Page 1

REBUILD KIT INSTRUCTIONS

5-Year Rebuild Kit Instructions for

FireLock NXT

SERIES 768 AND 769

™

Valves

I-NXT.RBKIT

WARNING

Failure to follow instructions and warnings can cause product

failure, resulting in serious personal injury and property damage.

• Read and understand all instructions before attempting

to install, remove, adjust, or maintain any Victaulic piping

products.

• Depressurize and drain the piping system before attempting

to install, remove, adjust, or maintain any Victaulic piping

products.

• Wear safety glasses, hardhat, and foot protection.

If you need additional copies of any literature, or if you

have any questions concerning the safe use of this product,

contact Victaulic, P.O. Box 31, Easton, PA 18044-0031, USA,

Telephone: 1-800 PICK VIC, e-mail: pickvic@victaulic.com.

www.victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2010 VICTAULIC COMPANY. ALL RIGHTS RESERVED. PRINTED IN THE USA.

REV_A

WARNING

Page 2

5-Year Rebuild Kit Instructions for

FireLock NXT

SERIES 768 AND 769

™

Valves

I-NXT.RBKITREBUILD KIT INSTRUCTIONS

TABLE OF CONTENTS

Hazard Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Contents of Rebuild Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Removing the System from Service . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Instructions for Replacing Internal Components of the Valve

(Items 1 - 10 on Page 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Instructions for Replacing the Diaphragm (Item 11 on Page 1). . . . . . . 9

HAZARD IDENTIFICATION

Definitions for identifying the various hazard levels are

provided below. When you see this symbol, be alert to the

possibility of personal injury. Carefully read and fully

u nderstand the message that follows.

WARNING

• The use of the word “WARNING” identifies the presence

of hazards or unsafe practices that could result in death or

serious personal injury if instructions, including recommended

precautions, are not followed.

CAUTION

• The use of the word “CAUTION” identifies possible hazards or

unsafe practices that could result in personal injury and product

or property damage if instructions, including recommended

precautions, are not followed.

NOTICE

• The use of the word “NOTICE” identifies special instructions

that are important but not related to hazards.

