Victaulic 795 Series, 906 Series, I-795, I-906 Installation And Maintenance Instructions Manual

Page 1

WARNING

• Read and understand all instructions before attempting to install, remove, adjust, or maintain any Victaulic piping products.

• Depressurize and drain the piping system before attempting to install, remove, adjust, or maintain any Victaulic piping products.

• Wear safety glasses, hardhat, foot protection, and hearing protection.

Failure to follow instructions and warnings could cause system failure, resulting in death or serious personal injury and property damage.

HANDWHEEL OPERATOR PNEU MATI C OP ERAT OR

HYDRAULIC OPERATOR

I-795/9 06

REV_D

I-795/906INSTALLATION AND MAINTENANCE INSTRUCTIONS

Series 795 and 906 Installation-Ready™ Knife Gate Valves

Page 2

Page 3

I-795 / 906 / Installation-Ready™ Knife Gate Valve / Installation and Maintenance Instructions

TABLE OF CONTENTS

Hazard Identification ......................................3

Knife Gate Valve Components ...............................4

Handwheel Operator Components ............................5

Pneumatic Operator Components ............................5

Hydraulic Operator Components .............................6

Dimensions – With Handwheel Operator .......................7

Dimensions – With Bevel Gear Operator........................8

Dimensions – With Pneumatic Operator ........................9

Dimensions – With Hydraulic Operator ........................10

Dimensions – Seat Cartridge ...............................11

Important Information ....................................12

Recommended Spare Parts and Tools ........................12

Manual Operation .......................................12

Pneumatic Operation.....................................12

Hydraulic Operation......................................12

SECTION I

Installing the 795 Valve Into a Steel Piping System............... 14

Installing the 906 Valve Into an HDPE Piping System .............18

SECTION II

Maintenance ...........................................24

Packing Adjustment....................................24

Lubrication ..........................................24

Removing the Existing Seat Cartridge.........................24

Installing the Replacement Seat Cartridge .....................29

HAZARD IDENTIFICATION

Definitions for identifying the various hazard levels are

provided below. When you see this symbol, be alert to the

possibility of personal injury. Carefully read and fully

u nderstand the message that follows.

DANGER

• The use of the word “DANGER” identifies an immediate

hazard with a likelihood of death or serious personal injury

if instructions, including recommended precautions, are not

followed.

WARNING

• The use of the word “WARNING” identifies the presence

of hazards or unsafe practices that could result in death or

serious personal injury if instructions, including recommended

precautions, are not followed.

CAUTION

• The use of the word “CAUTION” identifies possible hazards or

unsafe practices that could result in personal injury and product

or property damage if instructions, including recommended

precautions, are not followed.

NOTICE

• The use of the word “NOTICE” identifies special instructions

that are important but not related to hazards.

I-795/9 06_ 3

REV_D

Page 4

I-795 / 906 / Installation-Ready™ Knife Gate Valve / Installation and Maintenance Instructions

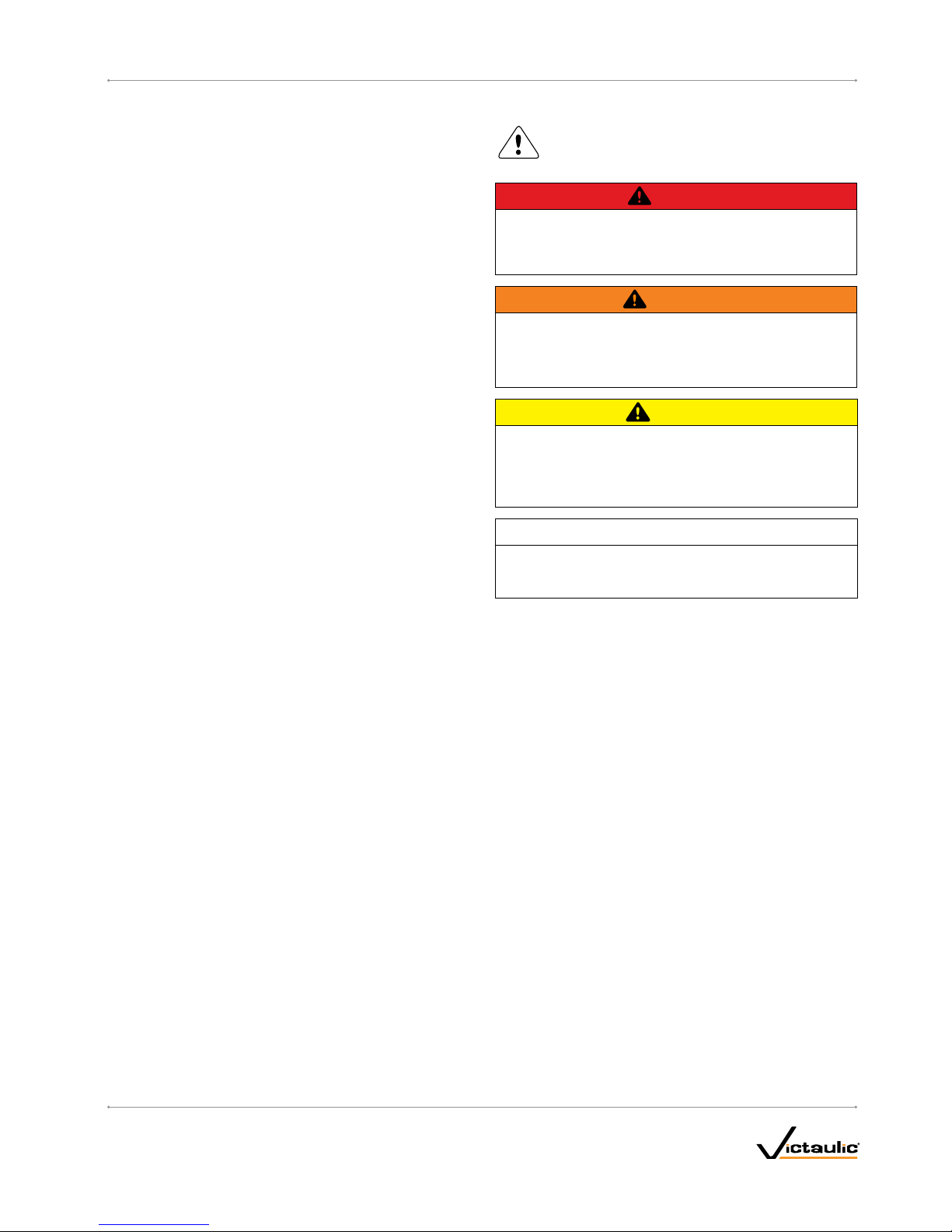

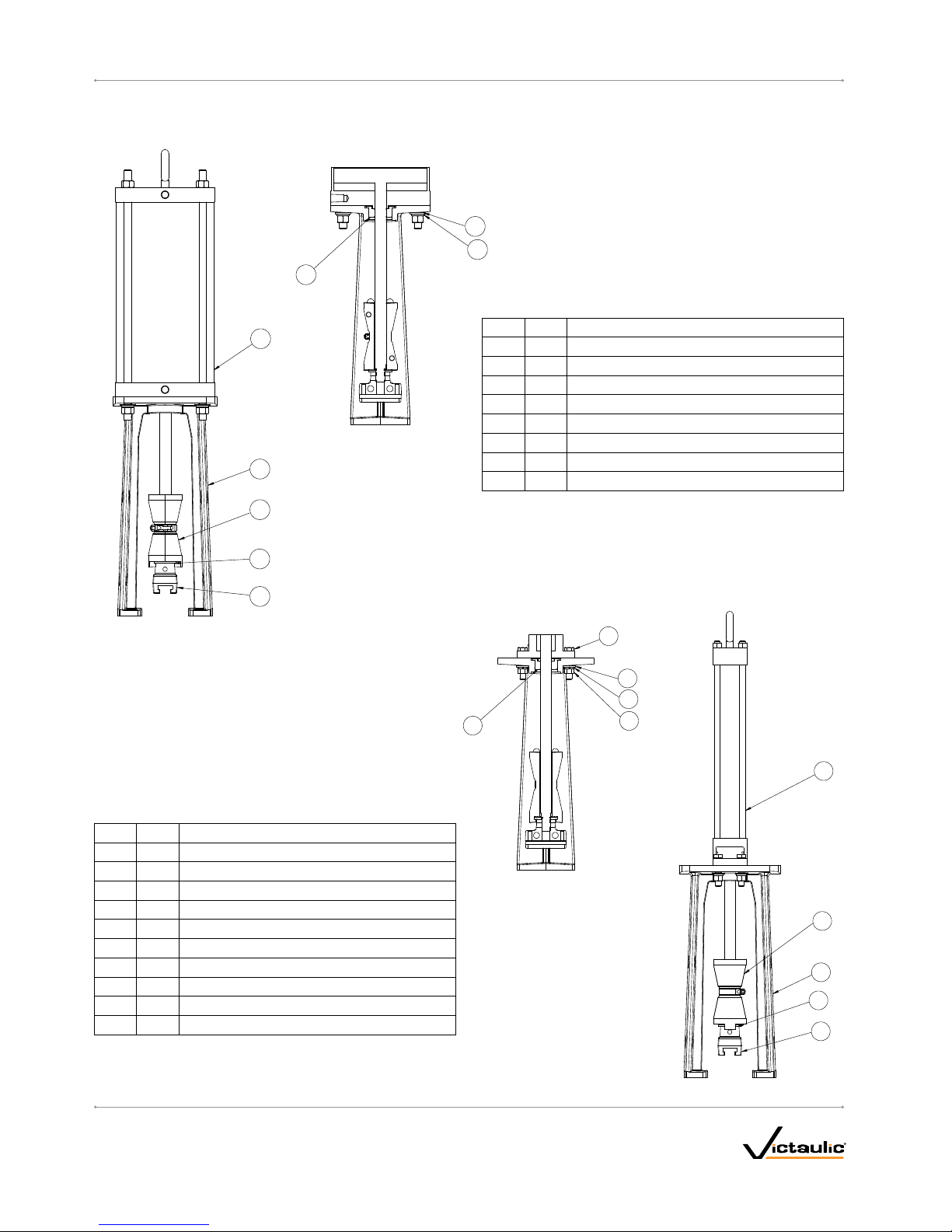

KNIFE GATE VALVE COMPONENTS

NOTICE

• Drawings and/or pictures in this manual may be exaggerated for clarity.

