Vicon V900-358-24C, V900-2.9HC-24, V900-2.8HB-24, V900-358HB-24, V900-358HC-24 Installation & Operation Manual

...

V900 IMPACT-RESISTANT

DOME CAMERAS

X986

Vicon Industries Inc. does not warrant that the functions contained in this equipment will meet

your requirements or that the operation will be entirely error free or perform precisely as

described in the documentati on. This system has not been designed to be used in life-critical

situations and must not be used for this purpose.

Copyright © 2001 Vicon Industries Inc. All rights reserved.

Product specifications subject to change without notice.

Vicon and its logo are registered trademarks of Vicon Industries Inc.

VICON INDUSTRIES INC., 89 ARKAY DRIVE, HAUPPAUGE, NEW YORK 11788

TEL: 631-952-CCTV (2288) FAX: 631-951-CCTV (2288) TOLL FREE: 800-645-9116

24-Hour Technical Support: 800-34-VICON (800-348-4266)

UK: 44/(0) 1489-566300 INFOFAX: 800-287-1207 WEB: www.vicon-cctv.com

Vicon part number 8006-8986-03-02 Rev 1001 Section 1

Contents

Contents...............................................................................................................................i

Quick Installation................................................................................................................ii

Introduction......................................................................................................................... 1

Installation ..........................................................................................................................2

Unpacking and Inspection............................................................................................................................ 2

Inspection for Visible Damage...................................................................................................................... 2

Inspection for Concealed Damage............................................................................................................... 2

Roughneck V900 Dome Components..........................................................................................................2

Mounting the Unit .......................................................................................................................................... 3

Cable Connections ........................................................................................................................................ 4

Coaxial Video Cable.....................................................................................................................................5

Camera Power Connections ........................................................................................................................ 6

Heater Connections...................................................................................................................................... 7

Camera Synchronization...............................................................................................................................7

Camera Adjustments..................................................................................................................................... 8

Accessing the DIP Switch ............................................................................................................................ 8

Final Installation............................................................................................................................................. 9

Operation ..........................................................................................................................11

Maintenance...................................................................................................................... 11

Care and Cleaning of Lower Dome ............................................................................................................11

Shipping Instructions....................................................................................................... 12

Reference.......................................................................................................................... 13

Technical Information......................................................................................................15

X986-03-02 Rev 1001 Roughneck V900 Dome Cameras Contents •••• i

Quick Installation

For experienced installers, us e the installation diagram below, Figure 1A f or indoor versions and Figure 1B f or

outdoor versions. For complete detailed instructions on how to install the V900, read the Installation section.

Installation Diagram Exploded View – Indoor Version

ii •••• Quick Installation X986-03-02 Rev 1101 Roughneck V900 Dome Cameras

Figure 1A

Figure 1B

Installation Diagram Exploded View – Outdoor Version

X986-03-02 Rev 1001 Roughneck V900 Dome Cameras Quick Installation •••• iii

Introduction

The information in this manual covers the installation, operation, and maintenance of the Roughneck V900

Series of Impact-Resistant Dome Cameras. These units should only be installed by a qualified technician

using approved materials in acc ordance with national, state and local wiring codes. Read this manual through

completely before attempting installation.

The Roughneck V900 Series of Impact-Resistant Dom e Cameras offer s high-security cameras in a compact

domed housing. They are available for indoor and outdoor applications. Indoor versions have sand cast

construction; outdoor models are permanent mold construction. Both have a high-impact polycarbonate plastic

dome. These camera packages are designed to handle the toughest environments, including correctional

facilities, warehouses and loading dock s. The outdoor models include neoprene sealing and heaters to allow

operation in low temperature and in all weather conditions. Tamper-resistant screws make both units resistant

to vandalism.

