Page 1

Design Guide & Applications Manual

For VI-200 and VI-J00 Family DC-DC Converters

and Configurable Power Supplies

Page 2

Design Guide & Applications Manual

or VI-200 and VI-J00 Family DC-DC Converters and Configurable Power Supplies

F

Table of Contents

VI-/MI-200 and VI-/MI-J00 DC-DC Converters Section Page(s)

Zero-Current-Switching 12

DC-DC Converter Pinouts 23

Module Do’s and Don’ts 3 4 – 6

vercurrent Protection

O

4

7

Output Voltage Trimming 5 8 – 10

Multiple GATE IN Connections 6 11

Application Circuits / Converter Array Design Considerations 7 12 – 13

Using Boosters and Parallel Arrays 8 14 – 17

EMC Considerations 9 18 – 28

Optional Output Filters 10 29

Battery Charger (BatMod) 11 30 – 32

Filter & Front-End Modules

AC Input Module (AIM / MI-AIM) 12 33 – 36

Harmonic Attenuator Module (HAM) 13 37 – 42

Input Attenuator Module (IAM / MI-IAM) 14 43 – 46

Ripple Attenuator Module (RAM / MI-RAM) 15 47

Offline Front End 16 48 – 51

Configurable Products

DC Input Power System (ComPAC / MI-ComPAC Family) 17 52 – 54

AC Input Power System (FlatPAC Family) 18 55 – 57

AC Input Power System (PFC FlatPAC) 19 58 – 59

General

Thermal and Module Mounting Considerations 20 60 – 67

Thermal Curves 21 68 – 77

Lead Free Pins (RoHS) 22 78 – 82

Tin Lead Pins 23 83 – 87

Module Packaging Options (SlimMod, FinMod, BusMod and MegaMod Families) 24 88

Product Weights 25 89

Glossary of Technical Terms 26 90 – 97

: This Design Guide and Applications Manual does NOT address Vicor’s Maxi, Mini and Micro DC-DC

NOTE

converters. For more information on these products go to vicorpower.com .

VI-200 and VI-J00 Family Design Guide Rev 3.5 vicorpower.com

Page 1 of 98

Apps. Eng. 800 927.9474 800 735.6200

Page 3

Referen ced

to –Vin

[a]

Not in VI-J00 Series

Gate

Out

Vs

Vout

Vin

Ip

Vp

2.5 V

REF.

Output Filter

Integrator

Vs

Ip

Vp

MOSFET

Input

Filter

OC2

OC1

[a]

–S

TRIM

+S

E/A

+

+

–

+Vout

–Vout

Co

Lo

C

D2

D1

Reset

Control

GATE

IN

-Vin

+Vin

Logic

Control

Load

C/L

OTS

[a]

OVP

[a]

GATE

OUT

–

T1

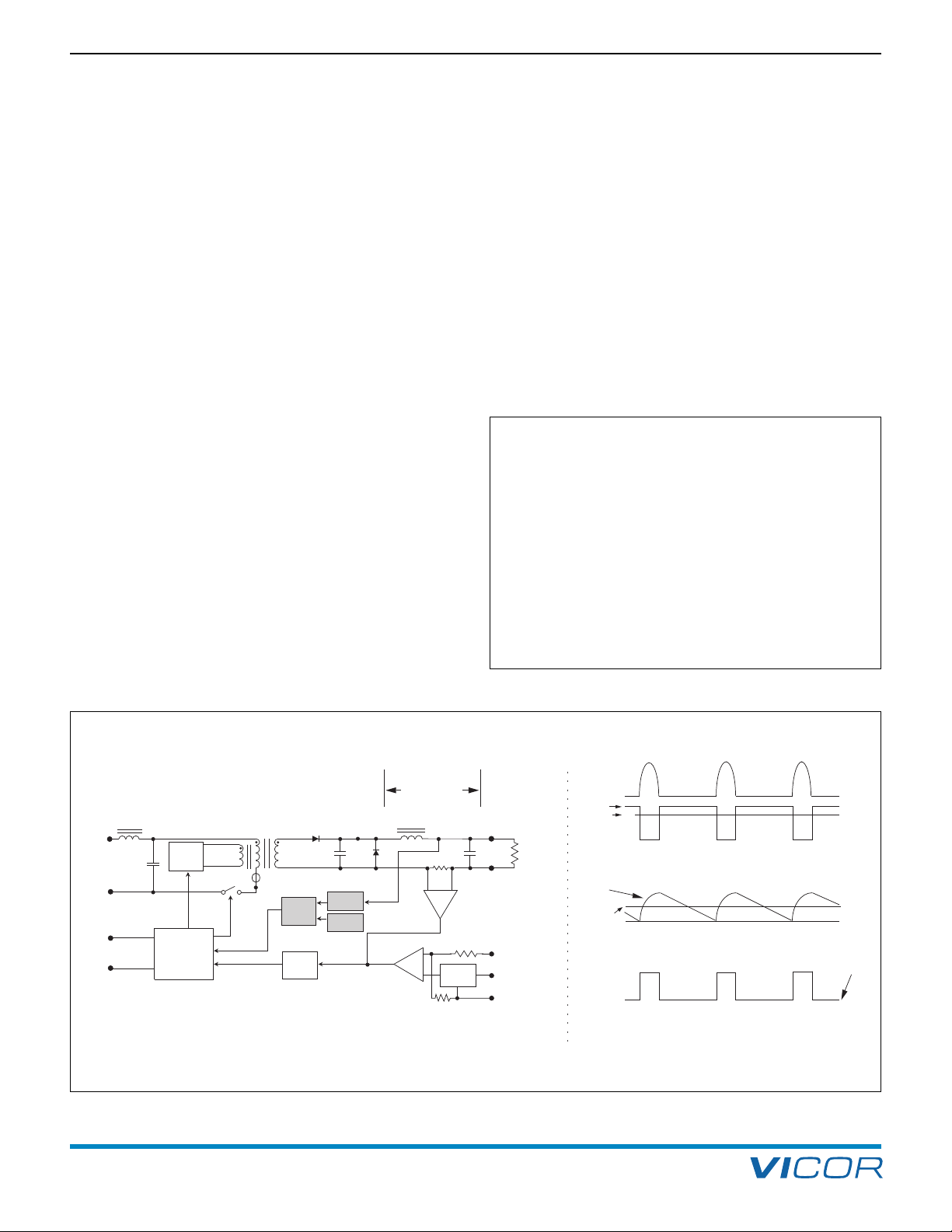

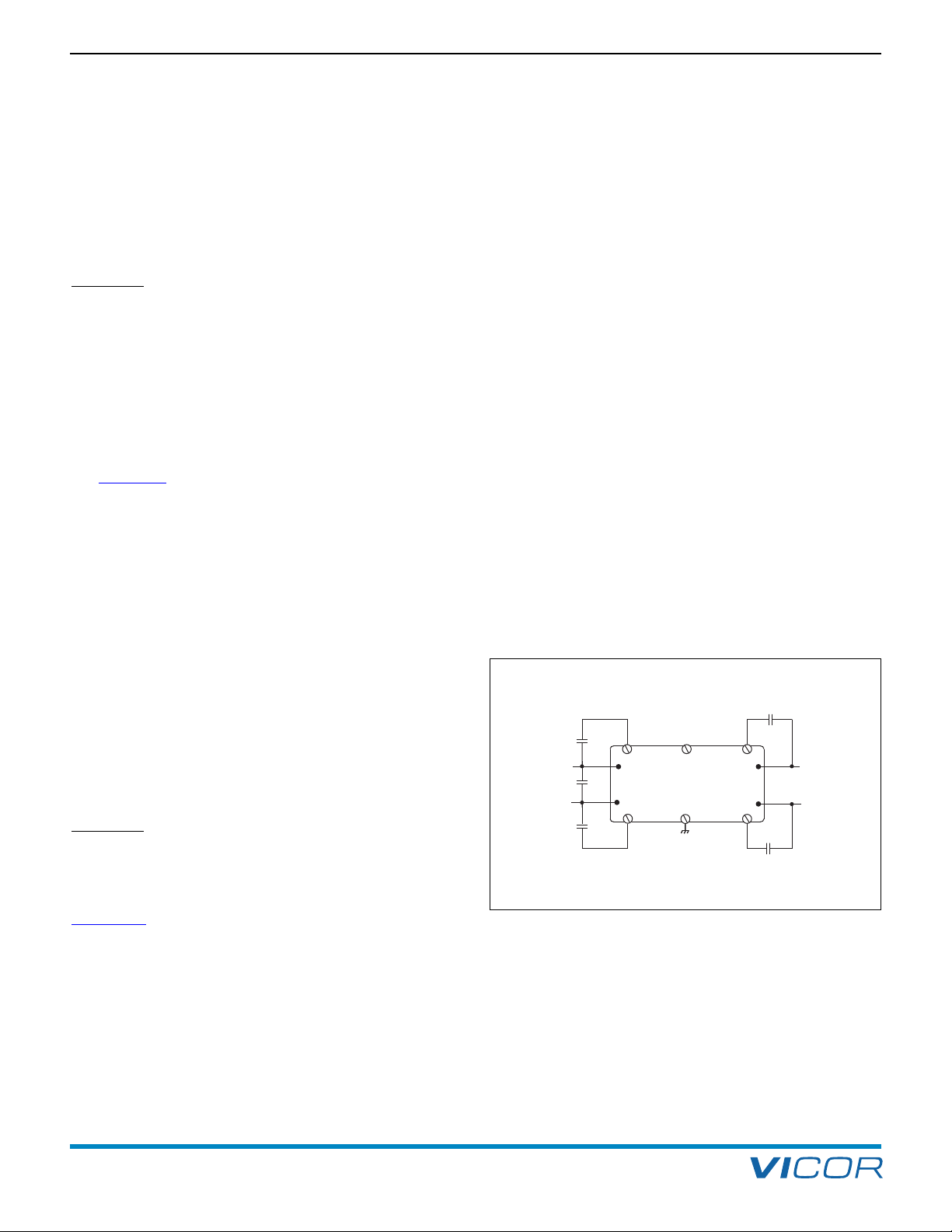

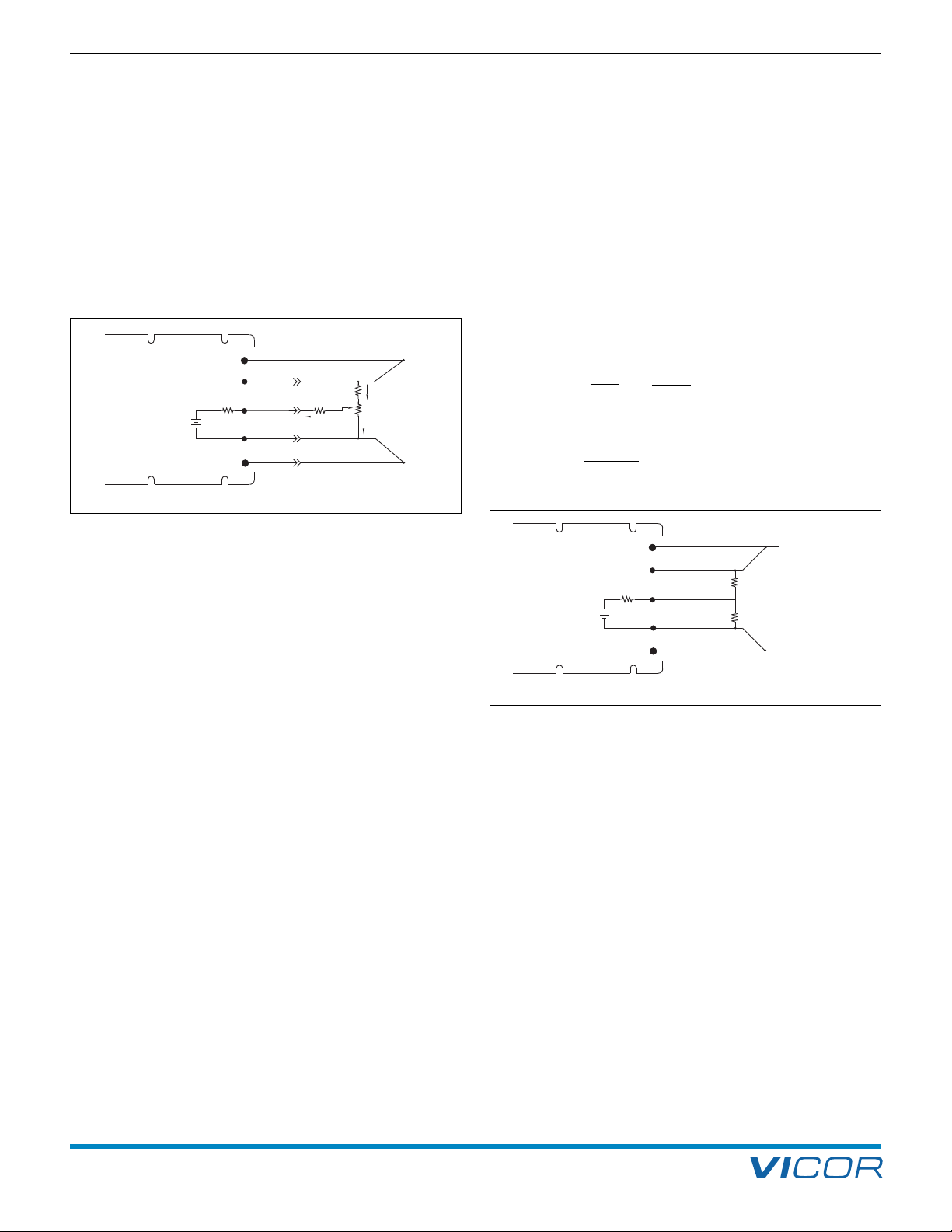

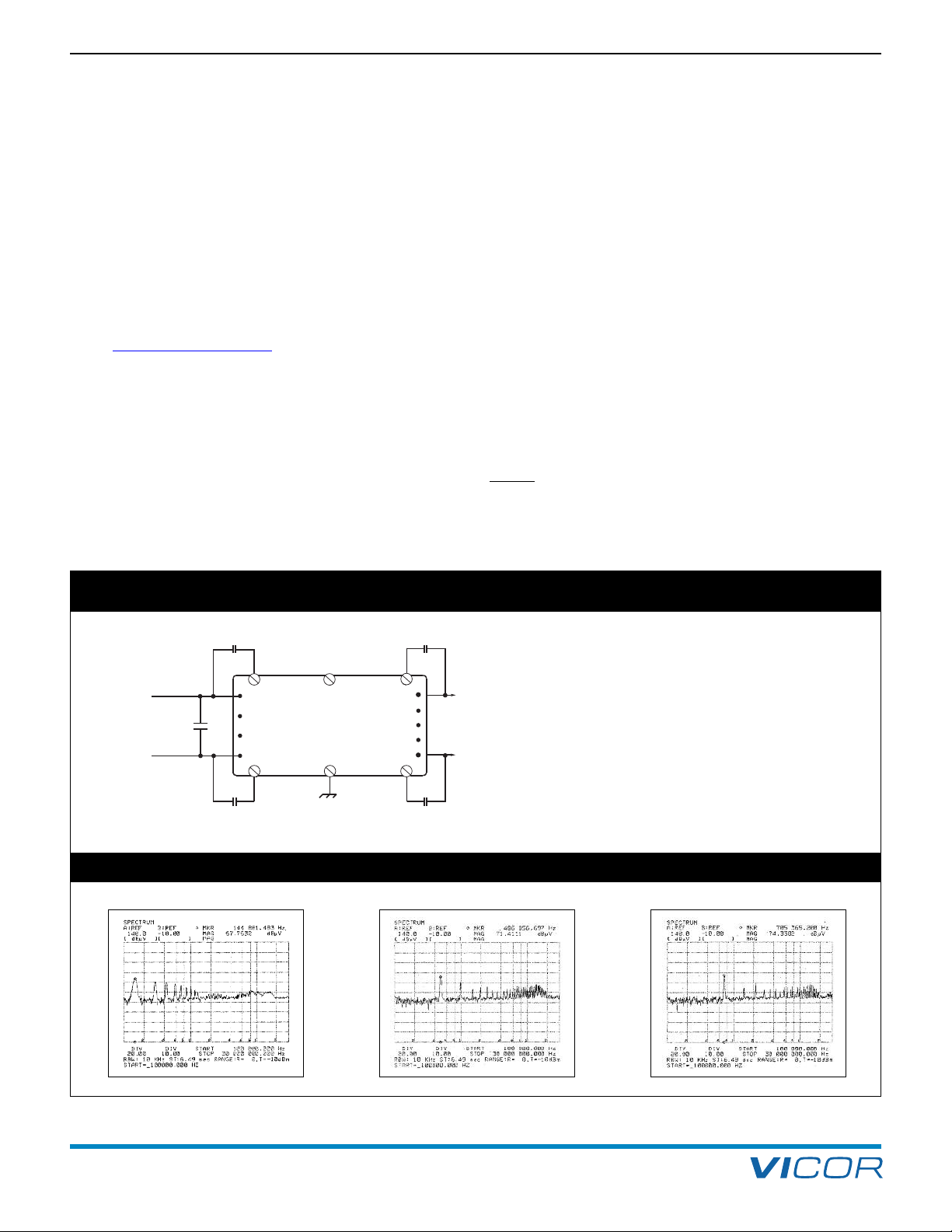

1. Zero-Current-Switching

or VI-200 and VI-J00 Family DC-DC Converters and Configurable Power Supplies

F

Design Guide & Applications Manual

OVERVIEW

Vicor offers RoHS compliant modules. These modules have

a “VE” prefix. The information presented herein applies to

both versions, and “VI” will be the default designation.

he heart of Vicor’s VI-/ MI-200 and VI-/ MI-J00 module

T

technology, zero-current-switching, allows Vicor

converters to operate at frequencies in excess of 1 MHz,

with high efficiency and power density. Depending on

input voltage and load, the converters operate at

frequencies ranging from the low hundreds of kilohertz

(light load, high line) to approximately one megahertz (full

load, low line). Another aspect of the Vicor topology is

that two or more power trains driven at the same

frequency will inherently load-share if their outputs are

tied together. Load sharing is dynamic and is within 5%.

The VI-200 and MI-200 product line offer both Driver and

Booster modules:

• Drivers and Boosters must have identical power trains.

• Drivers close the voltage loop internally, Boosters do not.

• Boosters may be slaved to a Driver, allowing

configurations of multi-kilowatt arrays, which

exhibit dynamic current sharing between modules.

• Only a single control connection is needed between

modules with all module’s power inputs and outputs,

connected together — no trimming, adjustments, or

external components are required to achieve load sharing.

LOSSLESS ENERGY TRANSFER

Referring to Figure and Table 1–1 below, turn-on of the

MOSFET switch transfers a quantized energy packet from

the input source to an LC “tank” circuit, composed of

inherent transformer leakage inductance of T1 and a

capacitive element, C, in the secondary. Simultaneously,

an approximately half-sinusoidal current flows through the

switch, resulting in switch turn-on at zero current and

turn-off when current returns to zero. Resonance, or

bidirectional energy flow, cannot occur because D1 will

only permit unidirectional energy transfer. A low-pass filter

(Lo, Co) following the capacitor produces a low ripple DC

output. The result is a virtually lossless energy transfer

from input to output with greatly reduced levels of

conducted and radiated noise.