• Dimensions listed are for reference only. Refer to Victaulic submittal 08.25 or submittal 19.06 for complete dimensional information.

• The product, along with these installation and maintenance instructions, contains trademarks, copyrights, and/or patented features that are

the exclusive property of Victaulic.

BILL OF MATERIALS

Item Qt y. Description

1 1 Upper Body

2 1 Lower Body

3 2 Pipe Gasket

4 1 Seat Gasket

5 1 Seat

6 1 Knife Seal

7 1 Knife

8 1 Retaining Plate

9 1 Packing Gland

10 4 Full Thread Hex Bolt

†

11 4 Washer

†

12 4 Heavy Hex Nut

†

13 4 Washer

14 4 Helical Spring-Lock Washer

15 4 Hex Cap Screw

16 1 Dowel Pin

17 1 Dowel Pin

18 4 Hex Bolt

19 4 Helical Spring-Lock Washer

20 4 Hex Nut

21 1 O-Ring

22 1 Plug

23 8 Washer

24 2 Square Head Set Screw

‡

25 2 Spacer Bolt

26 2 Retainer *

27 2 Hex Cap Screw **

NOTES:

†

Items 10, 11, and 12 comprise the assembly hardware.

‡

Item 24 is used for 795 valve (carbon steel) only.

* Item 26 is used for 906 valve (HDPE) only.

** Item 27 is required when servicing the valve. Vic taulic offers a kit to replace

the entire seat cartridge. Refer to Section II in this manual for complete removal

and replacement instructions.

7

15

14

13

9

18

8

6

5

4

1

3

3

17

16

2

10

22

NIPPLES

SHOWN FOR

CLARITY

ONLY

21

12

11

20 19

23

24

24

23

25

25

27

26

I-795/9 06_ 4

REV_D

Page 5

I-795 / 906 / Installation-Ready™ Knife Gate Valve / Installation and Maintenance Instructions

