Page 1

USER GUIDE | UG:301

PI31xx-xx-EVAL1 Cool-Power® ZVS Isolated

DC-DC Converter Evaluation Board

Chris Swartz

Principal Applications Engineer

May 2013

Contents Page

Introduction 1

Product Description 2

Board Connections 2

Thermal Considerations 3

Max I/O Ratings 5

Schematic

BOMs 6

Test Setup 11

PCB Artwork 12

Mechanical Outline 14

Ordering Information 14

Introduction

The PI31xx-xx-EVAL1 evaluation board allows the user to test the basic operating

principles of the PI31xx series of high density DC-DC power converters and experience

the performance and value of this solution compared to alternate conventional

solutions. Each evaluation board is populated with the components that could be used

in a final design. It is not designed or intended to be used in end product applications.

Please read this document prior to the connection of test equipment and refer to the

product datasheet for device specifications, descriptions and characteristics. Remember

to follow good lab safety practices and use safety glasses at all times.

The PI31xx-xx-EVAL1 is configured to support one single input and one single output.

Each board oers pin strap options for trimming the output voltage up and down,

turning the converter on and o and adding EMI system “Y” capacitors. Additional

parts are included to compensate for line impedance associated with long leads from

the bench power supply to the converter. Additional component footprints are made

available to allow the user to test dierent design configurations that may be required

to meet their end needs. Kelvin type test points are included to allow for easy and

convenient connections of testing instruments for evaluation of eciency, line/load

regulation and transient response. A low impedance oscilloscope connection using a

Johnson jack is included for ripple measurement and evaluation of the output voltage

during transient events. Each demo board is equipped with a heatsink to allow high

power operation with a small amount of air flow and to allow operation of the board

over various temperature extremes.

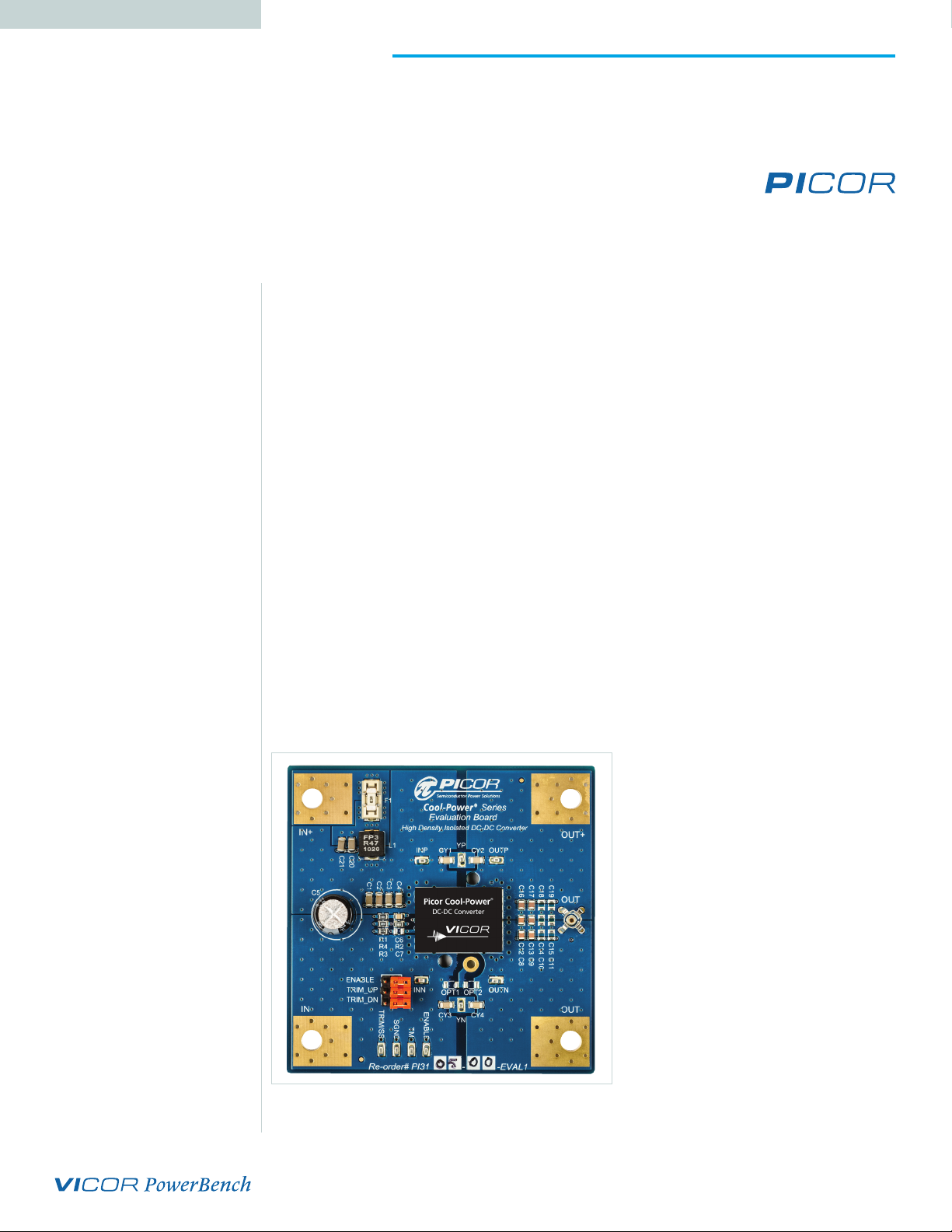

Figure 1.

