Page 1

USER GUIDE | UG:100

PF175 AC-DC Converter Evaluation Board

with External Input Filter

January 2013

Contents Page

Set Up 2

Recommended 4

Hardware

Theory of Operation 5

Thermals

Ordering Information 8

Bill of Materials 8 – 10

Features

n Oscilloscope probe jack for output voltage and ripple measurements

n Simple to use

n Ring lug, screw terminal, and solder connection options

n Replaceable fuse (5A, 216 Littelfuse recommended)

IMPORTANT NOTICE

Please read this document before setting up an evaluation board.

Introduction

This Evaluation Board oers a convenient means to evaluate the performance of Vicor’s

VI Brick® PFM Isolated AC-DC Converter modules with Power Factor Correction, and

has been optimized for user convenience. Refer to Table 1 for operating conditions

and limits.

This reference design contains an input line filter. It is important to remember the

response of the AC line filter is dependent upon the wiring connected to the evaluation

board. Care should be exercised to minimize stray source impedances in order to fully

exercise the features of the converter.

UG:100 vicorpower.com Applications Engineering: 800 927.9474 Page 1

Page 2

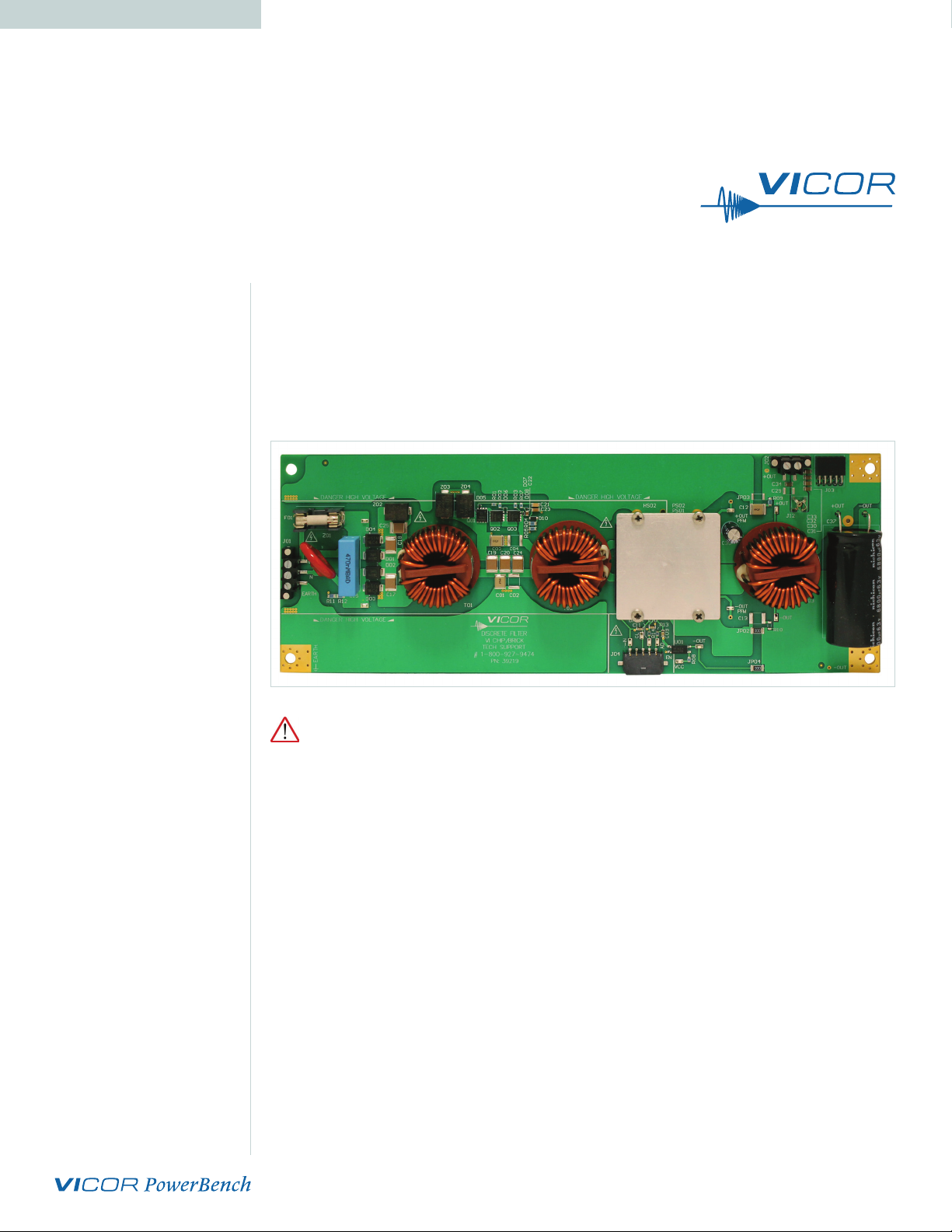

Figure 1.

VI Brick PFM AC DC Converter

Evaluation Board layout

and dimensional drawing,

component side

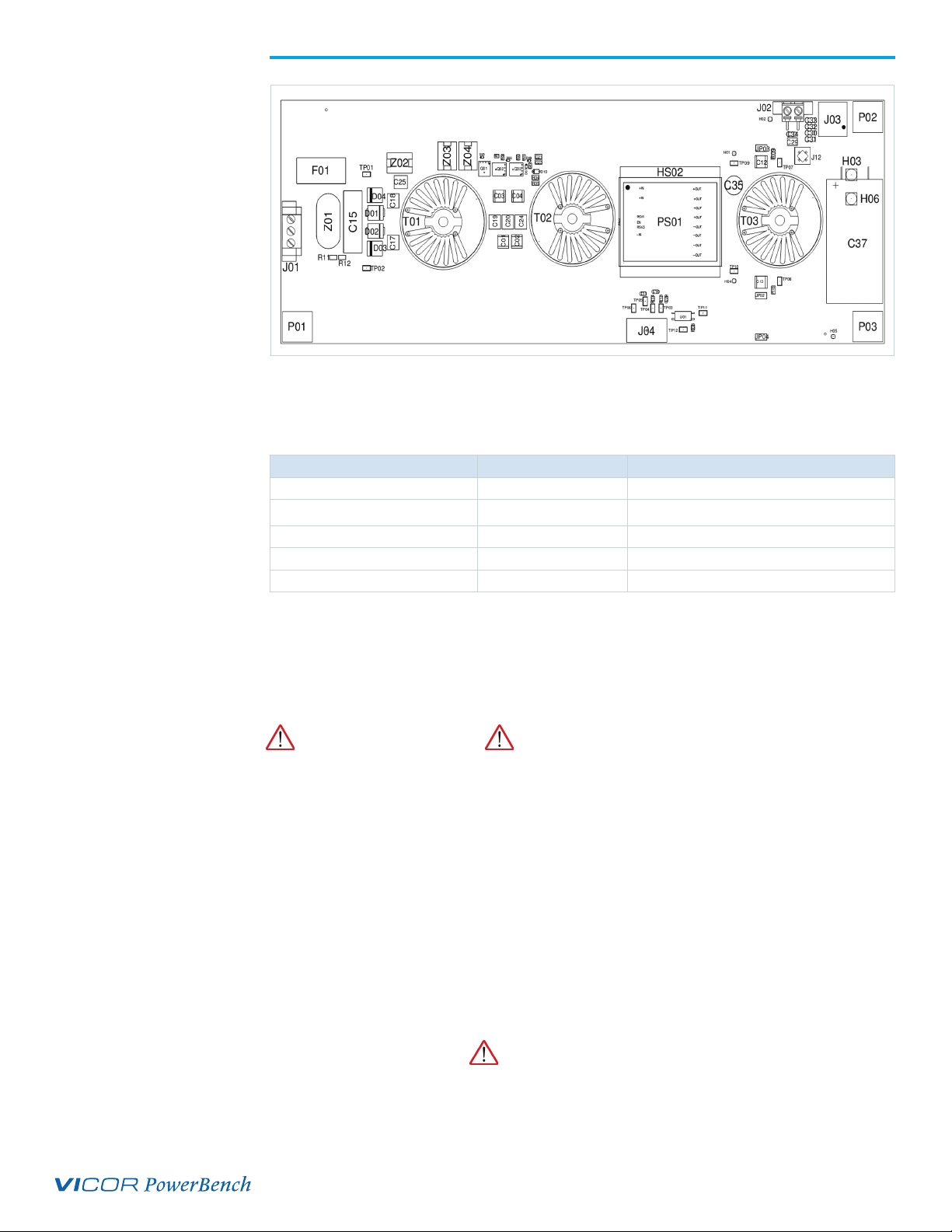

Basic Specifications and Operating Limits

Please use the following table for operating limits:

Table 1.