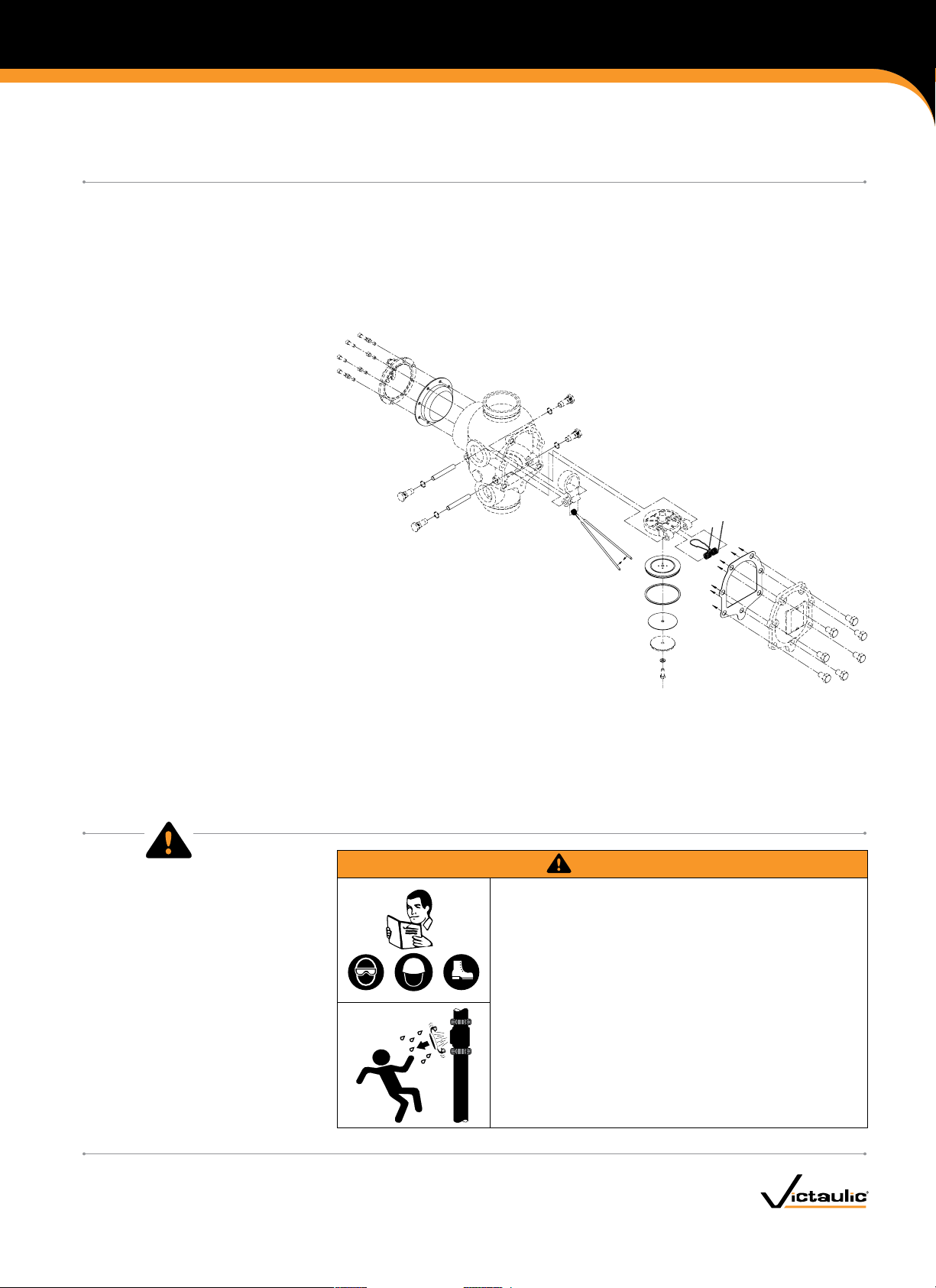

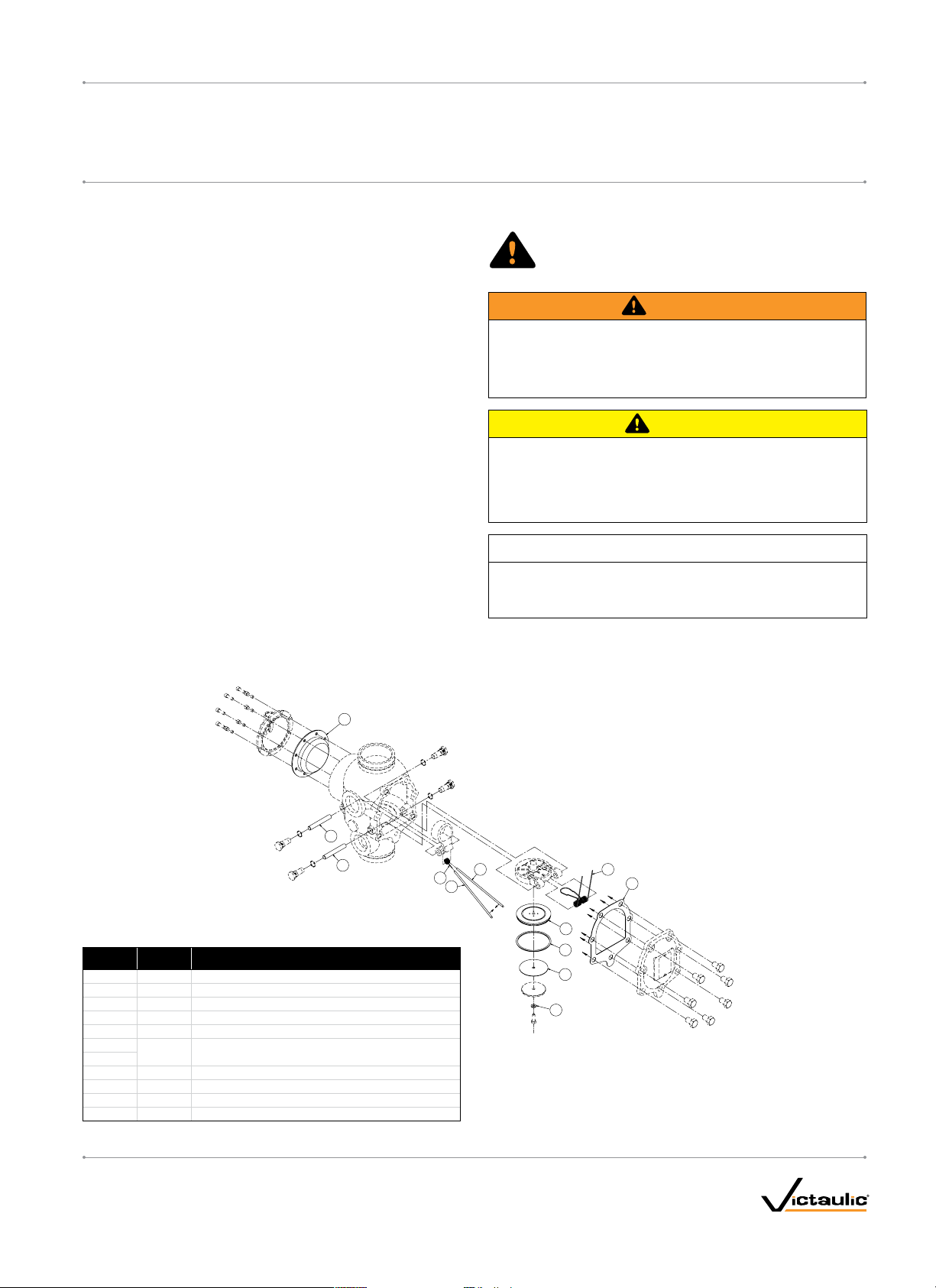

CONTENTS OF REBUILD KIT

11

6

5

Internal Components of the Valve

Item Qty. Description

1

2

3*

4

5

6

7

8

9

10

11

* Item #3 is not applicable for 1 ½ – 2-inch/48.3 – 60.3-mm valve sizes.

Clapper Seal

1

1

Seal Ring

Seal Washer

1

1

Bolt Seal

Clapper Shaft

1

Latch Shaf t

1

Clapper Spring

1

Latch Spring

1

Latch Spring Insertion Tool

2

Cover Plate Gasket

1

Diaphragm

1

9

8

9

4

7

10

1

2

3

www.victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2010 VICTAULIC COMPANY. ALL RIGHTS RESERVED. PRINTED IN THE USA.

REV_A

I-NXT.RBKIT_1

Page 3

REBUILD KIT INSTRUCTIONS

5-Year Rebuild Kit Instructions for

FireLock NXT

SERIES 768 AND 769

REMOVING THE SYSTEM FROM SERVICE

™

Valves

WARNING

• Depressurize and drain the piping system

before attempting to remove the cover plate

from the valve.

Failure to follow this instruction could result

in serious personal injury and/or property

damage.

CAUTION

• Any activities that require taking the

valve out of service may eliminate the fire

protection provided.

• Before servicing or testing the system,

notify the authority having jurisdiction.

• Consideration of a fire patrol should be

given in the affected areas.

Failure to follow these instructions could

result in serious personal injury and/or

property damage.

