Page 1

HANG THESE INSTRUCTIONS ON THE

INSTALLED VALVE FOR FUTURE REFERENCE

WARNING

• Read and understand all instructions before attempting to install, remove, adjust, or perform maintenance on any Victaulic piping products.

• Depressurize and drain piping systems before attempting to install, remove, adjust, or perform maintenance on any Victaulic piping

products.

• Wear safety glasses, hardhat, and foot protection.

• Save this installation, operation, and maintenance manual for future reference.

Failure to follow instructions and warnings could cause system failure, resulting in death or serious personal injury and property damage.

I-867-42TINSTALLATION, OPERATION, AND MAINTENANCE MANUAL

867-42T Pressure Reducing Valve

I- 867- 42T

REV_B

Page 2

Page 3

I-867-42T / Pressure Reducing Valve / Installation, Operation, and Maintenance Manual

TABLE OF CONTENTS

Hazard Identification ..................................4

Safety Instructions ................................... 4

Introduction ........................................4

Pressure and Flow Ratings ..............................5

Head Loss .........................................5

Installation .........................................6

Operation ..........................................7

Start Up..............................................8

Readjusting ...........................................8

Maintenance And Inspection Tests ........................9

Weekly Inspection ......................................9

Monthly Inspection And Test ..............................9

Troubleshooting......................................9

Difficulty In Performance ..............................9

I- 867- 42T_ 3

REV_B

Page 4

I-867-42T / Pressure Reducing Valve / Installation, Operation, and Maintenance Manual

HAZARD IDENTIFICATION

Definitions for identifying the various hazard levels are provided below.

This safety alert symbol indicates important safety messages.

When you see this symbol, be alert to the possibility of

personal injury. Carefully read and fully understand the

message that follows.

DANGER

• The use of the word “DANGER” identifies an immediate

hazard with a likelihood of death or serious personal injury

if instructions, including recommended precautions, are not

followed.

WARNING

• The use of the word “WARNING” identifies the presence

of hazards or unsafe practices that could result in death or

serious personal injury if instructions, including recommended

precautions, are not followed.

CAUTION

• The use of the word “CAUTION” identifies possible hazards or

unsafe practices that could result in personal injury and product

or property damage if instructions, including recommended

precautions, are not followed.

NOTICE

• The use of the word “NOTICE” identifies special instructions that

are important but not related to hazards.

SAFETY INSTRUCTIONS

WARNING

• An experienced, trained installer

must install this product in

accordance with all instructions.

These i nstructions contain important

information.

• Depressurize and drain the piping

system before attempting to install,

remove, adjust, or maintain any

Victaulic piping products.

Failure to follow these instructions

can cause product failure, resulting in

death or serious personal injury and

property damage.

1. Read and understand all instructions before proceeding with the

installation, operation, and maintenance of this valve. For proper

operation and approval, the 867-42T valve and accessories

must be installed in accordance with the specific instructions included

with the shipment.

2. Use only recommended accessories. Accessories and equipment

that are not approved for use with this valve may cause improper system

operation.

3. Wear safety glasses, hardhat, foot protection, and hearing

protection. Wear hearing protection if you are exposed to long periods of

noisy jobsite operations.

4. Prevent back injury. Large and pre-trimmed valves are heavy

and require more than one person (or mechanical lifting equipment)

to position and install the assembly. Always practice proper lifting

techniques.

5. Avoid using electrically powered tools in dangerous environments.

When using electrically powered tools for installation, ensure that the

area is moisture-free. Keep the work area well lit, and allow enough

space to accommodate proper installation of the valve, trim, and

accessories.

6. Watch for pinch points. Do not place fingers under the valve body

where they could be pinched by the weight of the valve. Use caution

around spring-loaded components.

7. Keep work areas clean. Cluttered areas, benches, and slippery floors

can create hazardous working conditions.

INTRODUCTION

NOTICE

• Drawings and/or pictures in this manual may be exaggerated for

cla rity.