PI31xx-xx-EVAL1

Evaluation Board

UG:301 vicorpower.com Applications Engineering: 800 927.9474 Page 1

Page 2

Cool-Power® PI31xx Series Product Description

The PI31xx operates over a wide range input, delivering 50 W or 60 W output power

depending on the individual model number. The PI31xx Series is available in a space

saving surface mountable 0.87” x 0.65” x 0.265” Power –System –in – a – Package (PSiP),

achieving ~50% space reduction versus alternative solutions.

The switching frequency of 900kHz allows for small input and output filter components

which further reduces the total size and cost of the overall system solution. The output

voltage is sensed and fed back to the internal controller using a proprietary isolated

magnetic feedback scheme which allows for high bandwidth and good common mode

noise immunity.

The PI31xx Series requires no external feedback compensation and oers a total

solution with a minimum number of external components. A rich feature set is

oered, including + 10%, -20% output voltage trim capability (depending on the model

number), remote enable, over-voltage protection, adjustable so-start, over-current

protection with auto-restart to protect against both short circuit and overload and over

and under input voltage lockout. A unique temperature monitor and protection circuit

is included that provides an analog voltage proportional to the internal die temperature,

as well as over temperature shutdown, restart and over temperature fault alarm signal.

Board Connections

1. Connect Test Equipment

a. Connect the input DC power supply to the target board as shown in Figure 6.

The negative terminal should be wired to –IN and the positive terminal should

connect to the positive terminal of the DMM wired as a DC Ammeter. Be sure

that the proper sized wires are used to allow minimum voltage drop for a

maximum input current of up to 4 A. Use ring lugs mated to the included

fasteners on the evaluation board. If your input power supply has remote sense

capability, it can be wired to the INN and INP test points if desired. Connect the

positive terminal of the DMM to the +IN lug on the evaluation board.

b. Connect the primary side DMM (for measuring the input voltage) to INN and

INP respectively.

c. Connect the oscilloscope as shown in Figure 6 if you are planning to measure

both primary and secondary signals at the same time. If you do not have an

isolated dierential amplifier, it is important to note that simultaneous

measurement of both primary and secondary referenced signals using an

oscilloscope with a grounded chassis is not recommended, as it will short circuit

the primary to secondary isolation barrier. Floating the oscilloscope is also not

recommended due to the large capacitance introduced by this long standing

practice. The best practice is to use an isolated dierential amplifier or use an

oscilloscope with isolated channels. That is, the input returns are isolated from

each other and earth ground.

d. Connect the output DC DMM to the test points OUTN and OUTP. These test

points are done in a Kelvin type manner so that they have no high current

flowing in them.

e. Connect the DC Load to the output lugs OUT+ and OUT-. It is critical for this

connection to be low inductance.

UG:301 vicorpower.com Applications Engineering: 800 927.9474 Page 2

Page 3

2. Default Pin Strap Configuration

a. Ensure the pin straps are in the following default locations before proceeding:

nENABLE = Not Used (enabled)

nTRIM_UP = Not Used

nTRIM_DN = Not Used

nOPT1 = Not Used

nOPT2 = Not Used

3. Pin Strap Functions

a. ENABLE – adding a strap on this pin will cause the converter to shut down.

b. TRIM_UP – Adding a strap in this location will adjust the output voltage

up by 10%.

c. TRIM_DN – Adding a strap in this location will adjust the output voltage down

by 10%. Only one strap can be connected at a time. If both trim straps are out,

the output voltage should be set to the model’s nominal output.

