Page 1

vicorpower.com 800-735-6200 V•I Chip Pre-Regulator Module P048F048T24AL Rev. 1.7

Page 1 of 14

PRELIMINARY

• 48 V input V•I Chip PRM

• Vin range 36 – 75 Vdc

• High density – 875 W/in

3

• Small footprint – 220 W/in

2

• Low weight – 0.5 oz (14 g)

• Adaptive Loop feedback

• ZVS buck-boost regulator

• 1.5 MHz switching frequency

• 96% Efficiency

• 125˚C operation

P048F048T24AL

Vin = 36 – 75 V

V

f = 26 – 55 V

Pf = 240 W

If = 5 A

©

V•I ChipTM– PRM-AL

Pre-Regulator Module

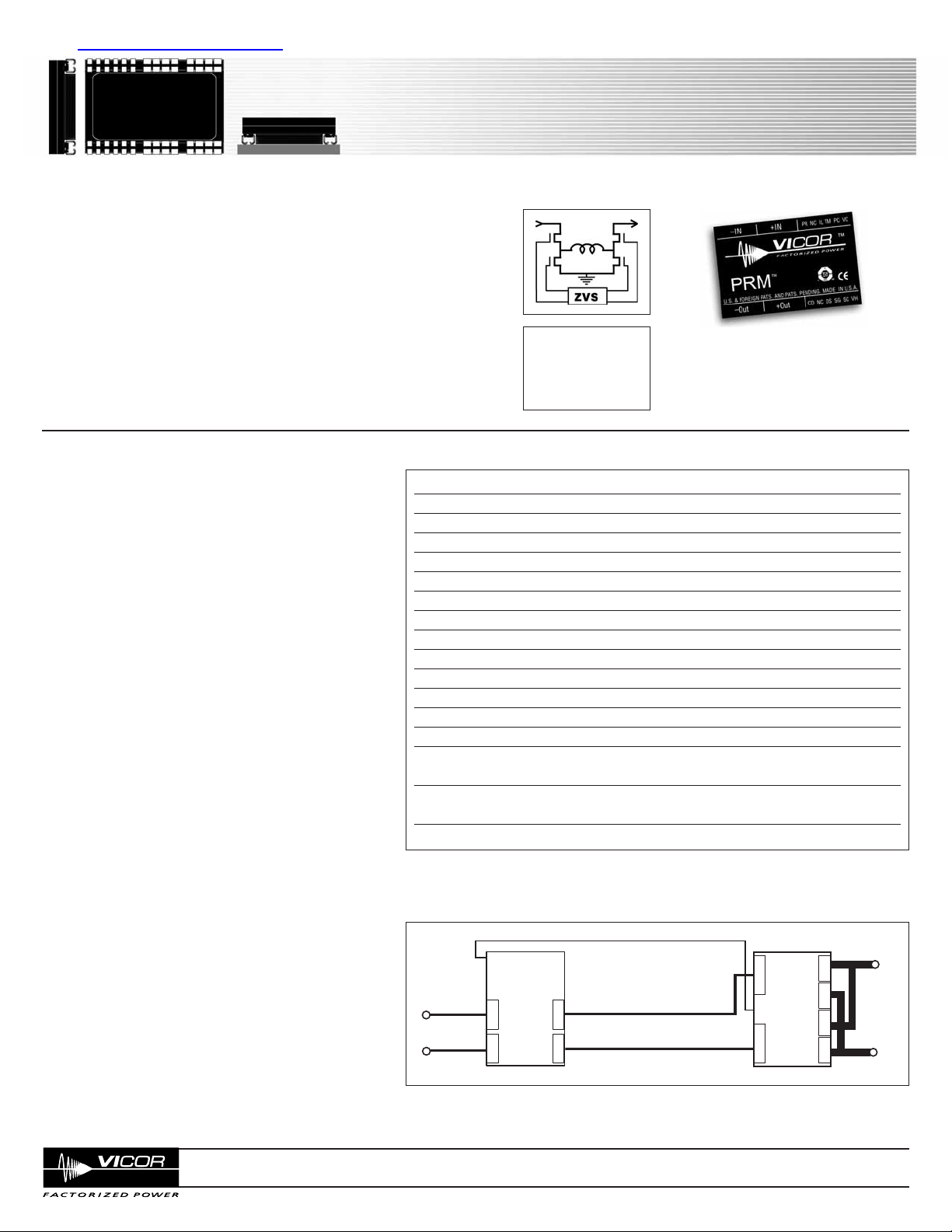

Product Description

The V•I Chip Pre-Regulator Module (PRM) is a very

efficient non-isolated regulator capable of both

boosting and bucking a wide range input voltage. It is

specifically designed to provide a controlled Factorized

Bus distribution voltage for powering downstream

V•I Chip Voltage Transformation Modules (VTMs) —

fast, efficient, isolated, low noise Point-of-Load (POL)

converters. In combination, PRMs and VTMs form a

complete DC-DC converter subsystem offering all of

the unique benefits of Vicor’s Factorized Power

Architecture (FPA): high density and efficiency; low

noise operation; architectural flexibility; extremely fast

transient response; and elimination of bulk capacitance

at the Point-of-Load (POL).

In FPA systems, the POL voltage is the product of the

Factorized Bus voltage delivered by the PRM and the

"K-factor" (the fixed voltage transformation ratio) of a

downstream VTM. The PRM controls the Factorized Bus

voltage to provide regulation at the POL. Because VTMs

perform true voltage division and current multiplication,

the Factorized Bus voltage may be set to a value that is

substantially higher than the bus voltages typically

found in "intermediate bus" systems, reducing

distribution losses and enabling use of narrower

distribution bus traces. A PRM-VTM chip set can

provide up to 100 A or 230 W at a FPA system density

of 200 A/in

3

or 460 W/in3— and because the PRM can

be located, or "factorized," remotely from the POL,

these power densities can be effectively doubled.

The PRM described in this data sheet features a unique

"Adaptive Loop" compensation feedback: a single wire

alternative to traditional remote sensing and feedback

loops that enables precise control of an isolated POL

voltage without the need for either a direct connection

to the load or for noise sensitive, bandwidth limiting,

isolation devices in the feedback path.

