Page 1

Design Guide & Applications Manual

For Maxi, Mini, Micro Family DC-DC Converter

and Accessory Modules

Page 2

Table of Contents

Maxi, Mini, Micro Family DC-DC Converters Section Pages

High Density DC-DC Converter Technology 1 2 – 4

Control Pin Functions and Applications 2 5 – 11

Design Requirements 3 12 – 17

EMC Considerations 4 18 – 19

Current Sharing in Power Arrays 5 20 – 24

Thermal Performance Information 6 25 – 30

Accessory Modules

Autoranging Rectifier Module (ARM) 7 31 – 35

Filter / Autoranging Rectifier Module (FARM) 8 36 – 40

Modular AC Front-end System (ENMod) 9 41 – 47

High Boost HAM 10 48 – 52

Filter Input Attenuator Module (FIAM) Family 11 53 – 55

Output Ripple Attenuator Module (MicroRAM) 12 56 – 61

Recommended Soldering Methods

Lead Free Pins (RoHS) 13 62 – 66

TIn Lead Pins 14 67 – 71

Mounting Options

Surface Mount Socketing System (SurfMate) 15 72 – 75

Through-hole Socket-mount System (InMate) 16 76 – 79

Glossary of Technical Terms 17 80 – 87

Maxi, Mini, Micro Design Guide Rev 4.9 vicorpower.com

Page 1 of 88

Apps. Eng. 800 927.9474 800 735.6200

Page 3

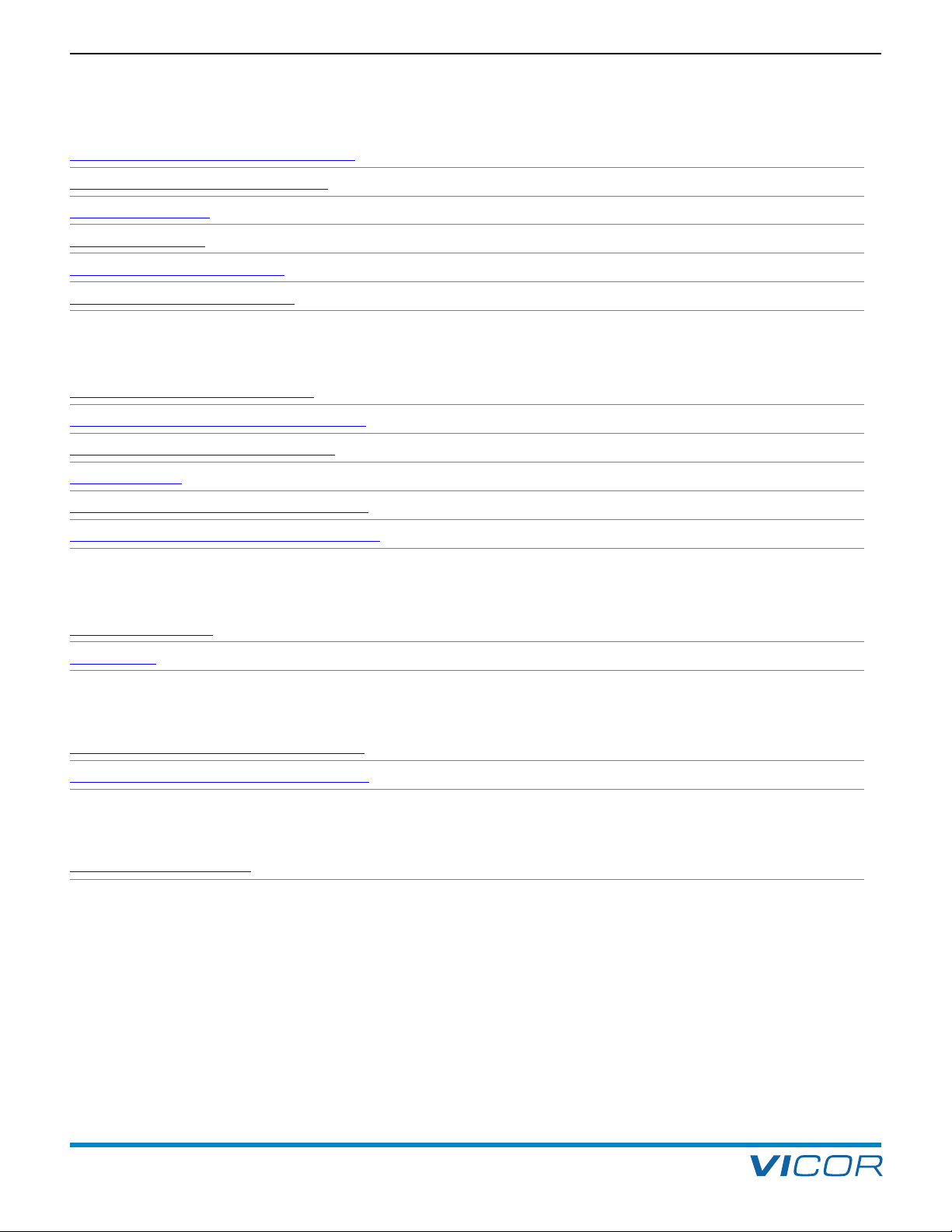

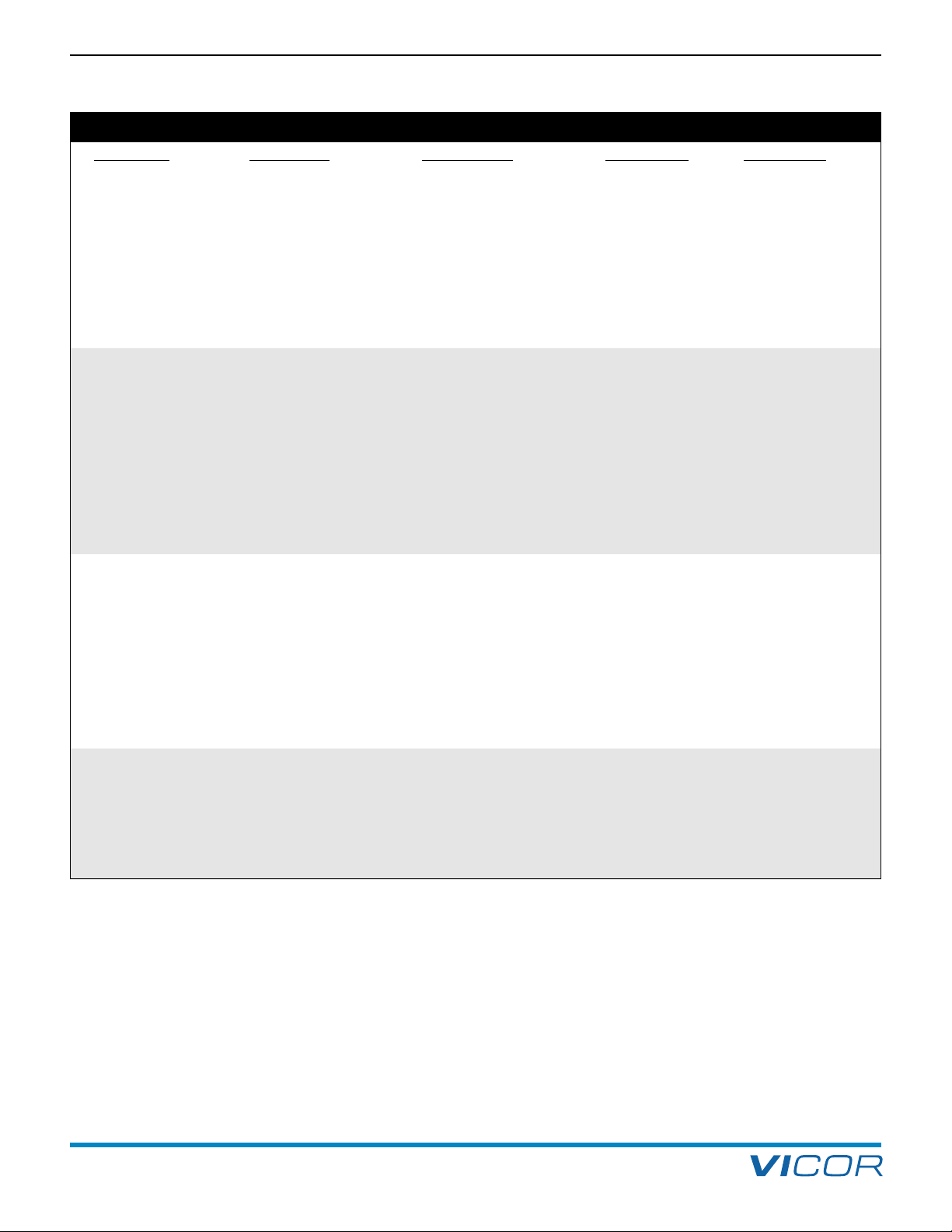

1. High Density DC-DC Converter Technology

AC-DC Products

DC-DC Products

Universal

85 – 264 Vac

Autoranging

90 – 132 Vac

180 – 264 Vac

Autoranging

90 – 132 Vac

180 – 264 Vac

Autoranging

115 – 230 Vac

Input

Nominal Input

18 – 425 Vdc

28 Vdc, 48 Vdc,

270 Vdc

24 Vdc, 28 Vdc,

48 Vdc

Harmonic Attenuator Module

Unity Power Factor

Up to 675 W

per module

Filter / Autoranging Rectifier Module

Up to 1,000 W

Autoranging Rectifier Module

Up to 1,500 W

Front-end System

for EN Compliance

Up to 550 W

Transient Protection,

Inrush Current Limiting EMI Filter

Up to 25 A

Active EMI Filter

Up to 576 W @ 48 V

DC-DC Converter

Up to 600 W per module

1 – 54 Vdc

M

INIHAM

FARM3

QPI

DC-DC Converter

Up to 300 W per module

1 – 48 Vdc

DC-DC Converter

Up to 150 W per module

1 – 48 Vdc

Single wire paralleling for

high power, fault tolerant arrays.

Output Ripple Attenuation Module

combines active and passive filtering.

QPO provides active filtering to

achieve differential noise attenuation.

QPO

DC-DC Products

High Boost

HAM

or Maxi, Mini, Micro Family DC-DC Converters and Configurable Power Supplies

Design Guide & Applications Manual

F

The Maxi, Mini, Micro Family of DC-DC converters are an

integral part of the company’s overall component power

solution strategy, (Figure 1–1), which includes advanced

actory and design automation. The modules are available

f

in an unlimited variety of standard versions, to the extent

hat the line between custom and standard DC-DC

t

converter bricks becomes almost indistinguishable.

The design of the control, magnetic, switching, and

packaging elements of the module resulted in a

component with a power density of up to 120 W/in

3

(7,3 W/cm3) in three package sizes:

Maxi 4.6" x 2.2" x 0.5" (117 x 55,9 x 12,7 mm)

Mini 2.28" x 2.2" x 0.5"(57,9 x 55,9 x 12,7 mm)

Micro 2.28" x 1.45" x 0.5"(57,9 x 36,8 x 12,7 mm)

The modules have one-third the number of parts of their

predecessors.

While the natural by-products of this reduction in parts

count has improved reliability and lower cost, the extra

space also means that the bulk of the converter can now

be devoted almost exclusively to the power train (i.e., the

magnetic and switching elements at the core of the design).

Resistors can be used to trim the output voltage up or

down, if necessary. Six pin styles, three baseplate options,

and a variety of data collection and reporting options are

available. The devices have an operating temperature

range of –55°C to 100°C and come in five product

grades – E, C, T, H, and M.

Other specifications include a typical no-load to full-load

regulation of ±0.5%, a programmable output of 10% to

110%, conversion efficiencies of up to 92% depending

on the voltage combination and power level chosen, and

an input-to-output isolation test voltage of 3,000 Vrms

(4,242 Vdc). All models are parallelable with N+M fault

tolerance and current sharing. Paralleling architectures

feature DC or AC-coupled interface.

Figure 1–1 — Component power solutions with the Maxi, Mini, Micro Family

Maxi, Mini, Micro Design Guide Rev 4.9 vicorpower.com

Page 2 of 88

Apps. Eng. 800 927.9474 800 735.6200

Page 4

Design Guide & Applications Manual

or Maxi, Mini, Micro Family DC-DC Converters and Configurable Power Supplies

F

1. High Density DC-DC Converter Technology

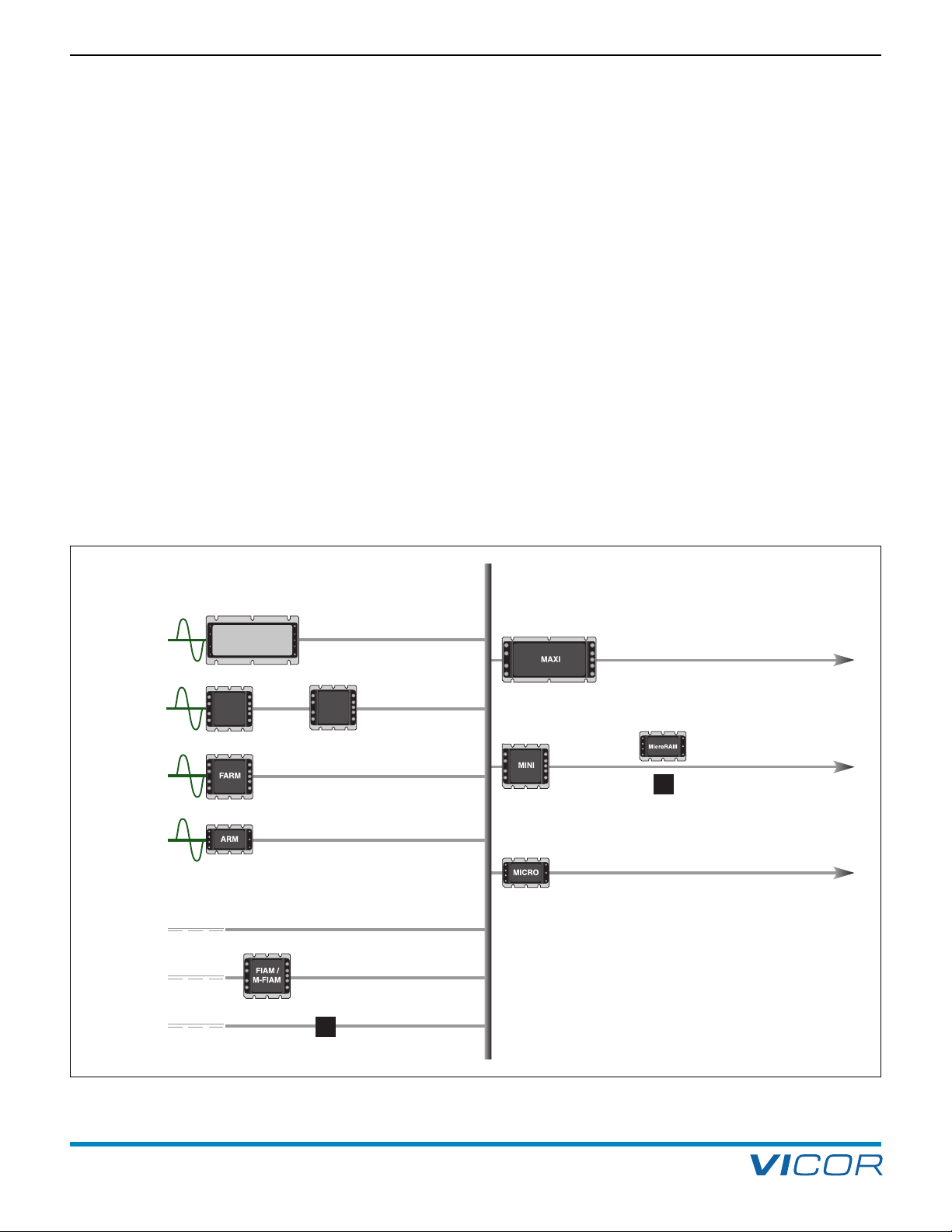

Key to the design of Maxi, Mini, Micro converters is its

high level of component-level integration. (Figure 1–2)

With the aid of hybrid technology, the device packs all

ontrol functions and active circuitry into two (primary

c

and secondary side) ICs occupying a total volume of less

han 1/10 in

t

3

(

1,6 cm

3

each.

)

With Maxi, Mini, Micro devices, the plated-cavity transformer cores use copper armor, plated onto the ferrite

core, to more closely confine the magnetic flux to couple

widely separated primary and secondary windings. The

wider separation provides greater isolation and therefore

lowers input-to-output parasitic capacitance and noise.

The plated cavity also serves to conduct heat away from

the transformer to the baseplate, thus increasing the

power-handling capability of the power train and minimizing temperature rise.

The power-train assembly is contained between the

baseplate and a terminal-block assembly, with input and

output pins recessed. This allows the converter body to be

mounted into an aperture in the PCB to reduce the height

above board. The modules may be wave soldered or

lugged into through-hole or surface-mount sockets.

p

The Maxi, Mini, Micro devices use a proprietary, low-noise,

integrated power device that has an order of magnitude

lower parasitic effect.

The advances made in the overall design of the Maxi,

Mini, Micro Family DC-DC converters have been complemented by equally significant advances in the technology

used to manufacture them. Vicor invested in a custom,

fully-automated assembly line specifically designed for the

assembly of Maxi, Mini, Micro power components. To

further augment its Maxi, Mini, Micro product offering,

Vicor has created an online user-interface tool,

PowerBenchTM, that allows customers to specify DC-DC

module requirements anytime, anywhere via the internet.

