Victaulic KOIL-KIT 799 Series, KOIL-KIT 79V Series, KOIL-KIT 79B Series, KOIL-KIT 79A Series Installation And Maintenance Instructions Manual

Page 1

I-KOIL.KITINSTALLATION AND MAINTENANCE INSTRUCTIONS

KOIL-KIT™ Coil Pack – Series 799, Series 79V with ATC Valve,

Series 79B with Bypass, and Series 79A with Bypass and ATC Valve

WARNING

• Read and understand all instructions before attempting to install

any Victaulic piping products.

• Depressurize and drain the piping system before attempting

to install, remove, adjust, or maintain any Victaulic piping

products.

• Wear safety glasses, hardhat, and foot protection.

Failure to follow these instructions could result in death or serious

personal injury and property damage.

RECEIVING THE SHIPMENT

Victaulic® KO IL-K I T™ Coil Packs are a pre-packaged and labeled system

designed to improve efficiency of hooking up HVAC coils. Upon receipt

of the shipment, ensure that the kit is the correct one for the coil being

installed. If any components are damaged or missing, contact Victaulic.

Union Port Fitting with Air Vent

The Series 78U Union Port Fitting with Air Vent

can be supplied to accommodate up to a threesize reduction. Connections can be configured,

as listed below:

• Sweat x Sweat Union (Two Size Reductions)

• Sweat x Female Thread Union (Two Size Reductions)

• Sweat x Male Thread Union (Three Size Reductions)

• Female Thread x Sweat Union (Two Size Reductions)

• Female Thread x Female Thread Union (Two Size Reductions)

• Female Thread x Male Thread Union (Three Size Reductions)

“Y” Strainer/Ball Valve Combination or “T” Ball Valve

SERIES 78Y SERIES 78T

The Series 78Y Strainer/Ball Valve Combination or Series 78T Ball

Valve can accommodate up to a two-size reduction from inlet to outlet.

Connections can be configured, as listed below:

• Sweat x Sweat Union (Two Size Reductions)

• Sweat x Female Thread Union (Two Size Reductions)

• Sweat x Male Thread Union (Three Size Reductions)

• Female Thread x Sweat Union (Two Size Reductions)

• Female Thread x Female Thread Union (Two Size Reductions)

• Female Thread x Male Thread Union (Three Size Reductions)

Bypass Tee Option

The Bypass Tee option connects to the Series 78Y

Strainer/Ball Valve Combination or Series 78T Ball

Valve for hookup of the Series 79B KOIL-KIT™ Coil

Pack with Bypass or Series 79A KOIL-KIT™ Coil

Pack with Bypass and ATC Valve.

Balancing Valves

Series 78 6 Balancing Valve

(Submittal D ocument 0 8.16)

Series 78 K Balancing Valve

(Submittal D ocument 0 8.16)

Series 76K Au tomatic Balan cing Valve

(Submittal D ocument 0 8.34)

Series 76 V Automatic Bal ancing Valve

(Submittal D ocument 0 8.34)

Series 7FP Pressure-Indep endent Combined

Balancing and Control Valve with Independent

EQM (Equal Percent age Value) Characteristics

(Submittal D ocument 0 8.53)

Series TCP Pressure-Independent

Balancing and Control Valve

(Submittal D ocument 0 8.39)

Series 787 B alancing Valve

(Submittal D ocument 0 8.16)

Series 76B Au tomatic Balan cing Valve

(Submittal D ocument 0 8.34)

Series 76T Automatic Bal ancing Valve

(Submittal D ocument 0 8.34)

Series 7FC C ombined Balancing and Contro l

Valve with Indep endent EQM

(Equal Percentage Value) Characteristics

(Submittal D ocument 0 8.52)

Series TC /TCM TBV Terminal Balancing

and Control Valves

(Submittal D ocument 0 8.38)

Manual or Automatic Air Bleed Valve

The manual or automatic air bleed valve is rated to 250 psi/17 Bar and

provides a means of bleeding off trapped air when used with the Series

78U Union Port Fitting, Series 78Y Strainer/Ball Valve Combination,

Series 78T Ball Valve, or Series 78K Balancing Valve.