I-NXT.RBKIT

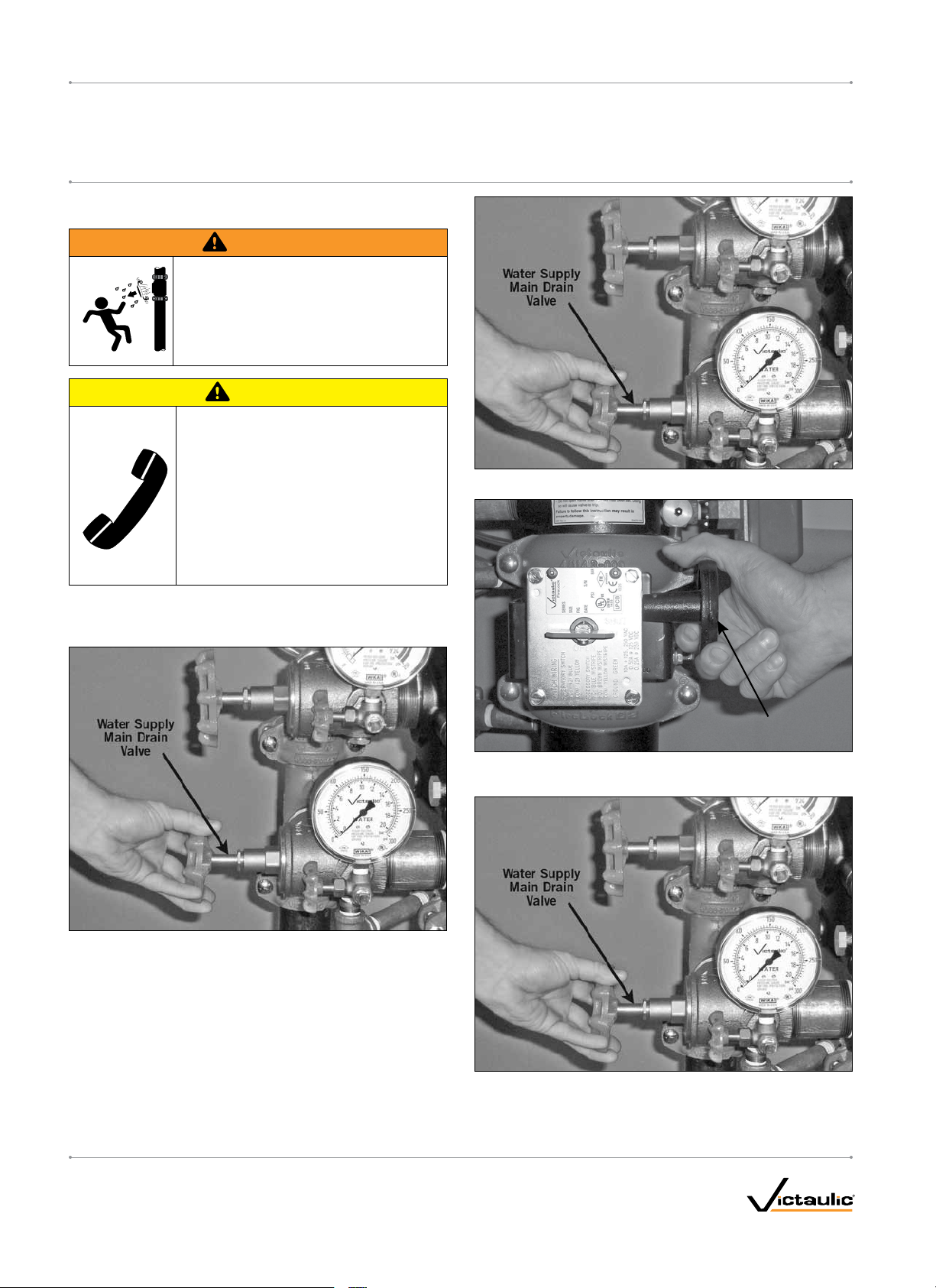

3. Close the water supply main drain valve.

1. Notify the authority having jurisdiction, remote station alarm

monitors, and those in the af fected area that the system is being

taken out of service.

2. Open the water supply main drain valve fully to flush the water

supply of any contaminants.

Water Supply Main

Control Valve

4. Close the water supply main control valve to take the system out of

service.

5. Open the water supply main drain valve.

6. Confirm that water is not flowing from the water supply main drain

valve.

www.victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2010 VICTAULIC COMPANY. ALL RIGHTS RESERVED. PRINTED IN THE USA.

