Page 1

USER GUIDE | UG:111

VI Brick® AC Front End

Evaluation Board

November 2012

Contents Page

Features 1

Introduction 1

Set Up 3

Bill of Materials 5

Recommended 6

Hardware

Thermals 6

Ordering Info 6

Features

n Oscilloscope probe jack for output voltage and ripple measurements

n Simple to use

n Ring lug, screw terminal, and solder connection options

n Replaceable fuse (5 A, 216 Littelfuse recommended)

IMPORTANT NOTICE:

Please read this user guide before operating evaluation board.

Introduction

The VI Brick® AC Front End Evaluation Board oers a convenient means to evaluate

the performance of Vicor’s VI Brick AC Front End module and has been optimized for

user convenience. Refer to the table below for operating conditions and limits.

This product contains an input line filter. It is important to remember the response

of the AC line filter is dependent upon the wiring connected to the evaluation board.

Care should be exercised to minimize stray source impedances in order to fully

exercise the features of the converter.

UG:111 vicorpower.com Applications Engineering: 800 927.9474 Page 1

Page 2

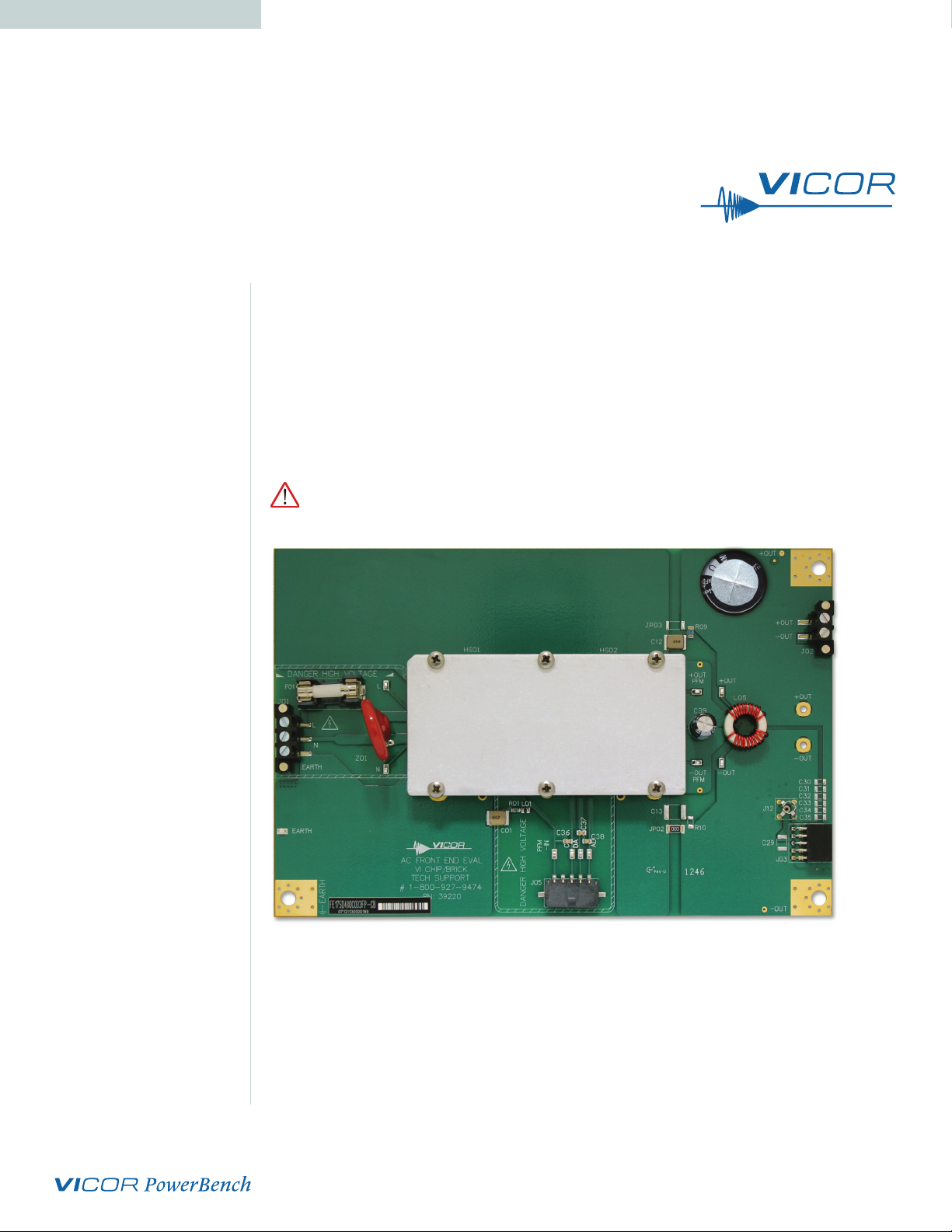

Figure 1

VI Brick® AC Front End

Evaluation Board layout and

dimensional drawing,

component side.