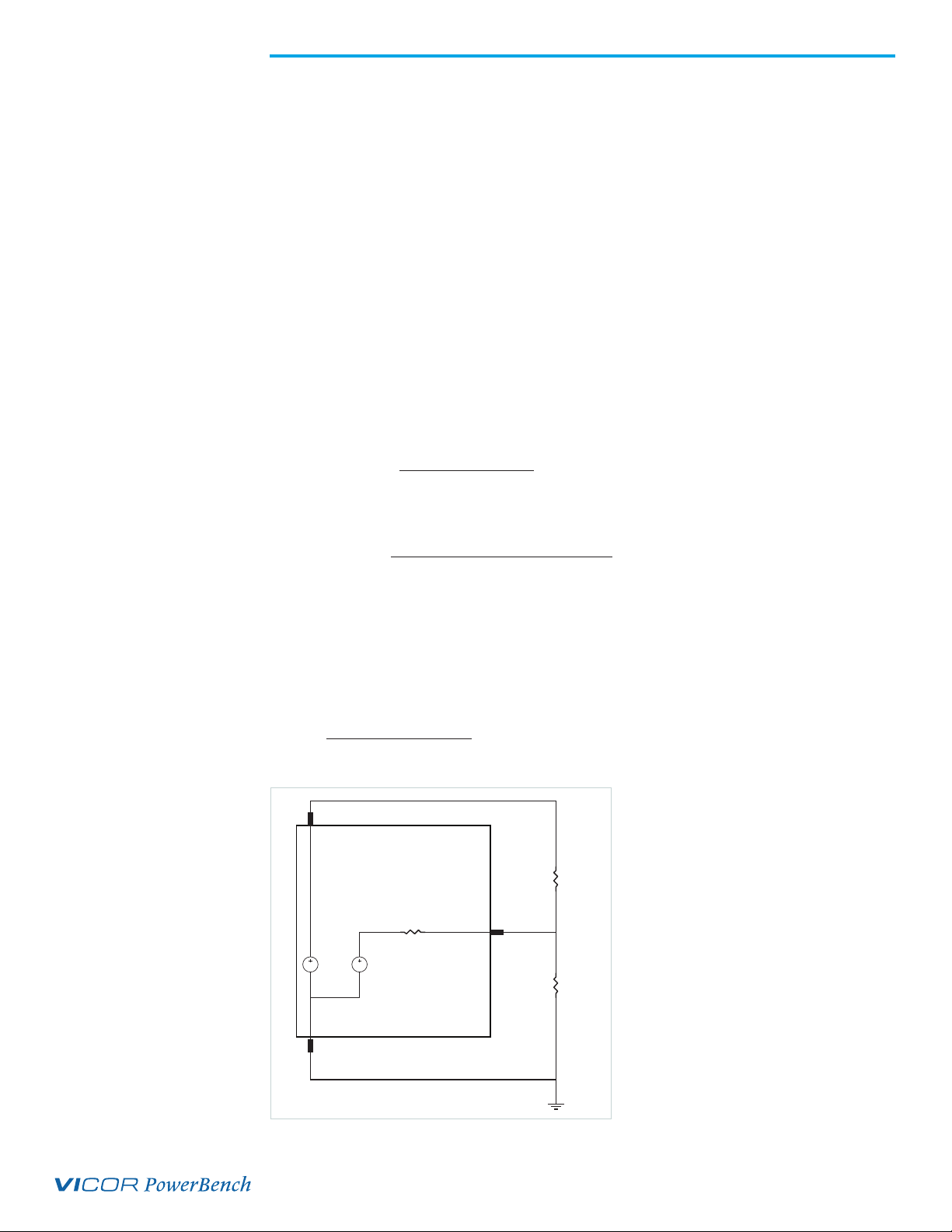

4. Trimming And Soft Start

a. For those customers who wish to trim to another voltage by changing the preset

trim resistors to another value, the trim equation shown in Figure 2 can be used:

Figure 2.

PI31xx Trim Equation

Figure 3.

PI31xx Soft Start Equation

Figure 4.

PI31xx Trimming Equivalent

Circuit

R

INT

+ V

)

nom

nom

V

(

–Vout

[

ref

desired

•

V

)

−6

+ V • V

ERO

) +

nom

V

desired

desired

ref

]

REF

R

= (–V

low

R

high

Where: R1 = Rlow R3 = Rhigh VERO = 4.9 and Vref can be found in the appropriate

model datasheet.

Figure 3 shows an equation for so start configuration where C7 = C

C

REF

desired

= (–RSS) •

T

ssdesired

=

ENABLE

•

)