I-NXT.RBKIT_2

REV_A

Page 4

5-Year Rebuild Kit Instructions for

FireLock NXT

SERIES 768 AND 769

™

Valves

I-NXT.RBKITREBUILD KIT INSTRUCTIONS

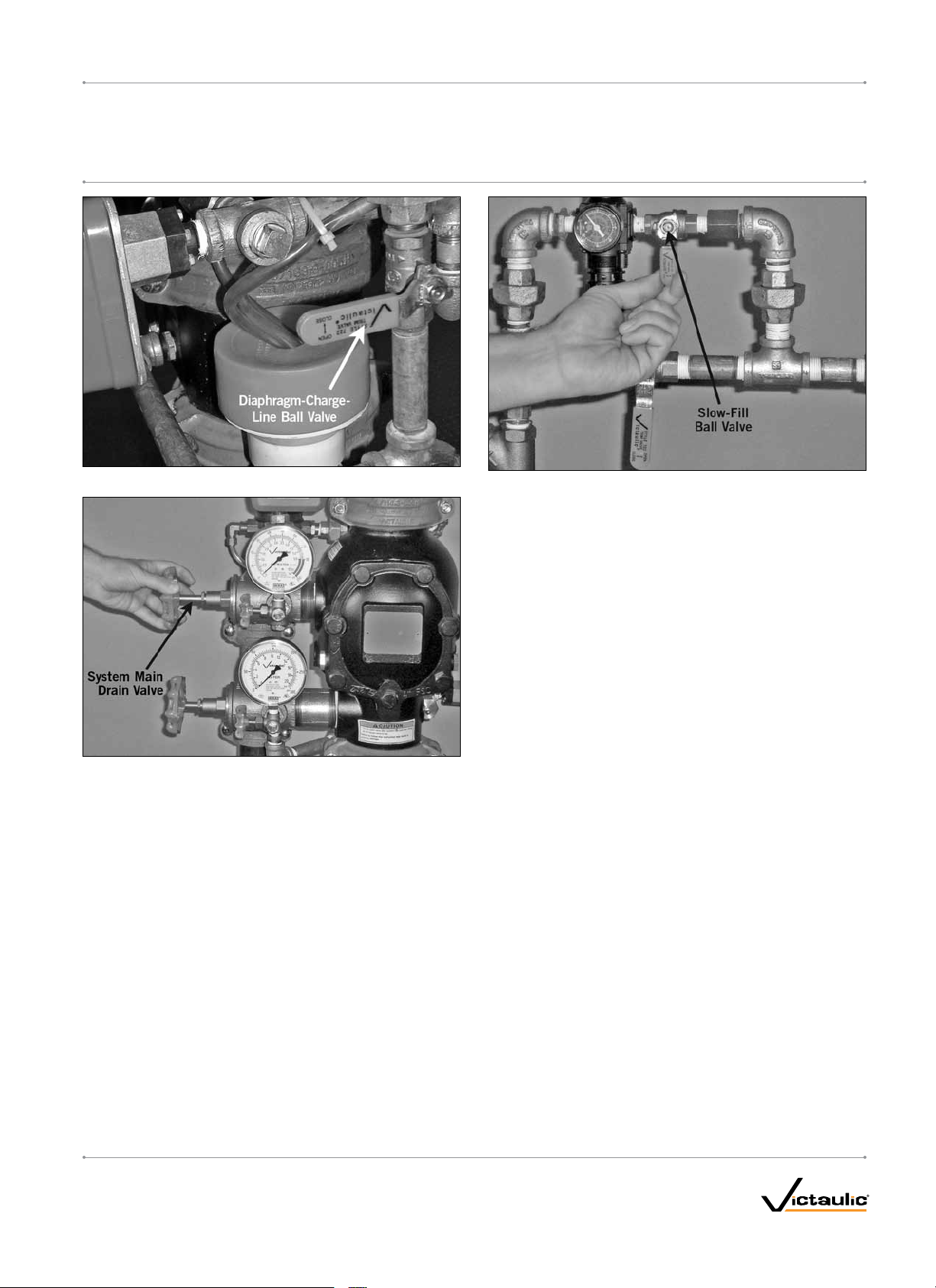

7. Close the diaphragm-charge-line ball valve.

8. Open the system main drain valve to drain any water that has

accumulated and to release system air pressure.