Bottom View

• Standard MLP power devices

• Efficient pick-and-place assembly

Top View

• Surface mount components for greater

manufacturing efficiency

• Standard reflow process

Figure 1–2 — Maxi assembly shows high level of integration.

Maxi, Mini, Micro Design Guide Rev 4.9 vicorpower.com

Page 3 of 88

Apps. Eng. 800 927.9474 800 735.6200

Baseplate

• Simplified baseplate construction

Serial No. & Date Code

Complete Assembly

• Insert molded terminal block for more

accurate pin positioning

• One piece cover with label

• Encapsulated for superior thermal performance

Model Number

Page 5

1. High Density DC-DC Converter Technology

+ OUT

+ SENSE*

SC

– OUT

– SENSE*

+ IN

PC

PR

– IN

Primary Control IC

Secondary Control IC

or Maxi, Mini, Micro Family DC-DC Converters and Configurable Power Supplies

F

Design Guide & Applications Manual

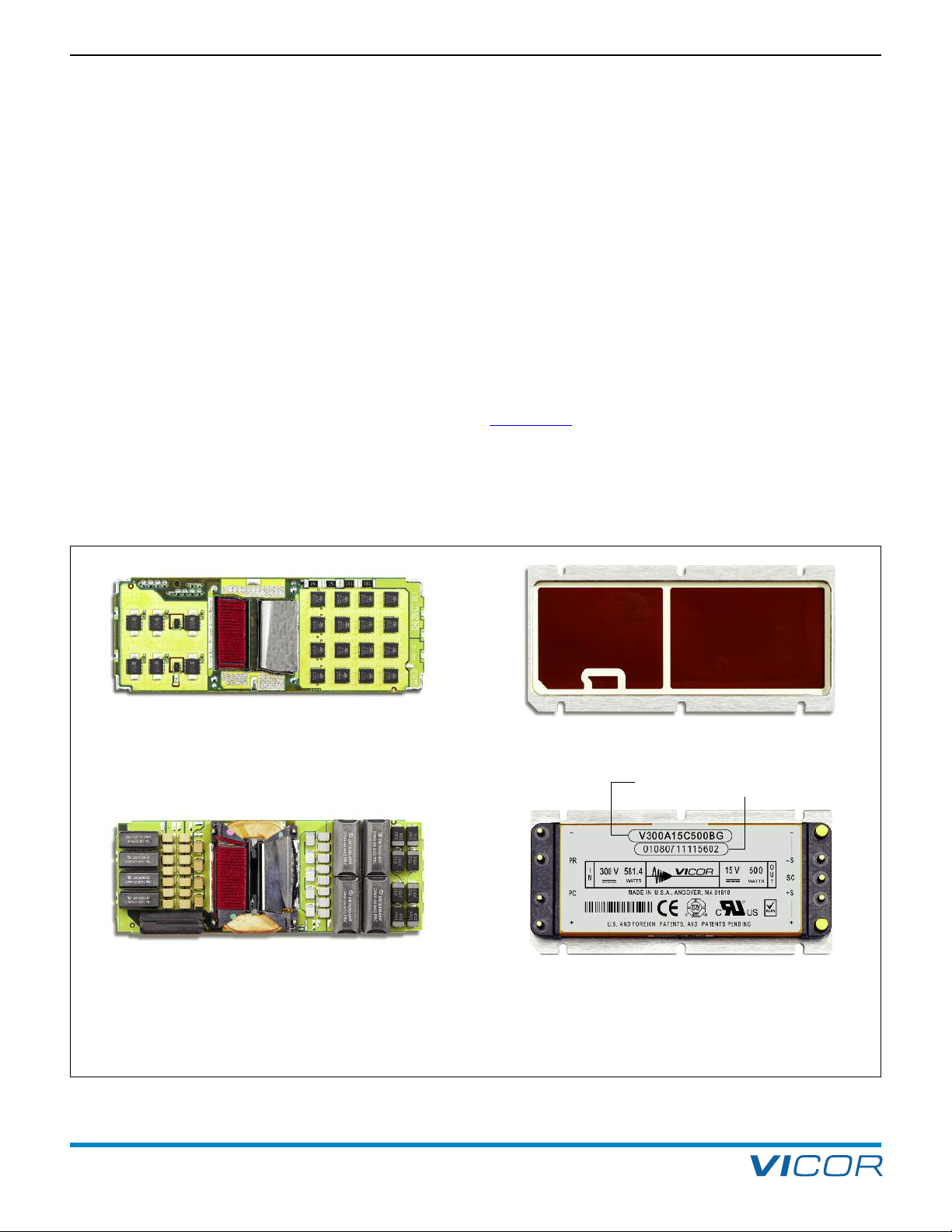

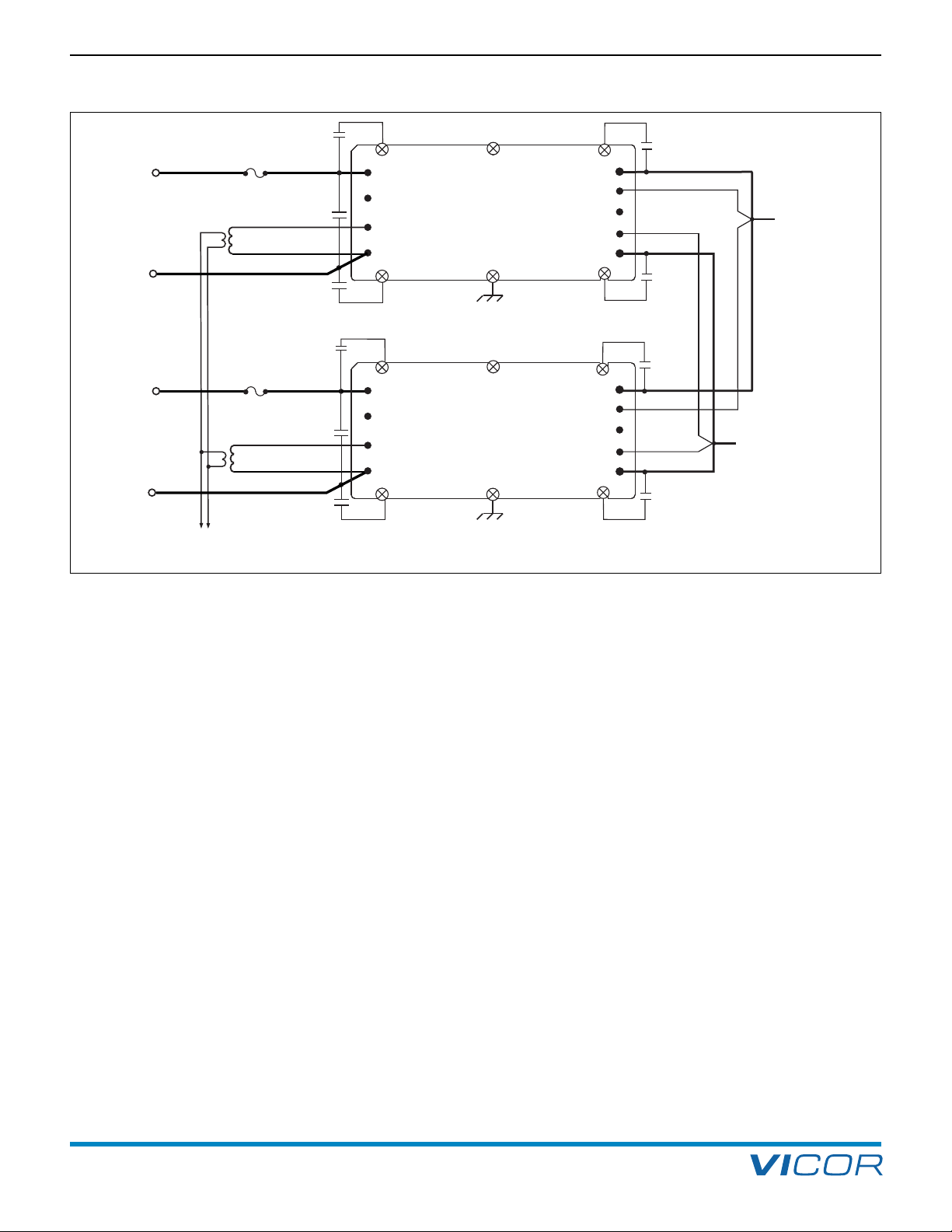

The Maxi, Mini, Micro’s ZCS / ZVS power-processing

architecture (Figure 1–3) enables efficient, low-noise,

high-frequency operation. The main switch is common

rain for improved thermal and noise management,

d

the reset switch located within the primary control IC

s common source for ease of control.

i

The control circuitry is integrated into two (primary and

secondary side) ICs. The result is a significant reduction in

parts with the ensuing savings in cost and increase in

reliability. This integration also provides extra room for

the power train.

Maxi, Mini, Micro transformers place the primary and

secondary windings far apart, but contain the magnetic

flux using a copper armor plated onto the ferrite core.

The armor also conducts excess heat to the baseplate.

Figure 1–3 — Maxi, Mini, Micro: Basic power train and control (*Not included in Micro family)

Maxi, Mini, Micro Design Guide Rev 4.9 vicorpower.com

Page 4 of 88

Apps. Eng. 800 927.9474 800 735.6200

Page 6

Design Guide & Applications Manual

+IN

PC

PR

–IN

4 kΩ

"Module

Enabled"

+IN

PC

PR

–IN

Disable

Disable = PC <2.3 V

+OUT

+S

SC

–S

– O U T

+IN

PC

PR

–IN

Input Undervoltage

2-20 ms typ.

f

(V

IN

)

Auto

Restart

5.7 Vdc

(0-3 mA)

50 Ω

SW2

SW3

1.23

Vdc

6 K

1 K

SW1

S

W1, 2, & 3

shown in

"Fault" position

Input Overvoltage (See Note 1)

Overtemperature

Module Faults

1

Not applicable for 300 Vdc input family

1 M

Input Undervoltage

Input Overvoltage

[a]

Over Temperature

Module Faults

2-20 ms typ.

f(VIN)

Auto

Restart

5.7 Vdc

(0-3 mA)

50 Ω

SW2

SW3

1.23

Vdc

6 K

1 K

SW1

SW1, 2, & 3 shown

in "Fault" position

+OUT

SC

–OUT

+IN

PC

PR

–IN

[a]

Not applicable for 300 Vdc Input family

1 M

or Maxi, Mini, Micro Family DC-DC Converters and Configurable Power Supplies

F

PRIMARY CONTROL (PC PIN)

2. Control Pin Functions and Applications

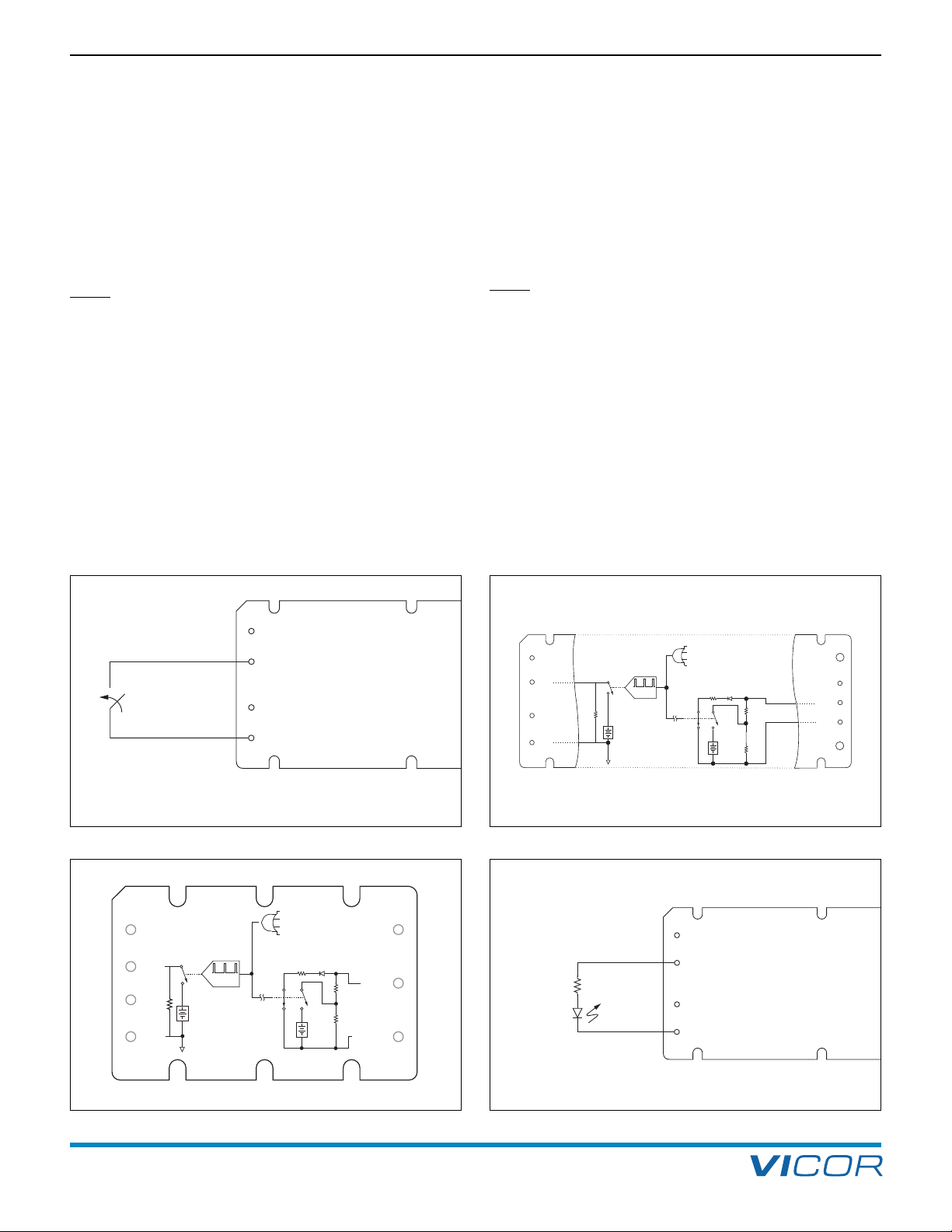

Module Enable / Disable. The module can be disabled

y pulling the PC below 2.3 V with respect to the –Input.

b

This should be done with an open-collector transistor,

relay, or optocoupler. Multiple converters may be disabled

with a single transistor or relay via “ORing” diodes. When

using a mechanical switch or relay to control the PC pin,

please ensure that the contacts are properly debounced

with a capacitor (10 nF max.) to avoid switch bounce.

: Do not exceed a repetitive on / off rate of

NOTE

1 Hz to the PC pin or input voltage pins.

An optocoupler must be used when converters are located

on different PC boards, when a common-mode inductor

is used directly at the module input, or when the distance

between the converters would cause excessive voltage

drops. Under no circumstances should the PC pin be

pulled negative more than a diode drop below the module

–IN. (Figure 2–1) When the PC pin is pulled low the PC

current will pulse similar to the PC voltage shown in

Figure 2–4. When the outputs of two or more converters

are connected in a parallel array to increase system power

the converters should be “group enabled” to ensure that

all the converters start at the same time. The PC pins of all

converters in the array should be controlled by an external

circuit which will enable the converters once the input

oltage is within the normal operating range.

v

Primary Auxiliary Supply. At 5.75 V, the PC can source

p to 1.5 mA. In the example shown in Figure 2–3, PC

u

powers a LED to indicate the module is enabled.

Another example of an isolated on-state indicator is

shown in Figure 2–5.

NOTE

: When the module has detected a fault or

when the input voltage is above or below the

normal operating range the PC voltage will pulse.

Module Alarm. The module contains “watchdog” circuitry

that monitors input voltage, operating temperature, and

internal operating parameters. (Figures 2–2a and 2–2b) If

any of these parameters is outside their allowable

operating range, the module will shut down and PC will

go low. (Figure 2–4) Then PC will periodically go high and

the module will check to see if the fault (as an example,

input undervoltage) has cleared. If the fault has not been

cleared, PC will go low again and the cycle will restart.

The SC pin will go low when a fault occurs and return to

its normal state after the fault has been cleared. An example

of using a comparator for monitoring on the secondary is

shown in Figures 2–6a and 2–6b.