Ip: Primary current

Vp: Primary voltage

Vs: Secondary voltage

OVP: Overvoltage protection (output)

OTS: Over temperature shutdown

OC1, OC2: Opto-coupler

E/A: Error amplifier

REF: Bandgap reference

C/L: Current limit amplifier

Table 1–1

Apps. Eng. 800 927.9474 800 735.6200

Figure 1–1 — VI-/MI-200 and VI-/MI-J00 series zero-current-switching block diagram

VI-200 and VI-J00 Family Design Guide Rev 3.5 vicorpower.com

Page 2 of 98

Page 4

Design Guide & Applications Manual

GATE

IN

G

ATE

OUT

+IN

–

OUT

–S

T

+S

+OUT

GATE

IN

GATE

OUT

+IN

–OUT

–S

T

+S

–IN

–IN

+OUT

or VI-200 and VI-J00 Family DC-DC Converters and Configurable Power Supplies

F

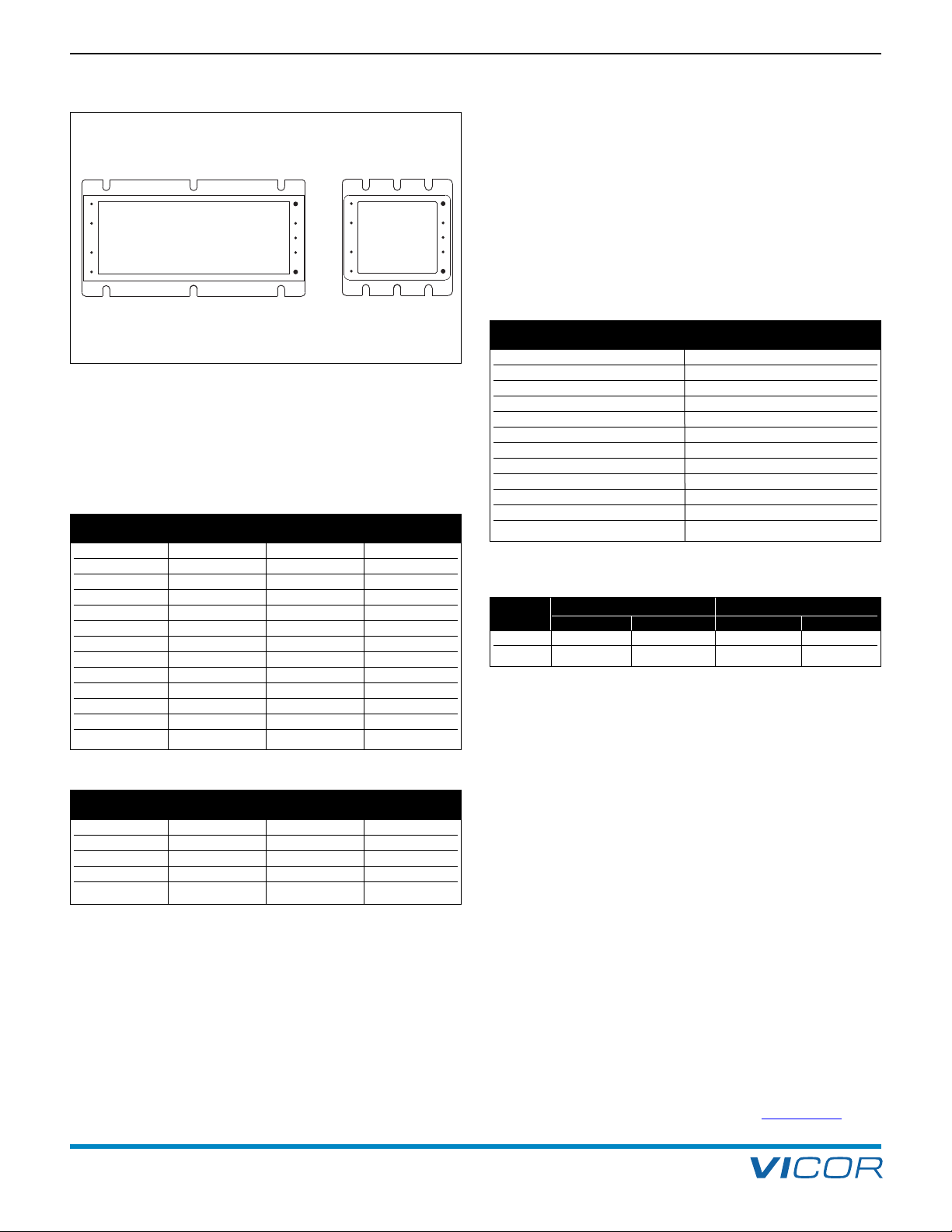

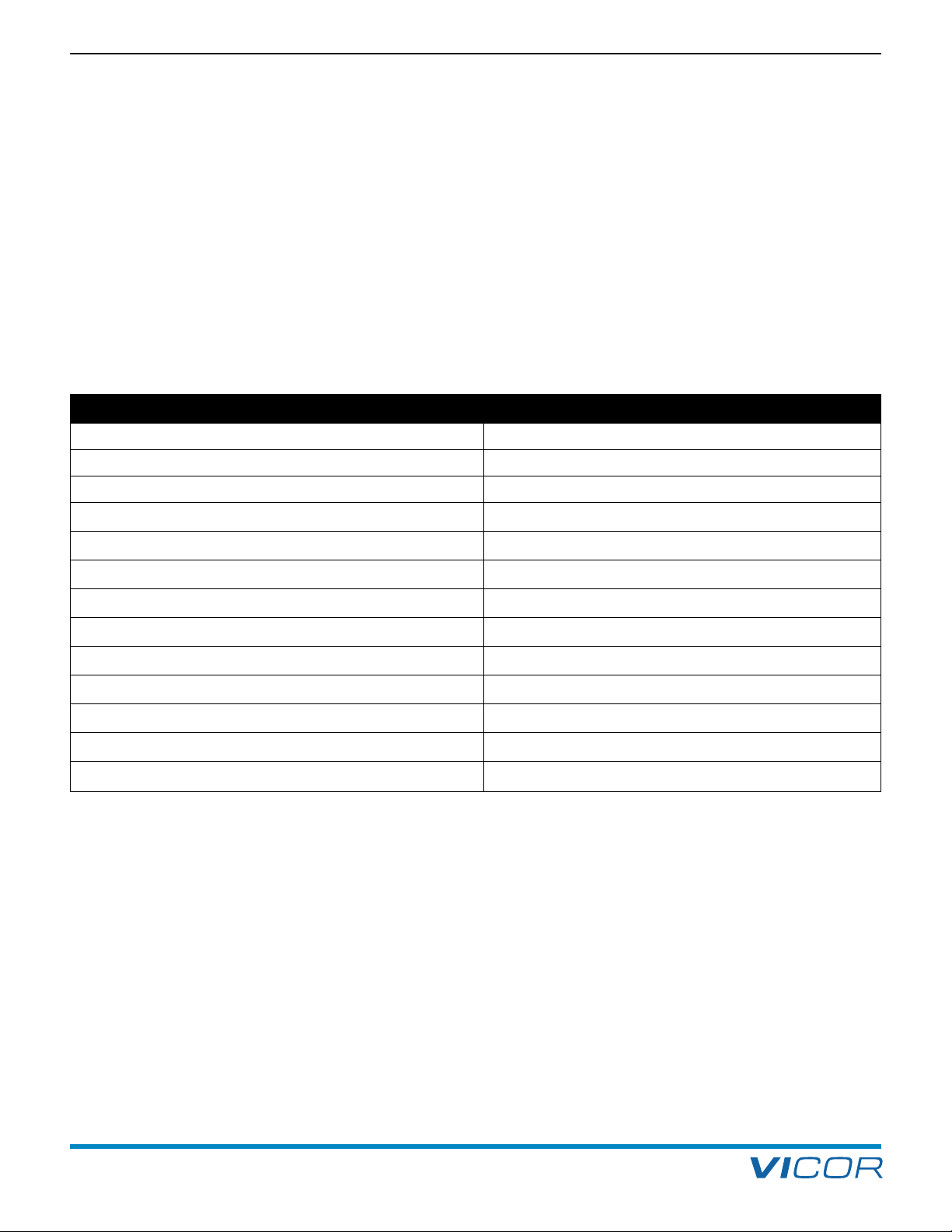

Figure 2–1 — VI-/MI-200, VI- / MI-J00

–IN, + IN. DC voltage inputs. See Tables 2–1 and 2–2 for

nominal input voltages and ranges for the VI-/MI-200 and

VI-/MI-J00 Family converter modules (data sheets contain

Low Line, 75% Max. Power and Transient ratings).

VI-200, VI-J00 Input Voltage Ranges

Designator Low Nominal High

0 10 V 12 V 20 V

V 10 V12/24 V 36 V

1 21 V 24 V 32 V

W 18 V 24 V 36 V

2 21 V 36 V 56 V

3 42 V 48 V 60 V

N 36 V 48 V 76 V

4 55 V 72 V 100 V

T 66 V 110 V 160 V

5 100 V 150 V 200 V

6 200 V 300 V 400 V

7 100 V 150/300 V 375 V

Table 2–1 — VI-200, VI-J00 input voltage ranges

MI-200, MI-J00 Input Voltage Ranges

Designator Low Nominal High

2 18 V 28 V 50 V

5 100 V 155 V 210 V

6 125 V 270 V 400 V

7 100 V 165 V 310 V

Table 2–2 — MI-200, MI-J00 input voltage ranges

2. DC-DC Converter Pinouts

GATE IN. The GATE IN pin on a Driver module may be

used as a logic Enable / Disable input. When GATE IN is

pulled low (<0.65 V @ 6 mA, referenced to –Vin), the

odule is turned off; when GATE IN is floating (open

m

collector), the module is turned on. The open circuit

oltage of the GATE IN pin is less than 10 V.

v

–OUT, +OUT. DC output pins. See the Table 2–3 and 2–4

below for output voltages and power levels of VI-/MI-200

and VI-/MI-J00 Family converter modules.

VI-200, VI-J00 Standard Output Voltages

Designator Output Designator Output

Z2V 215 V

Y 3.3 VN18.5 V

05V 324 V

X 5.2 VL28 V

W 5.5 VJ36 V

V 5.8 VK40 V

T 6.5 V448 V

R 7.5 VH52 V

M 10 VF72 V

1 12 VD85 V

P 13.8 VB95 V

Table 2–3 — VI-200, VI-J00 output voltage designators

Output

Voltage

<5 Vdc 10 – 40 A 5 – 20 A 10 – 30 A 5 – 10 A

≥5 Vdc 50 – 200 W 25 – 100 W 50 – 100 W 10 – 50 W

Table 2–4 — Output voltage vs. power level

Special output voltages from 1 – 95 V; consult factory.

T (TRIM). Provides fixed or variable adjustment of the

module output.

Trimming Down. Allows output voltage of the module to

be trimmed down, with a decrease in efficiency. Ripple as

a percent of output voltage goes up and input range

widens since input voltage dropout (loss of regulation)

moves down.

Trimming Up. Reverses the above effects.

Power Level Power Level

VI-200 VI-J00 MI-200 MI-J00

–S, +S (–SENSE, +SENSE). Provides for locating the point

of optimal voltage regulation external to the converter.

GATE OUT. The pulsed signal at the GATE OUT pin of a

regulating Driver module is used to synchronously drive

the GATE IN pin of a companion Booster module to effect

power sharing between the Driver and the Booster. Daisychaining additional Boosters (connecting GATE OUT of

one unit to GATE IN of a succeeding unit) leads to a

virtually unlimited power expansion capability.

Output OVP in VI-/MI-200 will trip if remote sense

compensates output voltage measured at output pins

above 110% of nominal. Discrete wire used for sense

must be tightly twisted pair. Do not exceed 0.25 V drop in

negative return; if the voltage drop exceeds 0.25 V in the

negative return path, the current limit setpoint will increase.

Connect +SENSE to +OUT and –SENSE to –OUT at the

module if remote sensing is not desired.

VI-200 and VI-J00 Family Design Guide Rev 3.5 vicorpower.com

Page 3 of 98

Apps. Eng. 800 927.9474 800 735.6200

(Figure 7–4)

Page 5

3. Module Do’s and Dont’s

or VI-200 and VI-J00 Family DC-DC Converters and Configurable Power Supplies

F

Design Guide & Applications Manual

ELECTRICAL CONSIDERATIONS

GATE IN AND GATE OUT PINS

Logic Disable. When power is applied to the input pins,

the GATE IN pin of a Driver can be pulled low with respect

to the –IN thus turning off the output while power is still

applied to the input. (Figure 7–1)

CAUTION: With offline applications –IN is not

earth ground.

In Logic Disable mode, the GATE IN pin should be driven

from either an “open collector” or electromechanical

switch that can sink 6 mA when on (GATE IN voltage less

than 0.65 V). If driven from an electromechanical switch

or relay, a 1 µF capacitor should be connected from GATE IN

to –IN to eliminate the effects of switch “bounce”. The 1 µF

capacitor may be required in all applications to provide a

“soft start” if the unit is disabled and enabled quickly. Do

not exceed a repetitive on / off rate of 1 Hz to the GATE

IN or input voltage pins.

High Power Arrays. The pulsed signal at the GATE OUT

pin of a regulating Driver module is used to synchronously

drive the GATE IN pin of a companion Booster module to

effect power sharing between the Driver and the Booster.

(Figure 7–5) Daisy-chaining additional Boosters (i.e.,

connecting GATE OUT to GATE IN of a succeeding unit)

leads to a virtually unlimited power expansion capability.

VI-/MI-200 series modules of the same family and power

level can be paralleled (i.e., Driver, VI-260-CU with

Booster, VI-B60-CU).

In general:

• Don’t drive the GATE IN pin from an “analog”

voltage source.

• Don’t leave GATE IN pins of Booster modules

unterminated.

• Don’t overload GATE OUT; limit load to a single Vicor

module GATE IN connection, or 1 kΩ, minimum, in

parallel with 100 pF, maximum.

• Don’t skimp on traces that interconnect module –IN

pins in high power arrays. GATE IN and GATE OUT

are referenced to –IN; heavy, properly laid out traces will

minimize parasitic impedances that could interfere with

proper operation.

• Do use a decoupling capacitor across each module’s

input (see Input Source Impedance that follows).

• Do use an EMI suppression capacitor from +/– input and

output pins to the baseplate.

• Do use a fuse on each module’s + input to prevent fire

in the event of module failure. See safety agency

conditions of acceptability for the latest information on

fusing. Please see the Vicor website

for Safety Approvals.

Input Source Impedance. The converter should be

connected to an input source that exhibits low AC

impedance. A small electrolytic capacitor should be

ounted close to the module’s input pins. (C3, Figure 3–1)

m

This will restore low AC impedance, while avoiding the

otential resonance associated with “high-Q” film

p

capacitors. The minimum value of the capacitor, in

microfarads, should be C (µF) = 400 ÷ Vin minimum.

Example: Vin, minimum, for a VI-260-CV is 200 V. The

minimum capacitance would be 400 ÷ 200 = 2 µF. For

applications involving long input lines or high inductance,

additional capacitance will be required.

The impedance of the source feeding the input of the

module directly affects both the stability and transient

response of the module. In general, the source impedance

should be lower than the input impedance of the module

by a factor of ten, from DC to 50 kHz.

To calculate the required source impedance, use the

following formula:

L

n

L

Z = 0.1(V

)2/ Pi

where: Z is required input impedance

VLL is the low line input voltage

Pin is the input power of the module

Filters, which precede the module, should be well damped

to prevent ringing when the input voltage is applied or

the load on the output of the module is abruptly changed.

Input Transients. Don’t exceed the transient input

voltage rating of the converter. Input Attenuator Modules

or surge suppressors in combination with appropriate

filtering, should be used in offline applications or in

applications where source transients may be induced by

load changes, blown fuses, etc. For applications where the

input voltage may go below low line it is recommended

that an undervoltage lockout circuit be used to pull GATE

IN low to disable the converter module. The undervoltage

lockout circuit should induce a delay of at least one

second before restarting the converter module. Longer

delays will be required if external capacitance is added at

the output to insure the internal soft-start is re-initialized.

NOTE: Do not allow the rate of change of the input

voltage to exceed 10 V/µs for any input voltage deviation.

The level of transient suppression required will depend on

the severity of the transients. A Zener diode, TRANSZORB™

or MOV will provide suppression of transients under 100 µs

and act as a voltage clipper for DC input transients. It may

be necessary to incorporate an LC filter for larger energy

transients. This LC filter will integrate the transient energy

while the Zener clips the peak voltages. The Q of this filter

should be kept low to avoid potential resonance problems.

See Section 14, Input Attenuator Module (IAM / MI-IAM)

for additional information on transient suppression.

VI-200 and VI-J00 Family Design Guide Rev 3.5 vicorpower.com

Page 4 of 98

Apps. Eng. 800 927.9474 800 735.6200

Page 6

Design Guide & Applications Manual

+OUT

+IN

–IN

–OUT

Zero Current

Switching

Converter

C1a

C1b

C2a

C2b

C3

or VI-200 and VI-J00 Family DC-DC Converters and Configurable Power Supplies

F

3. Module Do’s and Dont’s

Output OVP. The VI-/MI-200, with the exception of

I-/ MI-J00s, has an internal overvoltage protection circuit

V

that monitors the voltage across the output power pins. It

is designed to latch the converter off at 115 – 135% of

rated output voltage. It is not a crowbar circuit, and if a

module is trimmed above 110% of rated output voltage,

OVP may be activated. Do not backdrive the output of

the converter module to test the OVP circuit.

CAUTION:

When trimming up VI-/MI-J00 modules,

additional care should be taken as an improper

component selection could result in module failure.

Improper connection of the sense leads on VI-/MI-J00

modules can also result in an excessive overvoltage

condition and module failure.

Input Reverse Voltage Protection. The module may be

protected against reverse input voltages by the addition of

a diode in series with the positive input, or a reverse

shunt diode with a fuse in series with the positive input.

See Section 14, the Input Attenuator Module (IAM/MI-IAM)

provides input reverse voltage protection when used with

a current limiting device (fuse).

THERMAL / MECHANICAL CONSIDERATIONS

Baseplate. Operating temperature of the baseplate, as

measured at the center mounting slot on the –IN, –OUT

side, can not exceed rated maximum. ThermMate or

thermal compound should be used when mounting the

module baseplate to a chassis or heat sink. All six

mounting holes should be used. Number six (#6) machine

screws should be torqued to 5-7 in-lbs, and use of Belville

washers is recommended.

THERMAL AND VOLTAGE HAZARDS

Vicor component power products are intended to be used

ithin protective enclosures. Vicor DC-DC converters

w

work effectively at baseplate temperatures, which could

be harmful if contacted directly. Voltages and high

currents (energy hazard) present at the pins and circuitry

connected to them may pose a safety hazard if contacted

or if stray current paths develop. Systems with removable

circuit cards or covers which may expose the converter(s)

or circuitry connected to the converters, should have proper

guarding to avoid hazardous conditions.

EMC CONSIDERATIONS

All applications utilizing DC-DC converters must be properly

bypassed, even if no EMC standards need to be met. Bypass

IN and OUT pins to each module baseplate as shown in

Figure 3–1. Lead length should be as short as possible.

Recommended values vary depending on the front end, if

any, that is used with the modules, and are indicated on the

appropriate data sheet. In most applications, C1a – C1b is a

4,700 pF Y-capacitor (Vicor Part # 01000) carrying the

appropriate safety agency approval; C2a – C2b is a 4,700 pF

Y-capacitor (Vicor Part # 01000) or a 0.01 µF ceramic

capacitor rated at 500 V. In PCB mount applications, each of

these components is typically small enough to fit under the

module baseplate flange.

The module pins are intended for PCB mounting either by

wave soldering to a PCB or by insertion into one of the

recommended PCB socket solutions.

CAUTION: Use of discrete wires soldered directly

to the pins may cause intermittent or permanent

damage to the module; therefore, it is not

recommended as a reliable interconnection scheme

for production as a final released product. See

Section 21 for packaging options designed for

discrete wire connections (BusMod, MegaMod).

Figure 3–1 — IN and OUT pins bypassed to the module baseplate

and input cap for low AC impedance

In addition, modules that have been soldered into printed

circuit boards and have subsequently been removed

should not be reused.

