Page 1

I-800

Victaulic FireLock® CPVC

Sprinkler System Products

DESIGN AND

INSTALLATION MANUAL

I-800

DESIGN AND INSTALLATION MANUAL

If you need additional copies of any instructions, or if you have

questions about the safe and proper installation of Victaulic products,

contact Victaulic.

For the most up-to-date information on Victaulic products, visit:

www.victaulic.com

Page 2

Page 3

I-800_1

FIRELOCK CPVC SPRINKLER

SYSTEM PRODUCTS REV_J

QUICK REFERENCE

Frequently Referenced Sections Page(s)

Handling and Storage of CPVC Pipe and Fittings ............... 7

Chemical Compatibility with CPVC Pipe and Fittings ............. 8

Use with Other Manufacturers’ Pipes, Fittings,

and Solvent Cements:................................. 20

Set and Cure Times ................................ 26 – 27

Painting Pipe and Fittings ............................... 35

Hanger/Support Spacing ............................ 44 – 46

Page 4

I-800_2

FIRELOCK CPVC SPRINKLER

SYSTEM PRODUCTS REV_J

TABLE OF CONTENTS

Purpose of This Manual .................................................3

Hazard Identification ...................................................3

Installer Safety Instructions ..............................................4

Introduction ..........................................................5

Helpful Information – English and Metric Conversion Chart .....................6

Handling and Storage of CPVC Pipe and Fittings..............................7

Chemical Compatibility with CPVC Pipe and Fittings...........................8

Handling and Storage of One-Step Solvent Cement............................9

System Approvals, Listings, Usage, and Standards ...........................10

Light Hazard Occupancies:............................................10

Residential Occupancies: .............................................10

Concealed Installations: ..............................................10

Ordinary Hazard Installations: ..........................................11

Exposed Installations: ................................................11

Extended Coverage Sprinklers: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Return Air Plenums Installations: .......................................12

Combustible Attic Installations with Specific-Application Sprinklers: .............12

Multi-Purpose Systems: ..............................................12

Combustible Concealed Installations with Specific-Application Sprinklers: ........13

Unfinished Basements with Exposed, Solid-Wood Joist Installations: ............13

System Risers (Protected and Exposed):..................................15

Garage Installations: .................................................17

High Temperature Areas: .............................................17

Cold Temperature Areas: .............................................18

Underground Fire Service: ............................................19

Factory Mutual:.....................................................19

NSF

®

International: ..................................................19

Penetrating Fire-Rated Walls and Partitions: ...............................20

Heat Sources and Open Ceiling Areas: ...................................20

Use with Other Manufacturers’ Pipes, Fittings, and Solvent Cements: ...........20

Installation & Joining Section............................................21

Cutting the Pipe ....................................................21

Deburring and Beveling...............................................22

Fitting Preparation ..................................................22

Solvent Cement Application ...........................................23

Assembly .........................................................26

Set and Cure Times .................................................26

Threaded Connections ...............................................28

Transition to Other Materials ...........................................30

Flange Connections .................................................30

Grooved Connections ................................................32

System Acceptance Testing (Hydrostatic Pressure Test) .......................34

Painting Pipe and Fittings ..............................................35

Cut-In Procedures for System Modification or Repair .........................36

Accessories..........................................................38

Adjustable Sprinkler Adapter Installation Instructions .........................42

Engineering Data Section ...............................................43

Pipe and Fitting Specifications .........................................43

Hydraulic Design....................................................43

Hanger/Support Spacing................................................44

Riser Supports .......................................................47

Exposed Installations ................................................47

Earthquake Bracing .................................................47

Tre nc hing ...........................................................48

Snaking/Deflection of Pipe..............................................49

Backfilling...........................................................51

Appendix A – Design Criteria for Combustible Concealed Installations

Incorporating Victaulic FireLock CPVC Sprinkler System Products and Victaulic

Model V2502 or Viking Coin™ (VK900) Specific Application Sprinklers ........52

Appendix B – Design Criteria for Combustible Concealed Installations

Involving Victaulic FireLock CPVC Sprinkler System Products and

Tyco Fire Products Model CC1 Combustible Concealed Sprinklers .............57

Material Properties ....................................................58

Expansion and Contraction..............................................59

Style #899 FireLock CPVC One-Step Solvent Cement MSDS Sheet ..............62

Warranty ............................................................64

Facilities ...........................................................B/C

Page 5

I-800_3

FIRELOCK CPVC SPRINKLER

SYSTEM PRODUCTS REV_J

PURPOSE OF THIS MANUAL

This manual is intended for use by specifiers, installers, and users in the selection,

design, installation, and inspection of Victaulic FireLock CPVC Piping Systems for Fire

Protection Service. Due to the critical safety and loss prevention uses of such systems,

all information contained herein is considered vital to obtain proper system performance

and must be read and understood carefully before starting the installation. If you have

any questions, or if you need additional copies of this manual, contact Victaulic at

(800) PICK VIC or (800) 742-5842.

HAZARD IDENTIFICATION

Definitions for identifying the various hazard levels are provided below.

This safety alert symbol indicates important safety messages. When you

see this symbol, be alert to the possibility of personal injury. Carefully read

and fully understand the message that follows.

DANGER

The use of the word “DANGER” •

identifies an immediate hazard

with a likelihood of death or serious

personal injury if instructions,

including recommended

precautions, are not followed.

WARNING

The use of the word “WARNING” •

identifies the presence of hazards

or unsafe practices that could

result in death or serious personal

injury if instructions, including

recommended precautions, are not

followed.

CAUTION

The use of the word “CAUTION” •

identifies possible hazards or

unsafe practices that could result

in personal injury and product or

property damage if instructions,

including recommended

precautions, are not followed.

NOTICE

The use of the word “NOTICE” •

identifies special instructions that

are important but not related to

hazards.

Page 6

I-800_4

FIRELOCK CPVC SPRINKLER

SYSTEM PRODUCTS REV_J

INSTALLER SAFETY INSTRUCTIONS

Read and understand this manual before proceeding with the installation 1.

and testing of the Victaulic FireLock CPVC System. Education and a complete

understanding of the instructions provided are requirements for the installer of the

Victaulic FireLock CPVC System. These instructions contain important information. If you

need additional copies, or if you have any questions about the safe installation and use

of this system, contact Victaulic Company, P.O. Box 31, Easton, PA 1804 4-0 031 USA,

Telephone 800-PICK-VIC or 800-742-58 42.

Use only recommended accessories.

2. Use of improper accessories or unapproved

system components in conjunction with the Victaulic FireLock CPVC System will void the

warranty and may result in improper operation of the system.

Avoid dangerous environments.

3. If utilizing electrically powered tools for installation,

be sure that the area is free of moisture or wetness that could create an unsafe condition.

Keep work area well illuminated. Allow sufficient space for measuring and system dry fit

to accommodate proper installation.

Prevent back injury.

4. Always practice safe lifting and installation techniques.

Use only tools specifically designed for plastic pipe and fittings.

5.

Inspect the products.6. Be sure that all parts are included and that you have all

necessary tools available to properly install the system.

Wear safety glasses, hardhat, and safety footwear.

7. Always practice safety first.

When solvent-cementing, always work in a well-ventilated area.

8.

Wear protective gloves.9. PVA-coated protective gloves are recommended for use

while solvent cementing. If hands come in contact with solvent cement, use a waterless,

abrasive soap.

When solvent-cementing, avoid sources of heat or open flames. DO NOT smoke.

10.

Keep work area clean.11. Cluttered areas and slippery floors invite accidents.

Wear ear protection.

12. Protect your hearing if you are exposed to long periods of very

noisy job-site operations.

Keep visitors away.

13. All visitors should be kept a safe distance away from the work

area.

Page 7

I-800_5

FIRELOCK CPVC SPRINKLER

SYSTEM PRODUCTS REV_J

INTRODUCTION

Victaulic FireLock CPVC Sprinkler System Products are manufactured from high-quality,

Post-Chlorinated Polyvinyl Chloride (CPVC), a specialty thermoplastic material. Victaulic

FireLock CPVC Sprinkler System Products are designed specifically for fire sprinkler

systems. They provide unique advantages over traditional sprinkler piping systems

through superior hydraulics, ease of installation and handling, and quick assembly using

readily available, inexpensive tools. In addition, Victaulic Style #899 FireLock CPVC

One-Step Solvent Cement eliminates the need for primers that are typical in two-step

cementing processes. The one-step process simplifies installation and reduces labor

time.

DANGER

Victaulic FireLock CPVC Sprinkler System Products must be used in wet systems •

only. A wet piping system contains water and is connected to a water supply

system so that the water will discharge immediately when the sprinkler activates.

Victaulic FireLock CPVC Sprinkler System Products must never be used in a •

system that uses compressed air or other gases.

Failure to follow these instructions could result in severe personal injury, significant

property damage, and product damage.

CAUTION

DO NOT use Victaulic FireLock CPVC Sprinkler System Products in outdoor •

applications. These products are not Listed for outdoor applications.

Failure to follow this instruction could result in product failure and property

damage and will not be covered under the Victaulic CPVC warranty.

