Page 1

28 Vdc MIL-COTS

DESIGN GUIDE

VIPAC

™

Page 2

ONTENTS

C

2 P

4 FEATURES

5 INPUT / OUTPUT OPTIONS

6 SPECIFICATIONS

RODUCT OVERVIEW

7 – 8 TE

9 INPUT CONNECTIONS

10 – 12 OU

13 CHASSIS CONFIGURATIONS

14 – 15 MOUNTING OPTIONS

16 MECHANICAL DRAWINGS

16 MECHANICAL INFORMATION

17 THERMAL MANAGEMENT

18 GENERAL INFORMATION

19 APPLICATION TIPS

CHNICALOVERVIEW

TPUTCONNECTIONOPTIONS

v i c o r p o w e r . c o m

1

Page 3

ODUCT

R

P

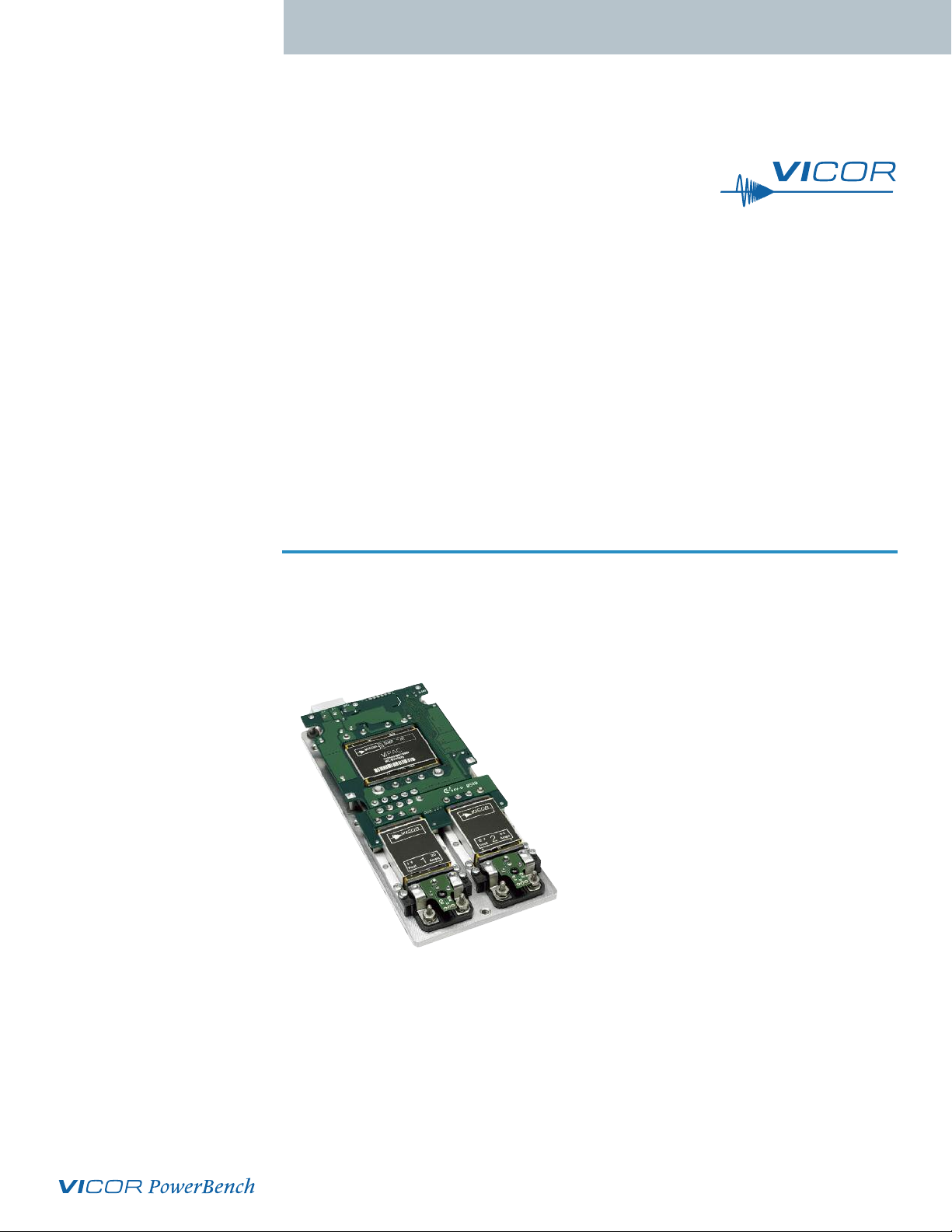

Vicor’s 28 V MIL-COTS VIPAC™is an integrated power system

leveraging the latest advances in DC-DC converter technology

and modular front ends. VIPAC combines application specific

power processing units (PPU) and a choice of chassis styles to

provide fast, flexible and highly reliable power solutions for a

wide range of demanding applications.

The PPU is the core element of the system and incorporates either

Vicor’s M-FIAM5B or M-FIAM9 to provide transient protec-

ion, EMI filtering and inrush current limiting.

t

The web-based VCAD tool enables designers to configure the

PPU with up to three independently regulated outputs having

power levels from 50 to 400 W. Vicor’s Maxi, Mini, Micro Series

DC-DC converters, in industry standard quarter, half and full

brick packages, are used to deliver output voltages from 3.3 to

48 Vdc. Additionally, the wide trim range of the modules can pro-

vide operating voltages as low as 500 mV.

The PPU is comprised of:

O

ERVIEW

V

PPU

• DC input modular front end

• Vicor’s Maxi, Mini, Micro Series high density

DC-DC converters

• Interface board

• Coldplate or finned chassis

• Choice of output termination styles

The VIPAC is offered in several chassis configurations facilitating

its use in a variety of applications using either conduction,

convection or forced convection cooling. The low profile,

conduction cooled version may be mounted to an existing

cabinet wall, coldplate or heat sink. The 0.5" or 1" finned

versions, available in longitudinal or transverse configurations,

are ideal for use in free or forced convection environments.

