Victaulic 809N Installation Instructions Manual

I-809N

I-809NINSTALLATION INSTRUCTIONS

REV_ A

Style 809N High-Pressure Coupling for Ring Systems

IMPORTANT INFORMATION

WARNING

• Read and understand all instructions before attempting to install, remove, adjust, or maintain any Victaulic piping products.

• Depressurize and drain the piping system before attempting to install, remove, adjust, or maintain any Victaulic piping products.

• Wear required personal protective equipment during the welding process, and follow all jobsite regulations regarding welding safety.

• Wear safety glasses, hardhat, and foot protection during the coupling installation process.

• DO NOT attempt to install this product on pipe that is grooved (roll or cut) or that contains a weld bevel. Pipe ends shall be square cut.

• DO NOT attempt to install this product with rings supplied by other manufacturers.

Failure to follow these instructions could result in death or serious personal injury and property damage.

The Style 809N High-Pressure Coupling for Ring Systems is designed for installation on pipe that is prepared with rings supplied by Victaulic. Refer to

Victaulic publication 15.03 for allowable pipe materials and joint performance.

PIPE PREPARATION/RING ATTACHMENT

"S" Max.

1a. SQUARE CUT THE PIPE ENDS: The

maximum allowable tolerance from squarecut pipe ends (“S” dimension shown) is

⁄ inch/1.6 mm. This is measured from

the true square line.

1b. INSPECT PIPE ENDS PRIOR TO

RING ATTACHMENT: The outside

surface of the pipe ends (approximately

2 inches/51 mm back from the ends) shall

be smooth and free from indentations and

projections. All oil, grease, loose paint, dirt,

and cutting particles shall be removed.

2a. INSTALL RING ON PIPE: Spread the ring apart using appropriate

tooling at the ring opening (refer to the ring detail on page 2). Slide the

ring over the pipe end.

2b. POSITION RING: Remove the tooling and position the ring at the

required distance (refer to page 2 for the “B” dimension, which is the

required distance from the edge of the ring to the pipe end).

NOTICE

• Use Victaulic ring clamps to hold the rings at the appropriate

location on the pipe during tack welding.

Ring Clamp for

4-inch/114.3-mm Pipe

Ring Clamp for

6-inch/168.3-mm and

8-inch/219.1-mm Pipe

Ring Clamp for

10-inch/273.0-mm Pipe

2c. CLAMP RING IN POSITION: Hold the ring in position by applying

a ring clamp at three locations around the pipe circumference. DO NOT

cover the butt ends of the ring with a ring clamp.

2d. TACK WELD THE RING: Tack weld the ring to the pipe in enough

locations so that the ring does not shift out of position when the ring

clamps are removed.

2e. REMOVE RING CLAMPS AND COMPLETE WELD PROCEDURE:

Remove ring clamps. Weld around the entire circumference on both

sides of the ring. Refer to page 2 for complete weld requirements.

3a. INSPECT RING: The ring shall not contain any weld splatter or arc

strikes.

3b. INSPECT WELDS: Weld size and geometry shall meet the

requirements on page 2.

I-809N_2

REV_ A

I-809N / Style 809N High-Pressure Coupling for Ring Systems / Installation Instructions