Description Specification Notes

Input range 85 – 264 Vac Universal input

Output voltage 48 Vdc Regulated

Output power 330 W Over entire input range

Operating temperature -40 to 85°C Limited by C37, T01-T03, U01, Z01-Z04

Output capacitance 6,000 to 12,000 μF 63 V rating, 20% tolerance

NOTE: Module operating temperature will depend on its Product Grade as specified in the data sheet.

Please refer to Figure 1 for locations of the input and output connections as viewed from

the component side. Wires may be soldered directly to the pads instead of ring lugs if

desired to minimize circuit impedances.

DANGER! HIGH VOLTAGE! DANGER! HOT SURFACE!

The VI Brick® AC-DC Converter Evaluation Board contains exposed hazardous

voltages. These voltages are within the area marked by the letter H on the PCB.

The VI Brick DC-DC Converter Evaluation Board may be operated at surface

temperatures which may pose a thermal hazard to the operator. Because of the thermal

and voltage hazards, be careful not to touch any exposed surface unless the power

is disconnected and the evaluation board has been given sucient time to cool. The

evaluation board is not intended for use in end item equipment.

Set Up

The Customer Evaluation Board should be set up as follows:

Note: Care should be taken to avoid reversing polarities if connecting to the opposite (solder) side of

the board.

AC Input Connections (J01) DANGER! HIGH VOLTAGE!

J01, the screw terminal connector, is for connection of AC input to the AC-DC converter

evaluation board. The interconnect leads should be appropriate for the current and

voltage supplied to the board.

UG:100 vicorpower.com Applications Engineering: 800 927.9474 Page 2

Page 3

For single phase power, connect LINE to the pin marked L, NEUTRAL to the pin marked

N and earth ground to the pin marked EARTH. Corresponding wires in an IEC cable are

brown, blue, and yellow with a green stripe.

The board can be used with three phase power. Connect LINE1 to L and LINE2 to N.

Earth ground should still be connected to the EARTH terminal of J1.

+OUT, –OUT

There are several connections available on the VI Brick AC-DC converter. Table 1 lists

the available connectors and their current rating. Do not exceed the rating of the

connector or the AC-DC converter.

Table 2.

Output Connector Ratings

Connector Rating Recommended Connection

J02 10 A Hold-up capacitor

J03 12 A (3 A/contact) Mating PRM and BCM eval boards

Ring lugs 100 A EARTH, +OUT, -OUT

2 mm holes beside C37 12 A Snap-in type capacitor 10 mm sp

Output bulk (electrolytic) capacitance must be attached across the output of the

VI Brick® AC-DC converter evaluation Board. Refer to the table above for the

appropriate range of output capacitance.

The load should be connected to +OUT and –OUT terminals of the evaluation board

with short leads of suitable gauge to carry the output current and minimize losses. A

sucient number of terminal connections should be used to ensure that no terminal

sees more than its maximum rated current. The evaluation board can be connected

directly to the application for which the AC-DC converter is intended. However the

interconnect impedances between the evaluation board and the application can greatly

aect the transient response. For applications where transient response is critical, the

user should consider mounting the VI Brick AC-DC converter directly to the target

application PCB.

Earth Connections

There is one EARTH connection available on the board, in the lower le hand corner,

P01 in the schematic diagram. The EARTH connection used for local return for the EMI

filter is the same as safety ground.

EARTH may optionally be connected to either of the AC-DC converter outputs in order

to provide a positive or negative voltage rail with respect to earth.

The default configuration of the evaluation board is to have the EARTH terminal

connected to –OUT through jumper JP02, while JP03 is unpopulated. To leave the

outputs floating, remove JP03 so that both JP02 and JP03 are unpopulated. To connect

EARTH to +OUT, remove JP02 and populate JP03.

