Page 1

Series 725S Diverter Valve

I-725SINSTALLATION AND OPERATING INSTRUCTIONS

WARNING

• Read and understand all instructions before attempting to install any Victaulic products.

• Always verify that the piping system has been completely depressurized and drained immediately prior to installation, removal, adjustment,

or maintenance of any Victaulic products.

• Wear safety glasses, hardhat, foot protection, and hearing protection.

Failure to follow these instructions could result in death or serious personal injury and property damage.

REV_B

I-725 S

Page 2

I-725S / Series 725S Diverter Valve / Installation and Operating Instructions

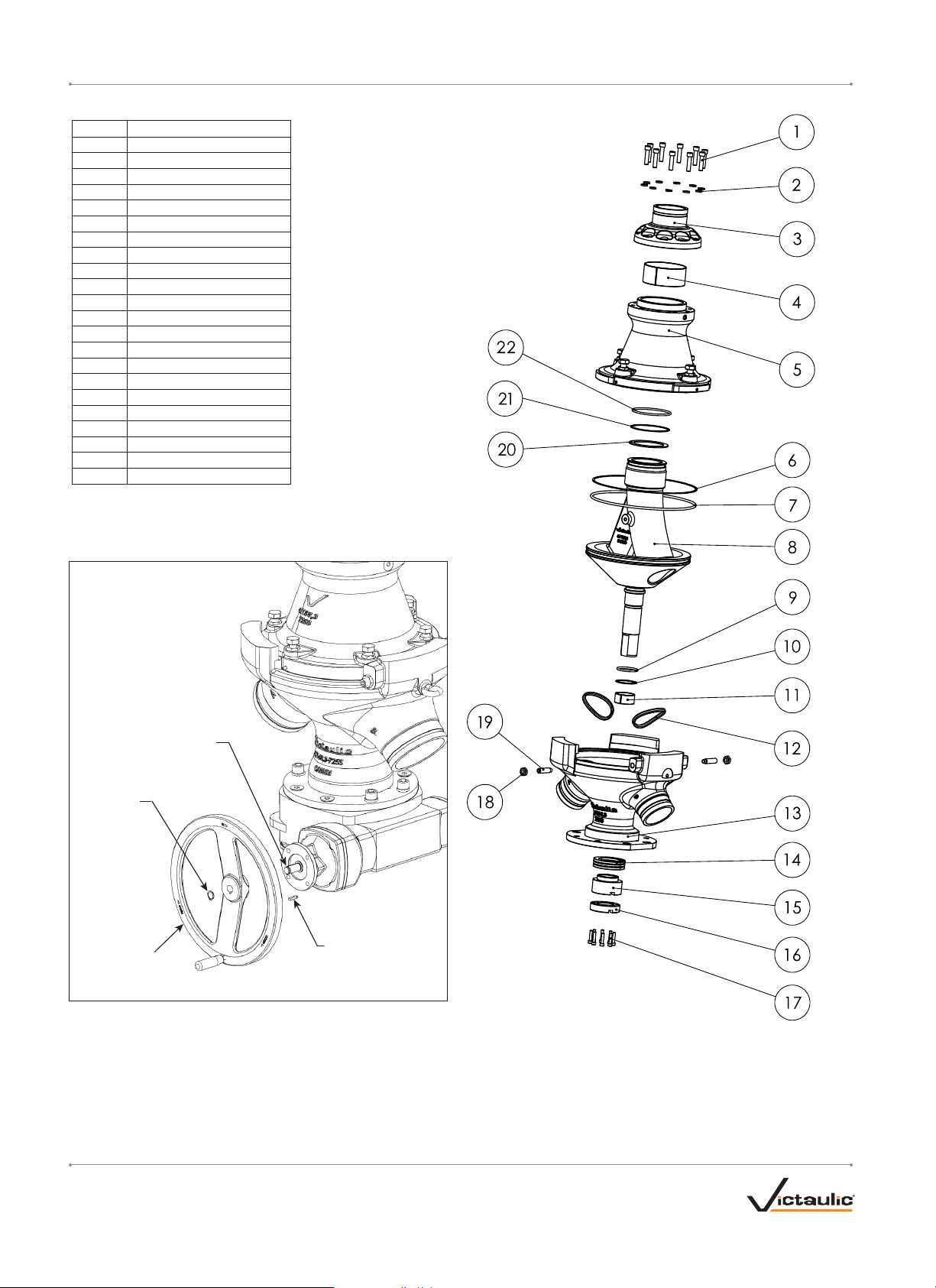

DIVERTER VALVE COMPONENTS

Item # Description

1 Hex Socket Head Cap Screw

2 Spring Lock Washer

3 Inlet Cap

4 Upper Shaft Bearing

5 Cover

6 O-Ring

7 Backup Ring

8 Plug

9 O-Ring

10 Backup Ring

11 Lower Shaft Bearing

12 Body Seal

13 Body

14 Thrust Bearing

15 Adjusting Nut

16 Counter Nut

17 Hex Socket Head Cap Screw

18 Hex Nut

19 Set Screw

20 Top S ea l

21 Backup Ring

22 O-Ring

ASSEMBLY OF THE HANDWHEEL

Gear Input Shaft

Circlip

Handwheel

Key

1. Place the key onto the gear input shaft.

2. Install the handwheel over the gear input shaft.

3. Attach circlip in front of the handwheel, onto the gear input shaft.

I-725 S_2

REV_B

Page 3

I-725S / Series 725S Diverter Valve / Installation and Operating Instructions

NOTICE

• Drawings and/or pictures in this manual may be exaggerated for clarity.

• The product, along with these installation and maintenance instructions, contains trademarks, copyrights, and/or patented features that are

the exclusive property of Victaulic.

INSTALLATION INFORMATION

Series 725S Diverter Valves are available with three different types of

Lifting

Lug

Lifting

Lug

Operator

ISO 5211

Mounting

Flange

pipe preparation, for use with three types of Victaulic products.

• Cut grooved pipe ends, for use with Victaulic EndSeal™ couplings

• Double grooved pipe ends, for use with Victaulic Style 80 8 couplings

• Pipe prepared with rings, for use with Victaulic Style 809 couplings

