Vicruns VD120-2S-2.2GB, VD120-2T-1.5GB, VD120-2T-0.4GB, VD120-2T-0.7GB, VD120-2T-2.2GB Series Manual

...

Preface

Thank you for purchasing VD120 Series Inverters!

Unpacking and Inspection:

Every inverter has been inspected rigorously before shipping.

Please confirm carefully when unpacking the packing carton:

● Check if any damage signs of the product and its package.

● Check if the model and inverter rated values on the nameplate are the same as stated on your order

and user manual.

● The box contains the inverter, manufacturer certificate, user manual.

If the product is damaged during transportation, or there is any omission or damage, please contact

our company or your local supplier immediately.

Contents

Chapter 1 Safety and Precautions ............ ............ ............ ............ .... - 1 -

1.1 Safety Precautions...... ............ ............ ...................... .......... - 1 -

Chapter 2 Product Information .. ...................... ............ ............ ....... - 3 -

2.1 Designation Rules ...... ............ ............ ...................... .......... - 3 -

2.2 Nameplate...... ............ ...................... ............ ............ ..... - 3 -

2.3 Inverter Series ............ ............ ............ ............ ................. - 3 -

2.4 Product Appearances and Installation Dimension .................... ............ .... - 4 -

2.5 Recommended Brake Resistor Selection Table ........ ............ ............ ...... - 7 -

2.6 Warranty Introduction.............. ...................... ............ ............ - 7 -

Chapter 3 Mechanical and Electrical Installation ........ ............ .................... - 8 -

3.1 Standard Wiring Diagram .. ............ ............ ...................... ........ - 8 -

3.2 Main Circuit Terminals ...................... .................................. ... - 8 -

3.3 Control Circuit Terminal .... ............ ............ ...................... ........ - 9 -

Chapter 4 Operation and Display .................... ............ ............ ........ - 12 -

4.1 Introduction to Operation and Display Interface...... ............ ............ ....... - 12 -

Chapter 5 Function Parameter Table ................ ...................... ........... - 14 -

Chapter 6 Parameter Description .... ............ ...................... ............ .. - 64 -

F0 Basic Function.. ............ ............ ............ ............ ............... - 64 -

F1 Start/Stop Control Group .... ............ ............ ............ ................ - 71 -

F2 Motor 1 Parameter ...... ............ ............ .......... ............ ......... - 77 -

F3 Motor 1 Vector Control Parameter ........ ............ ............ ............ .... - 79 -

F4 Motor 1 V/F Control Parameter .............. ............ ............ ............ . - 82 -

F5 Input Terminal Group ............ ............ ............ .......................- 86 -

F6 Output Terminal Function Group............ ............ ...................... .... - 98 -

F7 Keyboard and Display Function Group ............ ............ ............ ....... - 103 -

F8 Protection Parameters ............................ ............ ............ ..... - 107 -

F9 Fault Record and Setting Parameter Group .. ............ ...................... ... - 110 -

FA Process PID Parameter Group .......................... ............ ............ - 114 -

Fb Enhance Function Group.. ...................... ............ ............ ....... - 118 -

Fd MODBUS Communication Parameter Group ........ ...................... ........ - 132 -

FF User Parameters Group.................... ............ ............ ............ - 133 -

FP Factory Parameter Group .. ............ ............ ...................... ...... - 135 -

A0 Motor 1 Torque Control Parameter Group...................... ............ ....... - 135 -

AI Optimize Control Parameter Group .................. ............ ............ ..... - 138 -

b0 User Customize Function Code............ ............ ............ ............ .. - 141 -

b1 Virtual IO Parameter Group ...................... ............ ............ ....... - 142 -

b2 AI Curve Setting Parameter Group .............................. ............ ..... - 146 -

b3 AIAO Correction Parameter Group .............................. ............ ..... - 148 -

U0 Basic Monitoring Parameters Group .................. ............ ............ ... - 149 -

Chapter 7 EMC Guide ........................ ............ ............ ............ - 151 -

7.1 Definition ................................ ............ ............ ............ - 151 -

7.2 EMC Standard Introduction ........ ............ ............ ............ ......... - 151 -

7.3 EMC Guide .............................. ............ ............ ............ - 151 -

Chapter 8 Fault Shooting and Solutions .................. ............ ............ ... - 153 -

8.1 Fault Alarm and Countermeasures .................. ............ ............ .... - 153 -

8.2 Common Faults and Solutions .................... ............ .................. - 157 -

Chapter 9 Communication Protocol .................. ............ ............ ....... - 158 -

9.1 About Protocol .......... ............ ............ ............ ............ ..... - 158 -

9.2 Application Methods........ ...................... ............ ............ ..... - 158 -

9.3 Bus Structure ........ ............ ............ ............ .................... - 158 -

9.4 Protocol Description............ ............ ............ ...................... . - 158 -

9.5 Communication Frame Structure ........................ ............ ............ - 158 -

9.6 Command Code and Communication Data Description ................ ............. - 159 -

Fd MODBUS Communication .................................. ............ ........ - 167 -

VD120 Series Inverter User Manual

Safety and Precautions

Chapter 1 Safety and Precautions

1.1 Safety Precautions

1.1.1 At Wiring

● Wiring must be performed only by qualified personnel under instructions described in this

manual. Failure to comply may result in unexpected accidents.

● A circuit breaker must be used to isolate the power supply and inverter. Failure to comply may

result in a fire.

● Ensure that the power supply is cut off before wiring. Failure to comply may result in electric

shock.

● Connect inverter to ground properly by standard. Failure to comply may result in electric shock.

● Do not connect the input power with output terminals U, V, W, confirm the mark on terminal

before connection to avoid wrong wiring. Failure to comply can damage the inverter!

● Never connect the braking resistor between the DC bus terminals P+ and P-. Failure to comply

may result in a fire.

● The wire size of main circuit should conformed to standard, the wiring should comply with EMC

and local safety standard. Failure to comply may result in accidents.

● Use shielded cable for input output control circuit of analog and rapid speed pulse signal, and

ensure the shielding layer is reliably grounded.

1.1.2 Before Power-on:

● Check that the following requirements are met:

● The voltage class of the power supply is consistent with the rated voltage class of the AC drive.

● The input terminals (R, S, T) and output terminals (U, V, W) are properly connected.

● No short-circuit exists in the peripheral circuit.

● The wiring is secured.

● The external units of inverter and wires are configured under the manual instructed, all matched

circuit and wiring are correctly connected.

● Failure to comply will result in damage to inverter!

1.1.3 After Power-on

● Do not open the cover after inverter power-on to prevent electric shock.

● Do not touch or operate the inverter with wet hands. Failure to comply will result in electric shock.

● Do not touch any terminal of inverter after power-on, or drag connection cable. Failure to comply

will result in equipment damage or electric shock.

● Do not try to check or change the manufacturer parameter. Failure to comply may result in

malfunction or damage to inverter!

● Make sure the mechanical equipment is ready to start before inverter run with loading, make sure

related staff is in safety zone. Failure to comply will result in damage or personal hurt!

● Please pay attention to hiding accident which may result in personal hurt or property damage

while motor is run, if it is necessary to identify the motor parameter.

- 1 -

Safety and Precautions VD120 Series Inverter User Manual

1.1.4 During Operation

● Do not touch the cooling fan or braking resistor etc, otherwise may cause personal injury!

● Do not do inspection while inverter run, except for professional technician, otherwise may cause

inverter damaged or personal injury.

● Do not move inverter or the installed cabinet while it is run, keep external objects falling into the

device. Failure to comply will result in damage.

● Start/Stop inverter via terminal function or other control method, try not to start inverter via directly

power-on control method. Do not use contactor on inverter output terminal to control motor starting

or stop.

1.1.5 During Maintenance

● Do not repair and maintain the equipment if power is connected. Otherwise there will be danger

of electric shock!

● If the LED is still on light on control panel, it is Disabled to disassemble the body in order to avoid

electric shock.

● The inverter shall be repaired and maintained only by the qualified person who has received

professional training. Otherwise, it may cause personal injury or equipment damage.

● For all the standard equipped or optional accessories, must be dismounted or mounted while the

inverter power is disconnected.

- 2 -

VD120 Series Inverter User Manual Product Information

KW)

Chapter 2 Product Information

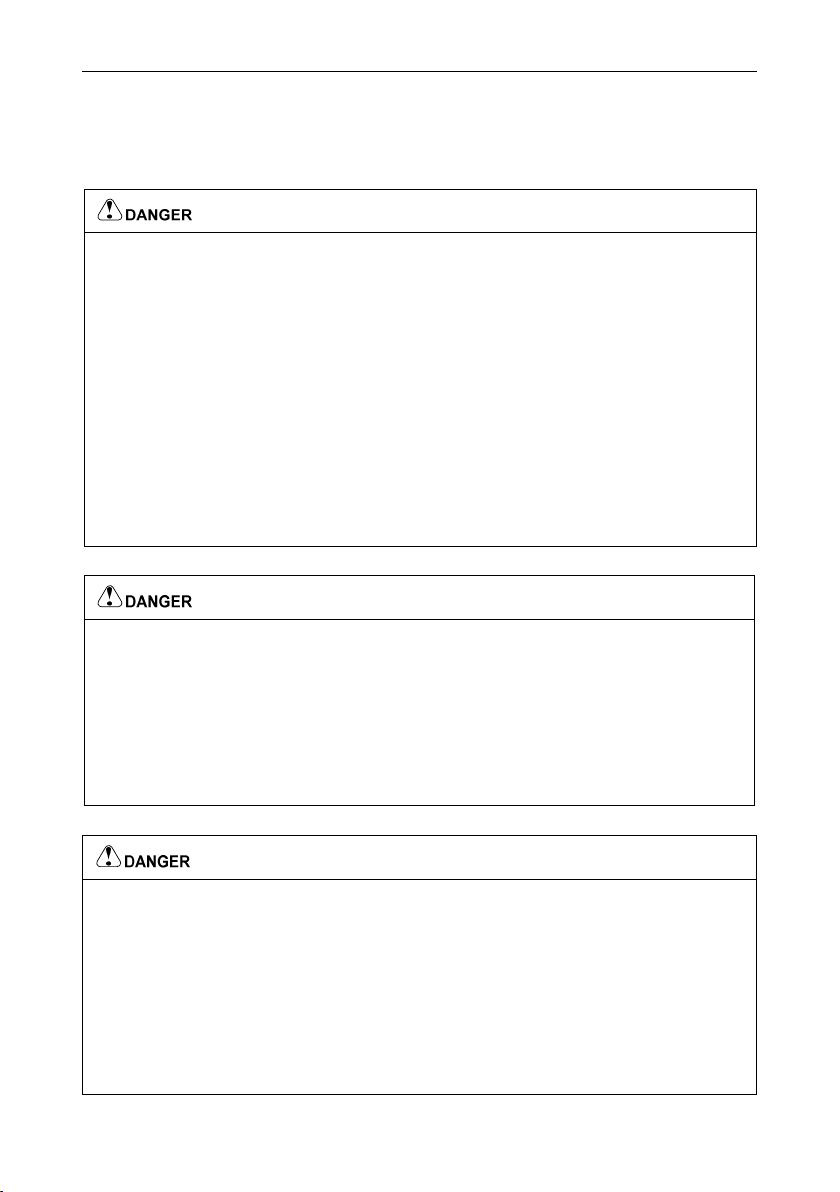

2.1 Designation Rules

Fig 2.1-1 Designation Rules

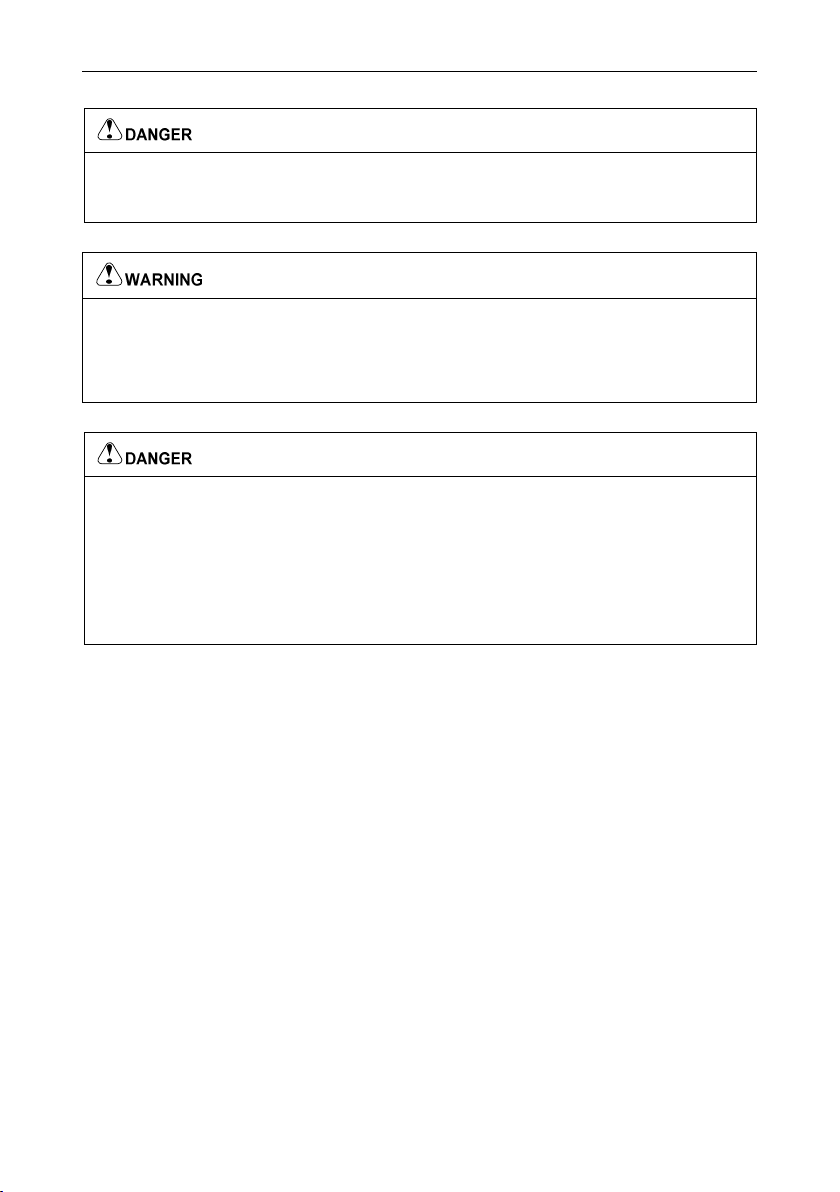

2.2 Nameplate

Fig 2.2-1 Namepate

● The bar code on inverter nameplate is the only code to recognize its identity, so the bar code is

the most important basis for the after sales service.