– 230 • 10

23000

–Vout

(

–Vout

(

PI31xx

Rhigh

VERO

10k

RSS

Vref

TRIM/SS

•

Rlow

•

SGND

•

UG:301 vicorpower.com Applications Engineering: 800 927.9474 Page 3

Page 4

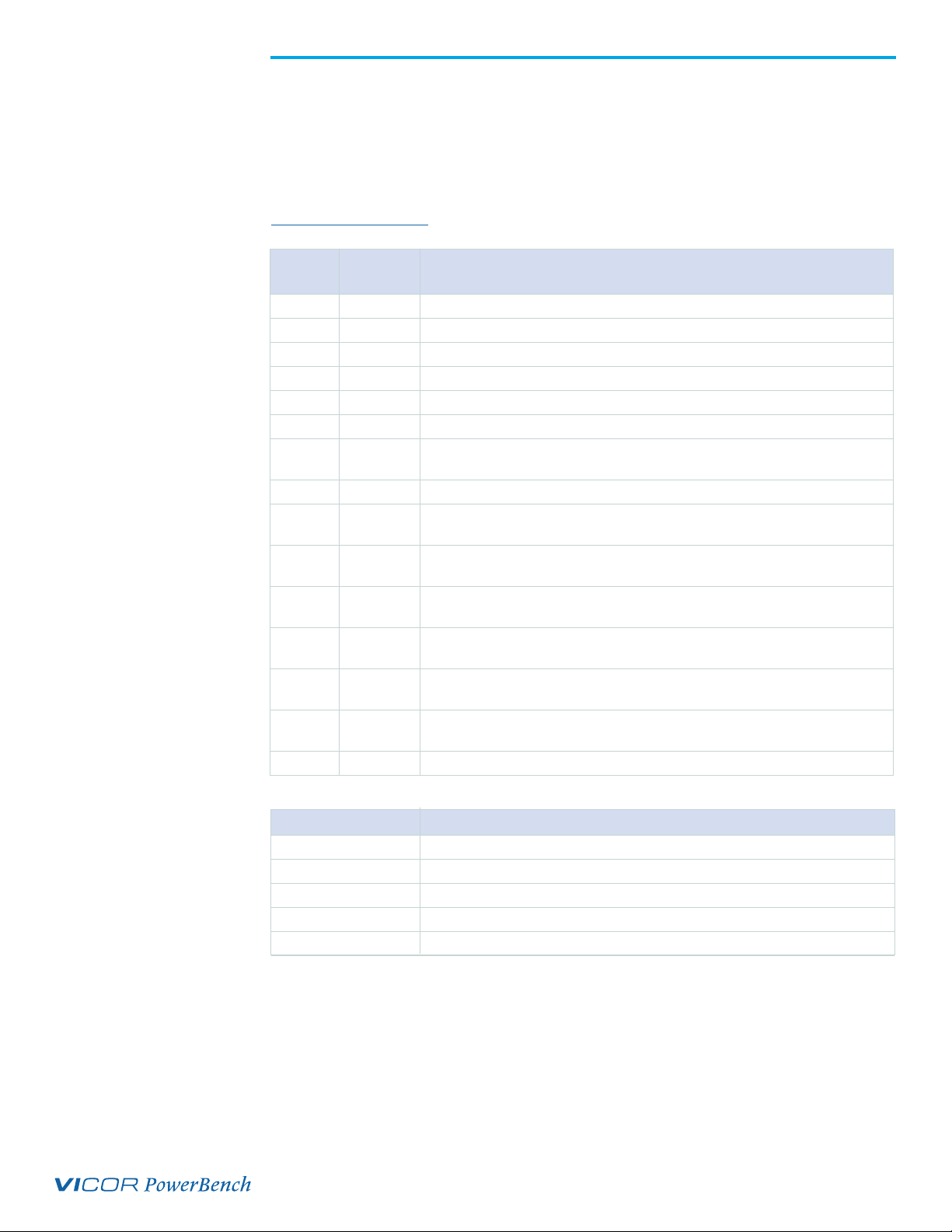

Table 1.

PI31xx-xx-EVAL1

Input-Output Pin Description

Thermal Considerations

The PI31xx-xx-EVAL1 is supplied with optional heat sinks. At present, Picor oers four

dierent heat sink options to accommodate the customers space and cooling needs.

Heatsinks are available in two sizes, one with 6.3mm fins and the other with 11mm fins.

Each of those heatsinks can be ordered with a specific air flow direction in mind, both

cross flow and longitudinal are supported. Please refer to the product website

www.vicorpower.com for more information.

Pin

Name

IN+ Input/Lug Primary side positive input voltage terminal.

IN- Input/Lug Primary side negative input voltage terminal.

OUT+ Output/Lug Isolated secondary DC output voltage positive terminal.

OUT- Output/Lug Isolated secondary DC output voltage negative terminal.

TM Test/Pin Temperature measurement output pin with respect to SGND. 3V=300°K 10mV/°K

SGND Test/Pin Signal ground, primary side referenced.

TRIM/SS Test/Pin

respect to SGND.

ENABLE Test/Pin Allows for monitoring of the ENABLE signal with respect to SGND.

INN Test/Pin

test point.

INP Test/Pin

test point.

YN Output/Pad

system ground.

YP Output/Pad

system ground.

OUTP Test/Pin

test point.

OUTN Test/Pin

test point.

OUT Test/PIn PCB test jack for low noise measurement of the output voltage.

Type Description

Monitor pin for the soft start voltage and trim voltage reference with

Kelvin sense connection for input supply (-) and input voltage measurement

Kelvin sense connection for input supply (+) and input voltage measurement

Optional test pad for connection of optional “YN” capacitor to external

Optional test pad for connection of optional “YP” capacitor to external

Kelvin sense connection for output voltage (+) and output voltage measurement

Kelvin sense connection for output voltage (-) and output voltage measurement

Table 2.

PI31xx-xx-EVAL1

Evaluation Board

Pin Strap and Jumper

Description

Name Description

ENABLE If strap is installed, unit is turned off. If strap is removed, unit will be enabled.

TRIM_UP If strap is installed, PI3105 trims output voltage up 10%

TRIM_DN If strap is installed, PI3105 trims output voltage down 10%

OPT1 Allows optional connection of heat sink assembly to secondary return (-IN)

OPT2 Allows optional connection of heat sink assembly to secondary return (-OUT)

