Page 1

USER GUIDE | UG:014

VI Chip® VTM

®

Evaluation Board

Written by: Ankur Patel

Applications Engineer

August 2013

Contents Page

Introduction 1

Contents 2

Features 2

Board Description 3

General Components 4

Test Points & Sockets 5

Schematic 7

Assembly Drawings 9

Bill of Materials 10

VTM Evaluation Boards 12

Introduction

This evaluation board oers a convenient means to evaluate the performance of

Vicor’s VTM® current multiplier. All evaluation boards include sockets for easy "plug

and play" insertion and removal of through-hole components and wires. The board

provides lugs for power connections, connectors for easy PRM-VTM evaluation board

interconnects, and kelvin voltage measurement test points of all pins of the VTM.

Please refer to the appropriate VTM datasheet for performance and operating limits,

available for downloading at www.vicorpower.com.

Standalone Operation 12

vs PRM-VTM

PRM-VTM Non-Isolated 12

Remote Sense

Paralleling 13

Push Pin Heat Sink 13

Installation

Part Ordering Information 13

IMPORTANT NOTICE:

Please read this document before setting up a VTM evaluation board

This user guide is not comprehensive and the operator should not substitute it for

common sense and good practice. The following procedures should be followed

during operation:

n Wear approved safety glasses when testing electronic product.

n Provide strain relief for wires and secure the board on the test bench to avoid

displacement.

n Remove the power and use caution when connecting and disconnecting all test

probes and interface lines to avoid unintentional short circuits and contact

with hot surfaces.

n Never attempt to disconnect the evaluation board from a PRM® evaluation board

while power is applied. This system is not designed to demonstrate the

hot plug capability.

UG:014 vicorpower.com Applications Engineering: 800 927.9474 Page 1

Page 2

Contents

All VTM® evaluation boards arrive with the following contents.

(The user guide can be downloaded from the www.vicorpower.com.)

n 1 x VTM Evaluation board

n 1 x VI Chip push pin heat sink

n 2 x VI Chip push pins for heat sink installation

n 1 x Hardware kit

n 2 x Through hole mating connectors

n 1 x Through hole 22 µF input capacitor

Features

1. Input filtering – ceramic capacitors and sockets for installation of throughhole

aluminum electrolytic capacitor

2. Output filtering – ceramic capacitors

3. Oscilloscope probe jack for output voltage signal measurement

4. Kelvin test points for measurement of input voltage, output voltage and all signal

pins of the VTM

5. Sockets for each test points for easy installation of through-hole components and

solid wires to facilitate wiring to external circuitry and test equipment

6. Input and output lugs for power supply and load connections

7. Input power and signal connectors for testing with PRM module

8. Provisions for non-isolated remote sense operation with PRM evaluation board

a. Provision to inject network analyzer signals

b. 2512 resistor footprint for installation of zero ohm resistor to break the VTM

isolation for non isolated remote sense operation

c. Sense pins with local Sense Resistors to +OUT and –OUT

UG:014 vicorpower.com Applications Engineering: 800 927.9474 Page 2

Page 3

Figure 1.