Page 8

I-800_6

FIRELOCK CPVC SPRINKLER

SYSTEM PRODUCTS REV_J

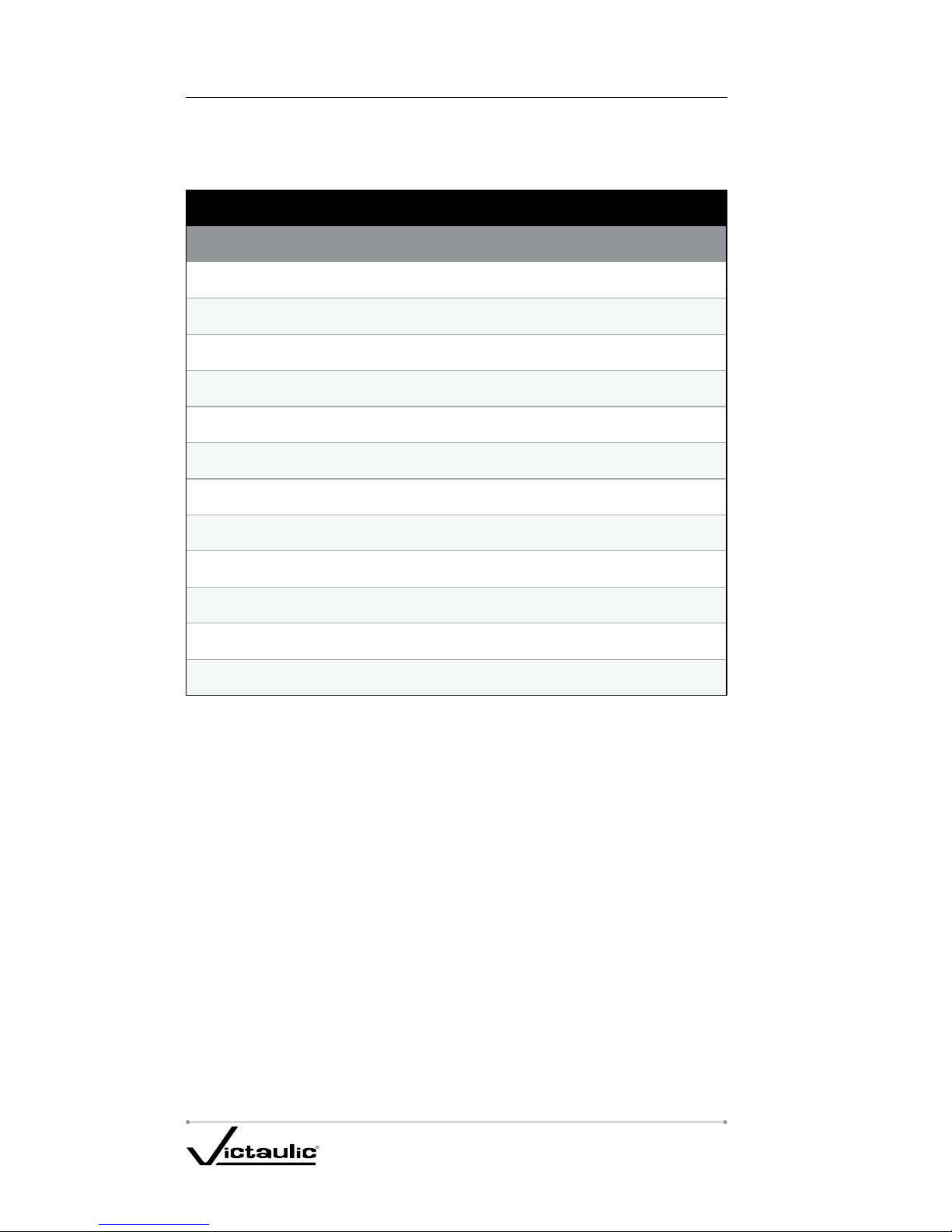

HELPFUL INFORMATION – ENGLISH AND METRIC

CONVERSION CHART

The following chart is a guideline for converting English and metric measurements.

The English measurements, given throughout this manual, are the actual values. It is

important that accurate metric conversions are made to ensure proper installation of

Victaulic FireLock CPVC Sprinkler System Products.

Convert Imperial (U.S.) to Metric

Convert Metric to Imperial (U.S.)

25.4 ×

Inches

(In.)

⇔

Millimeters

(mm)

× 0.03937

0.3048 ×

Feet

(Ft.)

⇔

Meters

(m)

× 3.281

0.4536 ×

Pounds

(Lbs.)

⇔

Kilograms

(kg)

× 2.205

28.35 ×

Ounces

(Oz.)

⇔

Grams

(g)

× 0.03527

6.894 ×

Pressure

(psi)

⇔

Kilopascals

(kPa)

× 0.145

.069 × Pressure

⇔

Bar × 14.5

4.45 ×

End Load

(Lbs.)

⇔

Newtons

(N)

× 0.2248

1.356 ×

Torque

(Lb. Ft.)

⇔

Newton Meters

(N•m)

× 0.738

F – 32 ÷ 1.8

Temp.

(°F)

⇔

Celsius

(°C)

C + 17.78 × 1.8

745.7 ×

Horsepower

(hp)

⇔

Watts

(w)

× 1.341 × 10

-3

3.785 ×

Gal. per Min.

(GPM)

⇔

Liters per min.

(L/M)

× 0.2642

3.7865 ×

10

-3

Gal. per Min.

(GPM)

⇔

Cubic Meters per min.

(m3/m)

× 264.2

Page 9

I-800_7

FIRELOCK CPVC SPRINKLER

SYSTEM PRODUCTS REV_J

HANDLING AND STORAGE OF

CPVC PIPE AND FITTINGS

Victaulic FireLock CPVC Sprinkler System pipe and fittings should be stored at normal

ambient temperatures, which must not exceed the maximum installation temperature of

1 50 °F.

Victaulic recommends storing FireLock CPVC Sprinkler System Products indoors where

the product will not be exposed to heat-producing sources or sunlight. For extended

indoor storage, the area must be well ventilated so that the ambient temperature does not

exceed 150ºF.

If stored outdoors, Victaulic FireLock CPVC Sprinkler System Products must be covered

with a non-transparent material to reduce the risk of extended exposure to sunlight and

heat absorption, which could cause discoloration and weakening of CPVC material.

Victaulic FireLock CPVC Sprinkler System Fittings must be stored in their original

containers to prevent dirt accumulation and to help reduce the possibility of damage.

Excessive loading (i.e. stacking, point loading, etc.) or excessive strapping or banding

must be avoided to prevent CPVC material from warping. DO NOT drop CPVC products or

allow anything to drop on them.

Before installation, CPVC products must be inspected for any scratches, splits, gouges,

or warping that may have occurred from improper handling or storage. Damaged sections

of CPVC pipe must be cut out and discarded. Any damaged fittings must be discarded.

WARNING

Victaulic FireLock CPVC Sprinkler System pipe and fittings MUST NOT be •

subjected to prolonged sunlight exposure.

The ambient storage temperature MUST NOT exceed 150ºF.•

If stored outdoors, fittings must be stored in the original shipping containers, •

and pipe must be covered with a non-transparent material.

DO NOT install Victaulic FireLock CPVC Sprinkler System pipe and fittings that •

have been damaged during handling or storage.

Failure to follow these instructions could cause system failure, resulting in property

damage and personal injury due to leaks.

Page 10

I-800_8

FIRELOCK CPVC SPRINKLER

SYSTEM PRODUCTS REV_J

CHEMICAL COMPATIBILITY WITH

CPVC PIPE AND FITTINGS

When combining steel with Victaulic FireLock CPVC products in a system, all steel

components must be degreased then flushed thoroughly to remove internal and external

oils before assembly.

FireLock CPVC products may be damaged by chemicals that are not corrosive to metallic

piping. These damaging chemicals can be found in common substances used in

construction and residential settings. Specific chemicals or chemical vapors that contact

CPVC can weaken or severely damage the material.

DO NOT expose product to edible oils, cooking oils, esters, ketones, or glycol-based antifreeze fluids.

DO NOT expose product to petroleum-based substances, such as cutting oils, packing

oils, traditional pipe thread paste and dope, termiticides, insecticides, surfactants,

plasticizers, and building caulks.

To avoid contamination with hydrocarbons, DO NOT store CPVC fittings in bins with metal

fittings or handle CPVC products with oil-contaminated hands or gloves.

Refer to the following:

“Threaded Connections” section for compatible thread sealants

“Grooved Connections” section for compatible lubricants

“Penetrating Fire-Rated Walls and Partitions” section for compatible fire-stopping

products

WARNING

CPVC piping components, including Victaulic FireLock CPVC Sprinkler System •

Products, may be damaged by chemicals that are not corrosive to metallic

piping. These damaging chemicals can be found in common substances used in

construction and residential settings.

DO NOT expose CPVC products to edible oils, cooking oils, esters, ketones, or •

glycol-based anti-freeze fluids.

DO NOT expose CPVC products to petroleum-based substances, such as •

cutting oils, packing oils, traditional pipe thread paste and dope, termiticides,

insecticides, surfactants, plasticizers, and building caulks.

When combining steel with CPVC products in a system, all steel components •

must be degreased then flushed thoroughly to remove internal and external oils

before assembly.

To avoid contamination with hydrocarbons, do not store CPVC products in •

containers with metal fittings.

Handle CPVC products with clean hands and gloves only.•

Failure to follow these instructions may cause cracks or fractures in CPVC

products, resulting in property damage and personal injury due to leaks or flooding.

Alternatively, partial or full system replacement may be required due to the

presence of visible cracks.

For questions regarding chemical compatibility with CPVC products, contact Victaulic at

1-800-554-4434 or by e-mail at engserv@victaulic.com.

Page 11

I-800_9

FIRELOCK CPVC SPRINKLER

SYSTEM PRODUCTS REV_J

HANDLING AND STORAGE OF

ONE-STEP SOLVENT CEMENT

Victaulic Style #899 FireLock CPVC One-Step Solvent Cement must be stored out of

direct sunlight in ambient temperatures between 40°F and 110°F. The solvent cement

may be used for a period of two years from the date stamped on the container. Expired

solvent cement must be discarded in an environmentally friendly fashion, in accordance

with local regulations. To prolong the life of the cement, the containers must be kept

tightly closed when not in use and covered as much as possible during use. Refer to the

“Solvent Cementing Procedures” section for more information.