Series 725S Diverter Valves can be installed in horizontal or vertical

positions, or in any intermediate position that allows for access to the

actuator or gear operator.

Series 725S Diverter Valves and connecting piping must be supported

to prevent the joints from being subjected to bending loads, shear loads,

or any other external loads.

• Using both lifting lugs, support the valve to ensure balanced

loading. In addition, a cradle or cribbing can be used to provide

increased support.

• WELDING TO SERIES 725S DIVERTER VALVES AND

COUPLINGS IS NOT PERMITTED.

ACTUATOR SETUP

Always refer to the actuator manufacturer’s manual for complete setup

and operating requirements.

Actuators are designed to operate within the parameters specified in

the table below. Additional information will be required to determine

appropriate specifications for your system.

SERIES 725S HELPFUL INFORMATION

Operator/Actuator Performance

Size Manual (Gear Operator) Pneumatic Hydraulic Electric

Number of

Supply Air

Nominal

inches

DN

DN10 0 630 69 6.3 15 172 1.84

DN150 630 91 6.3 20 172 1.84

DN200 630 104 6.3 40 * 172 1.84

NOTE: For additional actuation requirements, contact Victaulic.

* for Australia only: 61 l/s

§

for Australia only: 192 RPM

†

electrical requirements vary based on voltage

Flow Position A

Flow Position B

4

6

8

to

80

80

109

Turns from

Hand Wheel

Dimensions

inches

mm

Rim Pull

lbf

N

Pressure

psi

bar

24.80 51 92 32

24.80 67 92 42

24.80 77 92 85

Flow

Rate

SFPM

l/s

RPM

109

100

90

§

Supply Fluid

Pressure

psi

bar

2500 30

2500 30

2500 30

Flow

Rate

gpm

l/s

RPM

2000 90

2000 90

2000 90

†

RPM

REV_B

I-725 S_3

Page 4

Series 725S Diverter Valve

I-725SINSTALLATION AND OPERATING INSTRUCTIONS

VALVE OPERATION

WARNING

• DO NOT actuate or operate the Series 725S Diverter Valve

with media in the system, or while the valve is pressurized. To

prevent permanent damage to internal valve components, the

system must be depressurized, flushed, and free of backfill

before attempting to index the valve.