Actual size

Parameter Values Unit

+In to -In -1.0 to 85.0 Vdc

PC to -In -0.3 to 6.0 Vdc

PR to -In -0.3 to 9.0 Vdc

IL to -In -0.3 to 6.0 Vdc

VC to -In -0.3 to 18.0 Vdc

+Out to -Out -0.3 to 59 Vdc

SC to -Out -0.3 to 3.0 Vdc

VH to -Out -0.3 to 9.5 Vdc

OS to -Out -0.3 to 9.0 Vdc

CD to -Out -0.3 to 9.0 Vdc

SG to -Out 100 mA

Continuous output current 5 Adc

Continuous output power 240 W

Operating junction temperature (M-Grade) -55 to 125 °C

(T-Grade) -40 to 125 °C

Storage temperature (M-Grade) -65 to 150 °C

(T-Grade) -40 to 150 °C

Case temperature during reflow: 208 °C

The P048F048T24AL is used with any 048 input series VTM to provide a regulated and

isolated output.

DC-DC Converter

Absolute Maximum Ratings

PRM

查询V040F033T060供应商

+In

-In

VTM

K

Ro

+Out

-Out

+Out

-Out

+Out

–Out

VH

SC

SG

OS

NC

CD

Factorized

Bus (Vf)

TM

VC

PC

VC

PC

TM

IL

NC

PR

PRM-AL

+In

Vin

–In

Vout

Page 2

vicorpower.com 800-735-6200 V•I Chip Pre-Regulator Module P048F048T24AL Rev. 1.7

Page 2 of 14

PRELIMINARY

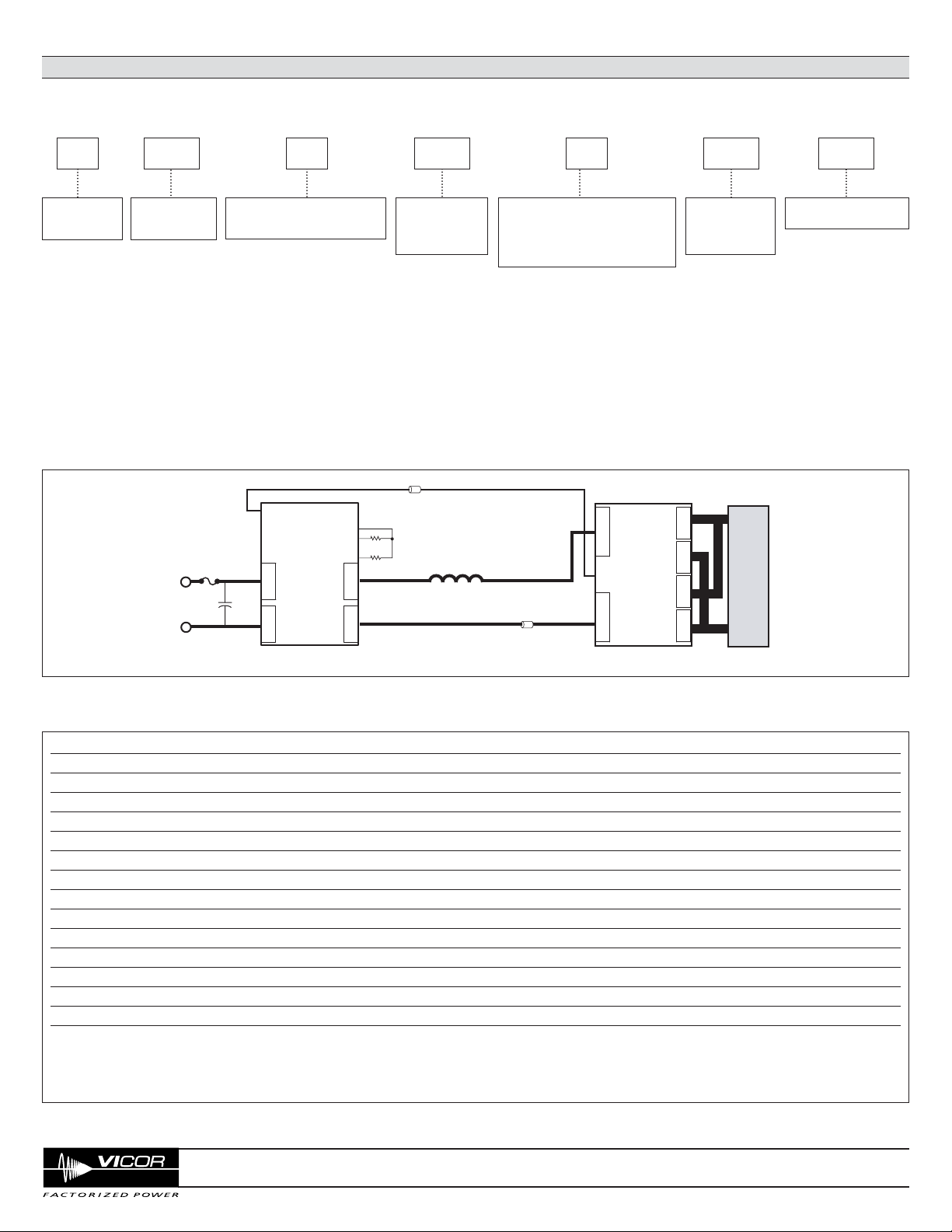

Overview of Adaptive Loop Compensation

Adaptive Loop compensation, illustrated in Figure 1, contributes to

the bandwidth and speed advantage of Factorized Power. The PRM

monitors its output current and automatically adjusts its output

voltage to compensate for the voltage drop in the output

resistance of the VTM. R

OS sets the desired value of the VTM

output voltage, Vout; R

CD is set to a value that compensates for

the output resistance of the VTM (which, ideally, is located at the

point of load). For selection of R

OS and RCD, refer to Table 1 below

or Page 9.

The V•I Chip’s bi-directional VC port :

1. Provides a wake up signal from the PRM to the VTM that

synchronizes the rise of the VTM output voltage to that of the PRM.

2. Provides feedback from the VTM to the PRM to enable the PRM

to compensate for the voltage drop in VTM output resistance, R

O.

Output Power

Designator

(=Pf /10)

P 048 F 048 T 24 AL

Pre-Regulator

Module

Input Voltage

Designator

Product Grade Temperatures (°C)

Grade Storage Operating

T -40 to150 -40 to125

M -65 to150 -55 to125

Configuration

(Fig.21)

Nominal

Factorized Bus

Voltage

AL = Adaptive Loop

Desired Load Voltage (Vdc) VTM P/N

(1)

Max VTM Output Current (A)

(2)

ROS (kΩ)

(3)

RCD (Ω)

(3)

1.0 V048F015T100 100 3.57 26.1

1.2 V048F015T100 100 2.94 32.4

1.5 V048F015T100 100 2.37 39.2

1.8 V048F020T080 80 2.61 35.7

2.0 V048F020T080 80 2.37 39.2

3.3 V040F033T060 60 2.89 32.6

5.0 V048F060T040 40 2.87 33.2

10 V048F120T025 25 2.86 32.9

12 V048F120T025 25 2.37 39.2

15 V048F160T019 18.8 2.49 37.4

24 V048F240T012 12.5 2.37 39.2

28 V048F320T009 9.4 2.74 35.7

36 V048F480T006 6.3 3.16 30.1

48 V048F480T006 6.3 2.37 39.2

Table 1 — Configure your Chip Set using the PRM-AL

Note:

(1) See Table 2 on page 9 for nominal Vout range and K factors.