Figure 2–1 — Module Enable / Disable

Figure 2–2b — PC and SC module alarm logic (Micro)

Maxi, Mini, Micro Design Guide Rev 4.9 vicorpower.com

Page 5 of 88

Figure 2–2a — PC and SC module alarm logic (Maxi / Mini)

Apps. Eng. 800 927.9474 800 735.6200

Figure 2–3 — LED on-state indicator

Page 7

2. Control Pin Functions and Applications

+IN

PC

PR

–IN

Optocoupler

4 kΩ

Alarm

1.00V

+OUT

+

S

SC

–S

–OUT

C

omparator

Alarm

1.0 0 V

+OUT

SC

–OUT

+IN

PC

PR

–IN

Comparator

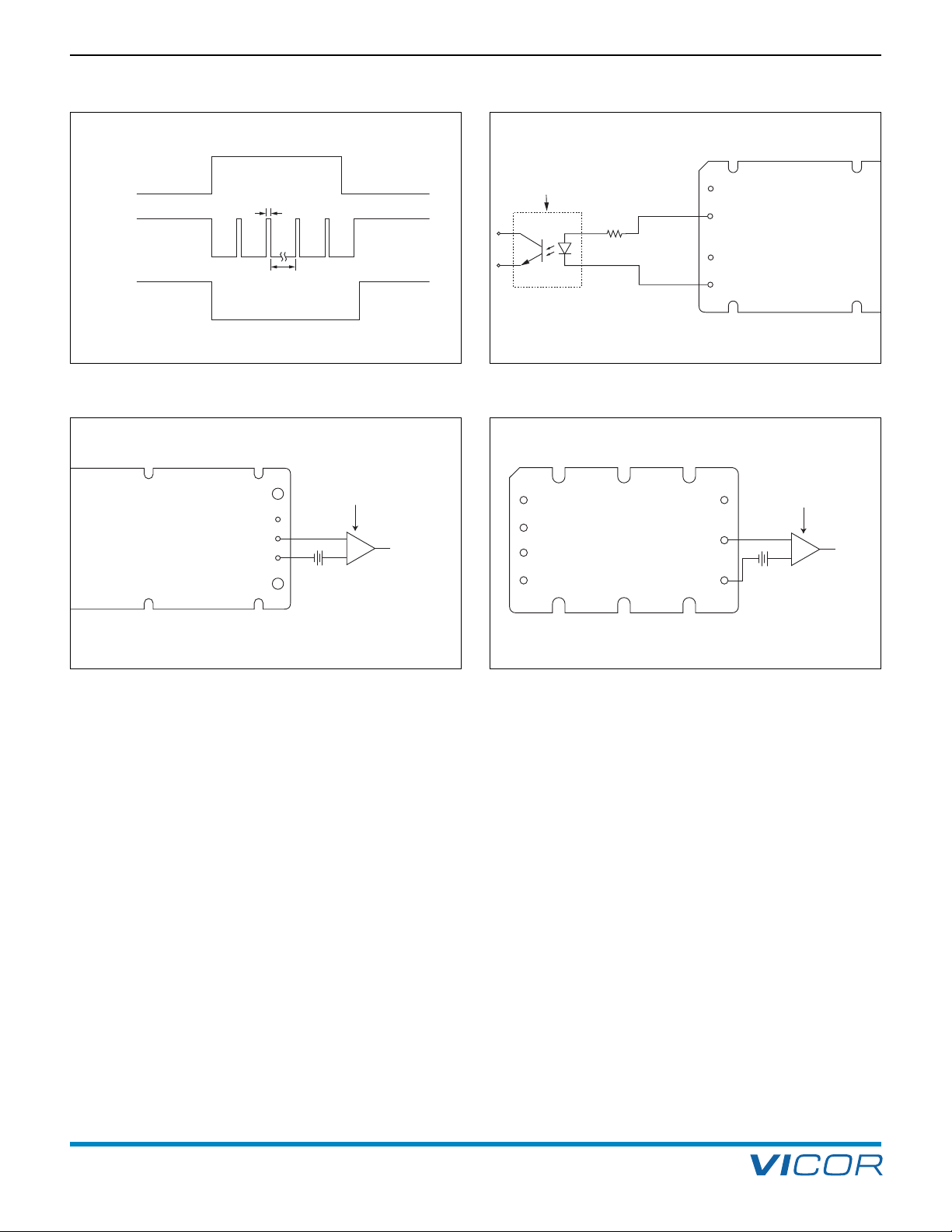

2–20 ms typ.

Fault

SC

PC

1.23 V

5.7 V

4

0 μs typ.

or Maxi, Mini, Micro Family DC-DC Converters and Configurable Power Supplies

F

Design Guide & Applications Manual

Figure 2–4 — PC / SC module alarm timing Figure 2–5 — Isolated on-state indicator

Figure 2–6a — Secondary side on-state (Maxi / Mini) Figure 2–6b — Secondary side on-state (Micro)

PARALLEL BUS (PR PIN)

A unique feature has been designed into Vicor Maxi, Mini,

Micro converter modules that facilitates parallel operation

for power expansion or redundancy. The PR pin is a bidirectional port that transmits and receives information

between modules. The pulse signal on the parallel (PR)

bus serves to synchronize the high-frequency switching of

each converter which in turn forces them to load share.

These modules possess the ability to arbitrate the leadership role; i.e., a democratic array. The module that

assumes command transmits the sync pulse on the parallel

bus while all other modules on the bus listen. In the event

of a failure of the lead module, the array “elects” a new

leader with no interruption of the output power.

Connection methods for the PR bus include:

1. AC-coupled single-wire interface: All PR pins are

connected to a single communication bus through

0.001 µF (500 V) capacitors. This interface supports

current sharing and is fault tolerant except for the

communication bus. (Figure 2–7) This method may

normally be used with a maximum of three converters.

2. Transformer-coupled interface: Modules or arrays of

modules may also be interfaced to share a load while

providing galvanic isolation between PR pins via a

transformer-coupled interface. For large arrays,

buffering may be required. The power source for the

buffer circuit may be derived from the PC pins. For

arrays of four or more modules, the transformer

coupled interface is recommended. (Figure 2–8)

Maxi, Mini, Micro Design Guide Rev 4.9 vicorpower.com

Page 6 of 88

Apps. Eng. 800 927.9474 800 735.6200

Page 8

Design Guide & Applications Manual

+IN

PC

PR

–IN

+IN

PC

PR

–IN

Module 2

Module 1

+

Parallel

Bus

–

0.2 µF

0.001 µF

0.2 µF

0.001 µF

Low inductance

ground plane

or bus

4.7 nF

4.7 nF

4.7 nF

4.7 nF

Z1*

Z1*

+IN

PC

PR

–IN

+IN

PC

PR

–IN

Module 2

Module 1

T1

T2

+

–

0.2 µF

0.2 µF

Parallel

Bus

4.7 nF

4.7 nF

4.7 nF

4.7 nF

Z1*

Z1*

or Maxi, Mini, Micro Family DC-DC Converters and Configurable Power Supplies

F

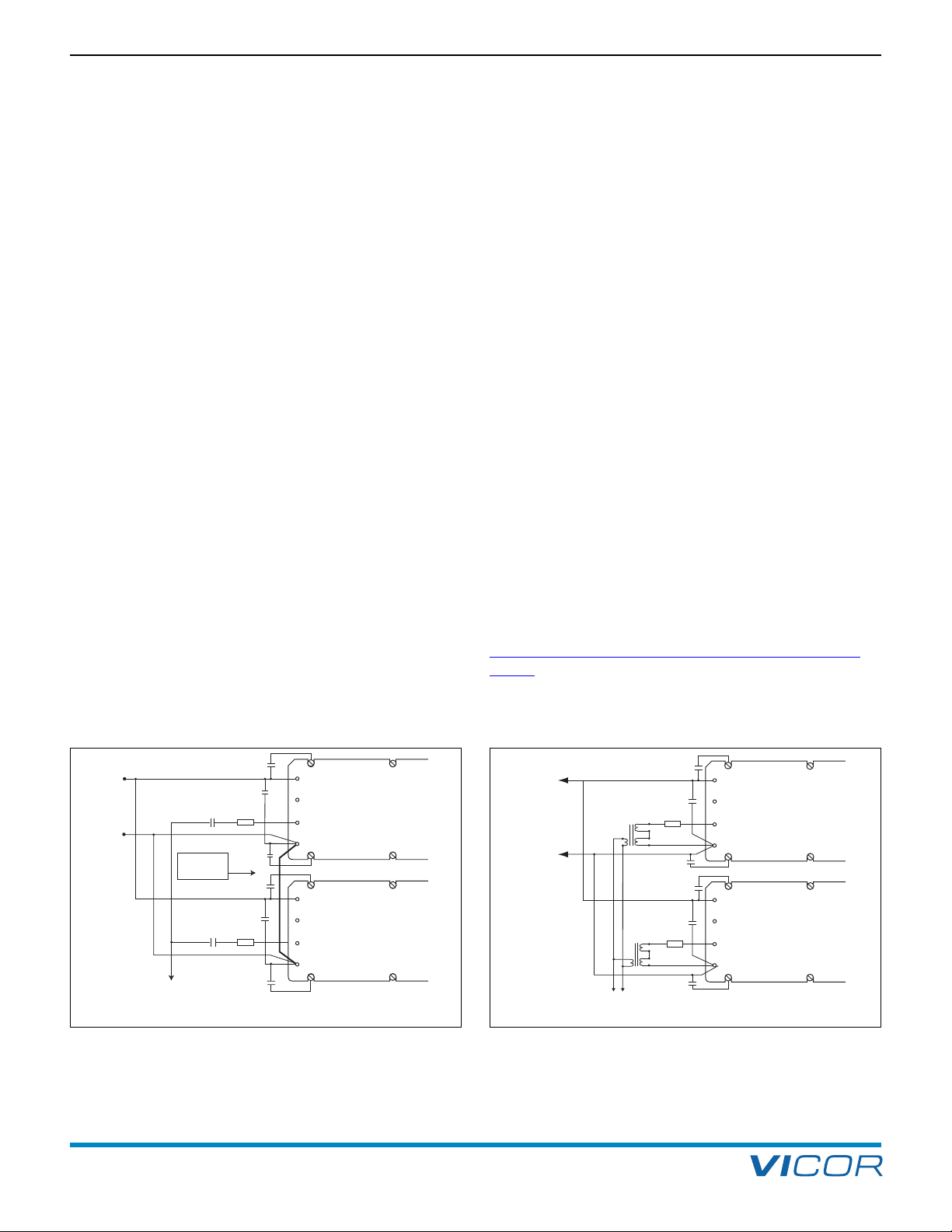

PARALLEL OPERATION CONSIDERATIONS

2. Control Pin Functions and Applications

are must be taken to avoid introducing interfering signals

C

(noise) onto the parallel bus that may prevent proper load

sharing between modules, instability, or module failure.

One possible source of interference is input ripple current

onducted via the + and –Input power pins. The PR signal

c

and DC power input share a common return, which is the

–Input pin. Steps should be taken to decouple AC components of input current from the parallel bus. The input to

each converter (designated as + and – pins on the input

side of the module) should be bypassed locally with a

0.2 µF ceramic or film capacitor. This provides a shunt

path for high frequency input ripple current. A Y-rated

4,700 pF capacitor should be connected between both

the + and –Input pins and baseplate of each module, thus

creating a shunt path for common-mode components of

current. Attention to the PC board artwork should minimize

the parasitic impedance between –Input pins of parallel

modules to ensure that all PR pins are referenced to the

same potential, or use a transformer coupled interface.

Modules should be placed physically close to each other

and wide copper traces (0.75 in./19 mm, 2 oz. copper)

should be used to connect power input pins. A dedicated

layer of copper is the ideal solution.

Some applications require physical separation of paralleled

modules on different boards, and/or input power from

separate sources. For applications using separate sources,

please refer to the “Hot-Swap Capability Eliminates

Downtime” application note on Vicor’s website. In these

cases, transformer coupling of the PR signal, per Figure 2–8,

is required to prevent inter-module common-mode noise

rom interfering with the sync pulse transmission. High-

f

speed buffering may be required with large arrays or if the

distance between modules is greater than a few inches.

This is due to the fact that all modules, except the one

hat’s talking, are in the listening mode. Each listener

t

presents a load to the master (talker), which is approximately 500 Ω shunted by 30 pF capacitance. Long leads

for the interconnection introduce losses and parasitic

reactance on the bus, which can attenuate and distort the

sync pulse signal. The bandwidth of the bus must be at

least 60 MHz and the signal attenuation less than 2 dB.

In most cases, transformer coupling without buffering is

adequate. Many applications may benefit from the addition

of Z1, in series with the PR Pin of each converter. A low Q 33 Ω

@ 100 Mhz ferrite bead or a 5 - 15 Ohm resistor may be

used to improve the PR signal waveform. Although this is

not a requirement, it can be very helpful during the debug

stage of large converter arrays to help improve the PR

pulse wave shape and reduce reflections. Again, careful

attention must be given to layout considerations. When

the outputs of two or more converters are connected in a

parallel array to increase system power the converters

should be “group enabled” to ensure that all the converters start at the same time. The PC pins of all converters in

the array should be controlled by an external circuit which

will enable the converters once the input voltage is within

the normal operating range. Please consult with

Applications Engineering at any Vicor Technical Support

Center for additional information.

