Page 1

Operating and

R

Maintenance

Instructions

Manual

HCT908

Variable Speed

Hole-Cutting Tool

If you need additional copies of any literature, or if you have any questions about the safe operation of this tool,

contact Victaulic Tool Company, 1326 Tatamy Road, Easton, PA 18042, Phone: 610-559-3300.

®

Victaulic

® Registered Trademark of Victaulic © Copyright 2000 Victaulic Printed in U.S.A.

Tool Company • 1326 Tatamy Road • Easton, PA 18045 • 1-800-PICK VIC • FAX: 610-250-7065

• Before operating or servicing the HCT908 Hole-Cutting Tool, read all

instructions in this manual and all warning labels on the tool.

• Always wear safety glasses, hardhat, foot protection, and hearing

protection.

• Save this operating and maintenance manual.

Failure to follow instructions and warnings can result in serious personal

injury, property damage, and/or product damage.

Page 2

HCT908

INDEX

Hazard Identification. . . . . . . . . . . . . . . . .2

Operator Safety Instructions . . . . . . . . . .3

Introduction . . . . . . . . . . . . . . . . . . . . . . . .4

Receiving Tool. . . . . . . . . . . . . . . . . . . . . .4

Tool Nomenclature . . . . . . . . . . . . . . . . . .4

Power Requirements. . . . . . . . . . . . . . . . .5

Installing the Hole Saw onto the

Arbor Assembly. . . . . . . . . . . . . . . . . . . . .6

Tool Setup and Operation. . . . . . . . . . . . .6

Removing the Hole Saw from the

Arbor Assembly. . . . . . . . . . . . . . . . . . . . .9

Maintenance . . . . . . . . . . . . . . . . . . . . . .10

Accessories . . . . . . . . . . . . . . . . . . . . . . .11

Troubleshooting. . . . . . . . . . . . . . . . . . . .12

HAZARD IDENTIFICATION

Definitions for identifying the various hazard levels are provided below.

This safety alert symbol indicates important safety messages. When you see this symbol,

be alert to the possibility of personal injury. Carefully read and fully understand the

message that follows.

The use of the word “DANGER” identifies an

immediate hazard with a likelihood of death or serious

personal injury if instructions, including

recommended precautions, are not followed.

The use of the word “WARNING” identifies the

presence of hazards or unsafe practices that could

result in death or serious personal injury if

instructions, including recommended precautions, are

not followed.

NOTICE

The use of the word “NOTICE” identifies special

instructions that are important but not related to

hazards.

2

Page 3

HCT908

OPERATOR SAFETY INSTRUCTIONS

The HCT-908 is designed only for cutting holes in steel and stainless steel pipe. Using this tool

requires dexterity and mechanical skills, as well as sound safety habits. Although this tool is manufactured for safe, dependable operation, it is impossible to anticipate those combinations of circumstances that could result in an accident. The following instructions are recommended for safe

operation of this tool. The operator is cautioned to always practice “safety first” during each phase of

use, including setup and maintenance.

1. Read this manual before operating or servicing this tool. Become familiar with the tool’s

operations, applications, and limitations. Be particularly aware of its specific hazards. Store this manual

in a clean area where it is always readily available. Additional copies of this manual are available upon

request by calling or writing to the Victaulic Tool Company.

2. Avoid using the tool in dangerous environments. Do not expose the tools to rain, and do not use

the tools in damp or wet locations. Do not cut holes into pressurized pipe or pipe that is filled with water,

other fluid, or compressed gas. Keep the work area well lit.

3. Do not operate tools in gaseous or explosive environments. The motors in these tools produce

a normal spark, which could ignite fumes.

4. Ground all tools to protect the operator from electric shock.

5. Inspect the equipment.

sure that the tool’s parts are installed and secured properly.

6. Wear proper apparel. Do not wear loose clothing or jewelry, and keep long hair tied back.

7. Wear protective items when working with tools. Always wear safety glasses, hardhat, foot

protection, and hearing protection. A face or dust mask may be necessary if the cutting operation

produces fine particles.

8. Stay alert. Do not operate the tool if you are drowsy from medication or fatigue. Avoid horseplay around

the equipment.

9. Keep visitors away from the immediate work area. All visitors should be kept a safe distance from

the equipment at all times.

10. Secure work. Use clamps or a vise to hold work.

11. Do not overreach. Maintain proper footing and balance at all times.

12. Remove adjustment keys and wrenches from the tool. Always check to make sure adjustment

keys and wrenches are removed from the tool before operation.