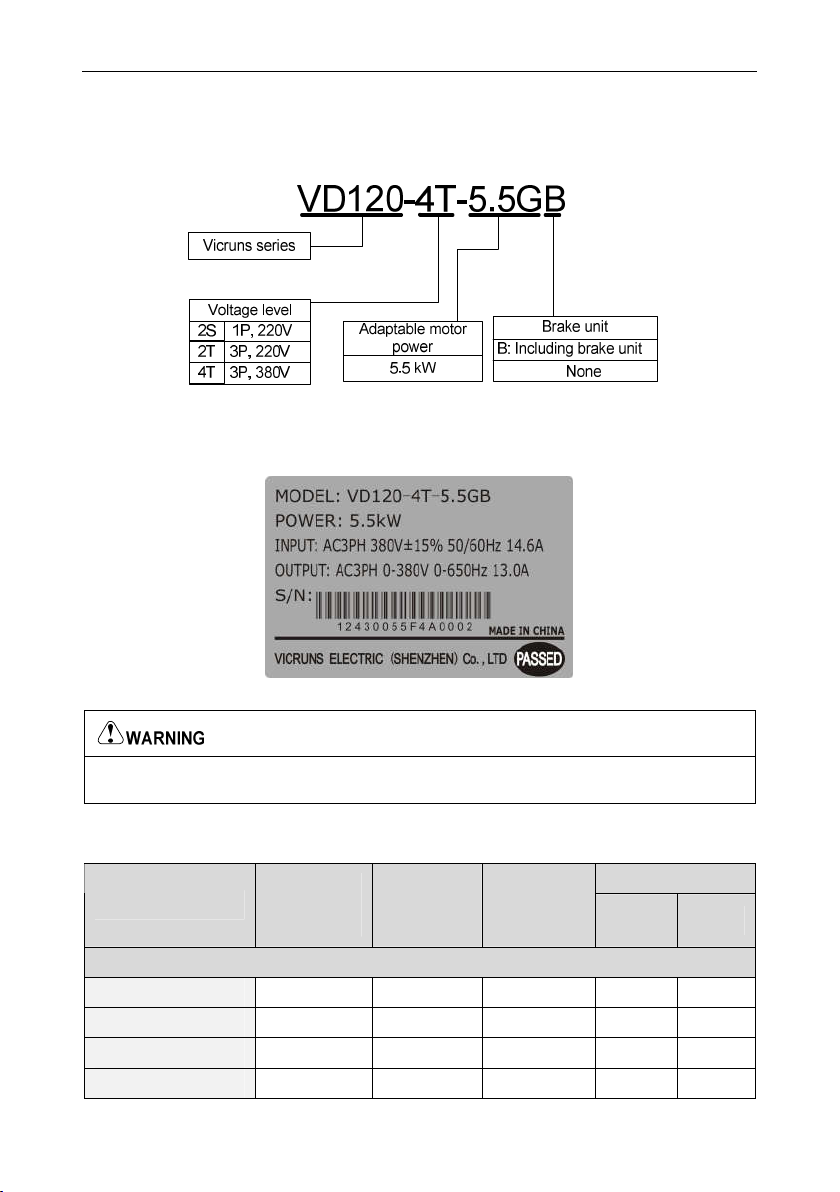

2.3 Inverter Series

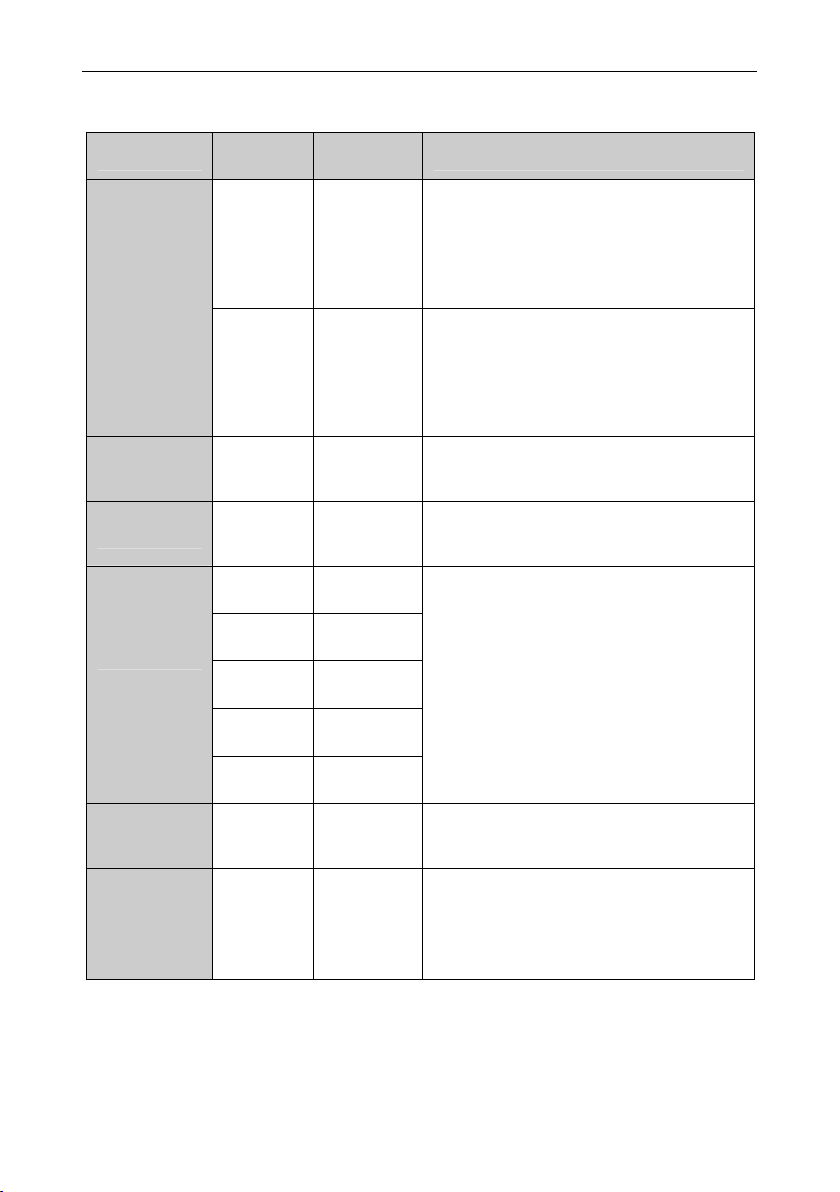

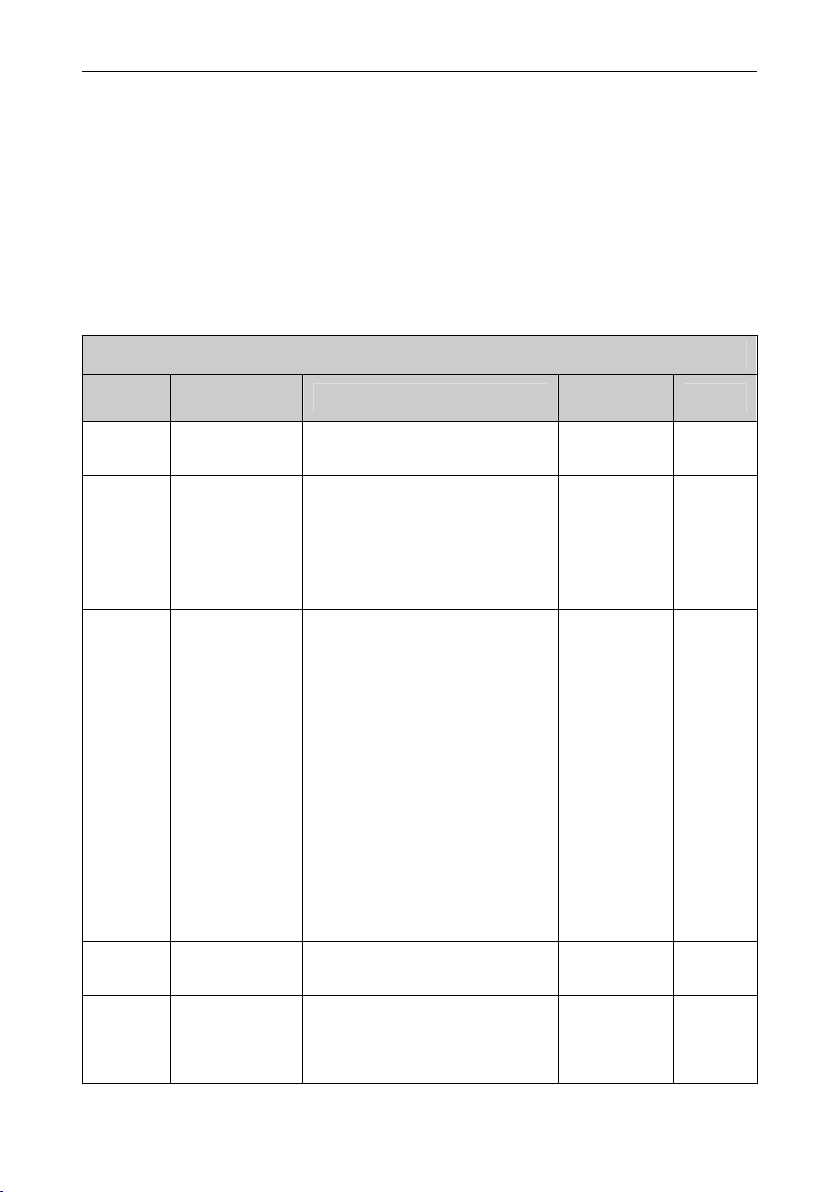

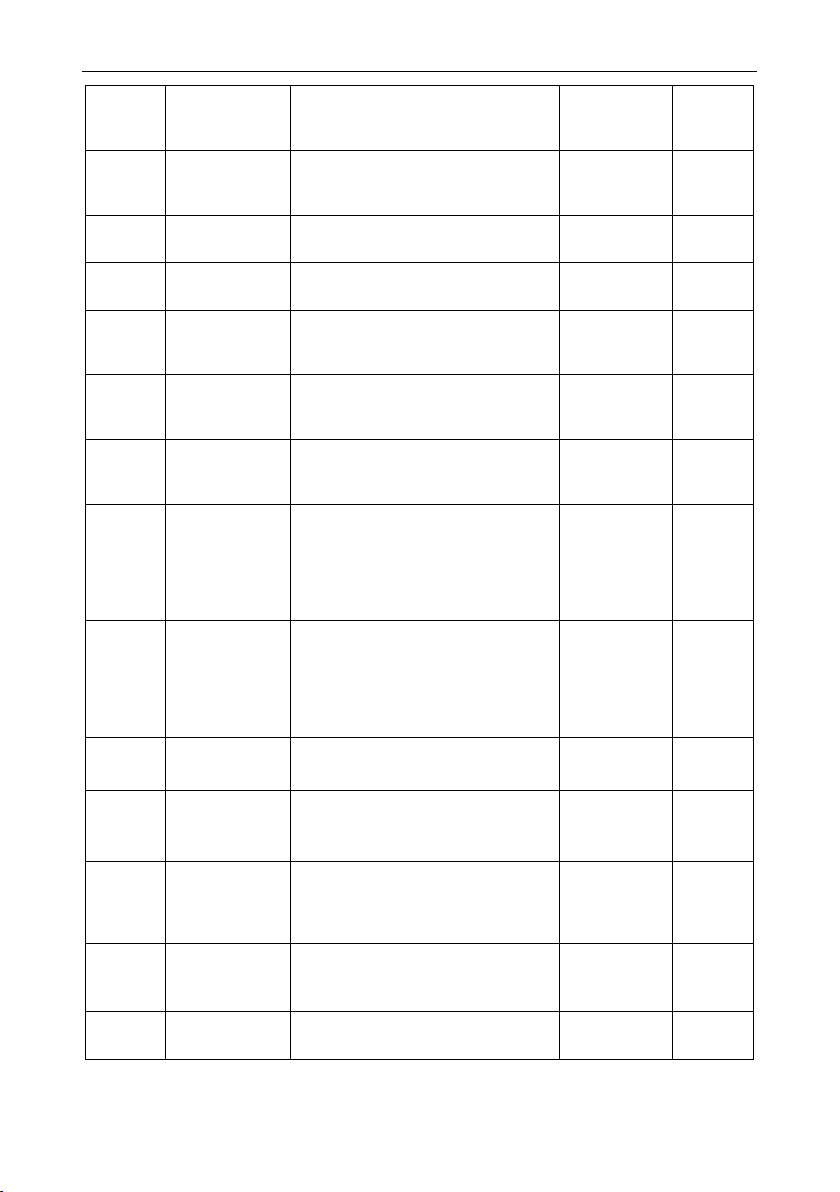

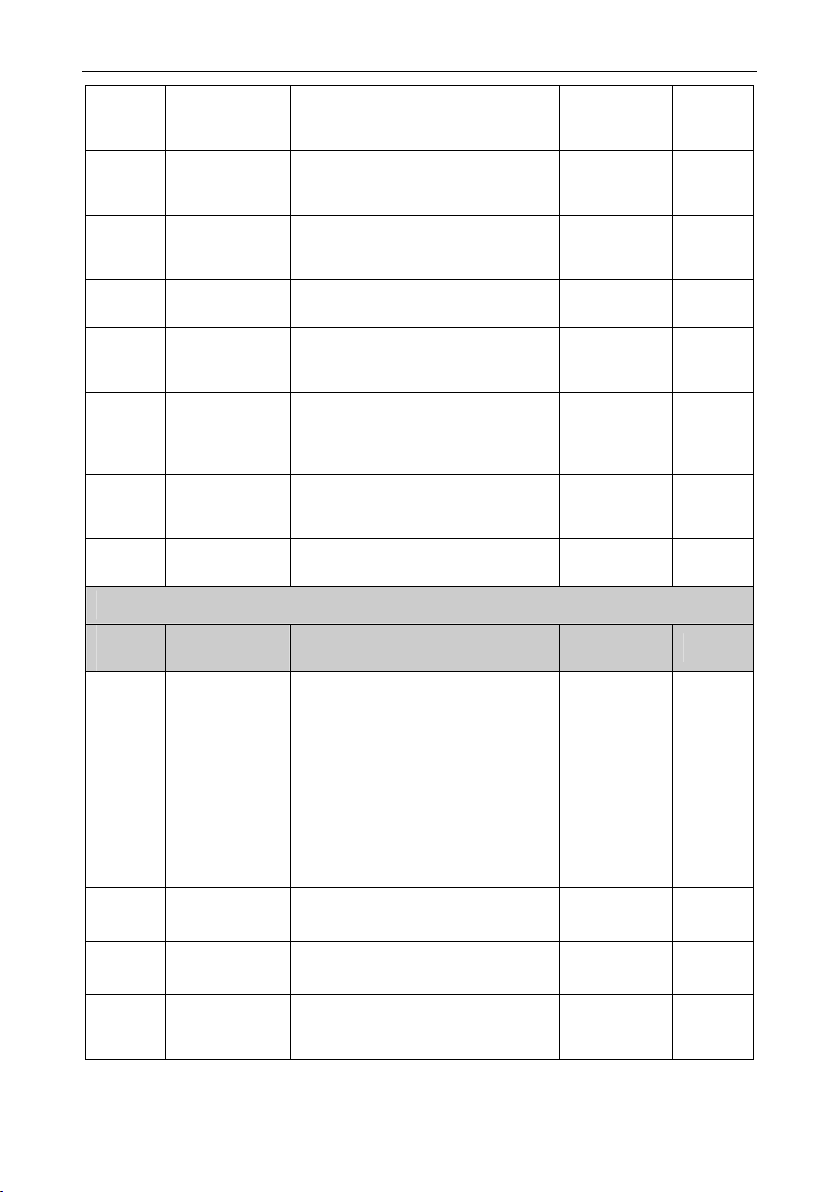

Table 2-1 Product specifications and technical data

Model No.