The insulation of the AC/DC converter modules supported by this evaluation board

has not been designed to exceed SELV voltages, and should not exceed +/-60Vdc from

EARTH potential by stacking.

Input Current Measurement

A current probe can be passed around either input lead connected to the VI Brick

evaluation board. This can be used to measure DC currents and AC currents in front of

the EMI filter and transient suppression circuits.

UG:100 vicorpower.com Applications Engineering: 800 927.9474 Page 3

Page 4

Output Voltage Measurement Jack (J12)

This connector is provided to make accurate measurements of the output ripple

voltage of the VI Brick® AC-DC converter. Many types of scope probes may be directly

connected to this point if the probe is equipped with a removable plastic sheath. To

avoid creating ground loops when making measurements of the output or input

voltage, these measurements should be made separately. Clamp on ferrite chokes, such

as Digikey PN 240-2132-ND placed over the leads of passive oscilloscope probes also

help to reduce common mode high frequency switching noise pickup. A capacitor can

be added at C29 to reduce high frequency noise at the probe if necessary.

Enable (EN) DANGER! HIGH VOLTAGE!

The EN pin can be used to disable the VI Brick AC-DC converter. Connecting EN to

the –IN-PFM pin will disable the AC-DC converter. This will also clear any latching

output OVP fault if one has occurred. Note that the EN pin is referenced to the primary

(hazardous voltage) side of the converter. The EN pin can be accessed from J04, for

which a mating connector can be used. The mating connector is Molex P/N 43645-0500

with Molex 43030 series pins.

An optocoupler has been provided to allow connection to output referenced equipment.

The input to the optocoupler is connected to –OUT by default. Jumper JP04 can be

removed, allowing the customer to provide their own reference for the enable input.

This input can be floated up to +/-1000V from EARTH.

Efficiency Measurement

As the VI Brick AC-DC Converter can deliver and consume large currents, the eect of

the PCB must be considered when making an eciency measurement. When testing

your design based on this reference design, be sure to probe dierent points in the input

filter and rectifier section to verify that voltage drops are not excessive in your layout.

If eciency tests are to be automated, then Kelvin type connections are recommended

to reduce common current errors during voltage measurements.

Recommended Hardware

The hardware kit provided with the evaluation board includes the following:

n 6 #10 lock washers

n 3 #10-32 screws

n 3 #10-32 hex nuts

Ring lugs are also recommended for making output connections.

UG:100 vicorpower.com Applications Engineering: 800 927.9474 Page 4

Page 5

Figure 2.

Input, rectifier, and filter

section schematic

Theory of Operation

The schematic diagram is presented in functional blocks with text descriptions.

Component values are given in Bill of Materials, layout in PCB Layout (Figure 7).

So copies are available with download.

Input, Rectifier, and Filter Section

Input power is connected to screw terminal block J01. A 5 A fuse in F01 protects against

overcurrent. 330 W at 93% eciency draws 355W. At 85 V input, 4.17A is drawn.

Z01 is a 20 mm disk MOV that can withstand higher surges than Z02-Z04. R11 and R12

discharge the input capacitors when the line cord is pulled. Capacitors C15, C17-C20,

C24, and C25 return high frequency dierential current before it exits the line cord.

D01 through D04 form the input bridge rectifier. T01 is a high frequency common mode

inductor chosen for its high impedance up to 5 MHz. C01 and C03 are Y caps that return

common mode high frequency currents to GND (EARTH) rather than through

LINE or NEUTRAL.

Active Transient Suppression Section

Input power enters from the filter at le. C24 and C01 are repeated in the schematic

snippet. Q01 through Q03 transistors turn o during a transient event, and can block up

to 200 V each. R04/R05 through to C22 form the control mechanism for the transistors.

T02 works with the capacitors inside the VI Brick® PFM® module as part of the

conducted emissions filter.

UG:100 vicorpower.com Applications Engineering: 800 927.9474 Page 5

Page 6

Figure 3.

Active transient suppression

section schematic

Figure 4.