VI-200 and VI-J00 Family Design Guide Rev 3.5 vicorpower.com

Page 5 of 98

Apps. Eng. 800 927.9474 800 735.6200

Page 7

3. Module Do’s and Dont’s

SAFETY CONSIDERATIONS

or VI-200 and VI-J00 Family DC-DC Converters and Configurable Power Supplies

F

Design Guide & Applications Manual

Shock Hazard. Agency compliance requires that the

baseplate be grounded.

Fusing. Internal fusing is not provided in Vicor DC-DC

onverters. To meet safety agency conditions, a fuse is

c

required. This fuse should be placed in the positive input

lead, not the negative input lead, as opening of the

negative input lead will cause the GATE IN and GATE OUT

to rise to the potential of the +IN lead, causing possible

damage to other modules or circuits that share common

GATE IN or GATE OUT connections.

Acceptable Fuse Types and Current Rating for the VI-200 and VI-J00 Family of Converters

Package Size Required Fuse Package Size Required Fuse

VI-27x-xx PC-Tron 2.5 A VI-J7x-xx PC-Tron 2.5 A

VI-26x-xx PC-Tron 3 A VI-J6x-xx PC-Tron 3 A

VI-25x-xx PC-Tron 5 A VI-J5x-xx PC-Tron 5 A

VI-2Tx-xx PC-Tron 5A VI-JTx-xx PC-Tron 5A

VI-24x-xx 6 A / 125 V VI-J4x-xx PC-Tron 5A

Safety agency conditions of acceptability require module

input fusing. The VI-x7x, VI-x6x and VI-x5x require the use

of a Buss PC-Tron fuse, or other DC-rated fuse. See below

for suggested fuse ratings.

The safety approvals section of the Vicor website should

always be checked for the latest fusing and conditions of

acceptability information for all DC-DC converters

including the MegaMod family.

VI-2Nx-xx 8A / 125 V VI-JNx-xx PC-Tron 5A

VI-23x-xx 8 A /125 V VI-J3x-xx PC-Tron 5A

VI-22x-xx 8 A / 60 V VI-J2x-xx PC-Tron 5A

VI-2Wx-xx 12 A / 50 V VI-JWx-xx 8 A / 60 V

VI-21x-xx 12 A / 32 V VI-J1x-xx 8 A / 60 V

VI-2Vx-xx 12 A / 32 V VI-J0x-xx 8 A / 60 V

VI-20x-xx 12 A / 32 V

VI-200 and VI-J00 Family Design Guide Rev 3.5 vicorpower.com

Page 6 of 98

Apps. Eng. 800 927.9474 800 735.6200

Page 8

Design Guide & Applications Manual

2 V

V

out

I

c

I

fb

I

max

I

out

I

short circuit

V

out

I

short circuit

I

c

I

max

I

out

or VI-200 and VI-J00 Family DC-DC Converters and Configurable Power Supplies

F

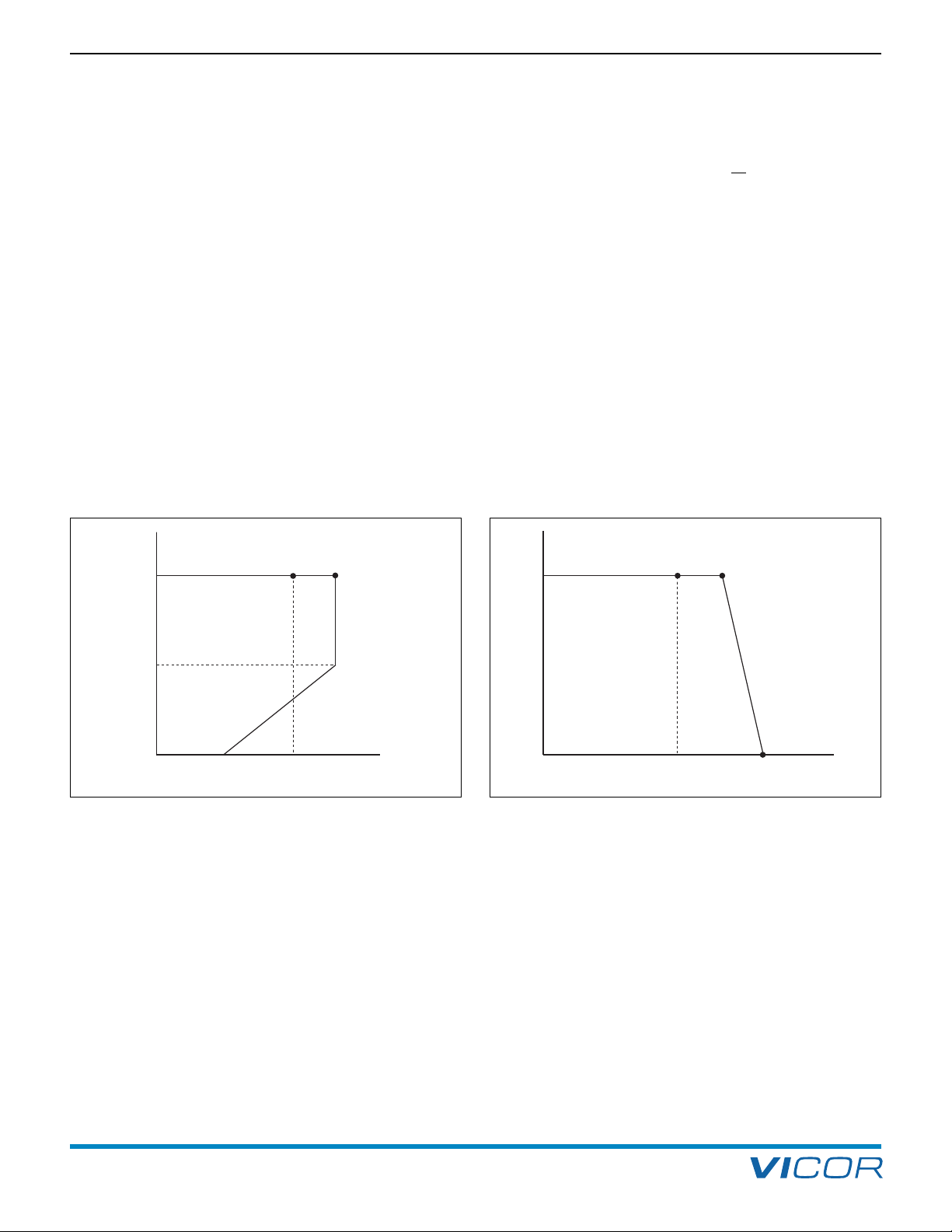

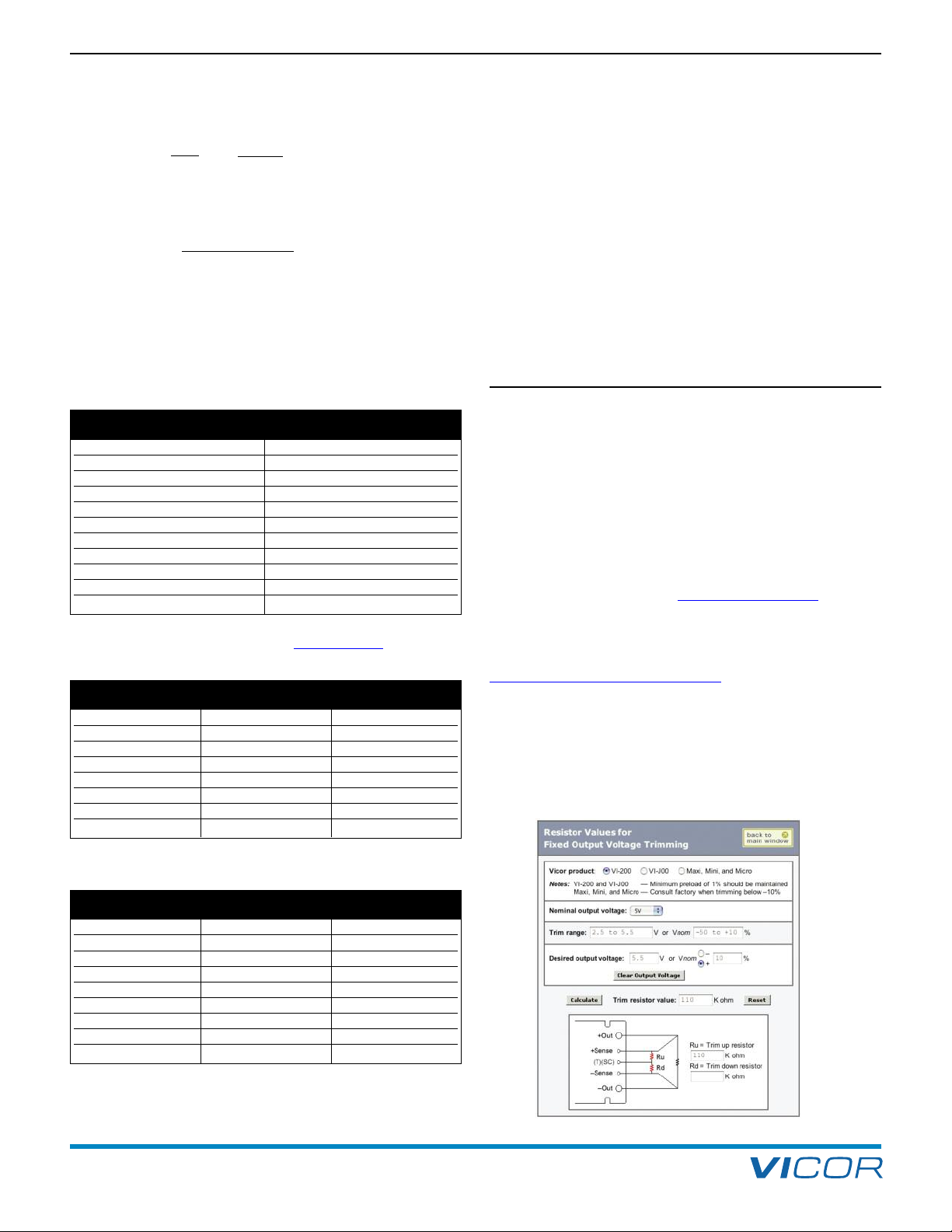

4. Overcurrent Protection

FOLDBACK CURRENT LIMITING

The VI-/MI-200 modules with output voltages of 5 V or

3.3 V incorporate foldback current limiting. (Figure 4–1) In

his mode, the output voltage remains constant up to the

t

current knee, (Ic), which is 5 – 25% greater than full-rated

urrent, (Imax). Beyond Ic, the output voltage falls along

c

the vertical line Ic– Ifb until approximately 2 V. At ≤2 V, the

voltage and current folds back to short circuit current

point (20 – 80% of Imax). Typically, modules will

automatically recover when overcurrent is removed.

When bench testing modules with foldback current limiting,

use a constant resistance load as opposed to a constant

current load. Some constant current loads have the ability

to pull full current at near zero volts. This may cause a

latchup condition. Also when performing a short circuit

test it is recommended to use a mercury wetted relay to

induce the output short as other methods may induce

switch bounce that could potentially damage the converter.

STRAIGHT LINE CURRENT LIMITING

The VI-/MI-200 modules with output voltages greater

than 5 V, 2 V (VI-/MI-200 only) and all

odules incorporate a straight-line type current limit.

m

VI-/MI-J00

(Figure 4–2) As output current is increased beyond Imax,

he output voltage remains constant and within its

t

specified limits up to a point, Ic, which is 5 – 25% greater

than rated current, (Imax). Beyond Ic, the output voltage

falls along the vertical line to Isc. Typically, modules will

automatically recover after overcurrent is removed.

Figure 4–1 — Foldback current limiting

Apps. Eng. 800 927.9474 800 735.6200

VI-200 and VI-J00 Family Design Guide Rev 3.5 vicorpower.com

Page 7 of 98

Figure 4–2 — Straight-line current limiting

Page 9

5. Output Voltage Trimming

+OUT

+SENSE

–OUT

R

3

–

+

C1

Load

[

a]

F

or Vout < 3.3 V, R5 = 3.88 kΩ and internal reference = 0.97 V.

E

rror Amp

R

1 47 Ω Typ.

R4 27 Ω Typ.

R2

R

5 10 kΩ

[

a]

TRIM

R6

–SENSE

R8

R

7

2.5 V

[a]

R6

TRIM

–SENSE

–OUT

R7 10 kΩ POT

R5 10 kΩ

[a]

(internal)

V1

R8

I

R6

2.5 V

[a]

reference

(internal)

[a]

For Vout < 3.3 V, R5 = 3.88 kΩ and internal reference = 0.97 V.

+OUT

+SENSE

–SENSE

OVERVIEW

or VI-200 and VI-J00 Family DC-DC Converters and Configurable Power Supplies

F

Design Guide & Applications Manual

Specifications such as efficiency, ripple and input voltage

range are a function of output voltage settings. As the

output voltage is trimmed down, efficiency goes down;

ripple as a percent of Vout goes up and the input voltage

range widens since input voltage dropout (loss of regulation)

moves down. As the units are trimmed up, the reverse of

the above effects occurs.

All converters have a fixed current limit. The overvoltage

protection setpoint is also fixed; trimming the output

voltage does not alter its setting. As the output voltage is

trimmed down, the current limit setpoint remains constant.

Therefore, in terms of output power, if the unit is trimmed

down, available output power drops accordingly.

The output voltage of most Vicor converters can be

trimmed +10%, –50%. Certain modules have restricted

trim ranges. Consult the latest datasheet for details.

Do not attempt to trim the module output voltage more

than +10%, as overvoltage shut down may occur. Do not

exceed maximum rated output power when the module is

trimmed up.

CAUTION: When trimming up VI- / MI-J00 converter

modules, additional care should be taken as an

improper component selection could result in module

failure. Improper connection of the sense leads on

VI-/ MI-J00 converter modules can also result in an

excessive overvoltage condition and module failure.

Example 1. For trimming –10% to +10% with a standard

off-the-shelf 10 kΩ potentiometer (R7), values for resistors

R6 and R8 need to be calculated.

esistor R6 limits the trim down range. For a given

R

percentage, its value is independent of output voltage.

Refer to

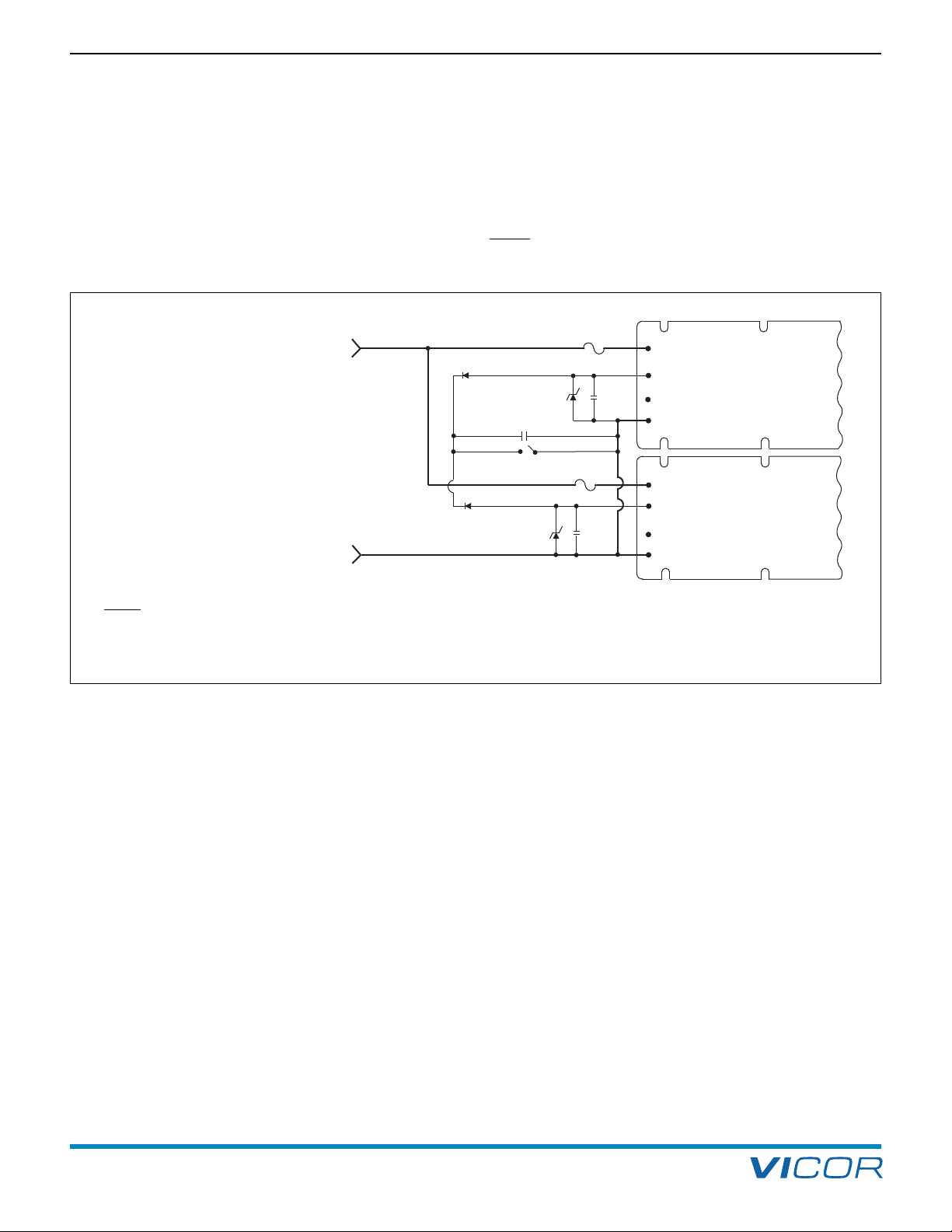

Figure 5–1 — External resistive network for variable trimming

Table 5–1, for limiting resistor values.

TRIMMING DOWN –10%

A 10% drop of the 2.5 V reference at the TRIM pin is

needed to effect a 10% drop in the output voltage.

(Figure 5–2)

The following procedures describe methods for output

voltage adjustment (–10 to +10% of nominal) of the

VI-/MI-200, VI-/MI-J00, ComPAC/MI-ComPAC, FlatPAC

and MegaMod / MI-MegaMod Families.

Modules with nominal 3.3 V outputs and above have

the 2.5 V precision reference and 10 k internal resistor.

For trim resistor calculations on modules with 2.0 V

outputs use 0.97 V in place of the 2.5 V reference

and substitute 3.88 kΩ for the internal 10 kΩ resistor.

Figure 5–2 — Circuit diagram “Trim Down”

Resistors are 0.25 W. When trimming down any module,

always maintain a minimum preload of at least 1% of

rated output power and in some cases up to 10% may be

required. For more specific information on trimming down

Therefore:

a specific module, please consult Vicor’s Applications

Engineering Department at (800) 927-9474.

RESISTIVE ADJUSTMENT PROCEDURE

Since IR5 = IR6 = 25 µA:

To achieve a variable trim range, an external resistor

network must be added. (Figure 5–1)

VI-200 and VI-J00 Family Design Guide Rev 3.5 vicorpower.com

Page 8 of 98

Apps. Eng. 800 927.9474 800 735.6200

This value will limit the trim down range to –10% of

nominal output voltage.

V1 = 2.5 V – 10% = 2.25 V

(2.5 V – 2.25 V)

IR5 =

R6 =

10 kΩ

2.25 V

25 µA

= 25 µA

= 90 kΩ

Page 10

Design Guide & Applications Manual

I

V2

R6 90 kΩ

TRIM

+ SENSE

–

SENSE

– OUT

R

5 10 kΩ

[a]

(internal)

V

1

R

8

R

8

R

7 10 kΩ POT

500 µA

25 µA

2.5 V

[a]

r

eference

(internal)

+ OUT

[a]

For Vout < 3.3 V, R5 = 3.88 kΩ and inter nal reference = 0.97 V.