DANGER

Before using Victaulic Style #899 FireLock CPVC One-Step Solvent Cement, •

refer to ASTM-F402-05, “Standard Practice for Safe Handling of Solvent

Cements, Primers, and Cleaners Used for Joining Thermoplastic Pipe and

Fittings.” In addition, refer to the solvent cement Material Safety Data Sheet

(MSDS) and the solvent cement can label for important information.

Victaulic Style #899 FireLock One-Step Solvent Cement is highly flammable. •

Make sure all ignition sources are eliminated before use.

Avoid breathing solvent cement vapors, and use solvent cement only in well-•

ventilated areas. Explosion-proof, general mechanical ventilation or local exhaust

is recommended to maintain vapor concentrations below recommended exposure

limits. In confined or partially enclosed areas, a NIOSH-approved, organic-vapor

cartridge respirator with a full-face piece is recommended.

Avoid frequent contact with skin. PVA coated gloves and an impervious apron •

are recommended.

Avoid contact with eyes. Splash-proof chemical goggles are recommended.•

Failure to follow these instructions could result in serious personal injury.

WARNING

Follow all instructions contained in this manual when solvent cementing •

Victaulic FireLock CPVC Sprinkler System products.

Avoid puddling solvent cement on or within the fitting or pipe.•

DO NOT allow solvent cement to run into the inside or on the outside of the pipe •

or fitting.

Failure to follow these instructions could cause the pipe or fitting to fracture,

resulting in serious personal injury and/or significant property damage.

Page 12

I- 80 0_10

FIRELOCK CPVC SPRINKLER

SYSTEM PRODUCTS REV_J

SYSTEM APPROVALS, LISTINGS,

USAGE, AND STANDARDS

Victaulic FireLock CPVC Sprinkler System Products are Underwriters Laboratories Inc.

(UL) Listed and Factory Mutual (FM) Approved for use in wet-pipe sprinkler systems.

In addition, these products are approved by NSF

®

International for use in potable water

systems (refer to page 19 for more information). Victaulic Style #899 FireLock CPVC

One-Step Solvent Cement meets ASTM-F493 and NSF International requirements.

National Fire Protection Association (NFPA) Standards 13, 13R, and 13D must be

referenced for design and installation requirements in addition to this manual.

The following section summarizes the agency approvals, listings, usage, and standards

that Victaulic FireLock CPVC Sprinkler System Products meet. For more specific listing

information concerning FM or NSF International, contact Victaulic.

Light Hazard Occupancies:

Victaulic FireLock CPVC Sprinkler System Products are UL Listed for use in Light

Hazard Occupancies, as defined in NFPA 13, “Standard for the Installation of Sprinkler

Systems.”

Residential Occupancies:

Victaulic FireLock CPVC Sprinkler System Products are UL Listed for use in:

Residential occupancies, as defined in NFPA 13R, “Standard for the Installation

1.

of Sprinkler Systems in Residential Occupancies up to and Including Four Stories in

Height.”

Residential occupancies, as defined in NFPA 13D, “Standard for the Installation of

2.

Sprinkler Systems in One- and Two-Family Dwellings and Manufactured Homes.”

Residential occupancies, as defined in NFPA 13, “Automatic Sprinkler Systems

3.

Handbook 2007 Edition”

Concealed Installations:

Victaulic FireLock CPVC Sprinkler System Products are UL Listed for use in concealed

installations with the following provisions.

The minimum protection shall consist of one layer of •

⁄-inch gypsum wallboard,

½-inch plywood soffits, or a suspended membrane ceiling with lay-in panels or

tiles having a weight of not less than .35 lbs/ft

2

when installed with metallic support

grids.

The minimum protection for residential occupancies, defined in NFPA 13D and 13R, •

may consist of one layer of

½-inch plywood.

Victaulic FireLock CPVC Sprinkler System Products must be used in sprinkler •

systems employing sprinklers rated at 225°F or lower.

NOTICE

Victaulic FireLock CPVC Sprinkler System Products CANNOT be installed in •

spaces defined by NFPA 13 as combustible, concealed spaces that require

sprinklers, unless the space is protected by sprinklers that are specifically Listed

for the application.

NFPA 13D and NFPA 13R permit the omission of sprinklers in combustible, •

concealed spaces. Victaulic FireLock CPVC Sprinkler System Products can be

installed in these areas when sprinkling residential occupancies in accordance

with these standards.

Page 13

I-8 00_11

FIRELOCK CPVC SPRINKLER

SYSTEM PRODUCTS REV_J

Ordinary Hazard Installations:

In accordance with NFPA 13 (2007 Edition), paragraph 6.3.6.2, “Pipe or tube listed •

for light hazard occupancies shall be permitted to be installed in ordinary hazard

rooms of otherwise light hazard occupancies where the room does not exceed

400 ft

2

.” Follow all instructions contained in this manual for proper installation of

Victaulic FireLock CPVC pipe and fittings.

Exposed Installations:

Victaulic FireLock CPVC Sprinkler System Products are UL Listed for use in installations

without protection (exposed), with the following restrictions:

Exposed CPVC Fire Sprinkler piping is installed below a smooth, flat, horizontal •

ceiling construction utilizing UL Listed support devices.

Listed, Quick-Response, ordinary temperature-rated pendent sprinklers having •

deflectors installed within 8 inches from the ceiling. Listed, Residential, ordinary

temperature-rated, pendent sprinklers located in accordance with their Listing. The

maximum distance between sprinklers must not exceed 15 feet. The piping must be

mounted directly to the ceiling.

Listed, Quick-Response, ordinary-temperature-rated horizontal sidewall sprinklers •

having deflectors installed within 6 inches from the ceiling and within 6 inches from

the sidewall. Listed, Residential, ordinary temperature-rated horizontal sidewall

sprinklers located in accordance with their Listing. The maximum distance between

sprinklers must not exceed 14 feet. Piping must be mounted directly to the sidewall.

Listed, Quick-Response, upright sprinklers having a maximum temperature rating •

of 155°F must be installed so that the deflectors are a maximum of 4 inches from

the ceiling. The maximum distance from the ceiling to the centerline of the main run

of pipe must be 7

½ inches. The maximum distance between sprinklers must not

exceed 15 feet. The distance from the centerline of a sprinkler to a hanger must be

3 inches. Rigid pipe hangers secured to the ceiling must be used.

Extended Coverage Sprinklers:

Victaulic FireLock CPVC Sprinkler System Products are UL Listed for installations without

protection (exposed) when installed with extended coverage sprinklers with the following

provisions.

Exposed piping must be installed below a smooth, flat, horizontal ceiling •

construction.

Listed pendent, light-hazard, quick-response, extended-coverage sprinklers with •

a maximum temperature rating of 155°F must be installed within 8 inches from

the ceiling. The distance between sprinklers must not exceed 20 feet, and the

application density must be at least 0.10 gpm/ft

2

. Piping must be mounted directly

to the ceiling.

Listed pendent, residential sprinklers with a maximum temperature rating of 155ºF •

must be installed within 8 inches from the ceiling. The distance between sprinklers

must not exceed 20 feet, and the application density must be at least 0.10 gpm/ft

2

.

Piping must be mounted directly to the ceiling.

Listed horizontal sidewall, light-hazard, quick-response, extended coverage •

sprinklers with a maximum temperature rating of 165ºF must be installed within

12 inches from the ceiling and within 6 inches from the sidewall. The distance

between sprinklers must not exceed 18 feet, and the application density must be at

least 0.10 gpm/ft

2

.

Listed, Quick-Response, (200°F maximum temperature-rated) horizontal sidewall •

sprinklers having deflectors installed within 12 inches from the ceiling and within 6

inches from the sidewall. Listed, Residential, ordinary temperature-rated horizontal

sidewall sprinklers located in accordance with their Listing. The maximum distance

between sprinklers must not exceed 14 feet. Piping must be mounted directly to the

sidewall.

Page 14

I-800_12

FIRELOCK CPVC SPRINKLER

SYSTEM PRODUCTS REV_J

Listed horizontal sidewall, light-hazard, quick-response, extended coverage •

sprinklers with a maximum temperature rating of 175°F must be installed with the

deflectors within 12 inches from the ceiling and within 6 inches from the sidewall.

The distance between sprinklers must not exceed 16 feet, and the application

density must be at least 0.10 gpm/ft

2

.

Listed horizontal sidewall, light-hazard, quick-response, extended coverage •

sprinklers manufactured by Reliable Automatic Sprinkler Co. (SIN RA0362) with a

maximum temperature rating of 155°F must be installed with the deflectors within

12 inches from the ceiling and within 6 inches from the sidewall. The distance

between sprinklers must not exceed 24 feet, and the flow must not be less than 40

gpm per sprinkler.

Listed horizontal sidewall, residential sprinklers with a maximum temperature rating •

of 165ºF must be installed within 12 inches from the ceiling and within 6 inches

from the sidewall. The distance between sprinklers must not exceed 18 feet, and the

application density must be at lest 0.10 gpm/ft

2

.

These installations require the use of Schedule 80 fittings in sizes 1 •

½ inches and

larger.

The piping for horizontal sidewall sprinklers shall be mounted directly to the sidewall.•

The end-use application is limited to unobstructed construction only.•

Solvent cemented joints may be made with Victaulic Style #899 FireLock CPVC One-•

Step Solvent Cement or any of the solvent cement products listed in this manual.

Return Air Plenums Installations:

Victaulic FireLock CPVC Sprinkler System Products meet the combustibility requirements

for thermoplastic sprinkler pipe, as described in the Standard for Installation of Air

Conditioning and Ventilating Systems, NFPA 90A.

Victaulic FireLock CPVC Sprinkler System Products must be installed in the plenum •

space adjacent to, but not over, an opening in the ceiling, such as a ventilation grill.

Combustible Attic Installations with

Specific-Application Sprinklers:

Specific Application Attic Sprinklers are designed to provide protection of specific, lighthazard combustible and non-combustible attic spaces that require sprinkler protection.