Output enable control

schematic

Output Enable Control

The EN pin is pulled low to disable the AC-DC converter. If pulled high to 3.3 V or

le floating, the VI Brick® PFM® will operate. A 1x5 0.100” spaced socket allows easy

connection to automated test equipment. This part of the circuit is referenced to

primary ground.

Users can connect their own secondary referenced control circuit by connecting

through the optocoupler U01, and connecting to TP12 and TP11 as needed. JP04 can be

removed to allow a floating reference for the enable input. On this TP12 input, a high

signal will result in shutdown of the AC-DC converter.

UG:100 vicorpower.com Applications Engineering: 800 927.9474 Page 6

Page 7

Output Filter Section

A common mode inductor should be used at the output to isolate switching noise from

this converter so it does not cause beat frequencies with downstream converters. The

one used in this reference design is the same used at the input so that a single part

number can be stocked. If space is at a premium, a smaller common mode inductor can

be substituted. Peak impedance should be between 500 kHz and 5 MHz.

C37 is the bulk capacitor default on this board. Hold time will be increased roughly 50%

and power factor increased roughly 0.5% if a 10,000 uF capacitor is substituted. This

default capacitor is a 25 mm x 45 mm capacitor that is laid on its side. There are also two

2 mm holes, 10 mm spacing, which can be used for snap in type electrolytic capacitors.

Diameters up to 35 mm will clear other components on the PCB. This capacitor filters

the rectified line ripple, which is twice the input frequency. RMS ripple current rating

should be 80% of output current or higher for longer lifetime. Ripple current ratings

vary as a function of ambient temperature.

C30 through C34 are output ceramic filter capacitors. There are used to reduce the

switching ripple on the 48 V bus near 1 MHz. Screw terminal J02 or 0.100” spaced J03

can be used to connect output wires to the load or connect an external capacitor.

J12 is a probe socket with a local capacitor to reduce switching noise. R09 and R10 are

used to connect either the positive or negative output terminal to GND (EARTH). Only

one should be connected at a time. Both can be removed for a floating output.

Figure 5.

Output filter section schematic

UG:100 vicorpower.com Applications Engineering: 800 927.9474 Page 7

Page 8

Bill of Materials

Thermals

For most lab environments a fan blowing across the evaluation board is recommended

See VI Brick® Thermal Management Application Note at:

www.vicorpower.com/documents/application_notes/AN200_VIBrickTherm.pdf

or contact Vicor Applications Engineering for assistance (800) 927-9474.

Ordering Information

Two models of the evaluation board are available:

Order Number Power Module On PCB AC-DC Format

PFM-DISCRETE-FILTR PS01 PFM175D480C330A00 VI Chip

PFB-DISCRETE-FILTR PS02 PF175B480C033FP-00 VI Brick

Ref. Des. Description

C01 CAPY X7R 4700pF 10% 250V 2220 Murata 490-3482-2-ND Murata GA355DR7GF472KW01L

C02 NOT APPLIED NOT APPLIED NOT APPLIED NOT APPLIED NOT APPLIED

C03 CAPY X7R 4700pF 10% 250V 2220 Murata 490-3482-2-ND Murata GA355DR7GF472KW01L

C04 NOT APPLIED NOT APPLIED NOT APPLIED NOT APPLIED NOT APPLIED

C09

CAP X7R .1uF 10% 25V 0805 Kemet 399-1170-2-ND AVX 08053C104KAT2AC10

C11

C12 CAPY X7R 4700pF 10% 250V 2220 Murata 490-3482-2-ND Murata GA355DR7GF472KW01L

C13 NOT APPLIED NOT APPLIED NOT APPLIED NOT APPLIED NOT APPLIED

C15 0.47uF/20/275VAC X2 CAP Kemet 399-5429-ND Wima MKS4 0.47/630/10 PCM 27.5

C17

C18

C19

C20

C21 CAP X7R .015uF 10% 630V 1206 TDK 445-4489-2-ND TDK C3216X7R2J153M

C22 CAP X7R 4.7uF 10% 25V 0805 TDK 445-5972-2-ND TDK CL21A475KAQNNNG

C23 CAP X7T 0.033uF 10% 630V 1206

C24

C25

C29 NOT APPLIED NOT APPLIED NOT APPLIED NOT APPLIED NOT APPLIED

C30

C31

C32

C33

C34

C35 CAP ALUM 100UF 63V 20% RADIAL Nichicon UVY1J101MPD-ND Nichicon UVY1J101MPD

C37 CAP ALEL 6800uF 20% 63V 25X50 Kemet 493-1135-ND Nichicon UVZ1J682MRD

D01

D02

D03

D04

CAP X7T 0.47uF 10% 630V 2220 TDK 445-8876-2-ND TDK C5750X7T2J474K

.060MAXHT

CAP X7T 0.47uF 10% 630V 2220 TDK 445-8876-2-ND TDK C5750X7T2J474K

CAP X7R 1.0uF 10% 100V 1206 TDK 445-4467-2-ND TDK C3216X7R2A105K

DPN 1000V 8A DO214AB Diodes Inc S8MCDITR-ND Diodes Inc S8MC-13

DPN 1000V 5A SMC *Stocked by Arrow NAC, Manufacturer: Taiwan Semiconductor, Part#: HS5M R7

Digi-Key

Manufacturer

TDK 445-7762-2-ND Yageo CC1206KKX7RZB333

Digi-Key

Part Number

Future

Manufacturer

Future

Part Number

UG:100 vicorpower.com Applications Engineering: 800 927.9474 Page 8

Page 9

Ref. Des. Description

D05

D06

D07

D08

D10 DPN 100V 200mA SOD-123 Diodes Inc BAV19W-7-F Diodes Inc BAV19W-7-F

F01 FUSE HOLDER, SMD, 5x20 Wickmann F4546-ND Schurter 31.8225

FUSE FUSE 5A 250V FAST 5X20 CARTRIDGE Littelfuse F2369-ND Littelfuse 6005.HXP

FW OUTPUT WASHER, FLATPAC Generic Generic Generic Generic

HS01 NOT APPLIED NOT APPLIED NOT APPLIED NOT APPLIED NOT APPLIED

J01 CON 3CKT TERM BLK SMD No Stock No Stock Weco 140-A-126-SMD/03

J02 CON 2 CKT TERM BLK SMD No Stock No Stock Weco 140-A-126-SMD/02

J03

J04 CONN 5POS SINGLE ROW RIGHT

J12 JACK VERTICAL MECH THRU HOLE *Stocked by Tektronix, Part#: 131-5031-00

JP02 RES 0 OHM 3/4W 5% 2010 Vishay Dale 541-0.0WTR-ND Vishay Dale CRCW20100000Z0EF

JP03 NOT APPLIED NOT APPLIED NOT APPLIED NOT APPLIED NOT APPLIED

JP04 RES 0 OHM 3/4W 5% 2010 Vishay Dale 541-0.0WTR-ND Vishay Dale CRCW20100000Z0EF

LARGE_PIN PIN .081 DIA X .21LG VICBRICK Generic Generic Generic Generic

LOCK_

WSHR

OUTPT_

NUT

PAD1 FOOT, FLIP FIXTURE Generic Generic Generic Generic

PAD2 FOOT, FLIP FIXTURE Generic Generic Generic Generic

PAD3 FOOT, FLIP FIXTURE Generic Generic Generic Generic

PAD4 FOOT, FLIP FIXTURE Generic Generic Generic Generic

PAD5 FOOT, FLIP FIXTURE Generic Generic Generic Generic

PAD6 FOOT, FLIP FIXTURE Generic Generic Generic Generic

PP1 NOT APPLIED NOT APPLIED NOT APPLIED NOT APPLIED NOT APPLIED

PP2 NOT APPLIED NOT APPLIED NOT APPLIED NOT APPLIED NOT APPLIED

PP3 NOT APPLIED NOT APPLIED NOT APPLIED NOT APPLIED NOT APPLIED

PP4 NOT APPLIED NOT APPLIED NOT APPLIED NOT APPLIED NOT APPLIED

PS01 Model Specific Vicor Model Specific Vicor Model Specific

Q01

Q02

Q03

R01 RES 12.4K OHM 1/8W 1% 0805 Vishay Dale 541-12.4KCTR-ND Vishay Dale CRCW080512K4FKEA

