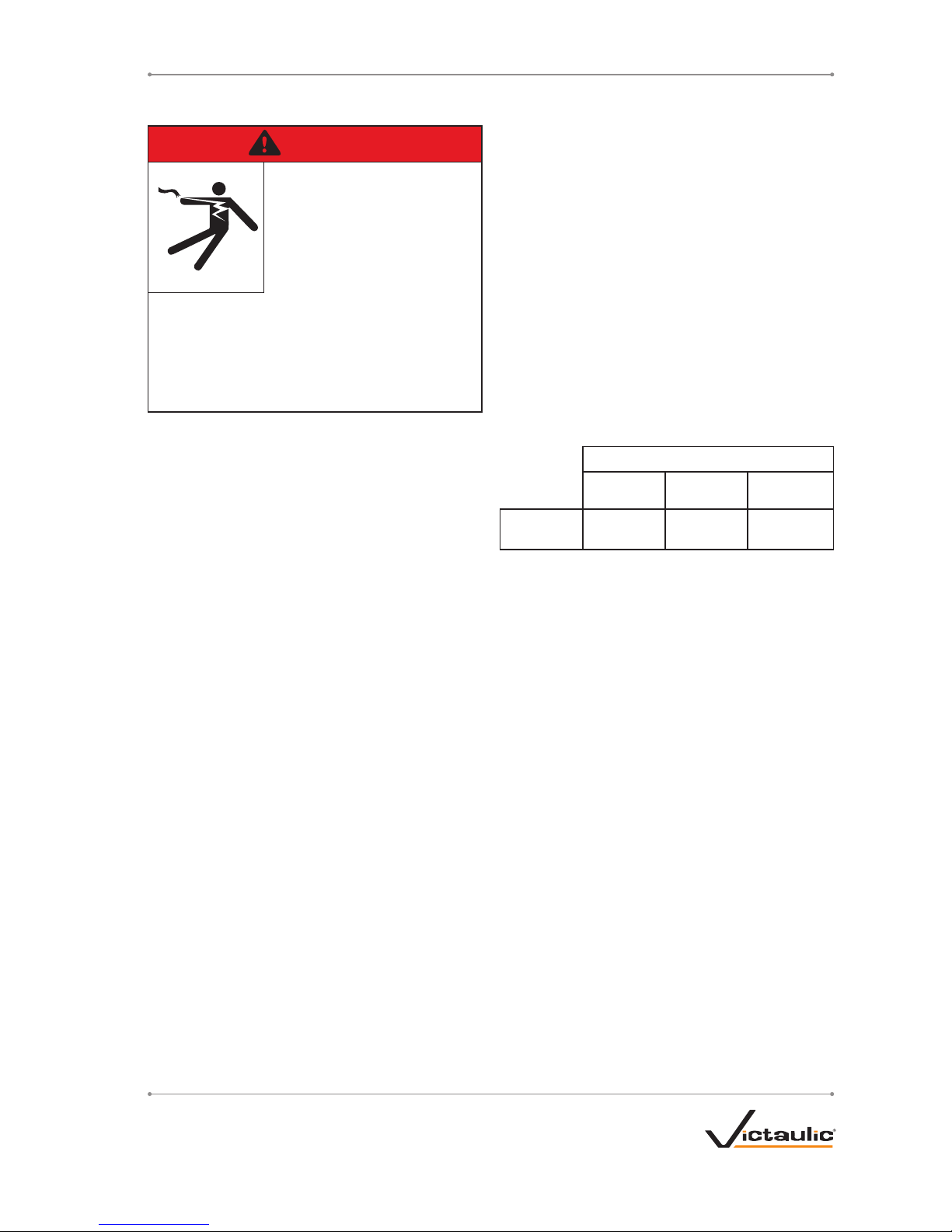

POWER REQUIREMENTS

DANGER

• To reduce the risk of

electric shock, check

the electrical source for

proper grounding and

follow all instructions.

• Before performing any repair or

maintenance, disconnect the tool from

the electrical source.

Failure to do so could result in death or

serious personal injury.

Maximum current draw is 8.5 amps.