• The valve, along with this operating and maintenance manual,

contains trademarks, copyrights, and/or patented features that

are the exclusive property of Victaulic.

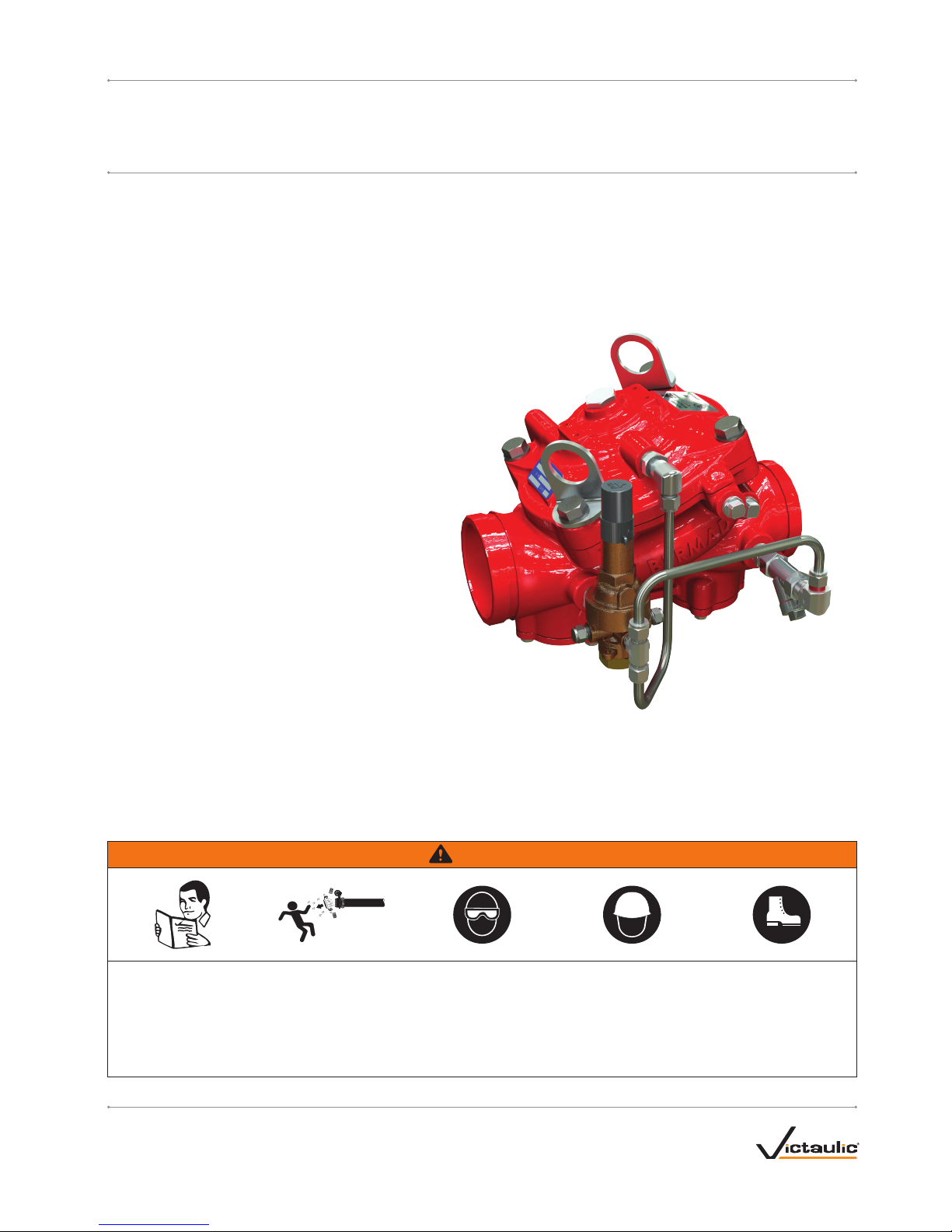

The 867-42T is an elastomeric, line-pressure driven, pilot-operated

pressure control valve that is designed for fire protection systems.