The base of the unit screws directly to a wall or ceiling. The camera mount offers adjustment to any view

required. The camera position is adjustable horizontally and vertically (there is full 180° camera mounting

adjustment). T he V900 series has an integral camera, high-r esolution monochrom e or color, with a choice of

lenses. Both monochrome and color cameras accept 24 VAC or 24 VDC, while color cameras also feature line

lock capability. If varifocal lens models are selected, there is lens adjustment capability and autoiris

adjustment is available by a potentiometer. Refer to Table 1 for a complete listing of models.

The Roughneck V900 Dome Camera series meets FCC requirements for a Class A device. This product

complies with European Comm unity EMC Directive 89/336. The product was subjected to the testing outlined

in European Normalization Standard EN 50081-1 (Electromagnetic Compatibility - General Emissions

Standard Part 1: Residential, Comm erc ial and Light Industry), and EN 50082-1 (Electr om agnetic Com patibility

- Generic Immunity Standard Part 1: Residential, Commercial and Light Industry).

Table 1

Models, Product Codes and Descriptions

Model Product Code Description

V900-2.8HB-24 6524-04 Indoor; 1/3-in. high-resolution monochrome camera and 2.8 mm

lens; 24 VAC/VDC. EIA.

V900-358HB-24/

V900-358-24C

V900-2.9HC-24 6514-04 Indoor; 1/4-in. high-resolution color camera and 2.9 mm lens;

V900-358HC-24/

V900-358HC-24C

V900-358HCA-24/

V900-358HCA-24C

6526-04/6526-03 Indoor; 1/3-in. high-resolution monochrome camera and

3.5 - 8 mm varifocal lens; 24 VAC/VDC. EIA/CCIR.

24 VAC/VDC. NTSC.

7567-00/7567-01 Indoor; 1/3-in. high-resolution color camera and 3.5 - 8 mm

varifocal lens; 24 VAC/VDC. NTSC/PAL.

7568-00/7568-01 Outdoor; 1/3-in. high-resolution color camera and 3.5 - 8 mm

varifocal autoiris lens; 24 VAC/VDC; heater. NTSC/PAL.

X986-03-02 Rev 1001 Roughneck V900 Dome Cameras Introduction •••• 1

Installation

Unpacking and Inspection

All Vicon equipment is tested and inspected before leaving the factory. It is the carrier’s responsibility to deliver

the equipment in the same condition as it left the factory.

Inspection for Visible Damage

Immediately inspect the cartons upon deliver y. Make a note of any visible damage on all copies of the carrier’s

freight bill.

Make sure the carrier’s agent (the person making the delivery) signs the note on all copies of the bill. If the

agent does not have claim forms, contact the carrier’s office.

Inspection for Concealed Damage

As soon as pos sible after delivery, unpack the unit and inspec t it for concealed damage. Do not discar d the

carton or packing m aterials. If the unit is dam aged, c ontact the carrier immediately and request forms for filing

a damage claim. Make arrangements for a representative of the carrier to inspect the damaged equipment.

If the equipment must be returned for repair, follow the Shipping Instructions at the end of this manual.

Roughneck V900 Dome Components

The Roughneck V900 units consist of a base (which includes the camera mounting bracket with the

camera/lens assembly) and a cover with a clear dome; some models include a mask. Some units are

delivered completely assembled; others require lens installation. Refer to Figure 1.

Base/Camera Mounting Bracket

The base of the indoor unit is cons tructed of sand cast aluminum; the outdoor unit’s base is constructed of

aluminum permanent mold casting. The base is mounted directly to the wall or ceiling. Two cable access

holes are provided. A safety cord is provided to connect the c over to the base. T he cam era mounting br acket

is attached to a yoke in the base; the camera is factory-installed (s ome units require lens installation, while

other have the lens factory installed). The camera/lens position can be manually adjusted. A heater is installed

on the yoke in outdoor units.

Mask

A gray foam mask is provided with some units to fit over the camera/lens assembly.