The RG3210 tool must be grounded properly in

accordance with all local and national electrical

code requirements.

If an extension cord is required, refer to the

“Extension Cord Requirements” section.

EXTENSION CORD REQUIREMENTS

When pre-wired outlets are not available and

an extension cord must be used, it is important

to use the proper cord size (gauge). Cord size

selection is based upon tool rating and cord

length. Use of a cord size (gauge) thinner than

required will cause significant voltage drop at

the motor while the tool is operating. Voltage

drops may cause damage to the motor and can

result in improper tool operation. NOTE: It is

acceptable to use a cord size that is thicker than

required.

Listed in the chart below are recommended

cord size (gauge) for cord lengths up to and

including 31 meters. Use of extension cords

beyond 31 meters in length should be avoided.

Cord Lengths

8 meters 15 meters 31 meters

Cord Size

(Gauge)

12 gauge 12 gauge 10 gauge

7

REV_E

TM-RG3210 / Operating and Maintenance Instructions Manual

Page 8

TOOL NOMENCLATURE

PS3210 Pipe Stand

Hydraulic Pump Handle

Lower Roll

Power Cord

Power Switch

Hydraulic Cylinder

Depth Adjuster Nut

Locking Nut

Hydraulic Pump Valve

Upper Roll

Foot Switch

8

REV_E

TM-RG3210 / Operating and Maintenance Instructions Manual

Page 9

TOOL SPECIFICATIONS

Tool weight: 137 kilograms

Voltage: 220-volt, single phase

Frequency: 50 Hz/60 Hz

Maximum working pressure: 8000 kg

Maximum oil cylinder pressure: 40 Mpa

Capacity of oil tank: 150 ml

TOOL SETUP

WARNING

• Do not connect power until instructed

otherwise.

• Tool must be lifted with a hoist and plate

clamp to safely handle the tool weight

(137 kilograms).

Failure to follow these instructions may

result in serious personal injury.

1. Remove all components and check to ensure

that all necessary items are included. Refer to

the “Receiving the Tool” section.

2. Select a location for the tool and pipe stand.

Choose a location that has:

a. The required power. Refer to the “Power

Requirements” section

b. The space necessary to adequately

handle the pipe to be grooved

c. A level surface for the tool and pipe

stand

3. Place the tool on a level surface. Place a

level on top of the motor to verify that the

tool is level front to back and side to side.

4. Make sure the hydraulic system is full of

oil. Refer to the “Maintenance” section for

hydraulic oil requirements.

TOOL DIMENSIONS

820 mm

1100 mm

1300 mm

9

REV_E

TM-RG3210 / Operating and Maintenance Instructions Manual

Page 10

PRE-OPERATION ADJUSTMENTS

Every RG3210 tool is checked, adjusted, and

tested at the factory prior to shipment. Before

grooving, however, the following adjustments

should be made to ensure proper tool operation.

WARNING

• Always turn off power before making any

tool adjustments.

Accidental startup of tool may result in

serious personal injury.

GROOVING ROLLS

Ensure that the proper roll set is on the tool.

Rolls are marked with the pipe size and part

number. Refer to the “Tool Ratings for Steel

Pipe” section. If proper rolls are not on the tool,

please refer to relative sections to change the

rolls.

CAUTION

• Ensure that roll retaining bolts are tight.

Loose retaining bolts could seriously

damage both the tool and the rolls.

PREPARING PIPE FOR GROOVING

CAUTION

• For maximum grooving roll life, remove

foreign material and loose rust from the

interior and exterior surfaces of the pipe

ends. Rust is an abrasive material that

will wear the surface of grooving rolls.

Foreign material may interfere with or

damage grooving rolls, resulting in distorted

grooves and grooves that are not within

Victaulic specifications.

For proper tool operation and production of

grooves that are within Victaulic specifications,

the following pipe preparation steps must be

followed.

1. Victaulic recommends square-cut pipe for

use with grooved-end pipe products.

2. Raised internal and external weld beads

and seams must be ground flush with the pipe

surface 50 mm back from the pipe ends.