The 867-42T reduces high upstream pressure to a precise, preset,

stable downstream pressure. The 867-42T is suitable for control of

fire pump discharge. It is also suitable for preventing over-pressure in

sprinklers, hose stations, and other discharge devices.

Valve sizes covered by this manual include 1.5 through 10 inches. Max

recommended pressure differential: 175 psi (12 bar) when normal inlet

operation pressure is below 330 psi/23 bar. Max recommended pressure

differential: 200 psi (14 bar) when normal inlet operation pressure is

above 330 psi/23 bar.

I- 867- 42T_ 4

REV_B

Page 5

I-867-42T / Pressure Reducing Valve / Installation, Operation, and Maintenance Manual

PRESSURE AND FLOW RATINGS

The 867-42T pressure reducing valve, sizes 1.5-, 2-, 2.5-, 3-, 4-, 6-, 8-, and 10-inch, are rated for the following pressure and flow capacities detailed

in Table 1.

NOTE: Maximum flows below are at a differential of 175 psi (12 bar). Contact Victaulic if your system has greater than 175 psi differential.

Table 1: Pressure Ratings and Flow Capacity

Valve Size

inches/mm

1.5

40

2

50

3

80

4

100

6

150

8

200

10

250

Max. inlet pressure

psi/bar

365 25365

25

365 25365

25

365

25

365 25365

25

Outlet pressure

setting range

psi/bar

30–175

2–12

30–175

2–12

30–175

2–12

30–175

2–12

30–175

2–12

30–175

2–12

30–175

2–12

Max. recommended flow

GPM / m³/h

106 24172

39

360 82640

145

1450

330

2570

580

4000

910

Min. recommended flow

GPM / m³/h

20

5

20

5

20

5

20

5

20

5

20

5

45

10

Pilot valve model

2-PB 2-PB 2-PB 2-PB 2-PB

2-UL/

2-PBL

2-UL/

2-PBL

Recommended relief valve

in/mm

¾

20

¾

20

1 ½

40

2

50

3

80

3

80

4

100

HEAD LOSS

The minimum ∆P across the valve is 5.8 psi (0.4 bar). In cases where the inlet pressure falls below or is equal to the intended outlet pressure, the

outlet pressure shall be determined according to Table 2: Frictional Resistance.

In the case of zero (static) flow through the valve, the maximum increase in the downstream (outlet) pressure above the set pressure of the valve will

not exceed 7.2 psi (0.5 bar).

Table 2: Frictional Resistance

Valve Size Full Open Equivalent Length of Pipe

Nominal Size

inches/DN

Actual Ouside Diameter

inches/mm

Flow Coefficient

C v / K

v

feet/meters

1 ½

DN40

1.900

48.3

79

68

7

2

2

DN50

2.375

60.3

92

80

16

5

2 ½

2.875

73.0

116

100

28

9

3

DN80

3.500

88.9

219

190

23

7

4

DN100

4.500

114.3

398

345

30

9

6

DN150

6.625

168.3

912

790

49

15

8

DN200

8.625

219.1

1160

1160

89

27

10

DN250

10.750

273.0

1662

1355

203

62

Note 1: Valve Equivalent L ength Value (Steel P ipe), for use in hydraulically c alculated syste m

I- 867- 42T_ 5

REV_B

Page 6

I-867-42T / Pressure Reducing Valve / Installation, Operation, and Maintenance Manual

