Page 1

USER GUIDE | UG:015

VI Chip® High Voltage BCM® Bus Converter 6123

Evaluation Board User Guide

Written by: Peter Makrum

Applications Engineer

November 2013

Contents Page

Important Notice 1

Introduction 1

Features 2

Using the High Voltage 3

BCM Bus Converter 6123

Evaluation Board

+IN, -IN 5

+OUT, -OUT 5

Output Voltage 5

Measurement Jack (J104)

Input Current 5

Measurement

Output Current 5

Measurement

Temperature Monitor (TM) 5

Enable Control (EN) 5

Auxiliary Voltage 5

Source (VAUX)

Input Filter Details 6

Thermal Considerations 7

Bill of Materials 9

Ordering Information 10

IMPORTANT NOTICE:

Hazardous voltages are present on the HV BCM Evaluation Board under power.

PERSONAL CONTACT WITH LINE VOLTAGE MAY RESULT IN SEVERE INJURY, DISABILITY,

OR DEATH. IMPROPER OR UNSAFE HANDLING OF THIS BOARD MAY RESULT IN

SERIOUS INJURY OR DEATH.

Read the precautions below entirely BEFORE using the HV BCM Evaluation Board. Do

not operate the evaluation board unless you have the appropriate safety precautions

in place on your bench to guarantee safety.

The list below is not comprehensive and is not a substitute for common sense

and good practice.

n During operation, the power devices and surrounding structures can be operated

safely at high temperatures.

n Remove power and use caution when connecting and disconnecting test probes

and interface lines to avoid inadvertent short circuits and contact with hot surfaces.

n When testing electronic products always use approved safety glasses. Follow good

laboratory practice and procedures.

n Avoid creating ground loops when making measurements of the isolated input or

output voltage.

n Care should be taken to protect the user from accidental contact when

under power.

n Care should be taken to avoid reversing polarities if connecting to the opposite

(solder) side of the board.

n The Customer Evaluation Board described in this document is intended to

acquaint the reader with the benefits and features of high voltage distribution.

They are not designed to be installed in end-use equipment.

n Refer to the specific HV BCM module data sheet for electrical details.

Introduction

This evaluation board oers a convenient means to evaluate the performance of

Vicor’s HV BCM Bus Converter 6123 and has been optimized for user convenience.

Refer to the appropriate data sheet for performance and operating limits. Data sheets

are available at vicorpower.com.