UG:301 vicorpower.com Applications Engineering: 800 927.9474 Page 4

Page 5

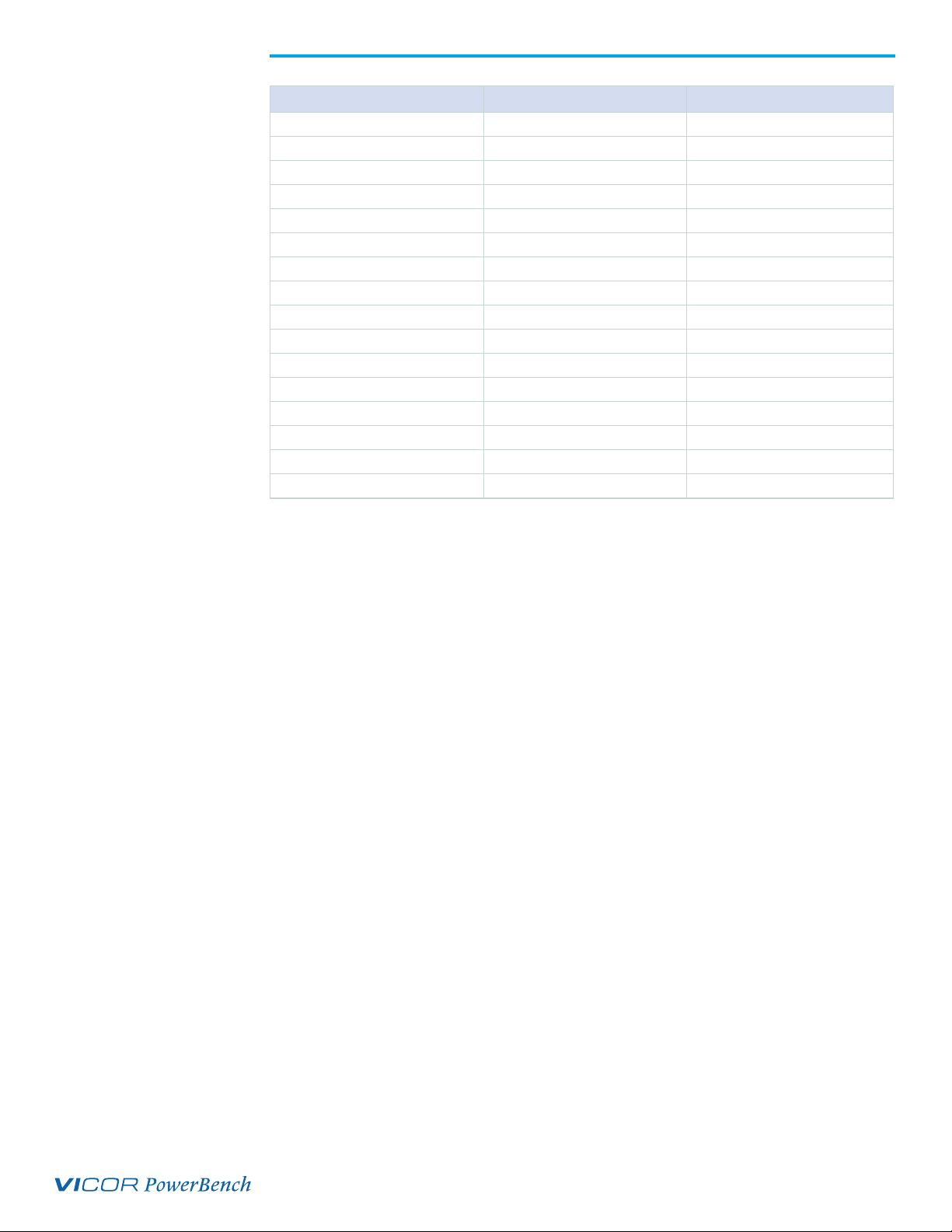

Table 3.

PI31xx-xx-EVAL1

Evaluation Board

Maximum I/O Ratings

Name Max Voltage Max Current

IN+ 100 V 20 A

IN- 100 V 20 A

OUT+ 20 V 20 A

OUT- 20 V 20 A

TRIM_DN 10 V 100 mA

OPT1 10 V 100 mA

OPT2 10 V 100 mA

OUT 10 V 100 mA

INP 10 V 100 mA

INN 10 V 100 mA

ENABLE 10 V 100 mA

TRIM/SS 10 V 100 mA

SGND 10 V 100 mA

TM 10 V 100 mA

OUTP 20 V 100 mA

OUTN 20 V 100 mA

UG:301 vicorpower.com Applications Engineering: 800 927.9474 Page 5

Page 6

Figure 5.

Schematic Diagram

OUTP

–OUT

OUT–

OUTN

OPT2

YN

OUT+

OUT

Scope

C17 C18 C19

C16

C13 C14 C15

C9 C10 C11 C12

C8

YP

CY2

+OUT

YP

HS

YN

PI31xx

CY1

4.7nF 4.7nF

TM

TRIM/SS

ENABLE

R2

100 K

C6 C7

390 pF DNP

C5

+

C3

C2

C20C21

R3

301 K

TRIM_UP

C4

R4

100

ENA

R1

TRIM_DN

C1

SGND

90.9 K

+IN

TM

INPSGND

L1

CY3 CY4

4.7nF 4.7nF

HS

–IN

OPT1

INN

ENABLE TRIM/SS

F1

IN+

IN–

UG:301 vicorpower.com Applications Engineering: 800 927.9474 Page 6

Page 7

Table 4.

PI3101-00-EVAL1

Evaluation Board BOM

Item

Qty Ref Design Part # Value U/M Description

1. 1 U1 PI3101-00-HVIZ NA EA Picor PI3101-00 High Density PSiP

2. 12 C8-C19

3. 6

4. 4 CY1-CY4

5. 1 L1 FP3-4R7-R 4.7u H Coilcraft Inductor

6. 1 C6

7. 1 C5 EEU-FC2A470 47u F Panasonic Electrolytic Capacitor 100V

8. 1 R1 MCR10EZPF9092 90.9k Ohm Rohm Resistor 0805 1% or equiv

9. 1 R3 MCR10EZPF3013 301k Ohm Rohm Resistor 0805 1% or equiv

10. 1 R2 MCR10EZPF1003 100k Ohm Rohm Resistor 0805 1% or equiv

11. 1 R4 MCR10EZPF1000 100 Ohm Rohm Resistor 0805 1% or equiv

12. 1 F1 0154003DR 3 A Littlefuse Fuseblock 3A SMT

13. 8 5015KCT-ND N/A N/A Digi-Key SMT PC Test Point

14. 1 OUT 131503100 N/A N/A Tektronix Test Jack Assembly

15. 6

C1-C4, C20-

C21

ENABLE,

TRIM UP,

TRIM_DN

GRM-

21BR71A106KE5

GRM-

31CR72A105KE1

GRM-

31BR73A472K

08055C391K-

AT2A

TSW-148-07-F-S N/A N/A J,Header 0.1"

10u F Murata X7R Ceramic Capacitor 10 V or equiv.