(2) See “PRM output power vs. VTM output power” on Page 10

(3) 1% precision resistors recommended

Figure 1 — With Adaptive Loop control, the output of the VTM is regulated over the load current range with only a single interconnect between the PRM and

VTM and without the need for isolation in the feedback path.

General Specifications

V•I Chip Pre-Regulator Module

Part Numbering

+Out

–Out

VH

SC

SG

OS

ROS

NC

CD

RCD

Vf =

Vin

VC

PC

TM

IL

NC

PR

PRM-AL

+In

–In

Factorized

Bus (Vf)

(

V

L

Io•Ro

+

K

K

Vo = VL ± 1.0%

+Out

+In

L

O

A

D

VTM

K

Ro

-Out

+Out

-Out

TM

VC

)

PC

-In

Page 3

vicorpower.com 800-735-6200 V•I Chip Pre-Regulator Module P048F048T24AL Rev. 1.7

Page 3 of 14

PRELIMINARY

Parameter Min Typ Max Unit Note

Input voltage range 36 48 75 Vdc

Input dV/dt 1 V/µs

Input undervoltage turn-on 33.8 35.3 Vdc

Input undervoltage turn-off 30.5 31.8 Vdc

Input overvoltage turn-on 75.8 77.3 Vdc

Input overvoltage turn-off 78.8 81.0 Vdc

Input quiescent current 0.5 1 mA PC low

Input current 5.2 Adc

Input reflected ripple current 580 mA p-p See Figures 4 & 5

No load power dissipation 3.0 W

Internal input capacitance 5 µF Ceramic

Recommended external input capacitance 100 µF See Figure 5 for input filter circuit.

Source impedance dependent

Input Specs (Conditions are at 48 Vin, 48 Vf, full load, and 25°C ambient unless otherwise specified)