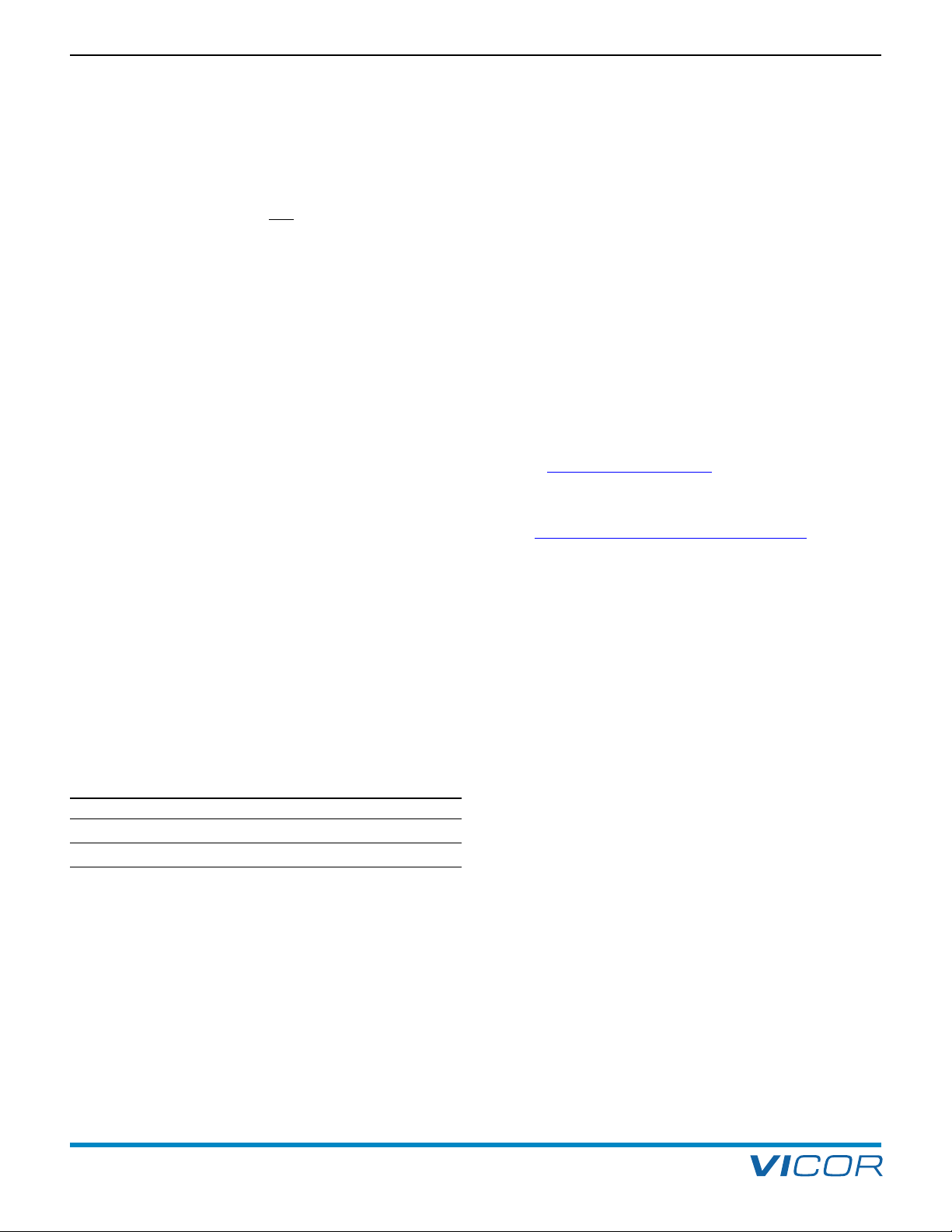

Figure 2–8 — Transformer-coupled interface

Apps. Eng. 800 927.9474 800 735.6200

Figure 2–7 — AC coupled single-wire interface

Maxi, Mini, Micro Design Guide Rev 4.9 vicorpower.com

Page 7 of 88

Page 9

2. Control Pin Functions and Applications

Module 2

Module 1

Module N+1

+OUT

+S

SC

–S

–OUT

Load

+S

–

S

+S

–S

+S

–S

+OUT

+S

SC

–S

–OUT

+OUT

+S

SC

–S

–OUT

+OUT

+S

SC

–S

–OUT

+Sense from

other modules

in the array

+OUT

SC

–OUT

L

O

A

D

Plane

Ground

Plane

Module #1

Designated

Master

Module #2

trimmed

down 2 %

Module #3

trimmed

down 4 %

+OUT

SC

–OUT

+OUT

SC

–OUT

CONTROL FUNCTIONS AND OUTPUT CONSIDERATIONS

or Maxi, Mini, Micro Family DC-DC Converters and Configurable Power Supplies

Design Guide & Applications Manual

F

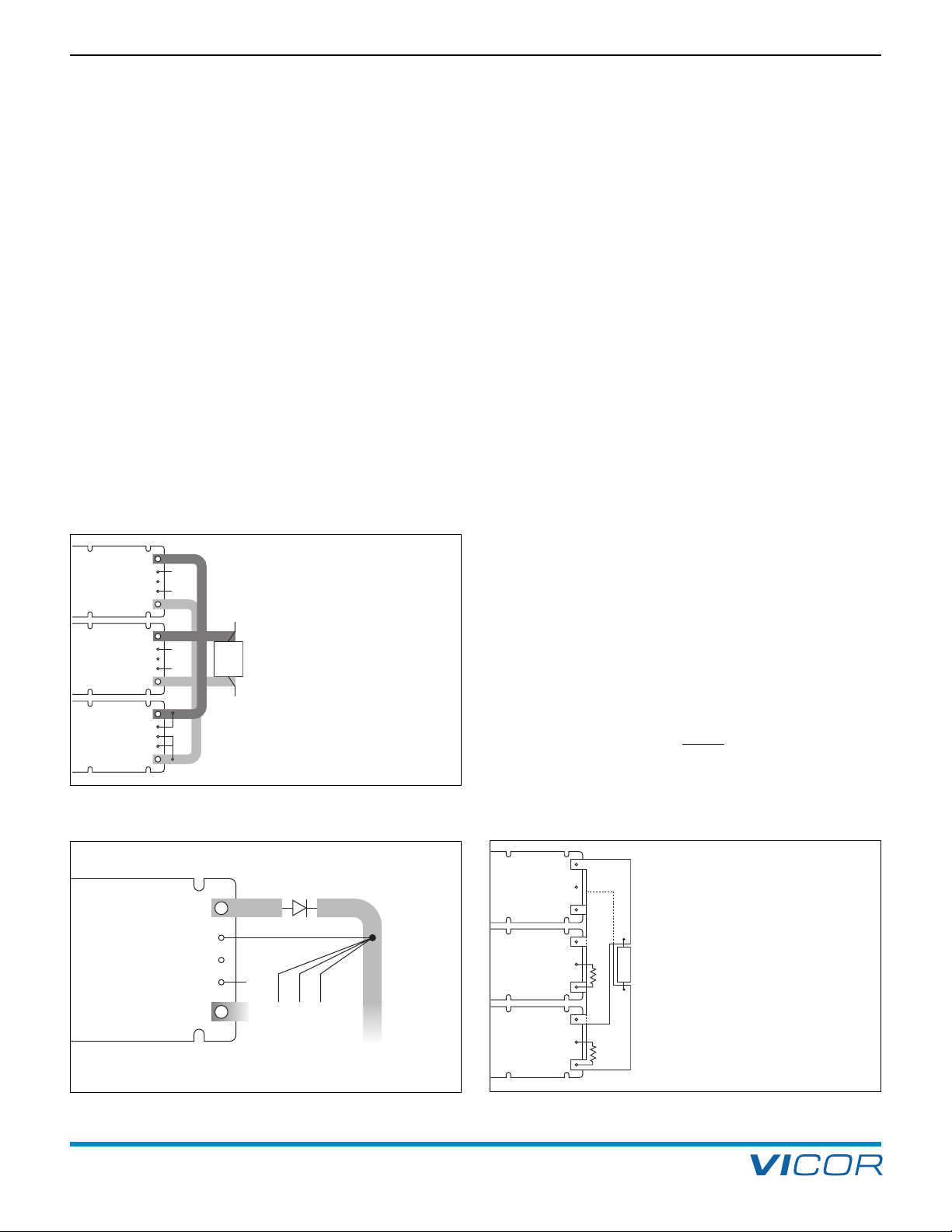

arallel Operation (PR Pin). The PR pin supports paral-

P

leling for increased power with N+1or N+M redundancy.

Modules of the same part number will current share if all

PR pins are suitably interfaced. Figures 2–9 and 2–10

how connections for the Maxi and Mini modules; Figure

s

2–11 shows connections for Micro array. Applications

containing two or more Micro modules must define a

designated master (talker) by stagger trimming the output

voltage of each subsequent module down by at least 2%,

or setting the remaining Micro modules in the system as

designated listeners by connecting the SC pin to the

negative output pin.

PR Pin Considerations. When paralleling modules, it is

important that the PR signal is communicated to all

modules within the parallel array. Modules that do not

receive a PR pulse in a parallel array will not current share

and may be damaged by running in an over-power

condition.

The +Out and –Out power buses

•

hould be designed to minimize and

s

balance parasitic impedance from

each module output to the load.

• The +Sense pins should be tied to the same

point on the +Out power bus; (Figure 2-10)

the –Sense pins should be tied to the same

point on the –Out power bus.

• At the discretion of the power system

designer, a subset of all modules within

an array may be configured as slaves

by shorting SC to –S.

• ORing diodes may be inserted in series

with the +OUT pins of each module to

provide module output fault tolerance.

Figure 2–9 — N+1 module array output connections (Maxi and Mini)

ll modules in an array must be of the same part

A

number.Series connection of outputs is accomplished

without connecting the PR pins and allowing each module

to regulate its own output voltage. Since the same current

asses through the output of each module with the series

p

connection, power sharing is inherent. Series connection

of inputs requires special precautions, please contact

Applications Engineering for assistance.

Array Output Overvoltage Protection (OVP). In order

to maintain the highest possible uptime of a parallel array

the converters use an output overvoltage protection

system (OVP) that is highly resistant to false tripping. For

the converter to shut down due to an OVP condition two

conditions must be satisfied (logical AND);

1. The voltage at the output terminals must be greater

than the OVP set point.

2. The secondary control IC within the converter must be

requesting a power conversion cycle from the internal

primary control IC.

By using this logic, false tripping of individual converters

due to externally induced OVP conditions such as load

dumps or, being driven by an external voltage source at

the output terminals is minimized.

Modules connected in a parallel array rely on the active

master module for OVP of the entire array. Modules acting

as boosters (slaves) in the array are receiving external

requests for power conversion cycles (PR pulse) and will

not shut down from an OVP condition. Therefore it is

imperative that the + and -Output pins of modules

connected in a parallel array never

be allowed to become

open circuited from the output bus. An open circuit at the

output terminals will result in terminal voltages far in

excess of the normal rating causing permanent damage

to the module and possible hazardous conditions.

Figure 2–10 — ORing diodes connections (Maxi and Mini)

Maxi, Mini, Micro Design Guide Rev 4.9 vicorpower.com

Page 8 of 88

Figure 2–11 — Parallel module array output connections (Micro)

Apps. Eng. 800 927.9474 800 735.6200

• The +Out and –Out power buses should

be designed to minimize and balance

parasitic impedance from each module

output to the load.

• At the discretion of the power system

designer, a subset of all modules within

an array may be configured as slaves

by shorting SC to –Out.

• Do not use output ORing diodes

with parallel arrays of the Micro.

Page 10

Design Guide & Applications Manual

or Maxi, Mini, Micro Family DC-DC Converters and Configurable Power Supplies

F

CONTROL FUNCTIONS, SECONDARY CONTROL (SC PIN)

utput Voltage Programming. The output voltage of

O

the converter can be adjusted or programmed via fixed

resistors, potentiometers or DACs.

Trim Down. The converter is not

a constant power

device; it has a constant current limit. Hence, available

output power is reduced by the same percentage that

output voltage is trimmed down. Do not exceed maximum

rated output current. The trim down resistor must be

connected to the –S pin (–Out pin on a Micro). (Figures

2–12a and 2–12b)

Trim Up. The converter is rated for a maximum delivered

power. To ensure that maximum rated power is not

exceeded, reduce maximum output current requirement

in the application by the same percentage increase in

output voltage. The trim up resistor must be connected to

the +S pin (+OUT pin on a Micro.) Do not trim the

converter above maximum trim range (+10%) or the

output over voltage protection circuitry may be activated.

(Figures 2–13a and 2–13b)

SC Pin and Output Voltage Trimming. If no connection

is made to the SC pin, the SC pin voltage will be 1.23 V

referenced to –S (-OUT pin on a Micro) and the output of

the converter will equal the nominal output voltage. When

the SC pin voltage is set by an external source such as a

D/A converter, the % change in SC will be equal the %

change in the output voltage.

For example, an application requires a +10, 0% (nominal),

and a –15% output voltage adjustment for a 48 V output

converter. Referring to the table below, the voltage that

should be applied to the SC pin would be as follows:

2. Control Pin Functions and Applications

or systems that require an adjustable output voltage, it is

F

good practice to limit the adjustment range to a value

only slightly greater than that required. This will increase

the adjustment resolution while reducing noise pickup.

It is recommended that the maximum rate of change

applied to the SC pin be limited to 30 Hz, sinusoidal.

Small step-up changes are permissible; however, the

resultant change in the output voltage can create significant current demands due to charge requirements of both

the internal and external output capacitance. In no case

should the converter be driven beyond rated continuous

output current. The response to programming a lower

output voltage is limited by the energy stored in both the

internal and external output capacitance and the load.

The converter cannot sink current to lower the output

voltage other than a minimal internal preload.

Contact

to be dynamically trimmed.

Trimming resistor calculators are available on Vicor’s web

site at http://www.vicorpower.com/powerbench. (Figure

2–16)

Resistor values can be calculated for fixed trim up, fixed

trim down, and for variable trim up or down. In addition

to trimming information, the web also includes design

tips, applications circuits, EMC suggestions, thermal

design guidelines and PDF data sheets for all Vicor

products. Evaluation Boards (Figure 2–15) are available

for the Maxi, Mini and Micro DC-DC converters.

Applications Engineering if the module’s output is

Change

VSC VOUT from

nominal

1.046 40.8 –15%

1.230 48.0 0%

1.353 52.8 +10%

Circuits such as op-amps and D/A converters, which

directly drive the SC pin, should be designed to limit the

applied voltage to the SC pin. It is also important to

consider voltage excursions that may occur during initialization of the external circuitry. The external circuit must

be referenced to the –S pin (–Out on Micro). See Figure

2–14 for remote sense implementation on Micro.

Maxi, Mini, Micro Design Guide Rev 4.9 vicorpower.com

Page 9 of 88

Apps. Eng. 800 927.9474 800 735.6200

Page 11

2. Control Pin Functions and Applications

+OUT

+S

SC

–S

–OUT

R

U

Trim Up

Load

Error

Amp

1 kΩ

1

.23 V

0.033 μF

1,000 (Vout –1.2 3) Vnom

1.23 (Vout – Vnom)

RU (ohms) =

– 1,000

R

U

Trim Up

Load

E

rror

A

mp

1 kΩ

1.2 3 V

0

.033 µF

+

OUT

S

C

–OUT

+

IN

PC

PR

–IN

1,000 (Vout –1.23 ) Vnom

1.23 (Vout – Vnom)

RU (ohms) =

– 1,000

++

––

++

––

R1

R2

U1

R3

2.55 k

R4

R5

1.00 k

U2

TLV431

C1

R7 21.0 k

C2

0.22 µF

R8

4.02 k

C3

R9

R

10

1.24 k

U3

LM10

+S

–S

+Out

SC

–Out

R Load

PS2701

R11

36.5 k

R6

1.65 k

470 pF

200 mV

Vcc

Gnd

Load

+

OUT

+S

SC

–S

–OUT

R

D

Trim Down

Error

Amp

1 kΩ

1.2 3 V

0

.033 μF

1,000 Vout

Vnom – Vout

R

D

(ohms) =

Load

R

D

Trim Down

Error

Amp

1

kΩ

1.2 3 V

0.033 μF

+OUT

SC

–OUT

+IN

PC

PR

–IN

1,000 Vout

Vnom – Vout

RD (ohms) =

1,000 (Vout –1.23) Vnom

1.23 (Vout – Vnom)

RU (ohms) =

– 1,000

R

U

Trim Up

or Maxi, Mini, Micro Family DC-DC Converters and Configurable Power Supplies

Design Guide & Applications Manual

F

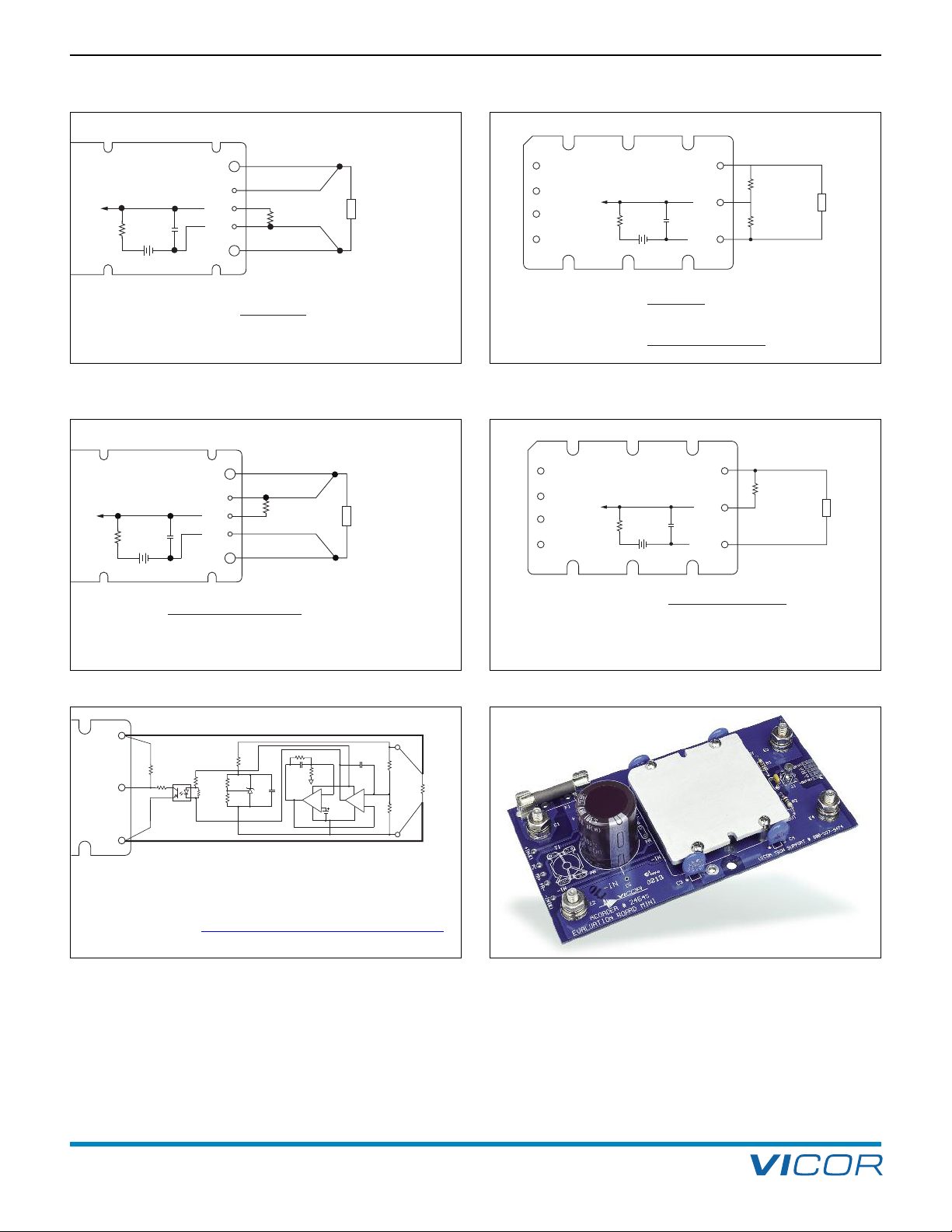

Figure 2–12a — Output voltage trim down circuit (Maxi/Mini)

Figure 2–13a — Output voltage trim up circuit (Maxi/Mini)

Figure 2–12b — Output voltage trim down circuit (Micro)

Figure 2–13b — Output voltage trim up circuit (Micro)

• This module is designed for point of load regulation, where remote sensing

is not required. Active voltage drop compensator, as shown here, may be

used in applications with significant distribution losses.

Please consult with the

for additional information.

Figure 2–14 — Voltage drop compensation (Micro).