INSTALLATION

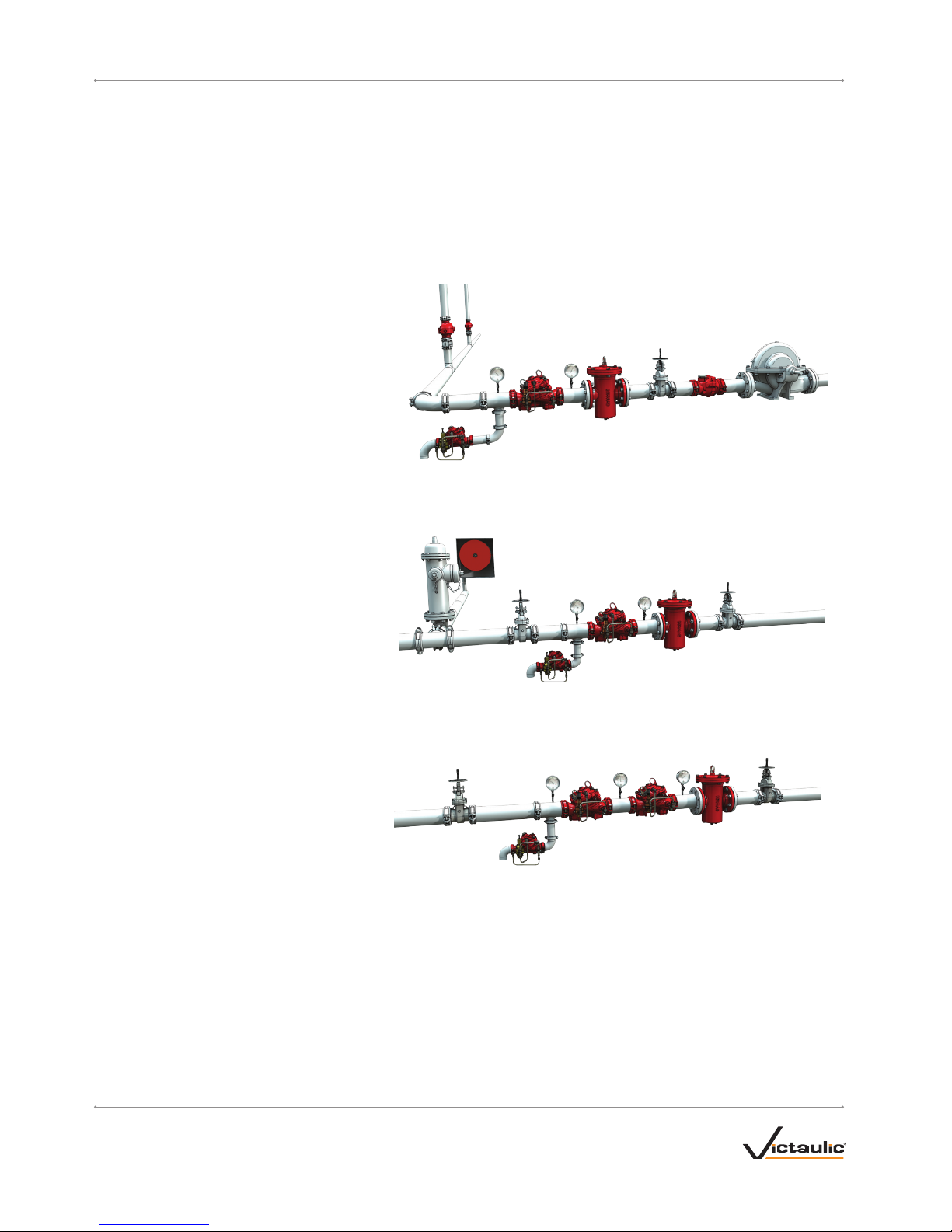

A typical installation of the 8 67-42T features a pilot valve for the automatic reduction of water pressure from a high upstream value to a preset lower

downstream value, regardless of fluctuating upstream pressure or flow. The actuator design ensures quick and smooth valve action.

Installed singly, the 867-42T provides a standard pressure-reducing system. Installed in parallel, two 867-42T valves provide high flow rates,

redundancy, and zero downtime for maintenance. Installed in series, two 867-42T valves provide a two-stage, high reduction in pressure and/or

added protection to a reduced-pressure zone.