The sprinklers must be installed in accordance with Tyco Fire Products’ Technical

Data Sheets TFP610 for Specific Application Attic Sprinklers. Victaulic FireLock CPVC

Sprinkler System Products can be installed within an attic space, provided that the

attic space is protected with UL Listed Tyco Fire Products Specific Application Attic

Sprinklers, and the CPVC pipe and fittings are used only to feed the wet sprinkler system

below the ceiling.

According to the guidelines found in TFP610, Victaulic FireLock CPVC pipe must be

covered by 6 inches minimum of non-combustible insulation that extends 12 inches

on each side of the pipe centerline (when protected above with Specific Application

Attic Sprinklers). If the pipe is installed between the ceiling joists, and the area above is

protected by Specific Application Attic Sprinklers, the joist channel must be covered or

filled with 6 inches of non-combustible insulation on top of the pipe. NOTE: Insulation is

for fire protection purposes only; it is not intended for freeze protection.

Multi-Purpose Systems:

Multi-purpose systems are defined as a piping system designed to serve both domestic

and fire protection needs in a residential occupancy. Victaulic FireLock CPVC Sprinkler

System Products are UL Listed for use in multi-purpose systems, as defined in NFPA

13R and NFPA 13D, where there are no provisions to prevent domestic water flow upon

activation of the sprinkler system. Design and installation of these types of systems shall

be in accordance with Chapter 6 of the 2002 edition of NFPA 13R and NFPA 13D.

Page 15

I-800_13

FIRELOCK CPVC SPRINKLER

SYSTEM PRODUCTS REV_J

Combustible Concealed Installations with

Specific-Application Sprinklers:

In accordance with the UL Listing, Victaulic FireLock CPVC Sprinkler System Products

can be used in specific light-hazard, combustible concealed and non-combustible

concealed spaces that require sprinkler protection when installed with UL Listed Victaulic

Model V2502, Viking Coin (VK900), or Tyco Fire Products Model CC1 specific-application

sprinklers. The system must be installed in accordance with the information contained in

Appendix A or Appendix B. For the Victaulic Model V2502, additional reference should

be made to Submittal 40.09. For the Viking Coin (VK900), additional reference should

be made to the “Technical Data” sheet (Form No. F_110503 or Form No. F_110603).

For the Tyco Fire Products Model CC1 sprinkler, refer to the “Model CC1 Combustible

Concealed Space Sprinkler Technical Data Sheet” (TFP630).

NOTICE

When installing Victaulic FireLock CPVC Sprinkler System Products in •

combustible concealed areas that require sprinkler protection, the Victaulic

Model V2502, Viking Coin (VK900), or Tyco Fire Products Model CC1 Sprinkler

must be used in accordance with the UL Listing. Contact the local authority

having jurisdiction with questions concerning code requirements.

Unfinished Basements with Exposed,

Solid-Wood Joist Installations:

NOTICE

Use of Victaulic FireLock CPVC Sprinkler System Products is limited to •

basements where the quantity and combustibility of contents is low and fires

with relatively low rates of heat release are expected.

Refer to NFPA 13D, “Standard for the Installation of Sprinkler Systems in •

One-and Two-Family Dwellings and Manufactured Homes” for more information

regarding installations in unfinished basements with exposed, solid-wood joists.

Victaulic FireLock CPVC Sprinkler System Products can be installed in unfinished

basements with exposed, solid-wood joists with the following limitations:

The ceiling must be horizontal and must be constructed of nominal 2-inch x 10-inch •

solid wood joists on 16-inch centers.

– OR –

The ceiling must be horizontal and must be constructed of nominal 2-inch x 12-inch •

solid wood joists on 16-inch centers. When Victaulic FireLock CPVC Sprinkler

System Products are used in constructions with 2-inch x 12-inch solid wood joists,

the maximum system working pressure under flowing conditions must not exceed

100 psi. The maximum system working pressure under non-flowing conditions must

not exceed 175 psi. Refer to Figure “A” on page 16.

For installations involving 2-inch x 10-inch solid wood joists or 2-inch x 12-inch

1.

solid wood joists, all solvent cement joints must be made by using Victaulic Style #899

FireLock CPVC One-Step Solvent Cement or any of the solvent cement products listed in

this manual.

Schedule 80 fittings are required for installations involving 1

2. ½-inch through 2-inch

piping.

The distance from the floor to the bottom of the solid wood joists must be between

3.

7 feet and 8 feet.

Page 16

I-800_14

FIRELOCK CPVC SPRINKLER

SYSTEM PRODUCTS REV_J

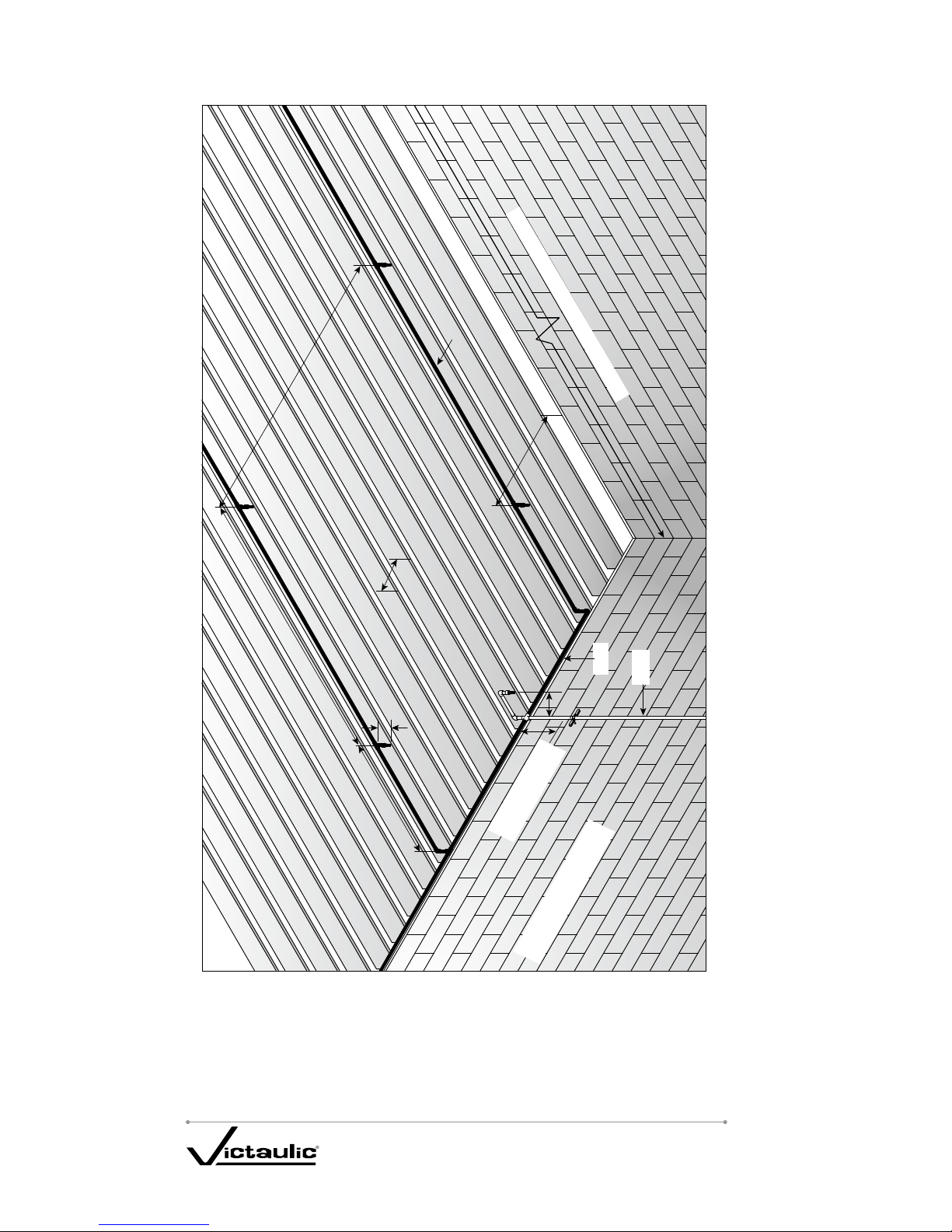

All system mains must run perpendicular to the joists, and all branch lines must run 4.

parallel to the joists.

CEILING

BLOCKING

16

inches

2 x 10 or 2 x 12

Solid Wood

Joists (Typical)

When the total protected area exceeds 1,000 square feet, blocking must be used 5.

in-between the joists to divide the area into sections; these sections must not exceed

1,000 square feet. Refer to the drawing above.

The maximum length along the joist must not exceed 32 feet. If the length exceeds

6.

32 feet, blocking must be used. The blocking must be constructed of minimum ½-inch

plywood and must be equal to the full depth of the wood joists.

Listed, residential-pendent sprinklers with a maximum temperature rating of 155°F

7.

and a minimum K-factor of 3.0 must be used for this type of installation. NOTE: The

maximum sprinkler spacing must not exceed 12 feet.

The system must be designed to UL Listed flows for the sprinkler being used.

8.

However, the flow must not be less than 11 gpm per sprinkler. Sprinklers must be

installed with the deflectors below the solid wood joists for future installation of a finished

ceiling. However, deflector placement must not exceed 1

¾ inches below the solid wood

joist in anticipation of a future finished ceiling installation (refer to Figures “B” and

“C” below). For more information, refer to NFPA 13D, “Standard for the Installation of

Sprinkler Systems in One-and Two-Family Dwellings and Manufactured Homes.”

Branches Supported with Blocking Branches Supported with Hangers

½ Joist

Depth Max.

1¾" Max.

FIGURE “B”

½ Joist

Depth Max.

1¾" Max.

FIGURE “C”

When installing Victaulic FireLock CPVC Sprinkler System Products perpendicular

9.