Cover/Dome

The cover of the indoor unit is constructed of sand cast aluminum ; the outdoor unit’s cover is construc ted of

aluminum permanent mold casting. Both have a 3.5 in. (89 mm) diameter dome constructed of clear

polycarbonate plastic. The cover is s ecured to the bas e with four tam perpr oof c aptive scr ews; a special tool is

supplied to loosen the screws. A safety cord is provided to anc hor the cover/dome to the base. A heater is

factory-installed inside the cover. Refer to the Maintenanc e section of this m anual for ins tructions on the care

and handling of the dome.

2 •••• Installation X986-03-02 Rev 1101 Roughneck V900 Dome Cameras

Mounting the Unit

Select a location for the installation of the V900 c amera. Be sure the area around the selected location is clear

of obstacles (such as steel beams, headers, pipes, electrical wiring, etc.) which would interfere with the

mounting of the cam era and that the location can support the weight of the unit [the V900 unit weighs 4 lb

(1.8 kg)]. Video and power cables must be routed to the installation location.

The V900 mounts direct ly to a ceiling or wall. The base has four mounting holes, and two cable access holes

are provided. As a mounting alternative, the m ounting holes align with a standard 4 x 4 electrical box, and the

unit may be mounted to that. Refer to F igure 2. All the hardware needed to mount the base to the wall or

ceiling is provided in the accessory kit. To mount the V900, follow the steps below.

Caution: Do not attach these units to drywall surfaces and do not install mounting screws into the end

grain of wood.

1. Loosen the four captive screws securing the cover to the base with the special tool supplied in the

accessory kit. T he cover remains attached to the base by a safety cord. Allow the cover to hang. Remove

the mask from the camera/lens assembly.

2. Using the base as a template, m ark the loc ation of the four m ounting holes [0.265 in. (6.7 mm) diameter].

See Figure 2.

3. Drill a hole in the wall or ceiling and route video and power cables to the location and through one of the

cable access holes provided. A 1/2-inch conduit c onnection (custom er- supplied connector) is provided on

the side of the base; a liquid-tight connector [threaded, 0.69 in. ( 17.5 mm) diameter] is provided in the

accessory kit for base mounting. See Figures 1 and 2.

Note: If the conduit fitting on the side is us ed, the base should be mounted so the conduit connection is as

close to the bottom of the unit as possible to prevent water from entering the unit.

4. Optional Step: If it is desirable to conver t the threaded port (D IN 40430 Pg 11) for the liquid tight fitting to

a 1/2-inch NPT, an adapter is needed (Pg11 to 1/2-in. NPT). This adapter is commer c ially available or can

be ordered from Vicon, part number 8004-9317-01. Screw the adapter clockwise into the fitting and

tighten with a wrench. Vicon recomm ends the use of Tef lon tape, wrapped clockwise around the threads

of the adapter, to ensure a snug fit. Refer to Figure 3 for installation options.

5. Fasten the base to the wall or ceiling with the appropr iate hardware provided for the mounting surface, the

lag bolts and sleeve f or cement surfaces or the m achine screws for other surfaces. A nylon washer is

provided at each mounting hole for envir onmental sealing. If the c able access on the m ounting surface is

used, the connector s hould be situated in the cut out cable access hole to allow a flush installation of the

base. As a mounting alternative, align the mounting holes with a 4 x 4 electrical box and fasten the base to

the box with the machine screws.

6. If the lens was not factory installed, screw the lens onto the camera.

7. On indoor models, loosen the set screw on the yoke holding the camera mounting plate to rotate the

camera/lens assem bly to desired position. Tighten the set screw. On outdoor models, sim ply rotate the

camera/lens assembly to desired position. To adjust the tilt position of the camera/lens assembly on

indoor versions, loosen the nuts on each side of the yoke and move the cam era to desired position. On

outdoor models, loosen the nuts on the vertic al adjustment bracket to move the camera to the desired

position. Tighten the nuts. Do not move the camera/lens assembly by holding onto the lens. For

outdoor units, there is a roll adjustment: loosen the two (2) thumb screws and rotate unit to desired

position; tighten thumb screws. If a unit with a varifocal lens is being installed, the lens can be m anually

adjusted for ir is, f ocus and angle of view (telephoto/wide). On autoir is m odels, ther e is a potentiom eter f or

adjustment. When making adjustments, be sure that the lens does not hit the dome.