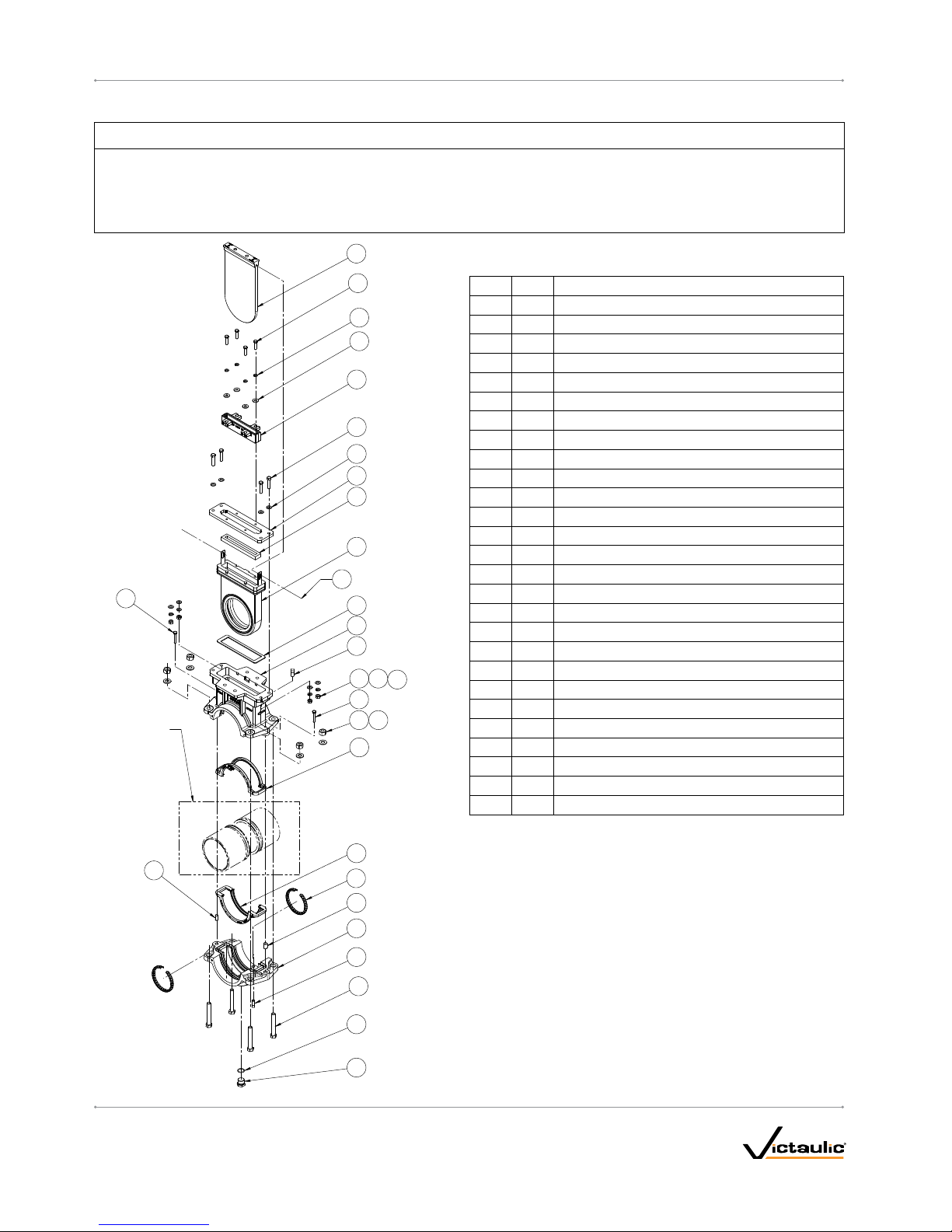

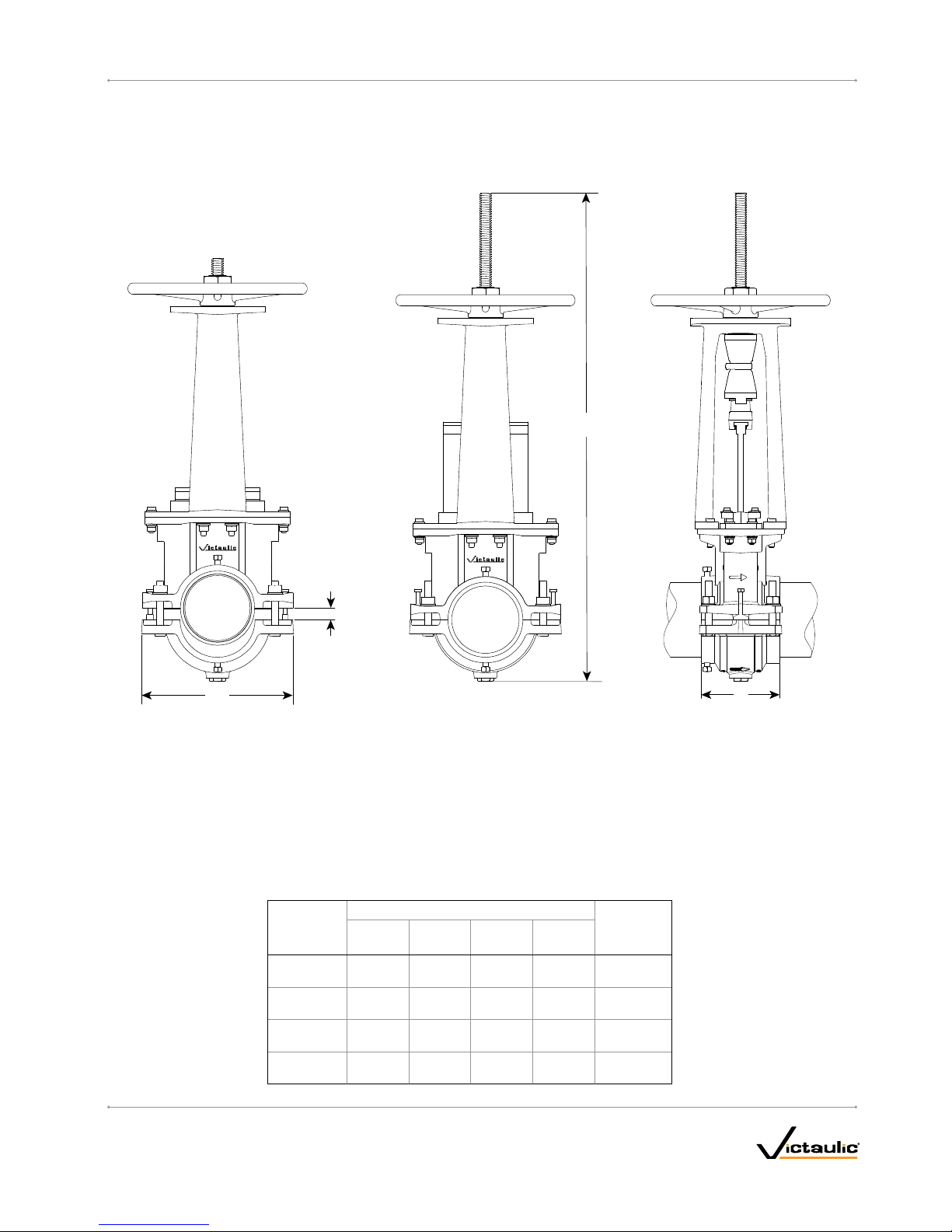

BILL OF MATERIALS

Item Qt y. Description

1 1 Yoke

2 1 Drive Nut

3 1 Spacer

4 1 Parallel Key

5 1 Handwheel

6 1 Washer

7 1 Stem

8 1 Hex Jam Nut

9 1 Gate Connector

10 1 Slotted Spring Pin

11 1 Stroke Limiter Assembly

12 1 Washer

1

5

8

7

2

4

6

3

9

10

11

12

HANDWHEEL OPERATOR COMPONENTS (3 TO 8 INCH)

BEVEL GEAR COMPONENTS (10 TO 12 INCH)

27

28

29

30

21

23

24

25

22

26

BILL OF MATERIALS

Item Qt y. Description

21 1 Yoke

22 1 Gear Actuator

23 4 Washer

24 4 Helical Spring-Lock Washer

25 4 Hex Cap Screw

26 1 Stem

27 1 Gate Connector

28 1 Slotted Spring Pin

29 1 Stroke Limiter Assembly

30 1 Washer

I-795/9 06_ 5

REV_D

Page 6

I-795 / 906 / Installation-Ready™ Knife Gate Valve / Installation and Maintenance Instructions

3

4

2

5

1

6

7

8

22

25

27

23

24

28

21

26

29

30

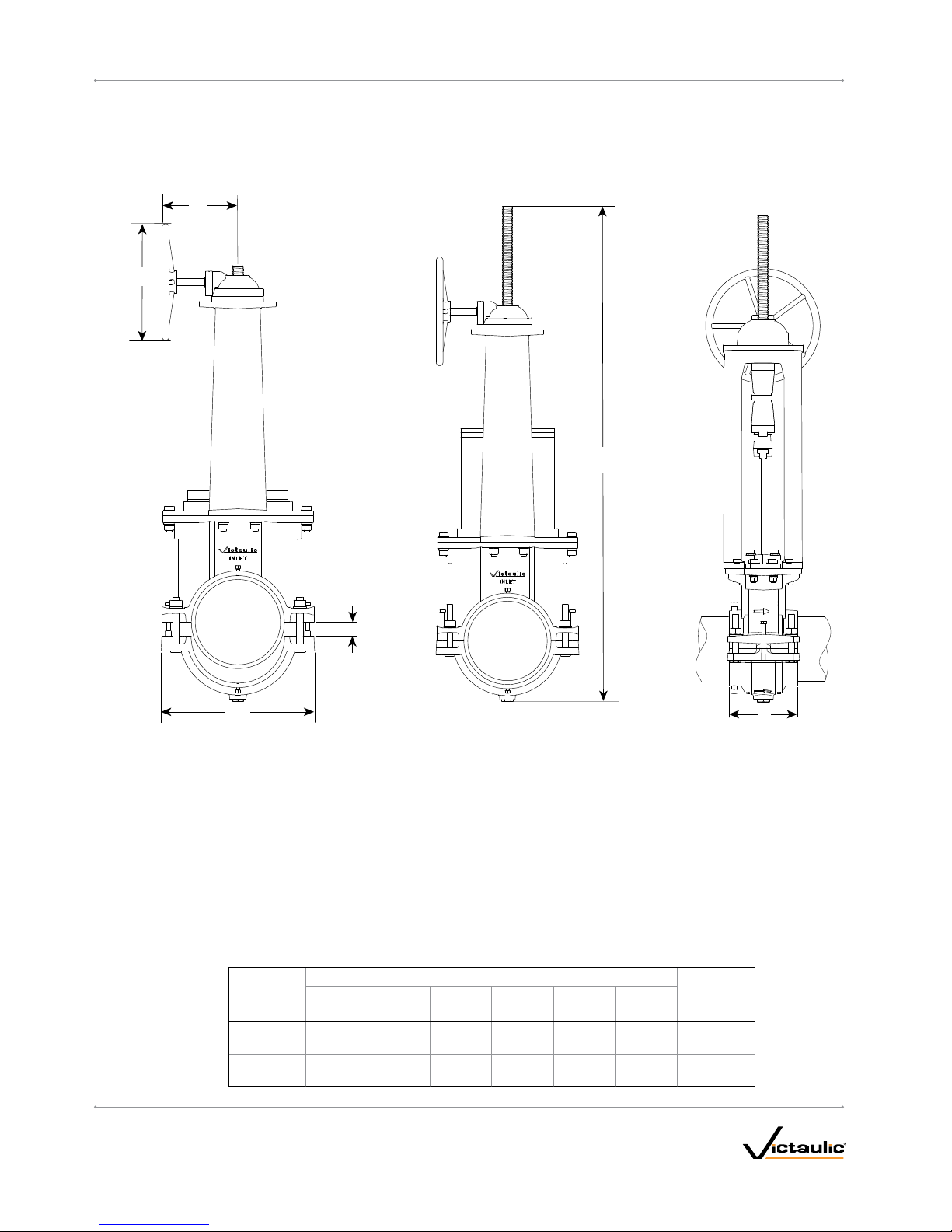

BILL OF MATERIALS

Item Qt y. Description

21 1 Yoke

22 1 Hydraulic Cylinder

23 4 Washer

24 4 Helical Spring-Lock Washer

25 1 Bushing

26 1 Gate Connector

27 4 Hex Cap Screw

28 4 Hex Nut

29 1 Stroke Limiter Assembly

30 1 Washer

HYDRAULIC OPERATOR COMPONENTS

BILL OF MATERIALS

Item Qt y. Description

1 1 Yoke

2 1 Pneumatic Cylinder with Nuts

3 4 Washer

4 4 Helical Spring-Lock Washer

5 1 Bushing

6 1 Gate Connector

7 1 Stroke Limiter Assembly

8 1 Washer

PNEUMATIC OPERATOR COMPONENTS

I-795/9 06_ 6

REV_D

Page 7

I-795 / 906 / Installation-Ready™ Knife Gate Valve / Installation and Maintenance Instructions