Single-phase power supply: 220V,50/60Hz Range:-15%~20%

VD120-2S-0.4GB 1.0 5.4 2.3 0.4 0.5

VD120-2S-0.7GB 2.0 9.8 4.8 0.7 1

VD120-2S-1.5GB 3.0 14.0 7.0 1.5 2

VD120-2S-2.2GB 4.0 23.0 9.6 2.2 3

Power

Capacity

(KVA)

Rated Input

Current

(A)

Rated Output

Current

(A)

Adaptable Motor

(

(HP)

- 3 -

Product Information VD120 Series Inverter User Manual

KW)

A

B

Model No.

Three-phase power supply: 220V,50/60Hz Range: -15%~20%

VD120-2T-0.4GB 1.5 4.0 2.3 0.4 0.5

VD120-2T-0.7GB 3.0 6.0 4.8 0.8 1

VD120-2T-1.5GB 4.0 5.8 7.0 1.5 2

VD120-2T-2.2GB 5.9 10.5 9.6 2.2 3

VD120-2T-4.0GB 8.9 14.6 13.0 3.7 5

Three-phase power supply: 380V,50/60Hz Range: -15%~20%

VD120-4T-0.4GB 1.0 1.9 1.5 0.4 0.5

VD120-4T-0.7GB 1.5 4.0 2.5 0.8 1

VD120-4T-1.1GB 2.0 4.5 3.3 1.1 1.4

VD120-4T-1.5GB 3.0 5.0 3.8 1.5 2

VD120-4T-2.2GB 4.0 5.8 5.1 2.2 3

VD120-4T-3.0GB 5.5 9.2 8.0 3.0 4

VD120-4T-4.0GB 6.5 11.0 9.6 4.0 5.5

VD120-4T-5.5GB 8.9 14.6 13.0 5.5 7.5

VD120-4T-7.5GB 11.0 20.5 17.0 7.5 10

Power

Capacity

(KVA)

Rated Input

Current

(A)

Rated Output

Current

(A)

Adaptable Motor

(

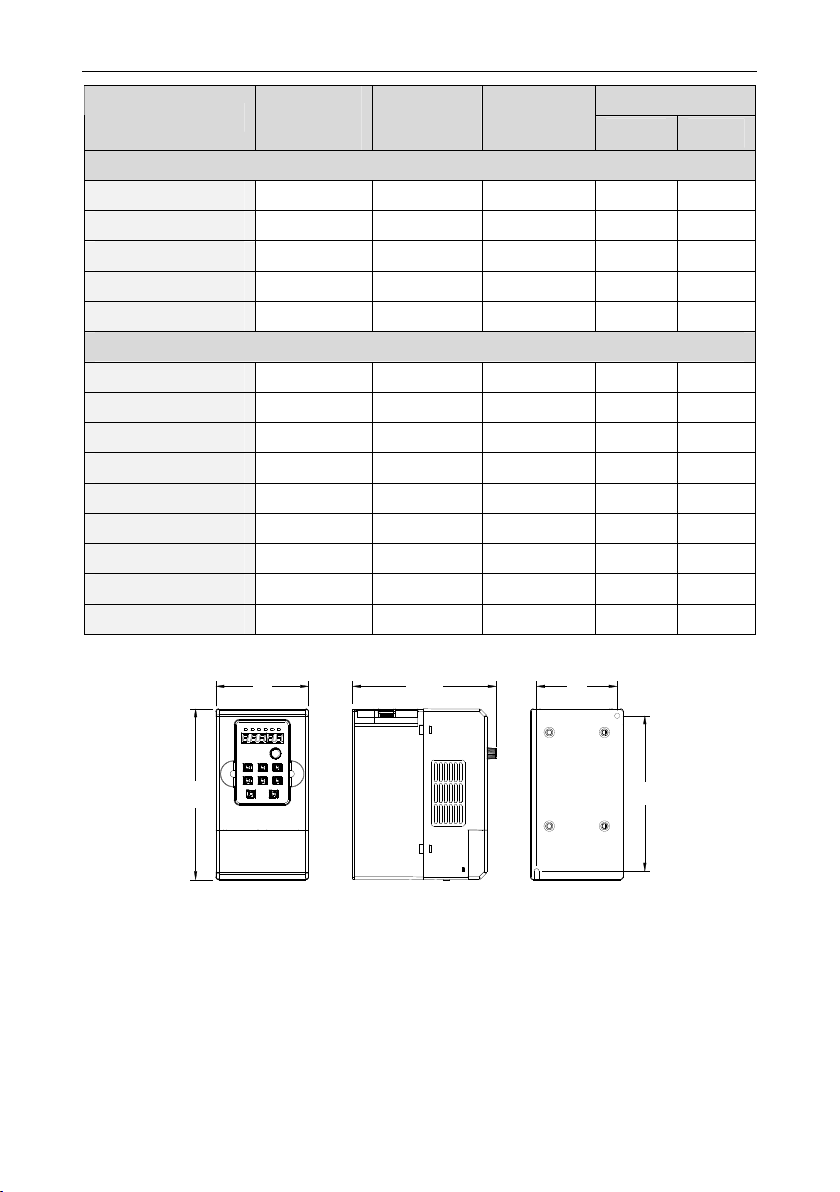

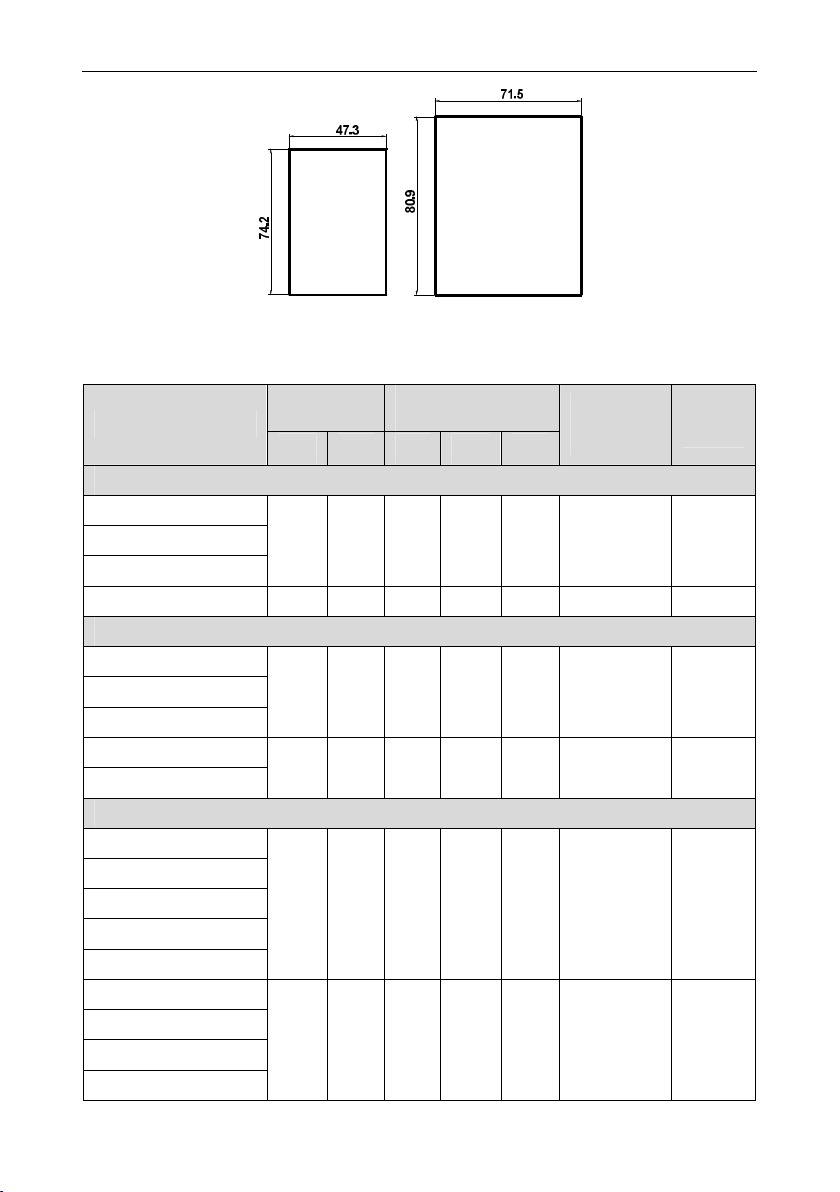

2.4 Product Appearances and Installation Dimension

W D

(HP)

H

Adaptive mode (wall mounting type, three phase 380V: 0.4kW-2.2kW /Single phase, three phase

220V: 0.4kW-1.5kW)

- 4 -

VD120 Series Inverter User Manual Product Information

W

A

B

H

D

Adaptive mode(wall mounting type, three phase 380V: 3kW-7.5kW/three phase 220V:

2.2kW~4.0kW/single phase 220V:2.2kW)

Fig 2.4-1 Schematic diagram of product appearance and installation dimensions

74

76.4

17.4 20.6

Schematic diagram of keyboard size

Schematic diagram of tray size

Fig 2.4-2 External lead keyboard and tray size (mm)