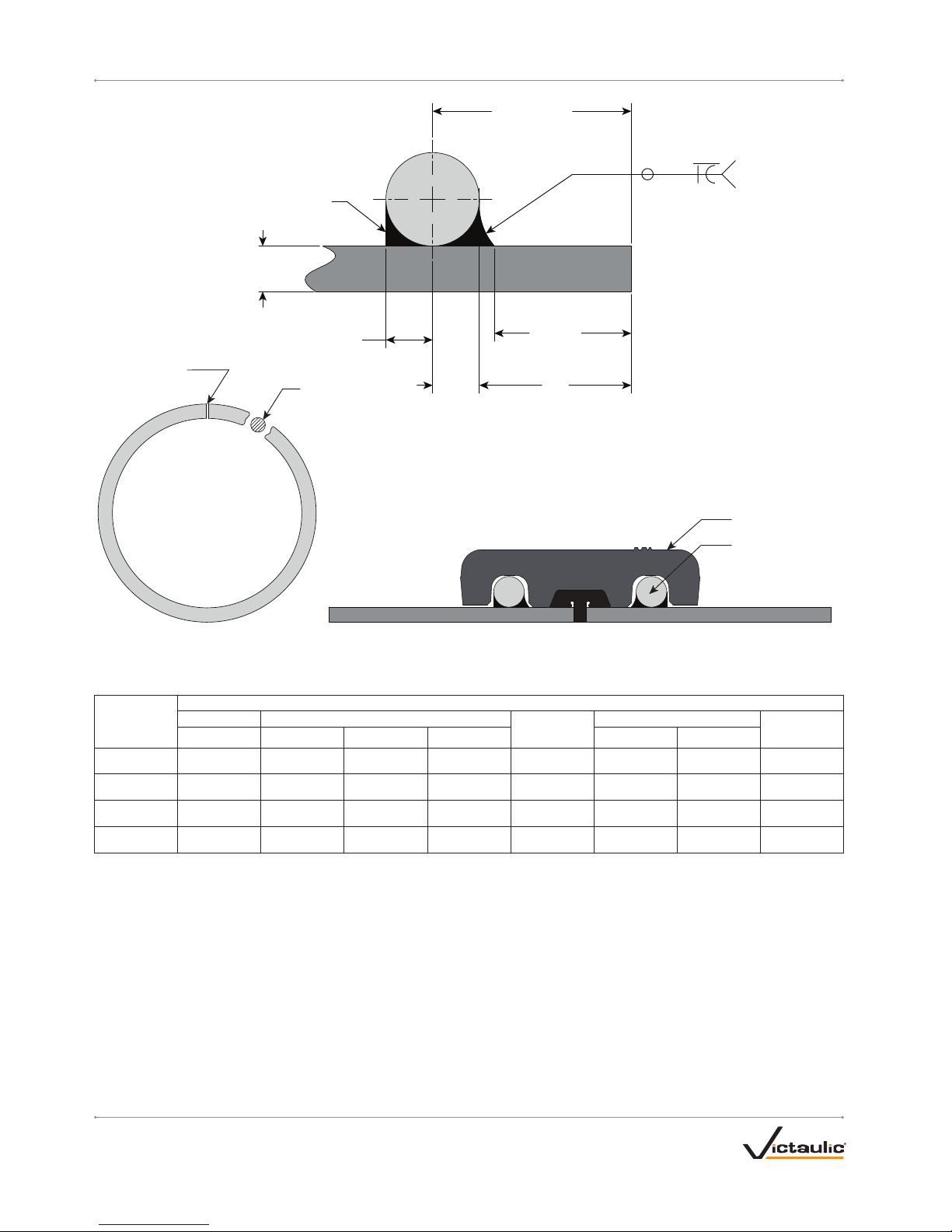

RING DETAIL

RING WELD DETAIL

MECHANICAL JOINT DETAIL

Style 809N Coupling

Ring

("Ø A")

SEE NOTE 4

"X" MIN

"B"

"T"

SEE NOTE 6

(”S”)

"E1"

("S")

"E2"

SEE NOTE 9

S(E1)

G

S(E2)

SEE NOTES 3 AND 8

Ring Opening

WELD SIZE TABLE

Nominal Pipe

Size inches /

Actual mm

Dimensions - inches/millimeters

Ring "B"

"S"

Weld Size

"X" Minimum("Ø A") Basic Maximum Minimum "E1" "E2"

4 ⁄ 1.0 0 1.03 0.97 ⁄ ⁄ ⁄ 0.91

114 .3 9.5 25.4 26.2 24.6 4.8 4.8 4.8 23.0

6 ½ 1. 22 1.2 5 1.19 ¼ ¼ ¼ 1.10

168 .3 12. 7 31. 0 31. 8 30.2 6 .4 6.4 6.4 27. 8

8 ⁄ 1.2 2 1. 25 1.19 ⁄ ⁄ ⁄ 1.10

219.1 15.9 31. 0 31.8 30.2 7. 9 7.9 7. 9 2 7.8

10 ¾ 1. 22 1. 25 1.19 ⁄ ⁄ ⁄ 1.10

273.0 19.1 31. 0 31.8 30.2 9.5 9.5 9. 5 2 7. 8

NOTES:

1. Victaulic ring to be supplied unpainted with a rust-inhibiting coating applied. Check rings to verify that all oil, grease, and dirt is

removed prior to welding.

2. Victaulic ring material: ASTM A108 Grade 1018, cold-rolled carbon steel

3. Weld metal: E70XX or greater

4. This area shall be free from indentations, projections, and weld splatter to ensure a leak-tight seal for the gasket. All oil, grease,

and dirt shall be removed.

5. Pipe material: Refer to Victaulic publication 15.03, which can be downloaded at victaulic.com

6. Pipe thickness: Refer to Victaulic publication 15.03, which can be downloaded at victaulic.com

7. Weld procedure by others

8. Take precautions during welding to keep heat buildup low. Excessive heat buildup can result in ring diameter shrinkage after

cooling to ambient temperature.

9. Final weld shall not extend past the edge of the ring. Excess weld material will compromise the joint.

Loading...

Loading...