The use of standard chassis footprints allowsdifferent input voltage

configurations of theVIPAC to be used interchangeably

depending on system and market requirements.

v i c o r p o w e r . c o m

2

Page 4

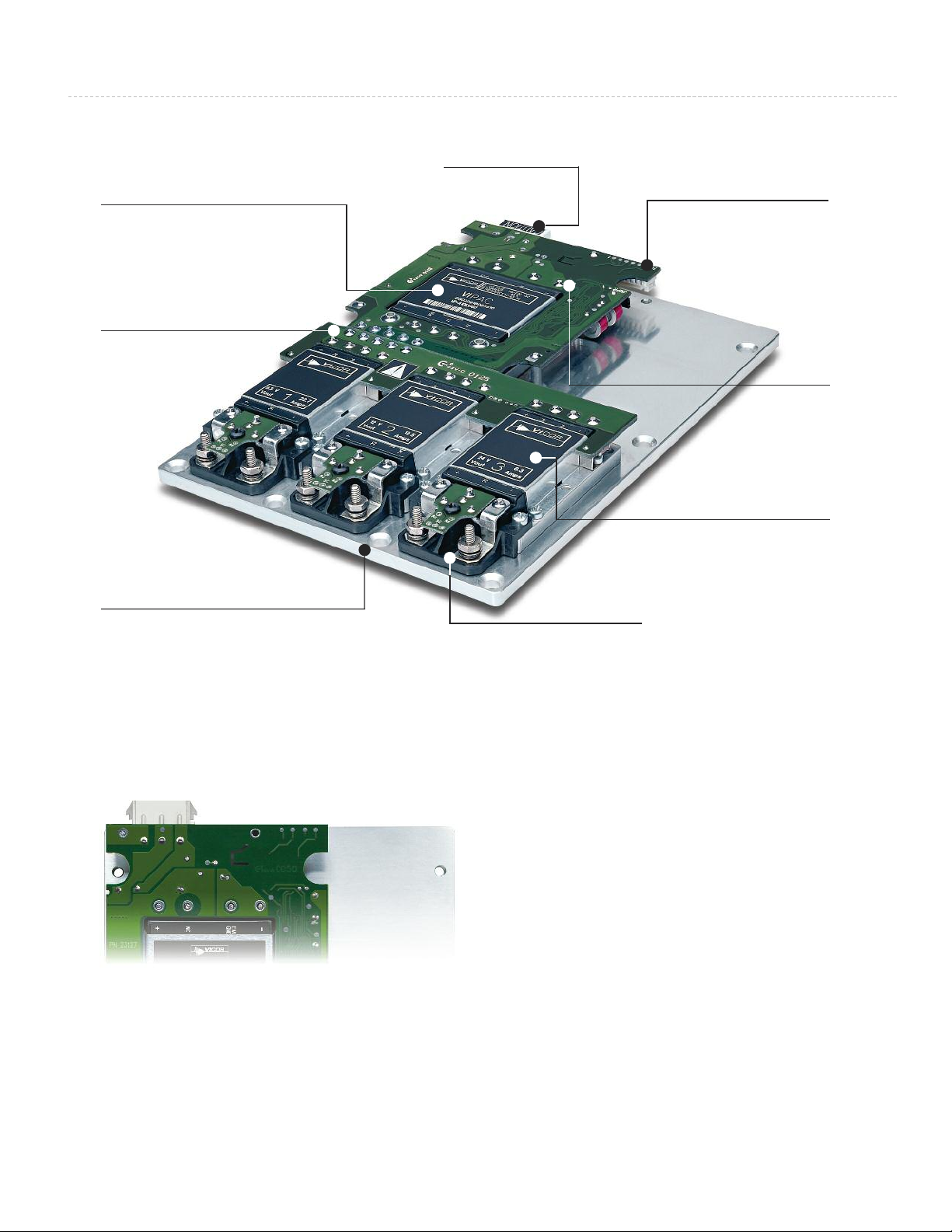

re-assembled and Tested Front Ends

P

M-FIAM5B – Filter Input Attenuator Module

-FIAM9 – Filter Input Attenuator Module

M

Rugged Interconnect Board

electable for Single, Multiple

S

r Parallel Outputs

o

Input Options

8 Vdc MIL-COTS version

2

Control Interface

Output Sequencing

BUS-OK /Bus Voltage Monitor

Output Enable / Disable

rotective Features

P

Inrush Current Limiting

nput Transient Protection

I

Auto Restart

EMI Filtering

Platform Options

Low Profile Coldplate

0.5" and 1" Optional Finned Configurations

DC Input

18 – 36 Vdc; 28 V nom.

Vicor’s Maxi, Mini, Micro Series

DC-DC Converters

Output Voltages 0.5 – 48 Vdc

50 – 400 W / Output

(1/4 Brick Modules Shown)

Choice of Output Termination

(LugMate Shown)

v i c o r p o w e r . c o m

3

Page 5

EATURES

–Out

–S

SC

+S

+Out

Load

R

D

Trim Down

Error

Amp

1k Ω

1.23 V

0.033 μF

–Out

SC

+Out

Load

R

D

Trim Down

Error

Amp

1 kΩ

1.23 V

0.033 μF

F

•

Control Interface

Power Up / Down control

Output sequencing for Turn-on, Turn-off

BUS-OK

•

Partitioned Power Architecture

Maximizes packaging flexibility

Enhanced reliability

Wide operating temperature range

–40˚ to +95˚C chassis H-Grade

–55˚ to +95˚C chassis M-Grade

•

Secondary Control

Output voltage trimming

10 – 110% Vout

Micro

Mini and Maxi

v i c o r p o w e r . c o m

4

Page 6

NPUT /

I

UTPUT

O

PTIONS

O

Output Voltage Selection

VIPAC

Configuration

MVC-G / MVX-G

MVC-D / MVX-D

MVC-A / MVX-A

# Outputs

Single

Single ll

Dual

Dual ll

Triple

# Outputs

Single

3.3 V 5 V 12 V 15 V 24 V 28 V 36 V 48 V Total

Micro Maximum Output Power (W)*

75 100 100 100 100 100 100 100 100

150 200 200 200 200 200 200 200 200

75 100 100 100 100 100 100 100

75 100 100 100 100 100 100 100

150 200 200 200 200 200 200 200

75 100 100 100 100 100 100 100

75

75 100 100 100 100 100 100 100 300

75 100

Mini Maximum Output Power (W)*

150 200 200 200 200 200 200 200 200

100 100 100 100 100 100 100

100 100 100 100 100 100

200

300

MVC-E / MVX-E

Single ll

MVC-B / MVX-B

MVC-F / MVX-F

*Model numbers and total output power capability are application specific.

Component tolerances may effect total output power (±5%) in parallel (//) configurations.