- 5 -

Product Information VD120 Series Inverter User Manual

Keyboard mounting hole size Keyboard mounting hole size

when without external lead when without external lead

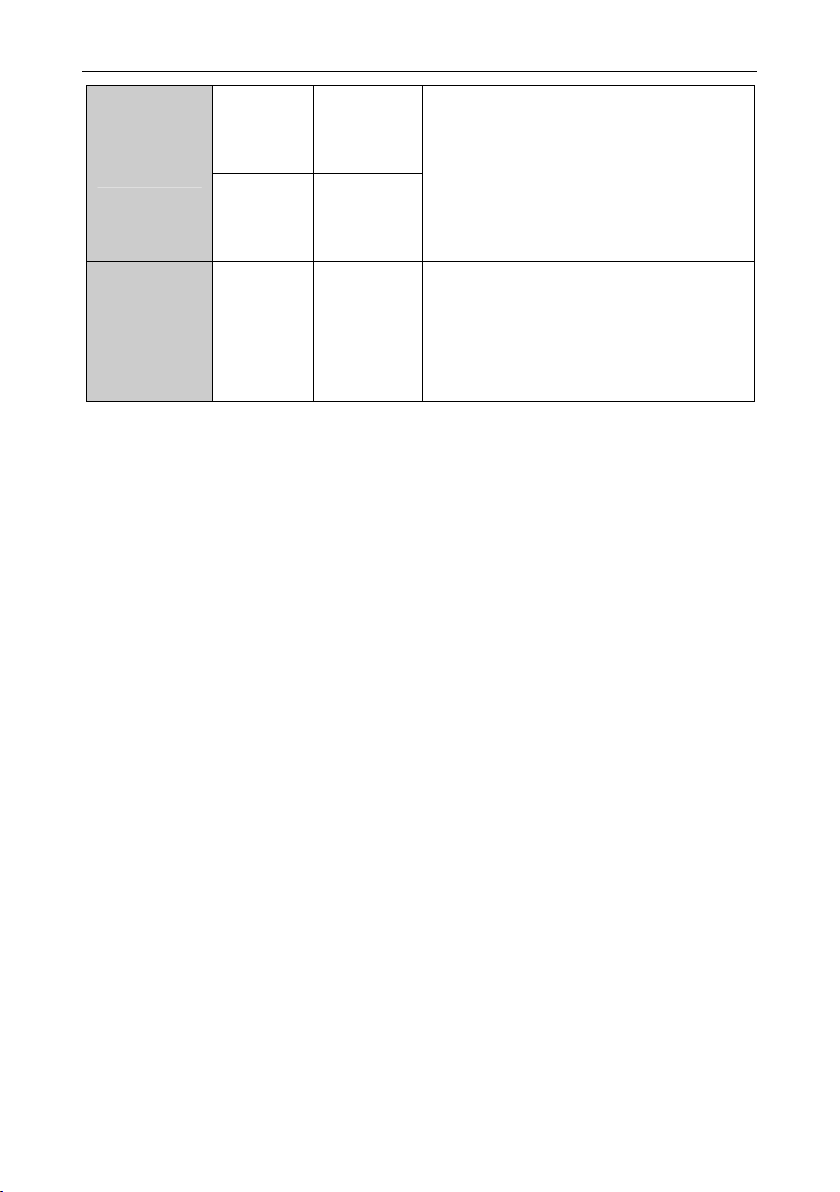

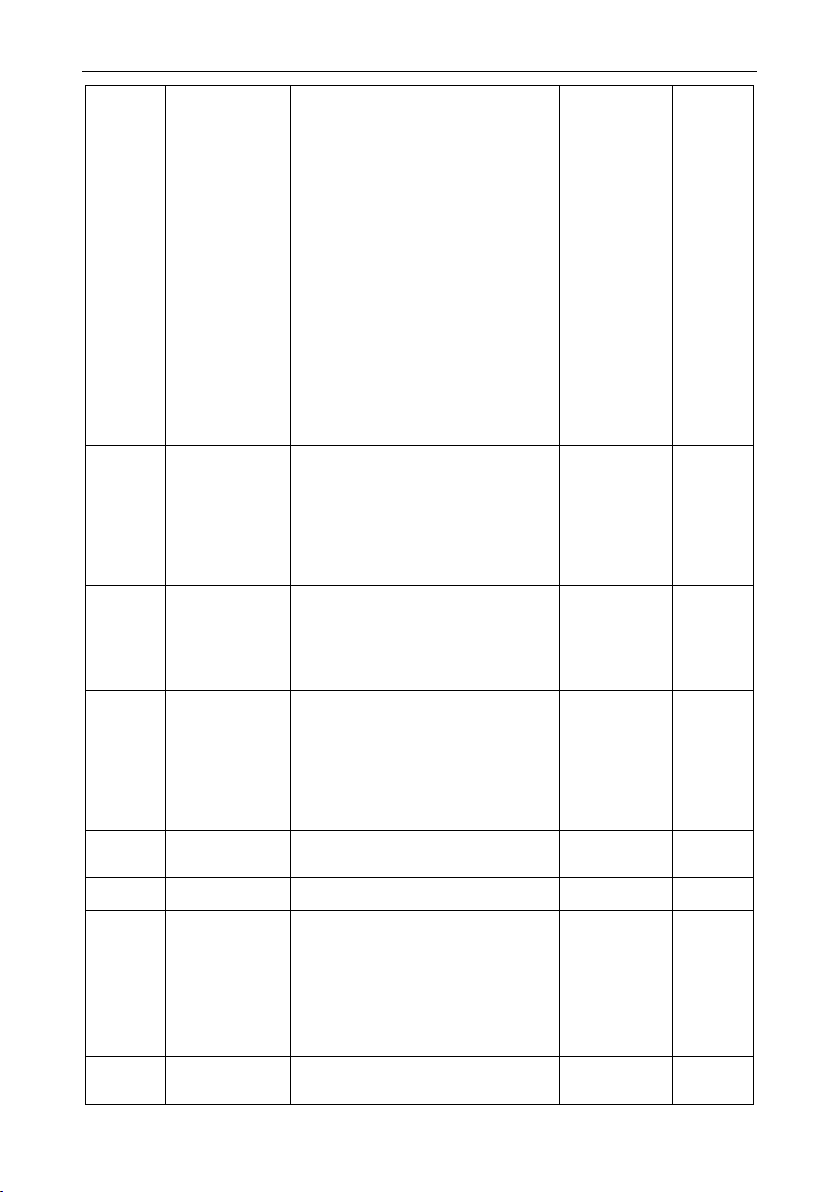

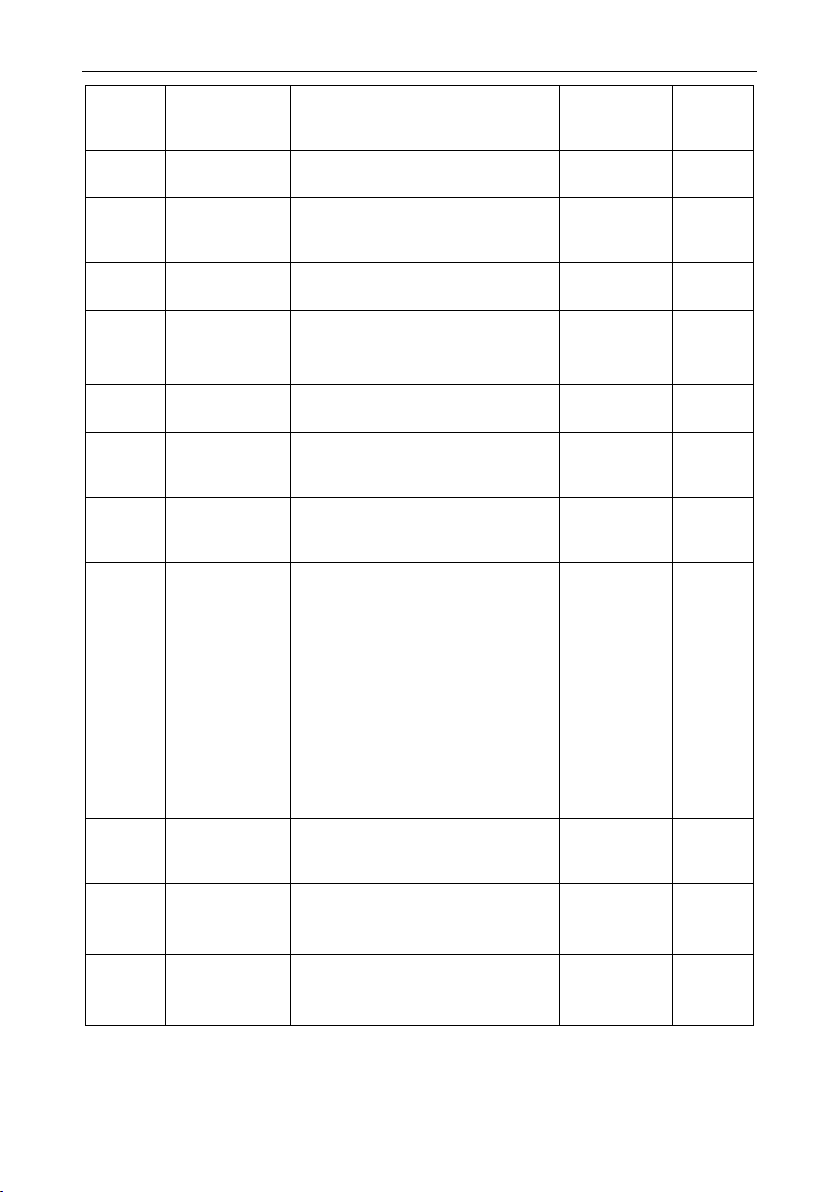

Table 2-2 Physical Dimensions and Installation Hole(mm)

Mounting

Model

Single phase: 220V, 50/60Hz Range: -15%~20%

VD120-2S-0.4GB

VD120-2S-0.7GB

VD120-2S-1.5GB

VD120-2S-2.2GB 107.6 201 215 120 146

Three phase: 220V, 50/60Hz Range: -15%~20%

VD120-2T-0.4GB

VD120-2T-0.7GB

VD120-2T-1.5GB

VD120-2T-2.2GB

VD120-2T-4.0GB

Three phase: 380V, 50/60Hz Range:-15%~20%

VD120-4T-0.4GB

VD120-4T-0.7GB

VD120-4T-1.1GB

VD120-4T-1.5GB

VD120-4T-2.2GB

VD120-4T-3.0GB

VD120-4T-4.0GB

VD120-4T-5.5GB

VD120-4T-7.5GB

Hole (mm)

A B H W D

73 141 155 84 130

73 141 155 84 130

107.6 201 215 120 146

73 141 155 84 130

107.6 201 215 120 146

Physical Dimensions

(mm)

Dieameter of

Mounting

Hole (mm)

Weight

(kg)