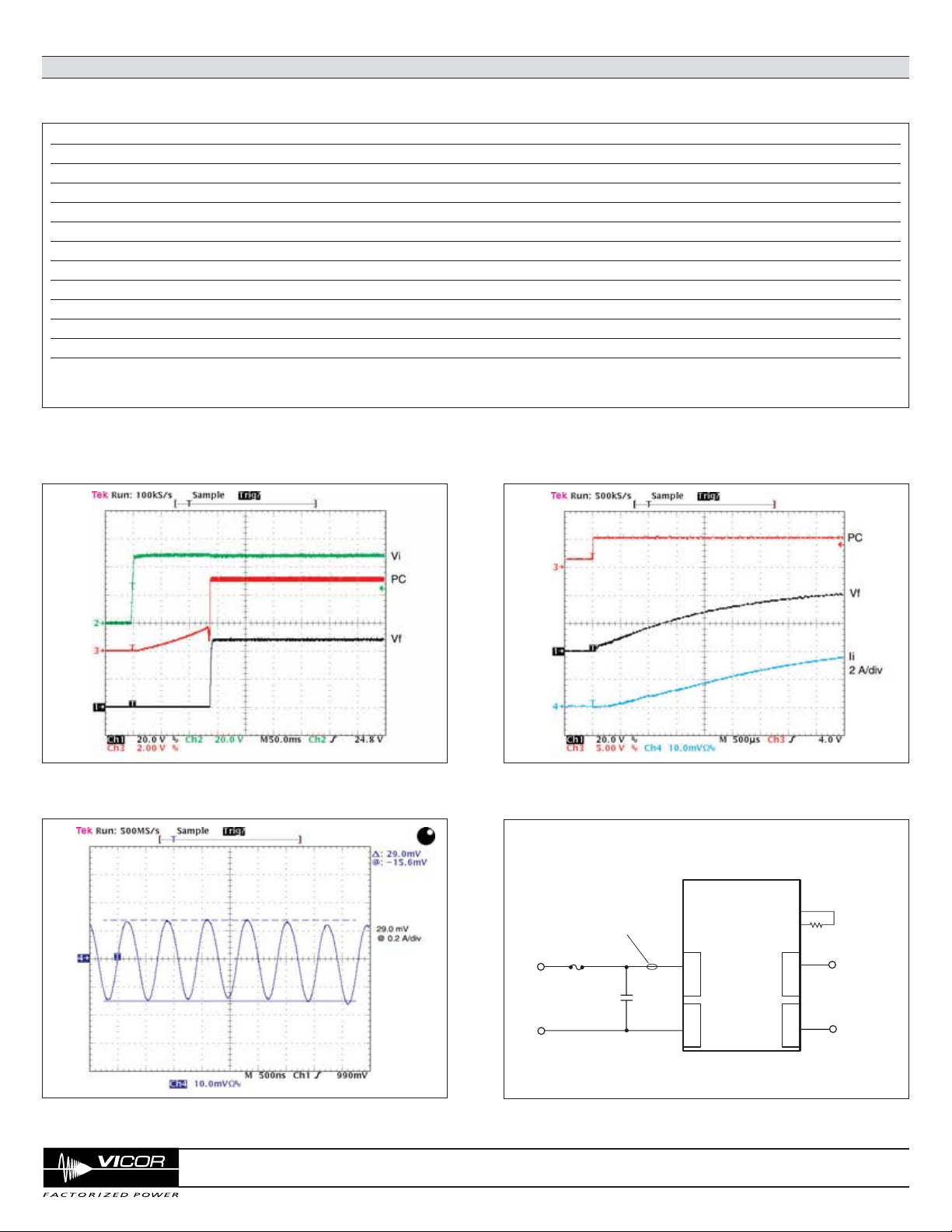

Figure 3 — Vf turn-on waveform with inrush current – PC enabled at

full load, 48 Vin

Figure 2 — Vf and PC response from power up

Figure 4 — Input reflected ripple current at full load and 48 Vin

Input Waveforms

Figure 5 — Input filter capacitor recommendation

Electrical Specifications

V•I Chip Pre-Regulator Module

+IN

–IN

Reflected

Measurement

10 A

100 μF

Al-Electrolytic

Ripple

VC

PC

TM

IL

NC

PR

PRM-AL

+In

–In

+Out

–Out

VH

SC

SG

OS

NC

CD

2.37 kΩ

+ OUT

– OUT

Page 4

vicorpower.com 800-735-6200 V•I Chip Pre-Regulator Module P048F048T24AL Rev. 1.7

Page 4 of 14

PRELIMINARY

Parameter Min Typ Max Unit Note

Output voltage range 26 48 55 Vdc Factorized Bus voltage (Vf) set by ROS

Output power 0 240 W

Output current 0 5 Adc

DC current limit 5.25 6.0 6.6 Adc IL pin floating

Average short circuit current 0.5 A Auto recovery

Set point accuracy 1.5 %

Line regulation 0.1 0.2 % Low line to high line

Load regulation 0.1 0.2 % No CD resistor

Load regulation (at VTM output) 1.0 2.0 % Adaptive Loop

Current share accuracy 5 10 %

Efficiency

Full load 96 % See Figure 6,7 & 8

Output overvoltage set point 56 59.4 Vdc

Output ripple voltage

No external bypass 2.3 2.5 % Factorized Bus, see figure 13

With 10 µF capacitor 1.0 1.1 % Factorized Bus, see figure 14

Switching frequency 1.35 1.45 1.55 MHz Fixed frequency

Output turn-on delay

From application of power 200 300 ms See Figure 2

From PC pin high 100 µs See Figure 3

Internal output capacitance 5 µF Ceramic

Factorized Bus capacitance 47 µF

Output Specs (Conditions are at 48 Vin, 48 Vf, full load, and 25°C ambient unless otherwise specified)

Electrical Specifications

(continued) V•I Chip Pre-Regulator Module

Page 5

vicorpower.com 800-735-6200 V•I Chip Pre-Regulator Module P048F048T24AL Rev. 1.7

Page 5 of 14

PRELIMINARY

Electrical Specifications

(continued) V•I Chip Pre-Regulator Module

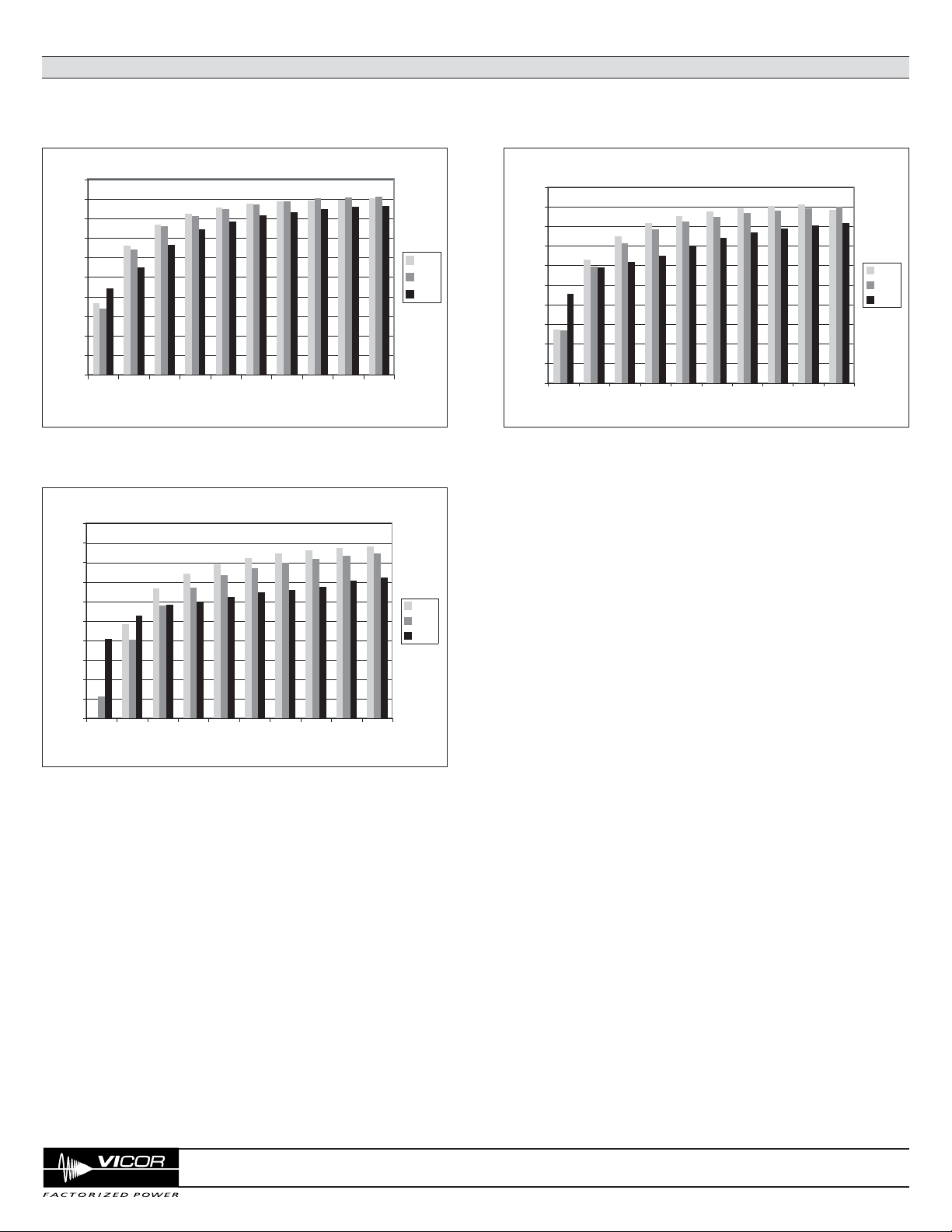

Figure 7 — Efficiency vs. output current at 36 Vf

Figure 8 — Efficiency vs. output current at 26 Vf

Efficiency Graphs

Figure 6 — Efficiency vs. output current at 48 Vf

Efficiency vs. Output Current

98

96

94

92

90

88

86

Efficiency (%)

84

82

80

78

0.5 1.1 1.5 2.0 2.5 3.0 3.5 4.0 4.6 5.0

Output Current (A)

Efficiency vs. Output Current

98

96

94

92

90

88

86

Efficiency (%)

84

82

80

78

0.5 1.0 1.6 2.0 2.5 3.0 3.5 4.0 4.6 5.0

Output Current (A)

Vin

Vin

36V

48V

75V

36V

48V

75V

Efficiency vs. Output Current

98

96

94

92

90

88

86

Efficiency (%)

84

82

80

78

0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0

Output Current (A)

Vin

36V

48V

75V

Page 6

vicorpower.com 800-735-6200 V•I Chip Pre-Regulator Module P048F048T24AL Rev. 1.7

Page 6 of 14

PRELIMINARY

Figure 10 — Transient response; PRM alone, 48 Vin, 0 – 5.0 – 0 A

no load capacitance. Local Loop

Figure 12 — PC during fault – frequency will vary as a function of line

voltage.