TRIM

+ OUT

+ SENSE

– SENSE

– OUT

Rd

Ru

Trim Resistor for UP

Programming

Trim Resistor for DOWN

Programming

or

2.5 V

[a]

reference

(internal)

R5 10 kΩ

[a]

(internal)

[a]

For Vout < 3.3 V, R5 = 3.88 kΩ and inter nal reference = 0.97 V.

or VI-200 and VI-J00 Family DC-DC Converters and Configurable Power Supplies

F

5. Output Voltage Trimming

TRIMMING UP +10%

To trim 10% above the nominal output voltage, the

following calculations are needed to determine the value

of R8. This calculation is dependent on the output voltage

of the module. A 12 V output will be used as an example.

(Figure 5–3)

It is necessary for the voltage at the TRIM pin to be 10%

greater than the 2.5 V reference. This offset will cause the

error amplifier to adjust the output voltage up 10% to 13.2 V.

Figure 5–3 — Circuit diagram “Trim Up”

FIXED TRIM

Converters can be trimmed up or down with the addition

of one external resistor, either Ru for programming up or

Rd for programming down. (Figure 5–4)

xample 2. Fixed Trim Up (12 V to 12.6 V).

E

To determine Ru, the following calculation must be made:

2.5 V + 5% = 2.625 V

5

= VT

RIM

R

V

– Vr

ef

VR5= 2.625 – 2.5 = 0.125 V

Knowing this voltage, the current through R5 can be found:

IR5 =

VR5

R5 10 kΩ

=

0.125

= 12.5 µA

VRu = 12.6 V – 2.625 V = 9.975 V

9.975

Ru =

12.5 µA

= 798 kΩ

V1 = 2.5 V + 10% = 2.75 V

(2.75 V – 2.5 V)

IR5 =

10 kΩ

= 25 µA

Since IR5 = IR6 ,

the voltage drop across R6 = (90 kΩ) (25 µA) = 2.25 V.

Figure 5–4 — Fixed trimming

Therefore, V2 = 2.75 V + 2.25 V = 5 V. The current

through R7 (10 kΩ pot) is:

IR7 =

V2

R7 10 k

5

=

= 500 µA

Using Kirchoff’s current law:

R8 = IR7 + IR6 = 525 µA

I

Thus, knowing the current and voltage, R8 can be

determined:

VR8 = (Vout + 10%) – V2 = 13.2 V – 5 V = 8.2 V

R8 =

(8.2 V)

525 µA

= 15.6 kΩ

Connect Ru from the TRIM pin to the +SENSE. Be sure to

connect the resistor to the +SENSE, not the +OUT, or

drops in the positive output lead as a function of load will

cause apparent load regulation problems.

Example 3. –25% Fixed Trim Down (24 V to 18 V).

The trim down methodology is identical to that used in

Example 2, except that it is utilized to trim the output of a

24 V module down 25% to 18 V. The voltage on the

TRIM pin must be reduced 25% from its nominal setting

of 2.5 V. This is accomplished by adding a resistor from

the TRIM pin to –SENSE.

2.5 V – 25% = 1.875 V

This resistor configuration allows a 12 V output module

to be trimmed up to 13.2 V and down to 10.8 V. Follow

this procedure to determine resistor values for other

output voltages.

VI-200 and VI-J00 Family Design Guide Rev 3.5 vicorpower.com

Page 9 of 98

Apps. Eng. 800 927.9474 800 735.6200

VR5 = Vbandgap – VTRIM

= 2.5 V – 1.875 V = 0.625 V

Page 11

5. Output Voltage Trimming

or VI-200 and VI-J00 Family DC-DC Converters and Configurable Power Supplies

F

Design Guide & Applications Manual

Knowing this voltage, the current through R5 can be found:

IR5 =

VR

R5 10 kΩ

=

0.625

= 62.5 µA

5

The voltage across the resistor, Rd, and the current

lowing through it are known:

f

Rd =

(2.5 V – 0.625 V)

= 30 kΩ

62.5 µA

Connect Rd (Figure 5–4) from the TRIM pin to the –SENSE

of the module. Be sure to connect the resistor to the

–SENSE, not the –OUT, or drops in the negative output

lead as a function of load will cause apparent load

regulation problems.

Values for Trim Down by Percentage

Percent Resistance

–5 % 190 kΩ

–10 % 90 kΩ

–15 % 56.7 kΩ

–20 % 40 kΩ

–25 % 30 kΩ

–30 % 23.3 kΩ

–35 % 18.6 kΩ

–40 % 15 kΩ

–45 % 12.2 kΩ

–50 % 10 kΩ

Table 5–1 — Values for trim down by percentage (Refer to product

data sheet for allowable trim ranges at

vicorpower.com)

Fixed Trim Down

Vnom V (Desired) Trim Resistor

5V 4.5 V 90.9 kΩ

3.3 V 19.6 kΩ

2.5 V 10.0 kΩ

15 V 13.8 V 115 kΩ

24 V 20 V 49.9 kΩ

48 V 40 V 49.9 kΩ

36 V 30.1 kΩ

Table 5–2a — Values for fixed trim down by voltage

[a]

DYNAMIC ADJUSTMENT PROCEDURE

Output voltage can also be dynamically programmed by

driving the TRIM pin from a voltage or current source;

programmable power supplies and power amplifier

applications can be addressed in this way. For dynamic

programming, drive the TRIM pin from a source referenced

to the negative sense lead, and keep the drive voltage in

the range of 1.25 – 2.75 V. Applying 1.25 – 2.5 V on the

TRIM pin corresponds to 50 – 100% of nominal output

voltage. For example, an application requires a +10, 0%

(nominal), and a –15% output voltage adjustment for a 48 V

output converter. Referring to the table below, the voltage

that should be applied to the trim pin would be as follows:

VT

RIM

VO

UT

Change from nominal

2.125 40.8 –15%

2.5 48 0

2.75 52.8 +10%

The actual voltage range is further restricted by the

allowable trim range of the converter. Voltages in excess

of 2.75 V (+10% over nominal) may cause overvoltage

protection to be activated. For applications where the

module will be programmed on a continuous basis the

slew rate should be limited to 30 Hz sinusoidal.

TRIMMING ON THE WEB (VICORPOWER.COM)

Trim values are calculated automatically. Design

Calculators are available on Vicor’s website in the

PowerBenchTMsection at

www.vicorpower.com/powerbench.

Resistor values can be easily determined for fixed trim up,

fixed trim down and for variable trimming applications.

In addition to trimming information, the website also

includes design tips, applications circuits, EMC

suggestions, thermal design guidelines and PDF data

sheets for all available Vicor products.

Fixed Trim Up

Vnom V (Desired) Trim Resistor

5V 5.2 V 261 kΩ

5.5 V 110 kΩ

12 V 12.5 V 953 kΩ

13.2 V 422 kΩ

15 V 15.5 V 1.62 MΩ

16.5 V 562 kΩ

24 V 25 V 2.24 MΩ

48 V 50 V 4.74 MΩ

Table 5–2b — Values for fixed trim up by voltage

[a]

Values listed in the tables are the closest standard 1% resistor values.

VI-200 and VI-J00 Family Design Guide Rev 3.5 vicorpower.com

Page 10 of 98

Apps. Eng. 800 927.9474 800 735.6200

[a]

Page 12

Design Guide & Applications Manual

+IN

–IN

GATE

OUT

GATE

IN

+IN

–IN

GATE

OUT

GATE

IN

Vicor

DC-DC Converter

F1

C1

Z1

C3

SW1

F2

DISABLE

D2

Z2 C2

D1

Vicor

DC-DC Converter

or VI-200 and VI-J00 Family DC-DC Converters and Configurable Power Supplies

F

OVERVIEW

6. Multiple GATE IN Connections

A number of GATE IN pins may be connected for remote

shut down and logic disable. (Figure 6-1) Diodes D1 and

D2 provide isolation and prevent multiple failures if the

GATE IN of a module becomes shorted to the +IN. The

Zener diodes Z1, Z2 and capacitors C1, C2 attenuate

transient voltage spikes caused by differential inductance

in the negative lead. Capacitors C1 and C2 will also

C1, C2, C3 = 1 µF

Z1, Z2 = 15 V (1N5245B)

D1, D2 = Small signal diode (1N4148)

[a]

For bus voltages greater than 75 V,

a 1N4006 diode should be used.

[a]

lengthen turn-on time. SW1 is a mechanical or solid state

switch that is used to disable both Driver modules. C3 is

used to minimize the effects of “switch bounce” associated

with mechanical devices.

NOTE: GATE IN voltage needs to be <0.65 V

referenced to –IN to ensure modules are disabled.

NOTE:

The –IN to –IN input lead should be kept as short as possible to minimize differential inductance.

Heavy lines indicate power connections. Use suitably sized conductors.

Opto-couplers or relays should be used to isolate GATE IN connections, if the converters are on

separate boards or the negative input lead’s impedance is high.

Figure 6–1 — Protection for multiple GATE IN connections

VI-200 and VI-J00 Family Design Guide Rev 3.5 vicorpower.com

Page 11 of 98

Apps. Eng. 800 927.9474 800 735.6200

Page 13

–OUT

–

S

+S

+OUT

+IN

GAT E

IN

G

AT E

OUT

–IN

Z

ero Current

Switching

Converter

Driver

+

–

1

6

TLP798G

Agilent 6N139

Load

2

5

TRIM

1µF

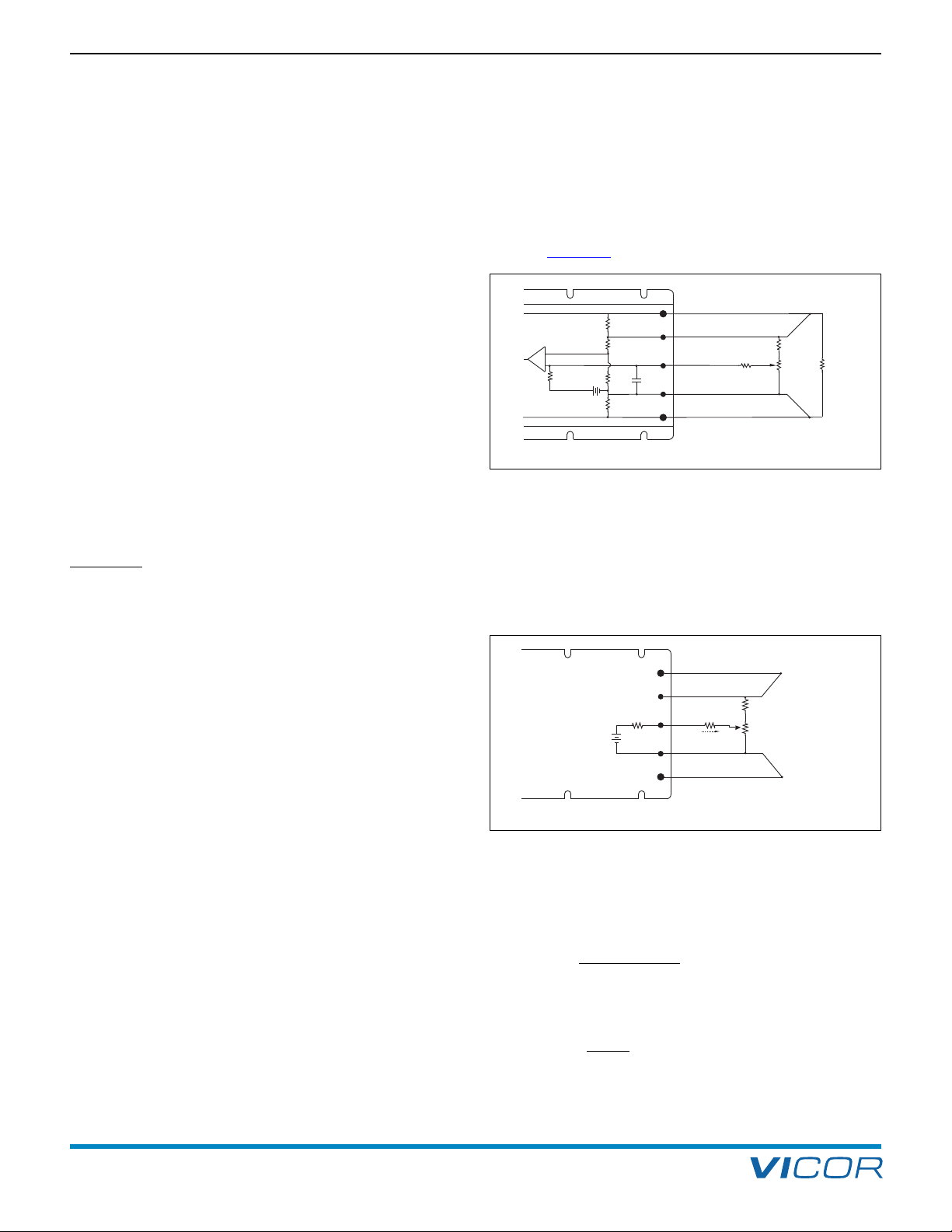

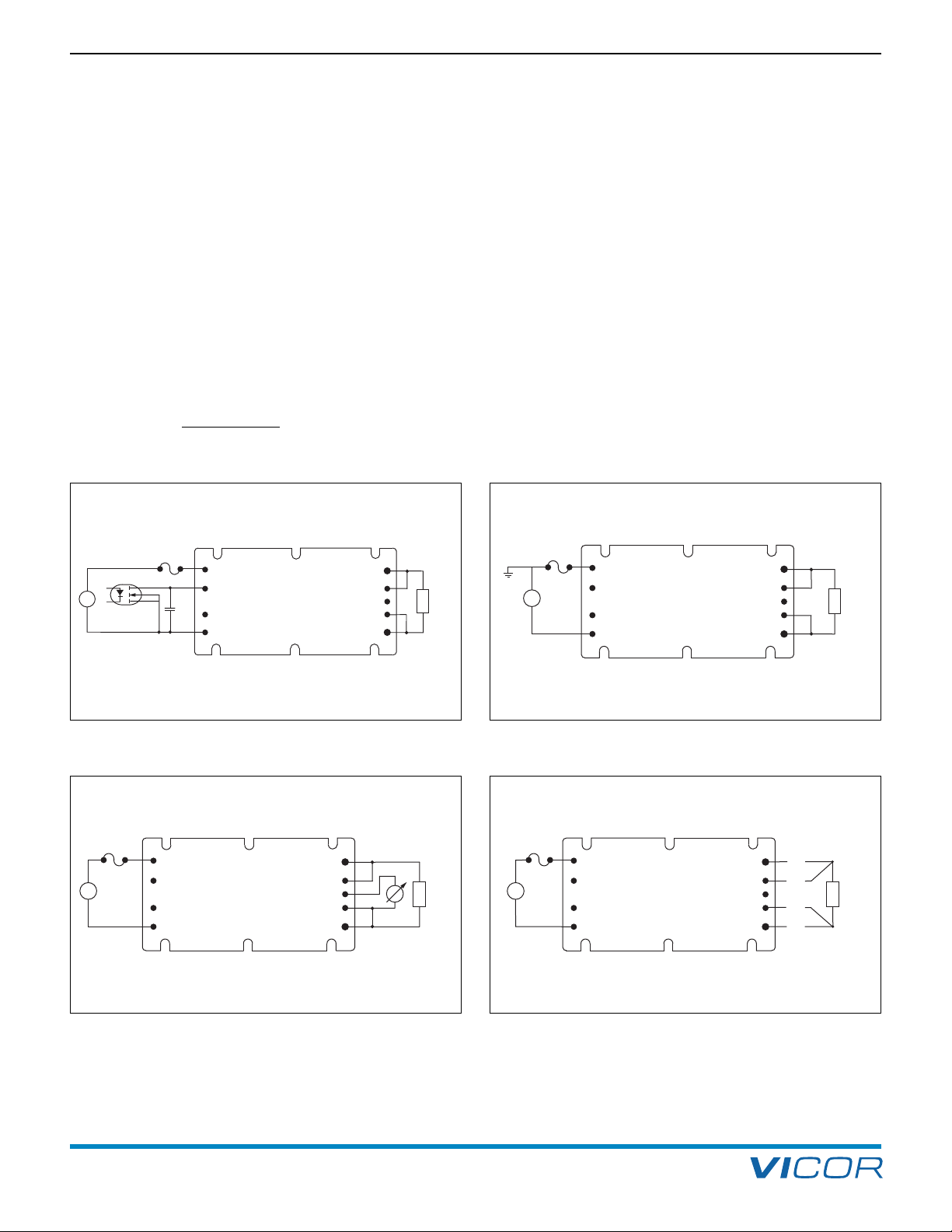

7. Application Circuits / Converter Array Design Considerations

–OUT

–S

TRIM

+S

+OUT

+IN

GATE

IN

GATE

OUT

–IN

Zero Current

Switching

Converter

Driver

+

–

Load

+

–

–OUT

–

S

TRIM

+

S

+OUT

+IN

GATE

IN

GATE

OUT

–IN

Z

ero Current

S

witching

C

onverter

D

river

+

–

L

oad

–OUT

–S

TRIM

+S

+OUT

+IN

GATE

IN

GATE

OUT

–IN

Zero Current

Switching

Converter

Driver

+

–

Load

• • •• • •

• • •• • •

• • •• • •

• • •• • •

or VI-200 and VI-J00 Family DC-DC Converters and Configurable Power Supplies

F

Design Guide & Applications Manual

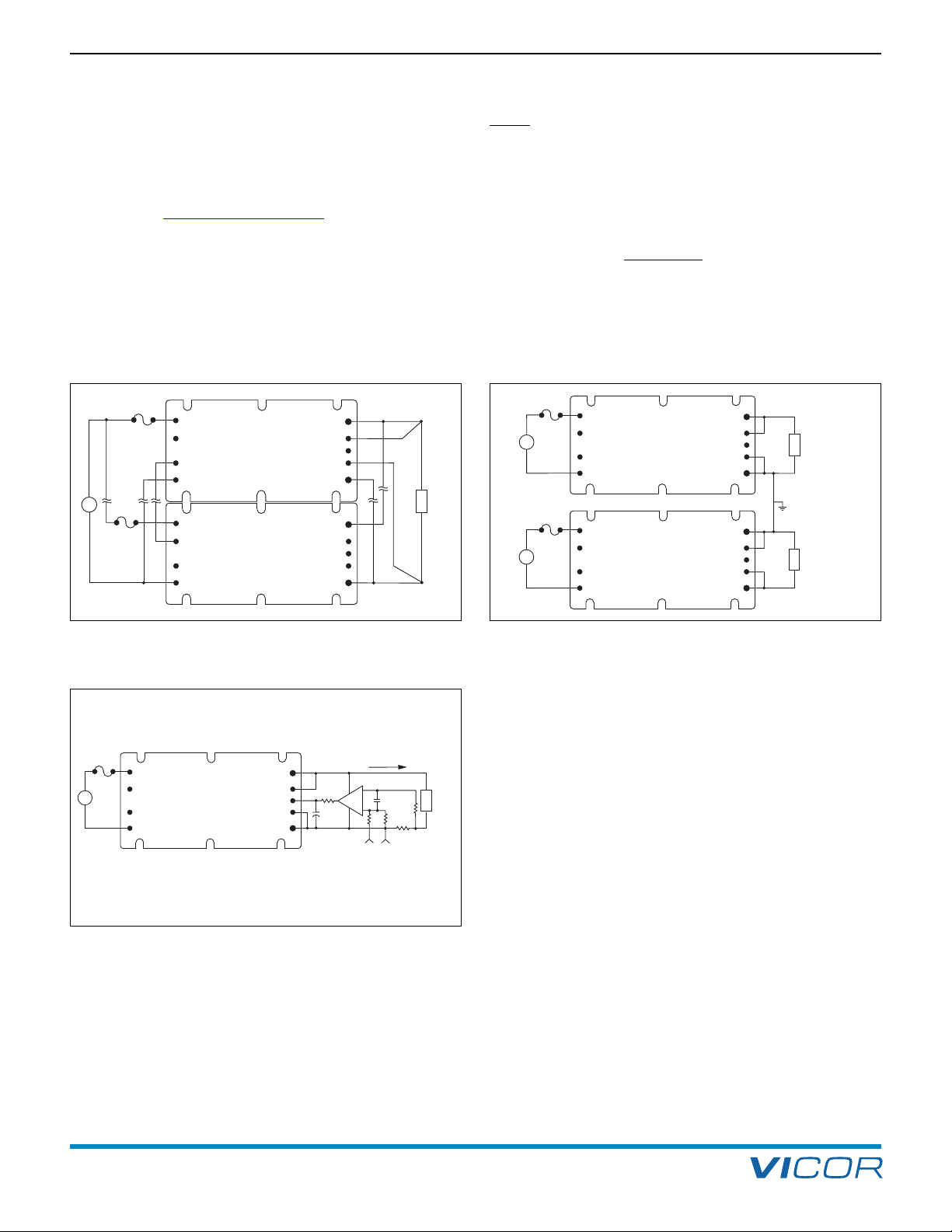

Logic Disable. (Figure 7–1) The GATE IN pin of the

module may be used to turn the module on or off. When

GATE IN is pulled low (<0.65 V @ 6 mA, referenced to

Vin), the module is turned off. When GATE IN is floating

–

(open collector), the module is turned on. The open circuit

oltage of the GATE IN pin is less than 10 V. This applies

v

to VI-/ MI-200, VI-/MI-J00 and MegaMod / MI-MegaMod

Family modules.