4.5 1.4

4.5 2.4

4.5 1.4

4.5 2.4

4.5 1.4

4.5 2.4

- 6 -

VD120 Series Inverter User Manual Product Information

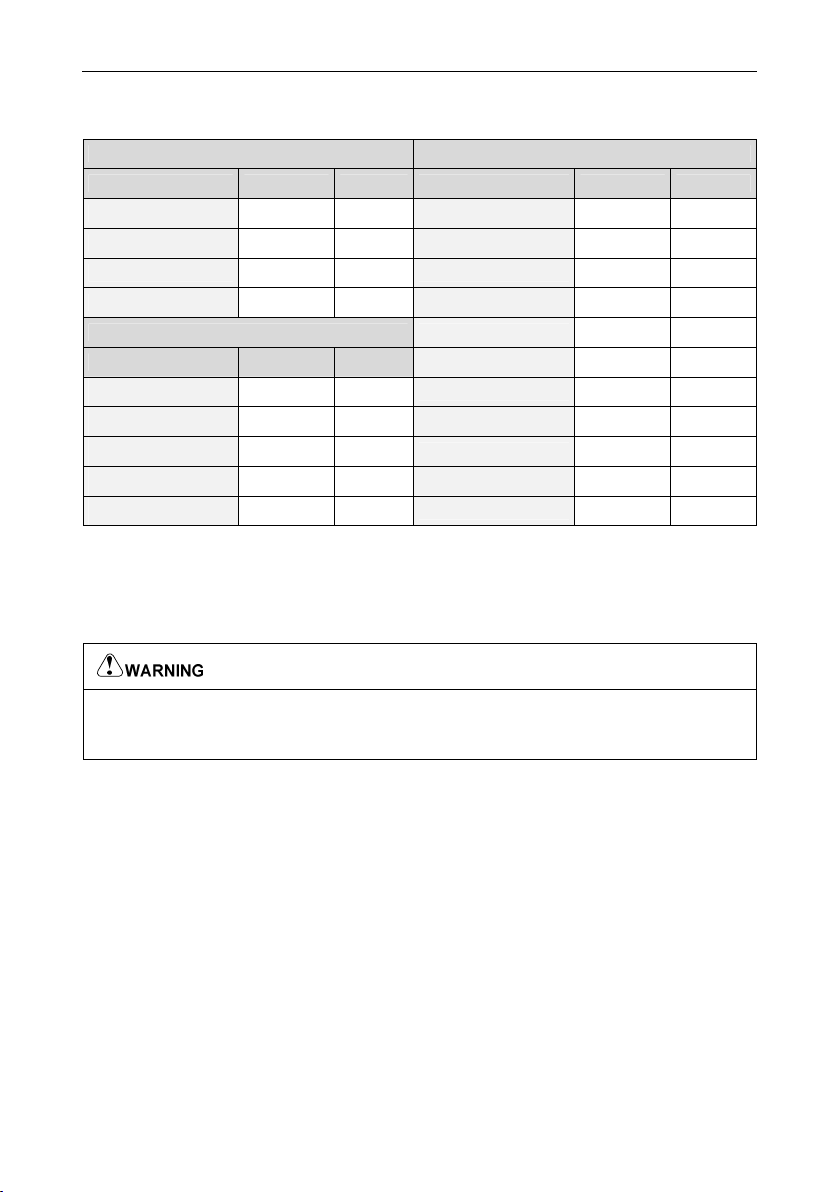

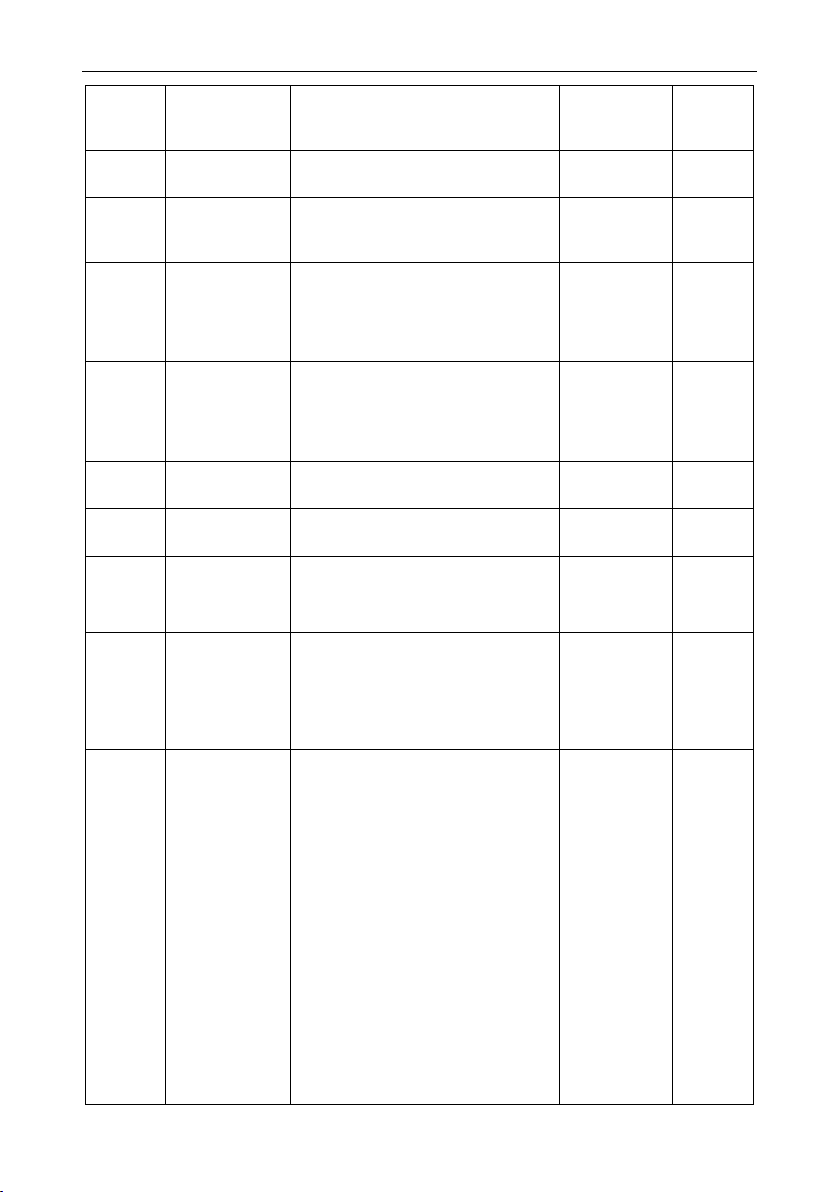

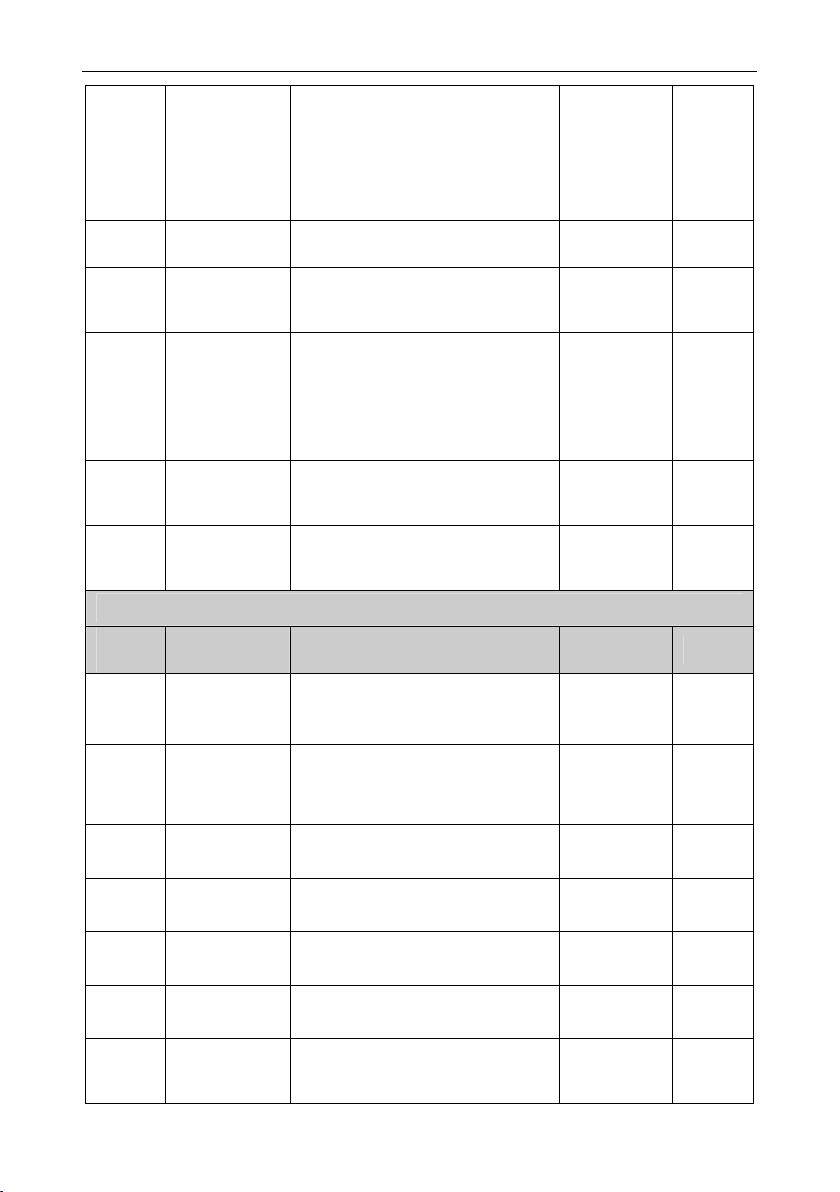

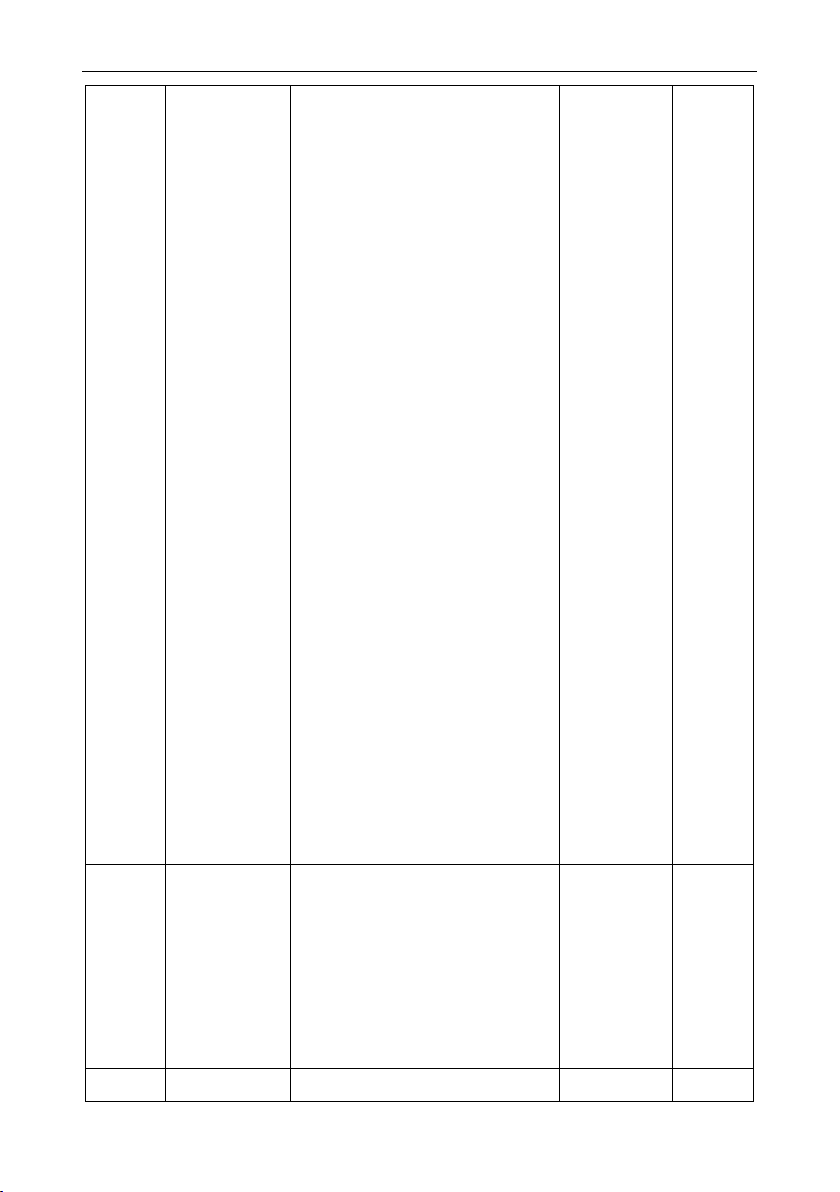

2.5 Recommended Brake Resistor Selection Table

Table 2-3 Recommended brake resistor selection table

Single phase, 220V Three phase, 380V

Model Resistor Power Model Resistor Power

VD120-2S-0.4GB ≥200Ω 80W VD120-4T-0.4GB ≥300Ω 150W

VD120-2S-0.7GB ≥150Ω 80W VD120-4T-0.7GB ≥300Ω 150W

VD120-2S-1.5GB ≥100Ω 100W VD120-4T-1.1GB ≥250Ω 150W

VD120-2S-2.2GB ≥70Ω 100W VD120-4T-1.5GB ≥220Ω 150W

Three phase, 220V VD120-4T-2.2GB 200Ω 300W

Model Resistor Power VD120-4T-3.0GB ≥150Ω 300W

VD120-2T-0.4GB ≥150Ω 150W VD120-4T-4.0GB ≥130Ω 300W

VD120-2T-0.7GB ≥110Ω 150W VD120-4T-5.5GB ≥90Ω 400W

VD120-2T-1.5GB ≥100Ω 250W VD120-4T-7.5GB ≥65Ω 500W

VD120-2T-2.2GB ≥65Ω 300W - - -

VD120-2T-4.0GB ≥45Ω 400W - - -

2.6 Warranty Introduction

For inverter manufactured by our factory, since the date of manufacture, under normal condition

application, if inverter failed or damaged within warranty period, the manufacturer response for repair.

If inverter is without in warranty period, user response for reasonable repair charge.

● Free warranty only refers to the frequency converter

● Please keep the machine outer packing boxes and other packaging materials, to facilitate future

inverter relocation or repair and other logistics transportation

2.6.1 In the warranty period, the following reasons lead to the failure of the inverter and

damage, the user must bear part of the maintenance costs.

① The machine failure caused by the user does not use the user manual or beyond the standard

specifications range use;

② The machine failure caused by the user repair and modify;

③ The machine failure caused by the user custody, maintenance improper.

④ Damage caused when the inverter is used for abnormal function;

⑤ The machine failure due to fires, floods, salt corrosion, corrosive gases, earthquake, storm,

lightning, abnormal voltage or other non resistance caused by damage to the machine.

2.6.2 Relevant service charges will be calculated in accordance with the manufacturer's

unified standard, if there is a contract, it is handled according to the relevant provisions of the

contract.

- 7 -

Mechanical and Electrical Installation VD120 Series Inverter User Manual

Chapter 3 Mechanical and Electrical Installation

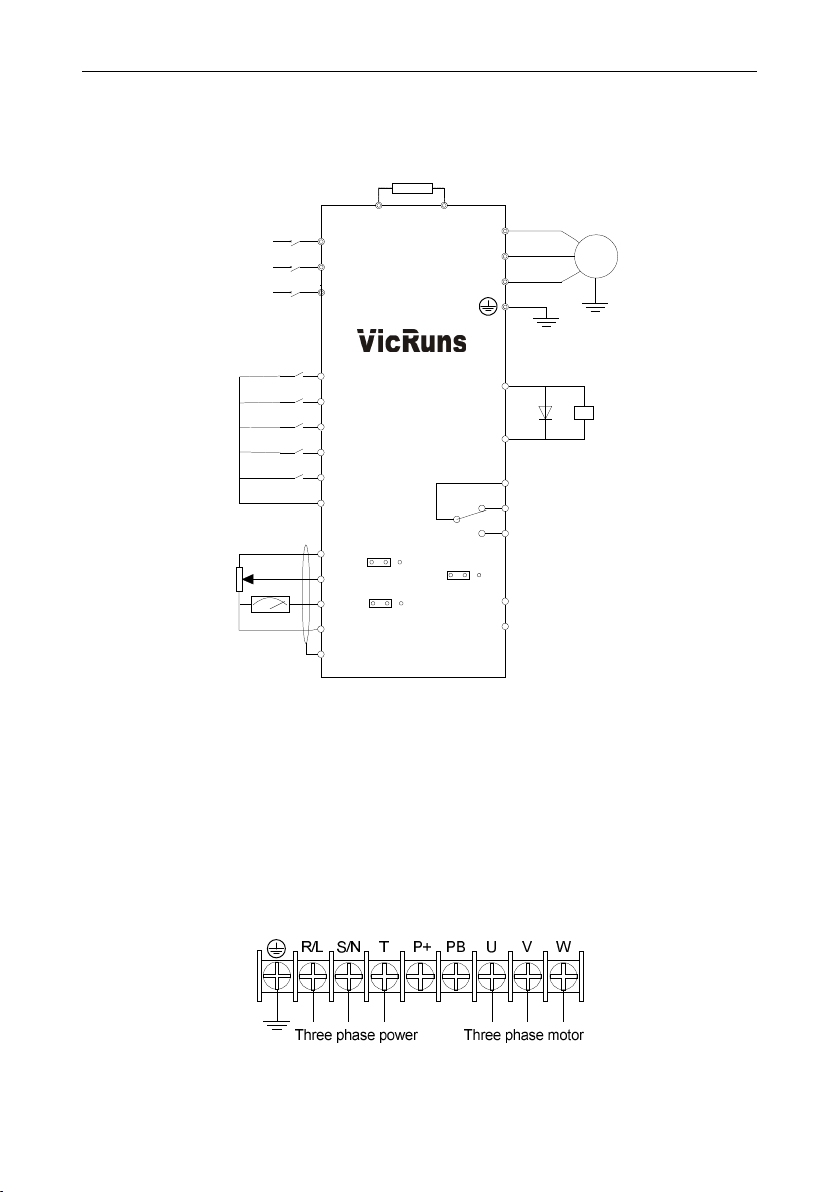

3.1 Standard Wiring Diagram

Brake unit

AI

AO

P+

DO1

+24V

T/A

T/B

T/C

485

R

RS-485+

RS-485-

U

V

W

Relay T output

RS-485

M

DO1 output

Comunication port

Input power

DI terminal

AI terminal

QF

L1/R

L2/S

L3/T

FWD/Stop

REV/Stop

Jog

Coast to stop

Fault reset

VR:1K~10K

R/L

S/N

T

DI1

DI2

DI3

DI4

DI5

GND

10V

AI1

AO1

GND

PB

V A

V A

PE

Fig 3.1-1 Schematic diagram of inverter standard wiring

Precautions are as follows:

1) Terminal ◎refers to Main circuit terminal, terminal ○ refers to control circuit terminal;

2) B which is followed the product model represents standard models built-in brake unit;

3) Braking resistor’s selection is based on the user demand. refer to Table 2-4;

4) Signal lines and power line must be separated alignments, if you want to control cables and power

cable cross, let them cross by 90 degree angle. It is best to choose shielded twisted-pair cabling for

analogue signal, the selection of power cable is shield three-core cable(The specification should

enlarge a class as much as the ordinary electric cables), or follow the inverter user manual.

3.2 Main Circuit Terminals

Three phase 380V: 0.4kW-2.2kW/Three phase, Signal phase 220V: 0.4kW-1.5kW

- 8 -

VD120 Series Inverter User Manual Mechanical and Electrical Installation

Three phase 380V: 3kW-7.5kW/Three phase 220V: 2.2kW~4.0kW/Signal phase 220V: 2.2kW

Fig 3.2-1 Schematic diagram of main circuit wiring

3.2.1 Function Instruction of Main Circuit Terminals

Table 3-1 Function Instruction of main circuit terminals

Terminals Function Instruction

R/L, S/N, T Power input terminals, external the ac power of grid rated voltage

U, V, W Output terminal of 3phase power supply, external connection of AC 3phase motor

P+, PB External connection of braking resistor terminal

P+, P- Voltage positive and negative terminals on DC side

Grounding terminal

● The voltage class of VD120 series inverter 3phase power has two grades: 220V, 380V, before

connecting power, please make sure the power class on inverter nameplate is the same with the

accessing power. Otherwise do not connect.