Coil Hoses

Coil hoses are available in 1-foot/0.3-meter, 2-foot/0.6-meter, or

3-foot/0.9-meter lengths for connecting to the inlet and outlet of the coil

and are available with the following union ends:

Male Coupling x Female Union End

Male Coupling x Male Swivel Union

Male Coupling x Female Union End with Adapter

REV_F

I-KOIL.KIT_1

Page 2

I-KOIL.KIT / KO I L-K IT™ Coil Pack / Installation and Maintenance Instructions

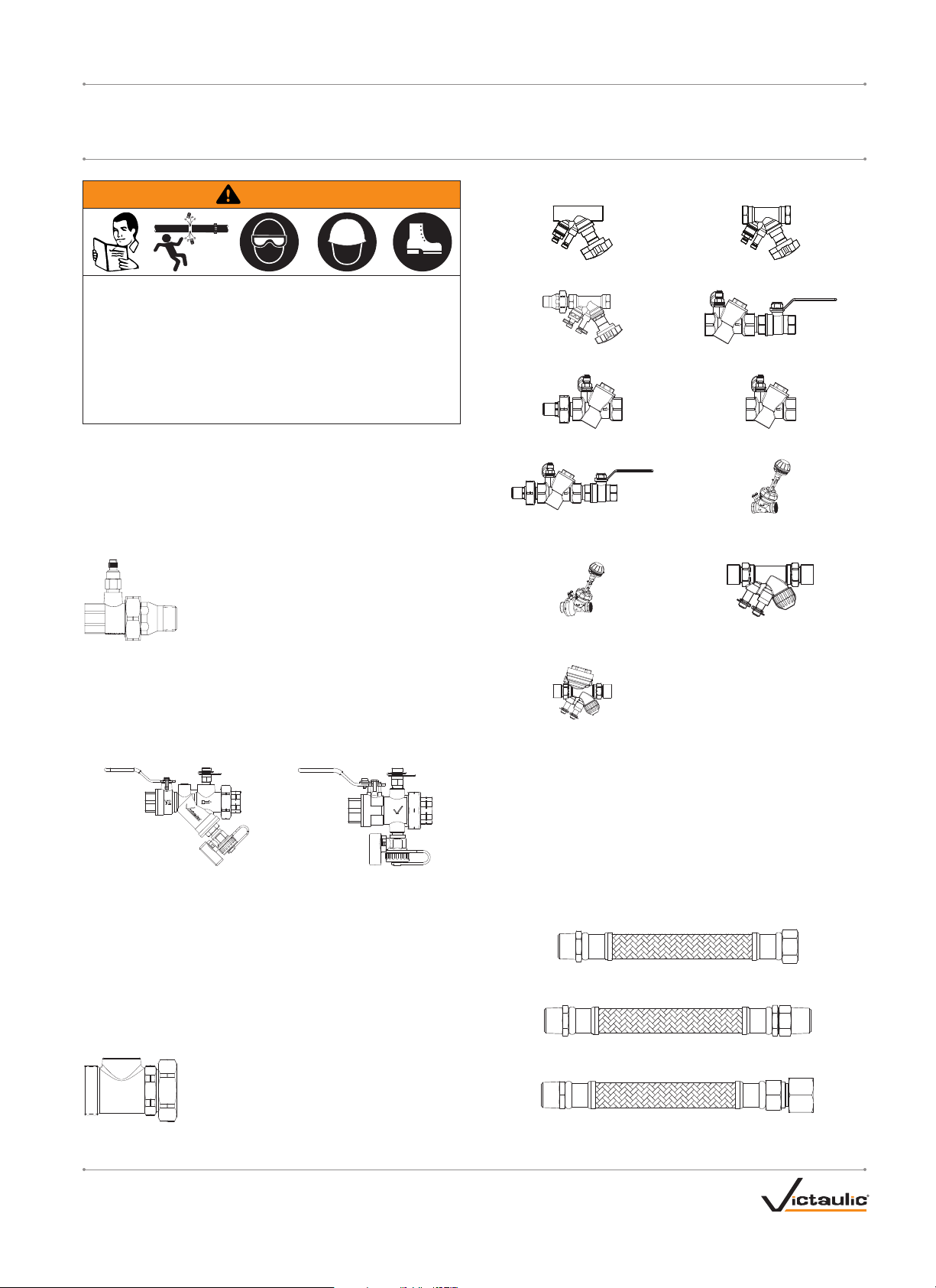

EXAMPLE COIL COMPONENT ASSEMBLY DRAWING

NOTE: THE FIGURES SHOWN BELOW ARE FOR REFERENCE ONLY AND ILLUSTRATE T YPICAL 2-WAY AND 3-WAY CONFIGURATIONS.

(By Others)

(By Others)

Hose (Optional)

Series 78U

Series 78K

Hose (Optional)

SUPPLY

Series 78Y

RETURN

SWEAT CONNECTIONS

CAUTION

• Valves must be in the fully-open position before attempting to

solder the ends.

Soldering a valve in the closed or partially-open position may

cause damage to internal components, resulting in valve leakage

and property damage.

Make sure the valve is installed in the correct direction of flow (refer

to applicable flow direction arrow on the valve body) and that the

valve is in the fully-open position before attempting to solder the ends.

Connections must be soft soldered with 95/5 (95% tin, 5% antimony)

type solder. The valve body must be heat sinked with a wet cloth

or putty at the closest joint to protect internal components, and the

flame must be directed away from the center of the valve body. DO

NOT exceed the temperature rating of the valve (250°F/121°C). Valve

bodies must be allowed to cool to room temperature before attempting

operation.

THREADED CONNECTIONS

Make sure all threaded connections are clean and free of any burrs.

Apply PTFE thread sealant tape or pipe dope to the external threads