13. Keep work areas clean. Keep the work area around the tool clear of obstructions that could limit the

movement of the operator. Clean up all oil and coolant spills. Remove shavings from the tool to maintain

proper operation.

14. Avoid accidental starting. Do not carry the plugged-in tool with your finger on the trigger.

15. Use proper extension cords for outdoor use. When using the tool outdoors, use only extension

cords marked suitable for outdoor use.

16. Do not force the tool. Do not force a smaller tool or attachment to do the job of a heavy-duty tool.

17. Do not abuse the power cord. Never carry the tool by the cord or yank it out of the receptacle. Keep

the cord away from heat, oil, and sharp objects.

18. Maintain tools with care. Keep tools sharp and clean at all times to ensure the best and safest

performance. Follow the instructions for lubricating and changing accessories.

19. Disconnect tools when not in use. Always disconnect tools when not in use; before servicing; when

changing accessories, such as blades, arbors, and chucks; and before removing the coupon from the hole

saw.

20. Store idle tools. When tools are not in use, store them in a dry, secure place.

21. Disconnect power cord before servicing the tool. Only authorized personnel should attempt to

change hole saws and perform maintenance on the tools. Always disconnect the power cord before

servicing or making any adjustments.

22. Use only Victaulic replacement parts and accessories. Use of any other parts may result in

improper operation and hazardous situations.

Before starting the tool, check the moveable parts for any obstructions. Make

3

Page 4

HCT908

NOTICE

Drawings and/or pictures in this manual may be exaggerated for clarity.

INTRODUCTION

The Victaulic HCT908 Variable Speed Hole-Cutting Tool is specifically designed to cut holes in steel

and stainless steel pipe for branch connections using Victaulic Hole Cut Products. This tool is not

designed for use on cast iron or PVC pipe. The HCT908 is suitable for 1 ¹⁄₄ - 8-inch (42,4 - 219,1-mm)

pipe sizes and can cut up to 4 ¹⁄₂ -inch (115-mm) hole sizes.

RECEIVING TOOL

Upon receipt of the tool, check to make sure all necessary parts are included. If the shipping

container does not contain the correct components, contact Victaulic Tool Company. NOTE: If the

tool is rented, save the shipping container for return shipment.

Quantity Description

1 Drill Motor Assembly with Chuck Key

1 Extra Pilot Drill with Coupon Saver

1 Arbor Assembly

1 Coupon Removal Tool

2 Instruction Manuals

1 Shipping Container

NOTE: Hole saws must be ordered separately.

Permanent carrying case is available and can be ordered separately.

