Page 1

Introduction

The PI2003-EVAL1 allows the user to test the basic principle

and operational characteristics of a low side Active ORing

function in a redundant power architecture, while also

experiencing the benefits and value of the PI2003 solution

versus conventional Active ORing solutions. The PI2003-EVAL1

evaluation board is configured to receive two independent

power source inputs, per a typical redundant power

architecture, through two Active ORing channels that are

combined to form a redundant power output. Each channel

contains a PI2003 controller and an N-channel power

MOSFET. The MOSFET foot print can take an SO-8 or Power

SO-8 MOSFET package. Each channel is capable of up to 6 A.

The PI2003-EVAL1 evaluation board is designed with

optimized PCB layout and component placement to represent

a realistic high density final design for an embedded low side

Active ORing solution for -48 Vbus applications requiring up

to 6 A. This evaluation board is intended as an easy and

simple way to test the electrical and thermal performance of

the PI2003 Active ORing controller.

Both dynamic and steady state testing of the PI2003 can be

completed on the PI2003-EVAL1 evaluation board, in addition

to using the key features of the product. Dynamic testing can

be completed under a variety of system level fault conditions

to check for response time to faults.

This document provides basic instructions for initial start-up

and configuration of the evaluation board. Further

information on the functionality of the PI2003 can be

found in the PI2003 product data sheet.

PI2003-EVAL1

Cool-ORing™ Series

PI2003-EVAL1 Active ORing

Evaluation Board User Guide

®

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 1

PI2003 Product Description . . . . . . . . . . . . . . . . . . Page 2

Evaluation Board Terminal Description . . . . . . . . Page 2

Evaluation Board Schematic . . . . . . . . . . . . . . . . . Page 3

Bill of Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 3

Test Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 4

PCB Layouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 7

Evaluation Board Mechanical Drawing . . . . . . . . Page 7

PI2003-EVAL1 Evaluation Board

featuring the Cool-ORing PI2003

Active ORing controller.

Cool-ORing™ Series

The PI2003-EVAL1 Evaluation Board is intended to acquaint the

user with the benefits and features of the Cool-ORing

TM

PI2003

full function Active ORing solution. It is not designed to be

installed in end-use equipment.

Please read this document before setting up the PI2003-EVAL1

Evaluation Board and refer to the PI2003 product data sheet

for device specifications, functional description and

characteristics.

During operation, the power devices and surrounding

structures can be operated safely at high temperatures.

• Remove power and use caution when connecting and

disconnecting test probes and interface lines to avoid

inadvertent short circuits and contact with hot surfaces.

• When testing electronic products always use approved

safety glasses. Follow good laboratory practice and

procedures.

Picor Corporation • www.picorpower.com PI2003-EVAL1 User Guide Rev 1.0 Page 1 of 8

Page 2

The Cool-ORing PI2003 with an external industry standard

100V N-channel MOSFET provides a complete Active ORing

solution designed for use in -48 Vbus redundant power

system architectures. The PI2003 controller with an N-channel

MOSFET enables extremely low power loss with fast dynamic

response to fault conditions, critical for high availability

systems.

The PI2003 controller with a low Rds(on) N-channel MOSFET

provides very high efficiency and low power loss during

steady state operation. The PI2003 controller provides an

active low fault flag output to the system during excessive

forward current, light load, or reverse current.