X986-03-02 Rev 1001 Roughneck V900 Dome Cameras Installation •••• 3

To assure a watertight seal, apply silicone sealant around the area where the base m eets the wall or

Note:

ceiling.

Figure 2

Mounting Hole Pattern

Figure 3

Installation of NPT Adapter

Cable Connections

Both power and video connections are m ade to the printed circuit board (PC board) mounted to the c amera

mounting plate. Refer to Figure 4A and 4B when perf orming these connections. Refer to the Coaxial Cable

Recommendation in the reference section.

4 •••• Installation X986-03-02 Rev 1101 Roughneck V900 Dome Cameras

Coaxial Video Cable

Some Roughneck V900 off ers two options for connecting video cables to the c amera. The first method is to

attach a customer-s upplied male BNC connector to the video cable and then connect it to the mating BNC

connector on the pendant cable on the PC board. As an alternative, there is a special video connector on the

PC board. Refer to Figure 4A and 4B.

1. Strip the video cable insulation to expose the ground. Refer to Figure 5.

2. Strip back the insulation to expose the conductor.

3. Slip the cable through the clamp to make ground contact and tighten.

4. Connect the center conductor to the screw terminal (P8) on the PC board.

Figure 4A

Camera/Lens PC Board – Indoor Ver sion

Figure 4B

Camera/Lens PC Board – Outdoor Version

X986-03-02 Rev 1001 Roughneck V900 Dome Cameras Installation •••• 5

Figure 5

Cable Preparation

Camera Power Connections

Note: Vicon systems and components, like most electronic equipment, require a clean, stable power source.

Voltage irregularities such as surges, drops, and interruptions can affect the operation of your

equipment and, in severe cases, damage certain c omponents. Vicon strongly recommends the use of

line conditioners, voltage regulators, and uninterruptible power supply (UPS ) systems.

Caution: Roughneck V900 series cameras are "electrically" non-isolated. This means that the AC power

input and the video output share a common ground connection. This common ground can cause

the electrical phenomenon of ground looping. "Ground loops" only occur on "multiple camera

installations" where a difference of ground potential exists between cameras, causing a base

frequency (50 Hz/60 Hz) distortion on the video signal. It affects the video by causing horizontal

line distortion, more commonly known as "hum bars".

To eliminate ground loops on multi-camera installations, Vicon suggests the following in an installation:

Use an electrically-isolated, multiple-channel power supply. This supply type provides a separate output for

each camera. These power supplies are available in several voltage and channel configurations.

Use a single-channel AC power supply for each camera. This power supply will provide the correct voltage

and electrical isolation for one camera.

Use a 1:1 voltage isolation transformer for each camera. This type of transformer is connected to an existing

AC power source and provides an isolated power source for the camera.

6 •••• Installation X986-03-02 Rev 1101 Roughneck V900 Dome Cameras

Power is connected through a three-position scr ew term inal connector on the PC board (P3). Ref er to T able 2

for the input power connections.

1. Locate the power cable screw terminal on the PC board.

2. Strip approximately 1 in. (25 mm) of insulation off power cables. Then strip off approximately 0.25 in.

(6 mm) of insulation off each individual wire. Attach the camera power cables to the cable connector

supplied in the accessory kit according to Table 2.

3. Press the cable connector onto the board screw terminal.

The camera is shipped prepared for 24 VAC/VDC.

Table 2

Camera Power Connections

Pin Number Function

1 24 VAC/24VDC

2 24 VAC Return

3 24 VDC Return

Heater Connections

The outdoor V900 has two (2) heaters, one inside the cover and one on the yoke in the base. Refer to Figure

1. The unit is deliver ed with the heater c onnec tions made to the two connectors (P4 and P6) on the PC board.

Refer to Figure 4. The heater in the cover is connected to the connector P6; the heater in the base is

connected to connector P4.