1u F Murata X7R Ceramic Capacitor 100V or equiv.

4700p F Murata X7R Ceramic Capacitor 1kV or equiv..

390p F Kemet X7R Ceramic Capacitor 50V 0805

Table 5.

PI3105-00-EVAL1

Evaluation Board BOM

Item

Qty Ref Design Part # Value U/M Description

1. 1 U1 PI3105-00-HVIZ NA EA Picor PI3105-00 High Density PSiP

2. 6 C8-C19

3. 6

4. 4 CY1-CY4

5. 1 L1 FP3-R47-R 470n H Coilcraft Inductor

6. 1 C6

7. 1 C5 EEU-FC2A470 47u F Panasonic Electrolytic Capacitor 100V

8. 1 R1 MCR10EZPF9092 90.9k Ohm Rohm Resistor 0805 1% or equiv

9. 1 R3 MCR10EZPF3013 301k Ohm Rohm Resistor 0805 1% or equiv

10. 1 R2 MCR10EZPF1003 100k Ohm Rohm Resistor 0805 1% or equiv

11. 1 R4 MCR10EZPF1000 100 Ohm Rohm Resistor 0805 1% or equiv

12. 1 F1 0154003DR 3 A Littlefuse Fuseblock 3A SMT

13. 8 5015KCT-ND N/A N/A Digi-Key SMT PC Test Point

14. 1 OUT 131503100 N/A N/A Tektronix Test Jack Assembly

15. 6

C1-C4, C20-

C21

ENABLE,

TRIM UP,

TRIM_DN

GRM-

21BR71A475KE5

GRM-

31CR72A105KE1

GRM-

31BR73A472K

08055C391K-

AT2A

TSW-148-07-F-S N/A N/A J,Header 0.1"

4.7u F Murata X7R Ceramic Capacitor 16V or equiv.

1u F Murata X7R Ceramic Capacitor 100V or equiv.

4700p F Murata X7R Ceramic Capacitor 1kV or equiv..

390p

F Kemet X7R Ceramic Capacitor 50V 0805

UG:301 vicorpower.com Applications Engineering: 800 927.9474 Page 7

Page 8

Table 6.

PI3106-00-EVAL1

Evaluation Board BOM

Item

Qty Ref Design Part # Value U/M Description

1. 1 U1 PI3106-00-HVMZ NA EA Picor PI3106-00 High Density PSiP

2. 6 C8-C19

3. 6

4. 4 CY1-CY4

5. 1 L1 FP3-R47-R 470n H Coilcraft Inductor

6. 1 C6

7. 1 C5 EEU-FC1J101L 100u F Panasonic Electrolytic Capacitor 63V

8. 1 R1 MCR10EZPF9092 90.9k Ohm Rohm Resistor 0805 1% or equiv

9. 1 R3 MCR10EZPF3013 301k Ohm Rohm Resistor 0805 1% or equiv

10. 1 R2 MCR10EZPF1003 100k Ohm Rohm Resistor 0805 1% or equiv

11. 1 R4 MCR10EZPF1000 100 Ohm Rohm Resistor 0805 1% or equiv

12. 1 F1 0154008DR 8 A Littlefuse Fuseblock 8A SMT

13. 8 5015KCT-ND N/A N/A Digi-Key SMT PC Test Point

14. 1 OUT 131503100 N/A N/A Tektronix Test Jack Assembly

15. 6

C1-C4, C20-

C21

ENABLE,

TRIM UP,

TRIM_DN

GRM21BR71E-

225KA73L

GRM31CR71H-

475KA12K

GRM-

31BR73A472K

08055C391K-

AT2A

TSW-148-07-F-S N/A N/A J,Header 0.1"

2.2u F

4.7u F Murata X7R Ceramic Capacitor 50V or equiv.

4700p F Murata X7R Ceramic Capacitor 1kV or equiv..

390p

Murata X7R Ceramic Capacitor 25V or equiv.

F Kemet X7R Ceramic Capacitor 50V 0805

Table 7.

PI3106-01-EVAL1

Evaluation Board BOM

Item

Qty Ref Design Part # Value U/M Description

1. 1 U1 PI3106-01-HVIZ NA EA Picor PI3106-01 High Density PSiP

2. 6 C8-C19

3. 6

4. 4 CY1-CY4

5. 1 L1 FP3-R47-R 470n H Coilcraft Inductor

6. 1 C6

7. 1 C5 EEU-FC1J101L 100u F Panasonic Electrolytic Capacitor 63V

8. 1 R1 MCR10EZPF9092 90.9k Ohm Rohm Resistor 0805 1% or equiv

9. 1 R3 MCR10EZPF3013 301k Ohm Rohm Resistor 0805 1% or equiv

10. 1 R2 MCR10EZPF1003 100k Ohm Rohm Resistor 0805 1% or equiv

11. 1 R4 MCR10EZPF1000 100 Ohm Rohm Resistor 0805 1% or equiv

12. 1 F1 0154008DR 8 A Littlefuse Fuseblock 8A SMT

13. 8 5015KCT-ND N/A N/A Digi-Key SMT PC Test Point

14. 1 OUT 131503100 N/A N/A Tektronix Test Jack Assembly

15. 6

C1-C4, C20-

C21

ENABLE,

TRIM UP,

TRIM_DN

GRM21BR71E-

225KA73L

GRM31CR71H-

475KA12K

GRM-

31BR73A472K

08055C391K-

AT2A

TSW-148-07-F-S N/A N/A J,Header 0.1"

2.2u F Murata X7R Ceramic Capacitor 25V or equiv.