3. The inside diameter of the pipe end must

be cleaned to remove coarse scale, dirt, and

other foreign material that might interfere with

or damage grooving rolls. The front edge of the

pipe end shall be uniform with no concave/

convex surface features that will cause improper

grooving roll tracking and result in difficulties

during coupling assembly.

PIPE LENGTH REQUIREMENTS

RG3210 tools are capable of grooving short pipe

lengths without the use of a pipe stand. Table 1

identifies the maximum pipe lengths that can be

grooved without the use of a pipe stand.

Pipe lengths, longer than those listed in

Table 1 (and up to 6 meters), must be

supported with a pipe stand. Pipe lengths,

from 6 meters up to double-random lengths

(approximately 12 meters), must be supported

with two pipe stands. Refer to the “Long Pipe

Lengths” section for instructions on how to

groove long pipe lengths.

If pipe is required that is shorter than the

minimum length listed in Table 1, shorten

the next-to-last piece so that the last piece is

as long (or longer) than the minimum length

specified.

EXAMPLE: A 6.2-m length of 219.1-mm

diameter steel pipe is required to finish a

section, and only 6.1-m lengths are available.

Instead of roll grooving a 6.1-m length of carbon

steel pipe and a 100-mm length of carbon steel

pipe, follow these steps:

1. Refer to Table 1, and note that for 219.1-mm

diameter carbon steel pipe, the minimum length

that should be roll grooved is 255 mm.

2. Roll groove a 5.945-m length of pipe and a

255-mm length of pipe. Refer to the “Long Pipe

Lengths” section.

10

REV_E

TM-RG3210 / Operating and Maintenance Instructions Manual

Page 11

Table 1- Pipe Lengths Suitable for Grooving

Actual Pipe

Outside Diameter

Minimum Length

mm

Maximum Length

mm

60.3 mm – 114.3 mm 205 915

127.0 mm – 141.3 mm 205 815

152.4 mm 255 760

165.1 mm – 168.3 mm 255 710

203.2 mm – 219.1 mm 255 610

267.4 mm – 273.0 mm 255 510

318.5 mm – 323.9 mm 305 460

LONG PIPE LENGTHS

1. A pipe stand must be used with pipe that is longer than the maximum length listed in Table 1.

Place the pipe stand at a distance slightly beyond half the pipe length from the tool.

2. With a length of pipe in position on the tool’s lower roll, adjust the pipe stand height to position

the pipe level to 1° below level for 60.3 − 219.1-mm pipe sizes or 0.75° to 1.25° below level for

267.4 − 323.9-mm pipe sizes.

Place Pipe Stand Slightly Beyond

Half the Pipe Length from the Tool

Tool Centerline

(Level)

Pipe Centerline

Level to 1° Below Level for

60.3 – 219.1-mm Pipe Sizes

0.75° to 1.25° Below Level for

267.4 – 323.9-mm Pipe Sizes

0 to ½° Max.

(0-51 mm)

6-meter

Length of Pipe

Pipe

Centerline

Tool

Centerline

Drawings are exaggerated for clarity

11

REV_E

TM-RG3210 / Operating and Maintenance Instructions Manual

Page 12

GROOVE DIAMETER STOP ADJUSTMENT

WARNING

• Always turn off power before making any

tool adjustments.

Accidental startup of tool may result in

serious personal injury.

The groove diameter stop must be adjusted

every time rolls are changed and for each

change in pipe size or wall thickness.

1. Verify that the correct, matching roll set is

installed on the tool. Rolls are marked with

the pipe size and part number. If the correct,

matching rolls are not on the tool, the roll set

must be changed by following the steps on

pages 14 and 15.

NOTICE

• To perform the following adjustments,

use several short scrap sections of pipe

that are the proper material, diameter,

and wall thickness. Refer to Table 1 for

the minimum pipe lengths required for

grooving.

Hand Pump

Valve

2. Insert a piece of pipe of the correct size and

wall thickness onto the lower roll.

3. Close the hydraulic pump valve.

4. Use the hydraulic pump handle to bring the

slide down until the upper roll contacts the pipe.