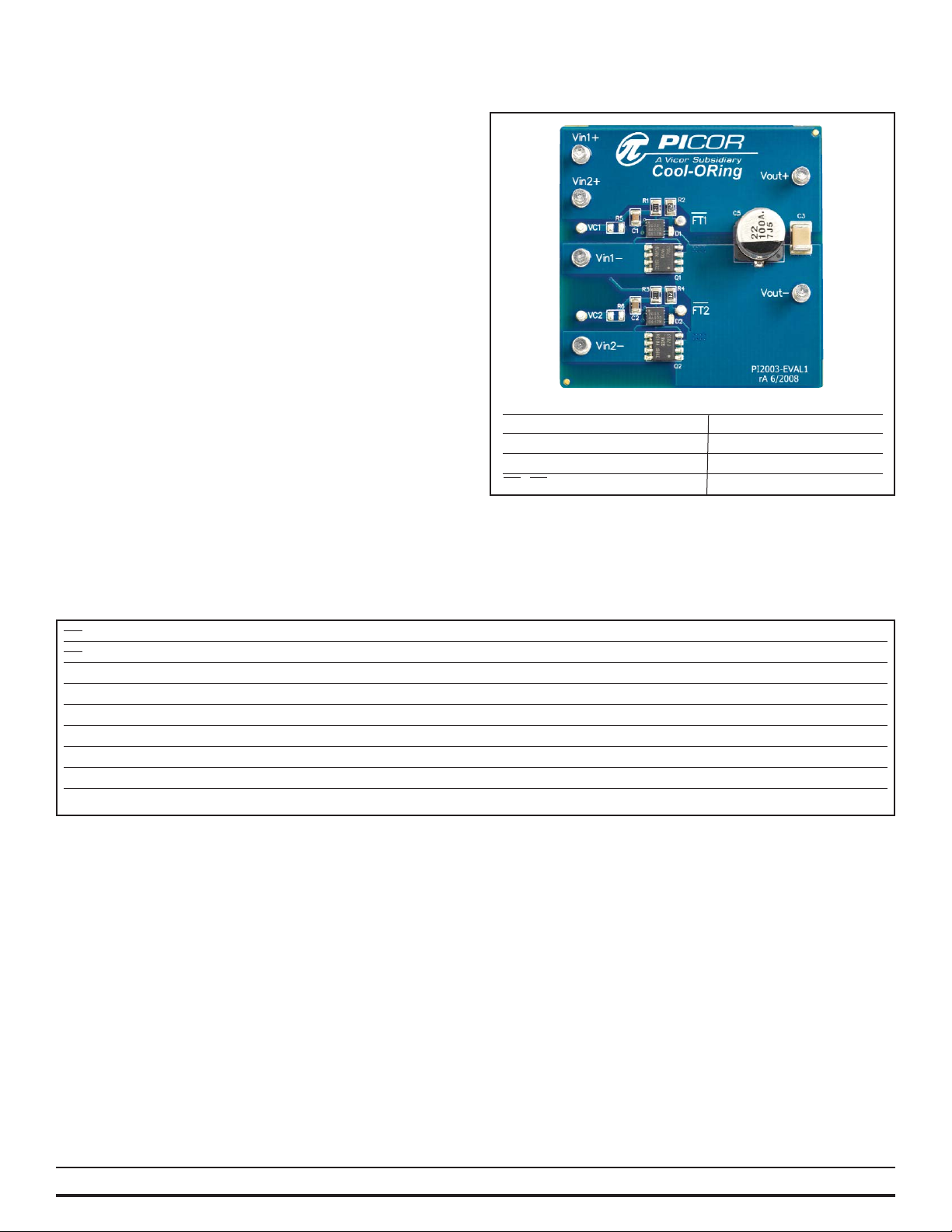

Figure 1 shows a photo of the PI2003-EVAL1 evaluation

board, with two PI2003 controllers and two N-channel

MOSFET used to form the two Active ORing channels. The

board is built with two identical Active ORing circuits with

options and features that enable the user to fully explore the

capabilities of the PI2003 universal Active ORing controller.

Figure 1 – PI2003 -EVAL1 Evaluation Board (1.8" x 1.8")

Terminals Rating

Vin1+ to Vin1-, 60 V / 8 A

Vin2+ to Vin2- 60 V / 8 A

VC1, VC2 -0.3 V to 17.3 V / 40 mA

FT1, FT2 -0.3 V to 17.3 V / 10 mA

Terminal Description

Vin1+ and Vin1- Power Source Input #1: or bus input designed to accommodate up to 60 V and 6 A continuous current.