(system mains) to solid wood joists, UL Listed support devices must be used to mount

the piping directly to the bottom of the solid wood joists. In addition, it is acceptable to

cut holes in the solid wood joists at or below the center depth of the solid wood joist for

support. Holes must be oversized to allow for movement and must be located in an area

that will not compromise joist integrity. Contact the local authority having jurisdiction for

information regarding structural integrity.

Page 17

I-800_15

FIRELOCK CPVC SPRINKLER

SYSTEM PRODUCTS REV_J

When installing Victaulic FireLock CPVC Sprinkler System Products parallel (branch 10.

lines) to solid wood joists, the pipe and fittings must be installed in the cavity below the

bottom of the ceiling and above the bottom of the joist. Branch lines must be located

at or below the center depth of the solid wood joist. UL Listed support devices must be

used to mount the piping directly to nominal 2-inch wood blocking. In addition, UL Listed

support devices can be used that offset the pipe a nominal distance of 1

½ inches from

the solid wood joists.

System Risers (Protected and Exposed):

Victaulic FireLock CPVC Sprinkler System Products are UL Listed for use as system risers

in accordance with NFPA 13R and NFPA 13D with the following limitations.

A. CPVC risers must be installed in accordance with NFPA 13, “Support of Risers.”

B. When the system riser is installed protected (concealed), the minimum protection

must consist of one layer of

⁄-inch gypsum wallboard or ½-inch plywood. Refer to the

“Hanger/Support Spacing” section for detailed installation instructions for riser supports.

C. When the system riser is installed without protection (exposed), the following

limitations apply. NOTE: Only NFPA 13R and NFPA 13D applications can be installed

exposed.

The riser must be installed below a smooth, flat, horizontal ceiling construction. •

A UL Listed, residential-pendent sprinkler must be located in accordance with its

Listing and must be installed at a maximum horizontal distance of 12 inches from

the centerline of the riser. Refer to Figure “A” on page 16.

– OR –

The riser must be installed below a horizontal, unfinished basement ceiling in •

accordance with NFPA 13D. The unfinished basement ceiling must be constructed

of nominal 2-inch x 10-inch or 2-inch x 12-inch exposed solid wood joists on

16-inch centers. Refer to Figure “A” on page 16.

When installing Victaulic FireLock CPVC Sprinkler System Products in constructions

1.

with 2-inch x 12-inch solid wood joists, the maximum system working pressure under

flowing conditions must not exceed 100 psi. The maximum system working pressure

under static (non-flowing) conditions must not exceed 175 psi.

A UL Listed residential-pendent sprinkler with a maximum temperature rating of

2.

155ºF and a minimum K-factor of 3.0 is required at a maximum horizontal distance of 12

inches from the centerline of the riser. The deflector must be a maximum of 1

¾ inches

below the bottom of the solid wood joist; this is in anticipation of a future finished ceiling.

The system must be designed to UL Listed flows for the sprinkler being used. However,

the flow must not be less than 11 gpm per sprinkler.

The riser must be supported vertically within 2 feet from the ceiling or bottom of the

3.

joist.

UL Listed riser pipe sizes must be between 1 inch and 2 inches inclusive.

4.

The maximum distance between the walls and the outside surface of the riser pipe 5.

must be 1 ½ inches. Refer to Figure “A” on page 16.

Solvent cemented joints may be made with Victaulic Style #899 FireLock CPVC

6.

One-Step Solvent Cement or any of the solvent cement products listed in this manual.

These installations require the use of Schedule 80 fittings for risers that are 1

7. ½

inches and larger.

Page 18

I- 80 0_16

FIRELOCK CPVC SPRINKLER

SYSTEM PRODUCTS REV_J

32 feet Maximum to Wall or Blocking

1½ inches Maximum from

Wall to Edge of Riser

2 feet Maximum

to Support

12 inches Maximum to Center of Riser

12 feet Maximum

6 feet Maximum

6 feet Maximum

2 x 10 or 2 x 12

16-inch centers

1¾ inches Max.

Branch

Main

Riser

Figure “A”

Page 19

I- 800_17

FIRELOCK CPVC SPRINKLER

SYSTEM PRODUCTS REV_J

Garage Installations:

Victaulic FireLock CPVC Sprinkler System Products are suitable for use in garages

requiring sprinklers, as defined in NFPA 13R, with the following requirements:

Minimum protection consisting of either one layer of

1. ⁄-inch thick gypsum or

½-inch thick plywood must be provided.

Listed pendent or sidewall sprinklers with a maximum temperature rating of 225°F

2.

must be used.

All sprinklers must be installed per the manufacturer’s published installation

3.

instructions.

The system must be installed per the requirements of NFPA 13R and these

4.

installation instructions.

High Temperature Areas:

Victaulic FireLock CPVC Sprinkler System Products are suitable for use in areas •

where ambient temperatures are within the range of 35°F to 150°F.

Victaulic FireLock CPVC Sprinkler System Products can be installed in areas, such •

as an attic, where the ambient temperature exceeds 150°F if ventilation is provided

or if insulation is used around the product to maintain a cooler environment.

WARNING

DO NOT install Victaulic FireLock CPVC Sprinkler System Products in an area •

where the ambient temperature will exceed 150°F, unless ventilation is provided

or insulation is used around the product.

Failure to follow this instruction could result in significant property damage and

product damage.

Page 20

I-800_18

FIRELOCK CPVC SPRINKLER

SYSTEM PRODUCTS REV_J

Cold Temperature Areas:

Victaulic FireLock CPVC Sprinkler System Products can be used if the ambient •

temperature remains above 35°F.

In addition, these products can be used if the installation is in an area subject •

to freezing temperatures; however, the sprinkler system must be protected from

freezing. Many standard cold weather piping design and installation practices can

be used to protect the system from freezing, including, but not limited to, the use

of glycerin, insulation installation techniques, and pipe insulation. Contact Victaulic

with questions concerning compatibility. NOTE: Attention must be given to local

insulating techniques and codes that require a particular method.

Antifreeze solutions of water and USP or CP grade GLYCERIN are acceptable for use •

with Victaulic FireLock CPVC Sprinkler System Products. Refer to NFPA 13, NFPA

13R, and NFPA 13D.

WARNING

DO NOT allow a sprinkler system to freeze. A frozen system will deactivate, and •

the pressure can damage pipe or cause sprinklers to open.

DO NOT use glycol-based antifreeze solutions. Glycol solutions are not •

chemically compatible with the CPVC material and can cause damage to the

Victaulic FireLock CPVC Sprinkler System.

Failure to follow this instruction can result in serious personal injury, property

damage, and product damage.

Consult the local authority having jurisdiction before using glycerin solutions in fire

sprinkler applications. Since very cold weather will make Victaulic FireLock CPVC

Sprinkler System Products more susceptible to damage, extra care should be taken to

avoid rough handling or impact to these products.

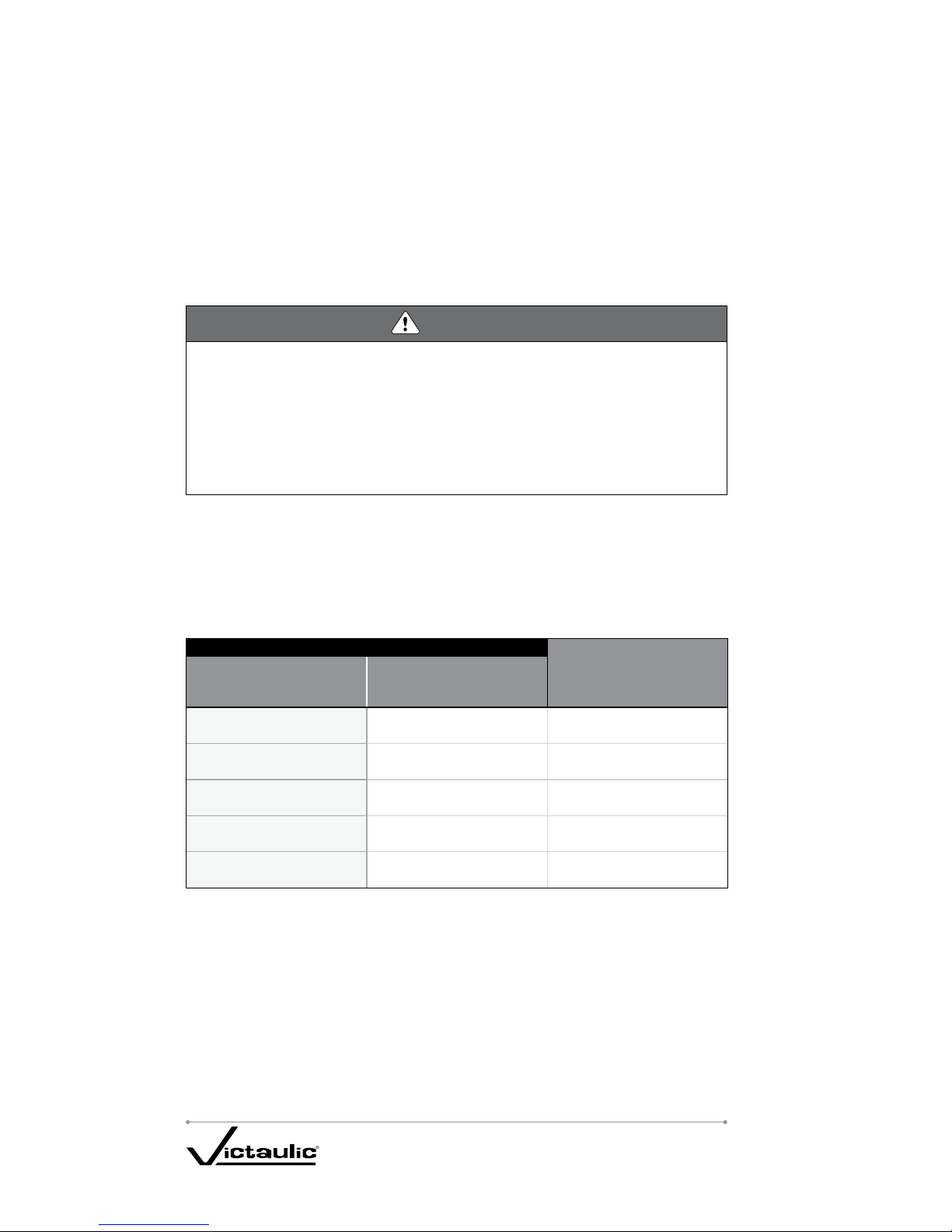

The following information can be used to determine the quantity of an antifreeze solution

needed to protect the piping system.