Output Waveforms

Figure 11 — Transient response; load change from 40 – 80 – 40 A,

at the output of a K=1/24 VTM with no Vf bus capacitance and 100 µF

load capacitance.

Figure 13 — Output ripple full load no bypass capacitance

Figure 9 — VTM output regulation and Vf bus during load step using

VTM with K = 1/24

Figure 14 — Output ripple full load 10µF bypass capacitance

Page 7

vicorpower.com 800-735-6200 V•I Chip Pre-Regulator Module P048F048T24AL Rev. 1.7

Page 7 of 14

PRELIMINARY

Auxiliary Pins (Conditions are at 48 Vin, 48 Vf, full load, and 25°C ambient unless otherwise specified)

Parameter Min Typ Max Unit Note

VC (VTM Control)

Peak voltage 14 V Referenced to –OUT

PC (Primary Control)

DC voltage 4.8 5.0 5.2 Vdc Referenced to –IN

Module disable voltage 2.3 2.4 Vdc Referenced to –IN

Module enable voltage 2.5 2.6 Vdc

Disable hysteresis 100 mV

Source only after start up; not to be used for

Current limit 1.75 1.90 mA aux. supply; 100 kΩ minimum load

impedance to assure start up.

Enable delay time 100 µs

Disable delay time 1 µs

IL (Current Limit Adjust)

Voltage 1 V

Accuracy ± 15 % Based on DC current limit set point

PR (Parallel Port)

Voltage 0.6 7.5 V Referenced to SG

Source current 1 mA

External capacitance 100 pF

VH (Auxiliary Voltage)

Range 8.7 9.0 9.3 Vdc Maximum source = 5 mA, referenced to SG

Regulation 0.04 %/mA

SC (Secondary Control)

Voltage 1.23 1.24 1.25 Vdc Referenced to SG

Internal capacitance 0.1 µF

External capacitance 0.7 µF

OS (Output Set)

Set point accuracy ± 1.5 % Includes 1% external resistor

Reference offset ± 4 mV

CD (Compensation Device)

External resistance 20 Ω Omit resistor for regulation at output of PRM

Parameter Min Typ Max Unit Note

MTBF

MIL-HDBK-217F 2.2 Mhrs 25°C, GB

Agency approvals (pending)

cTÜVus UL/CSA 60950, EN60950

CE Mark Low voltage directive

Mechanical parameters See mechanical drawing, Figure19

Weight 0.5 / 14 oz / g

Dimensions

Length 1.26 / 32 in / mm

Width 0.87 / 22 in / mm

Height 0.25 / 6,2 in / mm

General Specs

Electrical Specifications

(continued) V•I Chip Pre-Regulator Module

Page 8

vicorpower.com 800-735-6200 V•I Chip Pre-Regulator Module P048F048T24AL Rev. 1.7

Page 8 of 14

PRELIMINARY

Pin / Control Functions

V•I Chip Pre-Regulator Module

+IN / -IN DC Voltage Ports

The V•I Chip maximum input voltage should not be exceeded. PRMs

have internal over / undervoltage lockout functions that prevent

operation outside of the specified input range. PRMs will turn on

when the input voltage rises above its undervoltage lockout. If the

input voltage exceeds the overvoltage lockout, PRMs will shut down

until the overvoltage fault clears. PC will toggle indicating an out of

bounds condition.

+OUT / -OUT Factorized Voltage Output Ports

These ports provide the Factorized Bus voltage output. The –OUT port

is connected internally to the –IN port through a current sense resistor.

The PRM has a maximum power and a maximum current rating and is

protected if either rating is exceeded. Do not short –OUT to –IN.

VC – VTM Control

The VTM Control (VC) port supplies an initial V

CC voltage to

downstream VTMs, enabling the VTMs and synchronizing the rise of

the VTM output voltage to that of the PRM. The VC port also provides

feedback to the PRM to compensate for voltage drop due to the VTM

output resistance. The PRM’s VC port should be connected to the VTM

VC port. A PRM VC port can drive a maximum of two (2) VTM VC ports.

PC – Primary Control

The PRM voltage output is enabled when the PC pin is open circuit

(floating). To disable the PRM output voltage, the PC pin is pulled low.

Open collector optocouplers, transistors, or relays can be used to

control the PC pin. When using multiple PRMs in a high power array,

the PC ports must be tied together to synchronize their turn on.

During an abnormal condition the PC pin will pulse (Fig.12) as the

PRM initiates a restart cycle. This will continue until the abnormal

condition is rectified. The PC should not be used as an auxiliary voltage

supply, nor should it be switched at a rate greater than 1 Hz.

TM – Factory Use Only

IL – Current Limit Adjust

The PRM has a preset, maximum, current limit set point. The IL port

may be used to reduce the current limit set point to a lower value. See

“adjusting current limits” on page 10.

PR – Parallel Port

The PR port signal, which is proportional to the PRM output power,

supports current sharing among PRMs. To enable current sharing, PR

ports should be interconnected. Bypass capacitance should be used

when interconnecting PR ports and steps should be taken to minimize

coupling noise into the interconnecting bus. Please consult Vicor

Applications Engineering regarding additional considerations.

VH – Auxiliary Voltage

VH is a gated, non-isolated, nominally 9 Volt, regulated DC voltage

(see “Auxiliary Pins” specifications, on Page 7) that is referenced to

SG. VH may be used to power external circuitry having a total current

consumption of no more than 5 mA.

SC – Secondary Control

The load voltage may be controlled by connecting a resistor or voltage

source to the SC port referenced to SG. The slew rate of the output

voltage may be controlled by controlling the rate-of-rise of the voltage

at the SC port (e.g., to limit inrush current into a capacitive load).

SG – Signal Ground

This port provides a low inductance Kelvin connection to –IN and

should be used as reference for the OS, CD, SC,VH and IL ports.

OS – Output Set

The application-specific value of the Factorized Bus voltage (Vf) is set

by connecting a resistor between OS and SG. Resistor value selection is

shown in Table 1 on Page 2, and described on Page 9. If no resistor is

connected, the PRM output will be approximately one volt. If set

resistor is not collocated with the PRM, a local bypass capacitor of

~200 pF may be required.

CD – Compensation Device

Adaptive Loop control is configured by connecting an external resistor

between the CD port and SG. Selection of an appropriate resistor

value (see Equation 2 on Page 9 and Table 1 on Page 2) configures the

PRM to compensate for voltage drops in the equivalent output

resistance of the VTM and the PRM-VTM distribution bus. If no resistor

is connected to CD, the PRM will be in Local Loop mode and will

regulate the +OUT / –OUT voltage to a fixed value.