Vin1+ and Vin1- Power Source Input #2: or bus input designed to accommodate up to 60 V and 6 A continuous current.

VC1 Optional Auxiliary Input Voltage #1: to supply PI2003 VC power. VC1 should be 10 V or higher to fully enhance the MOSFET.

VC2 Optional Auxiliary Input Voltage #1: to supply PI2003 VC power. VC1 should be 10.V or higher to fully enhance the MOSFET.

FT1 PI2003 (U1) Fault Pin: Monitors U1 fault conditions

FT2 PI2003 (U2) Fault Pin: Monitors U2 fault conditions

Vout + Output +: connected to input return

Vout- Output -: connected to MOSFETs sources

Table 1 – PI2003-EVAL1 Evaluation Board terminals description

Cool-ORingTMPI2003 Product Description

Picor Corporation • www.picorpower.com PI2003-EVAL1 User Guide Rev 1.0 Page 2 of 8

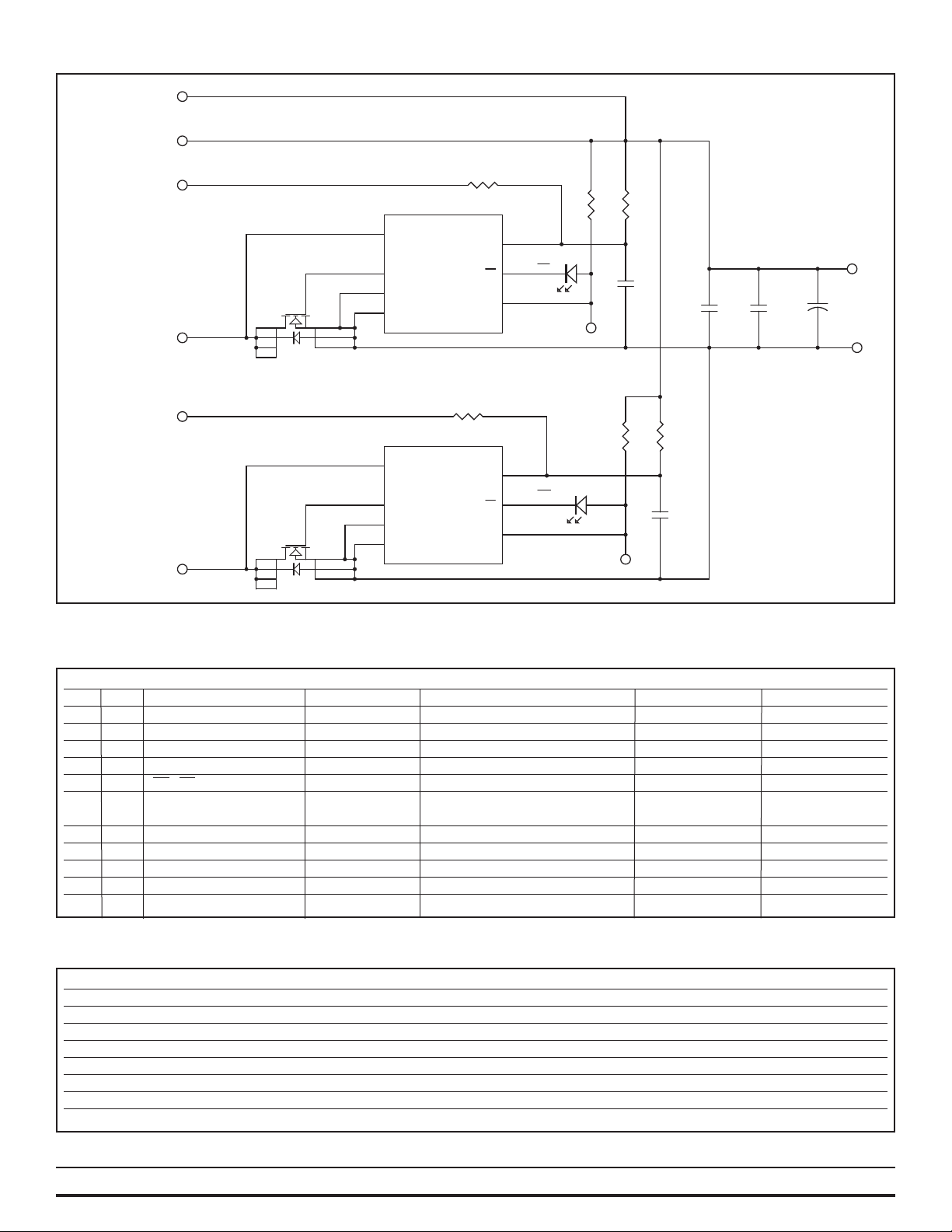

Page 3

Vin1+

Figure 2 – PI2003-EVAL1 Evaluation Board schematic.

Item QTY Reference Designator Value Description Footprint Manufacturer

1 2 C1, C2 1 µF Capacitor, MLCC X5R, 1 µF,16 V 0603

2 1 C3 2.2 uF Capacitor, MLCC X7R, 2.2 uF, 100 V 1812

C4 Not installed 1812

C5 22 µF Capacitor, Electrolytic, 22 µF 100 V

4 2 D1, D2 LED, Super Red THIN 0603 Lite-On, Inc.,

5 4 FT1, FT2, VC1, VC2 Turret Test point TURRET-1528 Keystone Electronics

66

Vin1+, Vin1-, Vin2+, Vin2-,

Turret Test point TURRET-1502 Keystone Electronics

Vout+, Vout9 2 Q1, Q2 IRF7853 100 V, 8.3 A, N-MOSFET SO-8 International Rectifier

10 2 R1, R3 11 KΩ Resistor, 11 KΩ,1/4 W, 5% 0805