NOTE: If the system has operated, open the remote system test valve

(inspector’s test connection) and any auxiliary drain valves.

9. Close the slow-fill ball valve on the Air Maintenance Trim Assembly

(AMTA).

10. PUSH DOWN ON THE AUTO DRAIN SCREW TO REMOVE

PRESSURE IN THE DIAPHRAGM CHARGE LINE.

www.victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2010 VICTAULIC COMPANY. ALL RIGHTS RESERVED. PRINTED IN THE USA.

REV_A

I-NXT.RBKIT_3

Page 5

REBUILD KIT INSTRUCTIONS

5-Year Rebuild Kit Instructions for

FireLock NXT

SERIES 768 AND 769

INSTRUCTIONS FOR REPLACING INTERNAL

COMPONENTS OF THE VALVE

(ITEMS 1 - 10 ON PAGE 1)

™

Valves

WARNING

• Make sure the valve is depressurized

and drained completely before the

cover plate bolts are removed.

The cover plate could blow off if the

cover plate bolts are removed while the

valve is pressurized, resulting in serious

personal injury and/or property damage.

I-NXT.RBKIT

4. Remove the clapper shaft bushings from the valve body.

1. After all pressure is released from the system, loosen the cover

plate bolts slowly. NOTE: DO NOT remove any cover plate bolts

until all cover plate bolts are loosened.

2. Remove all cover plate bolts, along with the cover plate and

cover plate gasket. Discard the old cover plate gasket. NOTE:

The 1 ½-inch/48.3-mm and 2-inch/60.3-mm valve sizes contain

washers under the heads of the cover plate bolts. Keep these

washers for re-installation.

3. Push the latch back (toward the diaphragm).

5. Remove the clapper shaft. NOTE: As the shaft is being removed,

the clapper spring will drop out of position. Discard the clapper

spring.

6. Remove the clapper from the valve body.

www.victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2010 VICTAULIC COMPANY. ALL RIGHTS RESERVED. PRINTED IN THE USA.

I-NXT.RBKIT_4

REV_A

Page 6

5-Year Rebuild Kit Instructions for

FireLock NXT

SERIES 768 AND 769

7. Remove the latch-shaft retaining plugs from the valve body.

™

Valves

I-NXT.RBKITREBUILD KIT INSTRUCTIONS

WARNING

• DO NOT allow the latch to drop onto the valve-body seat ring.

Failure to follow this instruction will damage the valve-body seat

ring and cause improper valve operation, resulting in serious

personal injury and/or property damage.

8. Remove the latch shaft. NOTE: As the latch shaft is being

removed, the latch and latch spring will drop out of position. BE

PREPARED TO SUPPORT THE LATCH AND LATCH SPRING

DURING REMOVAL OF THE LATCH SHAFT. DO NOT ALLOW

THE LATCH TO DROP ONTO THE VALVE-BODY SEAT RING.

Discard the latch shaft and latch spring. Save the latch for

re-installation.

This Side Must

Face Toward

Outside of Valve

9. Insert the new latch shaft (supplied with the kit) through the

valve body and into the first arm of the shaft. MAKE SURE

THE RECESSED SIDE OF THE LATCH FACES TOWARD THE

OUTSIDE OF THE VALVE BODY, AS SHOWN ABOVE.

This Side Must

Face Toward

Diaphragm

WARNING

• Make sure the latch is re-installed in the correct orientation.

Failure to re-install the latch in the correct orientation could

cause improper valve operation, resulting in serious personal

injury and/or property damage.

www.victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2010 VICTAULIC COMPANY. ALL RIGHTS RESERVED. PRINTED IN THE USA.

REV_A

10. Place a spring insert tool (supplied with the kit) onto each arm of

the new latch spring (supplied with the kit). Using the spring insert

tool to close the latch spring arms together slightly, install the latch

spring onto the latch shaft, as shown above.