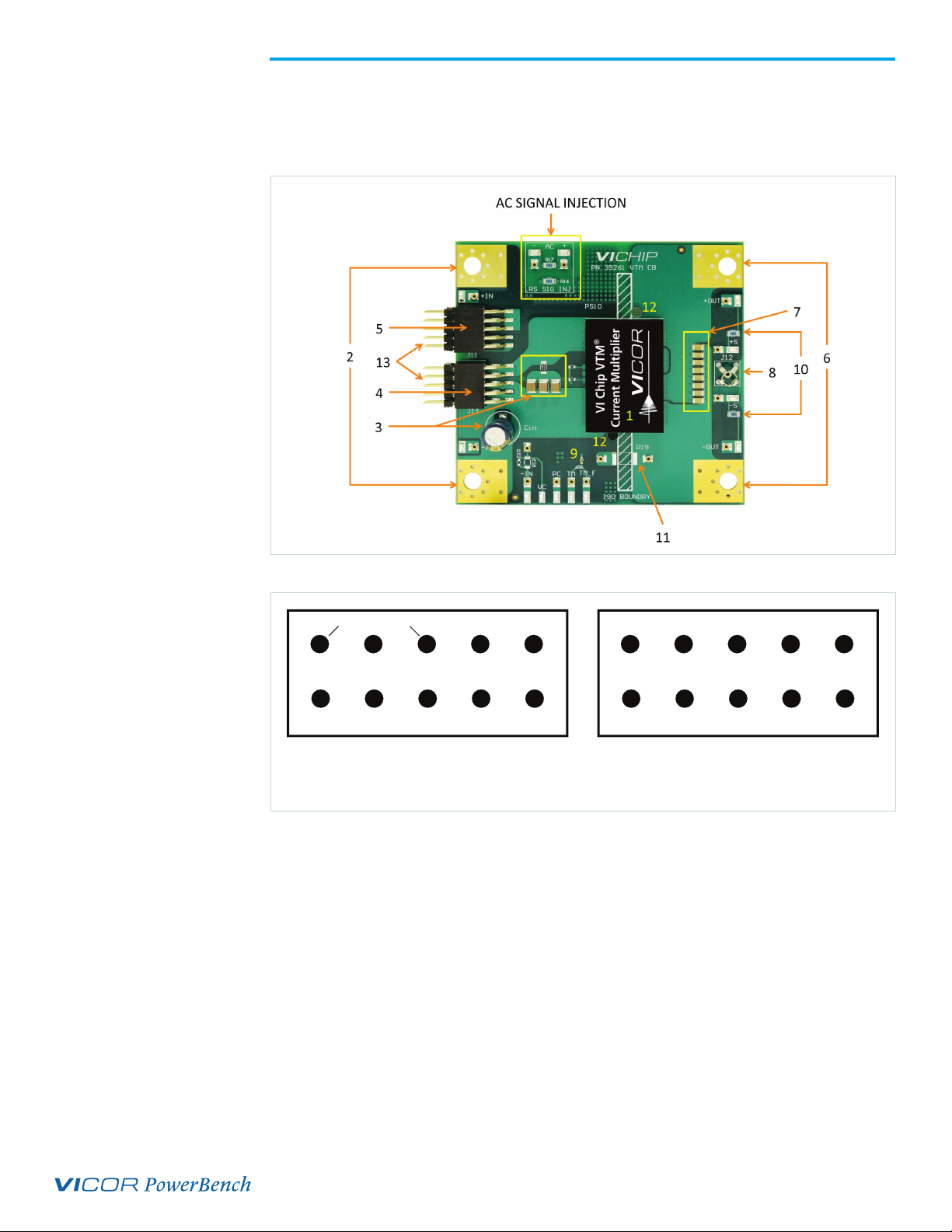

Board Description

Board Description

The following section provides a detailed description of the evaluation board

components, test points and sockets.

Figure 2.

Power/signal connectors

pinout, front view

VTM_-IN

10

9

V_IM

J11

Signal connector

8

7

V_PC

6

5

V_TM

-OUT

4

3

VC

VC

2

1

-OUT

-S

4

3

2

1

+S

+OUT

10

+OUT

J14

Power/signal connector

+OUT

8

9

7

+OUT

-OUT

6

5

-OUT

UG:014 vicorpower.com Applications Engineering: 800 927.9474 Page 3

Page 4

General Components

1. VTM® (PS10)

2. Input lugs (+IN and –IN): Sized for #10 hardware. Use these for making connection

to the input source. This board does not contain reverse polarity protection. Check

for proper polarity before applying power.

3. Input filtering: Input capacitor (CIN) and filtering (ceramic capacitors) allows for

stable operation with most input sources. Sockets can be used for easy installation

of aluminum-electrolytic input capacitor.

4. Power/Signal connector (J14): Used to receive the power (+OUT/-OUT) and VC from

upstream PRM board when used.

5. Signal connector (J11): Used to transfer VTM PC, IM, TM, -IN and output sense

signals between the VTM and PRM® boards. TM pin of the VTM provides feedback

to the VT pin of the PRM in adaptive loop operation of PRM and VTM. +S and –S

signals provide voltage sensing to the PRM remote sense circuitry for non-isolated

remote sense operation.

6. Output lugs (+OUT, -OUT): Sized for #10 hardware. Use these lugs to connect the

output directly to the load.

7. Output filtering(ceramic capacitors): Helps to minimize switching ripple

of the output voltage.

8. Output oscilloscope probe jack (J12): Used for making accurate scope

measurements of the output voltage (i.e. ripple). Remove scope grounding lead

and insert probe directly into jack ensuring a good connection between the jack

and the probe ground barrel. Do not attempt to install while power is applied. May

not be compatible with all scope probes.

9. TM filtering: Filters the TM signal noise. Corner frequency of the filter is set well

below the VTM switching frequency.

10. Sense pins and local sense resistors: Used to sense the output votage of the VTM

for non-isolated remote sense operation. Local sense resistors can be bypassed by

connecting twisted pair from the sense test points directly to the load.

11. VTM isolation boundry: Zero ohm shunt can be soldered or use sockets to break the

isolation for non isolated remote sense operation of VTM board and PRM board.

12. Heat sink push-pins: Secure the heat sink to the board using these pins. Use of a fan

across the heat sink is highly recommended for proper cooling.

13. Mating connectors: Connect the PRM and VTM with the connecters to share power

and signal connection.