Camera Synchronization

When the V900 is being powered by 24 VAC, c am era synchronization is line lock ed. If ther e is m ore than one

unit in a system, the cameras have to be s ynchronized to ensure there is no disruption of video display. If the

camera will be used in a line lock video application (high-r esolution color c amer as only), the camer a interface

board is already set in line lock mode by default. The use of line-locking synchronization using a V-phase

potentiometer (pot) is typically included in video equipment requiring external video synchronization. As an

example, equipment like a video switcher unit uses the camera’s line lock to reduce “video jump” on its

monitor during c amer a switching. T he V-phas e pot allows video to power line phase adjus tment up to 180°. If

more than 180° of adjustment is required, swap the lines attached to the 24 VAC terminal block connector. For

1/3-inch color cam eras, be sure that the selector s witch is set to position “LL” shown in Figure 8 and jum per

JP1 must be in place; for the 1/4-inch color c amera, j umper JP1 mus t be in place. Note that the perf ormanc e

of the cam era’s line lock depends on the quality of the power source. If the camera experienc es roll or jitter

due to the quality of the power source, then it is best to set the camer a to internal “c rystal” mode. T his is done

by setting the selector switch to “INT.” as shown in Figure 8 and removing JP1 for 1/3-inch cameras or

removing jumper JP1 for 1/4-inch cameras.

A potentiometer on the PC board (R5) is s upplied to adjust synchronization. Refer to Figure 4. With a sm all

screwdriver (preferably plastic to avoid the risk of shorting out other internal components), turn the

potentiometer on each PC board until the video im ages on the monitor are steady so there is no rolling or

disruption of the display.

X986-03-02 Rev 1001 Roughneck V900 Dome Cameras Installation •••• 7

Camera Adjustments

The lens can be manually adjusted for iris, focus and angle of view. On the lens, focus (near to infinity) is the

front ring, the telephoto/wide adjustment is the middle ring and iris (open and close) is the end ring. On autoiris

lenses, iris adjus tment may be required if the pic ture appears dark or grainy or has poor color. There is a

potentiometer (VR1, located diagonally opposite the connector cables) on the camera board to adjust the

autoiris. Turning the potentiometer opens and closes the iris to regulate light extremes. Turning the

potentiometer clock wise opens the iris wider, allowing more light. Always adjust the potentiometer from f ull

bright (wide open iris) to an acceptable video level to provide the sharpest picture possible. Line lock and

autoiris control are DIP switch selectable on the 1/3- inch high-resolution color versions . Refer to Figure 8 for