Output Voltage Programming. (Figure 7–2) Consult

Vicor’s Applications Engineering Department before

attempting large signal applications at high repetition

rates due to ripple current considerations with the internal

output capacitors. This applies to VI-/ MI-200, VI-/MI-J00,

ComPAC /MI-ComPAC, FlatPAC and MegaMod/

MI-MegaMod Family modules.

Vout =

Vtrim x Vnom

2.5

Negative Inputs (with positive ground). (Figure 7–3)

Vicor modules have isolated inputs and outputs making

negative input configurations easy. Fusing should always

e placed in the positive lead.

b

Remote Sensing. (Figure 7–4) Output voltage between

+OUT and –OUT must be maintained below 110% of

nominal. Do not exceed 0.25 V drop in negative return as

the current limit setpoint is moved out proportionately.

The sense should be closed at the module if remote

sensing is not desired. Applies to VI-/ MI-200, VI-/ MI-J00,

ComPAC /MI-ComPAC, FlatPAC and MegaMod/

MI-MegaMod Family modules. Excessively long sense leads

and / or excessive external capacitance at the load may

result in module instability. Please consult Vicor

Applications Engineering for compensation methods.

Figure 7–1 — Logic disable

Figure 7–2 — Output voltage programming

VI-200 and VI-J00 Family Design Guide Rev 3.5 vicorpower.com

Page 12 of 98

Apps. Eng. 800 927.9474 800 735.6200

Figure 7–3 — Negative inputs (with positive ground)

Figure 7–4 — Remote sensing

Page 14

Design Guide & Applications Manual

–OUT

–S

T

RIM

+S

+OUT

+IN

GATE

IN

GATE

O

UT

–IN

Zero Current

S

witching

C

onverter

#1

Driver

VI-2xx-xx

+

–

–OUT

–S

TRIM

+S

+OUT

+IN

GATE

IN

GATE

OUT

–IN

Zero Current

Switching

Converter

#n

Booster

VI-Bxx-xx

Load

–OUT

-S

TRIM

+S

+OUT

+IN

GATE

IN

GATE

OUT

–IN

Zero Current

Switching

Converter

Driver

+

–

Load

V Control

0.1 V/A

1K

OP

AMP

–

+

1K

1K

0.05 Ω

1K

0.01

I

10 µF

–OUT

–S

TRIM

+S

+OUT

+IN

GATE

IN

GATE

OUT

–IN

Zero Current

Switching

Converter

Driver

+

–

Load requiring

positive output

–OUT

–S

T

RIM

+S

+OUT

+

IN

GATE

IN

GATE

OUT

–IN

Z

ero Current

S

witching

C

onverter

Driver

+

–

Load requiring

negative output

or VI-200 and VI-J00 Family DC-DC Converters and Configurable Power Supplies

F

7. Application Circuits / Converter Array Design Considerations

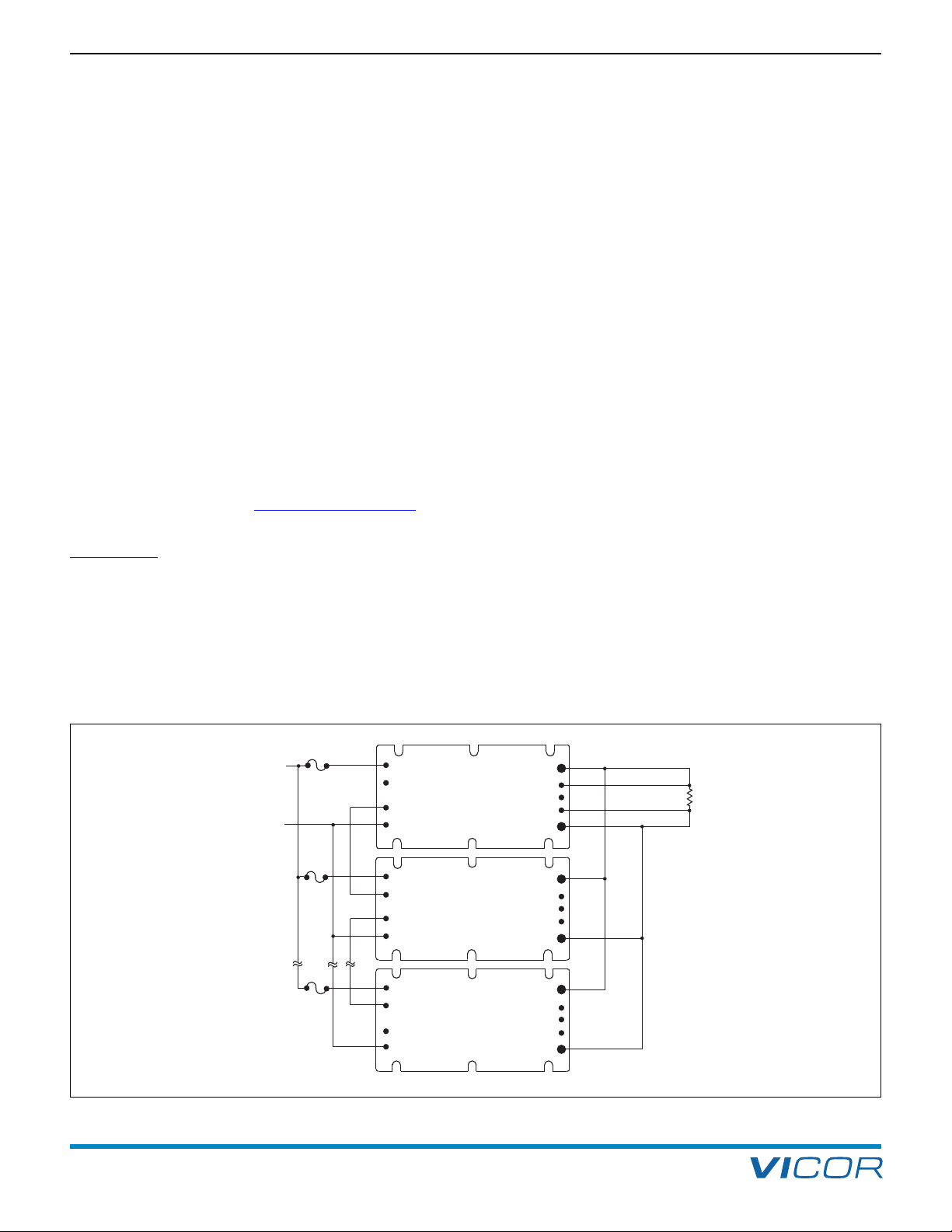

Parallel Boost. (Figure 7–5) U.S. Patent #4,648,020 —

other patents pending. To retain accurate power sharing

between a Driver and (n) number of Boosters, provide

dequate input and output power bussing. This applies to

a

VI-/MI-200 and MegaMod / MI-MegaMod Family

odules. See

m

odule Do’s and Don’tsfor recommended

M

external components. (Section 3)

Programmable Current Source. (Figure 7–6) Module

output voltage should not exceed the rated voltage of the

operational amplifier. This applies to VI-/ MI-200,

VI-/MI-J00, ComPAC/ MI-ComPAC, FlatPAC and

MegaMod/MI-MegaMod Family modules.

: When using a VI-J00 module, the TRIM pin

NOTE

voltage should be clamped to 2.75 V to avoid

damage to the module. This corresponds to the

aximum trim up voltage. This circuit or functional

m

equivalent must be used when charging batteries.

o not exceed the nominal current ratings of the

D

converter. Example,

Pout

Vnominal

Dual Output Voltages. (Figure 7–7) Vicor modules have

isolated outputs so they can easily be referenced to a

common node creating positive and / or negative rails.

Figure 7–5 — Parallel boost. U.S. Patent #4,648,020 — other

Figure 7–7 — Dual output voltages

patents pending.

Figure 7–6 — Programmable current source

VI-200 and VI-J00 Family Design Guide Rev 3.5 vicorpower.com

Page 13 of 98

Apps. Eng. 800 927.9474 800 735.6200

Page 15

INPUT

LOAD

+S

TRIM

–S

–OUT

+IN

GATE

IN

GATE

OUT

–IN

+S

TRIM

–S

–OUT

+IN

GATE

IN

GATE

OUT

–IN

+S

TRIM

–S

–OUT

+IN

GATE

IN

GATE

OUT

–IN

+

–

Zero-Current-

Switching

Driver

VI-2xx-xx

Zero-Current-

Switching

Booster

VI-Bxx-xx

Zero-Current-

Switching

Booster

VI-Bxx-xx

+OUT

+OUT

+OUT

8. Using Boosters and Parallel Arrays

or VI-200 and VI-J00 Family DC-DC Converters and Configurable Power Supplies

F

Design Guide & Applications Manual

OVERVIEW

The VI-/MI-200 Family of DC-DC converters are available

as Driver or Booster modules. The Driver can be used as a

stand alone module, or in multi-kilowatt arrays by adding

parallel Boosters. Booster modules do not contain

feedback or control circuitry, so it is necessary to connect

the Booster GATE IN pin to the preceding Driver or

Booster GATE OUT, to synchronize operation. Drivers and

Boosters have identical power trains, although Drivers

close the voltage loop internally while Boosters do not.

The concept behind Driver / Booster operation is that two

or more ZCS power trains driven at the same frequency

will inherently load-share if their inputs and outputs are

tied together. Slaved modules require only one connection

between units when their outputs are connected

together; no trimming, adjustments or external

components are required to achieve load sharing. The

load sharing is dynamic and typically within 5%.

For additional information, refer to Electrical Considerations

– High Power Arrays in the Module Do’s and Don’ts.

(Section 3)

IMPORTANT: It is important to remember that when

using Boosters, the input voltage, output voltage and

output power of the Boosters must be the same as

the Driver.

Whenever power supplies or converters are operated in a

parallel configuration—for higher output power, fault

tolerance, or both—current sharing is an important

consideration. Most current-sharing schemes employed

with power converters involve analog approaches. One

analog method artificially increases the output impedance

f the converter modules, while another actually senses

o

the output current of each module and forces all of the

urrents to be equal by feedback control.

c

Synchronous current sharing offers an alternative to

analog techniques. In a synchronous scheme, there is no

need for a current-sensing or current-measuring device on

each module. Nor is there a need to artificially increase

output impedance, which compromises load regulation.

There are advantages and disadvantages associated with

each approach to current sharing. In choosing the best

approach for a given application, designers should be

aware of the tradeoffs as well as tips for implementing a

successful design.

Most paralleled power components, such as transistors,

rectifiers, power conversion modules, and offline power

supplies, will not inherently share the load. With power

converters, one or more of the converters will try to

assume a disproportionate or excessive fraction of the

load unless forced current-sharing control is designed into

the system.

One converter, typically the one with the highest output

voltage, may deliver current up to its current limit setting,

which is beyond its rated maximum. Then, the voltage will

drop to the point where another converter in the array—

the one with the next highest voltage—will begin to

deliver current. All of the converters in an array may

Figure 8–1 — Parallel array

VI-200 and VI-J00 Family Design Guide Rev 3.5 vicorpower.com

Page 14 of 98

Apps. Eng. 800 927.9474 800 735.6200

Page 16

Design Guide & Applications Manual

or VI-200 and VI-J00 Family DC-DC Converters and Configurable Power Supplies

F

8. Using Boosters and Parallel Arrays

deliver some current, but the load will be shared unequally.

With built-in current limiting, one or more of the converters

will deliver current up to the current limit (generally 15 or

0% above the module’s rated maximum), while other

2

converters in the array supply just a fraction of load.

Consider a situation where one module in a two-module

array is providing all of the load. If it fails, the load on the

second module must go from no load to full load. During

that time, the output voltage is likely to droop temporarily.

This could result in system problems, including shutdown

or reset.

On the other hand, if both modules were sharing the load

and one failed, the surviving module would experience a

much less severe transient (one-half to full load). Also, the

output voltage would be likely to experience no more

than a slight momentary droop. The dynamic response

characteristic of all forward converters, resonant or pulsewidth modulated, is degraded when the load is stepped

from zero (no load) where the output inductor current is

discontinuous.

In the same two-module array example, the module

carrying all of the load also is generating all of the heat.

That results in a much lower mean time between failure

for that module. An often-quoted rule of thumb says that

for each 10°C increase in operating temperature, average

component life is cut in half.

In a current-sharing system, the converters or supplies all

run at the same temperature. This temperature is lower

than that of the hot-running (heavily loaded) modules in

a system without current sharing. Furthermore, sametemperature operation means that all of the modules in

a current-sharing arrangement age equally.

Current sharing, then, is important because it improves

system performance. It optimizes transient and dynamic

response and minimizes thermal problems, which improves

reliability and helps extend the lifetimes of all of the

modules in an array. Current sharing is an essential

ingredient in most systems that use multiple power supplies

or converters to achieve higher output power or fault

tolerance.

When parallel supplies or converters are used to increase

power, current sharing is achieved through a number of

approaches. One scheme simply adds resistance in series

with the load. A more practical variant of that is the

“droop-share” method, which actively causes the output

voltage to drop in response to increasing load.

Nevertheless, the two most commonly used approaches

to paralleling converters for power expansion are Driver /

Booster arrays and analog current-sharing control. They

appear to be similar, but the implementation of each is

quite different.

Driver / Booster arrays usually contain one intelligent

module or Driver, and one or more power-train-only

modules or Boosters. Analog current-sharing control

nvolves paralleling two or more identical modules, each

i

containing intelligence.

One of the common methods of forcing load sharing in

an array of parallel converters is to sense the output

current of each converter and compare it to the average

current. Then, the output of a given converter is adjusted

so that its contribution is equal to the average. This is

usually accomplished by current-sense resistors in series

with the load, a sensing amplifier for each converter

module, and a summing amplifier. Load sharing is

accomplished by actively trimming the output voltage

using TRIM or SENSE pins.

Occasionally, a designer is tempted to avoid the expense

of a current-sense resistor by using the IR drops in the

wire as a means of sensing the current. Unfortunately,

there are a number of negative issues associated with

that idea. First of all, there’s the temperature coefficient

of copper. As the wire heats up, its resistance increases,

negating its value as a stable current-sensing device.

Second, there are oxidation and corrosion issues, which

also cause parametric changes. Consequently, a highprecision current-sensing device, such as a precision

resistor, is a must.

The resistor values typically range from a few milliohms

up to about 100 mΩ, depending on the power level or

current range of operation. Selecting the right value

requires a tradeoff between power dissipation and

sensitivity (signal-to-noise ratio or noise immunity). The

larger the resistor value, the better the noise immunity—

and the greater the power dissipation.

Determining the size of the resistor needed to generate a

signal above the noise can be a bit tricky. Another

potential pitfall with this (or, for that matter, any other)

approach is the need for good electrical and mechanical

design and layout. This requires adequate trace widths,

minimized trace lengths, and decoupling to reduce noise.

An experienced designer should have no difficulty with

this, but it is an area rich with opportunities for error.

The droop-share method artificially increases the output

impedance to force the currents to be equal.

It’s accomplished by injecting an error signal into the

control loop of the converter, causing the output voltage

to vary as a function of load current. As load current

increases, output voltage decreases. All of the modules

will deliver approximately the same current because they

are all being summed into one node.

If one supply is delivering more current than another

supply, its output voltage will be slightly forced down so

VI-200 and VI-J00 Family Design Guide Rev 3.5 vicorpower.com

Page 15 of 98

Apps. Eng. 800 927.9474 800 735.6200

Page 17

–OUT

–S

TRIM

+S

+OUT

+IN

GATE

IN

GATE

OUT

–IN

–OUT

–S

TRIM

+S

+OUT

+IN

GATE

IN

GATE

OUT

–IN

Return

Zero Current

Switching

Converter

#1

Driver

Zero Current

Switching

Converter

#n

Driver

+V

IN

+V

OUT

–V

IN

8. Using Boosters and Parallel Arrays

or VI-200 and VI-J00 Family DC-DC Converters and Configurable Power Supplies

F

Design Guide & Applications Manual

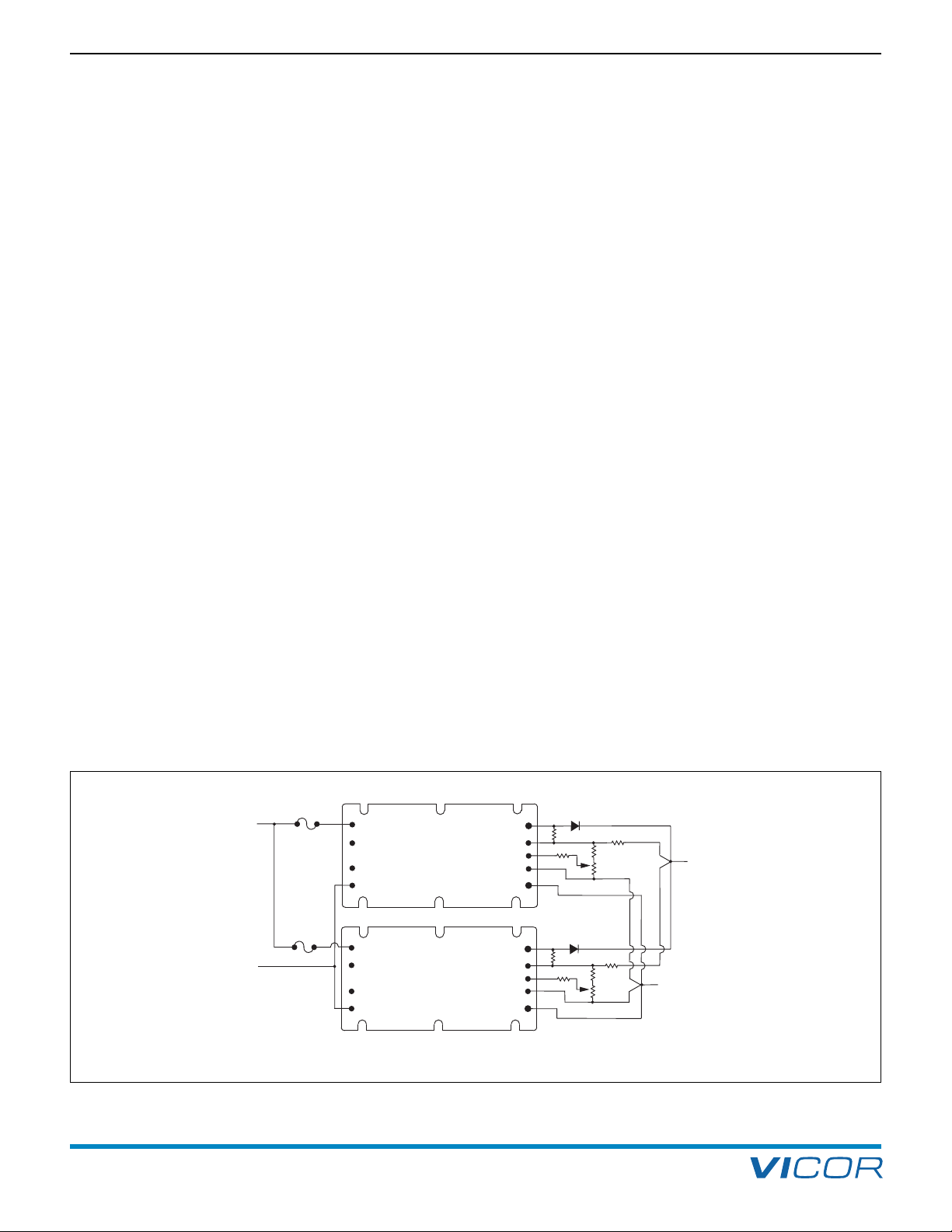

that it will be delivering equal current for an equal voltage

at the summing node. A simple implementation of the

droop-share scheme uses the voltage dropped across an

Ring diode, which is proportional to current, to adjust

O

the output voltage of the associated converter. (Figure 8–2)

Droop share has advantages and disadvantages. One of

the advantages is that it can work with any topology. It’s

also fairly simple and inexpensive to implement. Though, a

major drawback is that it requires that the current be

sensed. A current-sensing device is needed in each of the

converters or power supplies. Additionally, a small penalty

is paid in load regulation, though in many applications this

isn’t an issue.