Figure 15 — PRM pin configuration

Signal Name Designation

+IN G1-K1,G2-K2

–IN L1-P1, L2-P2

VC A1,A2

PC B1, B2

TM C1, C2

IL D1, D2

PR F1, F2

VH A3, A4

SC B3, B4

SG C3, C4

OS D3, D4

CD F3, F4

+OUT G3-K3, G4-K4

–OUT L3-P3, L4-P4

AL Version

+OUT

–OUT

4 3 2 1

A

VH

B

SC

C

SG

D

OS

E

NC

F

CD

G

H

J

K

L

M

N

P

VC

A

PC

B

TM

C

IL

D

NC

E

PR

F

G

H

+IN

J

K

L

M

–IN

N

P

Bottom View

Page 9

vicorpower.com 800-735-6200 V•I Chip Pre-Regulator Module P048F048T24AL Rev. 1.7

Page 9 of 14

PRELIMINARY

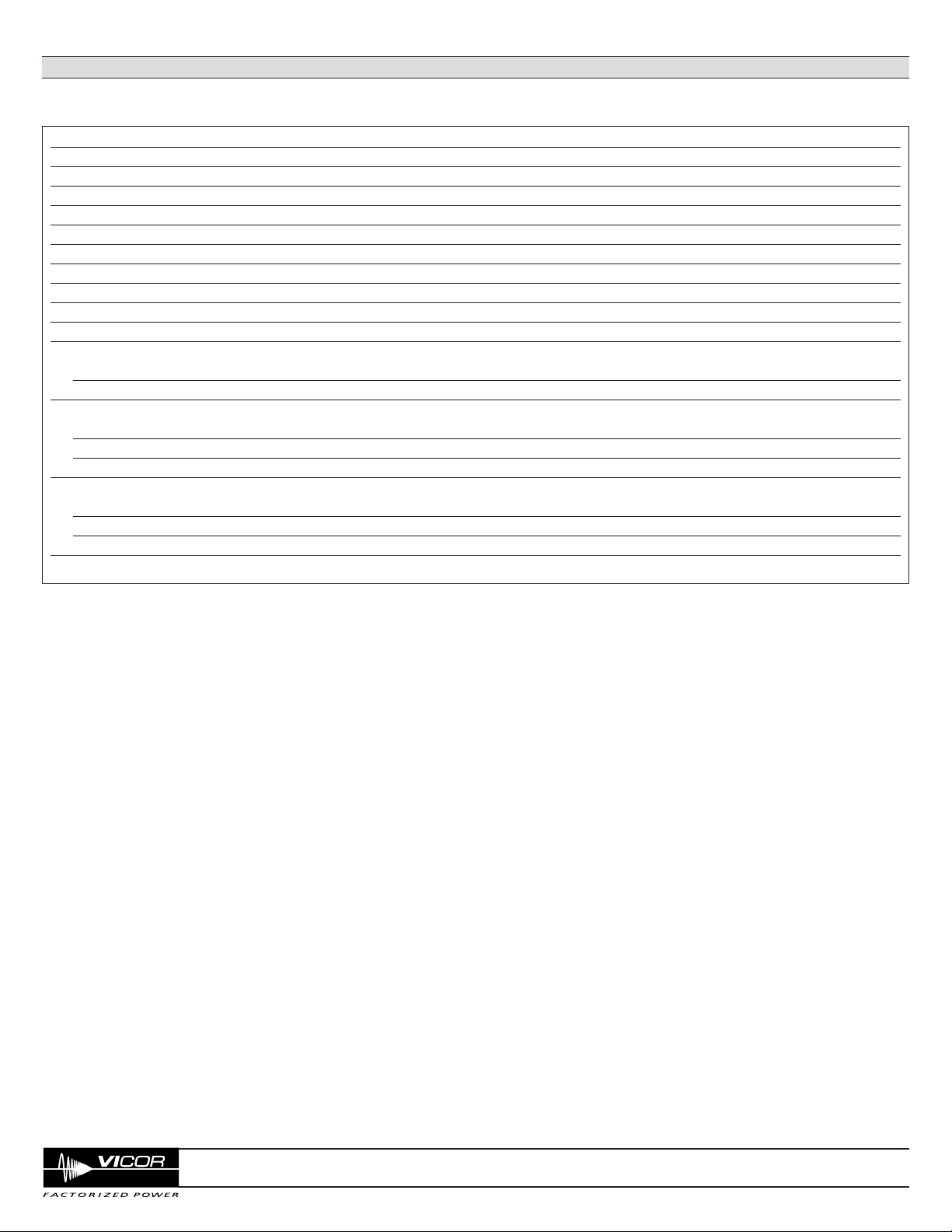

Output Voltage Setting with Adaptive Loop

The equations for calculating R

OS and RCD to set a VTM output

voltage are:

93100

ROS =

(

VL • 0.8395

)

–

1

(1)

K

RCD =

91238

+ 1

(2)

ROS

VL = Desired load voltage

V

OUT = VTM output voltage

K = VTM transformation ratio

(available from appropriate VTM data sheet)

V

f = PRM output voltage, the Factorized Bus (see Figure 16)

R

O = VTM output resistance

(available from appropriate VTM data sheet)

I

L = Load Current

(actual current delivered to the load)

Output Voltage Trimming (optional)

After setting the output voltage from the procedure above the output

may be margined down (26Vf min) by a resistor from SC-SG using this

formula:

RdΩ =

10000 V

fd

Vfs - Vfd

Where Vfd is the desired factorized bus and Vfs is the set factorized bus.

A low voltage source can be applied to the SC port to margin the load

voltage in proportion to the SC reference voltage.

An external capacitor can be added to the SC port as shown in Figure 16

to control the output voltage slew rate for soft start.

Figure 16 — Adaptive Loop compensation with soft start using the SC port.