Sprinkler System Pressure Reduction

• Reduces a high, unstable pressure supply

to a preset, stable system pressure.

• Sets the sprinkler pressure to suit the system design

• For pressure control of zones

Hose System Pressure Reduction

• Reduces a high/unstable pressure supply

to suit fire hose pressure

• Limits fire hose pressure to 100 psi/7 bar

to meet NFPA 14 regulations for maximum

allowable hose pressure supply.

Two-Stage Pressure Reduction

• High pressure reduction to a low, preset,

stable system pressure (when required pressure

reduction differential is more than 175 psi/12 bar)

• Backup pressure reducing valve in-line to a

master valve to secure pressure zone rating

at all times.

Figure 1 Installation Drawing

I-867-42T_6

REV_B

Page 7

I-867-42T / Pressure Reducing Valve / Installation, Operation, and Maintenance Manual

OPERATION

The 867-42T pressure control valve reduces water pressure

automatically from a high inlet pressure to a lower, pre-set outlet

pressure. The outlet set pressure can be adjusted with the pilot

valve adjusting screw (Figure 2, call out 5). The valve operates

under both flow and static conditions. The pressure-reducing pilot

valve (Figure 2, call out 4) senses changes in outlet pressure

(Figure 2, call out 6) and modulates the control valve to maintain

the pre-set outlet pressure.

When outlet pressure rises above the pre-set pressure, the pilot valve

throttles, enabling pressure to accumulate in the control chamber

(Figure 2, call out 1). This causes the control valve to close further and

reduce outlet pressure. When outlet pressure falls, the pilot valve opens

wider, releasing pressure from the control chamber. This causes the

control valve to open wider and increase outlet pressure. An integral

restrictor (Figure 2, call out 3A) controls the valve’s closing speed.

For valves 8 inches and larger, an adjustable needle valve (Figure 2,

call out 3B) is provided.

Figure 2 Operation Drawing

Valve Closed Valve Open (pressure relief)

4

5

6

2

3

A

1

Valve Closed Valve Open (pressure relief)

2

3B

6

4

5

1

Valves 6 inches

and smaller

Valves 8 inches

and larger

I- 867- 42T_ 7

REV_B

Page 8

I-867-42T / Pressure Reducing Valve / Installation, Operation, and Maintenance Manual

START UP

When performing this procedure, refer to Figure 2.

1. Open a hydrant, relief valve, drain valve, or other flow-consumer

downstream of the 867-42T pressure reducing valve, creating a

system demand.

2. Fully open upstream indicating valve.

3. Gradually open downstream indicating valve to fully open, allowing

flow through the 867-42T valve.

4. Wait for downstream pressure stability.

5. Slowly close the flow-consumer that was opened in step #1 above

to fully closed.

6. There should be no system flow; the downstream pressure should

be between the factory the pre-set pressure and up to 10%

different. Follow the readjusting procedure if needed to be changed.

READJUSTING

The pilot valve is factory pre-set according to the stated demands of the

customer.

The pre-set is clearly indicated on the pilot valve tag. If readjustment to

either the pressure or valve response is required, perform the following

steps.

1. When readjusting the outlet pressure, the inlet pressure should be

at least 20 psi (1.4 bar) higher than the set outlet pressure.

2. The flow rate during adjustment should be as close as possible to

the systems design flow rate. Where this is not possible, at least a

minimal flow is essential.

3. Free the tension between the adjusting screw on the pressure

reducing pilot valve (Figure 2, call out 4) and the fastening nut by

turning the fastening nut counterclockwise.

4. By alternately turning the adjusting screw on the pilot valve a

half turn and then reading the downstream pressure, gradually

adjust the pressure counterclockwise to decrease the downstream

pressure, or clockwise to increase the downstream pressure.