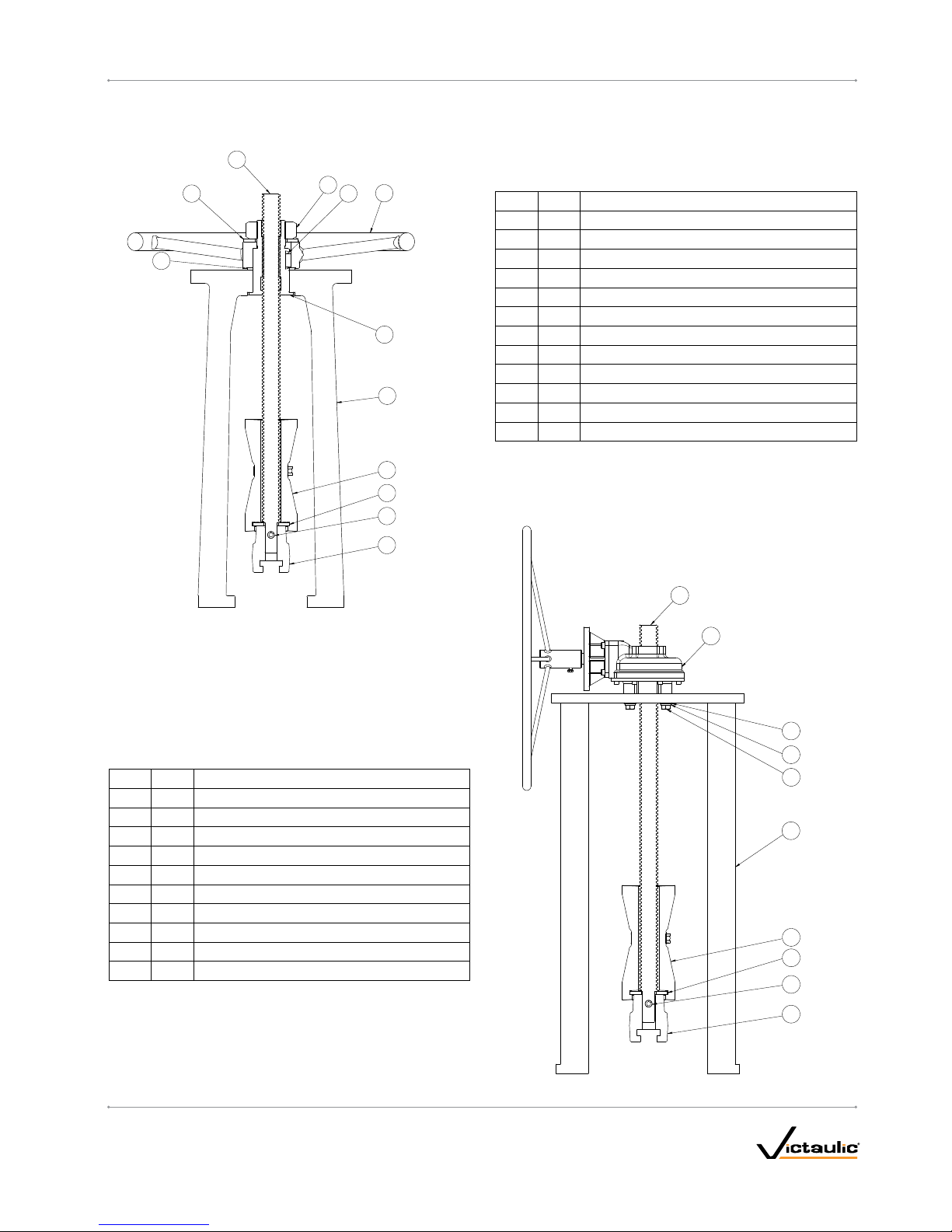

DIMENSIONS – WITH HANDWHEEL OPERATOR

VALVE CLOSED

NOT INSTALLED

VALVE OPEN

INSTALLED

VALVE OPEN

INSTALLED

E

C

H

F

Nominal Size

in

DN

Dimensions – inches/millimeters

Weight

lbs

kg

C E F H

3 0.88 10.25 6.75 32.25 113 .0 0

DN80 22.4 260.4 171. 5 819. 2 51.3

4 0.88 11. 25 6.75 34.75 122 .00

DN10 0 22.4 285.8 171. 5 882.7 55. 3

6 1.13 13.75 7. 00 43.75 166 .00

DN150 28.7 349.3 17 7.8 1111. 3 75.3

8 1.63 15. 50 7.00 53.25 23 7.0 0

DN200 41.4 393.7 17 7.8 1352. 6 107. 5

I-795/906_7

REV_D

Page 8

I-795 / 906 / Installation-Ready™ Knife Gate Valve / Installation and Maintenance Instructions

DIMENSIONS – WITH BEVEL GEAR OPERATOR

VALVE CLOSED

NOT INSTALLED

VALVE OPEN

INSTALLED

VALVE OPEN

INSTALLED

E

C

H

F

B

J

Nominal Size

in

DN

Dimensions – inches/millimeters

Weight

lbs

kg

B C E F H J

10 11. 22 1.75 19.0 0 7. 50 68.50 16.00 465.00

DN250 284.9 44.5 482.6 19 0.5 173 9. 9 406.4 210.9

12 11.22 2.00 21.00 7. 50 73.00 16.0 0 497.00

DN300 284.9 50.8 533.4 190 .5 1854. 2 406.4 225.4

I-795/9 06_ 8

REV_D

Page 9

I-795 / 906 / Installation-Ready™ Knife Gate Valve / Installation and Maintenance Instructions

DIMENSIONS – WITH PNEUMATIC OPERATOR

VALVE CLOSED

NOT INSTALLED

VALVE OPEN

INSTALLED

VALVE OPEN

INSTALLED

H

C

E

F

Nominal Size

in

DN

Dimensions – inches/millimeters

Weight

lbs

kg

C E F H

3 0.88 10.25 6.75 42.0 0 126 .00

DN80 22.4 260.4 171. 5 106 6. 8 5 7.2

4 0.88 11. 25 6.75 44.50 133 .00

DN10 0 22.4 285.8 171. 5 1130.3 60.3

6 1.13 13 .75 7.0 0 53.75 215. 00

DN150 28.7 349.3 17 7.8 13 65.3 97. 5

8 1.63 15.50 7.0 0 55.75 348.00

DN200 41.4 393.7 177. 8 1416 .1 15 7.9

10 1.75 19.0 0 7.50 79.50 550.00

DN250 44.5 482.6 19 0. 5 2 019.3 249.5

12 2.00 21. 00 7. 50 86.50 586.00

DN300 50.8 533.4 19 0. 5 2 19 7.1 265.8

I-795/906_9

REV_D

Page 10

I-795 / 906 / Installation-Ready™ Knife Gate Valve / Installation and Maintenance Instructions