Maxi, Mini, Micro Design Guide Rev 4.9 vicorpower.com

Page 10 of 88

Micro Family Isolated Remote Sense Application Note

Apps. Eng. 800 927.9474 800 735.6200

Figure 2–15 — Evaluation Boards; Available for Maxi, Mini and Micro

Family DC-DC converters

Page 12

Design Guide & Applications Manual

or Maxi, Mini, Micro Family DC-DC Converters and Configurable Power Supplies

F

2. Control Pin Functions and Applications

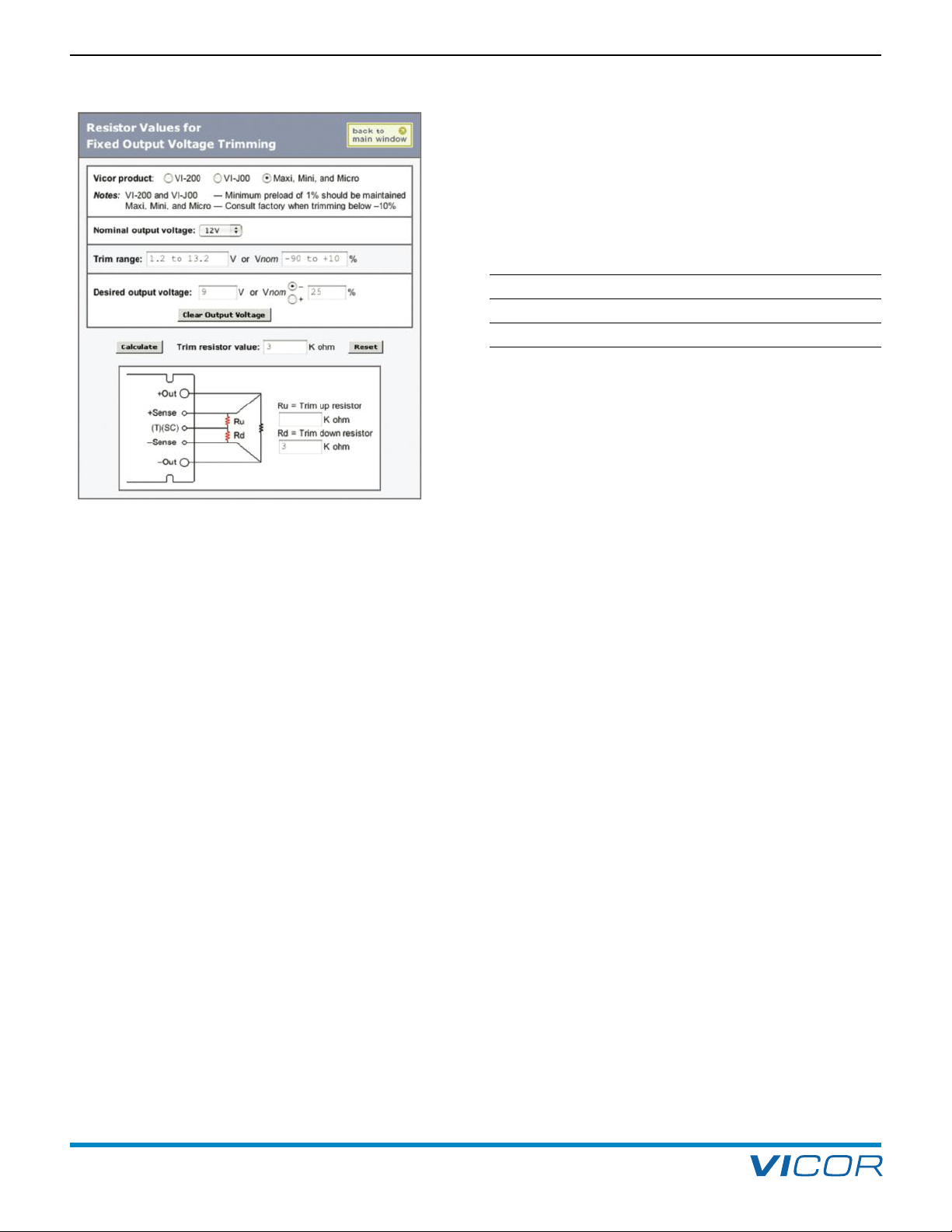

EVALUATION BOARDS

• Three styles: Maxi, Mini or Micro

• Short pin and Long pin compatible

• Easy I / O and control connections

• Includes fusing and capacitors

• Can be paralleled for higher power arrays

DESCRIPTION PART NUMBER

Maxi board style 24644R

Mini board style 24645R

Micro board style 24646R

Figure 2–16 — Online trim calculator

Maxi, Mini, Micro Design Guide Rev 4.9 vicorpower.com

Page 11 of 88

Apps. Eng. 800 927.9474 800 735.6200

Page 13

3. Design Requirements

SAFETY CONSIDERATIONS

or Maxi, Mini, Micro Family DC-DC Converters and Configurable Power Supplies

F

Design Guide & Applications Manual

using. Safety agency conditions of acceptability require

F

that the module positive (+) Input terminal be fused and

the baseplate of the converter be connected to earth

ground. The following table lists the acceptable fuse types

nd current rating for the Maxi, Mini, Micro Family of

a

DC-DC converters. Safety Certifications on the Vicor web

site should always be consulted for the latest fusing

requirements.

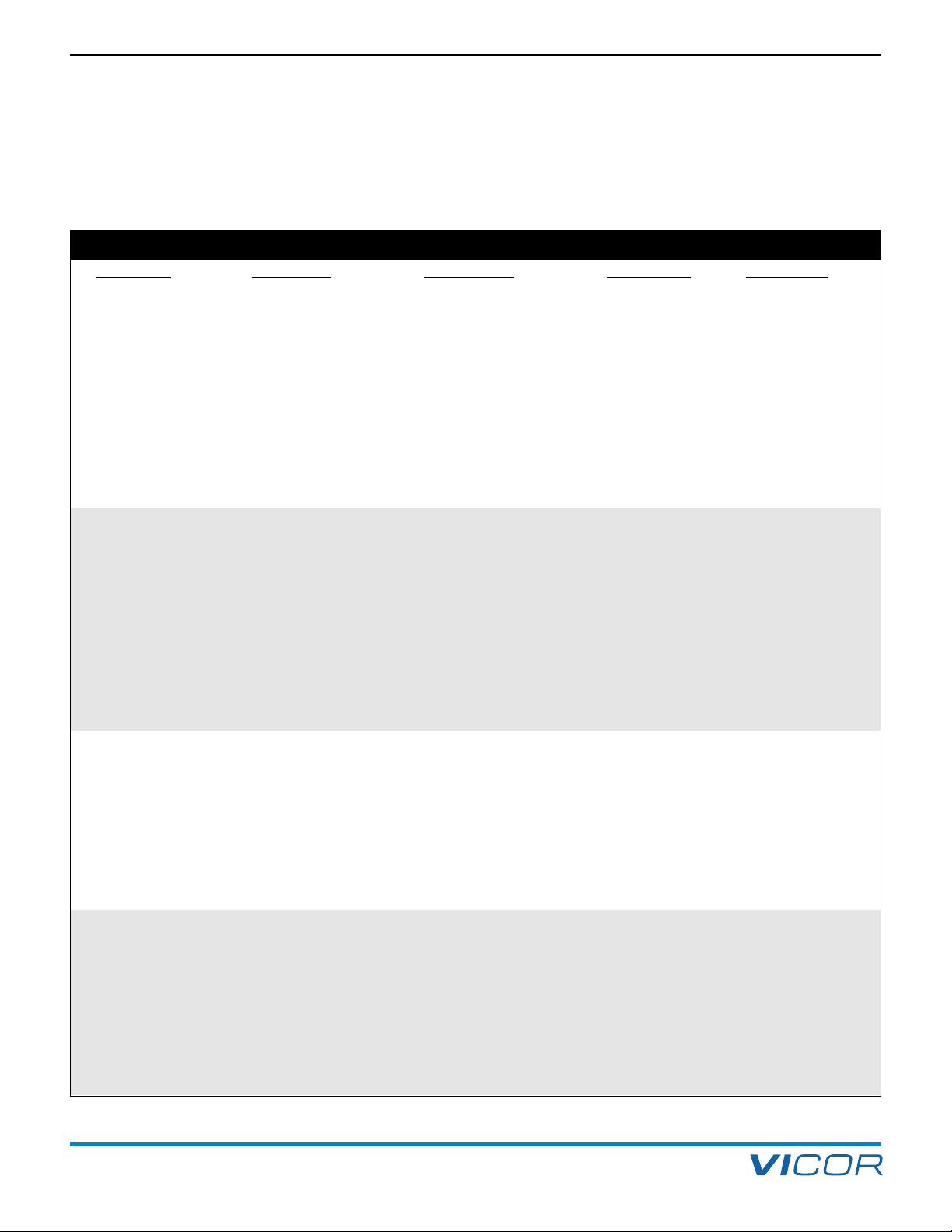

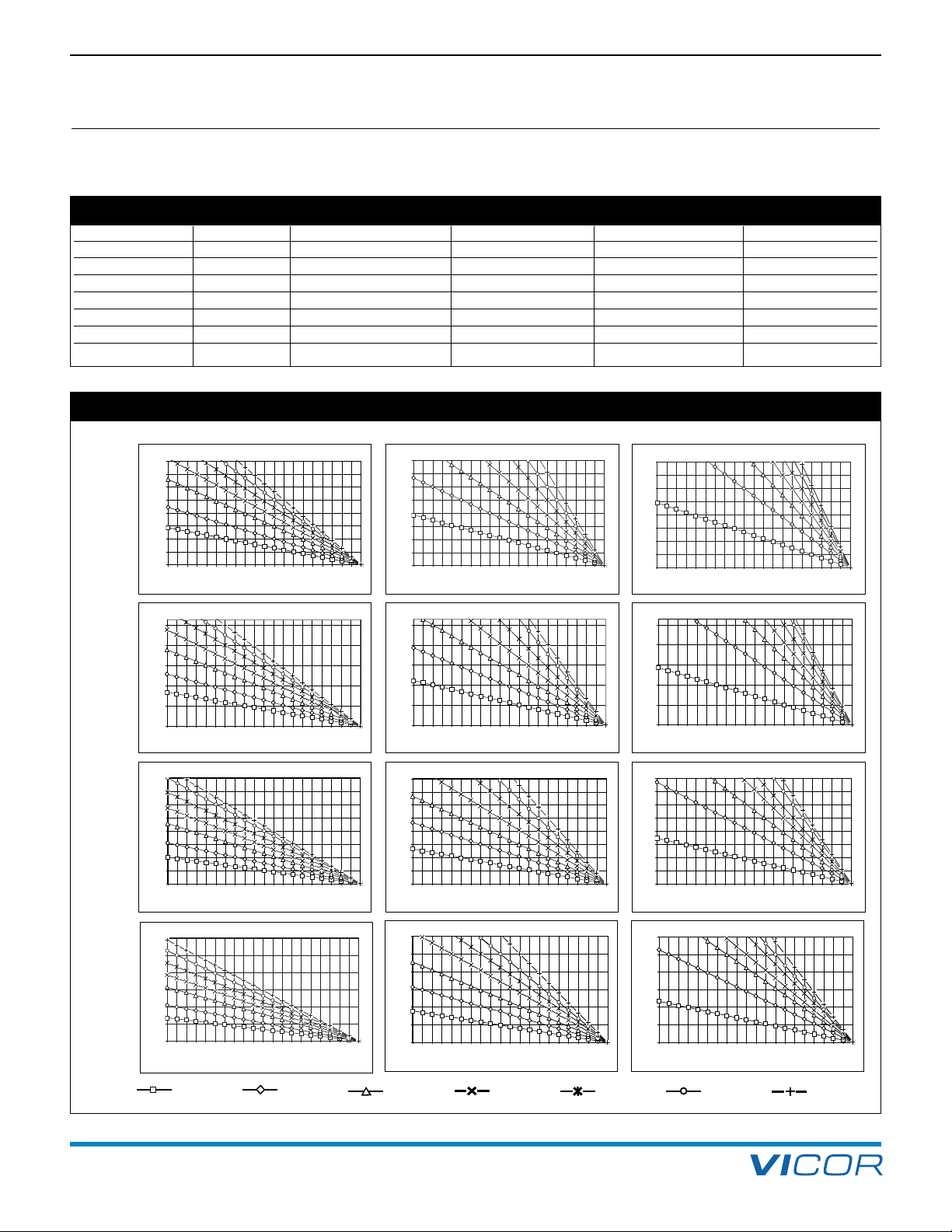

Acceptable Fuse Types and Current Rating for the Maxi, Mini, Micro Family of Converters

Package Size Input Voltage Output Voltage Output Power Required Fuse

Maxi (A) 375 2 160 Bussmann PC-Tron 5A

Maxi (A) 375 3.3 264 / 200 Bussmann PC-Tron 5A

Maxi (A) 375 5, 8 400 / 300 Bussmann PC-Tron 5A

Maxi (A) 375 12, 15, 24, 28, 32, 36, 48, 54 600 / 400 Bussmann PC-Tron 5A

Mini (B) 375 2 100 Bussmann PC-Tron 5A

Mini (B) 375 3.3 150 / 100 Bussmann PC-Tron 5A

Mini (B) 375 5, 8 200 / 150 Bussmann PC-Tron 5A

Mini (B) 375 12, 15, 24, 28, 36, 48 300 / 200 Bussmann PC-Tron 5A

Micro (C) 375 2 50 Bussmann PC-Tron 3A

Micro (C) 375 3.3 75 / 50 Bussmann PC-Tron 3A

Micro (C) 375 5, 8 100 / 50 Bussmann PC-Tron 3A

Micro (C) 375 12, 15, 24, 28, 36, 48 150 / 75 Bussmann PC-Tron 3A

Maxi (A) 300 2 160 Bussmann PC-Tron 5A

Maxi (A) 300 3.3 264 / 200 Bussmann PC-Tron 5A

Maxi (A) 300 5, 8 400 / 300 Bussmann PC-Tron 5A

Maxi (A) 300 12, 15, 24, 28, 36, 48 500 / 400 Bussmann PC-Tron 5A

Mini (B) 300 2 100 Bussmann PC-Tron 5A

Mini (B) 300 3.3 150 / 100 Bussmann PC-Tron 5A

Mini (B) 300 5, 8 200 / 150 Bussmann PC-Tron 5A

Mini (B) 300 12, 15, 24, 28, 36, 48 250 / 150 Bussmann PC-Tron 5A

Micro (C) 300 2 50 Bussmann PC-Tron 3A

Micro (C) 300 3.3 75 / 50 Bussmann PC-Tron 3A

Micro (C) 300 5, 8 100 / 50 Bussmann PC-Tron 3A

Micro (C) 300 12, 15, 24, 28, 36, 48 150 / 75 Bussmann PC-Tron 3A

Maxi (A) 150 3.3 264 / 200 Bussmann ABC-8

Maxi (A) 150 5, 8 400 / 300 Bussmann ABC-8

Maxi (A) 150 12, 15, 24, 28, 36, 48 500 / 400 Bussmann ABC-8

Mini (B) 150 3.3 150 / 100 Bussmann PC-Tron 5A

Mini (B) 150 5, 8 200 / 150 Bussmann PC-Tron 5A

Mini (B) 150 12, 15, 24, 28, 36, 48 250 / 150 Bussmann PC-Tron 5A

Micro (C) 150 3.3 75 Bussmann PC-Tron 3A

Micro (C) 150 5, 8 100 Bussmann PC-Tron 3A

Micro (C) 150 12, 15, 24, 28, 36, 48 150 Bussmann PC-Tron 3A

Maxi (A) 110 3.3 200 / 150 Bussmann ABC-8

Maxi (A) 110 5, 8 300 / 200 Bussmann ABC-8

Maxi (A) 110 12, 15, 24, 28, 36, 48 400 / 300 Bussmann ABC-8

Mini (B) 110 3.3 100 / 75 Bussmann PC-Tron 5A

Mini (B) 110 5, 8 150 / 100 Bussmann PC-Tron 5A

Mini (B) 110 12, 15, 24, 28, 36, 48 200 / 150 Bussmann PC-Tron 5A

Micro (C) 110 3.3 50 Bussmann PC-Tron 3A

Micro (C) 110 5, 8 75 Bussmann PC-Tron 3A

Micro (C) 110 12, 15, 24, 28, 36, 48 100 Bussmann PC-Tron 3A

Maxi, Mini, Micro Design Guide Rev 4.9 vicorpower.com

Page 12 of 88

Apps. Eng. 800 927.9474 800 735.6200

Page 14

Design Guide & Applications Manual

or Maxi, Mini, Micro Family DC-DC Converters and Configurable Power Supplies

F

3. Design Requirements

Acceptable Fuse Types and Current Rating for the Maxi, Mini, Micro Family of Converters

Package Size Input Voltage Output Voltage Output Power Required Fuse

Maxi (A) 72 3.3 264 Bussmann ABC-12

Maxi (A) 72 5, 8 300 Bussmann ABC-12

Maxi (A) 72 12, 15, 24, 28, 36, 48 400 Bussmann ABC-12

Mini (B) 72 3.3 100 Bussmann ABC-8

Mini (B) 72 5, 8 150 Bussmann ABC-8

Mini (B) 72 12, 15, 24, 28, 36, 48 250 Bussmann ABC-8

Micro (C) 72 3.3 75 Bussmann PC-Tron 5A

Micro (C) 72 5, 8 100 Bussmann PC-Tron 5A

Micro (C) 72 12, 15, 24, 28, 36, 48 150 Bussmann PC-Tron 5A

Maxi (A) 48 3.3 264 Bussmann ABC-10

Maxi (A) 48 5, 8 400 Bussmann ABC-15

Maxi (A) 48 12, 15, 24, 28, 36, 48 500 Bussmann ABC-20

Mini (B) 48 2 100 Bussmann ABC-8

Mini (B) 48 3.3 150 Bussmann ABC-8

Mini (B) 48 5, 8 200 Bussmann ABC-10

Mini (B) 48 12, 15, 24, 28, 36, 48 250 Bussmann ABC-10

Micro (C) 48 2 50 Bussmann PC-Tron 5A

Micro (C) 48 3.3 75 / 50 Bussmann PC-Tron 5A

Micro (C) 48 5, 8 100 / 75 / 50 Bussmann ABC-8

Micro (C) 48 12, 15, 24, 28, 36, 48 150 / 75 Bussmann ABC-8

Maxi (A) 28 3.3 150 Bussmann ABC-25

Maxi (A) 28 5 175 Bussmann ABC-25

Maxi (A) 28 6.5, 8, 12, 15, 24, 28, 36, 48 200 Bussmann ABC-30

Mini (B) 28 3.3 75 Bussmann ABC-15

Mini (B) 28 5 75 Bussmann ABC-15

Mini (B) 28 12, 15, 24, 28, 36, 48 150 Bussmann ABC-15

Micro (C) 28 3.3 50 Bussmann ABC- 8

Micro (C) 28 5 50 Bussmann ABC-10

Micro (C) 28 12, 15, 24, 28, 36, 48 100 Bussmann ABC-10

Maxi (A) 24 3.3 264 / 200 Bussmann ABC-25

Maxi (A) 24 5, 8, 12, 15, 24, 28, 36, 48 400 / 300 Bussmann ABC-30

Mini (B) 24 3.3 150 / 100 Bussmann ABC-15

Mini (B) 24 5, 8, 12, 15, 24, 28, 36, 48 200 / 150 Bussmann ABC-15

Micro (C) 24 3.3 75 / 50 Bussmann ABC-8

Micro (C) 24 5, 8, 12, 15, 24, 28, 36, 48 100 / 50 Bussmann ABC-10

Maxi, Mini, Micro Design Guide Rev 4.9 vicorpower.com

Page 13 of 88

Apps. Eng. 800 927.9474 800 735.6200

Page 15

3. Design Requirements

or Maxi, Mini, Micro Family DC-DC Converters and Configurable Power Supplies

F

Design Guide & Applications Manual

The fuse must be in series with the positive (+) Input lead.