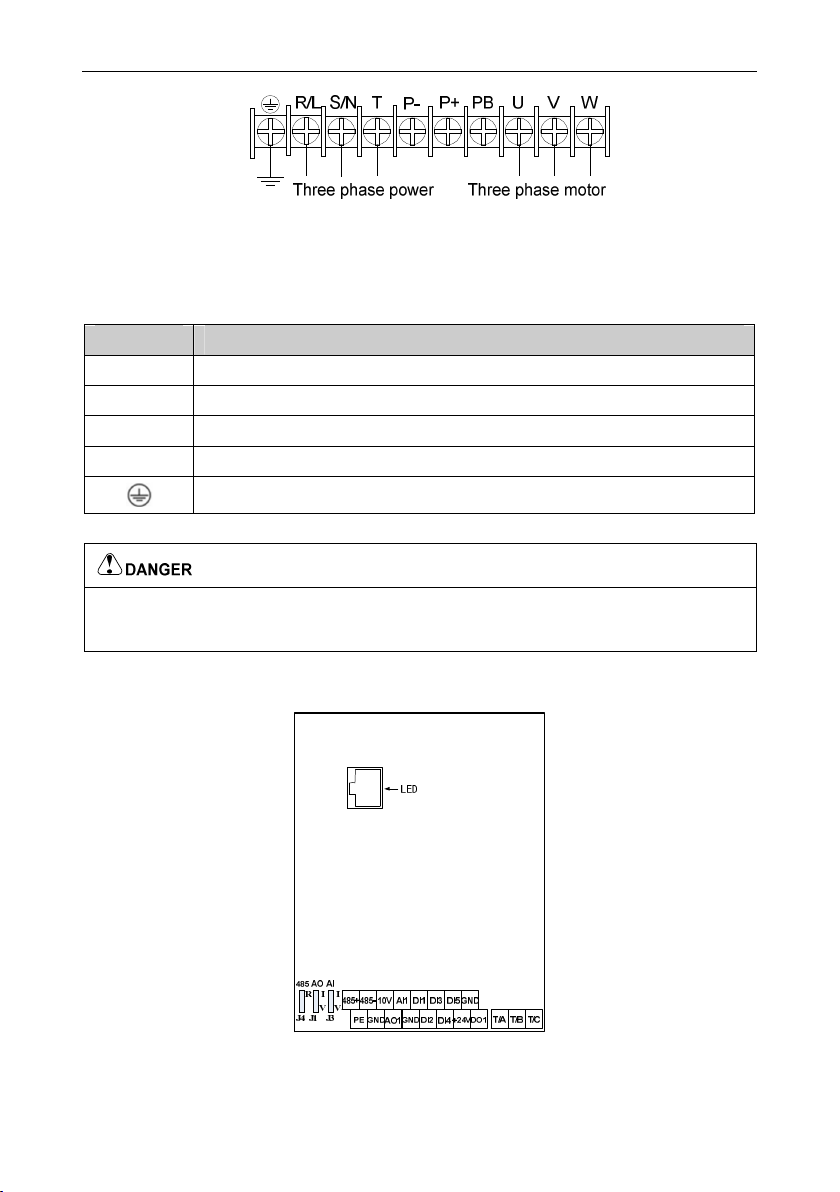

3.3 Control Circuit Terminal

3.3.1 Schematic diagram of control board layout

Fig 3.3-1 Schematic diagram of control board layout

- 9 -

Mechanical and Electrical Installation VD120 Series Inverter User Manual

3.3.2 Function Description of Control Circuit Terminal

Table 3-1 Function description of control circuit terminal

Type

Power Supply

Communication 485+-485-

Analog Input AI1-GND

Digital Input

Analog Output AO1-GND

Digital Output DO1

Terminal

Sign

10V-GND

+24V-GND

DI1-GND

DI2-GND

DI3-GND

DI4-GND

DI5-GND

Terminal

10V power

24V power

RS-485

communicati

on terminals

Analog input

terminal 1

Digital input

terminal 1

Digital input

terminal 2

Digital input

terminal 3

Digital input

terminal 4

Digital input

terminal 5

Analog

terminal 1

Digital output

Name

supply

supply

output

1

Function

1. Provide 10V power supply for

external-units.

2. It is generally used as the external

potentiometer power. The potentiometer

resistance range is 1kΩ~10KΩ.

3. Maximum output current 10mA.

4. Provide +24V power supply for external

units, only used as the working power

supply of digital output terminals.

5. The maximum output current 100mA.

6. Don’t use this power as an external

power supply.

Standard RS-485 communication terminal,

should use twisted pair cable

Support 0V~10V voltage or 0/4Ma~20mA

current input, selected by AI jumpers, default

to 0V~10V voltage input.

Multi-function digital input, the function set by

F5-01~F5-05.

Support 0V~10V voltage or 0/4mA~20mA

current output, selected by jumper J3, default

to 0V~10V voltage output

1. Optical coupling isolation, dual polarity

open collector output;

2. Pull-up voltage range: 5V~24V(pull-up

resistance range: 0.48kΩ~10kΩ);

3. Output current range: 2mA~50mA.

- 10 -

VD120 Series Inverter User Manual Mechanical and Electrical Installation

Relay T1

T1/A-T1/B

Relay Output

T1/A-T1/C

Shield Ground PE

Shield cable

normally

closed

terminal

Relay T1

normally

open

terminal

ground

terminal

Contact driving capacity:

AC250V, 3A; DC30V, 5A

1. Used to control cable shield grounding,

when the interference is big on site or

control cable is too long, the PE should

be well grounded to reduce EMC affect.

2. PE terminal is not allowed to connect with

power N line, otherwise will damaged the

inverter.

- 11 -

Operation and Display VD120 Series Inverter User Manual

Chapter 4 Operation and Display

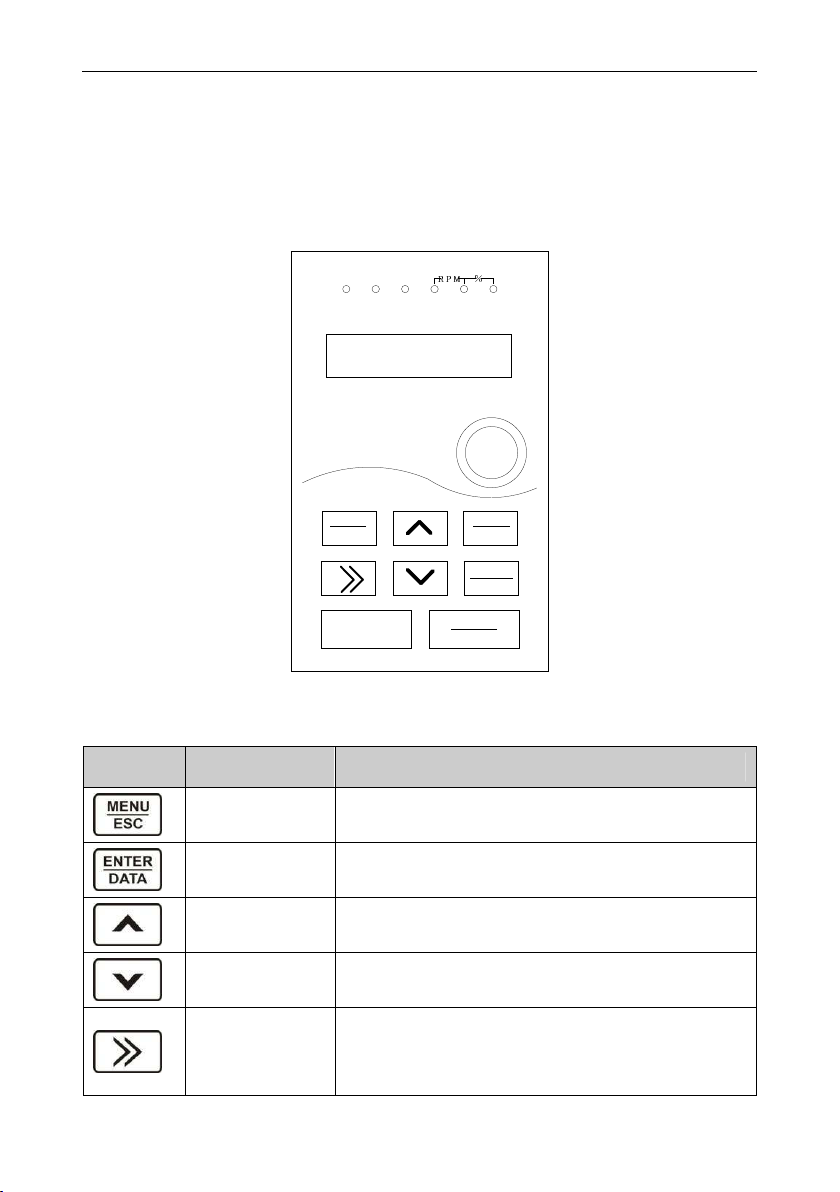

4.1 Introduction to Operation and Display Interface

With the operation panel, it can perform such operations on the inverter as function parameter

modification, inverter working status monitoring and inverter run control (startup and stop).

Refer to Fig 4-1 for the physical appearance and functional zone of the operation panel:

Hz

A

-

MENU

ESC

ENTER

DATA

STOP

RESET

V

+

L/R

FWD/REVRUN

LED DIGITAL PANEL

JOG

REV

RUN

Fig 4.1-1 Operation panel schematic

4.1.1 Keyboard Button Description

Buttons Name Function Description

Programming key

Enter key

Enter or escape from the first level menu and remove the

parameters quickly

Enter the menu step-by-step

Confirm parameters

UP key Increase data or function code progressively

DOWN key Decrease data or function code progressively

Move right to select the displaying parameters circularly in

Right-shift key

stopping and running mode.

Select the parameters modifying digit during the parameter

modification

- 12 -

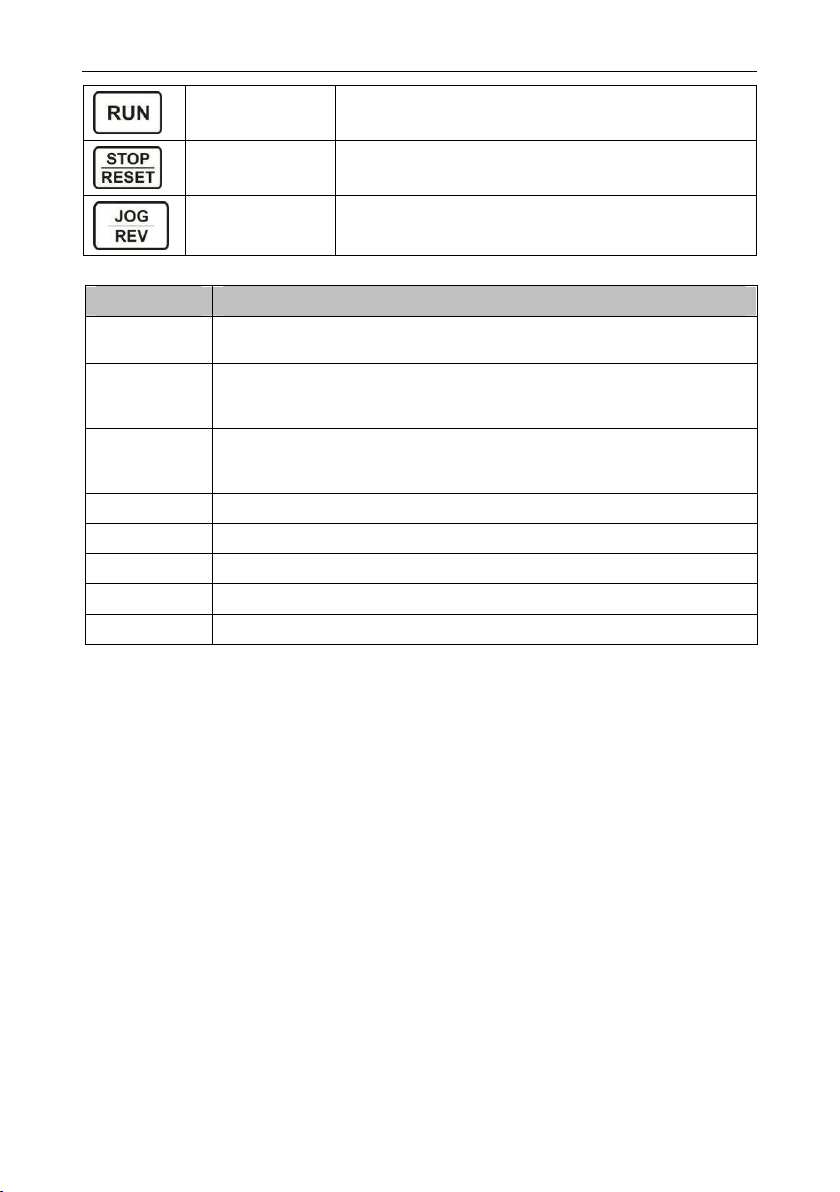

VD120 Series Inverter User Manual Operation and Display

Run key

Stop/Reset key

Quick key The function of this key is confirmed by function code FA-01

4.1.2 Description of Function LED Indictor

Name Description

RUN

FWD/REV

L/R

Hz The unit of frequency(Hz)

A The unit of current(A)

V The unit of voltage(V)

RPM The unit of rotation speed(RPM)

% Unit:%

When it is off, it indicates the inverter is in stop status; when it is on, it indicates

the rotation status; light flashes that inverter in automatic running.

It is the LED indictor for forward/reverse rotation. When it is on, it indicates the

inverter is in forward rotation status; when it is off, it indicates the inverter is in

reverse rotation

When it’s off, it indicates the keypad operation control status; when it’s on, it

indicates the terminal operation control status; when it’s flicker, it indicates the

remote operation control status

This key is used to operate on the inverter in key operation

mode

This key is used to stop in running state and it is limited by

function code F7-01

- 13 -

Function Parameter Table VD120 Series Inverter User Manual

Chapter 5 Function Parameter Table

The symbols in the function table are described as follows:

○——It indicates that the parameter setup value can be modified when the inverter is in run state;

◎——It indicates that the parameter setup value cannot be modified when the inverter is in the run

state;

●——It indicates that the numerical value of the parameter is the actually measured value, which

cannot be modified;

☆——It indicates this parameter is “Factory default parameter” and can be set only by the

manufacturer.