5. Repeat the start up procedure in the previous section.

CAUTION: If needle valve is furnished (optional), changes in

the adjustment of the needle valve will have impact on the valve

performance. The needle valve is factory set at one-half turn open to one

and one-half turn open. The maximum number of turns is 3 from fully

closed to fully open. More than 3 turns open might cause the valve to

perform at less than optimal functioning. Perform Start Up step 5 with

this in mind.

I-867-42T_8

REV_B

Page 9

I-867-42T / Pressure Reducing Valve / Installation, Operation, and Maintenance Manual

MAINTENANCE AND INSPECTION TESTS

NOTICE

• Any activities that require taking the valve out of service may

eliminate the fire protection provided.

• Consideration of a fire patrol should be given for the affected

areas.

• Before servicing or testing the system, notify the authority having

jurisdiction.

Prior to turning off any valves or activating any alarms, notify local

security guards and the central alarm station, if used, so that a false

alarm will not be signaled.

In any of the following inspections or testing procedures, if an abnormal

condition exists, see the troubleshooting section for possible cause and

corrective action.

The 867-42T valve is to be inspected, tested, and maintained in

accordance with this manual and with NFPA 25.

WEEKLY INSPECTION

1. The system should be inspected under flow conditions.

2. Check that the main valve, pilot system, accessories, tubing, and

fittings are all in good condition, are free of damage, and are not

leaking.

3. The fastening nut of the pilot valve adjusting screw (Figure 2, call

out 5) should be fastened tightly.

4. For circulation-type installations, verify that sufficient water is

flowing through the valve when the fire pump is operating at

shut-off pressure (churn) to prevent the pump from overheating.

5. Verify that the pressure upstream of the relief valve fittings in the

fire pump discharge piping does not exceed the pressure for which

the system components are rated.

MONTHLY INSPECTION AND TEST

1. Complete weekly inspection.

2. During the monthly fire pump flow test, verify that the pressure

relief valve is correctly set to relieve at the appropriate pressure and

to close below the pressure setting.

TROUBLESHOOTING

Problem Possible Cause Solution

Valve fails to regulate. Needle valve not properly adjusted. Factory set at ½ or 1½ open. Adjust.

Pulsates or hunts. Slowly adjust needle valve until pulsation stops.

Air trapped in main valve cover.

Loosen cover tube tting at the highest point, allow the air

to escape, and re-tighten.

Filter screen blocked.

Remove lter’s cap and screen to clean. Filter might be

insucient. See note below.

Valve fails to open. Insucient inlet pressure. Check/create inlet pressure.

Pilot is adjusted too high. Turn adjusting screw CCW on pilot.

Valve fails to seal inlet

pressure.

Filter screen blocked. Remove lter’s cap and screen to clean. Filter might be

insucient. See note below.

Debris trapped in main valve. Remove and inspect actuator assembly. Check seat. Check for

foreign bodies. Rinse at high ow rate.

Diaphragm in main valve is leaking.

Open the valve cover and inspect diaphragm. If damaged,

replace.

Diaphragm in pilot valve is leaking.

NOTE: Mark “F” – Large Filter

In cases where the filter screen frequently becomes blocked, install a filter with filtration capacity of at least 80 mesh / 250 µm.

DIFFICULTY IN PERFORMANCE

Where difficulty in performance is experienced, the manufacturer or an

authorized representative should be contacted to determine if any field

adjustment is to be made.

I- 867- 42T_ 9

REV_B

Page 10

I-867-42TINSTALLATION, OPERATION, AND MAINTENANCE MANUAL

867-42T Pressure Reducing Valve

For complete contact information, visit victaulic.com

I-867-42T 9680 REV B UPDATED 11/2016

VICTAULIC IS A REGISTERED TRADEMARK OR TRADEMARK OF VICTAULIC COMPANY AND/OR ITS AFFILIATED ENTITIES

IN THE UNITED STATES AND/OR OTHER COUNTRIES. © 2016 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

Loading...

Loading...