Pipe Size

Gallons of Water/Foot

Nominal

Diameter

inches/mm

Actual Outside

Diameter

inches/mm

¾ 1.050

.0311

20 26.9

1 1.315

.0494

25 33.7

1 ¼ 1.660

.0792

32 42.4

1 ½ 1.900

.1042

40 48.3

2 2.375

.1636

50 60.3

* Note: The gallons per foot column can be used for calculations when adding GLYCERIN to the piping

system for freeze protection. All fire protection systems winterized with glycerin solutions must conform

to local, state, and NFPA requirements. Glycerin based solutions are the only antifreeze solutions

recommended for use. Glycol solutions are not chemically compatible with the CPVC material, and their

use may result in damage to the Victaulic FireLock CPVC Sprinkler System.

Page 21

I-800_19

FIRELOCK CPVC SPRINKLER

SYSTEM PRODUCTS REV_J

Underground Fire Service:

Victaulic FireLock CPVC Sprinkler System Products are UL Listed for use in underground

water service when installation is in accordance with:

ASTM-D2774, “Standard Recommended Practice for Underground Installation of •

Thermoplastic Pressure Piping”

ASTM-F645, “Standard Guide for Selection, Design and Installation of Thermoplastic •

Water Pressure Piping Systems”

NFPA 24, “Standard for the Installation of Private Fire Service Mains and Their •

Appurtenances”

The installation procedures detailed in this manual apply to Victaulic FireLock CPVC

Sprinkler System Products with solvent cemented joints in sizes

¾ inch through 2 inches.

Factory Mutual:

Victaulic FireLock CPVC Sprinkler System Products are FM Approved for use only in wet

pipe systems, as defined in:

Light Hazard occupancies, as defined in NFPA 13, “Standard for the Installation of •

Sprinkler Systems”

Residential occupancies, as defined in NFPA 13R, “Standard for the Installation of •

Sprinkler Systems in Residential Occupancies Up to and Including Four Stories in

Height”

Residential occupancies, as defined in NFPA 13D, “Standard for the Installation of •

Sprinkler Systems in One and Two-Family Dwellings and Manufactured Homes”

Underground fire service systems, as defined in NFPA 24, “Standard for the •

Installation of Private Fire Service Mains and Their Appurtenances”

Concealed Installations

Minimum protection shall be a permanently installed, non-combustible barrier •

that cannot be removed without substantial cosmetic damage. Drop-in ceiling tiles

used in suspended ceilings are not to be considered permanently installed for the

purposes of this definition.

Victaulic FireLock CPVC Sprinkler System Products are FM Approved for use with •

Fire Resistant Barriers for CPVC Pipe and Fittings in Light Hazard Occupancies

under FM Approval of the Soffi-Steel™ System manufactured by Grice Engineering,

Inc. Installation is to be made in accordance with the FM Approval requirements for

the Soffi-Steel™ System.

Exposed Installations

Victaulic FireLock CPVC Sprinkler System Products are FM Approved for exposed •

environments in Light Hazard Occupancies.

Where piping is installed above drop-in ceiling tiles, it shall be considered exposed.•

Piping may be installed under combustible or non-permanently installed smooth, •

flat, horizontal ceilings.

Piping shall be installed according to the information in this manual, and the •

sprinklers shall be FM Approved.

NSF® International:

Victaulic FireLock CPVC Sprinkler System Products are approved by NSF International for

potable water applications. These products meet all applicable performance standards

for a pressure rated application, as required in ANSI/NSF Standard 14, and they comply

with ANSI/NSF Standard 61 for health effects. Victaulic FireLock CPVC Sprinkler System

Products carry the NSF-pw end-use marking. Victaulic FireLock CPVC pipe and fittings

conform to ASTM-F438 and ASTM-F442 requirements. In addition, Victaulic Style #899

FireLock CPVC One-Step Solvent Cement meets ASTM-F493 and NSF International

requirements.

Page 22

I-800_20

FIRELOCK CPVC SPRINKLER

SYSTEM PRODUCTS REV_J

Penetrating Fire-Rated Walls and Partitions:

Before beginning, consult the building codes and authorities having jurisdiction in your

area. Several UL Classified, through-penetration firestop systems are approved for use

with CPVC pipe. Consult the UL Building Materials Directory, the UL Fire Resistance

Directory, and the system manufacturer for proper selection and application. Two

manufacturers of Listed systems for use with CPVC pipe are Nelson Fire Stop Products

(800 -331-7325) and Tremco (800-321-7906). Contact Victaulic for further information.

Heat Sources and Open Ceiling Areas:

Victaulic FireLock CPVC Sprinkler Systems must be laid out so that the piping is not closely

exposed to heat producing sources, such as light fixtures, ballasts, and steam lines. Pipe

must not be positioned directly over open ventilation grills. During remodeling or ceiling

repair, appropriate precautions must be implemented to properly protect the piping.

Use with Other Manufacturers’ Pipes, Fittings,

and Solvent Cements:

Victaulic FireLock CPVC Sprinkler System Products are UL Listed for use in combination

with UL Listed CPVC sprinkler products manufactured by Central (pipe and fittings),

Harvel (pipe), Ipex (pipe and fittings), Tyco Fire Products (pipe and fittings), Spears

(fittings), Thompson Plastics (fittings), Viking (pipe), or Nibco (fittings).

Victaulic recommends the use of Victaulic Style #899 FireLock CPVC One-Step Solvent

Cement. However, Spears FS-5; Ipex BM-5; Tyco Fire Products TFP-500; Thompson

Plastics, Inc. TPI-50; and Central Sprinkler CSC-500 CPVC Solvent Cements can also be

used in place of Victaulic Style #899 FireLock CPVC One-Step Solvent Cement, provided

that the assembly and curing information referenced within this manual is used. Contact

Victaulic at 1-800 -PICK VIC (1-800-742-5842) for further information on Listings and

Approvals.

NOTICE

The “Victaulic FireLock CPVC Sprinkler System Products Warranty” applies only •

to products supplied by Victaulic. Refer to the “Warranty” section in this manual

for details.

Page 23

I- 800_21

FIRELOCK CPVC SPRINKLER

SYSTEM PRODUCTS REV_J

INSTALLATION & JOINING SECTION

Cutting the Pipe:

Victaulic FireLock CPVC Sprinkler System pipe can be cut easily with a ratchet cutter,

wheel-type plastic tubing cutter, a power saw, or any other fine-tooth saw. Tools used to

cut CPVC must be designed for plastic use and must be in good condition, in accordance

with the tool manufacturer’s recommendations. It is important to cut the pipe square. A

square cut provides the surface of the pipe with maximum bonding area.

If any indication of damage or cracking is evident at the pipe end, cut off at least 2

inches beyond any visible crack.

CAUTION

Care must be exercised if using ratchet cutters, since they may split the pipe if •

not used and maintained properly.

Use only ratchet cutters that contain a sharp blade (blades dull quickly)•

Use only ratchet cutters at temperatures of 50° F or warmer.•

Use only good quality ratchet cutters capable of producing consistent, square •

cuts.

Failure to follow these instructions could result in leakage and property damage.

Be careful not to split the pipe if a ratchet-type cutter is being used, especially in •

temperatures below 50°F. If any damage or cracking is evident, cut off at least 2

inches of the pipe beyond any visible crack.

It is important that the cutting tools and blades being used are designed for plastic •

pipe. To ensure that the pipe is cut square, use a miter box when cutting the pipe

with a saw. Cutting the pipe as square as possible provides the maximum bonding

surface area.

Page 24

I-800_22

FIRELOCK CPVC SPRINKLER

SYSTEM PRODUCTS REV_J

Deburring and Beveling:

Burrs and filings can prevent proper contact between the pipe and fitting during •

assembly and must be removed from the pipe inside and outside diameters. A

chamfering tool or file is suitable for deburring pipe.

A slight bevel (approximately 10° to 15°) shall be placed at the end of the pipe to •

ease entry of the pipe into the fitting socket. A bevel on the pipe end will minimize

the amount of solvent cements that is wiped from the fitting socket during insertion.

Fitting Preparation:

WARNING

Before assembling any Victaulic FireLock CPVC Sprinkler System Products, all •

components must be inspected for cuts, scratches, gouges, split ends, or any

other irregularities that have occurred during shipping and handling.

Failure to check all products for damage before installation could result in

significant property damage, joint failure, and/or joint leakage.

The pipe should enter the fitting socket easily •

⁄ to ⁄ of the way. Contact between

the pipe and fitting is essential for assembling a good joint. This contact allows the

solvent cement, which is applied in the following step, to effectively join the pipe and

fitting.

Using a clean, dry rag, wipe all loose dirt and moisture from the fitting socket and •

pipe end. Moisture can slow the cure time and, at this stage of assembly, excessive

water can reduce joint strength.