Evaluation Board Basic Specifications and Operating Limits

Please use the following table for operating limits:

Table 1

Operating Limits

Description Specification Notes

Input Range 85 – 264 Vac Universal input

Output voltage 48 Vdc Partially Regulated, SELV

Output Power 330 W Over entire input range

Operating temperature -40 to 85°C

and Z01

Output capacitance 6,000 to 12,000μF 63V rating

Note: VI Brick AC Front End Module operating temperature will depend on its Product Grade as

specified in the datasheet.

Limited by hold-up capacitor

Please refer to Figure 1 for locations of the input and output connections as viewed

from the component side. Wires may be soldered directly to the pads instead of ring

lugs if desired to minimize circuit impedances.

UG:111 vicorpower.com Applications Engineering: 800 927.9474 Page 2

Page 3

DANGER! HIGH VOLTAGE! DANGER! HOT SURFACE!

The VI Brick® AC Front End Evaluation Board contains exposed hazardous voltages.

These voltages are within the area marked by the hashed line on the board.

The VI Brick AC Front End Evaluation Board may be operated at surface temperatures

which may pose a thermal hazard to the operator. Because of the thermal and voltage

hazards, be careful not to touch any exposed surface unless the power is disconnected

and the evaluation board has been given sucient time to cool. The evaluation board

is not intended for use in end item equipment.

Set Up

The Customer Evaluation Board should be set up as follows:

Note: Care should be taken to avoid reversing polarities if connecting to the opposite (solder) side of

the board.

AC Input Connections (J01) DANGER! HIGH VOLTAGE!

J01, the screw terminal connector, is for connection of AC input to the AC-DC

converter evaluation board. The interconnect leads should be appropriate for the

current and voltage supplied to the board.

For single phase power, connect LINE to the pin marked L, NEUTRAL to the pin

marked N and earth ground to the pin marked EARTH. Corresponding wires in an IEC

cable are brown, blue, and yellow with a green stripe.

The board can be used with three phase power. Connect LINE1 to L and LINE2 to N.

Earth ground should still be connected to the EARTH terminal of J1.

Table 2

Output Connector Ratings

+OUT, –OUT

There are several connections available on the VI Brick AC Front End Evaluation

Board. Table 1 lists the available connectors and their current rating. Do not exceed

the rating of the connector or the module.

Connector

J02 10 A Hold-up capacitor

J03

boards

Ring Lugs 100 A General Purpose

Rating

12 A (3 A/contact)

Mating PRM and BCM eval

Recommended

Connection

Output bulk (electrolytic) capacitance must be attached across the output of the VI

Brick AC Front End Evaluation Board. It is recommended that the hold-up capacitor is

to be applied between H12 and H10 or H14 and H10. RTV adhesive should be used if

laying the capacitor on its side. Refer to table 1 from previous page for the

appropriate range of output capacitance.

UG:111 vicorpower.com Applications Engineering: 800 927.9474 Page 3

Page 4

The load should be connected to +OUT and –OUT terminals of the evaluation board

with short leads of suitable gauge to carry the output current and minimize losses.

A sucient number of terminal connections should be used to ensure that no

terminal sees more than its maximum rated current. The evaluation board can be

connected directly to the application for which the module is intended. However

the interconnect impedances between the evaluation board and the application

can greatly aect the transient response. For applications where transient response

is critical, the user should consider mounting the VI Brick® AC Front End module

directly to the target application PCB. Test points TP12 (–OUT) and TP07 (+OUT) can

be used to monitor the output and are located on the PCB adjacent to the output

terminals of the AC Front End module.

Earth Connections

There are several earth connections available on the board. Earth must be connected

via a low impedance connection in order for the internal line filter to function. These

earth connections also provide a safety ground for the baseplate of the module.

Earth may optionally be connected to either of the VI Brick AC Front End outputs in

order to provide a positive or negative voltage rail with respect to earth.

Output Voltage Measurement Jack (J12)

This connector is provided to make accurate measurements of the output ripple

voltage of the VI Brick AC Front End. Many types of scope probes may be directly

connected to this point if the probe is equipped with a removable plastic sheath.

To avoid creating ground loops when making measurements of the output or input

voltage, these measurements should be made separately.

Figure 2

VI BRICK AC Front End

Output capacitor (C29) can be

added to reduce switching frequency

voltage ripple at the probe.

(Click on drawing to view larger.)