UG:014 vicorpower.com Applications Engineering: 800 927.9474 Page 4

Page 5

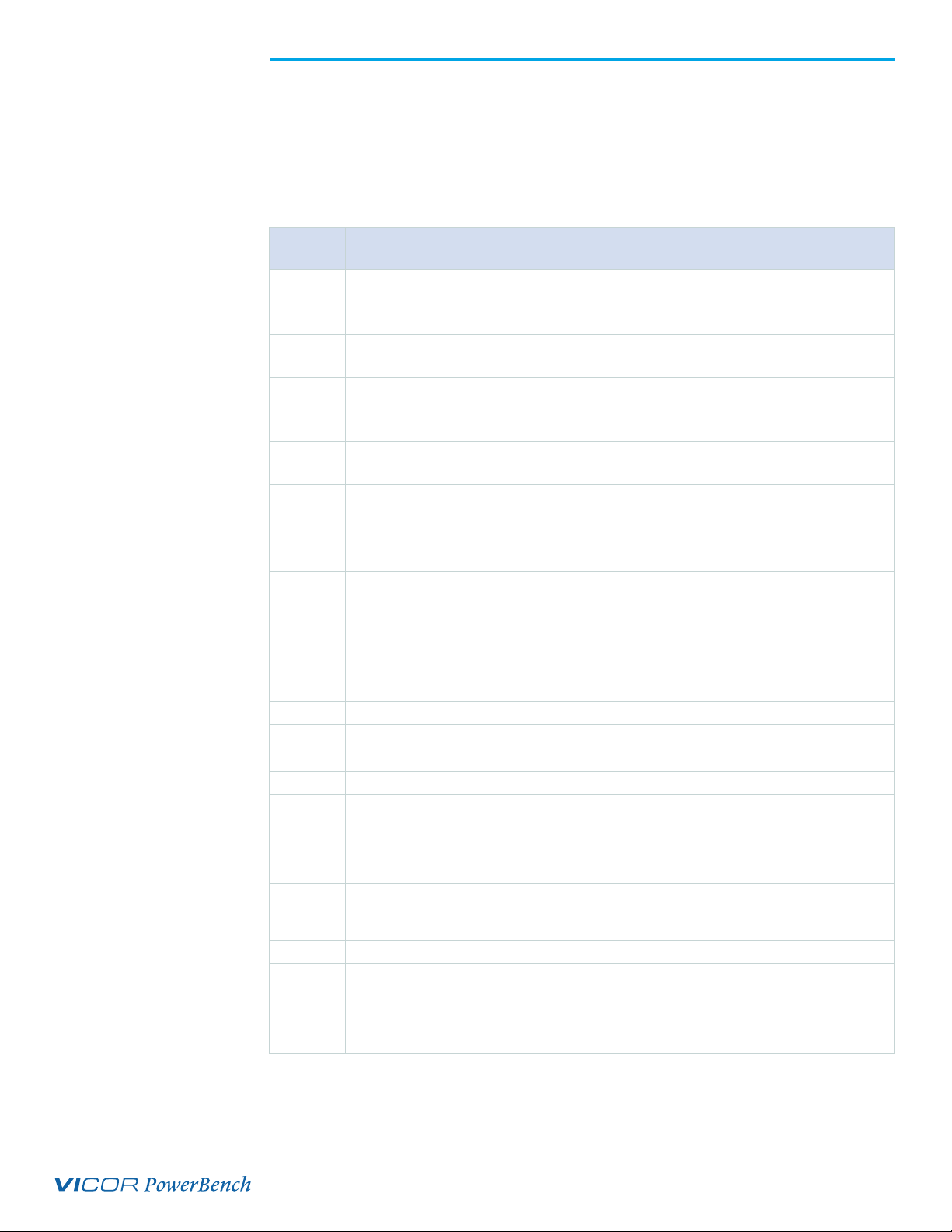

Test Points and Sockets Description

Each test point socket accepts 0.015 – 0.025 inch diameter leads of solid wires and

through-hole components for use with external circuitry and test equipment. All test

points are aligned on the board’s edge for easy access, measurement and external

circuitry connections. Each point is labeled and is accompanied by an additional

adjacent socket.

Table 1.

Test points and

sockets description

Reference

Designator

TP20,

TP21

H20,

H21

TP17,

TP22

H17,

H22

Functional

Name

+IN,

–IN

+IN,

–IN

+OUT,

–OUT

+OUT,

–OUT

Functional

Description

Input voltage test points provide kelvin connection to input pins of the

®

. Use these test points for measuring the input voltage of the VTM

VTM

to avoid error due to interconnect losses.

Sockets for +IN and –IN test points. Kelvin connected to the VTM input

pins.