CAUTION

• Right-to-left tracking angle must be kept to a minimum. Keep the pipe as centered as

possible on the lower roll.

• Verify that the tool is level. The pipe may not track properly if the back end of the pipe is

higher than the end being grooved.

Failure to follow these instructions may result in grooves that are not within specification.

12

REV_E

TM-RG3210 / Operating and Maintenance Instructions Manual

Page 13

Locking Nut

Depth Adjuster Nut

5. Loosen the locking nut from the depth

adjuster nut. Tighten the depth adjuster nut

downward against the top of the tool head.

6. Adjust the depth adjuster nut upward to a

distance equal to the required groove depth.

One rotation of the depth adjuster nut equals

2.5 mm.

7. Prevent the depth adjuster nut from rotating.

Tighten the locking nut downward against the

top of the depth adjuster nut.

WARNING

Grooving rolls can crush

or cut fingers and hands.

• Keep hands away from

grooving rolls.

• Never reach inside pipe end or across the

tool or pipe during operation.

• Always groove pipe in a clockwise

direction only.

• Never groove pipe shorter than what is

recommended.

• Never wear loose clothing, loose gloves,

or jewelry while operating tool.

8. Groove the sample pipe by following the

“Grooving Operation” section. Continue the

grooving operation until the depth adjuster nut

contacts the tool head. Allow the pipe to rotate

an additional one to two turns to ensure groove

completion.

9. After a trial groove is prepared and the pipe

is removed from the tool, carefully check the

“C” groove diameter. Refer to the “Roll Groove

Specifications” section. The “C” groove diameter

dimension is best checked with a pipe tape.

If a vernier caliper or narrow-land micrometer

is used, the groove must be checked at two

locations, 90° apart. The average reading must

equal the required groove diameter specification.

10. If the “C” groove diameter is too large (too

shallow), loosen the locking nut and adjust the

depth adjuster nut upward to half the distance

of the value of the desired adjustment to the “C”

groove diameter.

11. If the “C” groove diameter is too small

(too deep), loosen the locking nut and adjust

the depth adjuster nut downward to half the

distance to the value of the desired adjustment

to the “C” groove diameter.

12. Prepare another trial groove and check

the “C” groove diameter again. Follow all steps

in this section until the “C” groove diameter is

within specification.

CAUTION

• The “C” groove diameter must always

conform to the dimensions listed in the

“Roll Groove Specifications” section to

ensure proper joint performance.

Failure to follow this instruction could cause

joint leakage or failure, resulting in personal

injury and property damage.

13

REV_E

TM-RG3210 / Operating and Maintenance Instructions Manual

Page 14

GROOVING OPERATION

DANGER

• To reduce the risk of

electric shock, check

the electrical source for

proper grounding.

• Before operating the tool, review the

“Operator Safety Instructions” section of

this manual.

Failure to follow these instructions could

result in death or serious personal injury.

CAUTION

• RG3210 tools are designed ONLY for roll

grooving pipe sizes and wall thicknesses

outlined in the “Tool Ratings for Steel

Pipe” section.

Failure to follow the instructions in

this manual will result in improper tool

operation.

1. Before grooving, ensure that all instructions in

the previous sections of this manual have been

followed.

2. Plug the RG3210 into an internally-grounded

electrical source.

3. Turn the switch on the side of the tool

to the “ON” position to verify that the tool

is operational and that lower roll is turning

clockwise.

4. Turn the switch on the side of the tool to the

“OFF” position.

Hydraulic

Pump

Valve

5. Open the hydraulic pump valve by turning it

counterclockwise. This will raise the slide and

upper roll to their highest positions.

6. Insert a piece of pipe of the correct size and

wall thickness onto the lower roll.

Hydraulic

Pump

Valve

7. Close the hydraulic pump valve by turning it

clockwise.

14

REV_E

TM-RG3210 / Operating and Maintenance Instructions Manual

Page 15

WARNING

Grooving rolls can crush

or cut fingers and hands.

• Keep hands away from

grooving rolls.

• Never reach inside pipe end or across the

tool or pipe during operation.

• Always groove pipe in a clockwise

direction only.