UG:015 vicorpower.com Applications Engineering: 800 927.9474 Page 1

Page 2

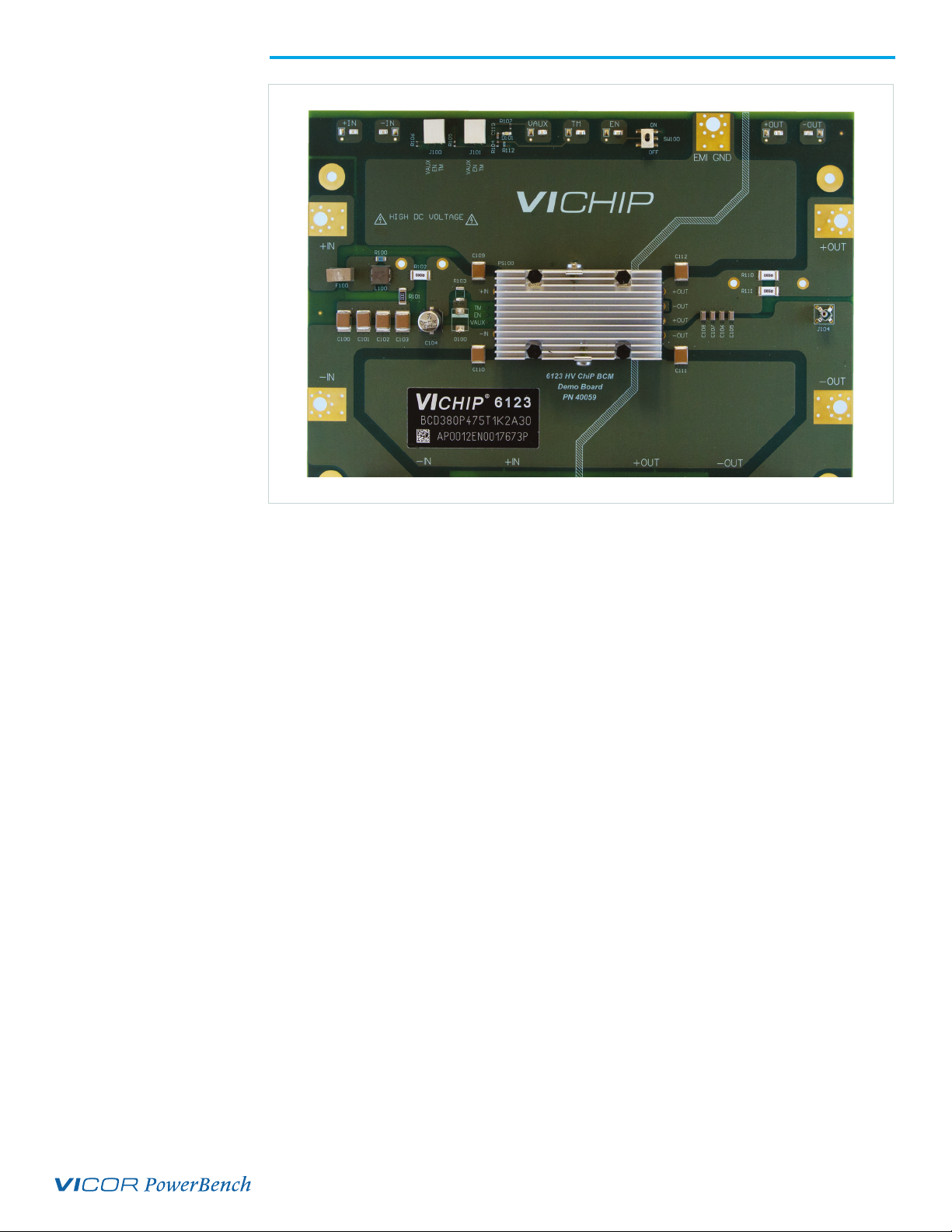

Features

1. Underbelly cooling planes in addition to surface mounted heat sink

2. Input and output accommodation for a current probe wire loops

3. Input, output and signals Kelvin test point

4. Oscilloscope output voltage probe jack for voltage and ripple measurements

5. Input and output board-to-board connector footprint reserved for future use

6. Ring lug or solder connections

UG:015 vicorpower.com Applications Engineering: 800 927.9474 Page 2

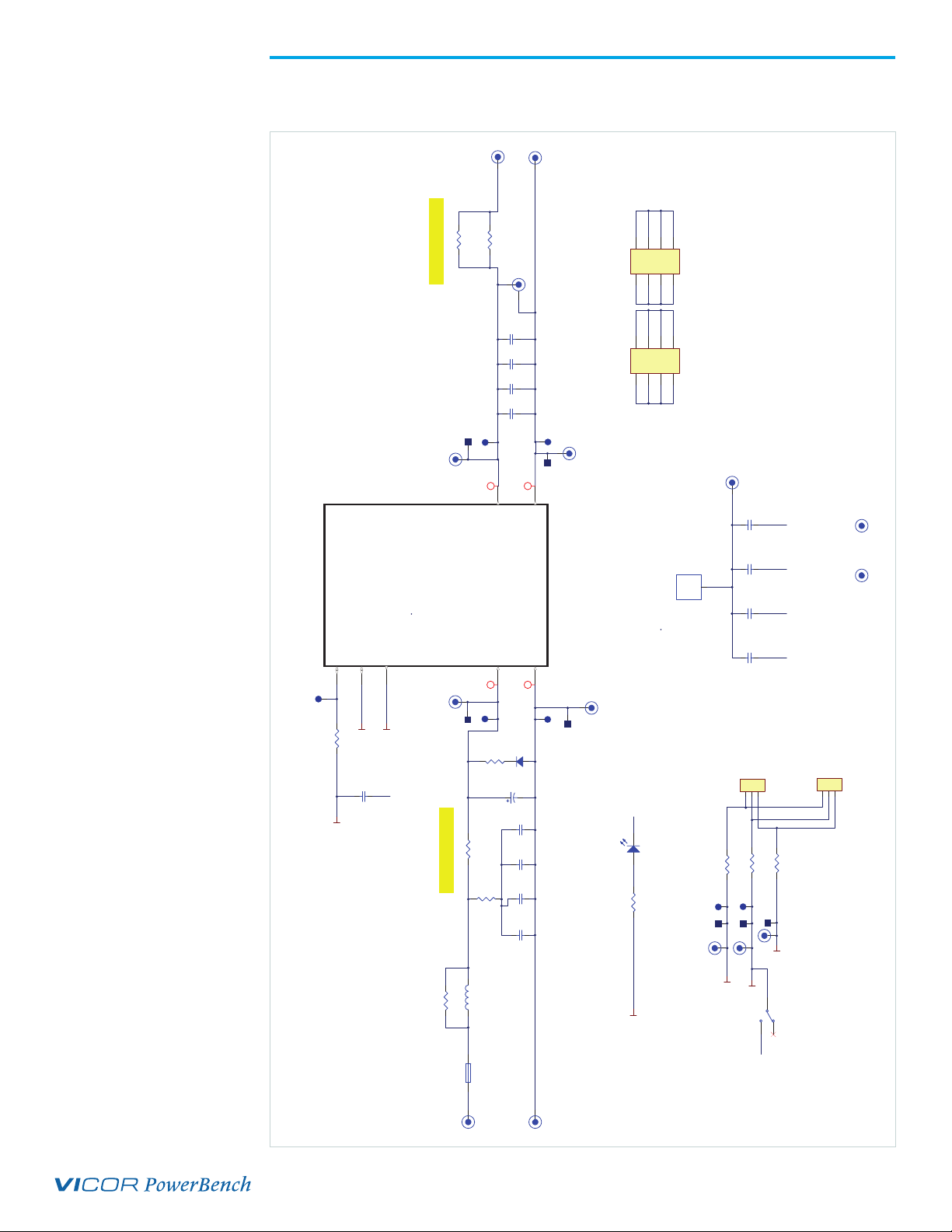

Page 3

Figure 1.

Eval Board Schematic

Using the High Voltage BCM® Bus Converter 6123 Evaluation Board

J107

+VOUT

J108

-VOUT

-VOUT

+VOUT

PS100

HV BCM 6123

AD

TMENVAUX

TP103

R112

1K

CL

DA

Pin 2

Pin 3

0603

15462-1001

29400-103

0603

0.01uF

C113

-VIN

POWER CONNECTOR TO MAIN BOARD

J103B

131415

+VOUT-VOUT+VIN-VIN

20

J102B

13

EMI GND / PCB BOTTOM HEATSINK

181920

Pins

39571

Power

16 17

CONN 8+12 POS RIGHT ANGLE TERMINAL TH

