VICOR M-FIAM5MN1, M-FIAM5M22, M-FIAM5M21, M-FIAM5M13, M-FIAM5M12 Datasheet

...

Vicor Corp. Tel: 800-735-6200, 978-470-2900 Fax: 978-475-6715 MFIAM5 Rev. 1.7 Page 1 of 5

Set your site on VICOR at www.vicorpower.com

Parameter Min Typ Max Remarks

Input voltage 18Vdc 28Vdc 36Vdc Continuous

Output current 20A

Inrush limiting 0.007A/µF

Transient immunity MIL-STD-704E See footnote 1

EMI:MIL-STD-461E

Conducted emissions: CE101, CE102

Conducted susceptibility: CS101, CS114, CS115, CS116

Dielectric withstand 1,500Vrms Input/Output to Base

2,121Vdc Input/Output to Base

Efficiency 96% 98%

Internal voltage drop 0.5 1.0 @20A, 100°C baseplate

ON/OFF control

Enable (ON) 0.0Vdc 1.0Vdc Referenced to –Vout.

Disable (OFF) 3.5Vdc 5.0Vdc 100kΩ internal pull-up resistor

External capacitance See illustration C1 on page 3.

330µF 1000µF 50V

Weight 3.1 (88) 4 (113) Ounces (grams)

Warranty 2 Years

Parameter Rating Unit Notes

+In to –In 36 Vdc Continuous

+In to –In 50 Vdc 100ms

Mounting torque 5(0.57) in-lbs 6 each, #4-40 or M3

Pin Soldering temperature 500 (260) °F(°C) <5 sec; wave solder

Pin Soldering temperature 750 (390) °F(°C) <7 sec; hand solder

Operating temperature H–Grade -40 to +100 °C Baseplate

Storage temperature H–Grade -55 to +125 °C

Operating temperature M–Grade -55 to +100 °C Baseplate

Storage temperature M–Grade -65 to +125 °C

Features

• EMI filtering-MIL-STD-461E

• Transient protection-MIL-STD-704E

1

• Environments-MIL-STD-810, MIL-STD-202

• Environmental stress screening

• Low profile mounting options

• Output current up to 20 Amps

• Mini sized package

• Inrush current limiting

• Reverse polarity protection

Product Highlights

The M-FIAM5 is a DC front-end module

that provides EMI filtering and transient

protection required in military applications.

The M-FIAM5 enables designers using

Vicor 2nd Generation 24V DC-DC converters

to meet conducted emission/conducted

susceptibility per MIL-STD-461E; and

input transients per MIL-STD-704E1. The

M-FIAM5 accepts an input voltage of

18-36Vdc and delivers output current

up to 20 Amps.

M-FIAM5 is housed in an industry

standard "half brick" module measuring

2.28" x 2.2" x 0.5" and depending upon

model selected, may be mounted on-board

or in-board for height critical applications.

Compatible Products

• 2nd Generation 24V Input

DC-DC converters

Part Number Format

*Compatible with SurfMate and InMate socketing system.

Thermal Resistance

Parameter Typ

Baseplate to sink; flat, greased surface 0.16°C/Watt

Baseplate to sink; thermal pad (P/N 20264) 0.1°C/Watt

Baseplate to ambient 7.9°C/Watt

Baseplate to sink; 1000 LFM 2.2°C/Watt

M-FIAM5

Military 28Vin Filter

Input Attenuator Module

45

Shown actual size:

2.28 x 2.2 x 0.5 in

57,9 x 55,9 x 12,7 mm

Specifications

(typical at TBP = 25ºC, nominal line, 75% load, unless otherwise specified)

Absolute Maximum Rating

M-FIAM5 M 2 1

Product

Baseplate

1 = Slotted

2 = Threaded

3 = Thru-hole

Product Grade(°C)

H = –40 to +100

M = –55 to +100

Temp Environment MTBF Unit

25°C Ground Benign:G.B. 3,334,295 Hrs

50°C Naval Sheltered:N.S. 786,893 Hrs

65°C Airborne Inhabited Cargo:A.I.C. 650,187 Hrs

MTBF per MIL-HDBK-217F

Pin Style

1 = Short

2 = Long

*S=Short ModuMate

*N=Long ModuMate

1

MIL-STD-704E Compliance requires an external circuit. See addendum A

Vicor Corp. Tel: 800-735-6200, 978-470-2900 Fax: 978-475-6715 MFIAM5 Rev. 1.7 Page 2 of 5