Output voltage test points provide kelvin connection to output pins of the

VTM. Use these test points for measuring the output voltage of the VTM

to avoid error due to interconnect losses.

Sockets for +OUT and –OUT test points. Kelvin connected to the VTM

output pins.

VC test point provides kelvin connection to VC pin of the VTM. Can be

TP12 VC

used to apply and measure the VC signal with reference to –IN signal. VC

is used to enable the VTM. Apply 14 V to VC to enable the VTM, when

not using PRM.

H12 VC

Socket for VC test point. Kelvin connected to VC pin of the VTM. Aligned

with –IN socket for placing through hole resistor from VC to –IN.

PC test point provides kelvin connection to PC pin of the VTM. Can be

TP10 PC

used to measure the PC signal with reference to –IN signal. PC can be

used to disable the VTM in the presence of input power. Connecting PC

to –IN will disable the VTM.

H10 PC Socket for PC test point. Kelvin connected to PC pin of the VTM.

TP11 TM

TM test point provides kelvin connection to TM pin of the VTM. Can be

used to measure and monitor the TM signal with reference to –IN signal.

H11 TM Socket for TM test point. Kelvin connected to TM signal of the VTM

TP16

H15

FILTEREDTMProvides the low noise measurement of TM signal.Output of the TM RC

filter can be measured using this testpoint with reference to –IN.

FILTERED

TM

Socket for TP16 test point.

TP13 –IN

-IN test point provides kelvin connection to –IN pin of the VTM. All signals

on inp ut s ide of t he VTM are mea sured with reference to –IN signal of the VTM.

H13 –IN Socket for –IN test point.

Output sense test points provide connection to the output pins of

TP15,

TP14

UG:014 vicorpower.com Applications Engineering: 800 927.9474 Page 5

+S,

–S

VTM through local sense resistors. Routed to connector J11 for use

in differential non isolated remote sense circuitry for Remote Sense

®

operation of VTM and PRM

.

Page 6

Test Points and Sockets Description (Cont.)

Reference

Designator

H15,

H14

TP18,

TP19

H18,

H19

Functional

Name

+S,

–S

Functional

Name

Sockets for +S and –S test points.

Can be used to inject the isolated signal of network analyzer for bode

AC SIG INJ

plot measurement to measure the stability in Remote Sense operation

using VTM and PRM

AC SIG INJ Sockets for AC +/- test points.

IM test point provides the kelvin connection to IM pin. Can be used to

TP30 IM

measure the IM signal of the half VTM. IM can be used to monitor the

output current of the VTM. Available on half VTM boards only.

H27 IM Socket for IM test point.

UG:014 vicorpower.com Applications Engineering: 800 927.9474 Page 6

Page 7

Figure 3a.

Schematic - Full Chip VTM

evaluation board

Schematics

J10

J16

J12

KELVIN

C19

1206

C18

1206

1206

C17

1206

C16

1206

C15

C14

1206

C13

1206

+OUT

1206

C12

H17

TP17

TP23

+OUT

PS10

+OUT

-OUT

R15

1206

R13

1206

TP15

-SENSE +SENSE

KELVIN WITH DIFFERENTIAL ROUTING

TP14

VTM

VC

TM

PC

H14 H15

TP24

PC

C10

0603

1206

R12

H12

TP12

R11

H11

H10

TP11TP10

R10

PC TM VC

H13

TP13

0603

-IN

0603

KELVIN -IN

TMTM_F

0603

R14

KELVIN -IN

C11

0603

-IN

H16

TP16

VC

TM

R16

1206

-IN

1 2

3 4

5 6

7 8

9 10

J11

PC

TM

TP27

TP20

H20

TP19TP18

1206

R17

H18 H19

TP26

TP25

J13

-OUT

H22

TP28

TP22

-OUT

HS10

2512

R19

ISOLATION BOUNDRY

+IN

R18

H23

PRIMARY SECONDARY

-IN

VTM_OFF_BD_VIBRICK

TP29

H21

C22

1210

C21

1206

1210

C20

1210

H24

CIN

VC

1 2

3 4

5 6

7 8

9 10

J14

J15

NO GND

H25 H26

TP21

FIDUCIAL

FID02

FIDUCIAL

FID01

-IN

UG:014 vicorpower.com Applications Engineering: 800 927.9474 Page 7

Page 8

Figure 3b.

Schematic - Half Chip VTM

evaluation board

Schematics (Cont.)