Page 25

I-800_23

FIRELOCK CPVC SPRINKLER

SYSTEM PRODUCTS REV_J

Solvent Cement Application:

WARNING

Before using Victaulic Style #899 FireLock CPVC One-Step Solvent Cement, •

refer to ASTM– F402, “Standard Practice for Safe Handling of Solvent Cements,

Primers, and Cleaners Used for Thermoplastic Pipe and Fittings;” the Material

Safety Data Sheet (MSDS) for the solvent cement; and the important product

information contained on the solvent cement can label.

Victaulic Style #899 FireLock CPVC One-Step Solvent Cement is highly •

flammable. Make sure all ignition sources are eliminated before use.

Avoid breathing solvent cement vapors, and use solvent cement only in well-•

ventilated areas. Explosion-proof, general mechanical ventilation or local exhaust

is recommended to maintain vapor concentrations below recommended exposure

limits. In confined or partially enclosed areas, a NIOSH-approved, organic-vapor

cartridge respirator with a full-face piece is recommended.

Avoid frequent contact with skin. PVA coated gloves and an impervious apron •

are recommended.

Avoid contact with eyes. Splash-proof chemical goggles are recommended.•

Failure to follow these instructions could result in serious personal injury.

CAUTION

DO NOT use solvent cement that exceeds 2 years from the date stamped on the •

container.

DO NOT use solvent cement that has a “JELLED” appearance.•

Jelled or expired cement will not provide the required strength for a proper joint

and can result in joint failure and/or property damage.

Before assembling any Victaulic FireLock CPVC Sprinkler System Products, verify •

the expiration date located on the Style #899 FireLock CPVC One-Step Solvent

Cement container. Solvent cement can be used for a period of 2 years from the date

stamped on the container. DO NOT use solvent cement that exceeds 2 years from

the date stamped on the container. Expired solvent cement must be discarded in an

environmentally friendly fashion, in accordance with local regulations.

Special care shall be exercised when assembling Victaulic FireLock CPVC Sprinkler •

System Products in temperatures below 40° F. In colder temperatures, extra time

must be allowed for the solvent cement to set. Extra care should be taken to prevent

damaging the pipe during handling. When applying cement to pipe and fittings in

colder temperatures, make sure the cement does not become “lumpy” or “gelled”.

Lumpy or gelled cement must be discarded in an environmentally-friendly fashion, in

accordance with local regulations.

At temperatures above 80° F, make sure both surfaces to be joined are still wet •

with cement during assembly. Higher temperatures and/or wind accelerate the

evaporation of the volatile solvents in the cement. Pipe stored in direct sunlight may

have surface temperatures of 20° F to 30° F above the air temperature. If possible,

store the pipe and fittings (or at minimum the ends to be solvent cemented) out of

direct sunlight prior to applying cement. The solvents will penetrate hot surfaces

more deeply and, in higher temperatures, it is very important to avoid puddling

solvent cement inside the fitting socket.

To prolong the life of solvent cement, keep containers tightly closed when not in use. •

Cover the container as much as possible during use.

Page 26

I-800_24

FIRELOCK CPVC SPRINKLER

SYSTEM PRODUCTS REV_J

If an unopened solvent cement container is subjected to freezing temperatures, •

the cement may become extremely thick. Place the closed container in a room

temperature area where, after a short time period, the cement will return to a usable

condition. DO NOT attempt to heat solvent cement. Contact Victaulic at

(800) PICK VIC or (800) 742-5842 with any questions concerning usability.

Use only solvent cements that have been formulated and listed/approved specifically •

for use with CPVC fire sprinkler systems and that have been approved by the pipe

and fitting manufacturers.

Use a dauber that is sized properly for the pipe. For •

¾-inch and 1-inch pipe sizes,

use a dauber that is

½-inch in size. For 1 ¼-inch through 2-inch pipe sizes, use a

dauber that is

¾-inch in size. Refer to the photos and steps below for the proper

application sequence.

Excess solvent cement can cause clogged waterways. DO NOT allow excess cement •

to puddle in the pipe and fitting assembly. To prevent puddling, the inside of the

fitting socket should receive a lighter coating of solvent cement than the outside of

the pipe. Excess solvent cement on the outside of the pipe should be wiped off. The

solvents will evaporate, but the cement inside the fitting will remain.

CAUTION

Improper installation techniques that result in excess solvent cement will weaken •

the wall of the CPVC pipe or fitting.

Failure to follow proper installation techniques may result in system leakage and

property damage.

Vigorously apply a heavy, even coat of cement to the outside of the pipe end. Work 1.

the cement into the joining surfaces using a continuous, circular motion.

Apply a medium coat to the fitting socket. Avoid getting cement into other sockets 2.

or threaded connections.

Page 27

I-800_25

FIRELOCK CPVC SPRINKLER

SYSTEM PRODUCTS REV_J

A second application of solvent cement shall be applied to the pipe end in the same 3.

manner as described in step 1 on the previous page. DO NOT apply a second coat of

solvent cement to the fitting socket.

WARNING

Follow all instructions contained in this manual when solvent cementing •

Victaulic FireLock CPVC Sprinkler System Products.

Too much solvent cement can cause clogged waterways or pipe failure.•

DO NOT allow excess solvent cement to puddle in the pipe and fitting assembly.•

To prevent puddling, the inside of the fitting socket should receive a lighter •

coating of solvent cement than the outside of the pipe.

Excess solvent cement on the outside of the joint should be wiped off and the •

solvents allowed to evaporate. However, the solvent cement inside the fitting will

remain.

Improper installation techniques that involve too much solvent cement will weaken

the wall at the pipe or fitting, resulting in leakage and/or significant property

damage.

Page 28

I-800_26

FIRELOCK CPVC SPRINKLER

SYSTEM PRODUCTS REV_J

Assembly:

After applying solvent cement, insert the pipe into the fitting socket immediately, •

while rotating the pipe a quarter turn until the pipe bottoms out at the fitting stop. At

this time, align the fitting properly for the installation. The pipe must bottom out at

the fitting stop. Hold the assembly for 30 seconds to ensure initial bonding. A bead

of solvent cement should be evident around the pipe and fitting juncture. If a bead

of solvent cement is not continuous around the socket shoulder, this may be an

indication that insufficient solvent cement was applied. If insufficient solvent cement

was applied, the fitting must be cut out and discarded. Cement in excess of the

bead should be wiped off with a clean, dry rag.

Care shall be exercised when installing sprinklers. Sprinkler fittings shall be allowed •

to cure a minimum of 30 minutes before attempting to install the sprinkler. When

installing sprinklers, anchor or hold the pipe drop securely to avoid rotating the pipe

in previously cemented connections. Previously cemented fittings shall be permitted

to cure a minimum of 30 minutes.

CAUTION

Sprinklers shall be installed only after all CPVC pipe and fittings, including the •

sprinkler adapters, are solvent cemented and allowed to cure a minimum of 30

minutes.

Sprinkler fittings should be visually inspected to ensure that the waterway and •

threads are clear of any excess solvent cement.

When the installation is complete and cured (per Tables 1, 2, or 3 in the “Set •

and Cure Times” section in this manual), the system shall go through system

acceptance testing (hydrostatic pressure testing).

Sprinklers shall not be installed in the fitting prior to the fittings being solvent •

cemented in place.

Failure to follow these instructions could cause system failure, resulting in property

damage.

Set and Cure Times:

Solvent cement set and cure times are a function of pipe size, temperature, relative

humidity, and tightness of fit. Curing time is faster for drier environments, smaller pipe

sizes, higher temperatures, and tighter fits. Curing times should be increased when

moisture is present, such as during cut-ins to active sprinkler lines. NOTE: A specific

procedure for modifications or repairs to existing CPVC fire sprinkler lines is included in

the “Cut-In Procedures for System Modification or Repair” section in this manual. The

assembly must be allowed to set without any stress on the joint for 5 minutes, depending

on pipe size and temperature. Following the initial set period, the assembly can be

handled carefully, avoiding significant stresses to the joint. Refer to the tables on the

following page for the minimum cure times prior to pressure testing. In addition, refer to

the “Solvent Cement Application” section in this manual.

Page 29

I-800_27

FIRELOCK CPVC SPRINKLER

SYSTEM PRODUCTS REV_J

Minimum Cure Times for Victaulic

Style #899 FireLock CPVC One-Step Solvent Cement Prior to

Pressure Testing

Table 1 – 225-psi (Maximum) Test Pressure

Size Ambient Temperature During Cure

Nominal Diameter

inches/mm

Actual Outside

Diameter

inches/mm 60°F to 120°F 40°F to 59°F 0°F to 39°F

¾ 1.050

1 hour 4 hours 48 hours

20 26.9

1 1.315

1 ½ hours 4 hours 48 hours

25 33.7

1 ¼ & 1 ½ 1.660 & 1.900

3 hours 32 hours 10 days

32 & 40 42.4 & 48.3

2 2.375

8 hours 48 hours Note 1

50 60.3

Table 2 – 200-psi (Maximum) Test Pressure

Size Ambient Temperature During Cure

Nominal Diameter

inches/mm

Actual Outside

Diameter

inches/mm 60°F to 120°F 40°F to 59°F 0°F to 39°F

¾ 1.050

45 minutes 1 ½ hours 24 hours

20 26.9

1 1.315

45 minutes 1 ½ hours 24 hours

25 33.7

1 ¼ & 1 ½ 1.660 & 1.900

1 ½ hours 16 hours 120 hours

32 & 40 42.4 & 48.3

2 2.375

6 hours 36 hours Note 1

50 60.3

Note 1: Solvent cement can be applied at temperatures below 40°F for all sizes. For the 2-inch size, the

temperature must be raised to 4 0°F or above and allowed to cure per the recommended times before

the system is filled and pressurized.

Table 3 – 100-psi (Maximum) Test Pressure

Size ‡ Ambient Temperature During Cure

Nominal Diameter

inches/mm

Actual Outside

Diameter

inches/mm 60°F to 120°F 40°F to 59°F 0°F to 39°F

¾ 1.050

15 minutes 15 minutes 30 minutes

20 26.9

1 1.315

15 minutes 30 minutes 30 minutes

25 33.7

1 ¼ 1.660

15 minutes 30 minutes 2 hours

32 42.4

‡ 1 ½-inch and larger sizes must be tested ONLY in accordance with Table 1 and Table 2.