Fusing the negative (–) Input lead does not provide adequate

protection since the PR and PC terminals of the converter

re referenced to the –Input. If a fuse located in the

a

–Input lead were to open, the PR and PC terminals could

ise to the potential of the +Input. This may damage any

r

converter or circuitry connected to these pins. The fuse

should not be located in an area with a high ambient

temperature as this will lower the current rating of the fuse.

THERMAL AND VOLTAGE HAZARDS

Vicor component power products are intended to be used

within protective enclosures. Vicor DC-DC converters work

effectively at baseplate temperatures, which could be

harmful if contacted directly. Voltages and high currents

(energy hazard) present at the terminals and circuitry

connected to them may pose a safety hazard if contacted

or if stray current paths develop. Systems with removable

circuit cards or covers which may expose the converter(s)

or circuitry connected to the converters, should have proper

guarding to avoid hazardous conditions.

The module pins are intended for PCB mounting either by

wave soldering to a PCB or by insertion into one of the

recommended PCB socket solutions. Use of discrete wire

soldered directly to the pins may cause intermittent or

permanent damage to the module; therefore, it is not recommended as a reliable interconnection scheme for production as a final released product. In addition, modules

that have been soldered into printed circuit boards and

have subsequently been removed should not be reused.

PC PIN

The PC pin should be used only to; disable the module,

provide a bias to input referenced circuitry or communicate

status of the module. The PC pin is referenced to the –Input

pin. All circuits that connect to the PC pin must use the

–Input as the reference. Do not break the connection

between the –Input and the circuitry connected to the

PC pin or damage to the module will result. Additional

requirements include:

HIGH-POWER ARRAYS AND PR PIN

To simplify the implementation of large arrays, a subset of

modules within the parallel array should be configured as

boosters (listeners) by connecting the SC pin to the –S pin.

Modules, which are configured as boosters, cannot assume

the role of drivers (talkers) for N+M redundant arrays.

Modules configured as boosters may be locally sensed.

Each module within the parallel array must be properly

bypassed with capacitors. Film or ceramic types should be

used across the input of the module and between each

input lead and the baseplate. Modules having input

sources, which are not connected to SELV sources, should

use X-capacitors across the input and Y-capacitors from

each input power pin to the baseplate. When in doubt

about capacitor safety approvals, always consult with the

governing safety regulatory agency or Vicor Applications

Engineering.

A maximum of 12 modules may be directly connected in

parallel. Please contact Vicor Applications Engineering for

assistance with larger arrays.

The PR pin is referenced to the –In pin; therefore, all

modules within the array must have a common lowimpedance connection between each –In pin. Special

precautions are necessary if a PCB is not used for interconnection of modules, because the wiring impedance

can be significant. Do not allow the connection between

the –In pin and the –In bus to become disconnected as

damage to the module will result.

Coupling transformers should be used to transmit the PR

pulse if long distances between each module are anticipated or if the interconnection impedance of the –In leads

is high or questionable. PR coupling transformer(s) should

be used if the PR pulse exits the PCB. For example, an

array constructed of multiple circuit cards plugged into a

backplane with a number of converters on each card

should have a PR coupling transformer at the entry point

of each card; however, no coupling transformer would be

required between each converter on the card of three or

less converters on a single PCB. Do not externally drive the

PR pin, connection to this pin is limited to Vicor module

application only.

• Circuits that derive their power from the PC pin must

not exceed 1.5 mA.

• Do not drive the PC pin with external circuitry.

• Do not attempt to control the output of the converter

by PWM pulsing of the PC pin, or exceed a repetitive

on / off rate of 1 Hz.

For applications where the converter will be disabled on a

INPUT SOURCE IMPEDANCE

The impedance of the source feeding the input of the

module directly affects both the stability and transient

response of the module. In general, the source impedance

should be lower than the input impedance of the module

by a factor of ten, from DC to 50 kHz.

regular basis or where capacitance is added to this pin,

please contact Vicor

Maxi, Mini, Micro Design Guide Rev 4.9 vicorpower.com

Page 14 of 88

Applications Engineering.

Apps. Eng. 800 927.9474 800 735.6200

Page 16

Design Guide & Applications Manual

or Maxi, Mini, Micro Family DC-DC Converters and Configurable Power Supplies

F

3. Design Requirements

To calculate the required source impedance, use the

following formula:

Z = 0.1(VLL)2/ Pin

where: Z is required input impedance

s the low line input voltage

VLLi

P

in is the input power of the module

Filters, which precede the module, should be well damped

to prevent ringing when the input voltage is applied or

the load on the output of the module is abruptly changed.

INPUT TRANSIENTS AND SURGES

The voltage applied to the input of the module must not

exceed the ratings outlined in the data sheet. Protection

devices such as Zener diodes and MOVs should be used

to protect the module from short-duration transients.

These shunt protection devices are effective only if the

source impedance is high relative to the impedance of

the protection device when it is conducting. For voltage

surges where the abnormal voltage is present for a long

period of time, shunt protection devices can easily be

damaged by the power dissipated. For this type of

condition, a voltage limiter in series with the input of

the module may be the best solution. Vicor Applications

Engineering can assist in recommending the appropriate

type of protection for the module.

NOTE: Do not allow the rate of change of the

input voltage to exceed 10 V/µs for any input

voltage deviation.

SENSE LEADS (Mini and Maxi only)

The sense leads of the module must always terminate

either directly to the output pins (local sense) or at the

load (remote sense). When remote sense is used, the

output wiring impedance in combination with the load

impedance can cause significant loss of phase margin and

result in oscillation and possible damage to the module,

poor transient response, or activation of the output

overvoltage protection. Long sense leads may require a

compensation circuit for stability.

Protection circuitry is required if the possibility of reversed

sense leads can occur. Please contact Vicor Applications

Engineering for specific recommendations.

Do not

exceed 1 V between –S and –Out leads. This is

an important consideration if the converter is used in a

Hot-Swap application. ORing diodes, if used, should be

located in the +Output lead to avoid exceeding this rating.

OUTPUT CONNECTIONS

For systems designed to charge batteries, subject the

module output to dynamic loading, or loads that have

large reactive components, please contact Vicor

Applications Engineering to discuss your application

in detail.

Do not externally drive the output of the module 10%

above its nominal setpoint voltage.

Modules, that are used to charge batteries should be

applied with a diode in series with the output of the

module. The charge current must be externally controlled

to ensure that the module is not operated in excess of its

power or current rating.

Current-carrying conductors should be sized to minimize

voltage drops.

Do not

use output ORing diodes with parallel arrays of

the Micro Family converters.

Output Overvoltage Protection (OVP). The OVP detection

circuitry within the converter is highly resistant to false

tripping. For the converter to shut down due to an OVP

condition two conditions must be satisfied (logical AND);

1. The voltage at the output terminals must be greater

than the OVP set point.

2. The secondary control IC within the converter must be

requesting a power conversion cycle from the internal

primary control IC.

By using this logic, false tripping of individual converters

due to externally induced OVP conditions such as load

dumps or, being driven by external voltage sources at the

output terminals is minimized. The user should not test

the OVP circuit by back driving the output terminals or by

any other means as the OVP circuitry is fully tested as part

of the inline manufacturing process.

OVERCURRENT PROTECTION

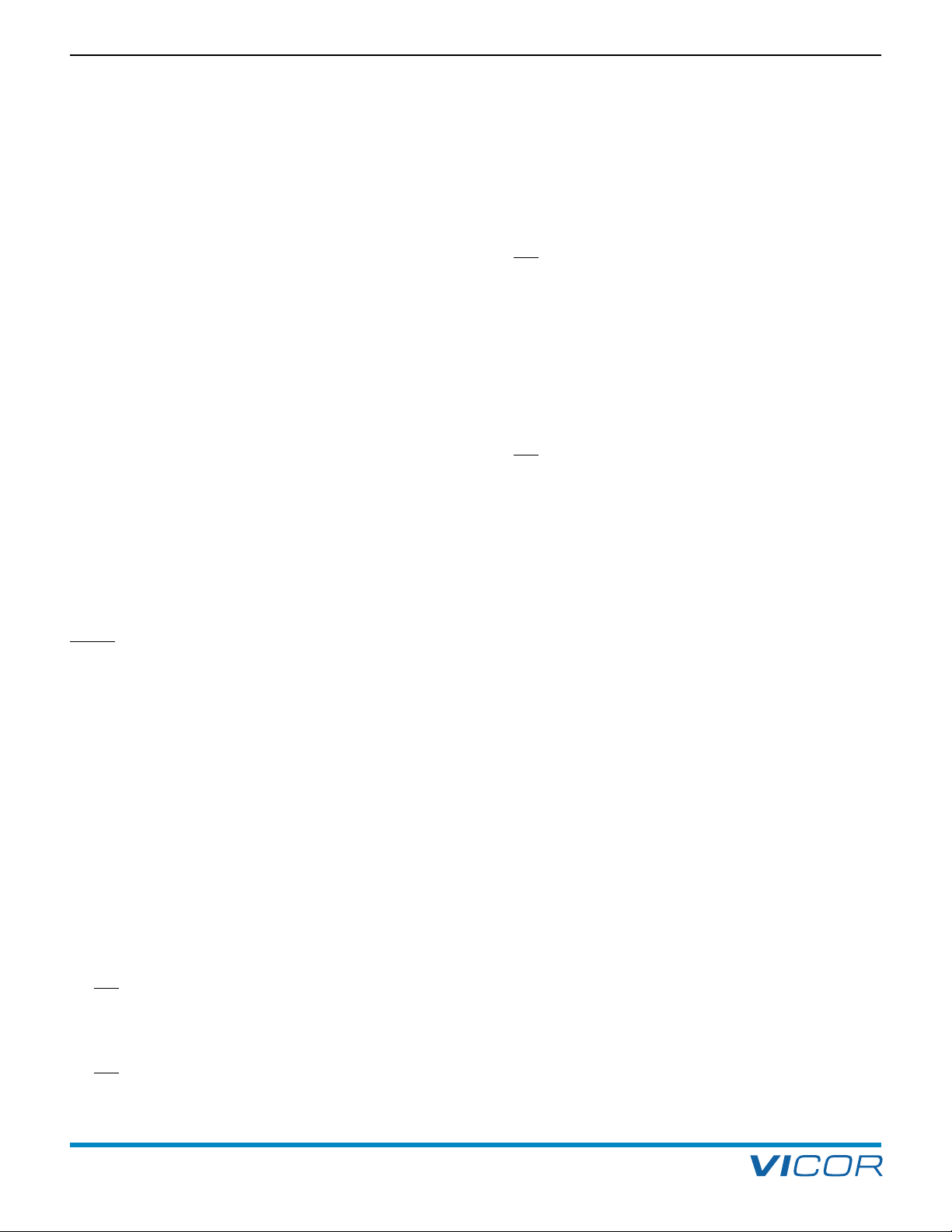

The Maxi, Mini, Micro converters incorporate a straightline type current limit. (Figure 3–1) As output current is

increased beyond Imax, the output voltage remains

constant and within its specified limits up to a point, IKNEE,

which is typically 5 – 25% greater than rated current,

Imax. Beyond IKNEE, the output voltage falls to Ishortcircuit.

Typically, modules will automatically recover after the overcurrent condition is removed.

Do not

exceed the rated power of the converter. The total

of the power consumed by the load plus the power lost in

conductors from the converter to the load must be less

than the output power rating of the converter.

Maxi, Mini, Micro Design Guide Rev 4.9 vicorpower.com

Page 15 of 88

Apps. Eng. 800 927.9474 800 735.6200

Page 17

3. Design Requirements

V

out

I

K

NEE

I

M

AX

I

S

HORT CIRCUIT

I

out

Figure 3–1 — Typical Maxi, Mini, Micro current limiting

MAXIMUM OUTPUT CAPACITANCE

In general, adding external capacitance to the Maxi, Mini,

and Micro’s output is not required. However, it is often

common practice with power supply designs to add external

capacitance to the converter output for attenuation of

output ripple and / or improving dynamic load performance.

The Maxi, Mini, Micro converters typically have a faster

response to dynamic loads than other power solutions;

hence, external capacitors may not be necessary. In addition,

the output ripple and noise specification listed on the data

sheet may be acceptable for many applications.

A general equation for determining the maximum recommended output capacitance is as follows:

Pout

C(farad) =Vout

(400x10

Vout

-

6

)

or Maxi, Mini, Micro Family DC-DC Converters and Configurable Power Supplies

F

Design Guide & Applications Manual

ABSOLUTE MAXIMUM RATINGS

Please consult the latest module data sheets available on

the Vicor website for maximum ratings concerning pin-topin voltages, isolation, temperature, and mechanical ratings.

GROUNDING OF BASEPLATE AND REFERENCING

OF INPUT AND OUTPUT TERMINALS

The baseplate of the converter should always be connected

to earth ground. If for any reason this is not possible in

your application please consult with Vicor Applications

Engineering for acceptable alternatives for your application.

The input and output leads of the converter should be

referenced to the baseplate at some point to avoid stray

voltages. For offline applications the input leads are often

referenced to earth ground at the AC source ahead of the

bridge rectifier. Either + or –Output terminal may be

referenced to earth ground and the baseplate. “Floating”

inputs or outputs should at a minimum have a highresistance divider to bleed off stray charges to avoid

damage to the insulation system.

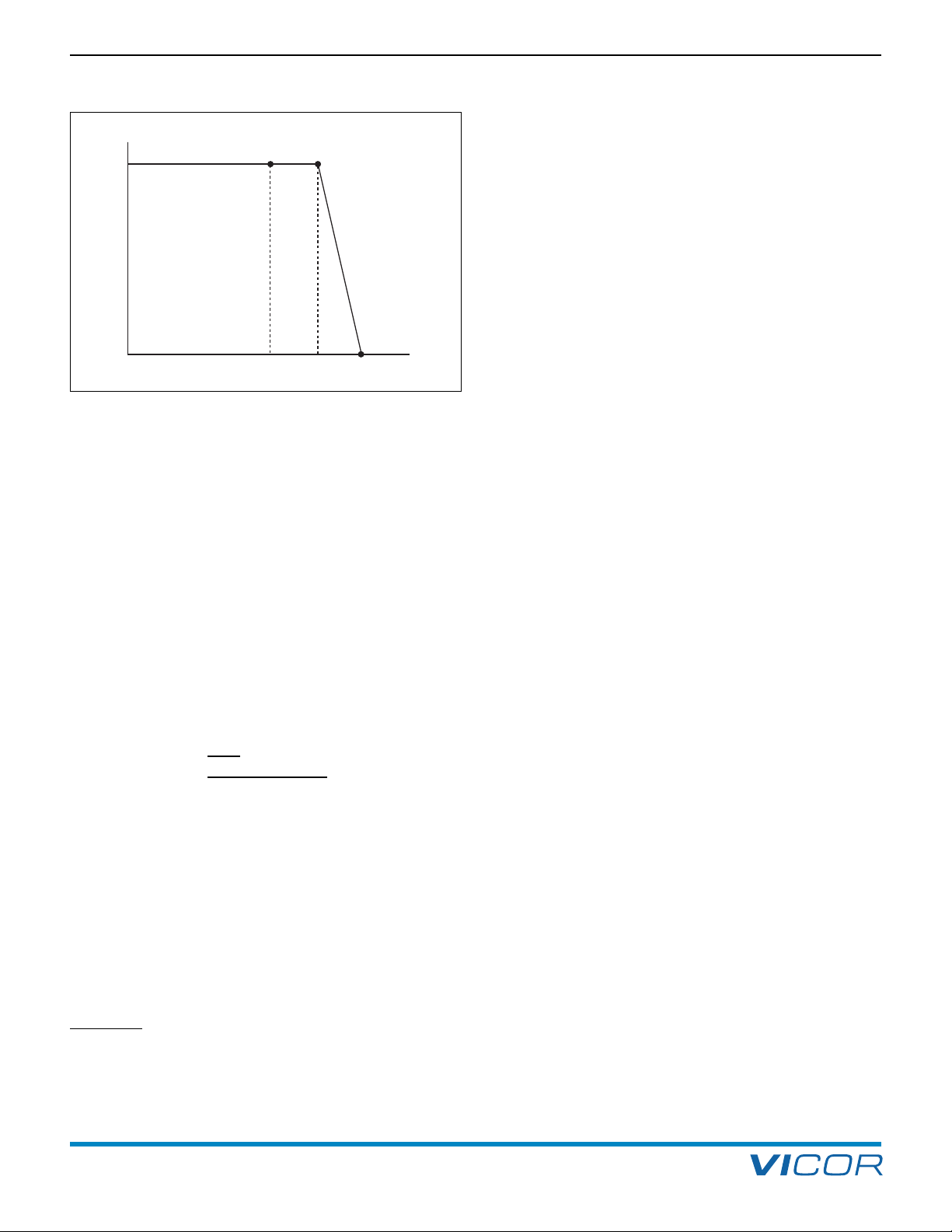

HIGH FREQUENCY BYPASSING

All Vicor converters must be bypassed for proper operation.