J10

J16

J12

KELVIN

C19

1206

C18

1206

C17

1206

1206

C16

C15

1206

C14

1206

C13

1206

+OUT

1206

C12

H17

TP17

TP23

+OUT

+OUT

-OUT

R15

1206

1206

R13

TP15

-SENSE +SENSE

KELVIN WITH DIFFERENTIAL ROUTING

TP14

HAL F VTM

PC

VC

TM

IM

-OUT

H22

TP28

TP22

-OUT

HS10

2512

R19

ISOLATION BOUNDRY

PS10

+IN

PRIMARY SECONDARY

-IN

NO GND

H25 H26

H14 H15

TP26

TP25

TP24

PC

C10

0603

1206

R12

H12

TP12

R11

0603

H11

H10

H27

TP11TP10

0603

R10

PC TM VC

0603

R20

IM

TP30

H13

TP13

-IN

KELVIN -IN

TMTM_F

R14

0603

KELVIN -IN

C11

0603

-IN

H16

TP16

TP31

IM

VC

TM

1206

R16

-IN

1 2

3 4

5 6

7 8

9 10

IM

PC

TM

TP27

TP20

H20

R18

1206

TP19TP18

1206

R17

J11

H23

H18 H19

9 10

J13

TP29

TP21

H21

C22

1210

C21

1210

C20

1210

FIDUCIAL

H24

CIN

VC

1 2

3 4

5 6

7 8

J14

-IN

FID02

FIDUCIAL

FID01

J15

UG:014 vicorpower.com Applications Engineering: 800 927.9474 Page 8

Page 9

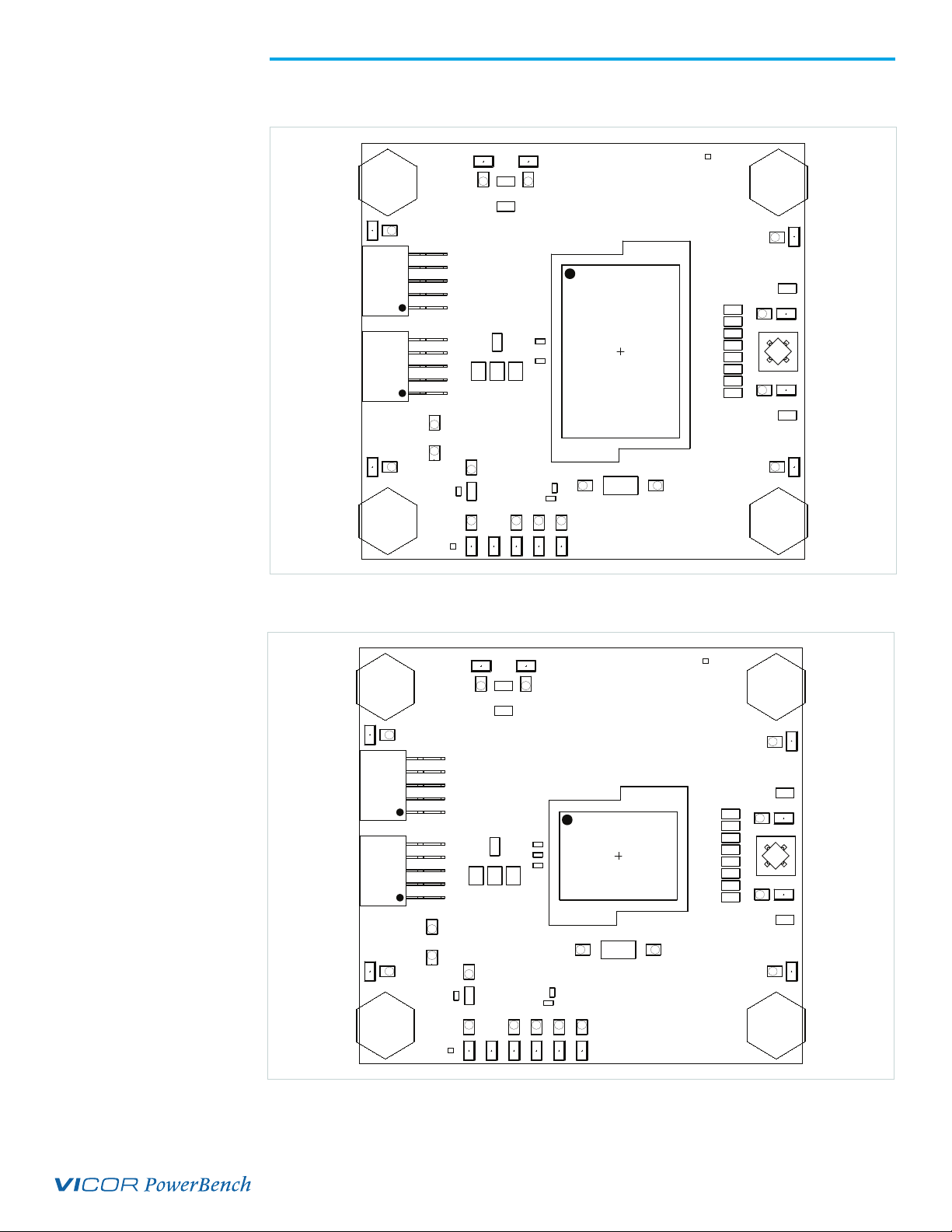

Figure 4a.