• Never groove pipe shorter than what is

recommended.

• Never wear loose clothing, loose gloves,

or jewelry while operating tool.

8. Operator should be positioned, as shown.

9. Use the hydraulic pump handle to bring the

slide down until the upper roll contacts the pipe.

10. Turn the switch on the side of the tool to the

“ON” position. Check the tracking of the pipe

as it rotates to verify that it remains against the

lower roll.

NOTE: If the pipe does not remain against the

lower roll, stop the tool by turning the switch to

the “OFF” position. Verify that the pipe is level

and positioned properly.

11. With the switch in the “ON” position, the

pipe will begin to rotate clockwise. As the pipe

rotates, begin grooving by using the hydraulic

pump handle.

NOTICE

• Do not pump the hydraulic pump handle

too fast, but at a rate sufficient to groove

the pipe and maintain a moderate load

on the tool’s motor.

12. Continue the grooving operation until the

locking nut/depth adjuster nut contact the tool

head. Allow the pipe to rotate an additional one

to two turns to ensure groove completion.

13. Turn the switch on the side of the tool to the

“OFF” position.

Hydraulic

Pump

Valve

14. To release the pipe, open the hydraulic

pump valve by turning it counterclockwise (be

prepared to support short pipe lengths when

opening the hydraulic pump valve). Remove pipe

from tool.

NOTICE

• The “C” groove diameter should be

checked periodically and adjusted, as

necessary, to ensure that the dimension

remains within specification.

15

REV_E

TM-RG3210 / Operating and Maintenance Instructions Manual

Page 16

LOWER ROLL REMOVAL

WARNING

• Always turn off power before making any

tool adjustments.

Accidental startup of tool may result in

serious personal injury.

The lower roll must be removed before the

upper roll.

Hydraulic

Pump

Valve

1. Open the hydraulic pump valve by turning it

counterclockwise. This will raise the slide and

upper roll to their highest positions.

2. Remove the main shaft fastening nut, then

remove the lower roll. Store the lower roll in a

safe location for future use.

UPPER ROLL REMOVAL

WARNING

• Always turn off power before making any

tool adjustments.

Accidental startup of tool may result in

serious personal injury.

Hydraulic

Pump

Valve

1. Open the hydraulic pump valve by turning it

counterclockwise. This will raise the slide and

upper roll to their highest positions.

Upper

Shaft

Retaining

Screw

2. Loosen the upper shaft retaining screw.

3. While supporting the upper roll, remove the

upper shaft from the slide/upper roll holder by

pulling it straight outward. Remove the upper

roll, and store it in a safe location for future use.

16

REV_E

TM-RG3210 / Operating and Maintenance Instructions Manual

Page 17

UPPER ROLL INSTALLATION

Clean the upper shaft to remove any dirt

before installation of the upper roll. Inspect the

roller bearing inside the upper roll for proper

lubrication and condition.

The upper roll must be installed before the

lower roll.

Upper

Shaft

Retaining

Screw

1. Carefully insert the desired size upper roll

behind the slide/upper roll holder with the

markings on the upper roll facing outward.

2. While supporting the upper roll, insert the

upper shaft into the slide/upper roll holder and

upper roll.

3. Tighten the upper shaft retaining screw to

retain the upper roll on the upper shaft.

4. Lubricate upper roll bearing with a

No. 2EP Lithium based grease. Refer to

the “Maintenance” section for additional

information.

LOWER ROLL INSTALLATION

Clean the main shaft and lower roll bore to

remove any dirt before installation of the lower

roll. NOTE: To aid in removing the lower roll at

a later time, apply a thin film of oil or grease

(anti-seize lubricant) to the main shaft before

installing the lower roll.

1. Slide the desired size lower roll fully onto main

shaft with the marked side facing outward.

2. Tighten the main shaft fastening nut

completely to retain the lower roll on the main

shaft.

17

REV_E

TM-RG3210 / Operating and Maintenance Instructions Manual

Page 18

MAINTENANCE

DANGER

• Before performing any

repair or maintenance,

disconnect the tool from

the electrical source

to prevent accidental

startup of tool.