In general, mixing and matching converters isn’t

recommended—especially those with incompatible

current-sharing schemes. The droop-share method,

however, is more forgiving in this regard than any of the

other techniques. With a little external circuitry, current

sharing can be achieved using arrays constructed from

different converter models or even from different suppliers.

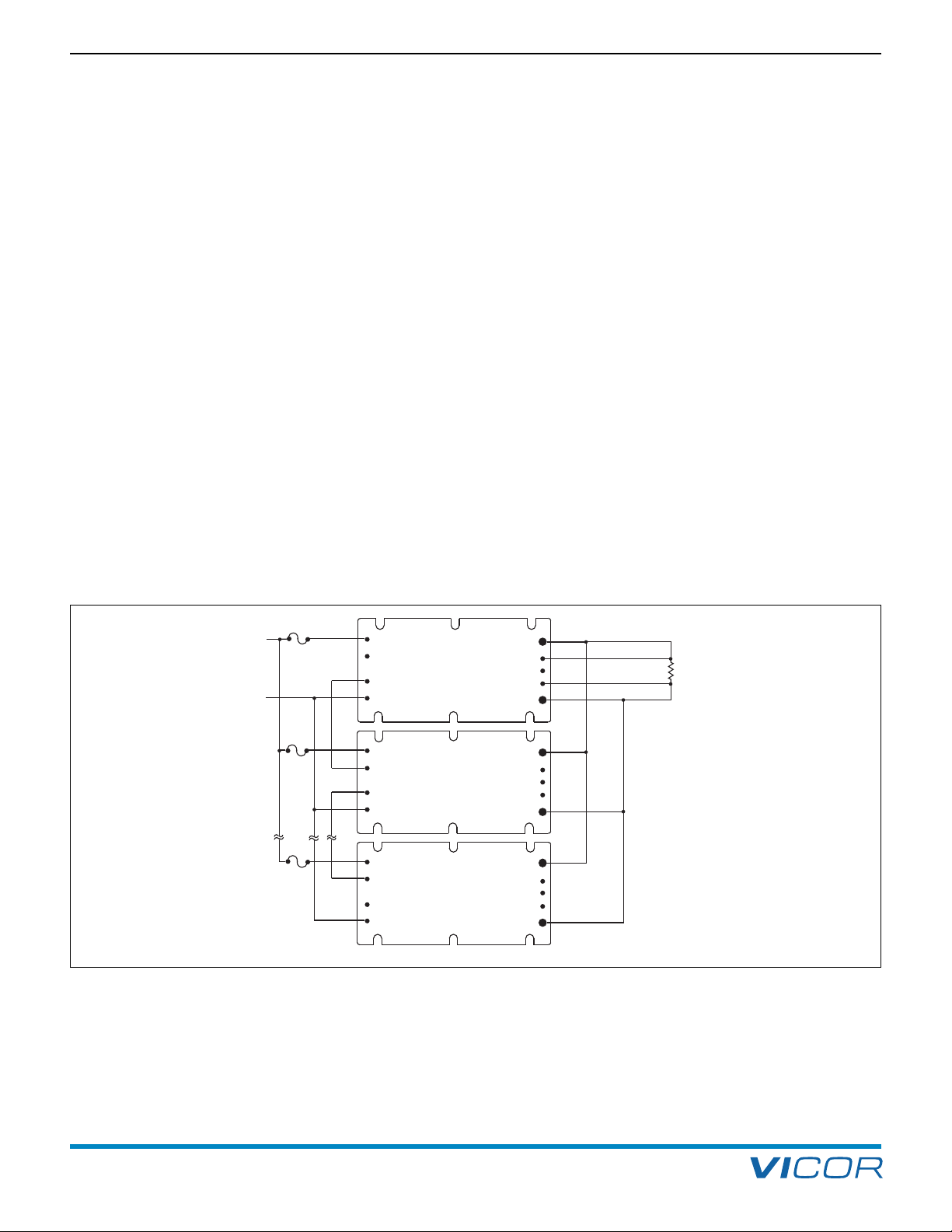

Most systems can employ the Driver / Booster (or master /

slave) array for increased power. (Figure 8–3) The Driver is

used to set and control output voltage, while Booster

modules, as slaves to the master, are used to extend

output power to meet system requirements.

Driver / Booster arrays of quasi-resonant converters with

identical power trains inherently current share because the

per-pulse energy of each converter is the same. If the

inputs and outputs are tied together and the units operate

at the same frequency, all modules will deliver equal

current (within component tolerances).

The single intelligent module in the array determines the

transient response, which does not change as modules

are added. Slaved modules require only one connection

etween units when their outputs are connected. No

b

trimming, adjustments, or external components are

equired to achieve load sharing. The load sharing is

r

dynamic and usually guaranteed within 5%. It’s important

to remember that when using Boosters, the input and

output voltage and output power specifications of the

Boosters must be the same as the Driver.

Driver / Booster arrays have two advantages. They have

only a single control loop, so there are no loop-within-aloop stability issues. And, they have excellent transient

response. However, this arrangement isn’t fault tolerant.

If the Driver module fails, the array won’t maintain its

output voltage.

Analog current-sharing control involves paralleling two or

more identical modules, each containing intelligence. The

circuit actively adjusts the output voltage of each supply

so the multiple supplies deliver equal currents. This method,

though, has a number of disadvantages. Each converter in

the array has its own voltage regulation loop, and each

requires a current-sensing device and current-control loop.

Analog current-sharing control does support a level of

redundancy. But it’s susceptible to single-point failures

within the current-sharing bus that at best can defeat

current sharing, and at worst can destroy every module in

the array. The major reason for this is the single-wire

galvanic connection between modules.

Current sharing is an essential element in fault-tolerant

arrays. Yet regardless of the approach, there is an inherent

Figure 8–2 — Droop-share current sharing artificially increases converter output impedance to force the currents to be equal. Diodes on the

output of each converter provide current sensing and fault protection.

VI-200 and VI-J00 Family Design Guide Rev 3.5 vicorpower.com

Page 16 of 98

Apps. Eng. 800 927.9474 800 735.6200

Page 18

Design Guide & Applications Manual

INPUT

LOAD

+ Sense

T

rim

–Sense

GATE

IN

–

IN

Zero-Current-

Switching Driver

+

OUT

GATE

OUT

+IN

–OUT

+Sense

Trim

–Sense

–IN

Zero-Current-

Switching Booster

+OUT

+IN

–OUT

+Sense

Trim

–Sense

–IN

Zero-Current-

Switching Booster

+OUT

+IN

–OUT

+V

I

N

-V

IN

GATE

IN

GATE

OUT

GATE

IN

GATE

OUT

or VI-200 and VI-J00 Family DC-DC Converters and Configurable Power Supplies

F

8. Using Boosters and Parallel Arrays

cost incurred by the addition of at least one redundant

onverter or supply.

c

ncidentally, most applications today that require fault

I

tolerance or redundancy also require Hot-Swap capability

to ensure continuous system operation. Hot-swappable

cards must be designed so the operator won’t come in

contact with dangerous potentials and currents.

It’s also essential that when a module fails, the failure is

detected and identified by an alarm or notice to provide

service. A Hot-Swap system must ensure that during

swap-out, there is minimal disturbance of the power bus.

Specifically, the affected voltage bus must not drop

enough to cause errors in the system, either on the input

bus or the output bus.

A power-supply failure can cripple an entire system, so the

addition of a redundant converter or supply is often

justified by the need to keep the system operating.

Adding an extra module (N+1) to a group of paralleled

modules will significantly increase reliability with only a

modest increase in cost.

The implementation of redundant converters is

determined in part by the available space and cost

requirements. For example, two 200 W full-size modules

could be used to provide a 400 W output with an

dditional 200 W module for 2+1 redundancy (a total of

a

600 W in a volume of about 16.5 in

3

).

Alternatively, four 100 W half-size modules might be used

with a fifth 100 W module to provide 4+1 redundancy (a

total of 500 W and 14 in3). Although the second solution

uses less space, it increases the accumulated failure rate

because it employs more converters, more ORing diodes,

more monitoring circuitry, and more assembly.

ORing diodes may be inserted in series with the output

of each module in an N+1 array to provide output fault

tolerance. (Figure 8–2) They’re important in a redundant

power system to maintain fault isolation. Without them,

a short-circuit failure in the output of one converter could

bring down the entire array.

But ORing diodes add losses to the power system,

reducing overall efficiency and decreasing reliability. To

ameliorate the negative effect on efficiency, ORing diodes

should run hot, thereby reducing forward voltage drop

and increasing efficiency. Reverse leakage current will be

an issue only if the output of a converter shorts and the

diode is reverse biased. This is an important consideration

with regard to operating temperature.

Figure 8–3 — Most converters can use the Driver / Booster array to increase output power. Driver / Booster arrays usually contain one

intelligent module or Driver, and one or more power-train-only modules or Boosters.

VI-200 and VI-J00 Family Design Guide Rev 3.5 vicorpower.com

Page 17 of 98

Apps. Eng. 800 927.9474 800 735.6200

Page 19

+IN

GATE

IN

GATE

OUT

–IN

+OUT

+S

TRIM

–S

–OUT

C2

C1

C2

C3

C3

C1 = 100 µF

C2 = 4,700 pF

C3 = 0.01 µF

Conditions:

Light Load = 3 A

Nominal Line = 48 V Nominal Load = 15 A

Full Load = 30 A

9. EMC Considerations

or VI-200 and VI-J00 Family DC-DC Converters and Configurable Power Supplies

F

Design Guide & Applications Manual

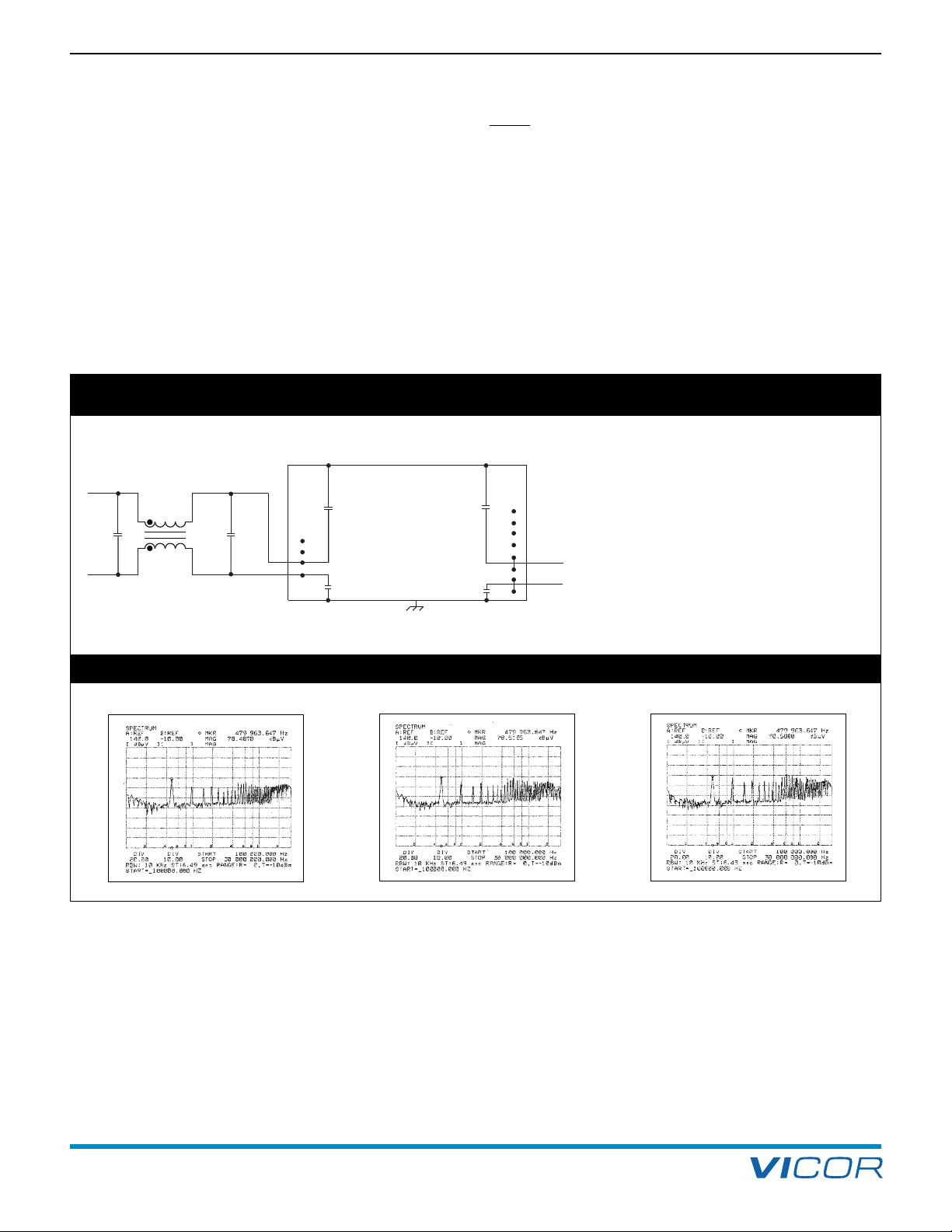

CONDUCTED NOISE

Conducted noise is the AC current flowing between the

source voltage and the power supply. It includes both

common-mode and differential-mode noise. Vicor zero-

urrent-switching converters are 20 – 40 dB lower in

c

conducted noise than a traditional board-mounted PWM

converter; however, if a specific EMC specification such as

FCC or VDE must be met, additional filtering may be required.

Since the noise generated is ten to a hundred times lower

than fixed frequency converters, an existing filter should

provide equal or better performance when the conditions

in the Module Do’s and Don’ts section are followed.

(Section 3)

In the event the system does not contain an existing filter,

the following will provide valuable information relative to

the attainment of system conducted noise objectives.

System requirements, such as Tempest (military) or UL544/

EN60601 (medical), require a somewhat different approach.

Medical requirements vary as a function of the application

and country — please contact Vicor Applications

Engineering for additional details.

Common-Mode Noise with No Additional Filtering.

Common mode conducted noise current is the

unidirectional (in phase) component in both the +IN and

–IN pins to the module. This current circulates from the

converter via the power input leads to the DC source and

returns to the converter via the grounded baseplate or

output lead connections. This represents a potentially

large loop cross-sectional area which, if not effectively

controlled, can generate magnetic fields. Common-mode

noise is a function of the dv/dt across the main switch in

the converter and the effective input to baseplate and

input to output capacitance of the converter.

The most effective means to reduce common-mode current

is to bypass both input leads to the baseplate with

Y-capacitors (C2), keeping the leads short to reduce

parasitic inductance. Additionally, a common-mode choke

(L1) is usually required to meet FCC/ VDE A or B. (Figure

9–2)

NOTE:

Acoustic Noise. Audible noise may be emitted

from the module under no load, light load, or

dynamic loading conditions. This is considered

normal operation of the module.