TP16

TP13

TP12

TP11

TP10

TP16

TP13

TP12

TP11

TP10

TP30

Assembly drawing – Top view:

Full Chip VTM evaluation board

Assembly Drawings

H20

H18

R17

R16

TP19TP18

FID02

J10J13

H19

H17

HS10

TP17

Figure 4b.

Assembly drawing – Top view:

Half Chip VTM evaluation board

J11

H15

C19

C18

FID02

C17

C16

C15

C14

C13

C12

H14

H22

J10J13

H17

R11

R18

J14

H21

TP21 TP20

J15 J16

FID01

H20

H23

H24

C20

H12

C10

R12

H13

H18

R17

R16

C21

H10

TP19TP18

C22

R14

H19

R10

H11

H16

PS10 J12

H26H25

R19

C11

HS10

R15

TP15

PF15

TP14

R13

TP22

TP17

J11

C19

C18

R20

R18

R11

J14

H21

TP21 TP20

J15 J16

FID01

H23

H24

C20

H12

C10

R12

H13

C21

H10

C22

R10

R14

H11

H16

PS10 J12

H26H25

R19

C11

H27

PF18

C17

C16

C15

C14

C13

C12

H22

H15

H14

R15

TP15

PF15

TP14

R13

TP22

UG:014 vicorpower.com Applications Engineering: 800 927.9474 Page 9

Page 10

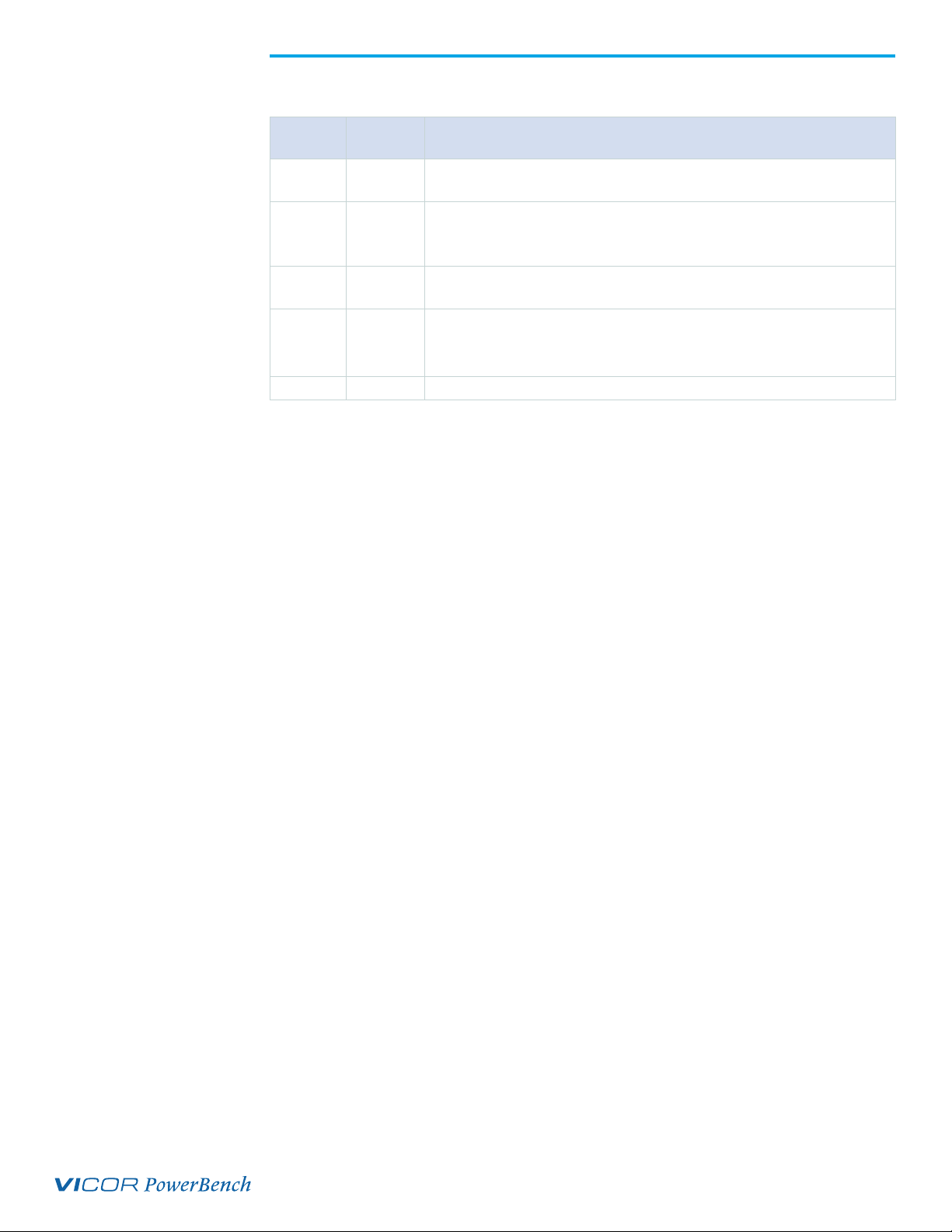

Bill of Materials

Following table describes the common components of all VTM evaluation boards.

