Page 1

I-871INSTALLATION INSTRUCTIONS

Victaulic® Series 871 Gate Valve

I-871_1

REV_ A

WARNING

• Read and understand all instructions before attempting to install, remove, adjust, or maintain any Victaulic piping products.

• Depressurize and drain the piping system before attempting to install, remove, adjust, or maintain any Victaulic piping products.

• Wear safety glasses, hardhat, and foot protection.

• The Series 871 Gate Valve is suitable for use in saturated steam service. Use extreme caution when working around steam systems.

• DO NOT impact the valve, pipe, couplings, or fittings when the system is pressurized.

• The valve shall be installed ONLY with Style 870 Rigid Couplings and pipe or fittings that are prepared to Victaulic OGS-200

Specifications. DO NOT install the valve with any other coupling or with pipe/fittings that are prepared to any other groove specification.

Failure to follow these instructions may cause joint failure, resulting in death or serious personal injury and property damage.

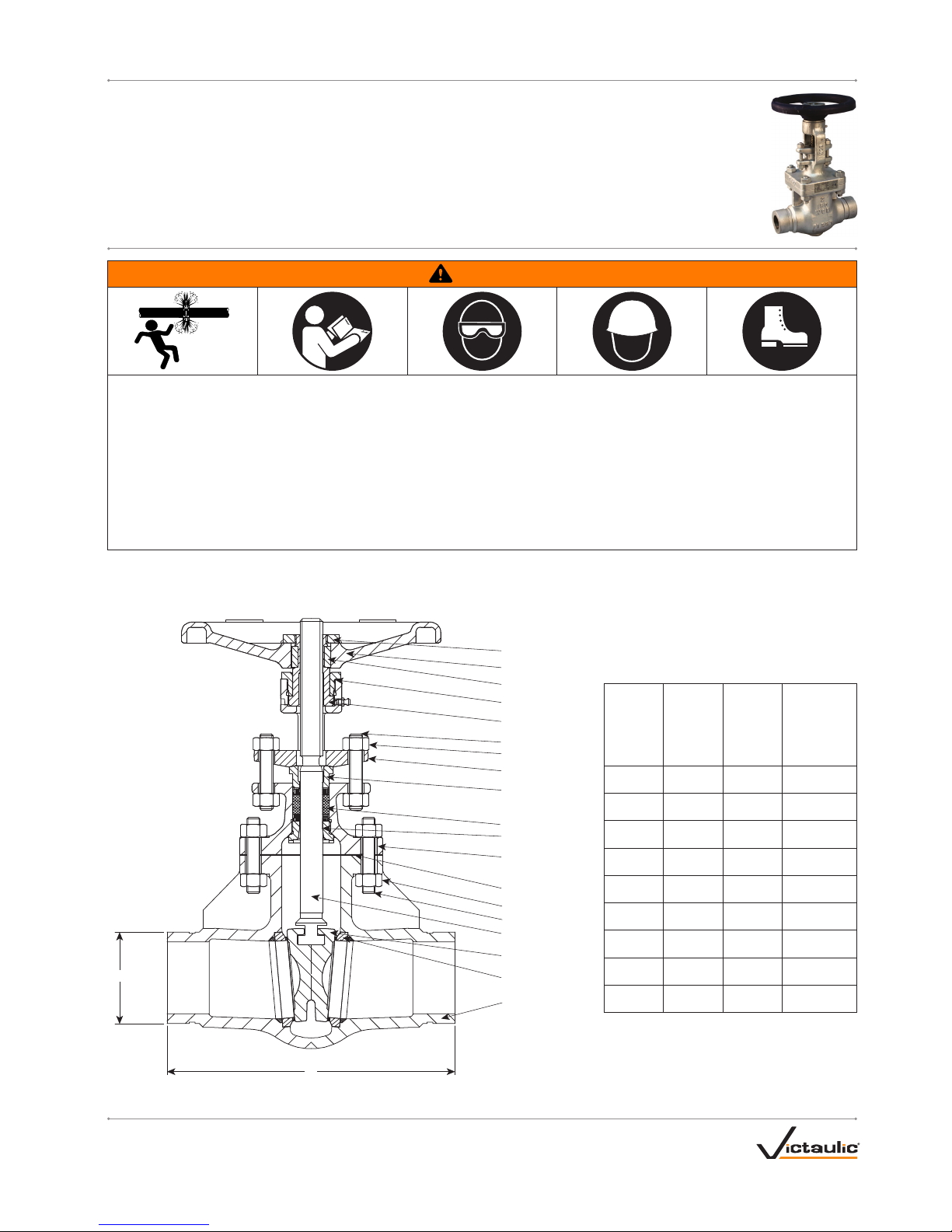

SECTION VIEW DRAWING, DIMENSIONS, AND WEIGHTS

Handwheel Nut

Handwheel

Key

Threaded Bushing

Stem Nut

Bolt

Nut

Gland Flange

Gland

Gland Packing

Back Seat Bushing

Bonnet

Nut

Bolt

Gasket

Stem

Flexible Wedge

Seat Ring

Valve Body

A

“OD”