18

19

Pins

Power

39571

14

15

16 17

CONN 8+12 POS RIGHT ANGLE TERMINAL TH

J109

EMI GND / PCB BOTTOM HEATSINK

C112

38830-474

0.47

2220

+VOUT_EMI

38830-474

2220

0.47

C111

-VOUT

HSGND

C110

38830-474

2220

GND

HS

BOM, HEATSINK, PUSH PIN, LF 6123, 11MM

40145

0.47

-VIN

38830-474

C109

2220

0.47

+VIN_EMI

37783

J100

CONN 3 POS WIRE TO BOARD SMD

1

3

2

FID01 FID02

37783

J101

CONN 3 POS WIRE TO BOARD SMD

1

3

2

2512

34727-00R0

0

2512

34727-00R0

0

R111

R110

J104

allowing the use of a current probe.

Plated large Via both ends of resistor

TP106

+VOUT

H105

33292

+VOUT_EMI

1206

1uF

C108

25185-105

1206

1uF

C107

25185-105

1206

1uF

C106

25185-105

1206

1uF

C105

25185-105

TP107

H106

-VOUT

i

i

SECONDARY

SECONDARY

-OUT

+OUT

BCM380P475T1K2A30

+IN

-IN

6123

i

i

PRIMARY

PRIMARY

H100

TP100

+VIN

+VIN_EMI

-VIN

TP101

-VIN

H101

NP

D100

R103

NP

40165-275

2.7

C104

CAP_ALEL

C103

38830-474

2220

Pin 1

R102

2512

34727-00R0

0

allowing the use of a current probe.