Failure to do so could result in death or

serious personal injury.

Prior to the start of each shift make sure all tool

and roll sets are clean. Lubricate the tool at the

grease ports.

Always lubricate upper roll bearings and main

shaft bearings when rolls are changed by

utilizing the grease ports. Use a No. 2EP Lithium

based grease.

On a monthly basis, lubricate the gear motor

with a spray-type, heavy-duty open gear

lubricant.

HYDRAULIC SYSTEM

The level of hydraulic fluid should be checked

before operation and must be checked several

times per year, especially if the hydraulic pump

is not operating properly. Use a 20# oil in the

summer and a 10# oil in the winter.

Relieve pressure in the hydraulic system by

opening the hydraulic pump valve, then remove

the plug indicated above to add hydraulic fluid.

PS3210 PIPE STAND

Regular lubrication is required for the PS3210

Pipe Stand. On a weekly basis, apply a light

machine oil to the location shown above at each

universal ball unit. Work the light machine oil in

by rotating the universal ball units.

REPLACEMENT PARTS

Any replacement parts must be ordered from

Victaulic to ensure proper tool operation.

18

REV_E

TM-RG3210 / Operating and Maintenance Instructions Manual

Page 19

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE SOLUTION

Pipe will not stay in grooving

rolls.

Incorrect pipe positioning of long pipe. Refer to “Long Pipe Lengths” section.

Pipe stops rotating during

grooving.

Rust or dirt has built up on lower roll. Remove accumulation from lower roll with sti wire brush.

Worn grooving rolls. Inspect lower roll for worn knurls. Replace if worn.

Motor has stalled due to excess pumping of the

hydraulic pump handle.

Open the hydraulic pump valve to free the pipe, then close

hydraulic pump valve. Continue grooving, pumping at a

moderate rate.

Circuit breaker has tripped or fuse has blown on

electrical circuit supplying motor.

Reset breaker or replace fuse.

While grooving, loud squeaks

echo through the pipe.

Incorrect pipe support positioning on long pipe.

Pipe is “overtracking”.

Refer to the “Long Pipe Lengths” section.

Pipe end is not cut square. Cut pipe end squarely.

Pipe is rubbing excessively hard on the lower

roll.

Remove pipe from tool and apply a lm of grease to the face of

the lower roll, as needed.

During grooving, loud thumps

or bangs occur about once

every revolution of the pipe.

Pipe has a pronounced weld seam. Raised internal and external weld beads and seams must

be ground ush with the pipe surface 50 mm back from the

pipe ends.

Tool won’t groove pipe. Hydraulic pump valve is not closed tightly. Tighten the hydraulic pump valve.

Hydraulic pump is low on oil. Refer to the “Maintenance” section.

Pipe is beyond tool’s wall thickness capability. Refer to the “Tool Ratings for Steel Pipe” section.

In the event of tool malfunction outside the scope of the troubleshooting section, contact Victaulic for

assistance.

19

REV_E

TM-RG3210 / Operating and Maintenance Instructions Manual

Page 20

EXPLANATION OF CRITICAL ROLL GROOVE DIMENSIONS

WARNING

• Pipe dimensions and groove dimensions must be within the tolerances specified in the

tables on the following pages to ensure proper joint performance.

Failure to follow these specifications could cause joint failure, resulting in serious personal

injury and/or property damage.

A B

D

B

T

COD

F

Standard Roll Groove

Exaggerated for clarity

Pipe Outside Diameter – The average pipe outside diameter must not vary from the specifications

listed in the tables on the following pages. Maximum allowable pipe ovality should not vary by more

than 1%. Greater variations between the major and minor diameters will result in difficult coupling

assembly.

The maximum allowable tolerance from square-cut pipe ends is:

0.8 mm for 60.3 – 101.6-mm sizes and 1.6 mm for 114.3-mm and larger sizes.

This is measured from the true square line.

"S" Max.

Raised internal and external weld beads and seams must be ground flush with the pipe surface

50 mm back from the pipe ends. The inside diameter of the pipe end must be cleaned to remove

coarse scale, dirt, and other foreign material that might interfere with or damage grooving rolls. The

front edge of the pipe end shall be uniform with no concave/convex surface features that will cause

improper grooving roll tracking and result in difficulties during coupling assembly.