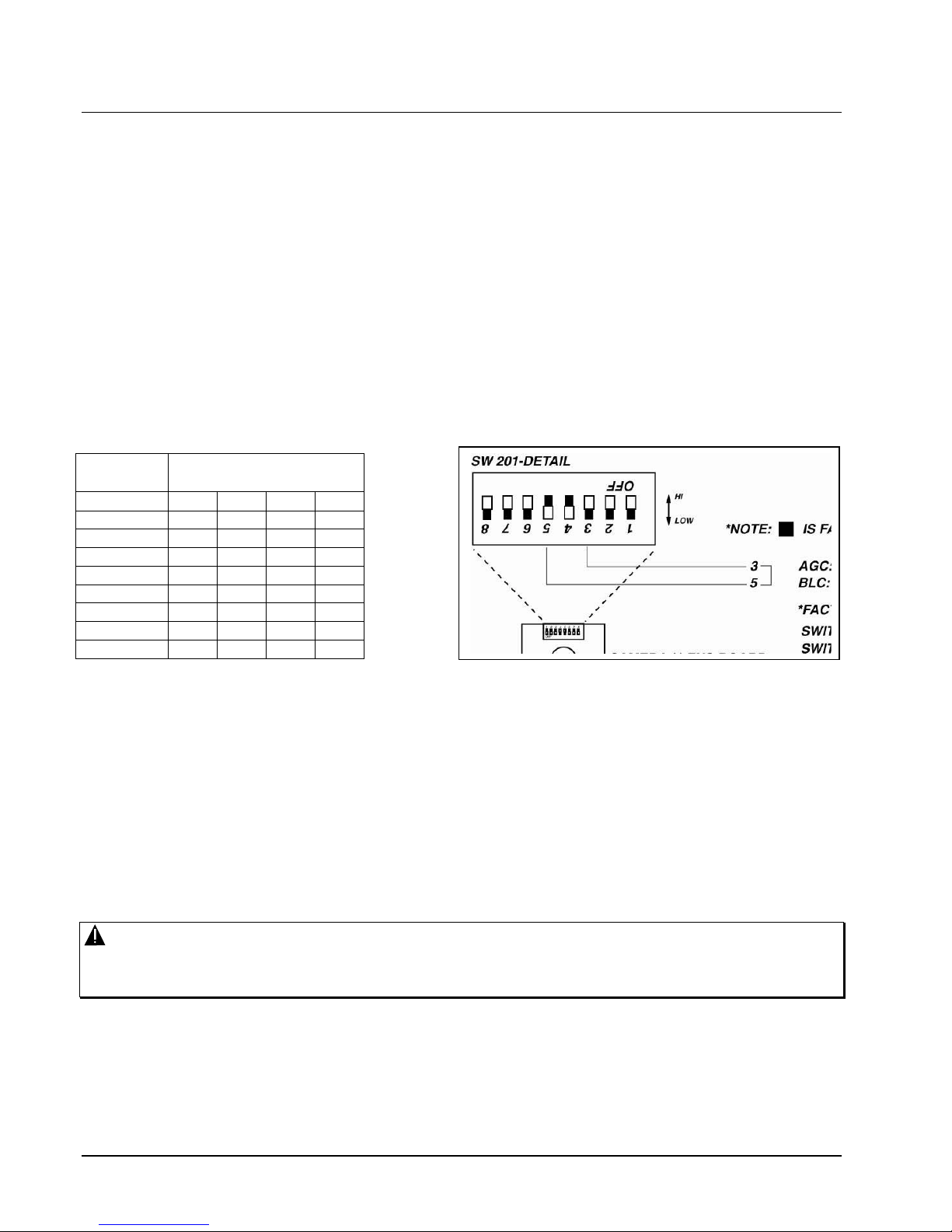

the location and setting of the switches. On the 1/4-inch high-resolution vers ion, DIP switch SW201, located

on the camera/lens board, is us ed to set camera/lens functions . Switch 7 toggles setting shutter speeds OR

setting BLC/AGC. W hen switch 7 is set OFF (Hi), switches 4, 5 and 6 control shutter s peed; when switch 7 is

set ON (Low), AGC and BLC can be set. Back light control (BLC) and automatic gain control (AGC) ON/OFF

are DIP switch selectable on this color camera (Table 3). BLC (switch 5) is factory set to OFF (Hi); AGC

(switch 3) is factory set to ON (Low). Ref er to Figure 6. In most cases, the f actory settings are preferred for

most lighting conditions.

Shutter Speed DIP Switch Settings

Shutter

Speed

1/60 (1/50) Hi Low Low Low

1/100 Hi Hi Low Low

1/250 Hi Low Hi Low

1/500 Hi Hi Hi Low

1/1000 Hi Low Low Hi

1/2000 Hi Hi Low Hi

1/4000 Hi Low Hi Hi

1/10000 Hi Hi Hi Hi

7 6 5 4

Switch No.

Figure 6

DIP Switch

Accessing the DIP Switch

Refer to Figure 7 to perform the following procedure to access the DIP switch on the 1/4-inch high-resolution

version.