(Figure 3–2) The minimum complement of high-frequency

bypass capacitors must consist of the following:

• 0.2 µF ceramic or film type connected between

+In and –In.

• 4.7 nF Y-capacitor between +In and baseplate

and –In and baseplate.

• 10 nF ceramic or film capacitor between +Out and

baseplate and –Out and baseplate.

where: Pout is the output power of the converter

out is the nominal output voltage of the converter

V

All applications utilizing Maxi, Mini, Micro converters

should be properly bypassed, even if no EMC standards

need to be met. Bypass Vin and Vout pins to each module

baseplate as shown in Figure 3–2. Lead length should

The capacitance value is not the absolute maximum value,

but the value for which general application of the converter

can be deemed appropriate. Testing will be required to

ensure that the module is stable if this value is exceeded.

Approximately 10X the value calculated will cause the

converter to go into current limit at turn-on.

CAUTION:

If exceeding this value, it is recommended

that Vicor Applications Engineering be consulted.

be as short as possible. Recommended values vary

depending on the front end, if any, that is used with the

modules, and are indicated on the appropriate data sheet

or application note. In most applications, C1 is a 4,700 pF

Y-capacitor (Vicor P/N 01000) carrying the appropriate

safety agency approval; C2 is a 4,700 pF Y-capacitor (Vicor

P/N 01000) or a 0.01 µF ceramic capacitor rated at 500 V.

In PC board applications, each of these components is

typically small enough to fit under the module baseplate

flange. For PCB mounting of the module. Please refer to

Figures 3–3 and 3–4.

Maxi, Mini, Micro Design Guide Rev 4.9 vicorpower.com

Page 16 of 88

Apps. Eng. 800 927.9474 800 735.6200

Page 18

Design Guide & Applications Manual

0. 53

Ch as si s

0. 46

Onboard Mount

Cross-sectional view of pins

and mounting hardware

Inboard Mount

Cross-sectional view of pins

and mounting hardware.

Exploded View Exploded View

P/ N 20 265 Th er mM ate

Ex . V3 00 C1 2M75 BL

(L on g Sol de r Pin ,

Sl ot te d B as ep lat e)

P/ N 18 157 S ta ndo ff K it

PC B th ick nes s is

0. 06 2

" (

1. 5m m)

Tap ped # 4– 40

sc rew h ol e

Pa d a nd pl at ed th ro ughho le c onn ec te d t o

ch as si s g roun d p la ne

P/ N 20 265 Th er mM ate

Ex . V3 00 C1 2M75 B

(S ho r t Sol de r Pin,

Sl ot te d B as ep lat e)

P/ N 18 151 S ta ndo ff K it

0. 06 2

" (1.5mm) PCB with

aperture to allow belly

of

th e mo dul e to re ce ss int o b oa rd

Tap ped # 4– 40

sc rew h ol e

Pa d a nd pl at ed th ro ughho le c onn ec te d t o

ch as si s g roun d p la ne

13 ,5m m

11 ,7 mm

’

’

’’

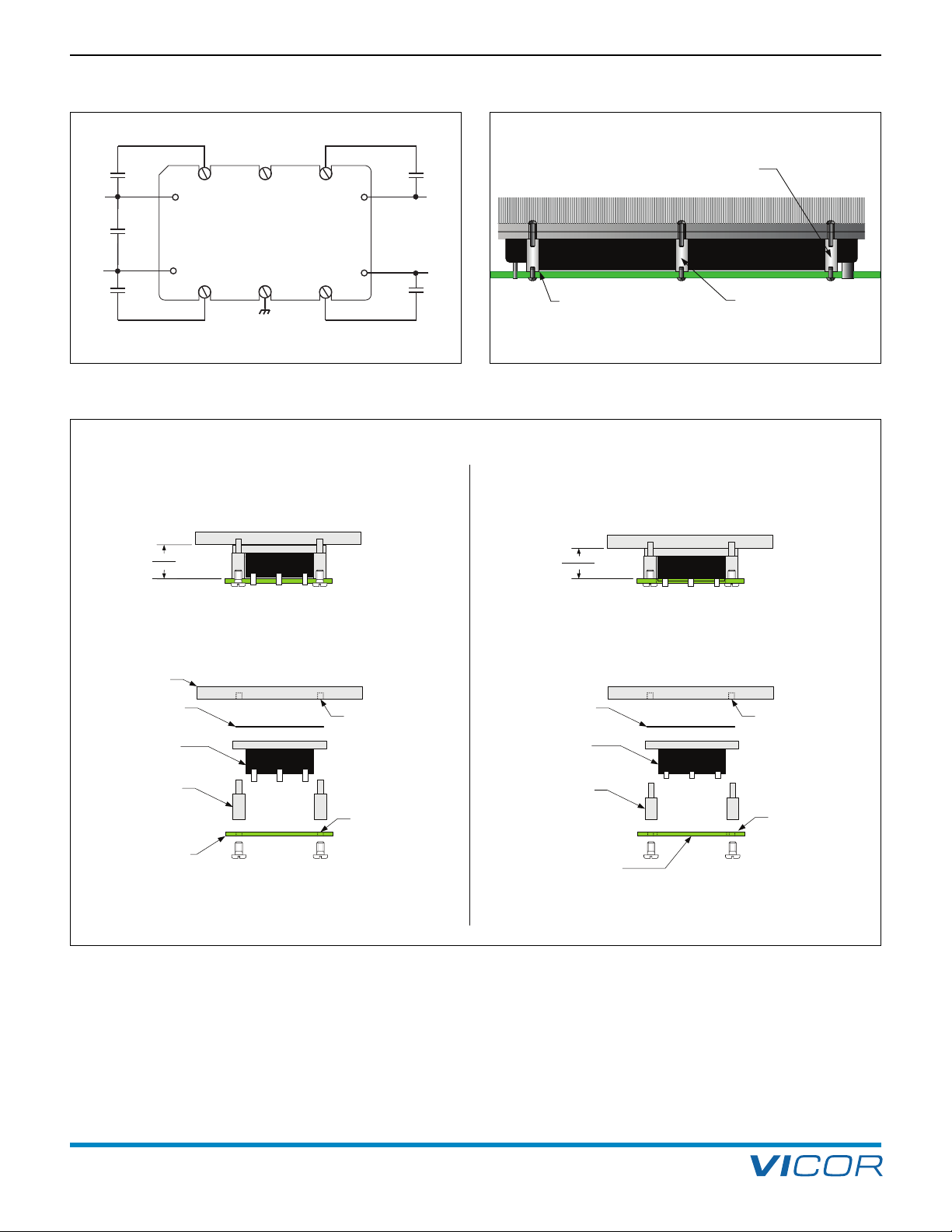

+OUT

+IN

–IN

–OUT

Maxi, Mini, Micro

D

C-DC Converter

C1a

C1b

C2a

C2b

CI

N

Baseplate grounded

Standoffs also provide necessary

mechanical support in order to

prevent mechanical stresses from

damaging the module during shock / vibration.

Standoff sitting on pad / plated through-hole

that is connected to the chassis

ground plane within the PCB.

Female-female standoffs are

s

hown, however standoffs are

also available in male-female versions.

or Maxi, Mini, Micro Family DC-DC Converters and Configurable Power Supplies

F

3. Design Requirements

Figure 3–2 — Minimum recommended bypassing for Maxi, Mini,

and Micro; Keep all leads short.

Figure 3–3 — Recommended mounting method using standoffs

Figure 3–4 — Onboard vs. inboard mounting of (1/4 brick) Micro with slotted baseplate

Maxi, Mini, Micro Design Guide Rev 4.9 vicorpower.com

Page 17 of 88

Apps. Eng. 800 927.9474 800 735.6200

Page 19

4. EMC Considerations

FILTERING AND TRANSIENT PROTECTION

or Maxi, Mini, Micro Family DC-DC Converters and Configurable Power Supplies

F

Design Guide & Applications Manual

ll switching power supplies generate potentially interfer-

A

ing signals as a result of high-frequency, high-power

switching. The Vicor power converter topology, to a large

extent, addresses the problem at the source by the use of

a quasi-resonant, zero-current switching (ZCS) and zerovoltage switching (ZVS) topology. The switching current

waveform is a half sine wave that generates far less

conducted and radiated noise in both frequency spectrum

and magnitude. EMI filtering, if properly designed and

implemented, reduce the magnitude of conducted noise

an additional 40 – 60 dB, and as a result, the noise radiated

by the power conductors is reduced proportionally.

BASIC GUIDELINES FOR SUCCESSFUL EMI FILTERING

1. Keep current loops small. The ability of a conductor to

couple energy by induction and radiation is reduced

accordingly.

2. For conductor pairs, use wide (low Z) copper traces

aligned above and below each other.

3. Locate filters at the source of interference; i.e., close

to the power converter(s).

4. Filter component values should be chosen with

consideration given to the desired frequency range of

attenuation. For example, capacitors are self-resonant

at a certain frequency, beyond which they look inductive.

Keep bypass capacitor leads as short as possible.

5. Locate components on the PCB with consideration

given to proximity of noise sources to potentially

susceptible circuits. For example, the FIAM is an input

line filter module that has been optimized for use

with Maxi, Mini, and Micro DC-DC converters. When

used in conjunction with the recommended external

components and layout, it will significantly reduce the

differential and common-mode noise returned to the

power source. The FIAM meets the requirements of

EN55022 “B”, FCC “B”, and Bellcore GR-001089CORE, Issue 2 when used with any combination of

Maxi, Mini, and Micro converters up to the FIAM’s

maximum rated current.

onducted noise on the input power lines can occur as

C

either differential-mode or common-mode noise currents.

Differential-mode noise, largely at low frequencies, appears

across the input conductors at the fundamental switching

frequency and its harmonics. Common-mode noise, which

has mostly high-frequency content, is measured between

the converter’s input conductors and ground.

The Vicor power converter being an electronic device may

be susceptible to high levels of conducted or radiated

emissions. It is the responsibility of the user to assess

testing protocols in order to determine applicability of the

converter in the intended application.

DC-DC converter inputs and outputs must be properly

bypassed, to system chassis or earth. Bypass Vin and Vout

pins to each DC-DC module baseplate. Capacitor lead

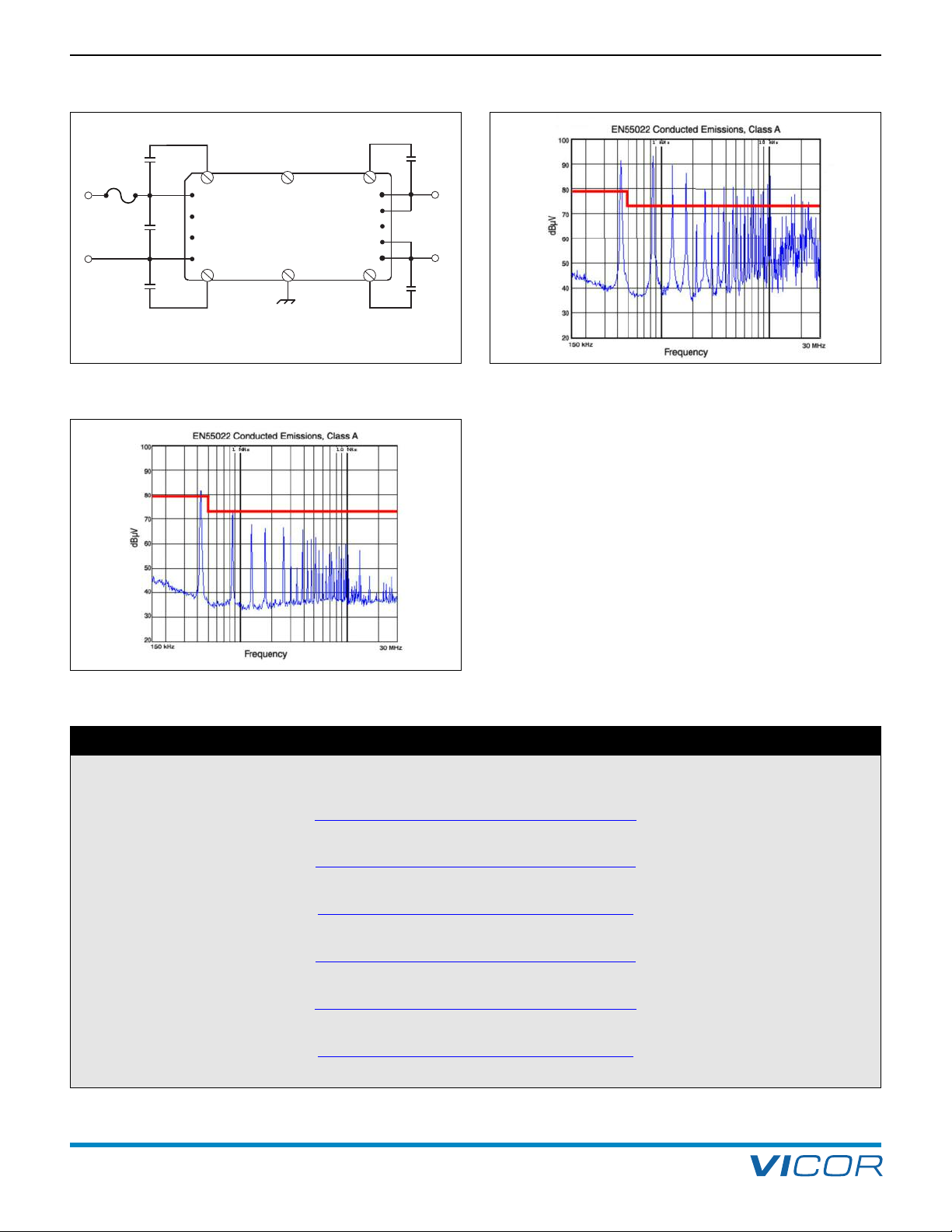

length must be as short as possible. (Figure 4–1)

EMI filtering can be application dependent. A packaged

filter module may not always be the appropriate solution,

and the general practice of bypassing Vin and Vout may

not produce optimal results. You may have to adjust the

values depending on the severity of common-mode and

differential-mode noise. (Figures 4–2 and 4–3)

Input transient suppression should be used in applications

where source transients may be induced by load changes,

blown fuses, etc. The level of transient suppression

required will depend on the expected severity of the transients. A Zener diode, TRANSORB™, or MOV will provide

transient suppression, act as a voltage clamp for DC input

spikes, and provide reverse input voltage protection. The

device voltage rating should be chosen above high-line

voltage limits to avoid conducting during normal

operation which would result in overheating.

Module shields that provide shielding around the belly

(label side) of the Maxi, Mini, Micro are also available for

applications that are highly noise sensitive. Module shield

information is available on the Vicor website, see links

provided, on the following page.

NOTE:

Acoustic Noise. Audible noise may be emitted

from the module under no load, light load, or

dynamic loading conditions. This is considered

normal operation of the module.

Maxi, Mini, Micro Design Guide Rev 4.9 vicorpower.com

Page 18 of 88

Apps. Eng. 800 927.9474 800 735.6200

Page 20

Design Guide & Applications Manual

+IN

PC

PR

–IN

+OUT

+S

SC

–S

–OUT

C3*

4.7nF

C

2*

4

.7nF

F

or C1 – C5, keep leads and connections short.

C

5*

4.7nF

C4*

4.7nF

F1*

C1*

0.2µF

or Maxi, Mini, Micro Family DC-DC Converters and Configurable Power Supplies

F

4. EMC Considerations

Figure 4–1 — Recommended bypassing capacitors must be in close

proximity, i.e., have short lead length to be effective.

Figure 4–3 — V48B28H250BN with recommended bypass caps

(330 µF across input)

Module Shield Information

Module shield for Maxi with threaded or through-hole baseplate P/N 30142

http://asp.vicorpower.com/CADPDF/H7CEX3.PDF

Figure 4–2 — V48B28H250BN without bypass caps

(330 µF across input)

Module shield for Maxi with slotted baseplate P/N 30199

http://asp.vicorpower.com/CADPDF/HXE113.PDF

Module shield for Mini with threaded or through-hole baseplate P/N 30180

http://asp.vicorpower.com/CADPDF/UT55TT.PDF

Module shield for Mini with slotted baseplate P/N 30198

http://asp.vicorpower.com/CADPDF/HXE112.PDF

Module shield for Micro with threaded or through-hole baseplate P/N 30143

http://asp.vicorpower.com/CADPDF/9YRD8X.PDF

Module shield for Micro with slotted baseplate P/N 30141

Maxi, Mini, Micro Design Guide Rev 4.9 vicorpower.com

Page 19 of 88

http://asp.vicorpower.com/CADPDF/NG6SIS.PDF

Apps. Eng. 800 927.9474 800 735.6200

Page 21

5. Current Sharing In Power Arrays

or Maxi, Mini, Micro Family DC-DC Converters and Configurable Power Supplies

F

Design Guide & Applications Manual

Whenever power supplies or converters are operated in

a parallel configuration — whether for higher output

power, fault tolerance, or both — current sharing is an

mportant consideration. Most current-sharing schemes

i

employed with power converters involve either artificially

ncreasing the output impedance of the converter module

i

or actually sensing each output current, forcing all of the

currents to be equal by feedback control. In a synchronous

current-sharing scheme, however, there is no need for

having a current-sensing or current-measuring device on

each module, nor is there a need to artificially increase the

output impedance, which compromises load regulation.