11. Continue to pass the latch shaft through the other arm of the latch

and valve body.

I-NXT.RBKIT_5

Page 7

REBUILD KIT INSTRUCTIONS

5-Year Rebuild Kit Instructions for

FireLock NXT

SERIES 768 AND 769

12. REMOVE THE SPRING INSERT TOOLS FROM THE ARMS OF

THE LATCH SPRING.

™

Valves

I-NXT.RBKIT

15. Insert the clapper shaft halfway into the valve body.

16. Install the clapper spring onto the clapper shaft. Make sure the

loop of the clapper spring is facing toward the clapper, as shown

above.

17. Finish inserting the clapper shaft through the clapper arm and

valve body.

13. Apply a thin coat of Victaulic lubricant or silicone lubricant to the

o-ring on each latch-shaft retaining plug. Install the latch-shaft

retaining plugs into the valve body.

13a. Tighten the latch-shaft retaining plugs until metal-to-metal contact

occurs with the valve body.

18. Apply a thin coat of Victaulic lubricant or silicone lubricant to the

o-ring on each clapper shaft bushing. Install the clapper shaft

bushings into the valve body until hand-tight.

19. Tighten the clapper shaft bushings until metal-to-metal contact

occurs with the valve body.

14. Place the new clapper assembly onto the valve-body seat ring.

Make sure the holes in the clapper arms align with the holes in the

valve body.

www.victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2010 VICTAULIC COMPANY. ALL RIGHTS RESERVED. PRINTED IN THE USA.

I-NXT.RBKIT_6

REV_A

Page 8

5-Year Rebuild Kit Instructions for

FireLock NXT

SERIES 768 AND 769

™

Valves

I-NXT.RBKITREBUILD KIT INSTRUCTIONS

20. Check the clapper for freedom of movement.

21. Rotate the clapper out of the valve body. Remove the seal

assembly bolt/bolt seal from the clapper seal, as shown above.

Save the seal assembly bolt for re-installation. Discard the bolt

seal.

23. Pry the edge of the old seal washer from inside the clapper seal.

Remove and discard the seal washer.

24. Pry the old clapper seal, along with the seal ring, out of the

clapper. Discard the clapper seal and seal ring.

25. Install the new clapper seal assembly (supplied with the kit) into

the clapper carefully. Make sure the seal ring snaps into the

22. Remove the seal-retaining ring. Save the seal-retaining ring for

re-installation.

www.victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2010 VICTAULIC COMPANY. ALL RIGHTS RESERVED. PRINTED IN THE USA.

REV_A

clapper completely.

I-NXT.RBKIT_7

Page 9

5-Year Rebuild Kit Instructions for

FireLock NXT

SERIES 768 AND 769

26. Install the new bolt seal (supplied with the kit) onto the sealassembly bolt.

™

Valves

I-NXT.RBKITREBUILD KIT INSTRUCTIONS

REQUIRED SEAL-ASSEMBLY BOLT/BOLT SEAL TORQUES

Nominal Size

inches

1 ½

2

2 ½

76.1 mm

3

4

165.1 mm

6

8

Size Torque

Actual

Outside D iameter

inches

mm

1.900 40

48.3 5

2.375 40

60.3 5

2.875 90

73.0 10

3.000 90

76.1 10

3.500 90

88.9 10

4.500 110

114.3 12

6.500 160

165.1 18

6.625 160

168.3 18

8.625 160

219.1 18

inch-lbs

N•m

27. Place the seal-retaining ring onto the seal washer of the clapper

seal. Install the seal-assembly bolt/bolt seal through the sealretaining ring and clapper.

29. Align the holes of the new cover plate gasket (provided with the

kit) with the holes in the cover plate.

28. Tighten the seal-assembly bolt/bolt seal to the torque value listed

in the table on this page to ensure a proper seal.