Set your site on VICOR at www.vicorpower.com

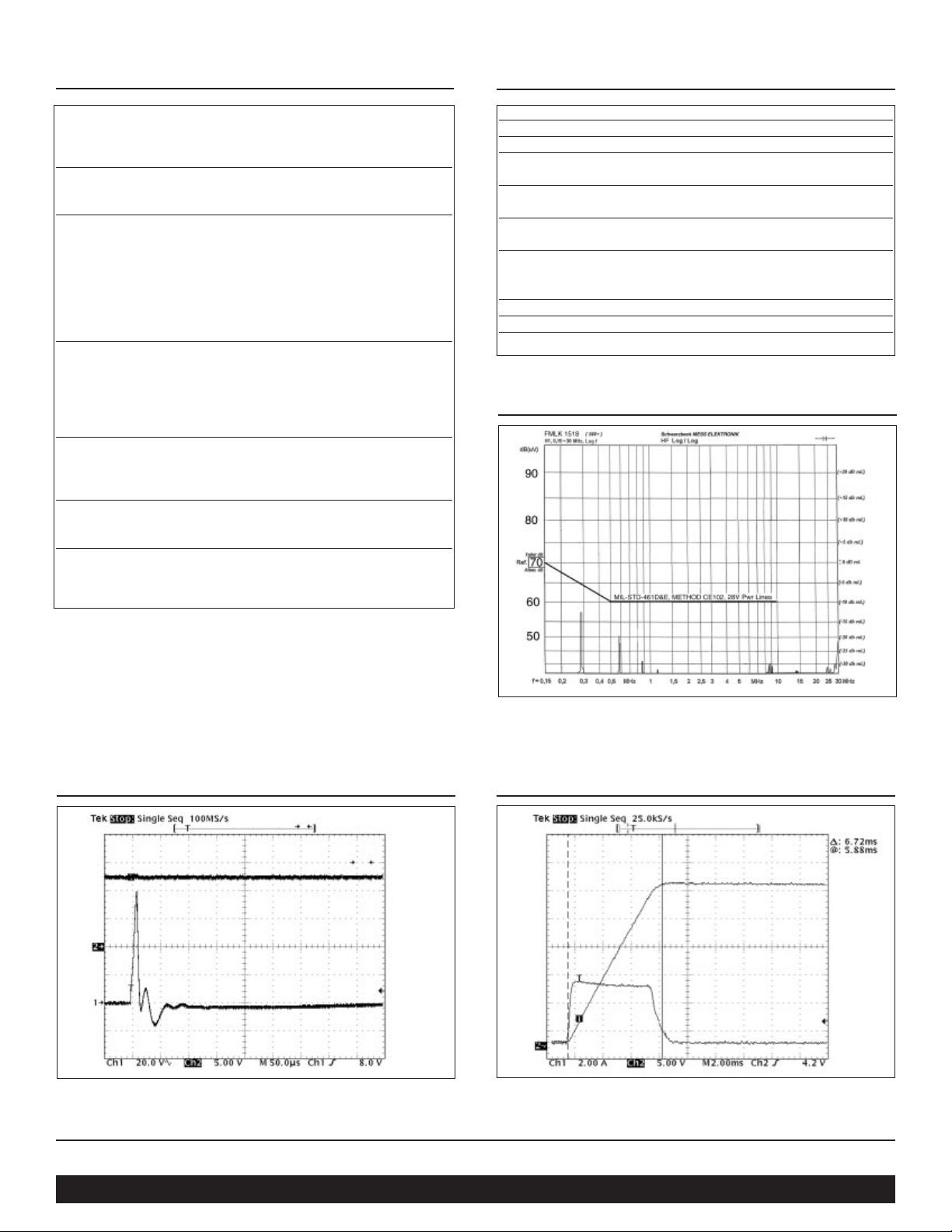

Transient Immunity

Inrush Limiting

Figure 2 – Transient Immunity: M-FIAM5 output response to

an input transient.

Figure 3– Inrush Limiting: Inrush current with

1000

µF

external capacitance.

Environmental Qualification

Altitude

MIL-STD-810C, Method 500.2, Procedure I & II, 40,000 ft. and

70,000 ft. Operational.

Explosive Atmosphere

MIL-STD-810F, Method 511.4, Procedure I, Operational.

Vibration

MIL-STD-810F, Method 514.5, Procedure I, Category 14, Sine

and Random vibration per Table 514.5C for Helicopter AH-6J

Main Rotor with overall level of 5.6 grams for 4 hours per axis.

MIL-STD-810F, Method 514.5C, General Minimum Integrity

Curve per Figure 514.5C-17 with overall level of 7.7 grams

for 1 hour per axis.

Shock

MIL-STD-810-F, Method 516.5, Procedure I, Functional Shock,40 G's.

MIL-S-901D, Lightweight Hammer Shock, 3 impacts/axis, 1,3,5 ft.

MIL-STD-202F, Method 213B, 60 G's, 9ms half sine.

MIL-STD-202F, Method 213B, 75 G's, 11ms Saw Tooth Shock.

Acceleration

MIL-STD-810F, Method 513.5, Procedure II, table 513.5-II,

Operational, 2-7 G's, 6 directions.

Humidity

MIL-STD-810F, Method 507.4, Procedure I, Cycle I, 240 hrs, 95% RH.

Solder Test

MIL-STD-202F, Method 208, 8 hour aging.

H Grade M Grade

Operating Temp. -40°C to +100°C -55°C to +100°C

Storage Temp. -55°C to +125°C -65°C to +125°C

Temp. Cycling:*

12 cycles 12 cycles

-65°C to +100°C -65°C to +100°C

Ambient Test

@ 25°C

Yes Yes

Power Cycling 12 hours, 24 hours,

Burn-In: 28 cycles 56 cycles

Functional and

Parametric

-40°C and -55°C and

ATE Tests:

+100°C +100°C

Hi-Pot Test Yes Yes

Visual Inspection: Yes Yes

Test Data vicorpower.com vicorpower.com

Environmental Stress Screening

Conducted Noise

Figure 1– M-FIAM5 and Model V24A12M400A

DC-DC converter operating at 28Vdc, 400W.

*Temperature cycled with power off, 17°C per minute rate of change.

Loading...

Loading...