of all threaded pipe connections. DO NOT use a combination of PTFE

thread sealant tape and pipe dope. DO NOT get any tape, dope, or

other foreign material into the flow path. NOTE FOR CONNECTING

TO FEMALE NPSM SWIVEL ENDS OF COIL HOSES: DO NOT use

PTFE thread sealant tape or pipe dope on any NPT threads connecting

into the female NPSM swivel end. Tape or dope may prevent proper

tightening of the threaded connection, reducing gasket compression.

UNION-TYPE ADAPTERS/CONNECTIONS

The o-rings in union-type adapters/connections must be lubricated

with Victaulic Lubricant or silicone to prevent the o-ring from pinching

or tearing during installation. Tighten union-type adapters/connections

hand-tight, then apply an additional quarter turn. DO NOT over-tighten

the connection.

Hose (Optional)

Hose (Optional)

Series 78U

Hose

(Optional)

Bypass

Valve

(Optional)

Series 78T

with Bypass Tee

Option

Series 787

RETURN

SUPPLY

COIL COMPONENT INSTALLATION

1. Connect the supply side of the Series 78Y Strainer/Ball Valve

Combination or Series 78T Ball Valve to the feed pipe via standard

threading or sweating practices, as described previously. Make

sure the applicable flow direction arrow on the valve body is facing

the direction of flow and that the valve body is rotated to the

desired position. NOTE: For effective operation, air vents must be

positioned at the highest possible location and must point upward.

2. If using coil hoses, make the connection to the coil first. Connect

the coil hose to the Series 78Y or Series 78T outlet union joint.

Ensure the o-ring is in place on the Series 78Y or Series 78T body.

Apply a thin coat of Victaulic Lubricant or silicone to the o-ring.

Refer to the “Coil Hose Installation” section for details on bend

radius specifications and additional installation requirements.