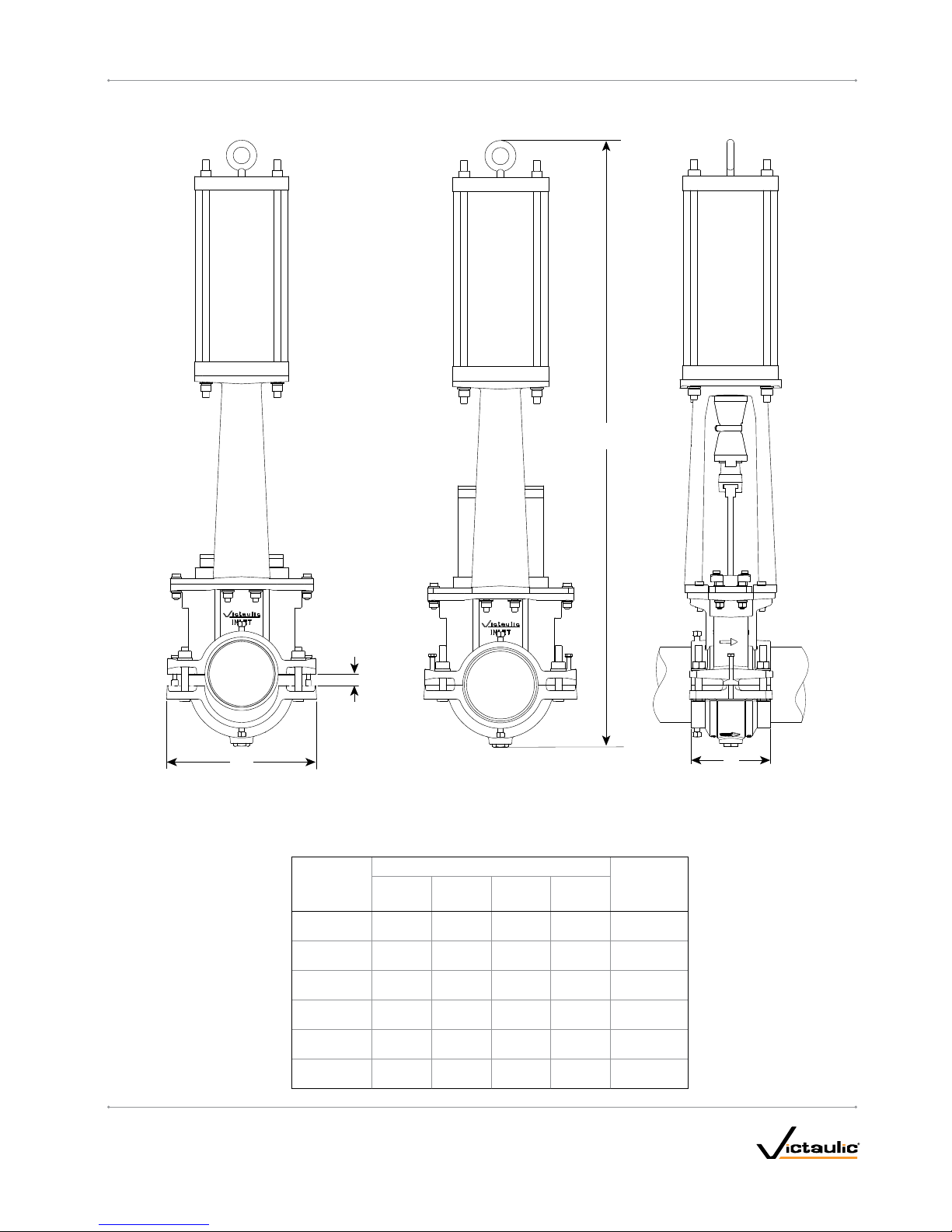

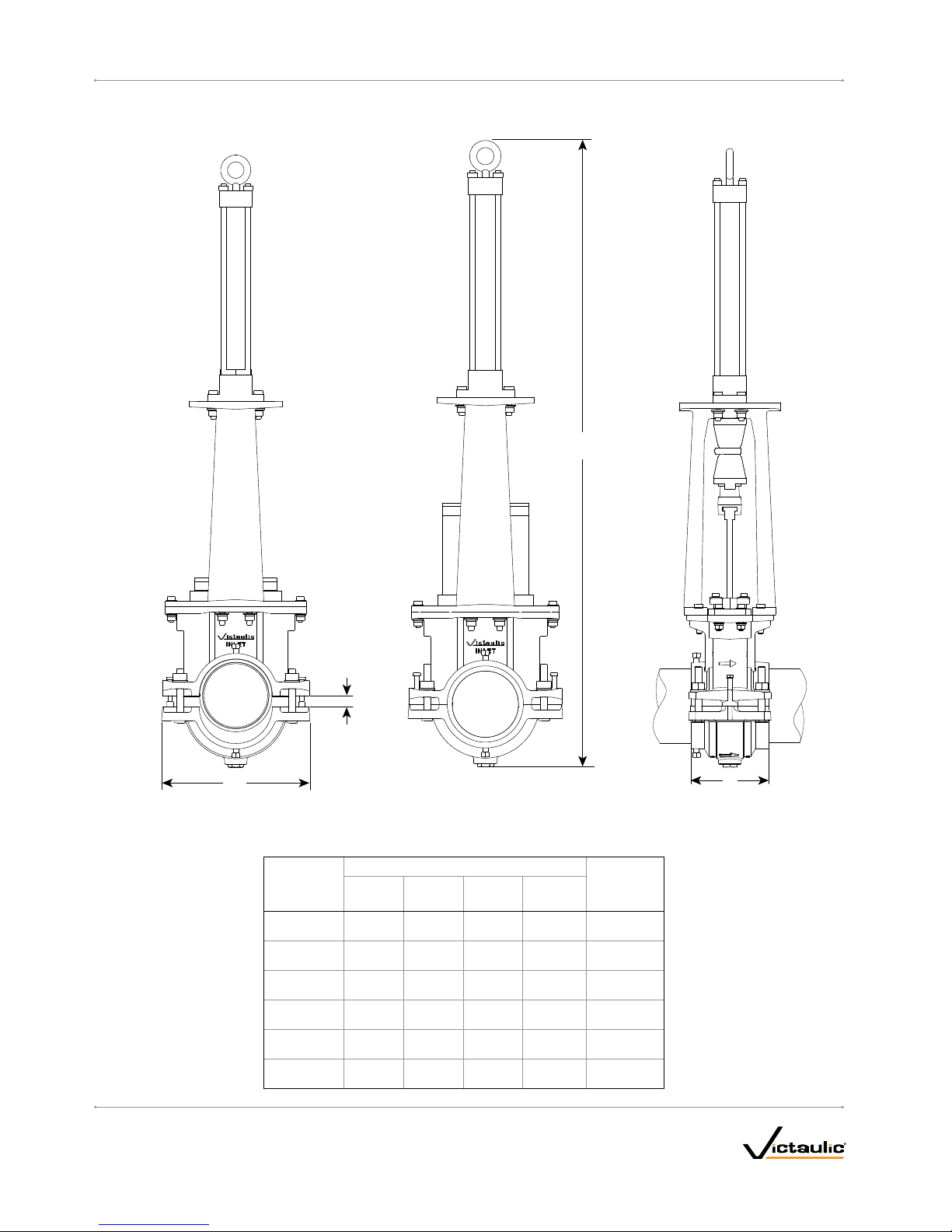

DIMENSIONS – WITH HYDRAULIC OPERATOR

VALVE CLOSED

NOT INSTALLED

VALVE OPEN

INSTALLED

VALVE OPEN

INSTALLED

H

C

E

F

Nominal Size

in

DN

Dimensions – inches/millimeters

Weight

lbs

kg

C E F H

3 0.88 10.25 6.75 43.88 115 .0 0

DN80 22.4 260.4 171. 5 111 4 . 6 52.2

4 0.88 11. 2 5 6.75 46.50 125. 00

DN10 0 22.4 285.8 171. 5 1181 .1 56.7

6 1.13 13 .75 7.0 0 55.00 17 2.0 0

DN150 28.7 349.3 17 7.8 13 97.0 78.0

8 1.63 15.50 7.0 0 66.50 259.00

DN200 41.4 393.7 177. 8 16 89.1 117. 5

10 1. 75 19 .0 0 7. 50 80.25 462.00

DN250 44.5 482.6 190. 5 2038.4 209.6

12 2.00 21. 00 7. 50 89.50 525.00

DN300 50.8 533.4 19 0. 5 2273.3 23 8.1

I-795/9 06_10

REV_D

Page 11

I-795 / 906 / Installation-Ready™ Knife Gate Valve / Installation and Maintenance Instructions

DIMENSIONS – SEAT CARTRIDGE

E

H

F

Nominal Size

in

DN

Dimensions – inches/millimeters

Weight

lbs

kg

E F H

3 9.88 3.88 10.8 8 16.30

DN80 2 51.0 98.6 276 .4 7.4

4 10.75 3.88 12 .13 19.7 0

DN10 0 273.1 98.6 308.1 8.9

6 13.0 0 3.88 15 .00 28.90

DN150 330.2 98.6 381.0 13.1

8 15.5 0 3.88 18. 25 40.70

DN200 39 7.3 98.6 463.6 18. 5

10 19. 00 5.00 23.00 82.0 0

DN250 482.6 127. 0 584.2 37. 2

12 20.63 5.00 25.50 10 0.60

DN300 524.0 127. 0 6 47. 7 45.6

I-795/ 9 06_ 11

REV_D

Page 12

I-795 / 906 / Installation-Ready™ Knife Gate Valve / Installation and Maintenance Instructions

IMPORTANT INFORMATION

• Series 795 Installation-Ready™ Knife Gate Valves are designed

for installation with grooved- end carbon steel or stainless steel

NPS pipe. For other pipe sizes and materials, contact Victaulic.

Welding of pipe ends to the valve is not permitted. Refer to the

Victaulic I-100 Field Installation Handbook for pipe preparation

requirements. The I-100 can be downloaded at victaulic.com.

• Series 906 Installation-Ready™ Knife Gate Valves are designed for

installation with plain-end HDPE pipe. Refer to the Victaulic I-900

Field Installation Handbook for pipe preparation requirements. The

I-900 can be downloaded at victaulic.com.

• Installation-Ready

™

Knife Gate Valves are rated for a maximum

working pressure of 150 psi/10 Bar.

• Installation-Ready

™

Knife Gate Valves are not intended for throttling

service. These valves are designed for shutoff applications only.

• Installation-Ready™ Knife Gate Valves are not intended for use in

air services.

• Installation-Ready™ Knife Gate Valves can be installed in any

orientation. NOTE: Additional supports shall be considered when

a 795 valve is installed horizontally, especially when a pneumatic,

electric, or hydraulic actuator is used. The 906 valve must be fully

supported in all installations.

• Installation-Ready

™

Knife Gate Valves and connecting piping must

be supported properly to prevent the joints from being subjected to

bending loads, shear loads, or any other external loads.

• DO NOT use Installation-Ready

™

Knife Gate Valves as a jack for

pipe alignment or support.

• DO NOT climb on or stand on Installation-Ready™ Knife Gate

Valves or other piping system components.

RECOMMENDED SPARE PARTS AND TOOLS

CAUTION

• Ensure that all spare seals and gaskets are compatible with the

line temperature and media.

Failure to follow this instruction will cause gasket degradation,

resulting in joint leakage and property damage.

• Spare Seat Cartridge

• Ratchet Wrenches

• Crescent Wrenches

• Pipe Wrenches

• Victaulic Lubricant or Silicone Lubricant

• Water-Stabilized Calcium Grease Containing Graphite and

Molybdenum Disulfide

• Anti-Seize Compound

MANUAL OPERATION

For Installation-Ready™ Knife Gate Valves installed with a handwheel operator, the following table contains the approximate number of complete

rotations required during standard operation (i.e. going from fully closed to fully open) or during maintenance to remove the seat cartridge.

Valve Size

inches

mm

Thrust Load

lbs

N

Approximate

Number of

Handwheel

Rotations

for Standard

Operation

Approximate

Number of

Handwheel

Rotations for

Maintenance

Maximum

Torq ue

Required

ft-lbs

N•m

Rim Pull

Effort

lb

N

3 150 0

20 45

11 16

80 6672 14 70

4 2100

25 55

15 22

100 9341 20 99

6 3000

35 70

22 33

150 13,344 29 145

8 4600

45 90

33 49

200 20,461 44 217

10* 7000

44 88

72 43

250 31,136 98 189

12* 7200

52 100

73 43

300 32,026 99 192

* These sizes come standard with a bevel gear operator.

PNEUMATIC OPERATION

Pneumatic cylinders are designed to be operated within 80–150 psi/6 –10 Bar air pressure. Contact Victaulic if your system air pressure is less than

80 psi/6 Bar. Additional information will be required to determine appropriate specifications for your system.

HYDRAULIC OPERATION

Hydraulic cylinders are designed to be operated within 1500–3000 psi/103–207 Bar hydraulic pressure. Contact Victaulic if your system hydraulic

pressure is less than 1500 psi/103 Bar. Additional information will be required to determine appropriate specifications for your system.

I-795/9 06_12

REV_D

Page 13

SECTION I

• Installing the 795 Valve

Into a Steel Piping System

• Installing the 906 Valve

Into an HDPE Piping

System

I-795_13

REV_D

Page 14

I-795 / 906 / Installation-Ready™ Knife Gate Valve / Installation and Maintenance Instructions

INSTALLING THE 795 VALVE INTO A STEEL

PIPING SYSTEM

WARNING

• This valve is intended for use on grooved-end carbon steel or

stainless steel NPS pipe and is NOT to be used on HDPE pipe.