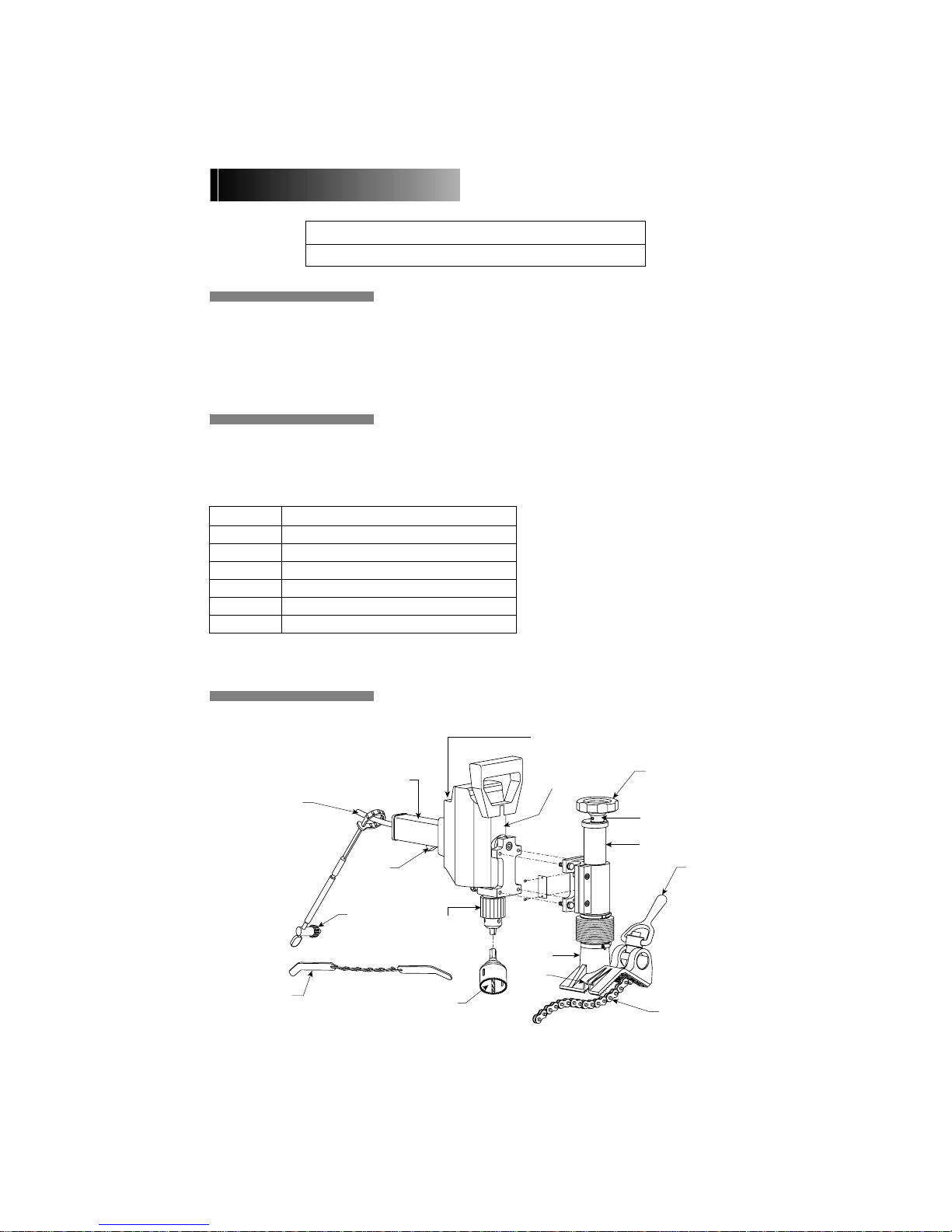

TOOL NOMENCLATURE

Drill Motor Handle

Power Cord

Trigger

Chuck Key

(attached to

power cord)

Coupon

Removal Tool

Assembly

Chuck

Arbor

Speed Control Dial

(on topside of Drill Motor Handle)

Drill Motor

Base

Chain

Slot

Feeder Knob

Bearing

Feeder Rod

Chain

Vise

Handle

4

Page 5

HCT908

POWER REQUIREMENTS

• To reduce the risk of electric shock, make sure the electrical source is properly grounded, and

follow all instructions carefully.

• Before performing any maintenance on the tool, disconnect it from the electrical source.

• Always unplug tool after each use.

Failure to follow these instructions could result in death or serious personal injury.

The tool is equipped with a three-prong plug and must be plugged into a grounded, single-phase

electrical receptacle (Figure A below). If an adapter is used to accommodate the three-prong plug,

the adapter’s wire must be attached to a known ground (refer to Figures A and B and power supply

chart below). Never remove the third prong.

GROUNDED

➥

OUTLET BOX

GROUNDING

PRONG IS

LONGEST OF

THE 3 PRONGS

➥

Figure A Figure CFigure B

GROUNDED

OUTLET BOX

➥

➥

METAL

SCREW

➥

ADAPTER

➥

GROUNDING

MEANS

NOTICE

• The tool is equipped with a UL Listed three-conductor cord and three-prong grounding type plug to fit the proper,

grounding type receptacle. The green (or green and yellow) conductor in the cord is the grounding wire. Never

connect the green (or green and yellow) wire to a live terminal.

Model

volts/(amps)

120

(7)

120 VAC, 15 amp, 50/60 cycle power supply

EXTENSION CORD REQUIREMENTS

FOR ELECTRICALLY-POWERED TOOLS

It is important to use the proper extension cord size (e.g. conductor-sized American Wire Gauge/circular mils) when pre-wired outlets are not available. Cord size selection is based upon tool rating

(volts/amps) and cord length (feet/meters). Use of cord size thinner than required will cause a significant voltage drop at the tool while it is operating. The voltage drop may cause damage to the tool

and can result in failure of the tool to operate properly. Use of a heavier cord size than required is

acceptable.

The chart below contains the required cord sizes for cord lengths up to and including 100 feet (30

meters). Avoid using cords beyond 100 feet (30 meters) in length.