3. Connect the outlet of the balancing valve to the return pipe via

standard threading or sweating practices. NOTE: In order to obtain

accurate differential pressure measurements, turbulence should

be minimized. Refer to the installation instructions supplied with

the applicable valve.

4. Connect the coil hose (if applicable) to the inlet of the Series 78U

Union Port Fitting.

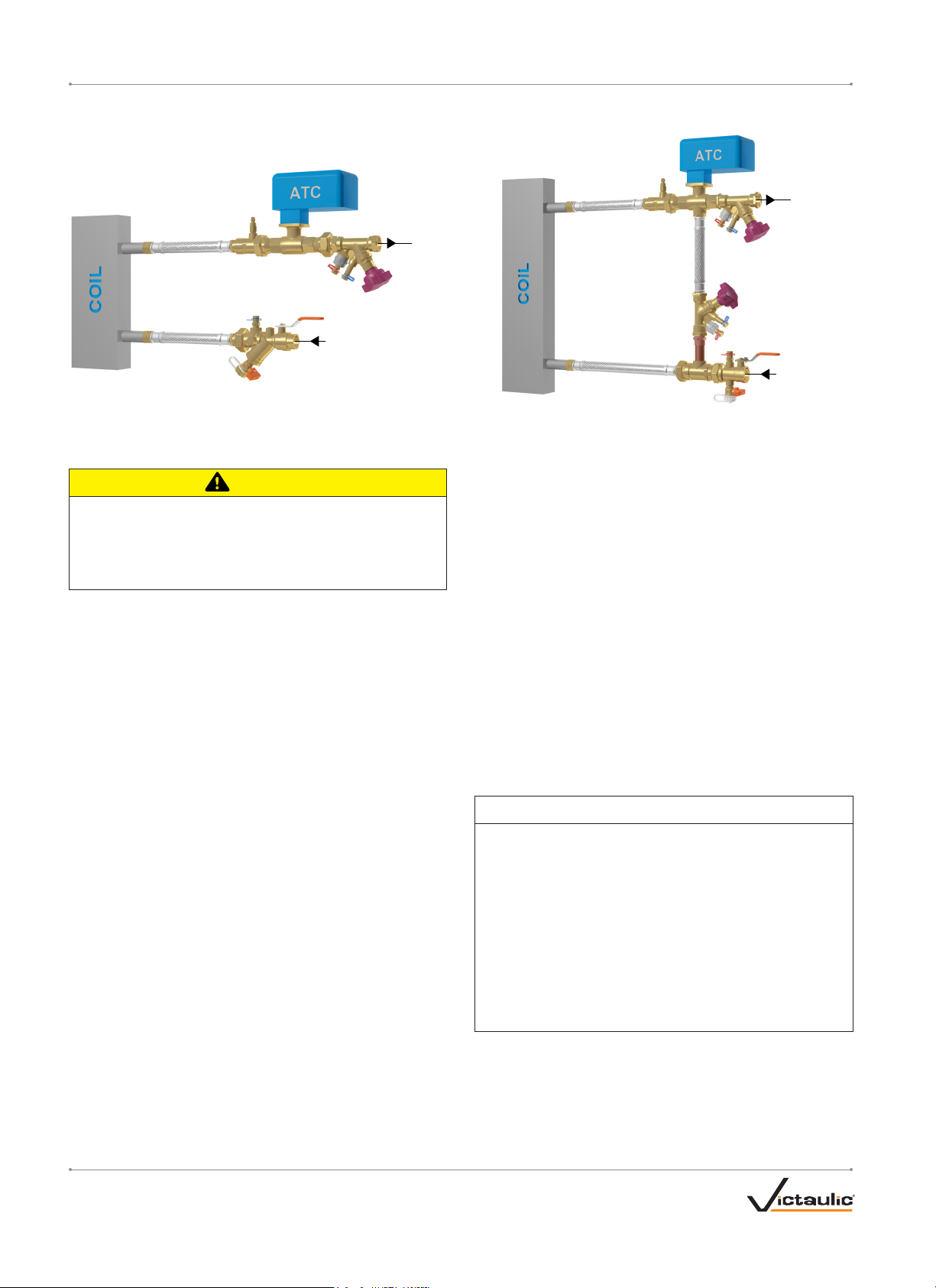

NOTICE

• Generally, between the male union outlet of the Series 78U and

the inlet of the balancing valve, there is a customer-specified

Automatic Temperature Control (ATC) Valve.

• Ensure that the ATC valve contains the correct inlet and outlet

sizes. Cutout lengths, etc. will need to be determined on a

case-by-case basis, depending on the type of ATC valve being

installed.

• If ATC valves are sent to Victaulic for inclusion in kits, verify that

the appropriate ATC valve is installed for the particular hook-up

to ensure proper design flows and performance.

• Refer to the instructions supplied with the ATC valve for

complete installation and maintenance requirements.

I-KOIL.KIT_ 2

REV_F

Page 3

I-KOIL.KIT / KO I L-K IT™ Coil Pack / Installation and Maintenance Instructions

NPT Male

COIL HOSE INSTALLATION

CAUTION

• DO NOT introduce chemicals into the system without verifying

compatibility with the EPDM material of the coil hoses.

Failure to follow this instruction could cause damage to the coil

hose, resulting in property damage.

Straight Pipe

NPSM Female

Swivel End

Compression

Gasket

Ferrule

Size Inlet Options – inches

Female

NPSM

Nominal ID

inches

Male End

Thread

Swivel

Union inches/mm psi/Bar

½ x ½NPT ½

¾ x ¾ NPT ¾

1 x 1 NPT 1

1¼ x 1 ¼ NPT 1 ¼

1½ x 1 ½ NPT 1 ½

2 x 2 NPT 2

The minimum temperature rating for coil hoses is 5°F/-15°C.

The maximum temperature rating for coil hoses is 230°F/110°C. Contac t Victaulic if