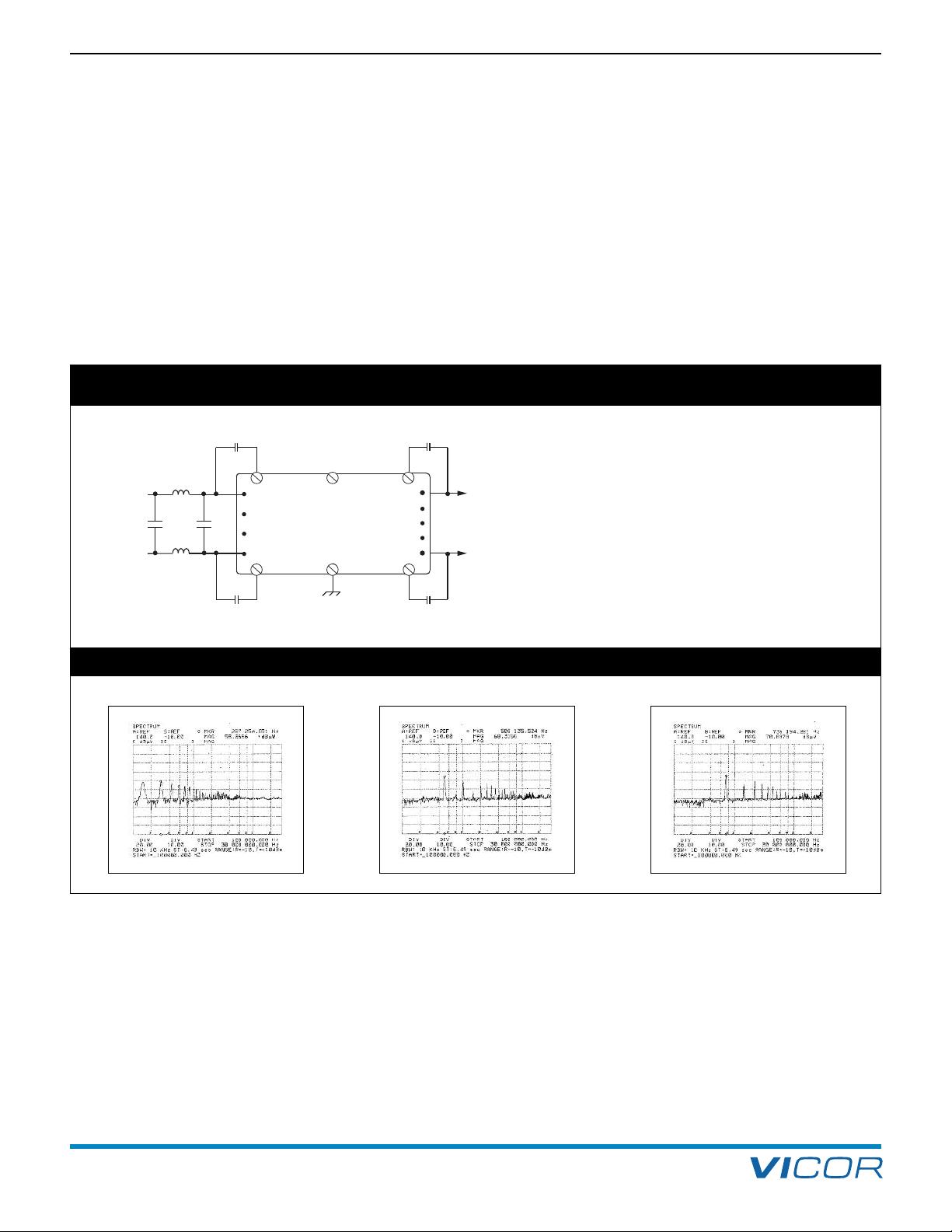

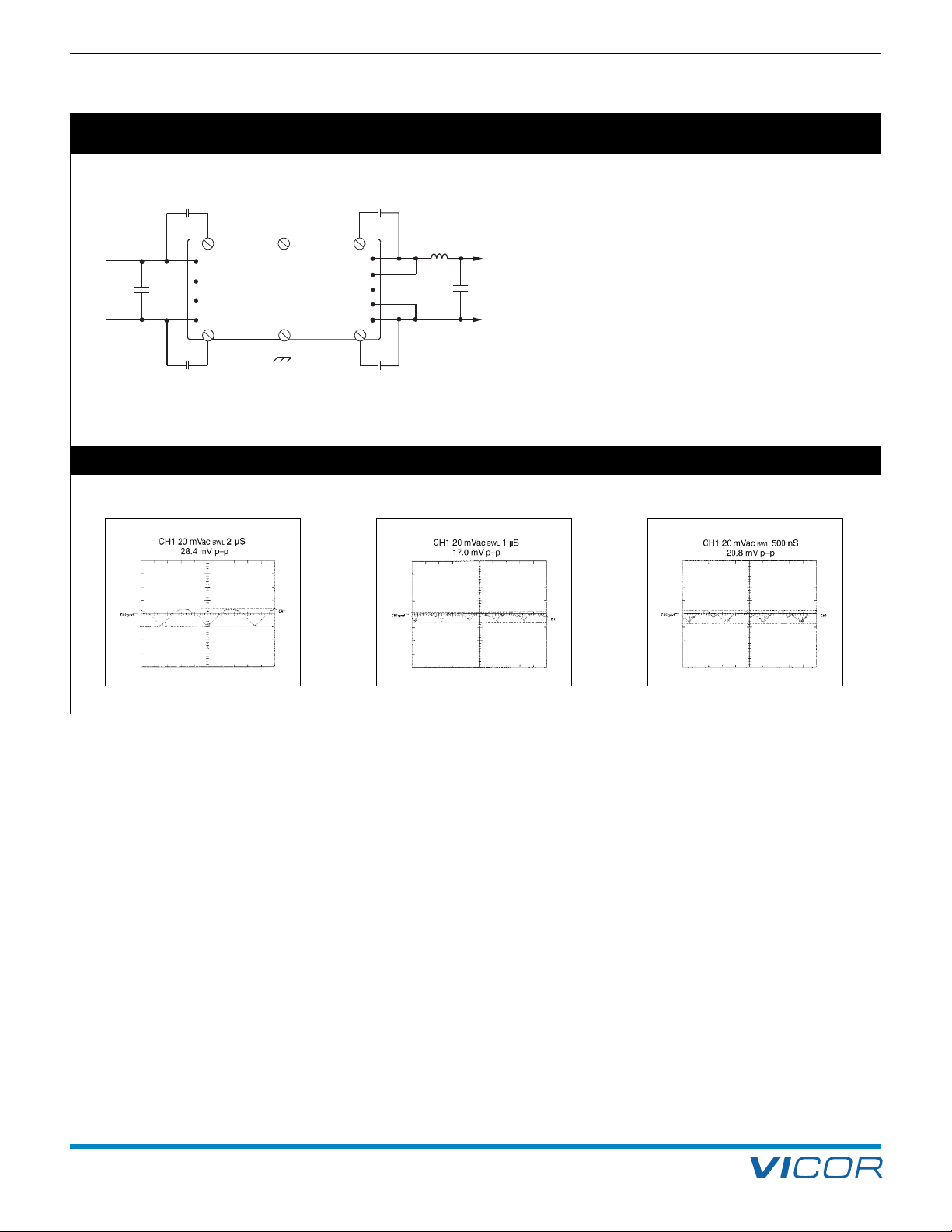

Typical Vicor Module

48 V Input, 5 V Output (VI-230-CV)

Conducted Noise vs. Load

3 Amp Load 15 Amp Load 30 Amp Load

Figure 9–1 — Conducted input noise, no additional filtering

VI-200 and VI-J00 Family Design Guide Rev 3.5 vicorpower.com

Page 18 of 98

Apps. Eng. 800 927.9474 800 735.6200

Page 20

Design Guide & Applications Manual

+IN

–IN

+OUT

–

OUT

C1 = 2.2 µF

C2 = 100 µF

C3 = Internal

C4 = Internal

L1 = 3 mH

Conditions:

L

ight Load = 3 A

Nominal Load = 15 A

Full Load = 30 A

C1

L1

C

2

C3

C3

C4

C4

Nominal Line = 48 V

C

M

or VI-200 and VI-J00 Family DC-DC Converters and Configurable Power Supplies

F

9. EMC Considerations

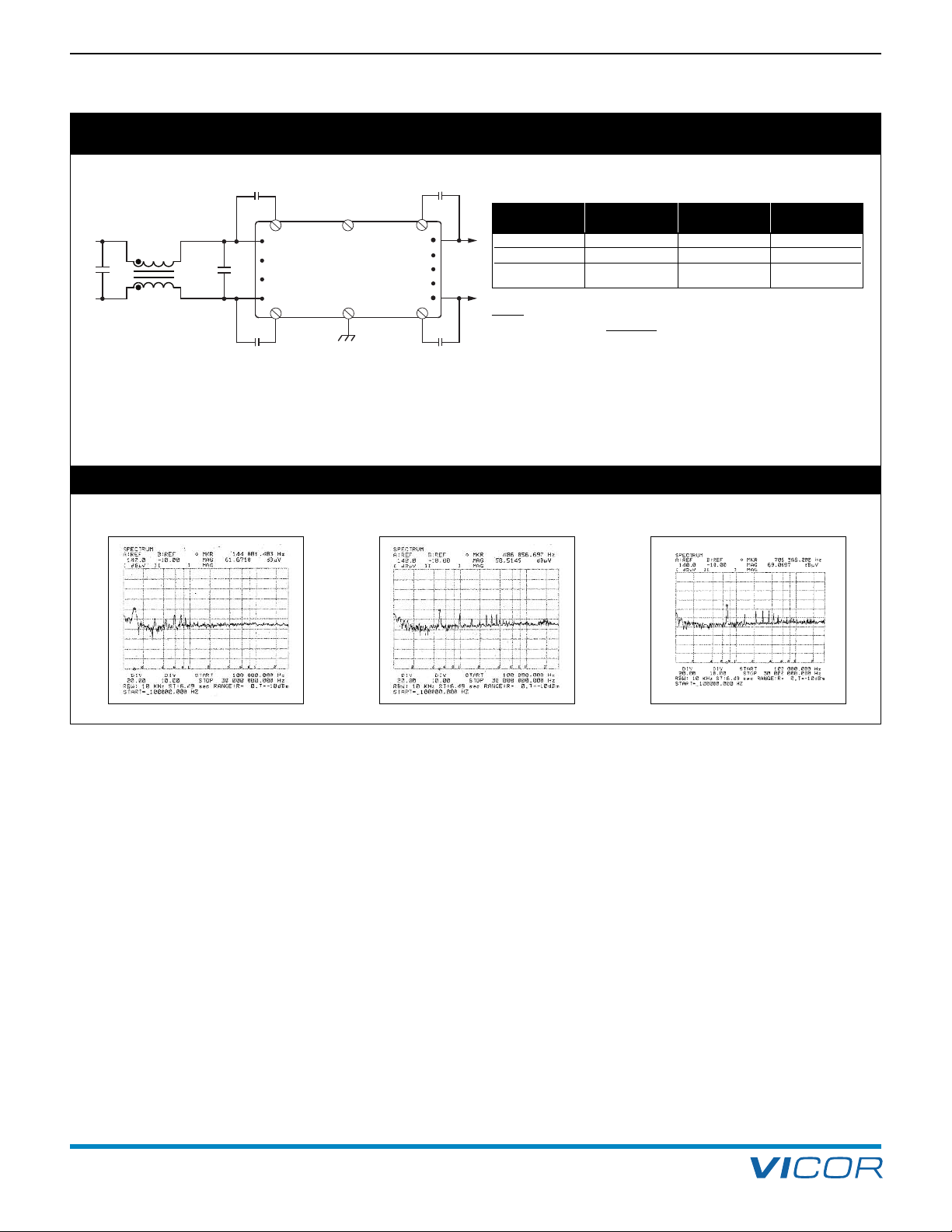

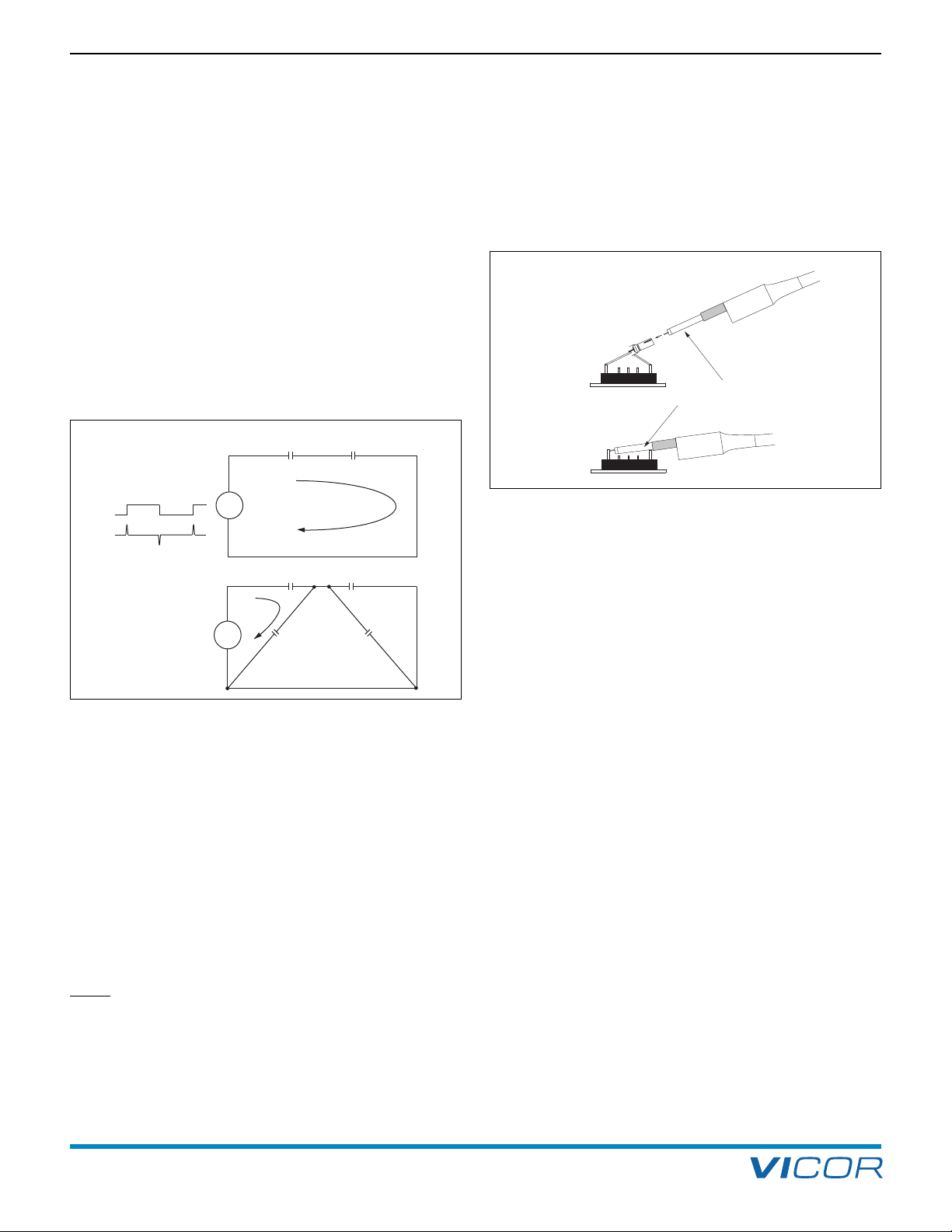

Common-Mode Noise with Common-Mode Choke.

There are no special precautions that must be exercised in

the design of input filters for Vicor converters. In fact, if

he system contains an EMC filter designed for typical

t

fixed frequency converters, it should be sufficient as is

although not optimal in terms of size), as zero-current-

(

switching converters inherently generate significantly less

conducted noise.

The plots in Figure 9–2 are representative of fixed

frequency converters with input filtering.

Typical Fixed Frequency Converter (PWM)

48 V Input, 5 V Output

: In most cases, a fixed frequency converter

NOTE

generates more input conducted noise with a filter

than Vicor’s zero-current-switching converter without

filter. Also note that fixed frequency converters

a

using a construction technique involving control

ircuitry on the same metal plate as power processing

c

components will generate significantly more input

noise than shown.

Conducted Noise vs. Load

3 Amp Load 15 Amp Load 30 Amp Load

Figure 9–2 — Conducted input noise, typical fixed frequency converter with filter

VI-200 and VI-J00 Family Design Guide Rev 3.5 vicorpower.com

Page 19 of 98

Apps. Eng. 800 927.9474 800 735.6200

Page 21

9. EMC Considerations

C

4

C1 = 100 µF

C2

a –

C

2

b

= 4,700 pF (Vicor Part # 01000)

C3

a

–

C3

b

= 0.01 µF

(Vicor Part # 04872)

C4 = 2.2

µF

L1 = 3,000

µH

(Vicor Part # 31742)

Conditions

L

ight Load = 3 A

Nominal Load = 15 A

Full Load = 30 A

+IN

GATE

I

N

GATE

OUT

–IN

+

OUT

+

S

T

RIM

–

S

–OUT

C

2

a

C

1

C

2

b

C

3

b

C

3

a

L1

CM

or VI-200 and VI-J00 Family DC-DC Converters and Configurable Power Supplies

F

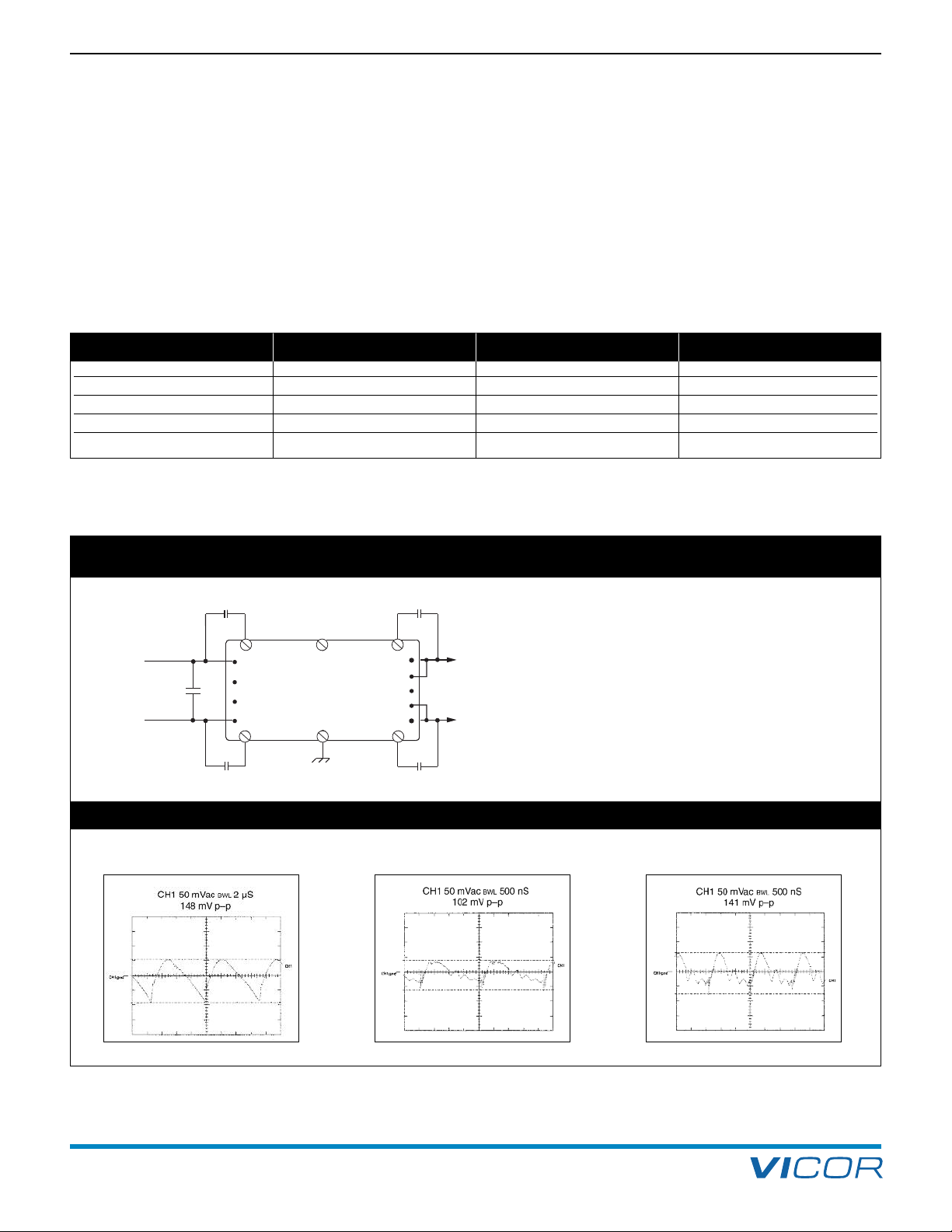

Typical Vicor Module (VI-230-CV)

48 V Input, 5 V Output

Three common-mode chokes are offered as standard accessories.

Part Inductance Maximum Resistance

Number Each Winding DC Current Each Winding

31743 1,000 µH 12 Amperes 6.5 mΩ

31742 3,000 µH 7 Amperes 18 mΩ

31943 2,163 µH 1 Ampere 42 mΩ

: Common-mode filters may be common to one or

NOTE

more modules, but only one

interconnected via GATE IN’s or, GATE OUT to GATE IN. As

an example, Driver / Booster arrays or Drivers with GATE IN’s

tied together to provide a common disable function.