Nominal

Size

inches

DN

Actual

Outside

Diameter

"OD"

inches

mm

"A"

inches

mm

Approximate

Weight Each

lbs

kg

2 2.375 8.54 31

DN50 60.3 217 14

2 ½

2.875 9.50 46

73.0 241 21

DN65

3.000 11.1 4 53

76.1 283 24

3 3.500 11.1 4 53

DN80 88 .9 283 24

4 4.500 12.01 77

DN10 0 114 .3 305 35

DN125

5.500 15.0 0 121

139. 7 381 55

6.500 15.8 7 14 8

165 .1 403 67

6 6.625 15.8 7 14 8

DN150 168 .3 403 67

8 8.625 16. 50 265

DN200 219.1 419 12 0

Page 2

I-871INSTALLATION INSTRUCTIONS

Victaulic® Series 871 Gate Valve

For complete contact information, visit victaulic.com

I-871 10176 REV A UPDATED 02/2017 Z000871000

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY AND/OR ITS AFFILIATED ENTITIES IN THE

UNITED STATES AND/OR OTHER COUNTRIES. © 2017 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

IMPORTANT INFORMATION

• The Series 871 is a flexible-wedge, metal-seated valve that is

designed for bidirectional shutoff service and is suitable for use in

saturated steam services. THIS VALVE IS NOT DESIGNED FOR

THROTTLING SERVICES.

• For complete valve ratings and applications, refer to Victaulic

publication 100.12, which can be downloaded at victaulic.com.

DO NOT exceed the performance capabilities listed in Victaulic

publication 100.12.

• Verify that there is adequate clearance around the valve for

operating and maintenance activities.

• The valve can be mounted in vertical and horizontal runs. For

horizontal pipe, the valve shall be installed with the stem in the

vertical "UP" position (handwheel pointing upward).

• Verify that proper pipe supports are in place to prevent strain on

the valve. The piping shall be laid out so that no thrust or bending

forces act on the valve body during operation.

• Verify that the piping is aligned and supported properly before

attempting to install the valve.

• The valve is supplied from the factory with a high-temperature

paint that may feel sticky to the initial touch. The paint is designed

to harden when exposed to higher temperatures.

• When painting a piping system, DO NOT apply paint to the stem

and bolts/nuts.

• Use lockout methods to prevent unauthorized operation of the

valve.

• DO NOT stand on or use the handwheel as a suppor t point.

• DO NOT over-torque the handwheel to force the valve into the

"CLOSED" position. Refer to the "Torque Limitations" table on this

page.

Handling

• The valve shall remain in the "CLOSED" position during handling.

• To prevent damage to the seats and sealing surfaces of the valve

body, the plastic shipping caps shall remain in place until the time

of installation.

• Refer to the weights listed on the opposite side of this page.

Verify that proper lifting equipment is available for handling larger,

heavier valve sizes. Lift the valve by placing straps around the

body. DO NOT lift or suspend the valve by the handwheel.

Storage

• Victaulic strongly recommends indoor storage of the valve. If

outdoor storage is required, the valve shall be stored in the

original shipping container and then covered completely with a

weatherproof tarp.

• The shipping caps shall remain in place to prevent debris from

entering the valve body during storage.

• The valve shall remain in the "CLOSED" position during storage.

• The valve shall be stored with the stem in the vertical "UP" position

(handwheel pointing upward).

INSTALLATION

WARNING

• The Series 871 Gate Valve shall be installed ONLY with Style

870 Rigid Couplings and pipe or fittings that are prepared to

Victaulic OGS-200 Specifications.

• DO NOT install the valve with any other coupling or with pipe/

fittings that are prepared to any other groove specification.

Failure to follow these instructions may cause joint failure,

resulting in death or serious personal injury and property damage.

1. Prior to installation, check the valve for any damage. DO NOT use

the valve if any damage is present.

2. Remove the plastic shipping caps from the valve body. To prevent

damage to the sealing surfaces of the valve body, DO NOT use any

sharp instruments to remove the shipping caps.

3. Verify that the valve is in the "CLOSED" position.

4. Install the valve by using two Victaulic Style 870 Rigid Couplings

and pipe or fittings that are prepared to Victaulic OGS-200

Specifications. Refer to the I- 870 installation instructions for

complete installation requirements. The I-870 is shipped with the

coupling and can be downloaded at victaulic.com.

5. Place the system into service af ter all installation requirements

have been met.

OPERATION

1. Operate the valve by turning the handwheel in the counter-

clockwise direction (top view) to the "OPEN" position, then by

turning the handwheel in the clockwise direction (top view) to the

"CLOSED" position. Repeat this process several times to verify

proper operation. NOTE: When the valve is in the fully "OPEN"

position, turn the handwheel a quarter turn in the clockwise

direction to prevent the stem/threads from locking up due to

thermal expansion.