higher temperature ratings are required.

Coil hoses are intended for liquid applications only. DO NOT attempt to use coil

hoses in gas/air applications.

Coil hoses can change in length approximately 4% when pressurized.

Allowance must be given to accommodate for this change in length;

therefore, coil hoses must not be stretched tightly between the coil and

mating component. Refer to the graphics below for examples of correct

and incorrect bend configurations.

INCORRECT INCORRECT INCORRECT INCORRECT

Stainless Steel

Braided Hose

Minimum

Bend

Radius

2⁄ 375

67 26

4½ 300

114 21

5½ 300

140 21

6¾ 225

172 16

8⁄ 150

213 10

11¼ 150

286 10

Ferrule

End

Maximum

Working

Pressure

The following table contains the minimum distance requirement from

each ferrule to the start of the bend. This table must be referenced to

prevent the coil hose from being bent too close to the ferrules.

Size

Nominal ID inches

½

¾

1

1¼

1½

2

Minimum Distance from Each Ferrule to

Start of Bend inches/mm

1

25

1½

38

2

51

2½

64

3

76

4

102

If male threaded connections have sharp burrs, a thin

wall, or rough or uneven edges, Victaulic recommends the

use of the female x male coil hose adapter (refer to table

below for part codes).

Coil Hose Adapter Size

inches Part Code

½ P- 004-799-ADP

¾ P- 006-799-ADP

1 P- 010-799-A DP

1 ¼ P- 012-799 -ADP

1 ½ P-014 -799 -ADP

2 P-020-799-ADP

If the female swivel connector is being used with the female x male

coil hose adapter, apply PTFE thread sealant tape or pipe dope to the

male threads that connect into the female swivel connector. DO NOT

apply PTFE thread sealant tape or pipe dope to the male threaded end

of the coil hose adapter. Tape or pipe dope on the male threaded end

of the coil hose adapter may prevent proper tightening of the threaded

connection, reducing gasket compression.