4.7u F Murata X7R Ceramic Capacitor 50V or equiv.

4700p F Murata X7R Ceramic Capacitor 1kV or equiv..

390p

F Kemet X7R Ceramic Capacitor 50V 0805

UG:301 vicorpower.com Applications Engineering: 800 927.9474 Page 8

Page 9

Table 8.

PI3109-00-EVAL1

Evaluation Board BOM

Item

Qty Ref Design Part # Value U/M Description

1. 1 U1 PI3109-00-HVMZ NA EA Picor PI3109-00 High Density PSiP

2. 6 C8-C19

3. 6

4. 4 CY1-CY4

5. 1 L1 FP3-R47-R 470n H Coilcraft Inductor

6. 1 C6

7. 1 C5 EEU-FC1J101L 100u F Panasonic Electrolytic Capacitor 63V

8. 1 R1 MCR10EZPF9092 90.9k Ohm Rohm Resistor 0805 1% or equiv

9. 1 R3 MCR10EZPF3013 301k Ohm Rohm Resistor 0805 1% or equiv

10. 1 R2 MCR10EZPF1003 100k Ohm Rohm Resistor 0805 1% or equiv

11. 1 R4 MCR10EZPF1000 100 Ohm Rohm Resistor 0805 1% or equiv

12. 1 F1 0154008DR 8 A Littlefuse Fuseblock 8A SMT

13. 8 5015KCT-ND N/A N/A Digi-Key SMT PC Test Point

14. 1 OUT 131503100 N/A N/A Tektronix Test Jack Assembly

15. 6

C1-C4, C20-

C21

ENABLE,

TRIM UP,

TRIM_DN

GRM21BR71A-

106KE5

GRM31CR71H-

475KA12K

GRM-

31BR73A472K

08055C391K-

AT2A

TSW-148-07-F-S N/A N/A J,Header 0.1"

10u F Murata X7R Ceramic Capacitor 10V or equiv.

4.7u F Murata X7R Ceramic Capacitor 50V or equiv.

4700p F Murata X7R Ceramic Capacitor 1kV or equiv..

390p

F Kemet X7R Ceramic Capacitor 50V 0805

Table 9.

PI3109-01-EVAL1

Evaluation Board BOM

Item

Qty Ref Design Part # Value U/M Description

1. 1 U1 PI3109-01-HVIZ NA EA Picor PI3109-01 High Density PSiP

2. 6 C8-C19

3. 6

4. 4 CY1-CY4

5. 1 L1 FP3-R47-R 470n H Coilcraft Inductor

6. 1 C6

7. 1 C5 EEU-FC1J101L 100u F Panasonic Electrolytic Capacitor 63V

8. 1 R1 MCR10EZPF9092 90.9k Ohm Rohm Resistor 0805 1% or equiv

9. 1 R3 MCR10EZPF3013 301k Ohm Rohm Resistor 0805 1% or equiv

10. 1 R2 MCR10EZPF1003 100k Ohm Rohm Resistor 0805 1% or equiv

11. 1 R4 MCR10EZPF1000 100 Ohm Rohm Resistor 0805 1% or equiv

12. 1 F1 0154008DR 8 A Littlefuse Fuseblock 8A SMT

13. 8 5015KCT-ND N/A N/A Digi-Key SMT PC Test Point

14. 1 OUT 131503100 N/A N/A Tektronix Test Jack Assembly

15. 6

C1-C4, C20-

C21

ENABLE,

TRIM UP,

TRIM_DN

GRM21BR71A-

106KE5

GRM31CR71H-

475KA12K

GRM-

31BR73A472K

08055C391K-

AT2A

TSW-148-07-F-S N/A N/A J,Header 0.1"

2.2u F

4.7u F Murata X7R Ceramic Capacitor 50V or equiv.

4700p F Murata X7R Ceramic Capacitor 1kV or equiv..

390p

Murata X7R Ceramic Capacitor 25V or equiv.

F Kemet X7R Ceramic Capacitor 50V 0805

UG:301 vicorpower.com Applications Engineering: 800 927.9474 Page 9

Page 10

Table 10.

PI3110-01-EVAL1

Evaluation Board BOM

Item

Qty Ref Design Part # Value U/M Description

1. 1 U1 PI3110-01-HVIZ NA EA Picor PI3110-01 High Density PSiP

2. 6 C8-C19

3. 6

4. 4 CY1-CY4

5. 1 L1 FP3-4R7-R 4.7n H Coilcraft Inductor

6. 1 C6

7. 1 C5 EEU-FC2A470 47u F Panasonic Electrolytic Capacitor 100V

8. 1 R1 MCR10EZPF9092 90.9k Ohm Rohm Resistor 0805 1% or equiv

9. 1 R3 MCR10EZPF3013 301k Ohm Rohm Resistor 0805 1% or equiv

10. 1 R2 MCR10EZPF1003 100k Ohm Rohm Resistor 0805 1% or equiv

11. 1 R4 MCR10EZPF1000 100 Ohm Rohm Resistor 0805 1% or equiv

12. 1 F1 0154003DR 3 A Littlefuse Fuseblock 3A SMT

13. 8 5015KCT-ND N/A N/A Digi-Key SMT PC Test Point

14. 1 OUT 131503100 N/A N/A Tektronix Test Jack Assembly

15. 6

C1-C4, C20-

C21

ENABLE,

TRIM UP,

TRIM_DN

GRM21BR71E-

225KA73L

GRM31CR71H-

475KA12K

GRM-

31BR73A472K

08055C391K-

AT2A

TSW-148-07-F-S N/A N/A J,Header 0.1"

2.2u F Murata X7R Ceramic Capacitor 25V or equiv.