Failure to follow this instruction could result in personal injury,

joint leakage, and property damage, and could void the product

warranty.

1. DO NOT REMOVE OR ADJUST THE ASSEMBLY HARDWARE:

Series 795 Installation-Ready™ Knife Gate Valves are designed so

that the installer does not need to remove the assembly hardware for

installation. This design facilitates installation by allowing the installer to

directly insert a grooved pipe end into each opening of the valve.

2. INSPECT PIPE ENDS: The outside surface of the pipe, between the

groove and the pipe end, must be smooth and free from indentations,

projections, weld seams, and roll marks to ensure a leak-tight seal. All

oil, grease, loose paint, dirt, and cut ting particles must be removed. The

pipe OD, groove dimensions, and maximum allowable flare diameter

must be within the tolerances published in current Victaulic grooving

specifications. NOTE: Maximum allowable pipe ovality shall comply

with the requirements of ASTM A-999 and API 5L. Greater variations

between the major and minor pipe diameters will result in difficult

assembly and potential joint leakage.

3. INSPECT PIPE GASKETS: Check the pipe gaskets to ensure that

they are suitable for the intended service. The color code identifies the

gasket grade. Refer to Victaulic publication 05.01 in the G-100 General

Catalog for the color code chart.

CAUTION

• A compatible lubricant must be used to prevent the pipe gaskets

from pinching /tearing during installation.

• Pipe gaskets are designed for one-time use only. DO NOT

attempt to reuse pipe gaskets that have been placed in service.

Failure to follow these instructions will cause gasket degradation,

resulting in joint leakage and property damage.

Lubricate

4. LUBRICATE PIPE GASKETS: Apply a thin coat of Victaulic Lubricant

or silicone lubricant only to the sealing lips of the pipe gaskets’ interior.

NOTE: The exterior surface of the pipe gaskets is supplied with a

factory-applied lubricant.

NOTICE

• It is not necessary to remove the pipe gaskets from the valve to

apply additional lubricant to the exterior surface.

TABLE 1: LUBRICANT COMPATIBILITY

Lubricant

Compatibility

with Grade “T”

Nitrile Gaskets

Compatibility

with Grade “E”

EPDM Gaskets

Victaulic Lubricant,

Soap-Based Solutions, Glycerin,

Silicone Oil, or Silicone Release Agent

Good Good

Corn Oil, Soybean Oil,

Hydrocarbon-Based Oils,

or Petroleum- Based Greases

Good

Not

Recommended

WARNING

• Keep hands away from the pipe ends and

the openings of the valve when attempting to

insert grooved pipe ends into the valve.

Failure to follow this instruction could result in

serious personal injury.

I-795/9 06_14

REV_D

Page 15

I-795 / 906 / Installation-Ready™ Knife Gate Valve / Installation and Maintenance Instructions

5a. ASSEMBLE JOINT: Assemble the joint by inserting a grooved pipe

end into each opening of the valve.

Inspect

5b. INSPECT KEYS: Each grooved pipe end must be inserted into

the valve until contact with the seat occurs, as shown above. This will

ensure that the valve body’s keys align with the grooves in the pipe

ends.

5c. REMOVE ONLY THE SPACER BOLTS: There is one spacer bolt

on each bolt pad to maintain spacing between the bolt pads during

shipping and assembly. After inserting pipe, remove only the spacer

bolts and the attached warning tags before tightening the four nuts in

step 6.

CAUTION

• Spacer bolts are designed to keep the valve’s housings at the

proper spacing during installation of the pipe ends.

• These spacer bolts must be removed prior to tightening the hex

nuts to bring the bolt pads into metal-to-metal contact. The

bolts will prevent proper tightening of the valve housings.

Failure to follow these instructions will cause damage to the valve

components. This may result in joint leakage or property damage,

and could void the product warranty.

NOTE: Do NOT discard the spacer bolts. Reinstall the spacer bolts

to finger-tight after valve installation is complete. If the valve must be

removed from the system, the spacer bolts will be necessary to separate

housings and maintain spacing (dimension "C", as defined in the

dimension tables found on pages 7–10) between the bolt pads during

storage, shipping, and reinstallation.

6. TIGHTEN NUTS: Tighten the hex nuts evenly by alternating sides

in a crossing pattern (as shown in the sequence above) until metal-tometal contact occurs at the bolt pads. Ensure that the valve body’s keys

engage the grooves completely during tightening.

NOTE: It is important to tighten the hex nuts evenly by alternating sides

to prevent pinching of the pipe gaskets. An impact wrench or standard

socket wrench with a deep-well socket can be used to bring the bolt

pads into metal-to-metal contact. Refer to the “Series 795 Helpful

Information” and “Impact Wrench Usage Guidelines” sections.

WARNING

• Visual inspection of each joint is critical.

• Improperly assembled joints must be corrected before the

system is placed into service.

Failure to follow these instructions could cause joint failure,

resulting in serious personal injury and/or property damage.

I-795/9 06_15

REV_D

Page 16

I-795 / 906 / Installation-Ready™ Knife Gate Valve / Installation and Maintenance Instructions

GOOD

BAD

7. INSPECT PADS: Visually inspect the bolt pads at each joint to ensure

that metal-to-metal contact is achieved across the entire bolt pad

section.

8. TIGHTEN 360° POSITIONING BOLTS: Tighten the two 360°

positioning bolts evenly by alternating sides until they reach a nominal

torque of 40 ft-lbs/54.23 N•m.

I-795/9 06_16

REV_D

Page 17

I-795 / 906 / Installation-Ready™ Knife Gate Valve / Installation and Maintenance Instructions

NOTICE

A locking pin is provided to assist with Lockout/Tagout procedures

during installation and maintenance. Ensure that the pin is

removed before attempting to place the valve into service.

IMPACT WRENCH USAGE GUIDELINES

WARNING

• It is important to tighten the nuts evenly by alternating sides

until metal-to-metal c ontact occurs at the bolt pads.

• DO NOT continue to tighten the nuts after the visual installation

guidelines for the product are achieved.

Failure to follow these instructions could cause gasket pinching and

product damage, resulting in joint failure, serious personal injury,

and property damage.

Due to the speed of assembly when using an impact wrench, the

installer should take extra care to ensure that nuts are tightened evenly

by alternating sides until proper assembly is complete. Always refer to

the specific product installation instructions for complete installation

requirements.

Impact wrenches do not provide the installer with direct “wrench feel” or

torque to judge nut tightness. Since some impact wrenches are capable

of high output, it is important to develop a familiarity with the impact

wrench to avoid damaging or fracturing the bolts or the bolt pads during

installation. DO NOT continue to tighten the nuts after the visual

installation guidelines are achieved.

If the battery is drained or if the impact wrench is under-powered, a new

impact wrench or a new battery pack must be used to ensure that the

visual installation guidelines for the product are achieved.

Perform trial assemblies with the impact wrench and check the

assemblies with socket or torque wrenches to help determine the

capability of the impact wrench. Using the same method, periodically

check additional nuts throughout the system installation.

For safe and proper use of impact wrenches, always refer to the impact

wrench manufacturer’s operating instructions. In addition, verify that

proper impact grade sockets are being used for product installation.

WARNING

Failure to follow instructions for tightening product hardware could

result in:

• Bolt fractures

• Damaged or broken bolt pads or product fractures

• Joint leakage

Series 795 Helpful Information

Valve

Size

Spacer

Bolt Size

Spacer Bolt

Socket

inches/mm

Coupling

Nut

Size

Coupling Nut

Deep-Well Socket

inches/mm

3

⁄" - 16 UNC x 2"

⁄

½" - 13 Heavy Hex

⁄

14 19

4

⁄" - 16 UNC x 2"

⁄

½" - 13 Heavy Hex

⁄

14 19

6

⁄" - 16 UNC x 3"

⁄

⁄" - 11 Heavy Hex

1 ⁄

14 27

8

⁄" - 16 UNC x 3"

⁄

⁄" - 11 Heavy Hex

1 ⁄

14 27

10

½" - 13 UNC x 3.5"

¾

⁄" - 9 Heavy Hex

1 ⁄

19 36

12

½" - 13 UNC x 3.5"

¾

⁄" - 9 Heavy Hex

1 ⁄

19 36

I-795/9 06_17

REV_D

Page 18

I-795 / 906 / Installation-Ready™ Knife Gate Valve / Installation and Maintenance Instructions

INSTALLING THE 906 VALVE INTO AN HDPE

PIPING SYSTEM

WARNING

• Wear gloves while handling valve. Retainer

teeth are sharp and may cause injury.

• This valve is intended for use on plain-end

HDPE pipe and is NOT to be used on steel

pipe.

Failure to follow these instructions could result

in personal injury, joint leakage, and property

damage, and could void the product warranty.

1a. DO NOT REMOVE OR ADJUST THE ASSEMBLY HARDWARE:

Series 906 Installation-Ready™ Knife Gate Valves are designed so

that the installer does not need to remove the assembly hardware for

installation. This design facilitates installation by allowing the installer to

directly insert a pipe end into each opening of the valve.