R02 RES 2.49K OHM 1/8W 1% 0805 Vishay Dale 541-2.49KCTR-ND Vishay Dale CRCW08052K49FKEA

R03 RES 499 OHM 1/8W 1% 0805 Vishay Dale 541-499CTR-ND Vishay Dale CRCW0805499RFKEA

R04

R05

R07 RES 2K OHM 1/8W 1% 0805 Vishay Dale 541-2.00KCTR-ND Vishay Dale CRCW08052K00FKEA

R08 RES 1K OHM 1/8W 1% 0805 Vishay Dale 541-1.00KCTR-ND Rohm MCR10EZPF1001

DZEN 16V 2% 300mW SOD523

DZEN 13V 2% 300mW SOD523

CONN 10POS 90DEG THRUHOLE

FEMALE 0.1SPC

ANGLE

PLTD #10 INT TOOTH LW PHOS/BR Generic Generic Generic Generic

OUTPUT NUT, FLATPAC Generic Generic Generic Generic

QMOS N 200V 32mR 36A 5X6 MLP Infineon BSC320N20NS3 GTR-ND No Stock No Stock

RES 2K OHM 1/4W 1% 1206 Vishay Dale 541-2.00KFTR-ND Vishay Dale CRCW12062K00FKEA

Digi-Key

Manufacturer

NXP

Semiconductor

NXP

Semiconductor

Sullins Electronics S5519-ND Sullins Electronics PPTC052LJBN-RC

Molex WM1893-ND TE Connectivity 1445057-5

Digi-Key

Part Number

BZX585-B16,115-ND

BZX585-B13,135

Future

Manufacturer

NXP

Semiconductor

NXP

Semiconductor

Future

Part Number

BZX585-B16,115

BZX585-B13,135

UG:100 vicorpower.com Applications Engineering: 800 927.9474 Page 9

Page 10

Ref. Des. Description

R09 RES 2.2 OHM 1/4W 1% 1206 Vishay Dale 541-2.20FFTR-ND Vishay Dale CRCW12062R20FKEA

R10 NOT APPLIED NOT APPLIED NOT APPLIED NOT APPLIED NOT APPLIED

R11

R12

R13

R14

SCREW SCREW, 10-32 X 3/8 PHIL PH Generic Generic Generic Generic

SMALL_PIN PIN .031 DIA X .21LG VICBRICK Generic Generic Generic Generic

STNDFF_

LGFF

T01

T03

TP01

TP02

TP03

TP04

TP05

TP06

TP07

TP08

TP09

TP10

TP11

TP12

U01 IC OPTO 70V 100mA SOP 4L No Stock No Stock Vishay TCLT-1009

Z01 VAR MOV, 300V 10KA 20mm DIA

Z02

Z04

RES 42.2K OHM 1/4W 1% 1206 Vishay Dale 541-42.2KFTR-ND Vishay Dale CRCW120642K2FKEA

RES 100 OHM 1/8W 1% 0805 Vishay Dale 541-100CTR-ND Vishay Dale CRCW0805100RFKEA

STANDOFF,.287 LG FEMALE-FEMALE Generic Generic Generic Generic

IND COM MODE 013 mH -30%+30%

016A Ø1.6mm

TEST POINT, SURFACE MOUNT Keystone 5017-ND Keystone 5017

RADIAL

VAR MOV 300V 11.5X8.3 SMD Littelfuse F3551TR-ND Littelfuse V300SM7Z03

Digi-Key

Manufacturer

*Stocked by VACUUMSCHMELZE Gmbh, part#: T60405-R6123-X616T02

Littelfuse TMOV20RP300EL2T7-ND Littelfuse TMOV20RP300E

Digi-Key

Part Number

Future

Manufacturer

Future

Part Number

UG:100 vicorpower.com Applications Engineering: 800 927.9474 Page 10

Page 11

Figure 6.

Schematic diagram

UG:100 vicorpower.com Applications Engineering: 800 927.9474 Page 11

Page 12

Figure 7.

PCB Layout

Left, top layer,

right, bottom layer.

The Power Behind Performance

Rev 1.0 12/2013 vicorpower.com Applications Engineering: 800 927.9474 Page 12

Loading...

Loading...