Recommended Extension Cord Conductor Size at Various Cord Lengths

Circuit Rating volts

(amps)

120

(15)

Power Supply

Requirements

Cord Length feet

Conductor Size American Wire Gauge

(meters)

25 12

(8) (6 530)

50 12

(15) (6 530)

100 10

(30) (10 380)

(circular mils)

5

Page 6

HCT908

3.

2.

1.

3.

1.

INSTALLING THE HOLE

SAW ONTO THE ARBOR

ASSEMBLY

Depending on the type of arbor assembly

included with the tool, thread or push the locking ring of the arbor assembly back as far as it

will go.

Thread the hole saw onto the arbor assembly just enough to line up the holes in the top of

the hole saw with the drive pins on the arbor

assembly. If the pins do not line up with the

holes, back off the hole saw just enough to line

up the holes with the drive pins

TOOL SETUP AND

OPERATION

• DO NOT plug the tool into the electrical source until

instructed.

Failure to follow this instruction could result in serious

personal injury.

Ensure that the pipe is secured before

attempting to use this hole-cutting tool.

2. Locate the center of the hole to be cut on

the pipe run. Mark this center point clearly

with a punch.

NOTICE

• When selecting the hole location, take into account

the width of the product you are installing. Ensure

that it will fit and not interfere with couplings or

grooves. Additionally, allow room on the pipe to

mount the hole-cutting tool.

Thread or push the locking ring of the arbor

assembly all the way down, making sure the

pins of the arbor assembly engage the holes in

the top of the hole saw. Make sure the hole saw

is flush with the arbor assembly and that the

hole saw is installed firmly onto the arbor

assembly.

6

Place the hole-cutting tool onto the pipe.

Hook the chain around the pipe and insert it

into the chain slot on the side of the tool’s base.

Leave the chain loose enough to allow base

movement.

Page 7

6.

8.

4.

9.

5.

HCT908

Raise the drill motor to its highest position

by rotating the feeder knob counterclockwise.

Take the hex-shaped end of the arbor

assembly, and insert it into the chuck of the

drill’s motor.

Support the arbor assembly, while tightening the chuck securely with the chuck key provided.

Using the vise handle, tighten the chain

around the pipe to secure the hole-cutting tool.

• To reduce the risk of electric

shock, check the electrical

source for proper grounding,

and follow the instructions

below.

Failure to follow these instructions could result in

death or serious personal injury.

Switch –

shown in

forward

position

Trigger

Check the switch on the underside of the

drill motor’s handle. Make sure the switch is in

the “forward” position, as shown above.

7. Align the hole saw’s drill bit with the center

punch mark.

10a. Install cord by aligning connector’s key-

ways. Push connector in as far as it will go.

Turn the cord’s nut ¹⁄₄ -turn to the right to lock

the cord in place.

7

Page 8

HCT908

10b. Plug the drill motor’s cord into an appro-

priate outlet or extension cord (refer to “Power

Requirements” section on page 5).

Speed

Control

Dial

11. Set the speed control dial (on the topside

of the drill motor’s handle) for the correct application. Refer to the chart below.

Hole Saw

1

¹⁄₄

¹⁄₂

³⁄₄

2

¹⁄₂

³⁄₄

¹⁄₂ *

¹⁄₂ *

Speed Control

Setting

for Steel Pipe

8 3 to 4

8 3 to 4

8 3 to 4

8 3 to 4

8 3 to 4

8 2 to 3

8 2 to 3

3 to 4 3 to 4

3 to 4 3 to 4

¹⁄₂ -inch (89 mm) and 4 ¹⁄₂ -inch (115 mm)

Size

inches

(mm)

(26 mm)

(32 mm)

(38 mm)

(45 mm)

(51 mm)

(64 mm)

(70 mm)

(89 mm)

(115 mm)

NOTE: All of the settings shown to the right are based on using Milwaukee^ 4/6 Super-Tough° BI Metal Hole Saws or Victaulic Hole Saws.

* Milwaukee 4/6 Super-Tough Bi-Metal Hole Saws or Victaulic Hole

Saws MUST be used for 3

sizes.

^Milwaukee is a registered trademark of Milwaukee Electric Tool Corporation.

°Super-Tough is a registered trademark of Milwaukee Electric Tool Corporation.

Speed Control

Setting for

Stainless Steel

Pipe

• NEVER use the HCT908 Hole-Cutting Tool on

applications where spark hazards exist or contact

with water can occur.

Failure to follow this instruction could result in serious

personal injury and product damage.