Plated large Via both ends of resistor

R101

2010

0

R100

1206

03203-3R65

3.65

L100

IND 2.2uH 20% 14A

33336-2R2

30276

F100

FUSE 5A 400VDC

+VIN

J105

+VIN

0.47

C102

38830-474

2220

0.47

38830-474

2220

0.47

C101

21571-0R00

0.47

C100

2220

38830-474

J106

-VIN

-VIN

40058

0805

LED SML-211UTT86

D101

0603

14695-7500

750

R107

LED INDICATOR

SIGNAL CONNECTORS

Pin 3

0

0

R106

VAUX

H102

0

R105

R104

0603

14695-00R0

0603

0603

14695-00R0

TP105

H104

Pin 3

SW100

14695-00R0

TP104

TM

EN

H103

Pin 1

Pin 2

2

3

1

-VIN

35919

BCM ON/OFF CONTROL

SW TOGGLE SPDT 1 POS SMD

UG:015 vicorpower.com Applications Engineering: 800 927.9474 Page 3

Page 4

Figure 2.

Eval Board Assembly Drawing

Using the High Voltage BCM® Bus Converter 6123 Evaluation Board (Cont.)

UG:015 vicorpower.com Applications Engineering: 800 927.9474 Page 4

Page 5

Using the High Voltage BCM® Bus Converter 6123 Evaluation Board (Cont.)

+ IN, –IN

Connect a high-quality, low-noise power supply to the +IN and –IN terminals of the

evaluation board. The interconnect leads should be capable of the rated DC current and

as short as possible. Additional capacitance may be required on the evaluation board to

compensate for impedances in the interconnect leads and source supply. It is important

to remember that noise from the source and voltage drops, will appear at the output

of the bus converter multiplied by its K factor. Test points +IN and –IN can be used to

monitor the input and are located on the PCB top le corner.

+ OUT, –OUT

An electronic or passive load could be connected to +OUT and –OUT terminals. Most

commercially available electronic loads do not have current slew rates capable of fully

exercising the BCM module. Test points +OUT and –OUT can be used to monitor the

output and are located on the PCB top right corner.

Output Voltage Measurement Jack (J104)

This connector is kelvin connected to the module output pins providing accurate

measurements of the output voltage ripple of the BCM module. Many types of scope

probes may be directly connected to this point.

Input Current Measurement

A current probe can be used when adding a wire loop to R102 side VIAs and removing

R102 resistor. Input bulk capacitor C104 is downstream of this measurement point.

Output Current Measurement

A current probe can be used when adding a wire loop to R110 and R111 side VIAs and

removing both R110 and R111 resistors.

Temperature Monitor (TM)

The BCM TM pin outputs a 250 kHz PWM signal. A 1 kΩ and a 10 nF low pass filter

precedes the TM test point for measurement simplicity.

Enable Control (EN)

Connecting the BCM EN pin to –IN will disable the module. SW100 can be used to

disable for convenience. During normal operation or while VIN is applied this pin will

be high if read using a DMM through the EN test point.

Auxiliary Voltage Source (VAUX)

The BCM VAUX can be used as a fault flag as well as an auxiliary 3.3 V up to 4 mA

current capability. An LED is placed on this pin indicating operation. A test point is

also provided.

UG:015 vicorpower.com Applications Engineering: 800 927.9474 Page 5

Page 6

Figure 3.

Eval Board Assembly Drawing

Input Filter Details

It is important to remember the fast response of most BCM® modules can readily show

the limitations of the source, load, and associated wiring connected to the evaluation

board. Care should be exercised to minimize stray source and load impedances in order

to fully exercise the module. The evaluation board is equipped with an input filter as

simulated in Figure 3.

UG:015 vicorpower.com Applications Engineering: 800 927.9474 Page 6

Page 7

Figure 4.

Double Side Cooling and Leads

Thermal Model

Thermal Considerations

A fan blowing across the evaluation board and heat sink assembly is required during

operation. It is recommended to use a typical (4 x 4) inches fan (similar to an EBMPAPST 3212). It is recommended to place the evaluation board using the supplied

rubber feet about 0.4 inches o a flat surface. As per the example below, the board was

tested using a fan about 4 inches from the board. The maximum internal temperatures

of the BCM® at full rated power should remain below 80°C at 25°C ambient air.