“A” Dimension – The “A” dimension, or the distance from the pipe end to the groove, identifies the

gasket seating area. This area must be free from indentations, projections (including weld seams),

and roll marks from the pipe end to the groove to ensure a leak-tight seal. All foreign material, such

as loose paint, scale, oil, grease, chips, rust, and dirt must be removed.

“B” Dimension – The “B” dimension, or groove width, controls expansion, contraction, and angular

deflection of flexible couplings by the distance it is located from the pipe and its width in relation to

the coupling housings’ “key” width. The bottom of the groove must be free of all foreign material,

such as dirt, chips, rust, and scale that may interfere with proper coupling assembly.

“C” Dimension – The “C” dimension is the average diameter at the base of the groove. This

dimension must be within the diameter’s tolerance and concentric with the OD for proper coupling

fit. The groove must be of uniform depth for the entire pipe circumference.

20

REV_E

TM-RG3210 / Operating and Maintenance Instructions Manual

Page 21

EXPLANATION OF CRITICAL ROLL GROOVE DIMENSIONS (CONT.)

“D” Dimension – The “D” dimension is the normal depth of the groove and is a reference for a

“trial groove” only. Variations in pipe OD affect this dimension and must be altered, if necessary, to

keep the “C” dimension within tolerance. The groove diameter must conform to the “C” dimension

described above.

“F” Dimension – Maximum allowable pipe-end flare diameter is measured at the extreme pipe-end

diameter. NOTE: This applies to average (pi tape) and single-point readings.

“T” Dimension – The “T” dimension is the lightest grade (minimum nominal wall thickness) of pipe

that is suitable for roll grooving.

NOTICE

• Coatings that are applied to the interior surfaces of Victaulic grooved pipe couplings must

not exceed 0.25 mm. This includes bolt pad mating surfaces.

• In addition, the coating thickness applied to the gasket-sealing surface and within the

groove on the pipe exterior must not exceed 0.25 mm.

21

REV_E

TM-RG3210 / Operating and Maintenance Instructions Manual

Page 22

TOOL RATINGS FOR STEEL PIPE

Actual Pipe Outside Diameter Nominal Wall Thickness Dimensions

60.3 mm – 219.1 mm Schedule 10 – Schedule 40

267.4 mm – 323.9 mm Schedule 10 – Schedule 20

Maximum ratings on steel are limited to pipe of 180 BHN (Brinnel Hardness Number) and less.

ROLL GROOVE SPECIFICATIONS FOR STEEL PIPE

Actual

Pipe

Outside

Diameter

mm

Dimensions – millimeters

Pipe Outside

Diameter

Gasket

Seat

“A”

Groove

Width

“B”

Groove

Diameter

“C”

Groove

Depth

“D”

(ref.)

Min.

Allow.

Wall

Thick.

“T”

Max.

Allow.

Flare

Dia.

“F”Max. Min. Basic Max. Min. Basic Max. Min. Max. Min.