Nominal Vout VTM

Range (Vdc) K Factor

0.8

↔

1.6 1/32

1.1

↔

2.2 1/24

1.6

↔

3.3 1/16

2.2

↔

4.4 1/12

3.3

↔

6.6 1/8

4.3

↔

8.8 1/6

6.5

↔

13.4 1/4

8.7

↔

17.9 1/3

13.0

↔

26.9 1/2

17.4

↔

36.0 2/3

26.0

↔

54.0 1

Table 2 — 048 input series VTM K factor selection guide

Application Information

V•I Chip Pre-Regulator Module

+Out

–Out

VH

SC

SG

OS

NC

CD

ROS

RCD

Factorized

Bus (Vf)

V

Vf =

K

L

VC

PC

TM

IL

NC

PR

PRM-AL

+In

Vin

–In

VTM

K

Ro

+Out

-Out

+Out

-Out

L

O

A

D

+In

0.4 μH

(

)

I

L•Ro

+

K

TM

VC

PC

-In

Page 10

vicorpower.com 800-735-6200 V•I Chip Pre-Regulator Module P048F048T24AL Rev. 1.7

Page 10 of 14

PRELIMINARY

Application Information

(continued) V•I Chip Pre-Regulator Module

OVP – Overvoltage Protection

The output Overvoltage Protection set point of the P048K048T24AL is

factory preset for 56 V. If this threshold is exceeded the output shuts

down and a restart sequence is initiated, also indicated by PC pulsing.

If the condition that causes OVP is still present, the unit will again shut

down. This cycle will be repeated until the fault condition is removed.

The OVP set point may be set at the factory to meet unique high

voltage requirements.

PRM output power versus VTM output power

As shown in Figure 17, the P048F048T24AL is rated to deliver 5 A

maximum, when it is delivering an output voltage in the range from

26 V to 48 V, and 240 W, maximum, when delivering an output

voltage in the range from 48 V to 55 V. When configuring a PRM for

use with a specific VTM, refer to the appropriate VTM data sheet. The

VTM input power can be calculated by dividing the VTM output power

by the VTM efficiency (available from the VTM data sheet). The input

power required by the VTM should not exceed the output power

rating of the PRM.

The Factorized Bus voltage should not exceed an absolute limit of

55 V, including steady state, ripple and transient conditions. Exceeding

this limit may cause the internal OVP set point to be exceeded.

Parallel considerations

The PR port is used to connect two or more PRMs in parallel to form a

higher power array. When configuring arrays, PR port interconnection

bypass capacitance must be used at ~1nF per PRM. Additionally one

PRM should be designated as the master while all other PRMs are set

as slaves by shorting their SC pin to SG. The PC pins must be directly

connected (no diodes) to assure a uniform start up sequence. The

factorized bus should be connected in parallel as well.

Adjusting current limit

The current limit can be lowered by placing an external resistor

between the I

L and SG ports (see figure 18 for resistor values). With

the I

L port open-circuit, the current limit is preset to be within the

range specified in the output specifications table on Page 4.

Input fuse recommendations

A fuse should be incorporated at the input to the PRM, in series with

the +IN port. A fast acting fuse, NANO2 FUSE 451/453 Series 10 A

125 V, or equivalent, may be required to meet certain safety agency

Conditions of Acceptability. Always ascertain and observe the safety,

regulatory, or other agency specifications that apply to your specific

application.

Product safety considerations

If the input of the PRM is connected to SELV or ELV circuits, the output

of the PRM can be considered SELV or ELV respectively.

If the input of the PRM is connected to a centralized DC power system

where the working or float voltage is above SELV, but less than or

equal to 75 V, the input and output voltage of the PRM should be

classified as a TNV-2 circuit and spaced 1.3 mm from SELV circuitry or

accessible conductive parts according to the requirements of UL60950,

CSA 22.2 60950, EN60950, and IEC60950.

Applications assistance

Please contact Vicor Applications Engineering for assistance,

1-800-927-9474, or email at apps@vicr.com.

Figure 18 — Calculated external resistor value for adjusting current limit,

actual value may vary.

Figure 17 — P048K048T24AL rating based on Factorized Bus voltage

5.1

5.0

4.9

4.8

4.7

4.6

Current (A)

4.5

4.4

4.3

~

~

0

20

22 24

Safe Operating Area

28 32 36 40 44 48 52

26 30

34

38 42

Factorized Bus Voltage (Vf)

46 50

54

56

58

60

100.00

10.00

Resistance (kΩ)

1.00

12345

Desired PRM Output Current Limit (A)

Page 11

vicorpower.com 800-735-6200 V•I Chip Pre-Regulator Module P048F048T24AL Rev. 1.7

Page 11 of 14

PRELIMINARY

Figure 19—PRM J-Lead mechanical outline

Figure 20— PRM J-Lead PCB land layout information

Mechanical Specifications

(continued) V•I Chip Pre-Regulator Module

22,0

0.87

OUTPUT

32,0

1.26

INPUT

TOP VIEW (COMPONENT SIDE)

6,2

0.25

30,00

(2) X

1.181

26,00

(2) X

1.024

22,00

(2) X

0.866

15,55

0.612

0,45

0.020

NOTES:

1- DIMENSIONS ARE .

2- UNLESS OTHERWISE SPECIFIED, TOLERANCES ARE:

.X/[.XX] = +/-0.25/[.01]; .XX/[.XXX] = +/-0.13/[.005]

3- PRODUCT MARKING ON TOP SURFACE

mm

inch

DXF and PDF files are available on vicorpower.com

(2) X

10,00

0.394

3,01

0.118

OUTPUT

15,99

0.630

C

L

BOTTOM VIEW

3,01

0.118

INPUT

C

L

(4) X

(2) X

8,10

0.319

(2) X

20,00

0.787

(12) X

24,00

0.945

1,10

0.043

(2) X

28,00

1.102

28,00

(4) X

1.102

24,00

(4) X

0.945

20,00

(4) X

0.787

(8) X

1,38

0.054

8,48

0.334

3,26

0.128

TYP

15,74

0.620

VC

PC

TM

IL

NC

PR

-IN +IN

RECOMMENDED LAND PATTERN

(COMPONENT SIDE SHOW)

3,26

0.128

0,51

TYP

0.020

VH

SC

SG

OS

NC

CD

+OUT

-OUT

(4) X

10,00

0.394

22,00

(4) X

0.866

15,96

0.628

NOTES:

1- DIMENSIONS ARE .