See VIPAC configuration tool at: vicorpower.com/vcad

MVC-xxx refers to M-FIAM5B

MVX-xxx refers to M-FIAM9

Dual

# Outputs

Single

300 400 400 400 400 400 400 400 400

150 200 200 200 200 200 200 200

150 200 200 200 200 200 200 200

Maxi Maximum Output Power (W)*

264 400 400 400 400 400 400 400 400

400

v i c o r p o w e r . c o m

5

Page 7

PECIFICATIONS

S

28 Vdc Input MIL-COTS Version

Parameter Min Typ Max Unit Notes

Operating input voltage 18 28 36 Vdc Continuous

Turn-on 18 Vdc

Inrush current 5.0 A pk

Inrush limiting 0.007 A µF

Transient immunity (M-FIAM5B) 50 Vdc 12.5 ms per MIL-STD-704E/F

Transient immunity (M-FIAM9) 100 Vdc 50 ms per MIL-STD-1275A/B/D

250 Vdc 70 ms per MIL-STD-1275A/B/D

70 Vdc 20 ms per MIL-STD-704A

50 Vdc 12.5 ms per MIL-STD-704E/F

EMI MIL-STD-461E Conducted emissions: CE101, CE102

Conducted susceptibility: CS101, CS114, CS115, CS116

Reverse Polarity Protection Internally fused

Environmental

Parameter Min Typ Max Unit Notes

Dielectric withstand

Input to chassis 1,500/2,121 Vrms/Vdc

Operating chassis temperature

H-Grade -40 95 °C

M-Grade -55 95 °C

Shock

(40 g for 15–23 ms, 75 g for 8–13 ms)

Vibration MIL-STD-810F Method 514.5, Procedure 1 (20–2000 Hz at 5 g)

Humidity 5 95 % Non-condensing

MIL-STD-810F

Method 516.5, Procedure 1

Output Specifications - General

Parameter Min Typ Max Unit Notes

Output voltage set point ±1 % Vout nom

Line regulation ±0.02 ±0.2 % Low line to high line; full load

Temperature regulation ±0.002 ±0.005 %/˚C Over operating temp. range

Over temperature shut down 115 ˚C

Power sharing accuracy ±2 ±5 % 10% to 100% of full load

Programming range 10 110 % Of nominal output voltage.

(For trimming below 90% of nominal, a minimum load

of 10% of maximum rated power may be required)

Current limit 115 % Iout max. Output voltage 95% of nominal

Short circuit current 115 % Iout max. Output voltage <250 mV

at 25°C, nominal line and nominal load, per module unless otherwise specified

Interface Control Functions

Type Master Output Output Bus Emergency

Enable Enable/Disable Sequencing OK Off

Local √ √ √

Ρεμοτε √ √ √ √ √

Output Sequencing

Power up will always occur in the defined sequence stored within the device. Any preprogrammed

power down sequence, except the default, will not be in effect upon loss or removal of the VIPAC

source voltage. Sequenced power down can only be achieved by issuing the requisite commands

through the interface before removing the source voltage.

v i c o r p o w e r . c o m

6

Page 8

ECHNICAL

DC-DC

Converter

Output #1

M-FIAM5B / M-FIAM9

+DC

-DC

+

PC

PR

–

+

PC

PR

–

+

PC

PR

–

+

S

C

–

DC-DC

Converter

Output #2

+

S

C

–

Line Filter

Transient Protection

Inrush Current Limiting

Reverse Polarity Protection

Logic Control

– Master Disable (Local mode)