11 2 R2, R4 24 KΩ Resistor, 24 KΩ,1/8 W, 5% 0805

12 2 R5, R6 Not Installed 0805

16 2 U1, U2 PI2003 Picor Active ORing Controller 3mmx3mm; 10-TDFN PICOR

Table 2 – PI2003-EVAL1 Evaluation Board bill of materials

Reference Designator Value Functional Description

C1, C2 1 uF VC Bypass Capacitor

C3, C4, C5, Output (Load) Capacitor

D1, D2 LED To indicate a fault exists when it is on

Q1, Q2 N-MOSFET ORing MOSFET

R1, R3 11 KΩ VC Bias resistor

R2, R4 24 KΩ LED current limit resistor

R5, R6 Not Installed Optional to connect VC to separate source

U1, U2 PI2003 Picor Active ORing Controller

Table 3 – Component functional description

Picor Corporation • www.picorpower.com PI2003-EVAL1 User Guide Rev 1.0 Page 3 of 8

BUS(+) A

Vin2+

VC1

Vin1-

Vin2-

VC2

BUS(+) B

BUS(- ) A

BUS(- ) B

Q1

IRF7853

5

6

7

8

Q2

IRF7853

5

6

7

8

R5

D1

VC2

R2

R1

24K

11k

C1

1uF

FT1

R4

R3

24K

11k

D2

C2

1uF

FT2

C3

2.2uF

C4

Not Installed

Vout+

C5

22uF

Vout-

PI2003

Not Installed

PI2003

Not Installed

VC

FT

FC

R6

VC

FT

FC

3

VC1

6

FT1

5

3

FT2

6

5

U1

8

SN

2

GATE

7

4

1

2

3

4

1

2

3

SP

1

GND

U2

8

SN

2

GATE

7

SP

1

GND

Page 4

Initial Test Set Up

Baseline Test Procedure (Refer to Figure 3)

1.0 Recommended Equipment

1.1 Two Isolated DC power supplies - 0 – 60 V; 10 A

1.1.1 If the DC power supply outputs are not isolated,

two 10 A 100 V Schottky diodes are required,

as shown in Figure 4.