To prevent damage to the connections, torque during assembly must

not exceed hand-tight plus a quarter turn. The wrench must engage

only the hex portion of the coil hose ends. NOTE: Over-tightening of

the threaded connection may cause cuts in the compression gasket,

resulting in leakage past the compression gasket.

After the system is pressurized, check the coil hoses for leaks or

discoloration on the stainless steel braided section or connections. If

leaks are present, replace the affected coil hose(s). DO NOT attempt to

repair coil hoses.

Tight

CORRECT

+4% Minimum

CORRECT CORRECT

If the minimum bend radius, specified in the table above, falls below

the dimension listed for the applicable coil hose size, an angle adapter

must be used to avoid sharp bends. NOTE: Failure to follow the

minimum bend radius requirements can cause increased pressure

drop and damage to the coil hose. If coil hoses are stored or installed at

temperatures of 40°F/4°C or lower, the bend radius should be increased

by 50%. Use caution to prevent the coil hose from collapsing.

REV_F

MAINTENANCE

WARNING

• Depressurize and drain the piping system before attempting to

perform any maintenance on Victaulic products.

Failure to follow this instruction could result in serious personal

injury and/or property damage.

A 20-mesh stainless steel strainer basket

is included in the body of the Series 78Y

Strainer/Ball Valve Combination and must be

20-Mesh Stainless

Steel Strainer Basket

in pressure drop, the 20-mesh stainless steel strainer basket may need

to be cleaned. To access the strainer basket, remove the drain valve

adapter from the valve body. Clean out the strainer basket and reinstall

it into the valve body in the same orientation. Replace the strainer

basket or o-ring of the drain valve adapter with new, Victaulic-supplied

components if damage is present.

inspected and cleaned after system startup.

Victaulic recommends blowing down the

valve every 6 months. If there is an increase

I-KOIL.KIT_ 3

Page 4

I-KOIL.KITINSTALLATION AND MAINTENANCE INSTRUCTIONS

KOIL-KIT™ Coil Pack – Series 799, Series 79V with ATC Valve,

Series 79B with Bypass, and Series 79A with Bypass and ATC Valve

INSTALLING THE BALANCING VALVE DRAIN KIT

NOTICE

• System depressurization is not required for drain kit installation;

however, caution must be taken to ensure that the long pressure/

temperature (PT) port is not loosened prematurely.

FLOW

Drainage

Nipple

Gasket*

Gasket*

Nut

Cover

The drain kit (part number K-000-786-CBV) for Series 786, 787, and

78K Balancing Valves is sold separately through Victaulic and comes

with two new gaskets, a drainage nipple, and a nut.

1. Remove the components from the long pressure/temperature (PT)

port, shown in the assembly drawings above. NOTE: The cover with red

holder will be re-used when the drain kit is installed.

2. Install the drain kit components, as shown in the drawing above. The

new gaskets (provided in the kit) must be installed to prevent leakage

from the port. Re-install the cover with red holder onto the nut.

3. Locate the recess under the cover. Insert a 5-mm allen key, and

apply 8 - 14 counterclockwise turns to drain from the PT port.

*NOTE: New gaskets

must be used.

PRE-SETTING, BALANCING, AND MEASURING

Refer to the applicable installation and setting instructions for the valve

supplied with the KOIL-KIT™ Coil Pack.

REPLACEMENT PART INFORMATION

WARNING

PT Ports for Series 78Y Strainer/Ball Valve

Combination, Series 78T Ball Valve, Series 78U

Union Port Fitting with Air Bleed, or Series

786/787/78K Balancing Valves

(Part Number P-002-78Y-PTP for 78Y/78T/78U

or K-000-740-003 for 786/787/78K)

The PT ports are field-replaceable. Remove the existing PT port(s), and

thread the new port(s) into the valve body. For Series 78Y/78T/78U:

Use PTFE thread sealant tape or pipe dope on the threads. For Series

786/787/78K: DO NOT use PTFE thread sealant tape or pipe dope on

the threads.