– Output Sequencing

– Module Status

– BUS-OK

Control 1

Control 2

Control 3

DC-DC

Converter

Output #3

+

SC

–

+

_

Remote

RS232

Local Control

OR

User

Interface

Output

18 – 36 Vdc

I

nput

VIPAC BLOCK DIAGRAM - DC INPUT

J1

J3

GND

T

VERVIEW

O

Overview

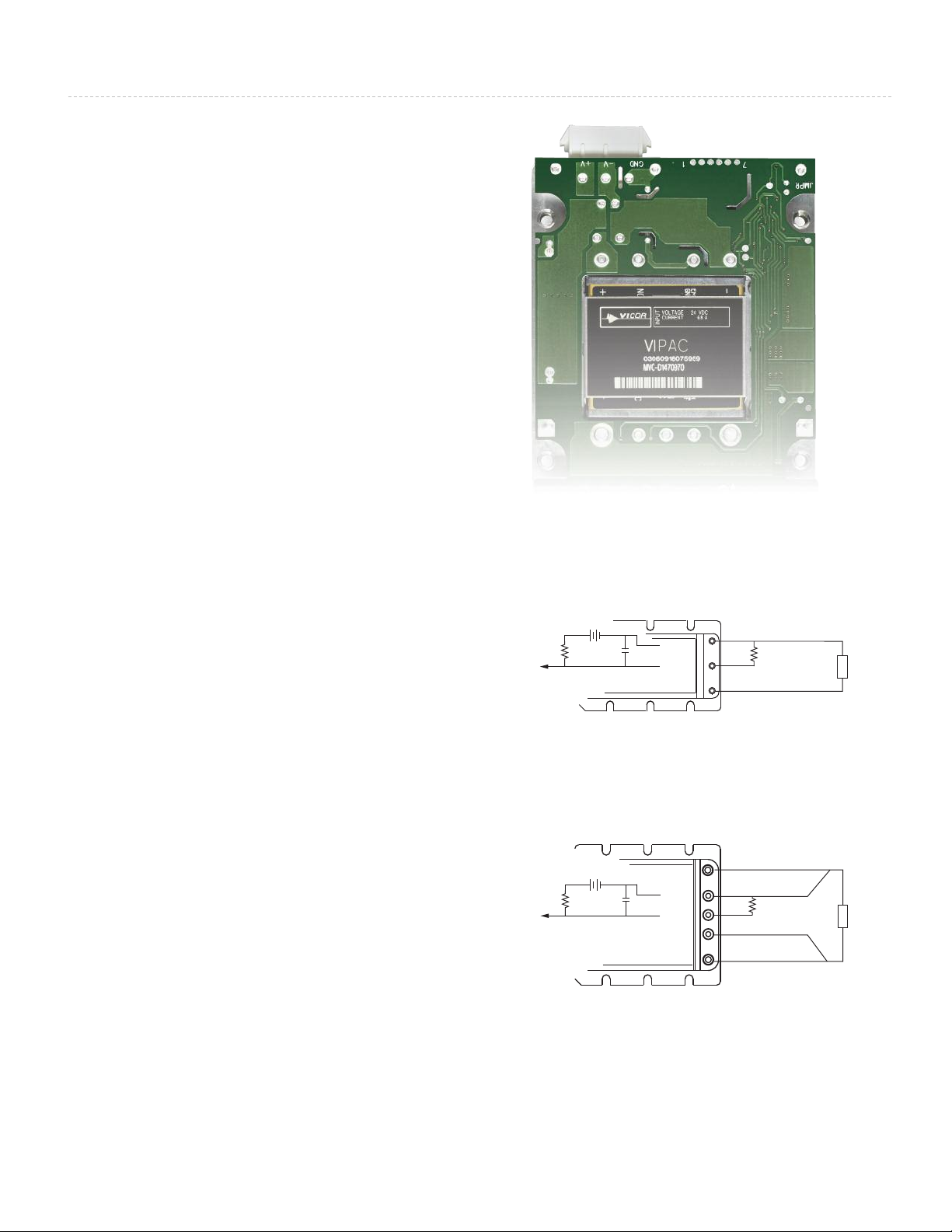

Vicor’s 28 Vdc for MIL-COTS VIPAC front-end section

utilizes either Vicor’s M-FIAM5B or M-FIAM9 input module to

provide EMI filtering, transient protection, inrush current limiting and rectification as appropriate. The front end also contains input connectors, fusing and control circuitry to which

the user can interface discrete circuitry.

Up to three Maxi, Mini, Micro Series DC-DC converters are

combined with the front end in an integrated mechanical as-

sembly providing a high efficiency power supply delivering up

to 400 W of output power.

Circuit Operation

The VIPAC utilizes either the M-FIAM5B or M-FIAM9 module

which provides inrush current limiting, transient protection

and EMI filtering. The DC voltage is applied via an agency approved 3-pin connector; a fuse in the the “+” lead protects the

VIPAC from damage due to internal shorts. At start up, inrush

current is limited by a FET. This FET serves as both an inrush

current limiter at power up and a voltage limiting device in

the event of an input transient over voltage condition.

The FET, driven by a DC bus voltage sense circuit, is brought to

a low impedance after initial power up.

The 28 V is applied to one or more Vicor Maxi, Mini, Micro DCDC converters which deliver the selected output voltage and

urrent levels. TheDC-DC converters provideoutput over volt-

c

age protection, output current limiting, voltage regulation trim

capability and input to output isolation.

Vicor’s VCAD configuration tool selects standard 24 V in Maxi,

Mini, and Micro modules for use within the VIPAC based on

the application requirements. The modules are

chosen based on the input and output requirements and the

closest, but higher power level that is available to that

specified. Specifications for these can be found on their respective data sheets.

v i c o r p o w e r . c o m

7

Page 9

1.5 mA

max.

V

+

r

BUS-OK

+

–

20 mA max.

Disable

MOD-DIS

V

+

+

–

VIPAC

J3

3

2

7

6

ECHNICAL

T

VERVIEW

O

VIPAC Control

The VIPAC provides the user with choices with respect to how

the unit is operated. It can be controlled locally by applying

he appropriate “digital” signals to the device.

t

BUS-OK

An internal replica of BUS-OK is wired to the PC pin of all in-

ternal DC-DC converter modules. The modules will be

disabled (no DC output) during initial power up of theVIPAC

until the internal DC input bus voltage to the DC-DC converters

is sufficient to support full load operation. The BUS-OK status

output reflects the status of this inhibit function. This same

logic circuit will shut down the converters when the internal

DC bus voltage is insufficient to support proper operation.

This shut down will occur during normal power down, line

dropouts exceeding the hold up time, or internal faults

causing the internal DC bus voltage at the input of the

converters to collapse. The BUS-OK output provides the user

with an optically isolated status indication of the internal

DC bus. This output, in AC powered system applications, can

provide power supply status, switch in backup (standby)

sources or initiate “power down”sequences to save volatile

memory contents in the event of a power loss. The time from

BUS-OK deassertion to output shut down is dependent upon

the value of hold upcapacitors used. The VIPAC online design

tool contains a hold up capacitor calculator which provides ap-

propriate values.

MOD-DIS+, MOD-DIS–

The MOD-DIS input is an optically coupled input and allows for

remote disabling of the output(s) of the VIPAC. Applying current

to the MOD-DIS+, MOD-DIS– input disables the supply.

The minimum input current for disabling the supplies is 3 mA.

he maximum allowable current is 20 mA.

T

Electrical Connections

Status output pair BUS-OK+, BUS-OK– are the collector (+) and

emitter (–) of an NPN optoisolator output transistor. In a typical

application, the collector terminal BUS-OK+ of the optocoupler

can be connected via current limiting resistors to a source no

greater than 70 Vdc. These resistors should limit the maximum

current to the optocoupler output transistors to 1.5 mA. The

emitter terminal BUS-OK– is connected to the return of the ex-

ternal source. The status OK condition will set the optocoupler

output transistors in saturation and are capable of sinking up to

1.5 mA with a Vce saturation voltage of 0.4 V. Users should be

cautioned that although the output of the VIPAC can be used as

the pull-up source, shortly after BUS-OK changes from OK

(saturated) to NOT OK (high Z), the pull-up voltage will be shut

down. If the pull-up source is one of theVIPACs outputs, it is

advisable to provide a capacitive reservoir in order to maintain

the pull-up potential after loss of DC current output. Use edge

sensing logicto detect assertion of logic outputs, or a separate

source of bias supply voltage (i.e., backup batteries) to provide a

safe pull-upvoltage source regardless of the line status.

v i c o r p o w e r . c o m

MOD-DIS Input

Apply a current of 3–20 mA

to disable output.

BUS-OK – Status Output

Transistor on when OK.

Vce sat. = < 0.4 V @ 1.5 mA

maximum external pull-up

is 70 Vdc.

BUS–OK signal is isolated

8

Page 10

NPUT CONNECTIONS

I

28 Vdc Input

Conn. Pin# Funct. Mating Conn.

J1 1 GND P/N 21394

2 – Vin

3 + Vin

I/O Interface*

Conn. Pin# Funct. Mating Conn.

I/O Interface

emovable Jumper

R

N= Local Control

I

P/N 22988

7

1

J3

8 Vdc Input

2

J3 1 NC P/N 22988

2 MOD-DIS–

3 MOD-DIS+

4 GND

5 NC

6 BUS-OK–

7 BUS-OK+

* See detailed description on Pgs 7– 8

P/N 21394

GND –Vin +Vin

J1

1

2

3

v i c o r p o w e r . c o m

9

Page 11

UTPUT CONNECTION

O

Discrete Output Configurations

PTIONS

O

LugMate

(Factory Installed Option)

Micro LugMate

1

1

1

R

ing Lugs LugMate Pin Out

Solder

Pin # Pad Function

1 – Vout

Rd Trim-Down

SC Secondary Control

Ru Trim-Up

3 + Vout

Micro LugMate - with Rd/Ru trim resistor

solder pads. (Design

#4-40 Torque 4 in. lbs.

calculator for trim resistors

located at vicorpower.com)

1

Rd

SC

Ru

Mini/Maxi LugMate

1

5

1

5

J4

J4

#10-32 Torque 16 in. lbs.