30. Insert one cover plate bolt through the cover plate and cover plate

gasket to ease alignment. NOTE: For 1 ½-inch/48.3-mm and

2-inch/60.3-mm valve sizes, a washer must be re-installed under

the head of each cover plate bolt.

www.victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2010 VICTAULIC COMPANY. ALL RIGHTS RESERVED. PRINTED IN THE USA.

I-NXT.RBKIT_8

REV_A

Page 10

5-Year Rebuild Kit Instructions for

FireLock NXT

SERIES 768 AND 769

™

Valves

I-NXT.RBKITREBUILD KIT INSTRUCTIONS

CAUTION

• DO NOT over-tighten the cover plate bolts.

Failure to follow this instruction could cause damage to the

cover plate gasket, resulting in valve leakage.

31. Align the cover plate/cover plate gasket to the valve. Make sure the

clapper spring’s arms are rotated to their installed position. Tighten

all cover plate bolts into the cover plate/valve body.

32. Torque all cover plate bolts in an even, crossing pattern. Refer

to the “Required Cover Plate Bolt Torques” table below for the

required torque values. DO NOT over-tighten the cover plate bolts.

INSTRUCTIONS FOR REPLACING THE

DIAPHRAGM (ITEM 11 ON PAGE 1)

WARNING

• Make sure the valve is depressurized and

drained before attempting to remove any trim

from the valve.

Failure to depressurize and drain the valve before

removing any trim from the valve could cause

serious personal injury and/or property damage.

If the system is in service, follow the “Removing the System from

Service” section.

1. Break the unions that connect the trim to the diaphragm cover.

Refer to the applicable trim drawing for details.

Required Cover Plate Bolt Torques

Size Torque

Nominal Size

inches

1 ½

2

2 ½

76.1 mm

3

4

165.1 mm

6

8

Outside D iameter

Actual

inches

mm

1.900 30

48.3 41

2.375 30

60.3 41

2.875 60

73.0 81

3.000 60

76.1 81

3.500 60

88.9 81

4.500 100

114.3 136

6.500 115

165.1 156

6.625 115

168.3 156

8.625 100

219.1 136

ft-lbs

N•m

2. Remove the cap screws from the diaphragm cover, and pull the

diaphragm cover/trim off the valve.

3. Remove the old diaphragm from the valve body. Discard the

diaphragm.

www.victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2010 VICTAULIC COMPANY. ALL RIGHTS RESERVED. PRINTED IN THE USA.

REV_A

I-NXT.RBKIT_9

Page 11

5-Year Rebuild Kit Instructions for

FireLock NXT

SERIES 768 AND 769

4. Clean the back of the valve body to remove any debris that may

interfere with proper diaphragm seating.

™

Valves

I-NXT.RBKITREBUILD KIT INSTRUCTIONS

5. Install the new diaphragm (provided with the kit) by aligning the

holes in the diaphragm with the holes in the valve body. Be careful

not to damage the diaphragm during installation.

4a. Clean the inside of the diaphragm cover to remove any foreign

material.

6. Align the holes of the diaphragm cover with the holes in the

CAUTION

• Use caution when installing a new diaphragm into the valve

body.

Failure to follow this instruction could cause damage to the

diaphragm, resulting in improper valve operation and valve

leakage.

For complete contact information, visit w ww.victaulic.com

I-NXT.RBKIT 6071 REV A UPDATED 03/2010 ZNXT5RBKIT

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2010 VICTAULIC COMPANY. ALL RIGHTS RESERVED. PRINTED IN THE USA.

I-NXT.RBKIT

diaphragm/valve body. Tighten all cap screws into the diaphragm

cover/valve body.

7. Re-attach the trim at the unions that were loosened in step 1.

Refer to the applicable trim drawing for details. MAKE SURE

ALL UNIONS THAT WERE LOOSENED TO PERMIT ACCESS

TO THE DIAPHRAGM COVER ARE RE-TIGHTENED BEFORE

ATTEMPTING TO PLACE THE SYSTEM BACK IN SERVICE.

8. Place the system back in service by following the “Placing

the System in Service” section in the applicable installation,

maintenance, and testing manual for the valve.

Loading...

Loading...