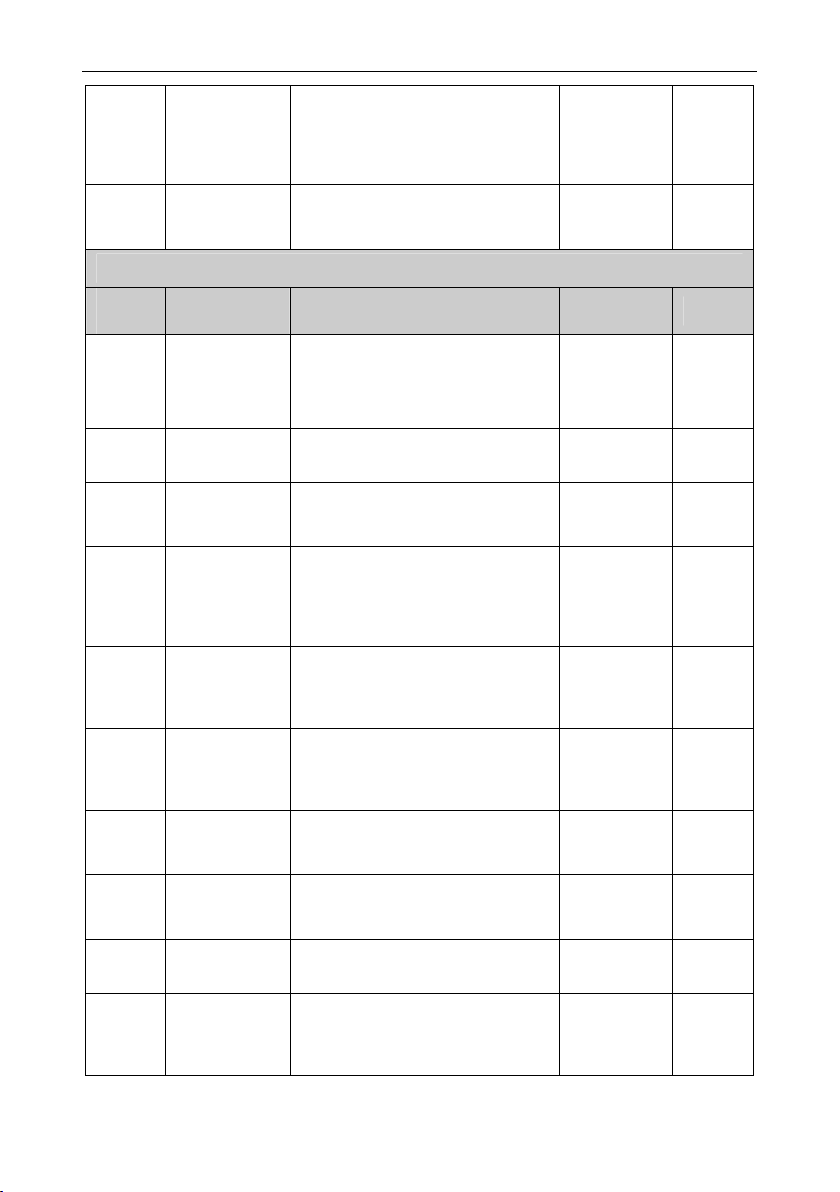

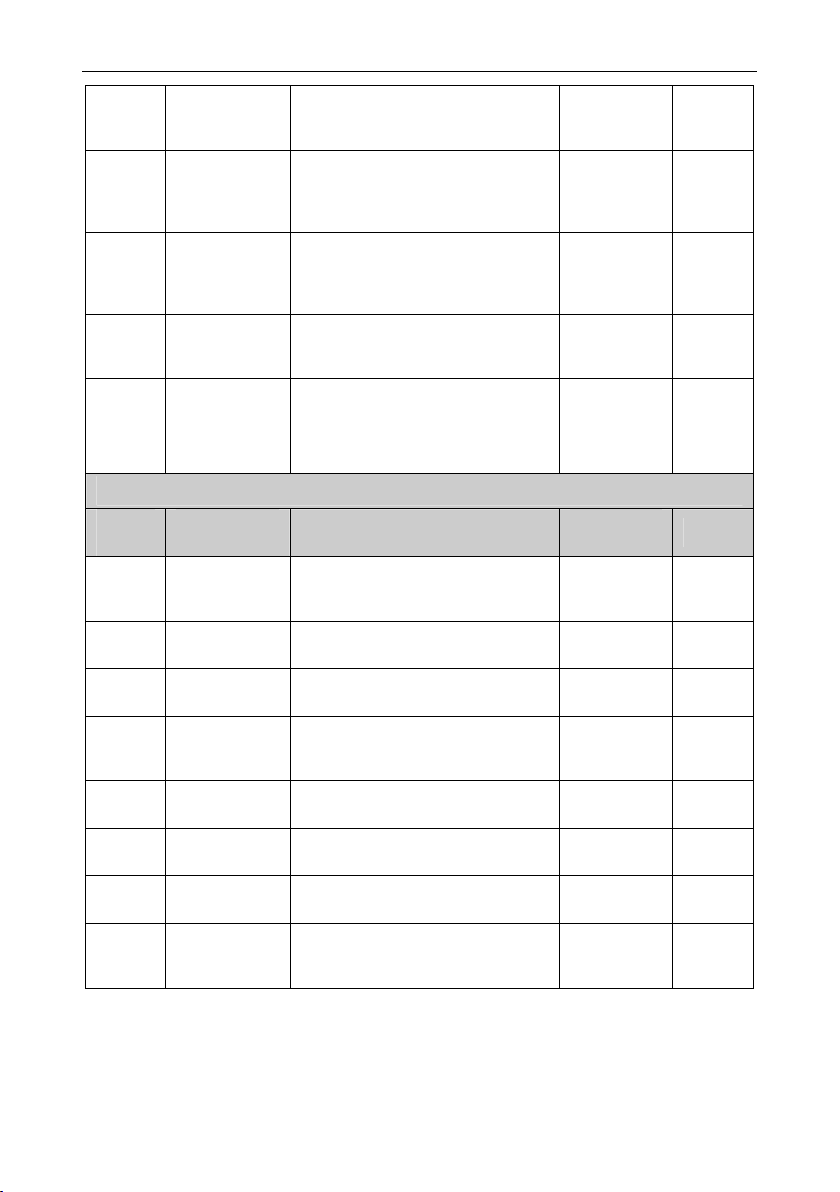

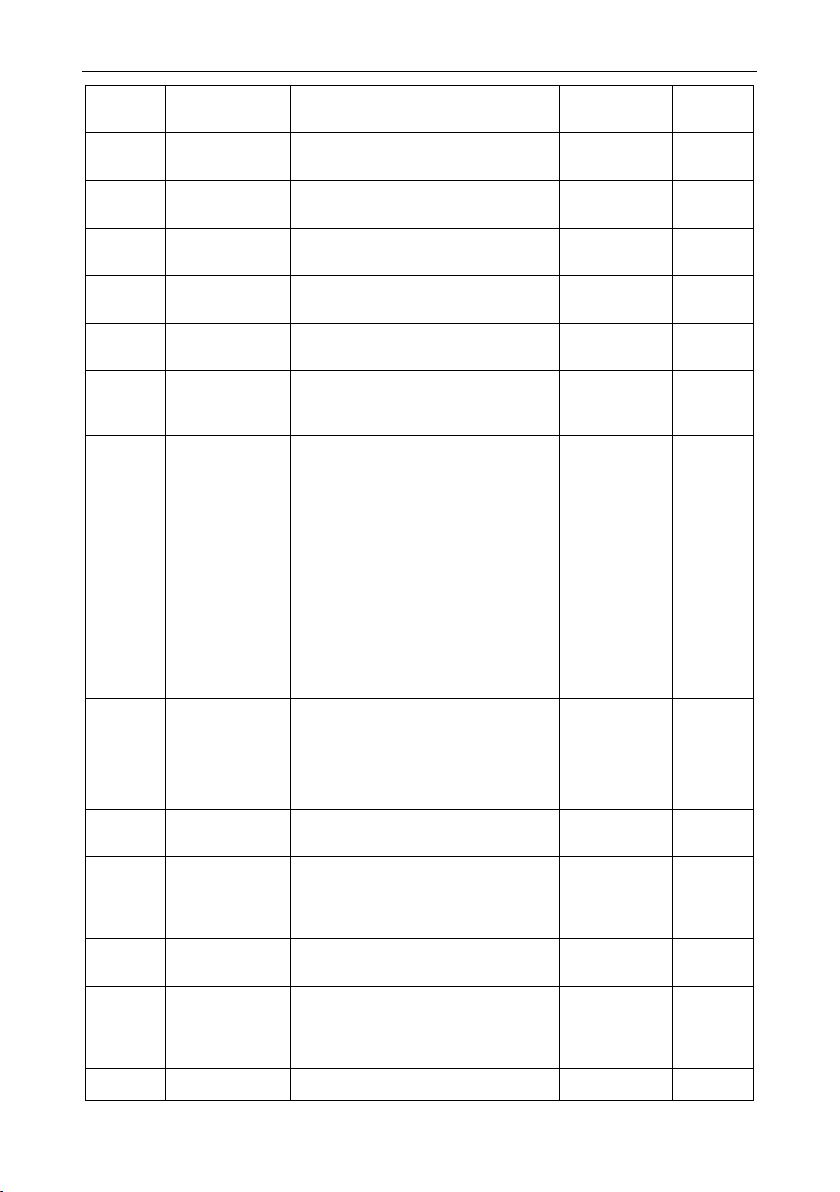

F0 Basic Parameter Group

Function

Code

F0-00

F0-01

F0-02

F0-03

F0-04

Parameter

Name

Motor Control

Mode

Running

Command

Source

Selection

Main Frequency

Source A

Selection

Main Frequency

A Gain

Auxiliary

Frequency

Source B

Selection

Setting Range

0: V/F control

1: SVC

0: Control panel command source

(L/R OFF)

1: Terminal command source

(L/R ON)

2:Communication command

source (L/R flashes)

0: Digital setting (F0-09,

UP/DOWN can be modified, no

memory when power failure)

1: Digital setting (F0-09,

UP/DOWN can be modified,

memory when power failure)

2: AI1

3: Reserved

4: Reserved

5: PULSE setting

6: MS reference

7: Simple PLC

8: PID

9: Communication setting

10: Keypad potentiometer

0.000~10.000 1.000

Same as F0-02 (Main Frequency

Source A Selection)

Default Value

- 14 -

Factory

0

0

10

0

Property

◎

○

◎

○

◎

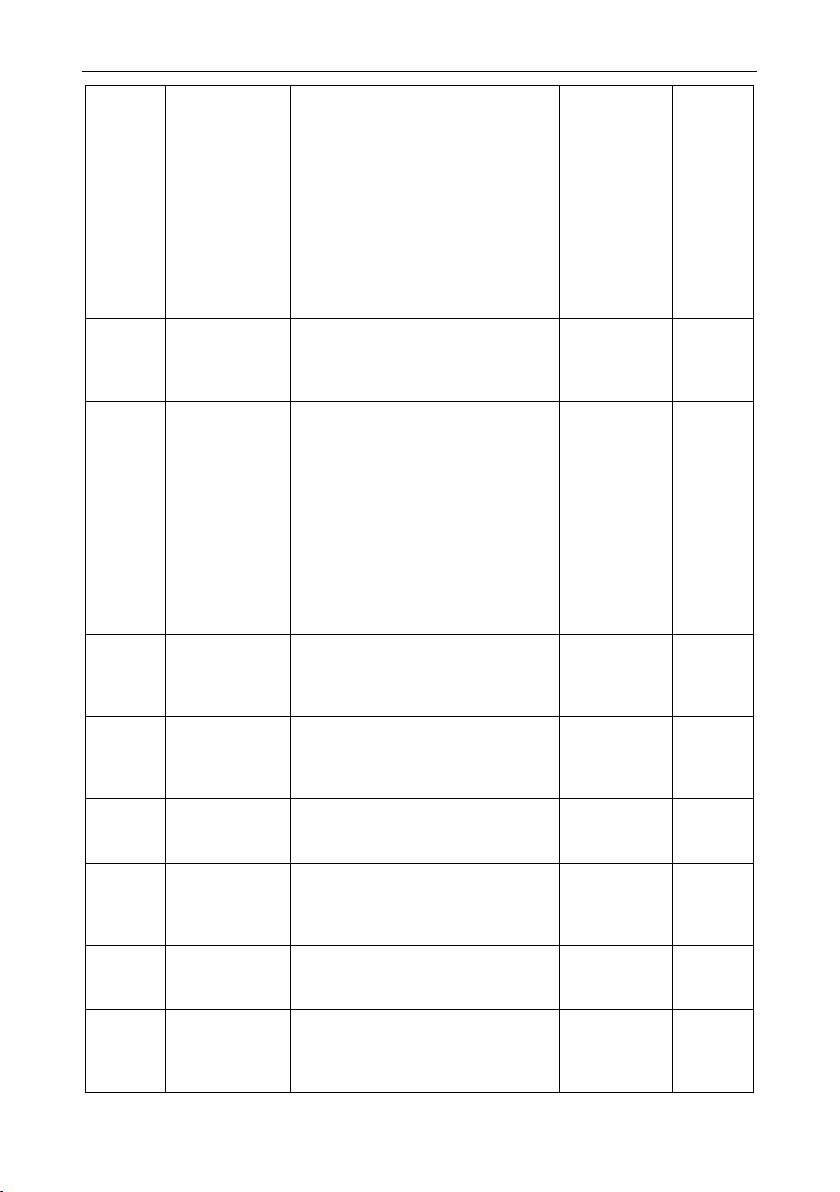

VD120 Series Inverter User Manual Function Parameter Table

Unit’s digit: frequency source

selection

0: Main frequency source A

1: Main auxiliary operation result

(operational relationship is

determined by ten bits)

2: Main frequency source A switching

Frequency

F0-05

F0-06

F0-07

F0-08

F0-09

F0-10 Max Frequency 50.00Hz~600.00Hz 50.00Hz

F0-11

F0-12

Source

Superposition

Selection

Auxiliary

Frequency

Source B

Range

Reference

Selection when

Superimposed

Auxiliary

Frequency

Source B

Range when

Superimposed

Auxiliary

Frequency

Source B

Offset

Frequency

when

Superimposed

Digital Setting

Frequency

Frequency

Upper Limit

Source

Frequency

Upper Limit

with auxiliary frequency source B

3: Main frequency source A switching

with main and auxiliary operation

result

Ten’s digit: frequency source main

and auxiliary operation relationship

0: Main + auxiliary

1: Main – auxiliary

2: Max value of the two

3: Min value of the two

1: Relative to the max frequency

2: Relative to frequency source A

0%~150% 100%

0.00Hz~max frequency F0-10 0.00Hz

0.00Hz~max frequency (F0-10) 50.00Hz

0: F0-12 setting

1: AI1

2: Reserved

3: Reserved

4: PULSE setting

5: Communication setting

Frequency lower limit F0-14~max

frequency F0-10

0x00

0

0

50.00Hz

○

○

○

○

○

◎

◎

○

- 15 -

Function Parameter Table VD120 Series Inverter User Manual

Frequency

F0-13

F0-14

F0-15

F0-16

F0-17

F0-18

F0-19

F0-20

F0-21

F0-22

Upper Limit

Offset

Frequency

Lower Limit

Frequency

Command

Resolution

Frequency

Command

UP/DOWN

Reference in

Running

Digital Setting

Frequency

Memory

Selection when

Stop

Acceleration

Time 1

Deceleration

Time 1

Acceleration /

Deceleration

Time Unit

Acceleration

and

Deceleration

Time

Reference

Frequency

Command

Source Bound

Frequency

Source

0.00Hz~max frequency F0-10 0.00Hz

0.00Hz~frequency upper limit F0-12 0.00Hz

2: 0.01Hz 2

0: Running frequency

1: Set frequency

0: No memory

1: Memory

0.00s~65000s

0.00s~65000s

0: 1s

1: 0.1s

2: 0.01s

0: Max frequency (F0-10)

1: Setting frequency

2: 100Hz

Unit’s digit: Operation panel

command binding frequency source

selection

0: No binding

1: Digital setting frequency

2: AI1

3: Reserved

4: Reserved

5: PULSE setting

6: MS reference

7: Simple PLC

8: PID

9: Communication setting

Ten’s digit: terminal command

binding frequency source selection

Hundred’s digit: communication

0

0

Model

dependent

Model

dependent

1

0

0x0000

○

○

●

◎

○

○

○

◎

◎

○

- 16 -

VD120 Series Inverter User Manual Function Parameter Table

command binding frequency source

selection

Thousand’s digit: Automatic

operation command binding

frequency source selection

F0-23

F1 Start/Stop Control Group

Communicatio

n Protocol

Selection

0: Modbus 0

●

Function

Code

F1-00 Start Mode

F1-01

F1-02

F1-03

F1-04

F1-05

F1-06

F1-07

F1-08 Stop Mode

F1-09

Parameter

Name

Starting

Frequency

Startup

Frequency

Holding Time

Starting DC

Braking

Current/

Pre-excitation

Current

Starting DC

Braking Time /

Pre-excitation

Time

Speed

Tracking Mode

Speed

Tracking

Speed

Speed

Tracking

Current

Initial

Frequency of

Stop DC

Braking

Setting Range

0: Direct start

1: Speed tracking restart

2: Pre excitation start (AC

asynchronous )