Failure to follow these instructions may cause valve damage,

resulting in serious personal injury and property damage.

DIVERSION SERVICE

For a directional change of backfill flow to stopes, complete the

following steps.

1. Shut down backfill pump/gravity feed system.

2. Flush piping system with clean water to remove build up on pipes

and valve.

3. Once flushing is complete, rotate the diverter plug from outlet

“A” to outlet “B”. (Refer to the “Series 725S Helpful Information”

table for actuation input requirements. Also, refer to the actuation

manufacturer’s manual provided with the valve.)

Alternatively, follow the method shown in the “Flush Service”

section of these instructions.

4. At operator’s option, flush the system prior introducing backfill

to identify and clear flow path blockages as well as providing

confirmation the backfill will be transported to the desired location.

CAUTION

• The Series 725S Diverter Valve should only be used when the

diverting plug is fully aligned with either outlet port. The valve

should never be used in a partially open position, or with the

diverting plug rotated 90 degrees in an attempt to shut off flow.

Failure to follow these instructions will cause premature valve

wear and leakage, resulting in property damage and voiding any

Victaulic warranty.

5. Resume backfill operation.

FLUSH SERVICE

When using one outlet for backfill service and one outlet for flush water

dump to a sump collection area, complete the following steps.

1. Shut down backfill pump/gravity feed system.

2. Flush piping system with clean water to remove build up on pipes

and valve.

3. Operate the valve from backfill service direction to the opposing

port, allowing the flush water to enter a sump collection area.

(Refer to the “Series 725S Helpful Information” table for actuation

input requirements. Also, refer to the actuation manufacturer’s

manual provided with the valve.)

CAUTION

• The Series 725S Diverter Valve should only be used when the

diverting plug is fully aligned with either outlet port. The valve

should never be used in a partially open position, or with the

diverting plug rotated 90 degrees in an attempt to shut off flow.

Failure to follow these instructions will cause premature valve

wear and leakage, resulting in property damage and voiding any

Victaulic warranty.

4. Once flushing is complete, return valve to backfill service location

and resume backfill operation.

DUMP SERVICE

To evacuate backfill from the borehole and piping upstream of the valve

in the event of a system blockage downstream of the valve, complete

the following steps.

1. Shut down backfill pump/gravity feed system.

2. Operate the valve from the backfill service direction to the

opposing port, allowing upstream backfill to flow to a safe

disposal area. (Refer to the “Series 725S Helpful Information”

table for actuation input requirements. Also, refer to the actuation

manufacturer’s manual provided with the valve.)

3. Flush remaining backfill from the upstream borehole piping with

clean water to remove build up on pipes and valves.

To recondition the valve for service after a dump event, complete the

following steps.

4a. If rotating the diverter plug back to the backfill blockage side, only

do so when clean flush water remains in the valve. Do not attempt

to rotate the diverter back while dry. After downstream blockage

is cleared, rotate the diverter plug through several full cycles with

low pressure water inside the valve to clear any internal debris that

may have accumulated during the dump event.

CAUTION

• After using the Victaulic Series 725S Diverter Valve to dump

upstream backfill due to a downstream blockage, the diverter

plug may be rotated back to the original position only with clean

flush water remaining in the valve. Rotating the valve while dry

will result in damage to seals and excessive operating torque.

Failure to follow these instructions will cause premature valve

wear and leakage, resulting in property damage and voiding any

Victaulic warranty.

4b. If the backfill has solidified in the downstream piping, the

diverter valve must be visually inspected to verif y that there is no

solidified backfill in the outlet where the blockage occurred. This

will require removal of the coupling at the outlet port where the

blockage occurred, and may require removal of the entire valve

from the system. Any debris must be fully removed, and the valve

must be flushed with water prior to returning the valve to service.

5. Resume backfill operation only after the valve has been thoroughly

cleaned and inspected.

For complete contact information, visit victaulic.com

I-725S 11665 REV B UPDATED 05/2019 Z000725S00

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY AND/OR ITS AFFILIATED ENTITIES IN THE UNITED STATES AND/OR OTHER COUNTRIES.

© 2019 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

Loading...

Loading...