1

5

1

5

P/N 16385

3

Pin # Conn. Function Mating Conn.

1 – Vout

J4-1 – Vout

J4-2 – Sense

J4-3 Secondary Control P/N 16385

J4-4 + Sense

J4-5 + Vout

5 + Vout

*Removable jumper is facto ry ins talled for local sensing.

See Pg 22 for details

**For units configured in paralle l, one module will have

the SC jumped to the –S and –Out.

*Removable

Jumper

*Removable

Jumper

v i c o r p o w e r . c o m

10

Page 12

UTPUT CONNECTION

O

arallel Output Configurations

P

Shown with the output of two modules connected in parallel using BUS BARS.

PTIONS

O

LugMate

Factory Installed Option)

(

Micro LugMate

1

1

1

Ring Lugs LugMate Pin Out

older

S

Pin # Pad Function

1 – Vout

Rd Trim-Down

SC Secondary Control

Ru Trim-Up

3 + Vout

Micro LugMate - with Rd/Ru trim

#4-40 Torque 4 in. lbs.

resistor solder pads.

(Design calculator

for trim resistors

located at vicorpower.com)

1

Rd

SC

Ru

Mini/Maxi LugMate

1

5

1

5

J4

J4

#10-32 Torque 16 in. lbs.

1

5

1

5

P/N 16385

3

Pin # Conn. Function Mating Conn.

1 – Vout

J4-1 – Vout

J4-2 – Sense

J4-3 Secondary Control** P/N 16385

J4-4 + Sense

J4-5 + Vout

5 + Vout

*Removable jumper is facto ry ins talled for local sensing.

See Pg 22 for details

**For units configured in paralle l, one module will have

the SC jumped to the –S and –Out.

*Removable

Jumper

*Removable

Jumper

v i c o r p o w e r . c o m

11

Page 13

UTPUT CONNECTION

14

5

8

1

9

10

1

8

1

12

13

24

O

PTIONS

O

PlugMate

Factory Installed Option)

(

Micro PlugMate

Mini PlugMate

Maxi PlugMate

Mating Connector Kits

icor P/N 25073

V

Vicor P/N 25067

PlugMate Pin Out

Looking into PlugMate)

(

Pin # Function Pin # Function

1 +Vout 5 +Vout

2 +Vout 6 N/C

3 –Vout 7 SC

4 –Vout 8 –Vout

Mating Connector Tyco Elect. P/N Vicor P/N

Housing TYC-794657-8 25056

Pin 1-106529-2 24796

Kit 25073

Pin # Function Pin # Function

1 +Vout 10 +Vout

2 +Vout 11 +Vout

3 +Vout 12 +Vout

4 N/C 13 +S

5 N/C 14 SC

6 N/C 15 –S

7 –Vout 16 –Vout

8 –Vout 17 –Vout

9 –Vout 18 –Vout

Mating Connector Tyco Elect. P/N Vicor P/N

Housing TYC1-794657-8 25050

Pin 1-106529-2 24796

Kit 25067

Note:

VIPACs that contain multiple modules configured as a single output (paralleled

for power or redundancy) MUST have their Outputs and Sense connected to each

other at the load.

DO NOT OPERATE A PARALLEL CONFIGURATION WITH ONLY ONE

MODULE CONNECTED.