Air Vent for Series 78Y Strainer/Ball Valve

Combination, Series 78T Ball Valve, Series 78U

Union Port Fitting with Air Bleed

(Part Number P-002-78U-MAV)

The air vents are field-replaceable. Remove the existing air vent, and

thread the new air vent into the valve body. Use PTFE thread sealant

tape or pipe dope on the threads.

Port Extender for Series 78Y Strainer/Ball Valve

Combination, Series 78T Ball Valve, or Series 78U

Union Port Fitting with Air Bleed

2-inch/51-mm Length

(Part Number P-000-78Y-2XT)

4-inch/102-mm Length

(Part Number P-000-78Y-4XT)

In applications where KOIL-KIT™ Coil Pack components will be

insulated, port extenders are available to extend the PT ports of the

Series 78Y or 78T or the air vent of the Series 78U to provide clearance

for 2 inches/51 mm or 4 inches/102 mm of insulation. Thread the port

extender into the existing PT ports or the existing air vent. Use PTFE

thread sealant tape or pipe dope on the threads. NOTE: Depending on

the configuration ordered, some KOIL-KIT™ Coil Packs may be supplied

with this option factory installed.

Handle Extension for Series 78Y Strainer/Ball

Handle Extension

Valve Combination or Series 78T Ball Valve

• Depressurize and drain the piping system before attempting to

perform any maintenance or replace any components.

Failure to follow this instruction could result in serious personal

injury and/or property damage.

The following parts are sold separately through Victaulic for KOIL-KIT™

Coil Packs. Contact Victaulic with any order requests or questions

regarding these par ts.

Hose-End Drain Assembly for Series 78Y Strainer/

Ball Valve Combination or Series 78T Ball Valve

(Part Number P-002-78Y-DRN for ¼-inch NPT or

P-004-78Y-DRN for ½-inch NPT)

The hose-end drain assembly is field-replaceable. Remove the existing

hose-end drain assembly from the drain valve adapter, and thread the

new assembly into the adapter. Use PTFE thread sealant tape or pipe

dope on the male threads that connect to the Series 78Y or 78T.

For complete contact information, visit victaulic.com

I-KOIL.KIT 2954 REV F UPDATED 07/2014 Z004799001

VICTAULIC AND KOIL-KIT ARE TRADEMARKS OR REGISTERED TRADEMARKS OF VICTAULIC COMPANY AND/OR ITS AFFILIATED ENTITIES

IN THE UNITED STATES AND/OR OTHER COUNTRIES. © 2014 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

In applications where KOIL-KIT™ Coil Pack components will be

insulated, the handle extension is available to extend the handle of the

Series 78Y or Series 78T valves to provide clearance for 2 inches/51

mm or 4 inches/102 mm of insulation. Remove the hex washer-head

screw from the handle assembly. Remove the handle assembly and

install the handle extension. Re-install the handle assembly onto

the handle extension by using the hex washer-head screw. NOTE:

Depending on the configuration ordered, some KOIL-KIT™ Coil Packs

may be supplied with this option factory-installed.

78Y

78T

Valve Inlet Size

inches

½ - 1 P- 004 -78Y-2HL P- 004 -78Y-4 HL

1 ¼ - 1 ½ P-012-78Y-2H L P- 012-78Y-4HL

2 P- 020-78Y-2HL P- 020-78Y-4HL

½ - ¾ P- 004 -78Y-2HL P- 004 -78Y-4 HL

1 - 1 ½ P- 012-78Y-2HL P - 012-78 Y-4HL

2 P- 020-78Y-2HL P- 020-78Y-4HL

Part Code for

2-inch/51-mm

Handle Extension

Part Code for

4- inch/102-m m

Handle Extension

Loading...

Loading...