2- UNLESS OTHERWISE SPECIFIED, TOLERANCES ARE:

.X/[.XX] = +/-0.25/[.01]; .XX/[.XXX] = +/-0.13/[.005]

(4) X

26,00

1.024

(4) X

mm

inch

30,00

1.181

(24) X

1,48

0.058

DXF and PDF files are available on vicorpower.com

Page 12

vicorpower.com 800-735-6200 V•I Chip Pre-Regulator Module P048F048T24AL Rev. 1.7

Page 12 of 14

PRELIMINARY

Configuration Options

V•I Chip Pre-Regulator Module

Configuration

Standard

(1)

Standard with 0.25"

(Figure 21) Heat Sink

(2)

Effective power density 875 W/in

3

437 W/in

3

Effective Junction-Board

2.4 °C/W 2.4 °C/W

thermal resistanc

Effective Junction-Case

1.1 °C/W N/A

thermal resistance

Effective Junction-Ambient

6.8 °C/W 5.0 °C/W

thermal resistance 300LFM

Note:

(1) Surface mounted to a 2" x 2" FR4 board, 4 layers 2 oz Cu

(2) Heat sink available as a separate item

STANDARD MOUNT

22.0

0.87

32.0

1.26

6.3

0.25

Figure 21—Standard mounting – package F

mm

in

Figure 22—Hole location for push pin heatsink relative to VIC

Symbol Parameter Min Typ Max Unit Note

Over temperature shutdown 125 130 135 °C Junction temperature

Thermal capacity 0.61 Ws/°C

RθJC Junction-to-case thermal impedance 1.1 °C/W

RθJB Junction-to-board thermal impedance 2.1 °C/W

RθJA Junction-to-ambient

(1)

6.5 °C/W

RθJA Junction-to-ambient

(2)

5.0 °C/W

Thermal

Notes:

(1) P048F048T24AL surface mounted to a 2" x 2" FR4 board, 4 layers 2 oz Cu, 300 LFM.

(2) P048F048T24AL with a 0.25"H heatsink surface mounted on FR4 board, 300 LFM.

Page 13

vicorpower.com 800-735-6200 V•I Chip Pre-Regulator Module P048F048T24AL Rev. 1.7

Page 13 of 14

PRELIMINARY

V•I Chip soldering recommendations

V•I Chip modules are intended for reflow soldering processes. The

following information defines the processing conditions required for

successful attachment of a V•I Chip to a PCB. Failure to follow the

recommendations provided can result in aesthetic or functional failure

of the module.

Storage

V•I Chip modules are currently rated at MSL 5. Exposure to ambient

conditions for more than 48 hours requires a 24 hour bake at 125ºC

to remove moisture from the package.

Solder paste stencil design

Solder paste is recommended for a number of reasons, including

overcoming minor solder sphere co-planarity issues as well as simpler

integration into overall SMD process.

63/37 SnPb, either no-clean or water-washable, solder paste should be

used. Pb-free development is underway.

The recommended stencil thickness is 6 mils. The apertures should be

20 mils in diameter for the Inboard (BGA) application and 0.9-0.9:1 for

the Onboard (J-Leaded).

Pick and place

Modules should be placed within ±5 mils.to maintain placement

position, the modules should not be subjected to acceleration greater

than 500 in/sec

2

prior to reflow.

Reflow

There are two temperatures critical to the reflow process; the solder

joint temperature and the module’s case temperature. The solder joint’s

temperature should reach at least 220ºC, with a time above liquidus

(183ºC) of ~30 seconds.

The module’s case temperature must not exceed 208 ºC at anytime

during reflow.

Because of the ΔT needed between the pin and the case, a forced-air

convection oven is preferred for reflow soldering. This reflow method

generally transfers heat from the PCB to the solder joint. The module’s

large mass also reduces its temperature rise. Care should be taken to

prevent smaller devices from excessive temperatures. Reflow of

modules onto a PCB using Air-Vac-type equipment is not recommended

due to the high temperature the module will experience.

Inspection

The solder joints should conform to IPC 12.2

• Properly wetted fillet must be evident.

• Heel fillet height must exceed lead thickness plus solder thickness.

Removal and rework

V•I Chip modules can be removed from PCBs using special tools such

as those made by Air-Vac. These tools heat a very localized region of

the board with a hot gas while applying a tensile force to the

component (using vacuum). Prior to component heating and removal,

the entire board should be heated to 80-100ºC to decrease the

component heating time as well as local PCB warping. If there are

adjacent moisture-sensitive components, a 125ºC bake should be used

prior to component removal to prevent popcorning. V•I Chip modules

should not be expected to survive a removal operation.

Figure 22—Thermal profile diagram

Figure 23— Properly reflowed V•I Chip J-Lead

Application Information

V•I Chip Pre-Regulator Module

239

Joint Temperature, 220ºC

183

165

degC

91

16

Soldering Time

Case Temperature, 208ºC

Page 14

vicorpower.com 800-735-6200 V•I Chip Pre-Regulator Module P048F048T24AL Rev. 1.7

11/05

Vicor’s comprehensive line of power solutions includes high density AC-DC

and DC-DC modules and accessory components, fully configurable AC-DC

and DC-DC power supplies, and complete custom power systems.

Information furnished by Vicor is believed to be accurate and reliable. However, no responsibility is assumed by Vicor

for its use. Vicor components are not designed to be used in applications, such as life support systems, wherein a

failure or malfunction could result in injury or death. All sales are subject to Vicor’s Terms and Conditions of Sale,

which are available upon request.

Specifications are subject to change without notice.

Intellectual Property Notice

Vicor and its subsidiaries own Intellectual Property (including issued U.S. and Foreign Patents and pending

patent applications) relating to the products described in this data sheet. Interested parties should contact

Vicor's Intellectual Property Department.

Vicor Corporation

25 Frontage Road

Andover, MA, USA 01810

Tel: 800-735-6200

Fax: 978-475-6715

email

Vicor Express: vicorexp@vicr.com

Technical Support: apps@vicr.com

Warranty

Vicor products are guaranteed for two years from date of shipment against defects in material or workmanship when in

normal use and service. This warranty does not extend to products subjected to misuse, accident, or improper application

or maintenance. Vicor shall not be liable for collateral or consequential damage. This warranty is extended to the original

purchaser only.

EXCEPT FOR THE FOREGOING EXPRESS WARRANTY, VICOR MAKES NO WARRANTY, EXPRESS OR IMPLIED, INCLUDING, BUT

NOT LIMITED TO, THE WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

Vicor will repair or replace defective products in accordance with its own best judgement. For service under this warranty,

the buyer must contact Vicor to obtain a Return Material Authorization (RMA) number and shipping instructions.

Products returned without prior authorization will be returned to the buyer. The buyer will pay all charges incurred in

returning the product to the factory. Vicor will pay all reshipment charges if the product was defective within the terms

of this warranty.

Information published by Vicor has been carefully checked and is believed to be accurate; however, no responsibility is

assumed for inaccuracies. Vicor reserves the right to make changes to any products without further notice to improve

reliability, function, or design. Vicor does not assume any liability arising out of the application or use of any product or

circuit; neither does it convey any license under its patent rights nor the rights of others. Vicor general policy does not

recommend the use of its components in life support applications wherein a failure or malfunction may directly threaten

life or injury. Per Vicor Terms and Conditions of Sale, the user of Vicor components in life support applications assumes

all risks of such use and indemnifies Vicor against all damages.

Loading...

Loading...