Thermal Resistance Top

1.24°C / W

MAX INTERNAL TEMP

Figure 5.

Example Setup

Power Dissipation (W)

Thermal Resistance Bottom

T

CASE_BOTTOM

1.33°C / W

(°C)

Thermal Resistance Leads

+

–

T

CASE_LEADS

7°C / W

(°C)

+

T

CASE_TOP

–

(°C)

+

–

Top airflow was measured above the edge of the midpoint of the output side of the PCB,

over the oscilloscope probe terminal. Bottom airflow was measured under the edge of

the midpoint of the output side of the PCB.

IR images were taken while evaluating several fans to guarantee full power operation

within data sheet thermal specification. Figure 6 shows one case where an o-the-shelf

fan “EBM-PAPSTJH3” was set to 12 VIN. The measured top airflow is 1,500 LFM and

bottom is 2,250 LFM. The internal temperature is estimated to be 66°C. Figure 7 shows

a top surface IR image max of 40°C. Figure 8 shows another case using the same fan

where VIN is set 6 V. In this case, the measured top airflow is 1,000 LFM and bottom is

1,750 LFM. The internal temperature is estimated to be 64°C. Figure 8 a top IR image

max of 44°C.

UG:015 vicorpower.com Applications Engineering: 800 927.9474 Page 7

Page 8

Figure 6.

IR with EBM-PAPSTJH3 Fan

Fan Input 12 V, Top 1,500 LFM,

Bottom 2,250 LFM

Figure 7.

IR image with EBM-PAPSTJH3 Fan

Fan Input 6 V, Top 1,000 LFM,

Bottom 1,750 LFM

Thermal Considerations (Cont.)

UG:015 vicorpower.com Applications Engineering: 800 927.9474 Page 8

Page 9

Bill of Materials

Table 1.

Reference

Designator

+IN, -IN, TM, EN, VAUX,

+OUT, -OUT

C100, C101, C102, C103, C109,

C110, C111, C112

C104 CAP ALEL 2.7 µF 20% 500 V 8 x 10 40165-275

C105, C106, C107, C108 CAP X7R 1.0 µF 10% 100 V 1,206 25185-105

C113 CAP X7R 0.010 µF 10% 50 V 0603 29400-103

D101 LED SML-211UTT86 0805 40058

HARDWARE BOM CONN KIT ARRAY EVAL BRD 26647

HS BOM, ASSEMBLY, 6123 LF PUSH PIN HEAT SINK 40145

F100 FUSE 5 A 125 V PCD-5-R 30276

J100, J101 CONN 3 POS WIRE TO BOARD SMD 37783

J104 JACK VERTICAL MECH THRU HOLE 33292

L100 IND 2.2 µH 20% 14 A 2,525 0.095HT 33336-2R2

PAD1, PAD2, PAD3, PAD4 BUMPER, ADHESIVE-BACKED, RECESSED 38269

PCB SNGLTD PCB 6123 CHIP HV BCM EVAL BRD 40059

R100 RES 3.65 Ω 1/4 W 1% 1,206 03203-3R65

R101 RES 0 Ω 3/4 W 5% 2,010 21571-0R00

R102, R110, R111 RES 0 Ω 2 W 2,512 34727-00R0

R104, R105, R106 RES 0 Ω JUMPER 1 A 0603 14695-00R0

R107 RES 750 Ω 1/10 W 5% 0603 14695-7500

R112 RES 1 kΩ 1/10 W 1% 0603 15462-1001

SW100 SW TOGGLE SPDT 1 POS SMD 35919

TEST POINT, SURFACE MOUNT 27995

CAP X7T 0.47 µF 10% 630 V 2,220 38830-474

Description Vicor Part Number

UG:015 vicorpower.com Applications Engineering: 800 927.9474 Page 9

Page 10

Ordering Information

To order evaluation boards, substitute BCM with BCD in part number.

For any questions, comments or further design support, please contact your local

Field Applications Engineer.

Go to: http://www.vicorpower.com/contact-us for ordering information and application

support.

The Power Behind Performance

Rev 1.1 12/2013 vicorpower.com Applications Engineering: 800 927.9474 Page 10

Loading...

Loading...