1.2 DC electronic load - 10 A minimum.

1.3 Digital Multimeter

1.4 Oscilloscope.

1.5 Appropriately sized interconnect cables.

1.6 Safety glasses.

1.7 PI2003 Product Data sheet.

Figure 3 – Layout configuration for a typical redundant power application, using isolated power supplies.

Figure 4 – Layout configuration for a typical redundant power application, using non-isolated power supplies.

Picor Corporation • www.picorpower.com PI2003-EVAL1 User Guide Rev 1.0 Page 4 of 8

Page 5

Before initial power-up follow these steps to configure the

evaluation board for specific end application requirements:

2.0 Controller Bias Voltage (VC):

2.1 The PI2003 Controller has a separate input (VC) that

provides power to the control circuitry and the gate

driver. An internal voltage regulator (VC) clamps the

VC voltage to 11 V typically. PI2003 EVAL1 is

configured to bias the controllers directly from the

bus voltage (Vin1 and Vin2). Two bias resistors

(R1 and R3: 11 kΩ, 1/4 W, 0805) are connected from

the return input (Vin1+ and Vin2+) to each controller

VC pin, see schematic in figure 2. The bias resistors

are selected to support -48 V bus voltage (36 V to 60 V).

2.2 If the bus voltage (Vin1 and Vin2) range is

different from 36 V to 60 V and higher than the

Clamp voltage, 11 V typical, the Rbias value has

to be changed using the following equations:

2.2.1 Select the value of Rbias using the

following equations:

Rbias =

Vbus

min –VCclampMAX

ICmax

2.2.2 Calculate Rbias maximum power

dissipation:

Pd

Rbias =

(Vbus

max –VCclampMIN )

2

Rbias

Where:

Vbus

min : V(bus) minimum voltage

Vbus

max : V(bus) maximum voltage

VC

clampMAX : Maximum controller clamp

voltage, 12 V

VC

clampMIN : Minimum controller clamp

voltage, 10 V

IC

MAX : Controller maximum bias current,

use 2.0 mA

2.2.3 For example, if the minimum

V(bus) = 36 V and the maximum

V(bus) = 60 V

Rbias =

Vbus

min –VCclampMAX

ICMAX

Rbias =

36 V – 12 V

= 12 KΩ

2.0 mA

Rbias maximum power dissipation is at maximum

input voltage.

PD

Rbias =

(Vbus

max –VCclampMIN)

2

=

(60 V – 10 V)

2

= 208 mW

Rbias 12 KΩ

2.3 The PI2003-EVAL1 is configured to allow the customer

to use a direct bias voltage to the controller VC pin

independent of the bus input. VC1 and VC2 terminals

can be connected directly to the controller VC pins

after removing R1 and R3 and populating R5 and R6.

3.0 Hook Up of the Evaluation Board,

refer to Figures 3 and 4.

3.1 If isolated power supplies are used, Figure 3.

3.1.1. Connect the positive terminal of PS1 power

supply to Vin1+. Connect the negative terminal

of PS1 Vin1-. Set the power supply to 48 V.

Keep PS1 output disabled (OFF).

3.1.2. Connect the positive terminal of PS2 power

supply to Vin2+. Connect the negative terminal

of PS2 Vin2-. Set the power supply to 48 V.

Keep PS2 output disabled (OFF).

3.2 If non-isolated power supplies are used, Figure 4.

3.2.1. Connect the positive terminal of PS1 power

supply to Vin1+ through a Schottky diode.

Connect the negative terminal of PS1 Vin1-.

Set the power supply to 48 V. Keep PS1 output

disabled (OFF).

3.2.2. Connect the positive terminal of PS2 power

supply to Vin2+ through a Schottky diode.

Connect the negative terminal of PS2 Vin2-.

Set the power supply to 48 V. Keep PS2 output

disabled (OFF).