Table 2.

Common components

Reference

Designator

Description Manufacturer

Manufacturer

Part Number

C10 NOT APPLIED

C11

CAP X7R .1uF 10%

100 V 0603

Murata

Manufacturing

GRM188R72A104KA35D

C12 - C19 Design Specific – See table 3

C20 - C22

CIN_PUT_IN_BOX

H10 - H27

HEADER_IN_BOX

J11, J14

J12

CAP X7R 2.2uF 10%

100 V 1210 .102 MAX HT

CAP ALEL 22uF 20%

100 V RADIAL 8 X 11.5

PIN RECPT .015/.025 DIA

0667 SER TH

CONN 10POS HEADER STR

M-M 3A/ 0.100

CONN 10 PINS 2.54MM PITCH

DUAL ROW SM HO

JACK VERTICAL MECH

THRU HOLE

TDK CORP OF

AMERICA

C3225X7R2A225KT5LOU

Panasonic EEUFC2A220

Mill-Max 0667-0-57-15-30-27-1

Sullins PEC05DABN

Global Connector

Technology

BG225-10-A-N-A

Tektronix 131-5031-00

PCB Design Specific – See table 3

PS10 Design Specific – See table 3

R10 NOT APPLIED

R11 NOT APPLIED

R12 NOT APPLIED

R13, R15 RES 10 OHM 1/4W 1% 1206

R14 RES 1K OHM 1/10W 1% 0603

R16, R17 RES 20 OHM 1/4W 1% 1206

KOA Speer

Electronics

KOA Speer

Electronics

KOA Speer

Electronics

RK73H2BTTD10R0F

RK73H1JTTD1001F

RK73H2BTTD20R0F

R18 RES 10m OHM 1/4W 1% 1206 Vishay WSL1206R0100FEA

R19 NOT APPLIED

TP10-TP22, TP30 TEST POINT, SURFACE MOUNT

Keystone

Electronics

5017

UG:014 vicorpower.com Applications Engineering: 800 927.9474 Page 10

Page 11

Bill of Materials (Cont.)

Following table describes the design specific components of all VTM® evaluation boards.

Table 3.

Design specific components

Reference

Designator

C12 - C19

C12 - C19

C12 - C19

PCB

PCB

Description Manufacturer

CAP X5R 47uF

20% 6.3 V 1206

CAP X5R 10uF

10% 25 V 1206

CAP X7R 1.0uF

10% 100 V 1206

SNGLTD PCB FULL

CHIP VTM CB

SNGLTD PCB HALF

CHIP VTM CB

Murata

Manufacturing

Murata

Manufacturing

Murata

Manufacturing

Vicor 39261

Vicor 39262

Manufacturer

Part Number

GRM31CR60J476ME19K

GRM31CR61E106KA12L

GRM31CR72A105KA01L

PS10 Full Chip / Half Chip VTM, Part Number refer to datasheet

Evaluation Board

K = 1/12, 1/16,

1/24, 1/32 VTMs

K = 1/3, 1/4, 1/5,

1/6, 1/8 VTMs

K = 1, 2/3, 1/2,

VTMs

Full Chip VTM

boards

Half Chip VTM

boards

UG:014 vicorpower.com Applications Engineering: 800 927.9474 Page 11

Page 12

Figure 5.

PRM evaluation board

connection to

VTM evaluation board

PRM® & VTM® Evaluation Boards

The VTM evaluation board has been designed for compatibility with all PRM evaluation

boards to accommodate any PRM-VTM combination. The VTM evaluation board contains

dual connectors designed to mate with J10 and J13 on PRM board. An additional signal

connector shares VTM signal pins along with TM, S+ and S- to the PRM board. When

connected to a PRM evaluation board the TM signal provides feedback to the VT pin of

the PRM enabling temperature compensation in Adaptive Loop configuration.

Standalone Operation vs PRM-VTM Operation

In standalone VTM operation, the VTM cannot self-start with only an input voltage

applied. A voltage of 14 V must be applied to its VC pin or test point for it to become

active. Ensure that the applied VC slew rate is within the specified limits of the device.