4.7u F Murata X7R Ceramic Capacitor 50V or equiv.

4700p F Murata X7R Ceramic Capacitor 1kV or equiv..

390p

F Kemet X7R Ceramic Capacitor 50V 0805

Table 11.

PI3111-00-EVAL1

Evaluation Board BOM

Item

Qty Ref Design Part # Value U/M Description

1. 1 U1 PI3111-00-HVMZ NA EA Picor PI3111-00 High Density PSiP

2. 6 C8-C19

3. 6

4. 4 CY1-CY4

5. 1 L1 FP3-4R7-R 4.7n H Coilcraft Inductor

6. 1 C6

7. 1 C5 EEU-FC1J101L 100u F Panasonic Electrolytic Capacitor 63V

8. 1 R1 MCR10EZPF9092 90.9k Ohm Rohm Resistor 0805 1% or equiv

9. 1 R3 MCR10EZPF3013 301k Ohm Rohm Resistor 0805 1% or equiv

10. 1 R2 MCR10EZPF1003 100k Ohm Rohm Resistor 0805 1% or equiv

11. 1 R4 MCR10EZPF1000 100 Ohm Rohm Resistor 0805 1% or equiv

12. 1 F1 0154003DR 3 A Littlefuse Fuseblock 3A SMT

13. 8 5015KCT-ND N/A N/A Digi-Key SMT PC Test Point

14. 1 OUT 131503100 N/A N/A Tektronix Test Jack Assembly

15. 6

C1-C4, C20-

C21

ENABLE,

TRIM UP,

TRIM_DN

GRM21BR71E-

225KA73L

GRM31CR71H-

475KA12K

GRM-

31BR73A472K

08055C391K-

AT2A

TSW-148-07-F-S N/A N/A J,Header 0.1"

2.2u F Murata X7R Ceramic Capacitor 25V or equiv.

4.7u F Murata X7R Ceramic Capacitor 50V or equiv.

4700p F Murata X7R Ceramic Capacitor 1kV or equiv.

390p

F Kemet X7R Ceramic Capacitor 50V 0805

UG:301 vicorpower.com Applications Engineering: 800 927.9474 Page 10

Page 11

Table 12.

PI31xx-xx-EVAL1

Packing List

Figure 6.

PI31xx-xx-EVAL1 Test Setup

Item

Qty Part # U/M Description

1. 1 PI31xx-xx-EVAL1 EA Evaluation PCB Assembly

2. 1 32786 EA 6.3mm Heatsink Assembly

3. 1

4. 1 33855 EA Heatsink Grounding Clip

5. 4 32434 EA Heatsink Pushpins

6. 4 N/A EA Screw, 6-32

7. 4 N/A EA Nut, 6-32

32784

EA 11mm Heatsink Assembly

OSCILLOSCOPE DC-20MHZ BW

DC

AMMETER 0-5A

+

+

PS1

0-100V DC

5A

-

DMM

+

-

-

CH1

ISOLATED DIFF.

AMPLIFIER

+

CH2

-

+ IN

DC

ELECT.

LOAD

0-30A

MIN

- IN

-

DMM

UG:301 vicorpower.com Applications Engineering: 800 927.9474 Page 11

+

Page 12

Figure 7.

Top Layer

Artwork 3 Oz Copper

Figure 8.

Midlayer 1

Artwork 2 Oz Copper

Top Layer

Figure 9.

Midlayer 2

Artwork 2 Oz. Copper

Midlayer 1

Midlayer 2

UG:301 vicorpower.com Applications Engineering: 800 927.9474 Page 12

Page 13

Figure 10.

Midlayer 3

Artwork 2 Oz. Copper

Figure 11.

Midlayer 4

Artwork 2 Oz. Copper

Midlayer 3

Figure 12.

Bottom Layer

Artwork 3 Oz. Copper

Midlayer 4

Bottom Layer

UG:301 vicorpower.com Applications Engineering: 800 927.9474 Page 13

Page 14

Figure 13.

Mechanical Drawing

3.100”

3.100” 2.430”

0.335”

0.250”

0.335”

0.150”

IN+

C5

C21

C22

ENABLE

TRIM_UP

TRIM_DN

2.600”

Cool-Power® Series

F1

Evaluation Board

High Density Isolated DC-DC Converter

C1C2C3

R1

R4R3R2

TRIM/SS

L1

C4

C6

C7

SGND

TM

INP

INN

CY1 CY2

OPT1 OPT2

ENABLE

CY3 CY4

PI31 - EVAL1

0.250”

0.750”

0.150”

C17

C18

OUT+

C19

YP

OUTP

C16

OUT

C12

C13

C14

C15

C8C9C10

C11

OUTN

1.55”

OUT–IN–

YN

0.750”

Ordering Information

The PI31xx Customer Evaluation Boards are specified by adding the sux “-EVAL1” to

the base PI31xx-xx model number.

Go to http://www.vicorpower.com/cms/home/company/contact-us for

ordering information.

Rev 1.0 6/13 vicorpower.com Applications Engineering: 800 927.9474 Page 14

Loading...

Loading...