v i c o r p o w e r . c o m

Vicor P/N 25061

Pin # Function Pin # Function

1 +Vout 13 +Vout

2 +Vout 14 +Vout

3 +Vout 15 +Vout

4 +Vout 16 +Vout

5 +Vout 17 +Vout

6 N/C 18 +S

7 SC 19 –S

8 –Vout 20 –Vout

9 –Vout 21 –Vout

10 –Vout 22 –Vout

11 –Vout 23 –Vout

12 –Vout 24 –Vout

Mating Connector Tyco Elect. P/N Vicor P/N

Housing TYC2-794657-4 25044

Pin 1-106529-2 24796

Kit 25061

12

Page 14

HASSIS CONFIGURATIONS

C

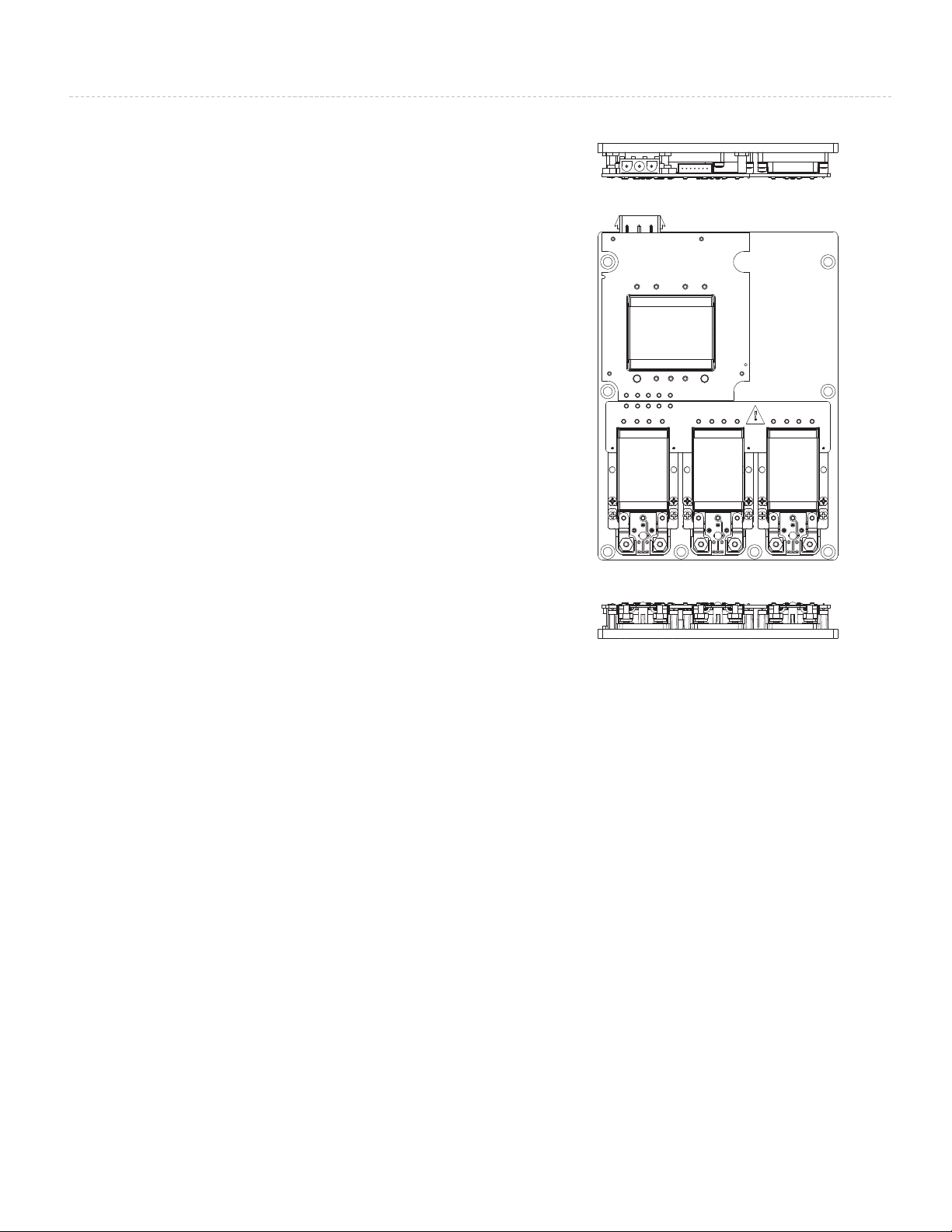

MVC-A / MVX-A

3 MICRO

• 4.96" x 6.8" (126,0 x 172,7 mm)

• Dual or Triple Output

• Up to 300 W

MVC-E / MVX-E

1 MINI

• 3.15" x 6.8" (80,0 x 172,7 mm)

• Single Output

• Up to 200 W

MVC-B / MVX-B MVC-D / MVX-D

2 MINI

• 4.96" x 6.8" (126,0 x 172,7 mm)

• Single or Dual Output

• Up to 400 W

MVC-F / MVX-F

1 MAXI

• 3.15" x 9.15" (80,0 x 232,4 mm)

• Single Output

• Up to 400 W

2 MICRO

• 3.15" x 6.8" (80,0 x 172,7 mm)

• Single or Dual Output

• Up to 200 W

MVC-G / MVX-G

1 MICRO

• 3.15" x 6.8" (80,0 x 172,7 mm)

• Single Output

• Up to 100 W

Finned Chassis Configurations

Coldplate

Optional 0.5" Fin

Optional 1" Fin

v i c o r p o w e r . c o m

Longitudinal

Transverse

13

Page 15

OUNTING

M

PTIONS

O

Through-hole Mounting

VIPAC with integral

inned heat sink

f

through-hole

ounted

m

S

urface Mounting

External user

supplied heat sink

hermal

T

compound

oth sides

b

VIPAC with integral finned heat sink

through-hole mounted

VIPAC with external user

supplied heat sink

v i c o r p o w e r . c o m

14

Page 16

Thermal compound

oldplate VIPAC

C

oldplate VIPAC mounted

C

to custom thermal interface

For proper clearance use:

Long standoff (P/N 23709) for

mounting 1" heat sink fins down.

Short standoff (P/N 23710) for mounting

0.5" heat sink fins down

or either heat sink fins up.

VIPAC with integral

finned heat sink (down)

VIPAC with integral

finned heat sink (up)

v i c o r p o w e r . c o m

15

Page 17

ECHANICAL

0.81

(20,6)

0.50

(12,7)

1.00

(25,4)

1.31

(33,3)

0.32

(8,1)

0.08

(2,0)

0.22

(5,6)

0.75

(19,1)

0.56

(14,2)

1.37

(34,8)

1.87

(47,5)

M

RAWINGS

D

Please reference the mechanical drawings on the MIL-COTS VIPAC Power System web page at

www.vicorpower.com.

Heat Sink Options

Coldplate 0.5" Fin Option 1" Fin Option

Fin spacing and relief

are the same for both Fin options.