Picor Corporation • www.picorpower.com PI2003-EVAL1 User Guide Rev 1.0 Page 5 of 8

Page 6

Figure 5 – Plot of PI2003 response time to reverse current detection

Picor Corporation • www.picorpower.com PI2003-EVAL1 User Guide Rev 1.0 Page 6 of 8

3.3 Connect the electronic load to the output between

Vout and Gnd. Set the load current to 1 A.

3.4 Enable (turn ON) PS1 power supply output.

3.5 Turn on the electronic load.

3.6 Measure the voltage across Q1, connect a voltmeter

between Vout- and Vin1-, the voltmeter should read

less than 30 mV to assure that the MOSFET is fully

enhanced.

3.7 LED D1 should be off indicating that controller U1 has

no fault. LED D2 should be on indicating that U2 is in

a fault mode and the controller Gate pin output

is low.

3.8 Disable (turn OFF) PS1 power supply output.

3.9 Enable (turn ON) PS2 power supply output.

3.10 Measure the voltage across Q2, connect a voltmeter

between Vout- and Vin2-, the voltmeter should read

less than 30mV to assure that the MOSFET is fully

enhanced.

3.11 LED D2 should be off indicating that controller U2 has

no fault. LED D1 should be on indicating that U1 is in

a fault mode and the controller Gate pin output is

low.

3.12 Enable (turn ON) PS1 and PS2.

3.13 Increase output load to 5 A. The power source, PS1

and PS2, should share the load current equally if

there output voltages are equal. Both LEDs, D1 and

D2, should be off indicating that both controllers

Gate pin output is high.

4.0 Input short circuit test

4.1 Apply a short at one of the inputs (Vin1 or Vin2). The

short can be applied electronically using a MOSFET

connected between low side off the source (Vin1- or

Vin2-) and the return (Vin1+ or Vin2+) or simply by

connecting Vin- to the return. Measure the response

time between when the short is applied and the

MOSFET Gate turns off. An example for PI2003

response time to an input short circuit is shown in

Figure 5.

Page 7

Picor Corporation • www.picorpower.com PI2003-EVAL1 User Guide Rev 1.0 Page 7 of 8

Mechancial Drawing

Figure 6a – PI2003-EVAL1 layout top layer. Scale 2.0:1 Figure 6b – PI2003-EVAL1 layout Bottom layer. Scale 2.0:1

1.800

1.600

1.300

1.100

0.895

0.500

0.295

0.000

Vin1+

Vin2+

VC1

VC2

Vin1-

Vin2-

1.800

Cool-ORing

R1

R5

C1

R3

R6

C2

R2

FT1

D1

Q1

R4

FT2

D2

Q2

Vout+

C5

Vout-

C3

C4

PI2003-EVAL1

rA 6/2008

1.450

1.145

0.650

0.535

0.000

0.000

0.150

0.830

1.650

1.800

Page 8

Vicor’s comprehensive line of power solutions includes high-density AC-DC & DC-DC

modules and accessory components, fully configurable AC-DC & DC-DC power supplies,

and complete custom power systems.

Information furnished by Vicor is believed to be accurate and reliable. However, no responsibility

is assumed by Vicor for its use. No license is granted by implication or otherwise under any patent

or patent rights of Vicor. Vicor components are not designed to be used in applications, such as

life support systems, wherein a failure or malfunction could result in injury or death. All sales are

subject to Vicor’s Terms and Conditions of Sale, which are available upon request.

Specifications are subject to change without notice.

Vicor Corporation

25 Frontage Road

Andover, MA 01810

USA

Picor Corporation

51 Industrial Drive

North Smithfield, RI 02896

USA

Customer Service: custserv@vicorpower.com

Technical Support: apps@vicorpower.com

Tel: 800-735-6200

Fax: 978-475-6715

Picor Corporation • www.picorpower.com PI2003-EVAL1 User Guide Rev 1.0 Page 8 of 8

Loading...

Loading...