Conducted Noise vs. Load

Design Guide & Applications Manual

should be used with modules

3 Amp Load 15 Amp Load 30 Amp Load

Figure 9–3 — Conducted input noise, with common-mode choke

VI-200 and VI-J00 Family Design Guide Rev 3.5 vicorpower.com

Page 20 of 98

Apps. Eng. 800 927.9474 800 735.6200

Page 22

Design Guide & Applications Manual

+IN

GATE

IN

G

ATE

OUT

–IN

+OUT

+S

T

–S

–OUT

Load 1

Load 2

L

2

C4

L1

C1

a

C

2

a

C2

d

C2

c

C2

b

C3

a

C3

b

C3

c

C3

d

C1

b

+IN

GATE

IN

GATE

OUT

–IN

+OUT

+S

T

–S

–OUT

C1a – C1b = 47 µF

C2a – C2d = 4,700 pF (Vicor Part # 01000)

C3a – C3d = 0.01 µF (Vicor Part # 04872)

C4 = 2.2 µF

L1 = 3,000 µH (Vicor Part # 31742)

L2 = 20 µH

C

onditions

Light Load = 3 A

Nominal Load = 15 A

Full Load = 30 A

CM

or VI-200 and VI-J00 Family DC-DC Converters and Configurable Power Supplies

F

9. EMC Considerations

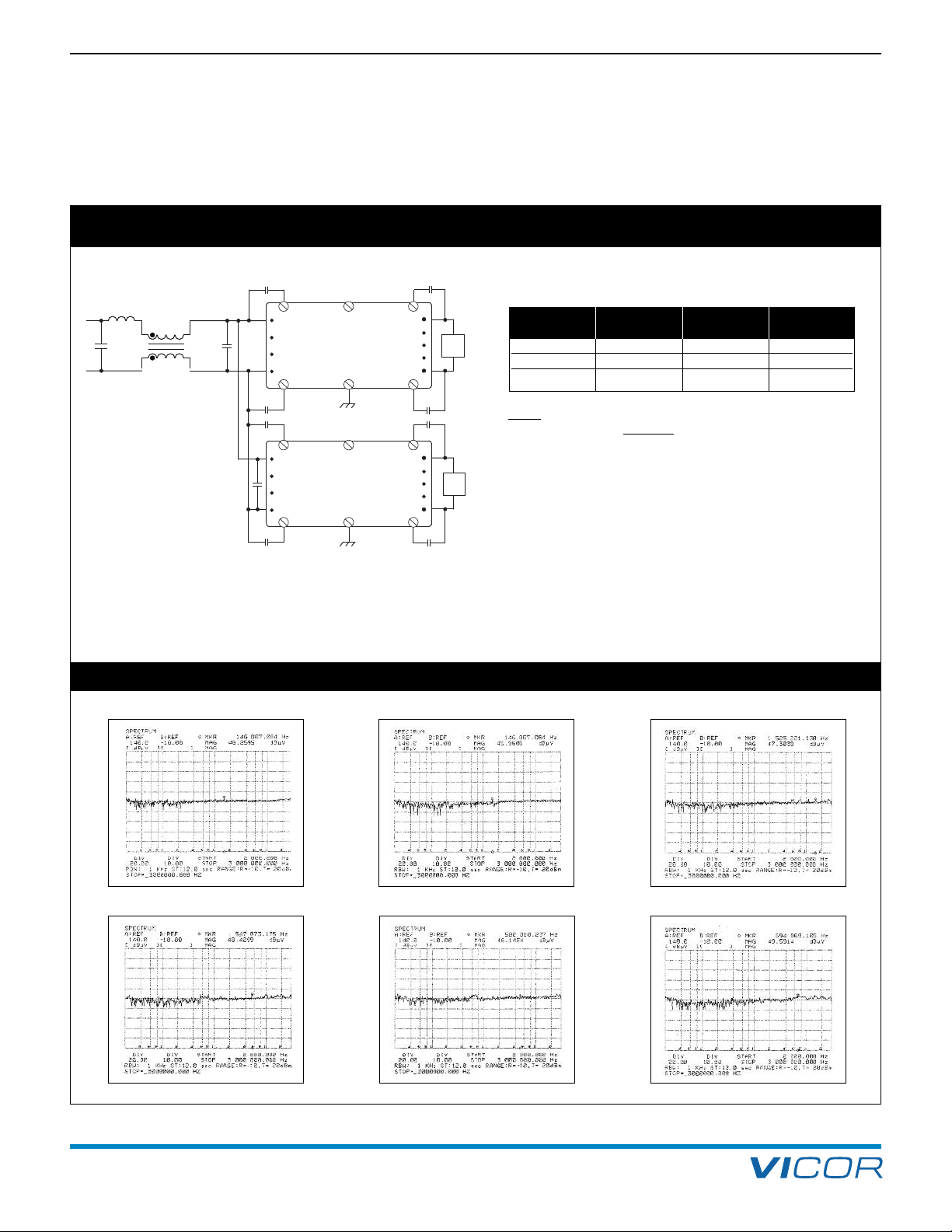

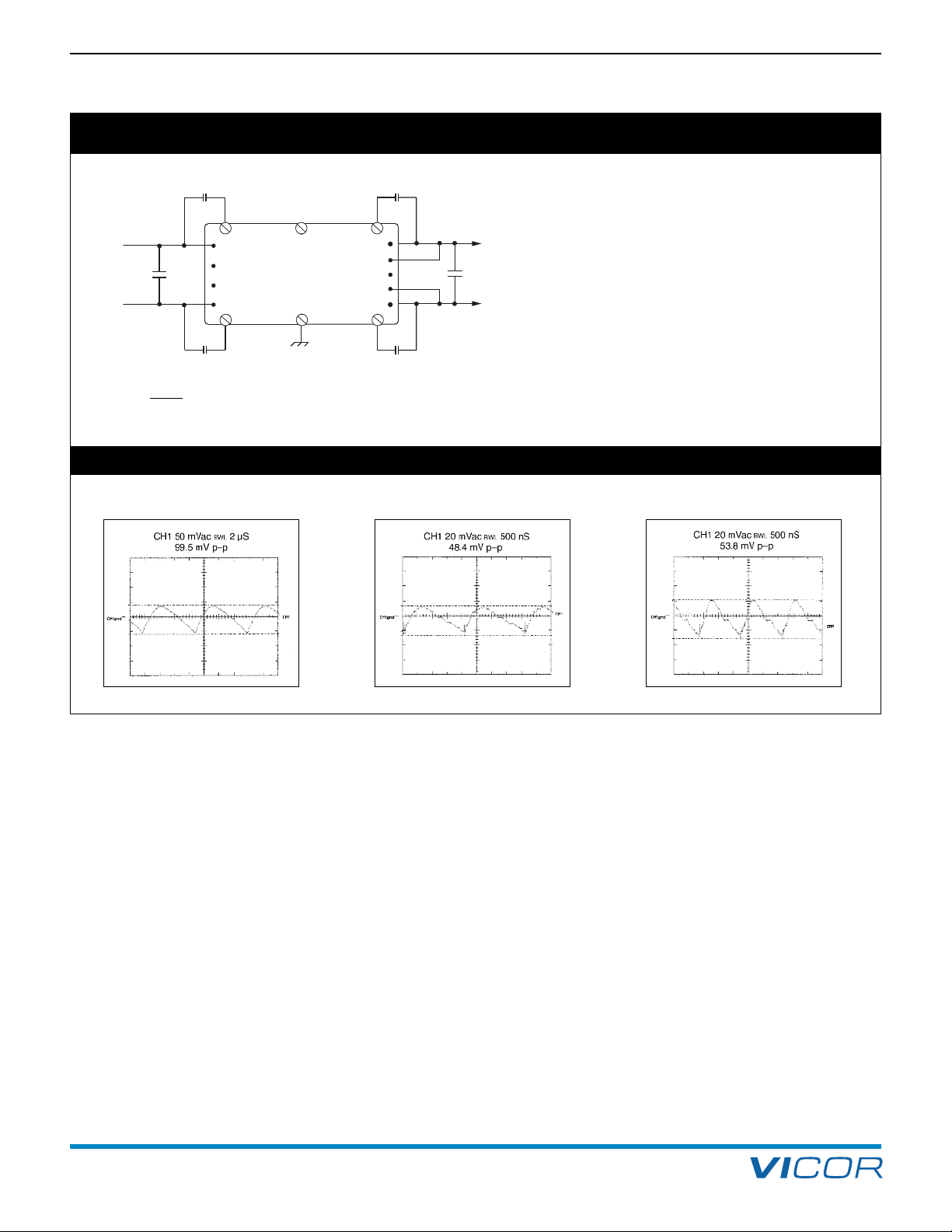

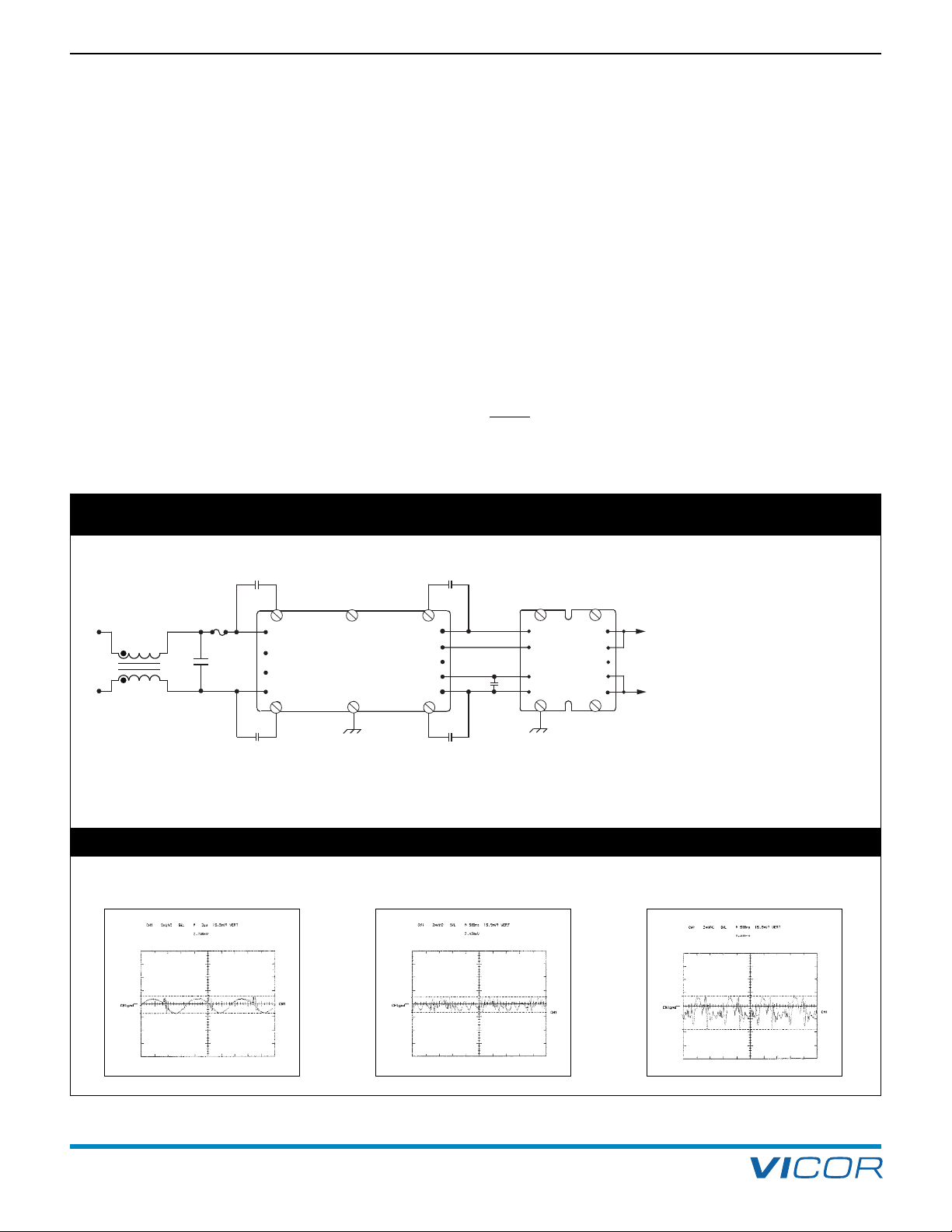

Differential and Common-Mode Filter with More

than One Module. No special precautions are needed

when using two or more modules. The filter required will

ave the same characteristics as a single module filter,

h

Differential and Common-Mode Filter with More than One Module

48 V Inputs, 5 V Outputs (Two Vicor VI-230-CV Modules)

however the wire size on the magnetics will need to

reflect the increased input current. Shown below is the

input conducted noise for two modules sharing a

ommon input source.

c

Three common-mode chokes are offered as standard accessories.

Part Inductance Maximum Resistance

Number Each Winding DC Current Each Winding

31743 1,000 µH 12 Amperes 6.5 mΩ

31742 3,000 µH 7 Amperes 18 mΩ

31943 2,163 µH 1 Ampere 42 mΩ

: Common-mode filters may be common to one or

NOTE

more modules, but only one should be used with modules

interconnected via GATE IN’s or, GATE OUT to GATE IN. As

an example, Driver / Booster arrays or Drivers with GATE IN’s

tied together to provide a common disable function.

Conducted Noise vs. Load

3 Amp / 3 Amp Load

15 Amp / 15 Amp Load

Figure 9–4 — Conducted noise, multiple zero-current-switching converters

3 Amp / 6 Amp Load

3 Amp / 30 Amp Load

15 Amp / 30 Amp Load 30 Amp / 30 Amp Load

VI-200 and VI-J00 Family Design Guide Rev 3.5 vicorpower.com

Page 21 of 98

Apps. Eng. 800 927.9474 800 735.6200

Page 23

9. EMC Considerations

C2

a

C

1

C2

b

C3

b

C3

a

L1

C

4

L2

C1 = 100 µF

C 2a – C2b = 4,700 pF (Vicor Part # 01000)

C 3a – C3b = 0.01 µF (Vicor Part # 04872)

C4 = 2.2 µF

L1 = 20 µH

L2 = 20 µH

+

IN

GATE

IN

GATE

OUT

–IN

+OUT

+S

T

RIM

–

S

–OUT

C

onditions

Light Load = 3 A

Nominal Load = 15 A

Full Load = 30 A

or VI-200 and VI-J00 Family DC-DC Converters and Configurable Power Supplies

F

Design Guide & Applications Manual

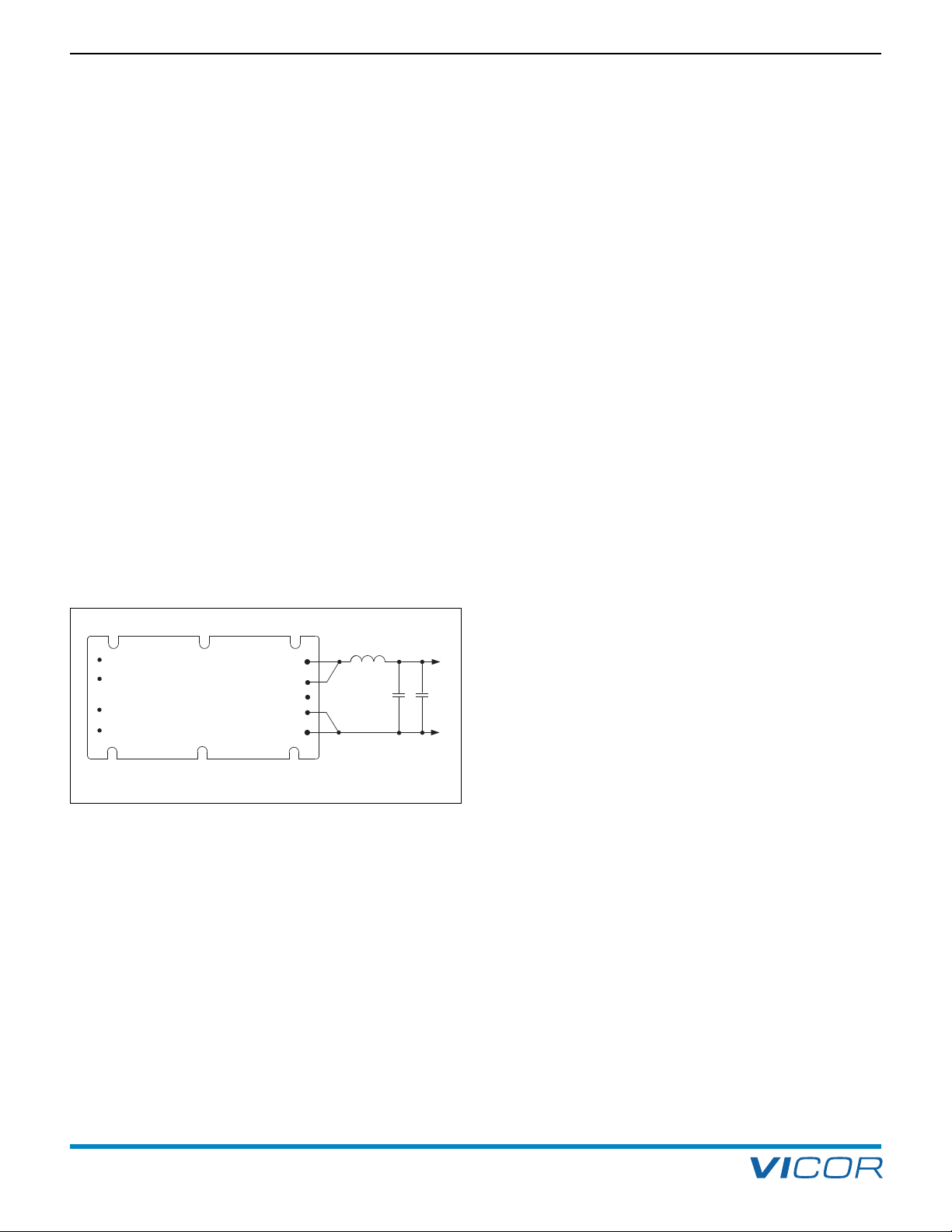

Differential-Mode Noise Filter. Differential-mode

conducted noise current is the component of current,

at the input power pin, which is opposite in direction or

hase with respect to the other input power pin.

p

All Vicor converters have an internal differential-mode LC

filter which, in conjunction with a small external capacitor

C1 (minimum value in µF) = 400 / Vin,

reduces differential-mode conducted noise. The external

capacitor should be placed close to the module to reduce

loop cross-sectional area.

Differential-Mode Filter

Typical Vicor Module (VI-230-CV) 48 V Input, 5 V Output

Care should be taken to reduce the loop cross-sectional

area of differential-mode current flowing between the

source and C1. Since differential-mode input current is by

efinition opposite in phase, twisting the input leads

d

causes noise cancellation. PCB power planes can reduce

adiated noise if the traces are on opposite sides of the

r

PCB directly over one another. If differential mode inductance

is used, it may be common to one or more modules.

Conducted Noise vs. Load

3 Amp Load 15 Amp Load 30 Amp Load

Figure 9–5 — Conducted noise, differential-mode filtering

VI-200 and VI-J00 Family Design Guide Rev 3.5 vicorpower.com

Page 22 of 98

Apps. Eng. 800 927.9474 800 735.6200

Page 24

L

C

Vs

Ip

+IN

–IN

Vp

+

OUT

–

OUT

Ceramic

Parasitic

Capacitance

Baseplate

Rectifier

Ceramic

FET

ShieldShield

Design Guide & Applications Manual

or VI-200 and VI-J00 Family DC-DC Converters and Configurable Power Supplies

F

RADIATED NOISE

Radiated noise may be either electric field or magnetic

field. Magnetic radiation is caused by high di/dt and is

generally what is measured by FCC, VDE or MIL-STD-461.

Vicor converters utilize zero-current-switching, with the

advantage over PWM non-zero-current-switching being

that zero-current-switching topologies contain minimal

discontinuities in the switched current waveforms,

resulting in lower di/dt’s. Electric field radiation (caused by

dv/dt) is “near-field,” i.e., it decays rapidly as a function of

distance and as a result does not typically affect radiated

measurements.

Figure 9–6 — Basic zero-current-switching converter topology

Radiation can be minimized by proper board layout. Keep

(VI-200 / VI-J00)

all leads with AC current short, twisted or routed as

overlapping planes to minimize loop cross-sectional area.

Also keep in mind the effects of capacitive coupling —

even when not expected. Do not put an unshielded filter

on the opposite side of the PCB from the module.

Conducted noise can be capacitively coupled around the

filter. Do not route input and output leads in the same

cable bundle. Again, no special precautions, just good

design practice.

Since the energy in every pulse is related to the square of

the applied voltage (CV

as approximately the square of the line voltage. For

example, a 300 V input unit can vary from 200 – 400 V,

or a factor of two, therefore it follows that the repetition

rate must vary by approximately a factor of four to regulate

the output. As previously established, the current in the

primary is a half-wave rectified sine wave, but the voltage

on the primary is a square wave. Since this voltage is a

square wave, it contains harmonics of the fundamental

NOISE CONSIDERATIONS

switching frequency. It also includes frequencies, that extend

to 70 MHz.

All switchmode power supplies generate a certain amount

of “noise”, yet it remains one of the least understood

parameters in power conversion.

These frequencies can be of interest in the following

circumstances. Rapidly changing voltages (high dv/dt) can

generate E-fields (primarily near-field) which do not usually

VI-200s and VI-J00s both use the same topology, so their

operation is very similar. These products are zero-currentswitching converters — i.e., the current is zero when the

main switch is turned on or off. While the switch is on,

the current through the switch or the primary of the

transformer is a half-wave rectified sine wave. Similar in

operation to a resonant converter, these products are

commonly referred to as quasi-resonant converters. The