1b. REMOVE SLEEVE: Remove the cardboard sleeve from the valve

interior. NOTE: This cardboard sleeve will be used as a guide for

marking the pipe ends in step 4.

2. INSPECT PIPE ENDS: Ensure that the pipe ends are clean and free

from damage and scratches within 2 ½ inches/64 mm from the ends. All

oil, grease, dirt, and cutting particles must be removed. Failure to do so

will result in difficult assembly and potential joint leakage.

3. INSPECT PIPE GASKETS: Check the pipe gaskets to ensure that

they are suitable for the intended service. The color code identifies the

gasket grade. Refer to Victaulic publication 05.01 in the G-100 General

Catalog for the color code chart.

CAUTION

• A compatible lubricant must be used to prevent the pipe gaskets

from pinching /tearing during installation.

• Pipe gaskets are designed for one-time use only. DO NOT

attempt to reuse pipe gaskets.

Failure to follow these instructions will cause gasket degradation,

resulting in joint leakage and property damage.

4. MARK PIPE: Using the cardboard sleeve and a paint stick, mark

each HDPE pipe end around the full circumference:

• 1 7/8 inches/48 mm for 2–3-inch pipe sizes

• 2 ¼ inches/57 mm for 4–8-inch pipe sizes

This mark will be used for visual inspection to ensure that the HDPE

pipe is inserted properly in the valve. If a full circumferential mark

cannot be achieved, make at least four marks equally-spaced around

the circumference of each HDPE pipe end.

5. LUBRICATE PIPE END: Apply a thin coat of lubricant to the pipe

end from the end of the pipe to the paint mark made in step 4.

Lubricate each pipe end in accordance with the “Lubricant

Compatibility” table. Always consult with the pipe manufacturer for

lubricant compatibility requirements.

I-795/9 06_18

REV_D

Page 19

I-795 / 906 / Installation-Ready™ Knife Gate Valve / Installation and Maintenance Instructions

TABLE 1: LUBRICANT COMPATIBILITY

Lubricant

Compatibility

with Grade “T”

Nitrile Gaskets

Compatibility

with Grade “E”

EPDM Gaskets

Victaulic Lubricant,

Soap-Based Solutions, Glycerin,

Silicone Oil, or Silicone Release Agent

Good Good

Corn Oil, Soybean Oil,

Hydrocarbon-Based Oils,

or Petroleum- Based Greases

Good

Not

Recommended

WARNING

• Keep hands away from the pipe ends and the

openings of the valve when attempting to insert

pipe ends into the valve.

Failure to follow this instruction could result in

personal injury.

5a. ASSEMBLE JOINT: Assemble the joint by inserting the marked

HDPE pipe end into each opening of the valve. The HDPE pipe ends

must be inserted into the valve until (1) contact with the seat occurs

AND (2) the marks on the HDPE pipe ends meets the edge of the valve

body, as shown above.

Inspect

5b. INSPECT SEAT: Each pipe end must be inserted into the valve until

contact with the seat occurs, as shown above. A visual check is required

to ensure that the seat meets the pipe ends.

5c. REMOVE ONLY THE SPACER BOLTS: There is one spacer bolt on

each bolt pad to maintain spacing between the bolt pads during shipping

and assembly. After inserting pipe, remove only the spacer bolts and the

attached warning tags before tightening the four nuts in step 6.

CAUTION

• Spacer bolts are designed to keep the valve’s housings at the

proper spacing during installation of the pipe ends.

• These spacer bolts must be removed prior to tightening the hex

nuts to bring the bolt pads into metal-to-metal contact. The

bolts will prevent proper tightening of the valve housings.

Failure to follow these instructions will cause damage to the valve

components. This may result in joint leakage or property damage,

and could void the product warranty.

NOTE: Do NOT discard the spacer bolts. Reinstall the spacer bolts

to finger-tight after valve installation is complete. If the valve must be

removed from the system, the spacer bolts will be necessary to separate

housings and maintain spacing (dimension "C", as defined in the

dimension tables found on pages 7–10) between the bolt pads during

storage, shipping, and reinstallation.

I-795/9 06_19

REV_D

Page 20

I-795 / 906 / Installation-Ready™ Knife Gate Valve / Installation and Maintenance Instructions

6. TIGHTEN NUTS: Tighten the hex nuts evenly by alternating sides in a

crossing pattern (as shown in the sequence above) until metal-to-metal

contact occurs at the bolt pads.

NOTE: It is important to tighten the hex nuts evenly by alternating sides

to prevent pinching of the pipe gaskets. An impact wrench or standard

socket wrench with a deep-well socket can be used to bring the bolt

pads into metal-to-metal contact. Refer to the “Series 906 Helpful

Information” and “Impact Wrench Usage Guidelines” sections.

WARNING

• Visual inspection of each joint is critical.

• Improperly assembled joints must be corrected before the

system is placed into service.

Failure to follow these instructions could cause joint failure,

resulting in serious personal injury and/or property damage.

GOOD

BAD

7. INSPECT PADS: Visually inspect the bolt pads at each joint to ensure

that metal-to-metal contact is achieved across the entire bolt pad

section.

I-795/9 06_ 20

REV_D

Page 21

I-795 / 906 / Installation-Ready™ Knife Gate Valve / Installation and Maintenance Instructions

NOTICE

A locking pin is provided to assist with Lockout/Tagout procedures

during installation and maintenance. Ensure that the pin is

removed before attempting to place the valve into service.

IMPACT WRENCH USAGE GUIDELINES

WARNING

• It is important to tighten the nuts evenly by alternating sides

until metal-to-metal c ontact occurs at the bolt pads.

• DO NOT continue to tighten the nuts after the visual installation

guidelines for the product are achieved.

Failure to follow these instructions could cause gasket pinching and

product damage, resulting in joint failure, serious personal injury,

and property damage.

Due to the speed of assembly when using an impact wrench, the

installer should take extra care to ensure that nuts are tightened evenly

by alternating sides until proper assembly is complete. Always refer to

the specific product installation instructions for complete installation

requirements.

Impact wrenches do not provide the installer with direct “wrench feel” or

torque to judge nut tightness. Since some impact wrenches are capable

of high output, it is important to develop a familiarity with the impact

wrench to avoid damaging or fracturing the bolts or the bolt pads during

installation. DO NOT continue to tighten the nuts after the visual

installation guidelines are achieved.

If the battery is drained or if the impact wrench is under-powered, a new

impact wrench or a new battery pack must be used to ensure that the

visual installation guidelines for the product are achieved.

Perform trial assemblies with the impact wrench and check the

assemblies with socket or torque wrenches to help determine the

capability of the impact wrench. Using the same method, periodically

check additional nuts throughout the system installation.

For safe and proper use of impact wrenches, always refer to the impact

wrench manufacturer’s operating instructions. In addition, verify that

proper impact grade sockets are being used for product installation.

WARNING

Failure to follow instructions for tightening product hardware could

result in:

• Bolt fractures

• Damaged or broken bolt pads or product fractures

• Joint leakage

Series 906 Helpful Information

Valve

Size

Spacer

Bolt Size

Spacer Bolt

Socket

inches/mm

Coupling

Nut

Size

Coupling Nut

Deep-Well Socket

inches/mm

3

⁄" - 16 UNC x 2"

⁄

½" - 13 Heavy Hex

⁄

14 19

4

⁄" - 16 UNC x 2"

⁄

½" - 13 Heavy Hex

⁄

14 19

6

⁄" - 16 UNC x 3"

⁄

⁄" - 11 Heavy Hex

1 ⁄

14 27

8

⁄" - 16 UNC x 3"

⁄

⁄" - 11 Heavy Hex

1 ⁄

14 27

I-795/9 06_ 21

REV_D

Page 22

This page intentionally blank

Page 23

SECTION II

• Maintenance

• Removing the Seat Cartridge

• Installing the Seat Cartridge

Page 24

I-795 / 906 / Installation-Ready™ Knife Gate Valve / Installation and Maintenance Instructions

MAINTENANCE

Maintenance should be performed on the Installation-Ready™ Knife

Gate Valve on a regularly scheduled basis, as established by job site

requirements, or when leakage occurs.

PACKING ADJUSTMENT

1

3

4

2

If leakage occurs at the packing, tighten the hex cap screws evenly in

¼ turns by alternating sides (as shown in the sequence above) until

leakage stops. If leakage persists, perform the instructions that follow

to remove and replace the seat cartridge.

LUB RICATION

For handwheel, bevel gear, or

electrically operated valves,

Victaulic recommends greasing

the threaded stem and drive nut

on a quarterly basis, depending on

the number of cycles. If the valve

is cycled on a daily basis, increase

the frequency of lubricating the

threaded stem to ensure proper

handwheel operation.

Apply a water-stabilized calcium

grease containing graphite and

molybdenum disulfide (Mobil

Mobilux™ EP 1 or equivalent)

to the entire threaded stem and

drive nut. Operate the handwheel to raise and lower the threaded stem

to ensure that grease is distributed evenly. NOTE: If the valve is in a

critical shutoff service and cannot be cycled, insert the locking pin

(referenced on page 17) through the yoke (page 5, item 1) into the gate

connector (page 5, item 9). Disconnect the threaded stem (page 5, item

7) from the gate connector by removing the slotted spring pin (page 5,

item 10). Cycle the threaded stem independent of the gate connector,

then replace the slotted spring pin and remove the lockout bolt.