1

1

1

2

12. Depress the trigger on the underside of

the drill motor’s handle, and feed the hole saw

by turning the feeder knob clockwise. Feed the

saw into the cut at a moderate rate to maintain

good cutting action. DO NOT feed the saw too

fast, since it can cause the motor to stall. If difficulties occur during the cutting operation,

refer to the “Troubleshooting” section on page

12.

13. After completing the cut, remove your fin-

ger from the trigger, and retract the hole saw

by turning the feeder knob counterclockwise.

NOTICE

• To extend hole saw life, apply steel pipe thread

cutting oil to the hole while you are performing the

cutting operation.

• Avoid touching the coupon with

your bare hands. Coupons can be

very hot and sharp.

Failure to follow this instruction

could result in serious personal

injury.

2

3

4

8

Page 9

14. Unplug the tool from the electrical source.

Remove the coupon from the hole saw by using

the coupon removal tool, as shown above. Use

care not to damage the wire wound into the

drill. Remove any chips from the drill.

NOTICE

• If the coupon fell out of the tool and into the pipe,

remove the coupon from inside the pipe.

HCT908

17. Brush away shavings from around the hole

so that the hole-cut product’s gasket can seal

properly on the pipe. Use a file, if necessary, to

remove burrs or scratches from the gasket sealing area. The pipe surface within ⁵⁄₈ " (16 mm)

of the hole must be clean, smooth, and free

from indentations that might affect gasket

sealing. The pipe around the entire circumference within the “A” dimension (refer to chart

and illustration above) must be free of any dirt

or projections that might prevent the hole-cut

product from seating fully on the pipe

3

3

1

1

2

4

15. Support the tool. Loosen the vise handle.

16. Continue to support the tool. Unhook the

chain from the slot. Remove the tool from the

pipe.

A

⁵⁄₈"

(16 mm)

Branch Size

inches

(mm)

¹⁄₂

(21,3) (90)

³⁄₄

(26,9) (90)

13

(33,7) (90)

¹⁄₄

(42,4) (100)

¹⁄₂

(48,3) (100)

24

(60,3) (115)

¹⁄₂

(73,0) (120)

76,1 mm

35

(88,9) (140)

46¹⁄₂

(114,3) (165)

“A” Dimension

inches

(mm)

¹⁄₂

¹⁄₂

¹⁄₂

4

4

¹⁄₂

³⁄₄

³⁄₄

4

(120)

¹⁄₂

9

Page 10

HCT908

REMOVING THE HOLE

SAW FROM THE ARBOR

ASSEMBLY

• Always unplug the tool from the electrical source

before removing the hole saw from the arbor

assembly.

Failure to follow this instruction could result in serious

personal injury.

1. Remove the arbor assembly from the drill by

using the chuck key provided.

LUBRICATION

The HCT908 Hole-Cutting Tool is lubricated at

the factory. However, periodic lubrication of

the following parts will maintain smooth and

proper operation of the tool.

1. Lubricate the feeder rod with light oil.

2. Lubricate the bearing with light oil.

ADJUSTING THE GIB

2. Depending on the type of arbor assembly

included with the tool, pull or thread the locking ring all the way up, making sure the pins in

the arbor assembly are completely free from the

hole saw. Unscrew the hole saw from the arbor

assembly and remove.

MAINTENANCE

• Before performing any maintenance on the tool,

disconnect it from the electrical source.

Failure to follow this instruction could result in serious

personal injury.

10

After many uses, play may develop at the gib,

allowing excessive side-to-side movement of

the drill motor assembly. This play is easily corrected by using the screw adjustment provided.

1. Loosen the lock nuts, and adjust the screws

to take up any slack (refer to the photo above).

2. Re-tighten the lock nuts while holding the

screws in place. Check the side-to-side movement in the assembly. Run the assembly up

and down by using the feeder knob, and check

for excessive drag. When properly adjusted,

very little side-to-side motion will occur, and

very little drag will be felt when rotating the

feeder knob.