0.00Hz~10.00Hz 0.50Hz

0.00s~100.0s 0.0s

0%~100% 0%

0.0s~100.0s 0.0s

0: Starting from the stop frequency

1: Starting from zero speed

2: Starting from the maximum

frequency

1~100 20

100%~150% 125%

0: Decelerate to stop

1: Coast to stop

0.00Hz~max frequency 0.00Hz

Default Value

Factory

0

0

0

Property

○

○

◎

◎

◎

◎

○

◎

○

○

- 17 -

Function Parameter Table VD120 Series Inverter User Manual

Waiting Time of

F1-10

F1-11

F1-12

F1-13

F1-14

F1-15

F1-16

F1-17

F1-18

F1-19 Run Direction

Stop DC

Braking

Stop DC

Braking

Current

Stop DC

Braking Time

Stop

Frequency

Stop

Frequency

Holding Time

Restart

Selection Upon

Power Failure

Waiting Time of

Restart Upon

Power Failure

Operation

Mode of Set

Frequency is

Lower than the

Frequency

Lower Limit

Start Selection

of Set

Frequency is

Lower than the

Start

Frequency

0.0s~100.0s 0.0s

0%~100% 0%

0.0s~100.0s 0.0s

0.00Hz~max frequency 0.50Hz

0.0s~60.0s 0.0s

0: Enabled

1: Disabled

0.0s~60.0s 0.0s

0: Running with frequency lower limit

1: Stop

2: Zero speed running

0: Don’t start

1: Zero speed running

0: Same direction

1: Opposite direction

0

0

1

0

○

○

○

○

○

○

○

○

◎

○

F1-20

F1-21

F1-22

F1-23

Reverse

Control Enable

FWD/REV

Rotation

Dead-zone

Time

Dynamic

Braking Enable

Braking Usage

Rate

0: Allow reverse

1: Prohibit reverse

0.0s~3000.0s 0.0s

0: Disabled

1: Enabled

0%~100% 100%

- 18 -

0

0

○

○

○

○

VD120 Series Inverter User Manual Function Parameter Table

0: The whole is valid

Over-excitation

F1-24

F1-25

F1-26

F1-27

F1-28

F1-29

F2 Motor Parameter

Function

Code

F2-00

Effective

Range

Over-excitation

Gain

Over-excitation

Filter

Coefficients

Acceleration/D

eceleration

Mode

Time Ratio of S

Curve Start

Segment

Time Ratio of S

Curve End

Segment

Parameter

Name

Motor Type

Selection

1: Only overpressure stall enable

effectively

2: Only deceleration process

effectively

3: The whole is invalid

0~200 100

0~10 3

0: Straight-line

acceleration/deceleration

1: S curve acceleration/deceleration

A

2: S curve acceleration/deceleration

B

0.0%~(100.0%-F1-29) 30.0%

0.0%~(100.0%-F1-28) 30.0%

Setting Range

0: Ordinary asynchronous motor

1: Frequency conversion

asynchronous motor

1

0

Factory

Default Value

0

◎

○

○

◎

◎

◎

Property

◎

F2-01

F2-02

F2-03

F2-04

F2-05

F2-06

Rated Motor

Power

Rated Motor

Voltage

Rated Motor

Current

Rated Motor

Frequency

Rated Motor

Rotation Speed

Asynchronous

Motor Stator

Resistance

0.1kW~11.0kW

1V~1000V

0.01A~100.00A

0.01Hz~max frequency

1RPM~65535RPM

0.001Ω~65.535Ω

- 19 -

Model

dependent

Model

dependent

Model

dependent

Model

dependent

Model

dependent

Tune

parameter

◎

◎

◎

◎

◎

◎

Function Parameter Table VD120 Series Inverter User Manual

Asynchronous

F2-07

F2-08

F2-09

F2-10

F2-26 Tune Selection

F3 Motor Vector Control Parameter

Function

Code

F3-00

F3-01

F3-02

F3-03

F3-04

F3-05

F3-06

F3-07

Motor Rotor

Resistance

Asynchronous

Motor Leakage

Inductive

Reactance

Asynchronous

Motor Mutual

Inductive

Reactance

Asynchronous

Motor No-load

Current

Parameter

Name

Speed Loop

Proportional

Gain 1

Speed Loop

Integral Time 1

Switch

Frequency 1

Speed Loop

Proportional

Gain 2

Speed Loop

Integral Time 2

Switch

Frequency 2

Vector Control

Slip Gain

Speed Loop

Filter Time

Constant

0.001Ω~65.535Ω

0.01mH ~655.35mH

0.1mH~6553.5mH

0.01A~F2-03

0: No operation

1: Asynchronous motor static tuning

2: Asynchronous motor complete

tuning

Setting Range

01~100 30

0.01s~10.00s 0.50s

0.00Hz~F3-05 5.00Hz

1~100 20

0.01s~10.00s 1.00s

F3-02~max frequency 10.00Hz

20%~200% 100%

0.000s~0.100s 0.000s

Tune

parameter

Tune

parameter

Tune

parameter

Tune

parameter

0

Factory

Default Value

◎

◎

◎

◎

◎

Property

○

○

○

○

○

○

○

○

- 20 -

VD120 Series Inverter User Manual Function Parameter Table

0: Encode F3-10 setting

1: AI1

2: AI2

3: AI3

4: PULSE setting

5: Communication setting

6: MIN (AI1, AI2)

7: MAX (AI1, AI2)

The full scale of options 1~7

corresponding to the F3-10

0%~200.0% 150.0%

0: Encode F3-12setting

1: AI1

2: AI2

3: AI3

4: PULSE setting

5: Communication setting

6: MIN (AI1, AI2)

7: MAX (AI1, AI2)

The full scale of options 1~7

corresponding to the F3-12

0%~200.0% 150.0%

0~60000 2000

0 ~60000 1300

0~60000 2000

0~60000 1300

0: Disabled

1: Enabled

0

0

0

○

○

○

○

○

○

○

○

○

F3-09

F3-10

F3-11

F3-12

F3-13

F3-14

F3-15

F3-16

F3-17

Motor Torque

Upper Limit

Source

Digital Setting

for Motor

Torque Upper

Limit

Brake Torque

Upper Limit

Source

Digital Setting

for Brake

Torque Upper

Limit

Excitation

Adjustment

Proportional

Gain

Excitation

Adjustment

Integral Gain

Torque

Adjustment

Proportional

Gain

Torque

Adjustment

Integral Gain

Speed Loop

Integral

Separation

Enable

- 21 -

Function Parameter Table VD120 Series Inverter User Manual

Max Weak

F3-20

F3-21

F3-22

F3-23

F3-24

F3-25

F3-26

F3-27

F4 Motor V/F Control Parameter

Magnetic

Current

Weak Magnetic

Automatic Gain

Adjustment

Weak Magnetic

Integral

Multiples

Torque Boost

Coefficient

Torque Boost

Cutoff

Frequency

Exciting

Current

Compensation

Gain

Torque Current

Compensation

Gain

Torque

Response Gain

1%~300% 50%

10%~500% 100%

2~10 2

0.0%~60.0% 10.0%

0.00Hz~max frequency 20.00Hz

0~500 0

0~500 0

1~1000 10

◎

○

○

○

◎

○

○

○

Function

Code

F4-00

F4-01

F4-02

F4-03

Parameter

Name

V/F Curve

Setting

Torque Boost

Mode Selection

Manual Torque

Boost

Manual Torque

Boost Cutoff

Frequency

Setting Range

0: Straight line V/F

1: Multipoint V/F

2: Square V/F

3: 1.2#power V/F

4: 1.4#power V/F

5: 1.6#power V/F

6: 1.8#power V/F

7: V/F complete separation mode

8: V/F half separation mode

0: Automatic torque boost

1: Manual torque boost

0.0%~30.0%

0.00Hz~max frequency 50.00Hz

Default Value

dependent

- 22 -

Factory

0

0

Model

Property

◎

◎

○

◎

VD120 Series Inverter User Manual Function Parameter Table

MS V/F

F4-04

F4-05

F4-06

F4-07

Frequency

Point 1

MS V/F

Voltage Point 1

MS VF

Frequency

Point 2

MS V/F

Voltage Point 2

0.00Hz~F4-06 0.00Hz

0.0%~100.0% 0.0%

F4-04~F4-08 0.00Hz

0.0%~100.0% 0.0%

◎

◎

◎

◎

F4-08

F4-09

F4-10

F4-12

F4-14

F4-15

F4-16

F4-17

MS V/F

Frequency

Point 3

MS V/F

Voltage Point 3

V/F Slip

Compensation

Gain

V/F Oscillation

Suppression

Gain

The Separation

of V/F Voltage

Source

V/F Separation

Voltage Digital

Setting

V/F Separation

Voltage Rise

Time

V/F Separation

Voltage Fall

Time

F4-06~Rated motor frequency

(F2-04)

0.0%~100.0% 0.0%

0.0%~200.0% 20.0%

0~100

0: Digital setting (F4-15)

1: AI1

2: Reserved

3: Reserved

4: PULSE setting

5: MS instruction

6: Simple PLC

7: PID

8: Communication given

Remark: 100% corresponding rated

motor voltage

0V~rated motor voltage 0V

0.0s~1000.0s

Remark: Indication the time that 0V

rise to rated motor voltage

0.0s~1000.0s

Remark: Indication the time that

rated motor voltage drop to 0V

0.00Hz

Model

dependent

0

5.0s

5.0s

◎

◎

◎

○

○

○

○

○

- 23 -

Function Parameter Table VD120 Series Inverter User Manual

F5 Input Terminal

Function

Code

F5-00

F5-01

F5-02

F5-03

F5-04

F5-05

Parameter

Name

Terminal

Command

Mode

DI1 Terminal

Function

Selection

DI2 Terminal

Function

Selection

DI3 Terminal

Function

Selection

DI4 Terminal

Function

Selection

DI5 Terminal

Function /

HDI1 Pulse

Input Function

Selection

(Optional)

Setting Range

0: Two-line mode 1

1: Two-line mode 2

2: Three-line mode 1

3: Three-line mode 2

4: Alternate control

5: Back and forth control

0: No function

1: Forward running (FWD)

2: Reverse running (REV)

3: Three-line mode run control

4: Forward Jog (FJOG)

5: Reverse Jog (RJOG)

6: Coast to stop

7: Run pause

8: Fault reset (RESET)

9: External fault normally open input

10: External fault normally closed

input

11: Terminal UP

12: Terminal DOWN

13: UP/DOWN setting clear (terminal,

keyboard)

14: Switching frequency source

15: Frequency source A switching

with preset frequency

16: Frequency source B switching

with preset frequency

17: MS reference terminal 1

18: MS reference terminal 2

19: MS reference terminal 3

20: MS reference terminal 4

21: Acceleration and deceleration

time selection terminal 1

22: Acceleration and deceleration

time selection terminal 2

23: PULSE frequency input

(Only effective for HDI1)

24: Control command switch terminal

1

25: Control command switch terminal

2

Factory

Default Value

0

1

2

4

6

8

Property

◎

◎

◎

◎

◎

◎

- 24 -

VD120 Series Inverter User Manual Function Parameter Table

26: Immediate DC braking

27: Deceleration DC braking

28: External stop terminal 1 (Only

effective for keypad control)

29: External stop terminal 2

(According to the deceleration time 4)

30: Emergency stop

31: PID pause

32: PID integral pause

33: Reverse PID action direction

34: PID parameter switching

35: PLC pause

36: PLC state reset

37: Swing frequency pause

38: Swing frequency reset

39: Switching between speed control

and torque control

40: Torque control prohibit

41: Acceleration and deceleration

prohibit

42: Reverse prohibit

43: Frequency modification prohibit

44: Counter input

45 Counter reset

46: Length count input

47: Length reset

48: Motor selection terminal

49: Reserved

50: User defined failure 1

51: User defined failure 2

52: Cleared the running time

53: Switching between two-line and

three-line mode (Switch is invalid in

running)

54~59: Reserved

Unit’s digit: DI1

0: High level effective

1: Low level effective

F5-10

F5-12 DI Filter Time 0.000s~1.000s 0.010s

DI1 Terminal

Mode Selection

1 Effectively

Ten’s digit: DI2, same as above

Hundred’s digit: DI3, same as above

Thousand’s digit: DI4, same as

above

Ten thousand’s digit: DI5, same as

above

0x00000

◎

○

- 25 -

Function Parameter Table VD120 Series Inverter User Manual

F5-13

F5-14

F5-15

F5-16

F5-17

F5-18

F5-19

F5-20

F5-21

F5-22

F5-23

F5-24

F5-25

F5-26 AI 1 Filter Time 0.00s~10.00s 0.10s

DI1 Close

Delay Time

DI2 Close

Delay Time

DI3 Close

Delay Time

DI1 Open

Delay Time

DI2 Open

Delay Time

DI3 Open

Delay Time

Terminal

UP/DOWN

change rate

AI Curve

Selection

AI is Lower

than Min Input

Setting

Selection

AI Curve 1 Min

Input

Corresponding

Setting of AI

Curve 1 Min

Input

AI Curve 1 Max

Input

Corresponding

Setting of AI

Curve 1 Max

Input

0.0s~3600.0s 0.0s

0.0s~3600.0s 0.0s

0.0s~3600.0s 0.0s

0.0s~3600.0s 0.0s

0.0s~3600.0s 0.0s

0.0s~3600.0s 0.0s

0.001Hz/s~65.535Hz/s 1.000Hz/s

AI1 curve selection

1: Curve 1

(2 point, see F5-22~F5-26)

2: Curve 2

(2 point, see F5-27~F5-31)

3: Curve 3

(2 point, see F5-32~F5-36)

4: Curve 4

(4 point, see b2~00-b2-07)

5: Curve 5

(4 point, see b2-08~b2-15)

AI1 is lower than min input setting

selection

0: Corresponding to the min input

setting

1: 0.0%

-10V~F5-24 0.00V

-100.0%~+100.0% 0.0%

F5-22~+10.00V 10.00V

-100.0%~+100.0% 100.0%

1

0

◎

◎

◎

◎

◎

◎

○

○

○

○

○

○

○

○

- 26 -

Loading...

Loading...