For pneumatically or hydraulically operated valves, refer to the actuator

manufacturer’s maintenance instructions.

REMOVING THE EXISTING SEAT CARTRIDGE

DANGER

• Depressurize and drain the piping

system completely before attempting

to remove the seat cartridge.

Failure to follow this instruction could

result in death or serious personal injury

and property damage.

WARNING

• Read and understand all instructions

before attempting to install, remove,

adjust, or maintain any Victaulic

piping products.

• Wear safety glasses, hardhat, foot

protection, and hearing protection.

Failure to follow instructions and warnings could cause system

failure, resulting in death or serious personal injury and property

damage.

1. DEPRESSURIZE AND DRAIN SYSTEM: Depressurize, drain, and

flush the piping system completely and return the knife to the fully

closed position before attempting to remove the seat cartridge.

Stroke

Limiter

2. REMOVE STROKE LIMITER: Remove the stroke limiter in order to

raise the stem completely.

Apply

grease

here

™ Mobilux is a trade mark of Ex xon Mobil Corp oration.

I-795/9 06_ 24

REV_D

Page 25

I-795 / 906 / Installation-Ready™ Knife Gate Valve / Installation and Maintenance Instructions

2a. Using a ⁄inch/11 mm deep-well socket wrench, remove the nut

on the T-bolt clamp and pull the clamp apart.

2b. Remove the T-bolt clamp and split the two halves of the stroke

limiter to remove.

Remove

3. REMOVE PLUG: Using a 1 ¼-inch/32 mm wrench (for the 3 to 8"

valves) or a 1 ½-inch/38 mm wrench (for the 10 to 12" valves), remove

the plug from the bottom of the valve body.

I-795/9 06_ 25

REV_D

Page 26

I-795 / 906 / Installation-Ready™ Knife Gate Valve / Installation and Maintenance Instructions

4. REMOVE AND RELOCATE GATE CONNECTOR SCREWS: Remove

the two hex cap screws from the gate connector. Relocate them through

the tab on each side of the seat and into the side of the knife, then

finger-tighten. This is necessary to attach the seat to the knife during

removal in later steps.

Valve

Size

Retaining Plate

Bolt Size

Retaining Plate

Socket Size

inches/mm

3–8"

⁄"

⁄-

inch/M16 Bo lt

¾-inch/M19 Nut

10 –12 "

¾"

1 ⁄-inch/M29 Bolt

1

⁄-inch/M29 Nut

5. REMOVE RETAINING BOLTS: Remove the four hex cap bolts and

nuts from the retaining plate, as shown above.

NOTE: Do NOT remove the packing screws. Doing so will damage the

seat.

I-795/9 06_ 26

REV_D

Page 27

I-795 / 906 / Installation-Ready™ Knife Gate Valve / Installation and Maintenance Instructions

6a. OPEN VALVE: For handwheel operated valves, operate the

handwheel in the “open” direction (counterclockwise) to draw the seat

out from the valve body.

CAUTION

• Support the seat cartridge during actuation to prevent lateral

movement. Though the valve is operable in any configuration,

angled placement may allow an unsupported seat cartridge to

slide out of the gate connector prematurely.

Failure to follow this instruction could result in personal injury or

property damage.

6b. For pneumatically or hydraulically operated valves, actuate the valve

open to draw the seat out from the valve body.

CAUTION

• Support the seat cartridge during actuation to prevent lateral

movement. Though the valve is operable in any orientation,

angled placement may allow an unsupported seat cartridge to

slide out of the gate connector prematurely.

Failure to follow this instruction could result in personal injury or

property damage.

I-795/9 06_ 27

REV_D

Page 28

I-795 / 906 / Installation-Ready™ Knife Gate Valve / Installation and Maintenance Instructions

WARNING

• Keep hands away from the edges of the knife

seat while lifting it from the valve body.

Failure to follow this instruction could result in

personal injury.

7. REMOVE CARTRIDGE: When the seat has cleared the opening of

the valve body, slide the seat cartridge out from the slot in the gate

connector, as shown above. For clearance measurements, reference the

E dimension in the table on page 11.

NOTE: When removing the seat cartridge, be prepared to suppor t

its weight with both hands. Refer to the table on page 11 for specific

weights before attempting to remove the seat cartridge. Larger sizes

may require the use of mechanical lifting equipment.

Sealing Faces

8. CLEAN VALVE: Ensure that the seat cavit y and drain plug are free

from debris by flushing the cavity with water. Wipe clean the sealing

faces with a rag or brush.

Inspect the cavity to ensure that par ticles have been removed. All

foreign matter should be cleared away before replacing the seat

cartridge.

NOTICE

• Victaulic recommends having a spare replacement seat cartridge

available to prevent maintenance delays.

I-795/9 06_ 28

REV_D

Page 29

I-795 / 906 / Installation-Ready™ Knife Gate Valve / Installation and Maintenance Instructions

INSTALLING THE REPLACEMENT SEAT

CARTRIDGE

Tab

Slot

1a. PREPARE CARTRIDGE SURFACES: Apply a thin coat of Victaulic

Lubricant or silicone lubricant to all exterior surfaces of the new seat

cartridge. NOTE: The seat contains a tab that must be installed facing

the slot in the valve body, as shown above.

1b. Add a thin coat of anti-seize compound to the top of the knife, as

shown to the right, to aid with installation and with future removal of the

cartridge.

Apply

anti-seize

compound

2. INSERT CARTRIDGE: Slide the replacement seat cartridge into the

slot in the gate connector, as shown above.

I-795/9 06_ 29

REV_D

Page 30

I-795 / 906 / Installation-Ready™ Knife Gate Valve / Installation and Maintenance Instructions

3a. CLOSE VALVE: For handwheel operated valves, operate the

handwheel slowly in the “closed” direction (clockwise) to bring the

seat toward the valve body. Ensure that the tab of the seat is facing the

slot in the valve body, as shown in step 1. To prevent damage to the

surfaces of the seat, do not attempt to operate the handwheel at an

increased rate, or by using a drill or impact gun.

3b. For pneumatically and hydraulically operated valves, actuate the

valve closed to bring the seat toward the valve body.

WARNING

• Keep hands away from the edges of the knife

seat while replacing it into the valve body.

• Keep hands away from the seat cartridge and

yoke while actuating the valve.

Failure to follow this instruction could result in

personal injury.

4. REPLACE RETAINING BOLTS: When the retaining plate is

1 inch/25 mm or less from the valve body, insert the four hex cap bolts

and flat washers through the retaining plate and into the valve body, as

shown ab ove.

5. TIGHTEN RETAINING BOLTS: Tighten the four hex cap bolts evenly

by alternating sides (as shown in the sequence above) until the lock

washers are fully compressed. There should be metal-to-metal contact

between the plate and the housing.

I-795/9 06_ 30

REV_D

Page 31

I-795 / 906 / Installation-Ready™ Knife Gate Valve / Installation and Maintenance Instructions

6. REMOVE AND RELOCATE GATE CONNECTOR SCREWS: Remove

the two hex cap screws from the knife and relocate them to the gate

connector, as shown above. Ensure that the hex cap screw is threaded

down so that the head is below the washer (page 5, item 12).

7. REPLACE PLUG: Replace the plug in the bottom of the valve body,

tightening the plug as directed in the chart below.

Valve Size

Plug Installation Torque

Lower Nut +/- 20%

3–8"

60 ft-lbs

81.3 N• m

10 –12"

100 ft-lbs

135.6 N•m

Stroke

Limiter

8. REPLACE STROKE LIMITER: Replace the stroke limiter on the stem

by reversing the procedure for removal. Do not tighten the T-bolt clamp

past 75 in-lbs.

CAUTION

• DO NOT attempt to place the valve back in service without

replacing the stroke limiter.

Failure to follow these instructions will cause damage to the valve

components. This may result in joint leakage or property damage,

and could void the product warranty.

9. INSPECT GAP: Operate the handwheel (or the pneumatic or hydraulic

operator) to raise the knife out of the valve body. Ensure that the gap on

both sides of the knife is equal, as shown above. The hex cap screws of

the packing gland can be adjusted, if necessary, to achieve an equal gap

on both sides of the knife. Refer to the "Packing Adjustment" section on

page 24 to review adjusting the hex cap screws.

I-795/9 06_ 31

REV_D

Page 32

I-795/906INSTALLATION AND MAINTENANCE INSTRUCTIONS

Series 795 and 906 Installation-Ready™ Knife Gate Valves

For complete contact information, visit victaulic.com

I-795/906 8413 REV D UPDATED 6/2017 Z000795000

VICTAULIC AND INSTALLATION-READY ARE REGISTERED TRADEMARKS OR TRADEMARKS OF VICTAULIC COMPANY AND/OR ITS AFFILIATED

ENTITIES IN THE UNITED STATES AND/OR OTHER COUNTRIES. © 2017 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

Loading...

Loading...