WHY IS CURRENT SHARING IMPORTANT

Most paralleled power components — transistors, rectifiers,

power conversion modules, offline power supplies — will

not inherently share the load. In the case of power converters, one or more of the converters will try to assume a

disproportionate or excessive fraction of the load unless

forced current-share control is designed into the system.

One converter — typically the one with the highest output

voltage — may deliver current up to its current limit setting,

which is beyond its rated maximum. Then the voltage will

drop to the point where another converter in the array —

the one with the next highest voltage — will begin to

deliver current. All of the converters in an array may deliver

some current, but the load will be shared unequally. Built-in

current limiting may cause all or most converters to deliver

current, but the loading will remain unbalanced, and

potentially cause damage to the converters.

Consider the situation when one module in a two-module

array is providing all of the load. If it fails, the load on the

second module must go from no load to full load, during

which time the output voltage is likely to droop temporarily.

This could result in system problems, including shutdown

or reset. If both modules were sharing the load and one

failed, however, the surviving module would experience a

much less severe transient (one half to full load), and the

output voltage would be likely to experience no more

than a slight momentary droop. The dynamic response

characteristic of all forward converters, resonant or pulsewidth modulated, is degraded when the load is stepped

from zero (no load) where the output inductor current is

discontinuous.

In the same two-module array example, the module

carrying all of the load is also generating all of the heat,

resulting in a much lower mean time between failure

(MTBF) for that module. An often-quoted rule of thumb

says that for each 10°C increase in operating

temperature, average component life is cut in half. In a

current-sharing system, all of the converters or supplies

run at a lower temperature than some modules would in

a system without current sharing. As a result, all of the

modules age equally.

Current sharing, then, is important because it improves

system performance; it minimizes transient / dynamic

response and thermal problems and improves reliability. It

is an essential ingredient in most systems that use multiple

power supplies or converters for higher output power or

for fault tolerance.

CURRENT-SHARING IN POWER EXPANSION ARRAYS

When parallel supplies or converters are used to increase

power, current sharing is achieved by a number of

approaches. One scheme simply adds resistance in series

with the load. A more practical variant of that is the

“droop-share” method, which actively causes the output

voltage to drop in response to increasing load. The two

most commonly used approaches to paralleling converters

for power expansion are the driver/booster or master/

slave arrays and analog current-share control. They appear

to be similar, but the implementation of each is quite

different. Driver/booster arrays usually contain one

intelligent module or driver, and one or more power-trainonly modules or boosters. Analog current-share control

involves paralleling two or more identical modules, each

containing intelligence.

Droop Share. The droop-share method, shown in Figure

5–1, increases the output impedance to force the currents

to be equal. It is accomplished by an error signal, which is

interjected into the control loop of the converter causing

the output voltage to operate as a function of load

current. As load current increases, output voltage

decreases. All of the modules will have approximately the

same amount of current because they are all being

summed into one node. If one supply is delivering more

current than another supply, its output voltage will be

forced down a little so that it will be delivering equal

current for an equal voltage out of that summing node.

Figure 5–1 illustrates a simple implementation of this

scheme where the voltage dropped across the ORing

diode, being proportional to current, is used to adjust the

output voltage of the associated converter.

Droop share has advantages and disadvantages. One of

the advantages is that it can work with any topology. It is

also fairly simple and inexpensive to implement. A major

drawback, though, is that it requires that the current be

sensed. A current-sensing device is needed in each of the

converters or power supplies. In addition, a small penalty

is paid in load regulation, although in many applications

this is not an issue.

Maxi, Mini, Micro Design Guide Rev 4.9 vicorpower.com

Page 20 of 88

Apps. Eng. 800 927.9474 800 735.6200

Page 22

Design Guide & Applications Manual

Return

+S

+OUT

SC

–S

–OUT

–IN

PR

PC

+IN

+S

+OUT

SC

–S

–OUT

–IN

PR

PC

+IN

DC-DC Converter

Maxi or Mini

+IN

– IN

+OUT

DC-DC Converter

Maxi or Mini

or Maxi, Mini, Micro Family DC-DC Converters and Configurable Power Supplies

F

5. Current Sharing In Power Arrays

In general, it is not recommended to mix and match converters, especially those with incompatible current-sharing

schemes. The droop-share method, however, is more

orgiving in this regard than with any of the other

f

methods. Current sharing can be achieved using arrays

onstructed from different converter models or even from

c

different suppliers with a little external circuitry.

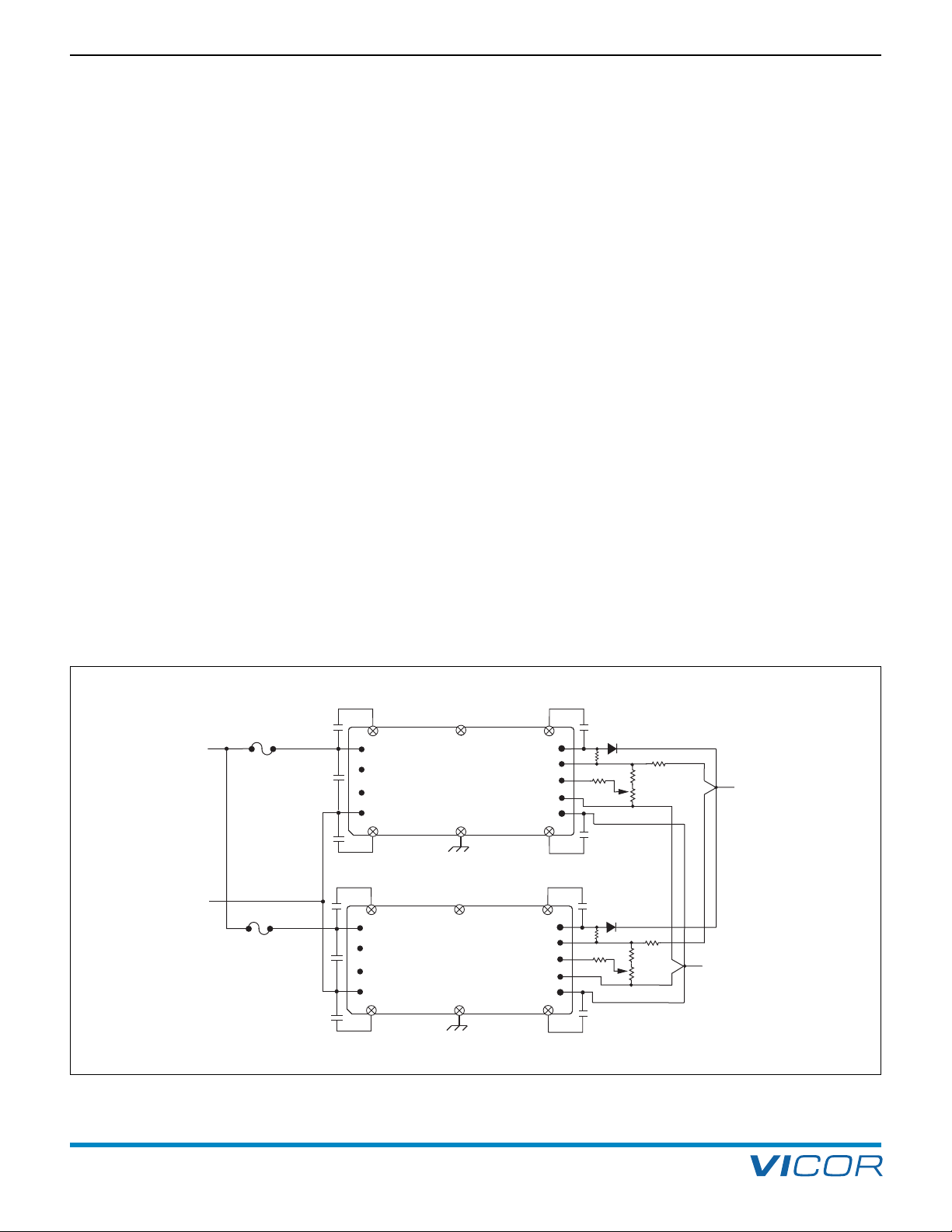

Driver/ Booster Arrays. Most Vicor converters can

employ the driver/booster array for increased power.

(Figure 5–2) Driver/booster arrays usually contain one

intelligent module or driver, and one or more power-trainonly modules or boosters. The driver is used to set and

control output voltage, while booster modules are used

to increase output power to meet system requirements.

Driver/booster arrays of quasi-resonant converters with

identical power trains inherently current share because

the per-pulse energy of each converter is the same. If the

inputs and outputs are tied together and the units have

the same clock frequency, all modules will deliver the

same current (within component tolerances). The single

intelligent module in the array determines the transient

response, which does not change as modules are added.

Booster modules require only one connection between

units when their outputs are connected; no trimming,

adjustments, or external components are required to

achieve load sharing. The load sharing is dynamic and

usually guaranteed to be within five percent.

It is important to remember that when using boosters, the

input voltage, output voltage, and output power of the

boosters must be the same as the driver.

The advantages of driver/booster arrays are that they

have only a single control loop so there are no loop-withina-loop stability issues, and they have excellent transient

response. However, this arrangement is not fault tolerant.

If the driver module fails, the array will fail to maintain its

output voltage.

Analog Current-Share Control. Analog current-share

control, typical of PWM type converters, involves

paralleling two or more identical modules, each

containing intelligence. The circuit actively adjusts the

output voltage of each supply so that the multiple

supplies deliver equal currents. This method, however, has

a number of disadvantages. Each converter in the array

has its own voltage regulation loop, and each requires a

current sensing device and current control loop.

Analog current-share control supports a level of redundancy,

but it is susceptible to single-point failures within the

current-share bus that can, at best, defeat current sharing,

and, at worst, destroy every module in the array. The

major reason for this is the single-wire galvanic connection

between modules.

Figure 5–1 — The droop-share method artificially increases the output impedance to force the currents to be equal.

Maxi, Mini, Micro Design Guide Rev 4.9 vicorpower.com

Page 21 of 88

Apps. Eng. 800 927.9474 800 735.6200

Page 23

5. Current Sharing In Power Arrays

or Maxi, Mini, Micro Family DC-DC Converters and Configurable Power Supplies

F

Design Guide & Applications Manual

CURRENT SHARING IN FAULT TOLERANT ARRAYS

Current sharing is an essential element in fault-tolerant

arrays, and regardless of the approach, there is an

inherent additional cost incurred by the addition of at

least one redundant converter or supply.

Most applications today that require fault tolerance or

redundancy also require Hot-Swap capability to ensure

continuous system operation. Hot swappable cards must

be designed so that the operator cannot come in contact

with dangerous potentials, currents or thermal hazards. It

is also essential that when a module fails, the failure is

detected and identified by an alarm or notice to provide

service. A Hot-Swap system must ensure that during swap

out there is minimal disturbance of the power bus.

Specifically, the affected voltage bus must not drop

enough to cause errors in the system, either on the input

bus or the output bus.

N+1 Redundancy. A power supply failure can cripple an

entire system, so a redundant converter or supply can be

added to ensure that, in the event of a failure, the system

will continue to operate. Adding an extra module (N+1) to

a group of paralleled modules will significantly increase

reliability with only a modest increase in cost.

How redundant converters are implemented is determined

in part by the available space and cost requirements. Two

500 W Maxi modules, for example, could be used to

provide a 1 kW output with an additional 500 W module

for 2+1 redundancy a total of 1.5 kW in a volume of

about 16.5 in3 (270 cm3). Four 200 W half-size modules

might be used instead with a fifth 200 W module for

4+1 redundancy, a total of 1 kW and 14 in3(229 cm3).

Although the second solution uses less space, it increases

the accumulated failure rate because it employs more

converters, more ORing diodes, more monitoring circuitry,

and more assembly.

ORing diodes may be inserted in series with the +Output

of each module in a N+1 array to provide output fault

tolerance (Figure 5–1). They are important in a redundant

power system to maintain fault isolation. Without them,

a short-circuit failure in the output of one converter could

bring down the entire array. As well, fusing the input of

each converter prevents a converter input short from

compromising the entire array.

ORing diodes, however, add losses to the power system,

reducing overall efficiency (and, potentially, decreasing

reliability). To ameliorate this negative effect on efficiency,

ORing diodes should run hot, thereby reducing forward

voltage drop and improving system efficiency. Reverse

leakage current will be an issue only if the output of a

converter shorts and the diode is reverse biased. This is an

important consideration with regard to operating temperature.

Current sharing, required to ensure system reliability, can

be implemented by a multiplicity of methods. Figure 5–1,

shown earlier as an example of the droop-share method,

s also an example of N+1 redundancy using ORing diodes.

i

Synchronous Current Sharing. Synchronous current

sharing is available with Maxi, Mini, Micro converters —

converters that use the zero-current-switching and zerovoltage-switching topology. Each module has the capability to assume control of the array, that is, they constitute a

democratic array. The module that assumes command

transmits a pulse on the parallel bus to which all other

modules on the bus synchronize.

The converters use this pulse as a current-sharing signal

for power expansion and fault-tolerant applications. The

pulsed signal on the parallel bus simplifies current-sharing

control by synchronizing the high-frequency switching of

each converter. The parallel pin is a bi-directional port on

each module used to transmit and receive information

between modules. If the lead module relinquishes control,

another module in the array will transparently take

command with little or no perturbation of the output bus.

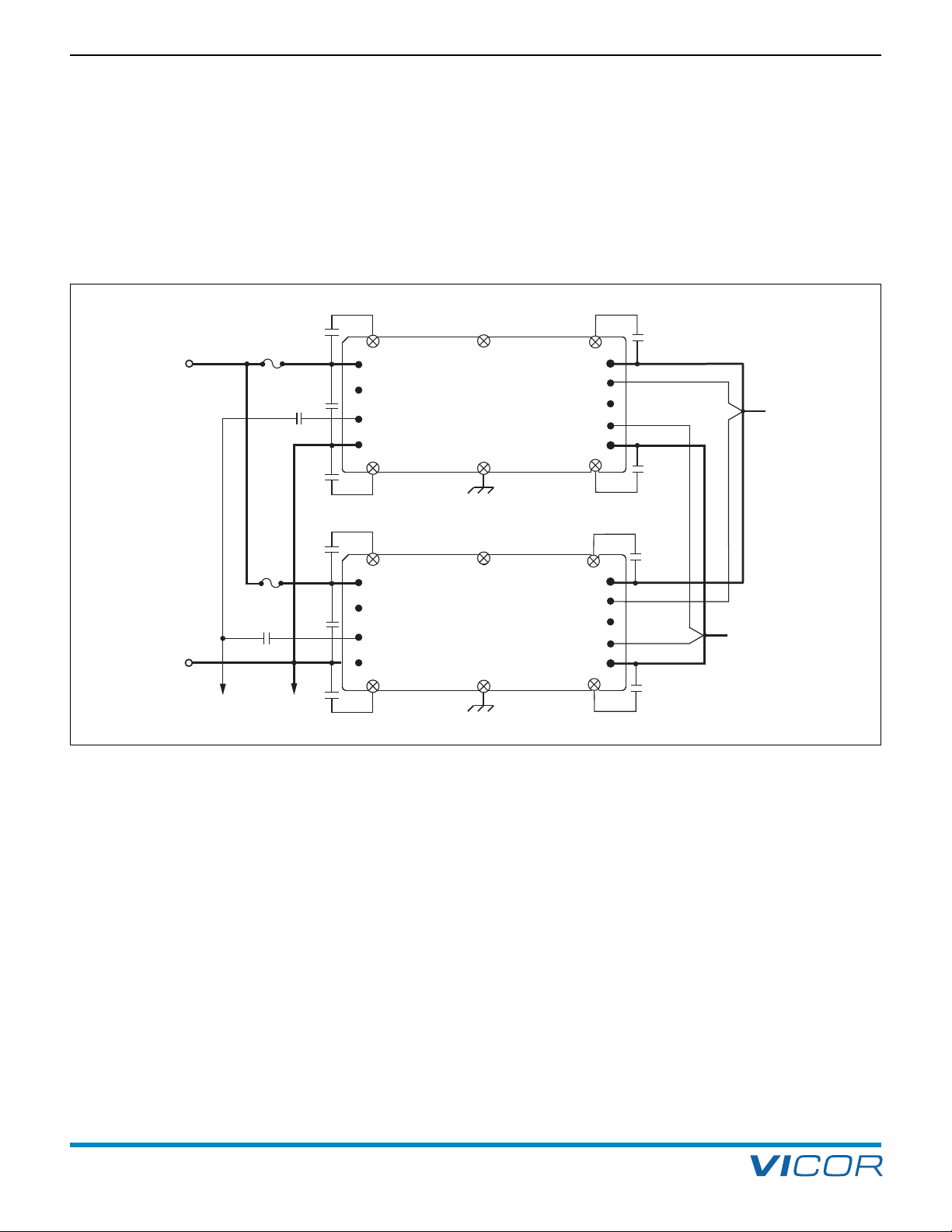

A pulsed signal gives designers the option to use capacitors (Figure 5–2) or transformers between parallel pins,

providing DC-blocked coupling. Such coupling

prevents certain failure modes internal to a single module

from affecting the other modules in the array, thus

providing an increased level of fault tolerance.

Use of a current-share bus transformer (Figure 5–3)

enables arrays of Maxi, Mini, Micro converters to current

share when they are widely separated or operated from

independent sources. Since the current-share signal is a

pulsed signal, it can be transformer coupled. Transformer

coupling this pulsed signal provides a high level of

common-mode noise immunity while maintaining SELV

isolation from the primary source. This is especially

useful when board-to-board load sharing is required

in redundant applications.