ECHANICAL INFORMATION

M

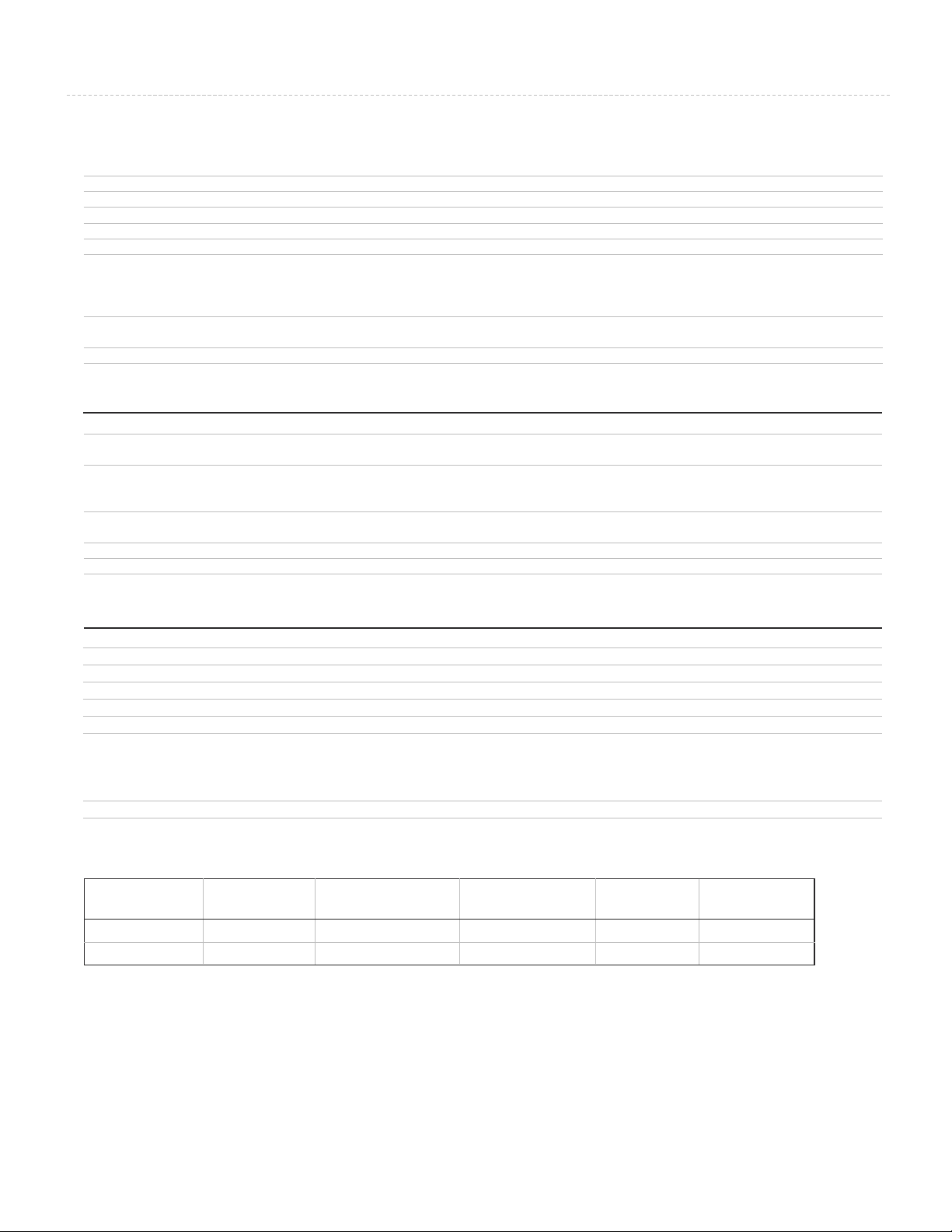

VIPAC Product Weight

Chassis Configuration

VIPAC Chassis Coldplate 0.5" Fins 1" Fins

Model Prefix Configuration

Pounds Grams Pounds Grams Pounds Grams

MVC-G / MVX-G 1 Micro 0.9 411 1.4 640 1.6 731

MVC-D / MVX-D 2 Micro 1.0 457 1.5 686 1.7 777

MVC-A / MVX-A 3 Micro 1.4 640 2.2 1006 2.5 1143

MVC-E / MVX-E 1 Mini 1.0 457 1.4 640 1.6 731

MVC-B / MVX-B 2 Mini 1.4 640 2.2 1006 2.6 1189

MVC-F / MVX-F 1 Maxi 1.3 594 2.0 914 2.3 1051

VIPAC Standoff Mounting Kits

Vicor Kit P/N Kit Description For use with:

23709 Qty. 6-#23655 long standoff 1” finned heat sinks

23710 Qty. 6-#23656 short standoff 1/2” finned heat sinks or coldplate

v i c o r p o w e r . c o m

16

Page 18

HERMAL

T

ANAGEMENT

M

Thermal Impedance Specifications

VIPAC Chassis Natural 200 400 600 800 1000 1200

odel Prefix Config. Heat Sink Convection (LFM) (LFM) (LFM) (LFM) (LFM) (LFM)

M

MVC-A / MVX-A 3 Micro 0.5" L 1.98 0.77 0.53 0.45 0.39 0.36 0.33

0.5" T 1.71 0.68 0.48 0.40 0.36 0.33 0.30

1.0" L 1.68 0.58 0.42 0.36 0.32 0.30 0.28

1.0" T 1.27 0.46 0.33 0.28 0.25 0.23 0.21

MVC-B / MVX-B 2 Mini 0.5" L 1.90 0.77 0.53 0.44 0.39 0.36 0.33

0.5" T 1.67 0.69 0.48 0.41 0.37 0.33 0.31

1.0" L 1.49 0.54 0.39 0.34 0.31 0.28 0.27

1.0" T 1.22 0.47 0.33 0.28 0.25 0.23 0.21

MVC-D / MVX-D 2 Micro 0.5" L 3.13 1.28 0.89 0.74 0.66 0.59 0.54

0.5" T 2.40 1.02 0.73 0.63 0.56 0.51 0.47

1.0" L 2.81 0.97 0.70 0.60 0.54 0.50 0.46

1.0" T 1.87 0.75 0.55 0.47 0.42 0.39 0.35

(˚C/W)