UG:111 vicorpower.com Applications Engineering: 800 927.9474 Page 4

Page 5

Table 3

Bill of Materials

Ref. Description Digi-Key Digi-Key Future Future

Desc. Manufacturer Part # Manufacturer Part #

CAP X7R 2200pF

C01

10% 250V 2220

CAPY X7R 4700pF

C12

10% 250V 2220

C13

C29

C30

C31

C32

C33

C34

C35

C36

C37

C38

C39

F01

SMD, 5x20

H03 & CAP ALEL 6800uF

H07 20% 63V 25X50

J01

BLK SMD

J02

BLK SMD

CONN 10POS

J03 90DEG THRUHOLE

FEMALE 0.1SPC

CONN 5POS

J05 SINGLE ROW Molex WM1893-ND TE Connectivity 1445057-5

RIGHT ANGLE

JP02

5% 2010

JP03 NOT APPLIED NOT APPLIED NOT APPLIED NOT APPLIED NOT APPLIED

L01

10% 5mA 0805 150K-ND

L05

600uH 30% 10A

PS01 Model Specific Vicor Model Specific Vicor Model Specific

R01

1/8W 1% 0805

R09

1/4W 1% 1206

R10 NOT APPLIED NOT APPLIED NOT APPLIED NOT APPLIED NOT APPLIED

VAR MOV, 300V

Z01 10KA 20mm Littelfuse

DIA RADIAL

NOT APPLIED NOT APPLIED NOT APPLIED NOT APPLIED NOT APPLIED

CAP X7R .1uF

10% 25V 0805

CAP ALUM 100UF

63V 20% RADIAL

FUSE HOLDER,

CON 3CKT TERM

CON 2 CKT TERM

RES 0 OHM 3/4W

IND 15.0uH Bourns Inc. CV201210- No Stock No Stock

IND COM MODE

RES 6.81 OHM

RES 2.2 OHM

Murata 490-3480-2-ND Murata GA355QR7GF222KW01L

Murata 490-3482-2-ND Murata GA355DR7GF472KW01L

Murata 490-1673-2-ND Murata GRM21BR71E104KA01L

Nichicon UVY1J101MPD-ND Nichicon UVY1J101MPD

Wickmann F4546-ND Schurter 31.8225

Kemet 493-1135-ND Nichicon UVZ1J682MRD

No Stock No Stock Weco 140-A-126-SMD/03

No Stock No Stock Weco 140-A-126-SMD/02

Sullins

Electronics

Vishay Dale 541-0.0WTR-ND Vishay Dale CRCW20100000Z0EF

Vishay Dale 541-6.81CCTRND Vishay Dale CRCW08056R81FKEA

Vishay Dale 541-2.20FFTRND Vishay Dale CRCW12062R20FKEA

S5519-ND

Stocked by Vicor, part#: 37052-601

TMOV20RP30

0EL2T7-ND

Sullins

Electronics

Littelfuse TMOV20RP300E

PPTC052LJBN-RC

UG:111 vicorpower.com Applications Engineering: 800 927.9474 Page 5

Page 6

Input Current Measurement

A current probe can be passed around either input lead connected to the VI Brick® AC

Front End Evaluation Board. Note that an input capacitor on the evaluation board is

downstream of this measurement point.

Enable (EN) DANGER! HIGH VOLTAGE!

The EN pin can be used to disable the VI Brick AC Front End module. Connecting EN

to the IN-PFM pin will disable the module. This will also clear any latching output OVP

fault if one has occurred. Note that the EN pin is referenced to the primary (hazardous

voltage) side of the converter. Warning: The EN Pin, or the –IN PFM Pin must not be

connected to line or output of the VI Brick AC Front End.

Efficiency Measurement

As the VI Brick AC Front End module can deliver and consume large currents, the eect

of the PCB must be considered when making an eciency measurement. Be certain to

accurately measure the voltage using test points TP08 (LINE1) , TP14 (LINE2/NEUTRAL),

TP18 (–OUT), and TP01 (+OUT). Using these test points will more closely represent the

eciency of the VI Brick AC Front End module.

Hardware

The hardware kit provided with the evaluation board includes the following:

n (3) #10-32 screws n (6) #10-32 lock washer

(for +OUT, -OUT, and Earth terminals) (for +OUT, -OUT, and Earth terminals)

n (3) #10-32 hex nut n (1) 6800 uF hold-up capacitor

(for +OUT, -OUT, and Earth terminals) (can be applied between H03 and

H07, H12 and H10, or H14 and H10)

Ring lugs are also recommended for making output connections.

Thermals

For most lab environments a fan blowing across the evaluation board is recommended.

See VI Brick Thermal Management Application Note at:

www.vicorpower.com/documents/application_notes/AN200_VIBrickTherm.pdf

or contact Vicor Applications Engineering for assistance (800) 927-9474.

Ordering Information

The evaluation board is specified by replacing the “–00” sux with “–CB” on the

VI Brick AC Front End model number.

The Power Behind Performance

Rev 1.4 12/2013 vicorpower.com Applications Engineering: 800 927.9474 Page 6

Loading...

Loading...