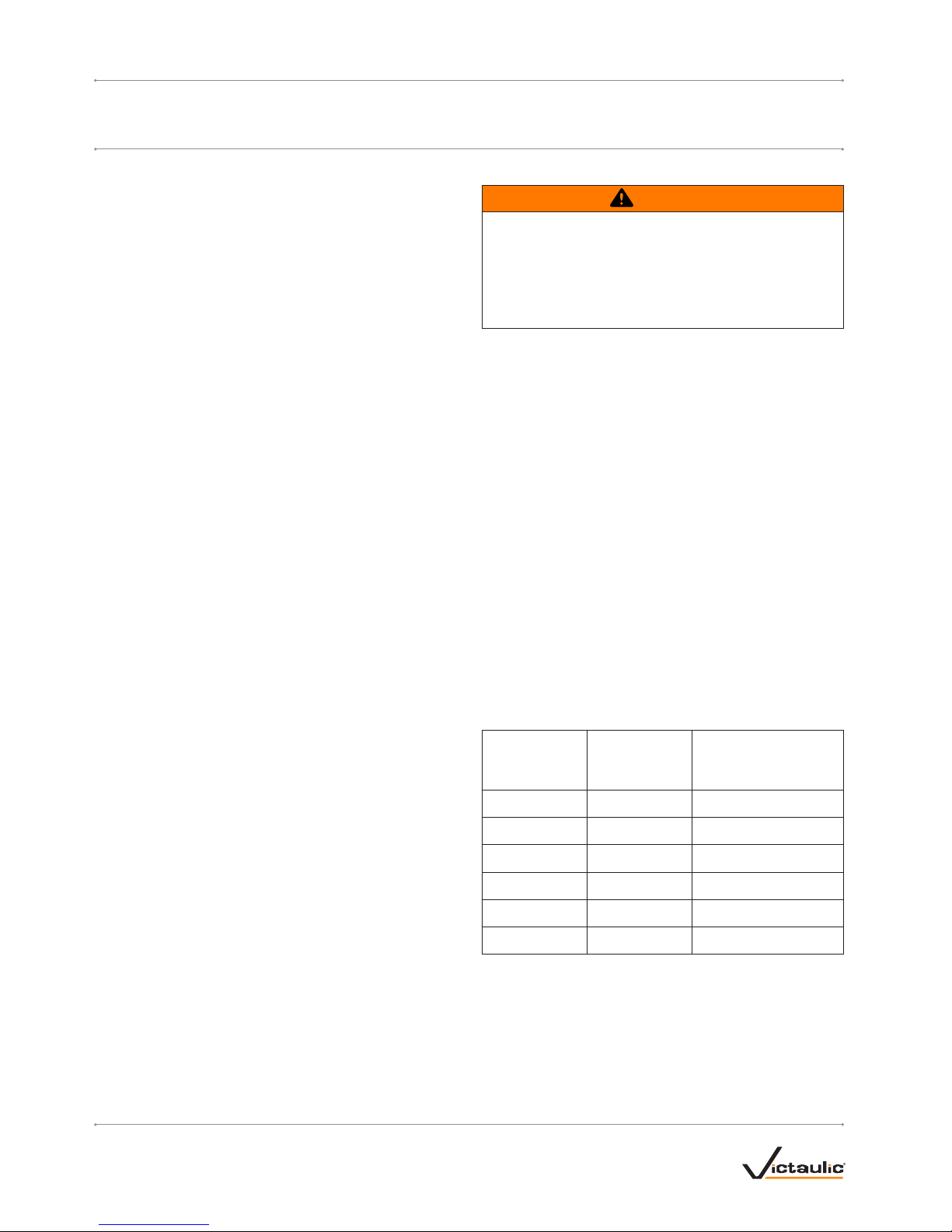

Torque Limitations

Nominal

Size

inches/DN

Actual Outside

Diameter

inches/mm

Maximum Torque to Reach

Fully "OPEN" Position or

Fully "CLOSED" Position

ft-lbs/N•m

2 2.375 24

DN50 60.3 32

2 ½, DN65, 3/DN80

2.875, 3.000, 3.500 38

73.0, 76.1, 88.9 52

4 4. 500 65

DN10 0 114. 3 88

DN125

5.500 106

139. 7 144

6 6.500 & 6.625 106

DN150 165.1 & 168 . 3 14 4

8 8.625 180

DN200 219.1 244

INSPECTION

Inspect the valve on a frequency required by the building owner or their

representative.

1. Verify that there is no leakage from the gland. If necessary, tighten

the nuts at the gland flange evenly by alternating sides.

2. If the handwheel becomes loose, open the valve by turning the

handwheel one to two turns in the counterclockwise direction, then

tighten the handwheel nut.

Loading...

Loading...