60.3 mm 60.9 59.7 15.9 16.7 15.1 8.7 9.5 8.0 57.2 56.8 1.6 1.2 63.0

73.0 mm 73.8 72.3 15.9 16.7 15.1 8.7 9.5 8.0 69.1 68.6 2.0 2.0 75.7

76.1 mm 77.0 75.4 15.9 16.7 15.1 8.7 9.5 8.0 72.3 71.8 2.0 2.0 78.7

88.9 mm 89.8 88.1 15.9 16.7 15.1 8.7 9.5 8.0 84.9 84.5 2.0 2.0 91.4

101.6 mm 102.6 100.8 15.9 16.7 15.1 8.7 9.5 8.0 97.4 96.9 2.2 2.0 104.1

108 .0 m m 109.0 107.2 15.9 16.7 15.1 8.7 9.5 8.0 103.7 103.2 2.2 2.0 110.5

114 . 3 m m 115.4 113.5 15.9 16.7 15.1 8.7 9.5 8.0 110.1 109.6 2.2 2.0 116.8

12 7. 0 mm 128.3 126.2 15.9 16.7 15.1 8.7 9.5 8.0 122.8 122.3 2.2 2.0 129.5

133 . 0 m m 134.7 132.6 15.9 16.7 15.1 8.7 9.5 8.0 129.1 128.6 2.2 2.0 135.9

139.7 mm 141.1 138.9 15.9 16.7 15.1 8.7 9.5 8.0 135.5 135.0 2.2 2.0 142.2

141. 3 mm 142.7 140.5 15.9 16.7 15.1 8.7 9.5 8.0 137.0 136.5 2.2 2.0 143.8

152 . 4 m m 153.8 151.6 15.9 16.7 15.1 8.7 9.5 8.0 148.1 147.5 2.2 2.0 154.9

165 .1 mm 166.7 164.3 15.9 16.7 15.1 8.7 9.5 8.0 160.8 160.2 2.2 2.8 167.6

168 . 3 mm 169.9 167.5 15.9 16.7 15.1 8.7 9.5 8.0 164.0 163.4 2.2 2.8 170.9

203.2 mm 204.8 202.4 19.1 19.8 18.3 11.9 12.7 11.1 198.5 197.9 2.4 2.8 207.5

216. 3 mm 217.9 215.5 19.1 19.8 18.3 11.9 12.7 11.1 211.6 211.0 2.4 2.8 220.7

219.1 m m 220.7 218.3 19.1 19.8 18.3 11.9 12.7 11.1 214.4 213.8 2.4 2.8 223.5

267. 4 m m 269.0 266.6 19.1 19.8 18.3 11.9 12.7 11.1 262.6 262.0 2.4 3.4 271.8

273.0 mm 274.7 272.3 19.1 19.8 18.3 11.9 12.7 11.1 268.3 267.6 2.4 3.4 277.4

318.5 m m 320.1 317.7 19.1 19.8 18.3 11.9 12.7 11.1 313.0 312.2 2.8 4.0 322.8

323.9 mm 325.5 323.1 19.1 19.8 18.3 11.9 12.7 11.1 318.3 317.5 2.8 4.0 328.2

22

REV_E

TM-RG3210 / Operating and Maintenance Instructions Manual

Page 23

MD_DoC_RGT_ 005_120517_en. docx

VICTAULIC IS A REGISTER ED TRADEMARK OF VICTAULIC CO MPANY. ©2013 VICTAULIC COMPANY. AL L RIGHTS RESERVED.

EC DECLARATION OF CONFORMITY

In Accordance with the Machinery Directive 2006/42/EC

Victaulic Company, headquartered at 4901 Kesslersville Road, Easton, PA 18040, USA, hereby declares

that the machinery listed below complies with the essential safety requirements of the Machinery

Directive, 2006/42/EC.

Product Models: RG3210

Serial No. : Refer to Machinery Nameplate

Product Description: Roll Grooving Tool

Conformity Assessment: 2006/42/EC, Annex I

Reference Standards: EN ISO 12100 : 2010

EN IEC 60204-1:2006+A1:2009

EN ISO 13857 : 2008

Technical Documentation: The relevant technical documentation prepared in

accordance with Annex VII (A) of the Machinery Directive

2006/42/EC, will be made available upon request to the

governing authorities.

Authorized Representative: Victaulic Company

c/o Victaulic Europe BVBA

Prijkelstraat 36

9810, Nazareth

Belgium

Signed for and on behalf of Victaulic Company,

Mr. Len R. Swantek

Director – Global Regulatory Compliance

Machinery Manufacturer Representative

Place of Issue: Easton, Pennsylvania, USA

Date of Issue: December 05, 2017

Page 24

UPDATED 03/2018

TM-RG3210 10275 REV E

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY AND/OR ITS AFFILIATED

ENTITIES IN THE UNITED STATES AND/OR OTHER COUNTRIES.

© 2018 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

OPERATING AND MAINTENANCE INSTRUCTIONS MANUAL

RG3210 Roll Grooving Tool

TM-RG3210

Loading...

Loading...