Page 11

ACCESSORIES

HCT908

ARBOR ASSEMBLY FOR

1¹⁄₄-INCH (32-mm) OR LARGER

DIAMETER HOLE SAWS

ARBOR ASSEMBLY FOR 1-INCH

(26-mm) DIAMETER HOLE SAW

412

413

415

402

Item

No. Part No. Qty. Description

450 R-450-900-HCT Ref. Arbor Assembly

402 R-402-900-HCT 1 Coupon-Retaining Drill Bit

412 N-M14-000-007 1 Arbor

415 N-S90-050-004 1 Nyloc Half Dog Set Screw

413 N-M18-000-011 * Hole Saw 1" (26 mm)

*Hole saws must be ordered separately

405

404

402

Item

No. Part No. Qty. Description

400 R-400-900-HCT Ref. Arbor Assembly

402 R-402-900-HCT 1 Coupon-Retaining Drill Bit

404 N-S90-050-010 1 Nyloc Half Dog Set Screw

405 N-M14-000-025 1 Arbor

406 N-M18-000-016 * Hole Saw 1¹⁄₄" (32 mm)

407 N-M18-000-021 * Hole Saw 1¹⁄₂" (38 mm)

408 N-M18-000-026 * Hole Saw 1³⁄₄" (45 mm)

409 N-M18-000-031 * Hole Saw 2" (51 mm)

411 N-M18-000-037 * Hole Saw 2¹⁄₂" (64 mm)

414 N-M18-000-040 * Hole Saw 2³⁄₄" (70 mm)

416 N-M18-000-047 * Hole Saw 3¹⁄₂" (89 mm)

417 N-M18-000-050 * Hole Saw 4¹⁄₂" (115 mm)

*Hole saws must be ordered separately.

1

Arbor assembly is supplied with the tool.

406 407 408 409

411 414 416 417

1

11

Page 12

HCT908

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE SOLUTION

Base will not fully tighten

onto the pipe.

Motor will not run.

Pilot drill will not cut.

Hole saw blade will not

cut.

Excessive torque is

required to rotate the

feeder knob.

Drill motor gets very hot.

Excessive side-to-side

play is occurring.

Pilot drill does not retain

the coupon.

Hole saw life is short. Speed control dial is set too high. Set the speed control dial to the recommended

Vise handle has run out of threads. Loosen vise handle and position one link tighter on

1) Tool is not plugged in.

2) A fuse is blown, or the circuit

breaker is off or tripped.

3) Motor trigger switch is defective.

4) Plug is not making good contact

with the receptacle.

5) Tool cord is damaged.

1) Drill motor is running in reverse.

2) Pilot drill is not tight in the arbor.

3) Pilot drill is dull.

1) Drill motor is running in reverse.

2) Hole saw blade is dull.

3) One or more teeth have been

broken off the hole saw blade.

4) Pipe has a hard spot or a hard weld

seam.

5) Chips are stuck in the cut.

1) Drill motor is running in reverse.

2) There is a lack of lubrication on the

feeder rod.

3) The gib is too tight.

1) Holes are being cut too fast.

2) Hole saw blade is dull.

3) An undersized or too long of an

extension cord is being used.

Gib is out of adjustment. Adjust the gib, according to the instructions in the

Coupon retaining drill bit is damaged. Replace the pilot drill.

chain slot. Re-tighten vise handle.

1) Plug the tool into the proper voltage outlet or

extension cord.

2) Replace the power supply fuse, or reset the

breaker.

3) Replace the motor trigger switch.

4) Inspect the connection and make repairs, as

necessary.

5) Replace the tool’s cord.

1) Move the motor switch to the forward position.

2) Tighten the arbor’s set screw. Make sure it

engages the pilot drill’s flats.

3) Replace the pilot drill.

1) Move the motor switch to the forward position.

2) Replace the hole saw blade.

3) Replace the hole saw blade. Inspect the cut to see

if teeth are lodged in the pipe. Remove lodged

teeth with a center punch or a small chisel (wear

eye protection).

4) Use a sharp hole saw blade and generously

lubricate the cut with thread-cutting oil. Cut the

hole slowly.

5) Remove chips from the hole saw’s teeth and the

cut.

1) Move the motor switch to the forward position.

2) Lubricate the feeder rod according to the

instructions in the “Maintenance” section of this

manual.

3) Re-adjust the gib according to the instructions in

the “Maintenance” section of this manual.

1) Feed the hole saw into the cut at a moderate rate,

and do not bog down the motor.

2) Replace the hole saw blade.

3) Replace the extension cord with one of the proper

size and length (refer to “Power Requirements”

section in this manual).

“Maintenance” section of this manual.

setting listed in this manual.

Victaulic reserves the right to change product specifications, designs and standard equipment

TM-HCT908 3022 Rev.B 9/01 RM00908000

12

Victaulic® Factory Representatives and Distributor Stocks Worldwide

without notice and without obligation.

Loading...

Loading...