Airflow

MVC-E / MVX-E 1 Mini 0.5" L 3.11 1.26 0.88 0.74 0.65 0.59 0.54

0.5" T 2.39 1.01 0.73 0.62 0.56 0.51 0.47

1.0" L 2.51 0.87 0.64 0.56 0.51 0.48 0.45

1.0" T 1.76 0.70 0.52 0.44 0.40 0.37 0.33

MVC-F / MVX-F 1 Maxi 0.5" L 2.42 1.02 0.69 0.57 0.50 0.45 0.41

0.5" T 1.72 0.77 0.55 0.47 0.42 0.38 0.37

1.0" L 2.01 0.72 0.52 0.45 0.41 0.38 0.36

1.0" T 1.26 0.53 0.38 0.33 0.29 0.27 0.25

MVC-G / MVX-G 1 Micro 0.5" L 3.13 1.28 0.89 0.74 0.66 0.59 0.54

0.5" T 2.40 1.02 0.73 0.63 0.56 0.51 0.47

1.0" L 2.81 0.97 0.70 0.60 0.54 0.50 0.46

1.0" T 1.87 0.75 0.55 0.47 0.42 0.39 0.35

v i c o r p o w e r . c o m

17

Page 19

ENERAL INFORMATION

G

Input Mating Connector Kits

art Number Description

P

23487 For use with: 28 Vdc Input VIPACs

Kit Contains: One 3-pin DC Input mating connector, Vicor P/N 21394

One I/O Interface mating connector, Vicor P/N 22988

O

utput Mating Connector Kits

Part Number Description

23488 For use with: Mini or Maxi LugMate

Kit Contains: One control connector, Vicor P/N 16385

Suggested Wire Gauge

Function Wire Gauge Application

DC Input/Output #20 0 A – 3 A

Leads

Two ring lugs

23489 For use with: Micro LugMate

Kit Contains: Two ring lugs

25061 For use with: Maxi PlugMate

Kit Contains: One 24 pin housing, Vicor P/N 25044

24 pins, Vicor P/N 24796

#18 4 A – 6 A

#16 7 A – 10 A

#14 11 A – 15 A

#12 16 A – 25 A

#10 26 A – 40 A

#8 41 A – 65 A

#6 66 A – 104 A

#4 105 A – 160 A

25067 For use with: Mini PlugMate

Kit Contains: One 18 pin housing, Vicor P/N 25050

18 pins, Vicor P/N 24796

25073 For use with: Micro PlugMate

Kit Contains: One 8 pin housing, Vicor P/N 25056

8 pins, Vicor P/N 24796

Mating Connector Cross Reference

Manufacturer Part Number Crimping Tools

Designator Description Vicor P/N

Pin & Housing Manufacturer Pin Housing Wire Size Hand Die Set

Tool P/N P/N

J1 VIPAC DC Input - 3 Pin 21394 Tyco

Electronics 12 AWG 69710-1 58380-1

J3 VIPAC I/O Interface - 7 Pin 22988 JST 07KR-6S N/A

J4 VIPAC Output Control - 5 Pin 16385 Tyco

Electronics

Micro PlugMate mating connector 25073 Tyco

8 pin Electronics

Mini PlugMate mating connector 25067 Tyco

18 pin Electronics

Maxi PlugMate mating connector 25061 Tyco

24 pin Electronics

* 770251-3 is an acceptable alternative

193842-1* 770018-1

644083-5 N/A

1-106529-2 794657-8 18-20 AWG 91508-1 N/A

1-106529-2 1-794657-8 18-20 AWG

1-106529-2 2-794657-4 18-20 AWG

14 AWG 91506-1 N/A

AMP

91508-1

91508-1

N/A

N/A

v i c o r p o w e r . c o m

18

Page 20

PPLICATION TIPS

A

Selecting Heat Sinks

VIPAC Power Systems are rated for operation in ambient

temperatures up to 65˚C with a maximum chassis temperature of

95˚C. Operation within these limits is essential for long life and

users should select an appropriate thermal management system.

The thermal performance of a particular VIPAC chassis

configuration can be approximated from the thermal resistance

of the chassis, ambient operating temperature and total power

issipation, using a few simple formulas shown below.

d

Thermal Resistance:

Ambient Temperature:

Power Dissipation:

Example:

Verify a 400 W, 28 Vdc output VIPAC does not exceed 95˚C

chassis temperature (Tc).

• MVP-B chassis configuration with 1" transverse heat

sink is selected and 200 LFM airflow is provided.

• Thermal resistance (θ) of 0.47˚C/W is obtained from

the chart on pg 20.

• Ambient operating temperature (TA) specified by the

user is 40˚C.

• VIPAC Power System efficiency (η) is 80% overall.

Formula:

Pout

Tc = (( – Pout) x θ) + TA

Conclusion:

This VIPAC will operate in the conditions specified and

not exceed maximum chassis temperature.

η

400

= (( – 400) x 0.47) + 40

0.8

= 87˚C

Refer to pg 20

User specified,not to exceed 65˚C

Calculated as: (Pout/Efficiency)–Pout

VIPAC Power System Dissipation

Pout (n)

Pdiss =

Remote Sense

A remote sense feature is provided on outputs configured

w

sense connections must be terminated either locally or re-

motely and may not be left open. The sense lines for

VIPACs configured with a single paralleled output must

be terminated to the same point. VIPACs provided with

the optional LugMate connectors are configured for local

sensing via removable jumpers installed at the factory.

The jumpers will need to be removed if access to the

secondary control function is made via mating connector

P/N 16385 and connections will need to be established

for local or remote sensing.

Wire Routing

Avoid routing wires over VIPAC Power System.

Do not bundle Input and Output leads together.

Parallel Outputs

The VIPAC can be configured with parallel modules for

increased power or redundancy. When used for increased

power, short the SC pin to –Sense on one module. This

configures the module as a Booster. The user must

properly connect the output and sense terminals (See

above). At no time operate a paralleled output with a load

applied only to one module! (See Output Connection

Options, pages 10 – 12)

Σ

1 – n

ith Mini or Maxi sized DC-DC converters. The output

η(n)

0.95

- Pout (n)

Comment:

Efficiency of a particularVIPAC will depend on the

specific output voltages and operating load conditions.

In general the efficiency ofVIPACs with outputs of

5 Vdc or less is approximately 70% and those with

outputs greater than 5 Vdc is 80%. A more accurate

calculation can be derived by summing dissipation of

each DC-DC converter module used in theVIPAC and

the front-end section of theVIPAC (using 95% efficiency

for the front end).

v i c o r p o w e r . c o m

19

Page 21

ECHNICAL SUPPORT CONTACTS

T

USA

vicorpower.com

Vicor Corporation

(Corporate Headquarters)

5 Frontage Road

2

Andover, MA 01810-5413

For General Information

Tel: 978-470-2900

Fax: 978-475-6715

For Technical Support

Tel: 800-927-9474

Fax: 978-749-3341

Email: apps@vicorpower.com

For Sales Support

In U.S. and Canada: 800-735-6200

Fax: 978-475-6715

Email: custserv@vicorpower.com

Vicor Corporation

Lombard, IL

Tel: 630-769-8780

Fax: 630-769-8782

Vicor Westcor Division

Sunnyvale, CA

Tel: 408-522-5280

Fax: 408-774-5555

westcorpower.com

Europe

vicoreurope.com

00 800 8426 7000 (Europe free phone)

Vicor France

aris

P

Tel: +33 1 34 52 18 30

Fax: +33 1 34 52 28 30

Email: expressfr@vicorpower.com

Asia-Pacific

Vicor Japan Co., Ltd.

Tel: +81 3 5487 3880

Fax: +81 3 5487 3885

vicorpower.jp

Vicor Hong Kong

Tel: +852 2956 1782

Fax: +852 2956 0782

vicor-asia.com

Vicor Germany

Munich

Tel: +49 89 962 439 0

Fax: +49 89 962 439 39

Email: expressde@vicorpower.com

Vicor Italy

Milan

Tel: +39 02 2247 23 26

Fax: +39 02 2247 31 66

Email: expressit@vicorpower.com

Vicor U.K.

Camberley

Tel: +44 1276 678222

Fax: +44 1276 681269

Email: expressuk@vicorpower.com

Picor Corporation

North Smithfield, RI

Tel: 401-235-1100

Fax: 401-235-1117

picorpower.com

Information furnished by Vicor is believed to be accurate and reliable. However, no responsibility is assumed by

Vicor for its use. No license is granted by implication or otherwise under any patent or patent rights of Vicor. Vicor

components are not designed to be used in applications, such as life support systems, wherein a failure or mal-

function could result in injury or death. All sales are subject to Vicor’s Terms and Conditions of Sale, which are

available upon request. No user serviceable components, contact Vicor to arrange for repair or replacement.

Specifications are subject to change without notice.

vi co rp owe r. co m

Rev. 1.6 10/13

Loading...

Loading...