Page 30

I-800_28

FIRELOCK CPVC SPRINKLER

SYSTEM PRODUCTS REV_J

WARNING

Make sure the cement is allowed to cure according to the times listed in the •

charts for the pipe size and ambient temperature. These cure times have been

tested and approved for Victaulic FireLock CPVC Sprinkler System Products.

DO NOT install any sprinklers until the piping system has cured for a minimum •

of 30 minutes.

Solvent cement set and cure times are a function of pipe size, temperature, •

relative humidity, and tightness of fit.

Curing time is faster for drier environments, smaller pipe sizes, higher •

temperatures, and tighter fits.

Cure times should be increased when moisture is present, such as during cut-ins •

to active sprinkler lines.

Failure to follow these instructions could cause improper system operation or

leakage, resulting in property damage.

The following guidelines provide an estimate of the quantities of Victaulic Style #899

FireLock CPVC One-Step Solvent Cement that will be required to complete the assembly.

Solvent Cement Requirements

Size Solvent Cement

Nominal Diameter

inches/mm

Actual Outside Diameter

inches/mm

Number of Joints

Per Quart (estimated)

¾ 1.050

270

20 26.9

1 1.315

180

25 33.7

1 ¼ & 1 ½ 1.660 & 1.900

130

32 & 40 42.4 & 48.3

2 2.375

100

50 60.3

WARNING

Make sure all assembly and curing times, outlined in this manual, are followed •

when installing Victaulic FireLock CPVC Sprinkler System Products.

Failure to follow this instruction could cause improper joint assembly and joint

failure, resulting in significant property damage and/or serious personal injury.

Threaded Connections:

Threaded connections require application of a thread sealant that has been tested

and approved for use with CPVC material. Victaulic recommends the use of Spears

Manufacturing Blue 75 Thread Sealant or IPS Weld-On Teal Seal. These products

have been tested specifically for compatibility with Victaulic FireLock CPVC Sprinkler

System Products. However, it is important to contact the sprinkler manufacturer to verify

chemical compatibility with their products.

In addition, cutting oils used while threading metal pipe can cause stress cracks in CPVC

material. Before making threaded connections, threaded metal pipe must be flushed and

degreased to remove cutting oil.

Victaulic strongly recommends the pastes listed above; however, tape can be used,

provided the following requirements are followed. NOTE: Tape sealant must be used

properly to prevent “wedging” of tapered pipe threads, which can cause joint failure due

Page 31

I-800_29

FIRELOCK CPVC SPRINKLER

SYSTEM PRODUCTS REV_J

to excessive stress on the fitting. DO NOT USE A COMBINATION OF PASTE AND TAPE

ON THREADED CONNECTIONS.

The thickness of the tape • MUST be a minimum of 25 mil. Tape less than 25-mil

thick will not provide sufficient sealing.

The initial wrap of tape • MUST fully cover the end of the threads. Failure to fully

cover the end of the threads can cause seizing of the threads, which produces a

false sense of tightening the joint properly. Additional attempts to tighten a joint with

seized threads can cause damage to the pipe and fittings.

Tape • MUST be wrapped CLOCKWISE for standard pipe threads. Tape that is

wrapped in the wrong direction will bunch and create uneven sealing.

DO NOT EXCEED 2 – 3 OVERLAPPING WRAPS OF TAPE.• Excess tape increases

the male thread diameter and causes stress to the joint.

Apply sealant to the male threads only. Make sure all threads are covered. DO NOT

1.

clog the waterway with excessive sealant.

Thread the sprinkler into the fitting by hand until finger-tight.

2.

To tighten the sprinkler completely into the fitting, use an adjustable wrench on 3.

the flats of the sprinkler adapter and a sprinkler wrench designed specifically for the

sprinkler. When a pipe wrench is used, Victaulic recommends the use of a smooth-jawed

wrench or a strap wrench when installing threaded connections. DO NOT use tools with

teeth or conventional pipe wrenches on any part of a fitting for CPVC pipe.

DO NOT over-torque threaded connections. Generally, one to two turns beyond

4.

finger-tight are required to make a threaded connection. Factory testing indicates

10 ft-lbs minimum to 25 ft-lbs maximum of torque for obtaining a proper seal.

Sprinklers must be installed only after all fittings, including sprinkler adapters, are

5.

cemented to the piping and have been allowed to cure for a minimum of 30 minutes.

Plastic threaded plugs are available for use during pressure testing. Before sprinklers are

installed, all fittings must be visually inspected or probed with a wooden dowel to ensure

the waterway and threaded areas do not contain excessive cement that may restrict

water flow.

CAUTION

Use only thread sealants recommended by Victaulic. Use of any other thread •

sealants may cause stress cracks in fittings for CPVC pipe. Contact Victaulic

with any questions concerning compatibility of thread sealants with Victaulic

FireLock CPVC Sprinkler System Products.

DO NOT use a combination of paste and tape on threaded connections.•

DO NOT over-torque threaded connections.•

DO NOT use tools with teeth on any part of a CPVC fitting. Tools with teeth can •

damage and weaken CPVC material.

Failure to follow these instructions could cause product damage and joint leakage,

resulting in property damage.

Page 32

I-800_30

FIRELOCK CPVC SPRINKLER

SYSTEM PRODUCTS REV_J

Transition to Other Materials:

Specifically designed female threaded adapters, grooved coupling adapters, and flanges

are UL Listed for connecting a Victaulic FireLock CPVC Sprinkler System to other

materials, valves, and accessories. A special, reinforced female threaded adapter is

available for connection to the sprinkler.

Flange Connections:

When using Victaulic supplied Spears® CPVC flange adapters, follow the instructions

below. Piping runs joined to the flanges must be installed in a straight line in relation

to the flange to avoid stress at the flange due to misalignment. In addition, piping must

be secured and supported to prevent lateral movement, which can create stress and

damage the flange.

FLANGE MAKEUP: Once a flange is joined to the pipe, the method for joining two

flanges is as follows:

A. With the gasket in place, align the bolt holes of the mating flanges by rotating the

ring into position.

NOTICE

Consideration should be given to aligning the one-piece flange before joining it •

with the pipe.

B. Insert all bolts, flat washers (place one washer under the bolt head and one under

the nut), and nuts. NOTE: Victaulic does not supply bolts, nuts, washers, and gaskets.

C. Make sure the faces of the mating surfaces are flush against the gasket before

bolting down the flanges.

D. Tighten the nuts by hand until they are snug. Establish uniform pressure over the

flange face by tightening the nuts in 5 ft-lb increments, according to the sequence shown

below in Figure 1.

1

2

3

4

Figure 1

E. Care must be taken to avoid bending the flange when joining a standard flange to a

“raised face” flange or a wafer-style valve.

CAUTION

DO NOT use the bolts to bring together improperly mated flanges.•

DO NOT over-torque the flange. Too much torque will damage the flange.•

Make sure the proper lubricant is used on the bolts, and insert one flat washer •

under the bolt head and one under the nut.

Failure to follow this instruction could result in property damage, product damage,

joint leakage, and/or joint failure.

Page 33

I- 800_31

FIRELOCK CPVC SPRINKLER

SYSTEM PRODUCTS REV_J

The following recommendations are based on the use of two standard flat washers,

standard nuts, and an

⁄-inch thick EPDM full-face gasket. Actual field conditions may

require a variation in these recommendations.

Size Recommended Torque

Nominal Diameter

inches/mm

Actual Outside Diameter

inches/mm ft-lbs

¾ – 1 ½ 1.050 – 1.900

12

20 – 40 26.9 – 48.3

2 2.375

25

50 60.3

Size Bolt Diameter

Minimum Bolt

Length

Nominal Diameter

inches/mm

Actual Outside

Diameter

inches/mm Bolt Holes inches inches

¾ 1.050

4 ½ 2

20 26.9

1 1.315

4 ½ 2 ¼

25 33.7

1 ¼ 1.660

4 ½ 2 ¼

32 42.4

1 ½ 1.900

4 ½ 2 ½

40 48.3

2 2.375

4 ⁄ 3

50 60.3

Page 34

I-800_32

FIRELOCK CPVC SPRINKLER

SYSTEM PRODUCTS REV_J

Grooved Connections:

WARNING

Read the following instructions carefully before installation occurs. The following •

instructions are required for proper assembly of Victaulic FireLock CPVC

No. 832 Grooved Adapters to grooved Iron Pipe Size (IPS) pipe and valves.

DO NOT use Victaulic Style 005 and Style 07 Rigid Couplings with Victaulic •

FireLock CPVC No. 832 CPVC Grooved Adapters. These style couplings may

damage the grooved adapter. Contact Victaulic with any questions concerning

proper coupling selection.

DO NOT attempt to direct groove Victaulic FireLock CPVC Sprinkler System •

Pipe.

Failure to follow these instructions could cause improper product installation,

resulting in serious personal injury and/or property damage.

Victaulic FireLock CPVC No. 832 Grooved Adapters are designed for use with Victaulic

Style 75 and Style 77 Flexible Couplings. DO NOT ATTEMPT TO DIRECT GROOVE

CPVC PIPE. THE VICTAULIC FIRELOCK CPVC NO. 832 GROOVED ADAPTER MUST

BE USED WHEN MAKING A TRANSITION FROM VICTAULIC FIRELOCK CPVC

SPRINKLER SYSTEM PIPE TO GROOVED IPS PIPE. DO NOT USE VICTAULIC STYLE

005 AND STYLE 07 RIGID COUPLINGS WITH VICTAULIC FIRELOCK CPVC NO. 832