The VC voltage may be removed once the VTM has started and the input voltage has

reached 26 V or VC can be applied continuously to allow operation down below 26 V

input voltage. When connected together, the PRM provides power and the VC pulse via

the J14 connector to the VTM. A 22 uF,100 V electrolytic input capacitor is provided with

the board and is recommended in standalone VTM operation.

Refer to the VI Chip PRM evaluation board UG:013 for more information on various

modes of PRM+VTM operation.

PRM-VTM Non-Isolated Remote Sense

To demonstrate non-isolated remote sense with a PRM evaluation board, the VTM

isolation must be broken by tying VTM -IN to –OUT. This can be done using sockets on

both side of R19 resistor footprint or by soldering a 2512 zero ohm resistor at the R19

location. Output sense test points are routed to connector J11 and provide feedback to the

PRM remote sense circuitry. By default, the +S and –S pins are connected to the output

pins of VTM through local sense resistors. To demonstrate sensing at a remote point of

load, the local sense resistors can be bypassed by connecting the +S and –S test points to

the desired sense location. Use a twisted pair to avoid noise pickup.

It is recommended to use a network analyzer to measure the closed loop frequency

response when adjusting compensation. The VTM boards provide test points which can

be used to inject the network analyzer AC signal and measure the closed loop response.

For PRM-VTM Remote Sense mode, test points are provided on the VTM board in series

with the +S connections (Labeled “RS Sig Inj +/-“) and should be used.

UG:014 vicorpower.com Applications Engineering: 800 927.9474 Page 12

Page 13

Paralleling

The paralleling and current sharing capability of the devices can be demonstrated by

stacking multiple evaluation boards and interconnecting the inputs and outputs with

standos of sucient current rating to create a parallel array. When paralleling VTMs,

in standalone VTM® operation, VC pins should be connected together to enable the

synchronized startup.

PRM® boards can also be connected in parallel to create high power PRM-VTM arrays.

PRM input, outputs and interconnect signals need to be connected in parallel using

same size standos. Each VTM requires a VC signal from a PRM in order to start and it is

recommended to connect one PRM VC to one VTM VC using the connector J13 on PRM

board and J14 on VTM board when possible. If needed a single PRM VC can be used to

drive up to two VTMs (will require additional o board connections).

Push Pin Heat Sink Installation

Each VTM demonstration board comes with its own heat sink and push pins for

installation. Before testing, it is highly recommended that the heat sink be installed in

the appropriate location for each board. When installing the push pin heat sink, use

caution not to exceed the maximum compression on the device listed in the data sheet.

For most lab environments a fan blowing across the evaluation board is recommended.

Using the VTM Evaluation Board for Reverse Operation

VTMs are capable of bidirectional power transfer between the Primary and

Secondary power terminals. Certain VTMs such as the VTM48EF040T050B0R, and

VTM48EF120T025A0R are qualified for continuous operation in reverse (power transfer

from Secondary to Primary).

Reversible VTMs are usually designated with an R as the last character of the part

number, however, refer to the datasheet to determine if a particular VTM is qualified for

continuous reverse operation.

Reverse operation with a PRM-VTM configuration is beyond the scope of this document.

In standalone operation, the applied VC voltage must be referenced to -PRI(-IN). VC

can be applied before or aer the secondary (source) voltage. Applying VC aer the

secondary voltage will result in a non-negligible amount secondary inrush current as

described in the datasheet. Refer to the datasheet for the peak secondary inrush value

and ensure the source is rated appropriately. Fusing for the evaluation board is located

on the primary side. If fusing on the secondary (source) side is required, then it should

be added externally based on the device ratings.

In order to test a qualified VTM in the reverse direction, follow the the procedure for

VTM standalone operation and make the following changes:

1. Connect the voltage source to the Secondary (Output) lugs.

2. Connect the load to the Primary (Input) lugs.

Ensure the applied source voltage has the correct polarity and is within the Secondary

Voltage ratings of the VTM. It may be necessary to install an input capacitor across the

Secondary terminals to decouple the input source.

UG:014 vicorpower.com Applications Engineering: 800 927.9474 Page 13

Page 14

Part Ordering Information

The VTM evaluation boards can be ordered from the Vicor website:

www.vicorpower.com. To order the demo boards, substitute VTM with VTD

in VTM part number.

See http://www.vicorpower.com/cms/home/products/vi-chip/vichip_VTM_current_

multiplier for part number listing.

The Power Behind Performance

Rev 1.2 11/14 vicorpower.com Applications Engineering: 800 927.9474 Page 14

Page 15

Mouser Electronics

Authorized Distributor

Click to View Pricing, Inventory, Delivery & Lifecycle Information:

Vicor:

VTD48EF030T070A00

Loading...

Loading...