1. Swing the camera/lens cradle up so that the bottom surface of the camera PCB is showing.

2. Remove the two (2) brass scr ews that secure the camera board to the lens m ount at the bottom of the

bracket.

3. Carefully remove (flip) the camera board so the DIP switch is visible.

Caution: Take care NOT to touch, move or lose the lens cover over the chip on the board.

Note the board position when removing it; it MUST be replaced exactly as it was.

4. Adjust the DIP switch settings according to Figure 6.

5. Remount the cam era board to the lens m ount in the exact orientation as it was removed using the two

screws previously removed.

8 •••• Installation X986-03-02 Rev 1101 Roughneck V900 Dome Cameras

Figure 7

Accessing the DIP Switch

Figure 8

Switch Settings

Final Installation

After all cable connections are m ade, test the camera/lens to see if any further adjustm ents are necessary.

When the camera and lens adjustments are com plete, r eplace the f oam mask over the camera/lens ass embly

(if necessary). Reattach the cover to the base by aligning the four captive sc rews with the holes in the base.

X986-03-02 Rev 1001 Roughneck V900 Dome Cameras Installation •••• 9

Any alignment of holes and screws is acc eptable. The cover can be rotated 90° by aligning the screws/holes

differently.

Caution: For moisture protection, Vicon recommends that when the cover is reattached, it compress the

gasket to a thickness of approximately 1/16 in. (1.6 mm).

10 •••• Installation X986-03-02 Rev 1101 Roughneck V900 Dome Cameras

Operation

When power is applied to the camera, the Roughneck V900 views the selected scene.

Maintenance

The Roughneck V900 Impact-Resistant Cameras require no scheduled maintenance except for the

occasional cleaning of the lower dome.

Care and Cleaning of Lower Dome

The inside surface of the smoked (gray-tinted) dome is easily scratched. Tak e the following precautions to

maintain the dome’s surface.

1. Always handle the dome by the flange and avoid touching the inside surface.

2. If dust or other contam inants ac cum ulate in the dom e’s inter ior, they should be removed with clean dry air

pressure (compressed air cans).

3. If spots, streaks or stains appear on the interior or exterior, they can be removed with a solution of

isopropyl alcohol and water using a microwave-safe (aluminum free) paper towel. Dry with clean, dry

pressurized air.

4. Sc ratches or surface blemishes on the exterior or interior may be removed with a nonabrasive wax using

a soft cleaning cloth. Either liquid or spray cleaner/wax suitable for fine furniture is acceptable.

Caution: Excessive pressure or rubbing on the dome’s surface can cause permanent scratches that may

render the dome unusable.

5. Clean all surfaces with any soft cleaning cloth and a mild cleaning agent suitable for acrylic plastic.

Caution: For warranty protection, implement this instruction exactly as stated.

X986-03-02 Rev 1001 Roughneck V900 Dome Cameras Operation •••• 11

Shipping Instructions

Use the following procedure when returning a unit to the factory:

1. Call or write Vicon for a Return Author ization (R.A.) at one of the locations lis ted below. Record the nam e

of the Vicon employee who issued the R.A.

Vicon Industries Inc.

89 Arkay Drive

Hauppauge, NY 11788

Phone: 631-952-CCTV (2288); Toll-Free: 1-800-645-9116; Fax: 631-951-CCTV (2288)

For service or returns from countries in Europe, contact:

Vicon Industries Ltd

Brunel Way

Fareham, PO15 5TX

United Kingdom

Phone: 44/(0)1489/566300; Fax: 44/(0)1489/566322

2. Attach a sheet of paper to the unit with the following information:

a. Name and address of the company returning the unit

b. Name of the Vicon employee who issued the R.A.

c. R. A. number

d. Brief description of the installation

e. Complete description of the problem and circumstances under which it occurs

f. Unit’s original date of purchase, if still under warranty

3. Pack the unit carefully. Use the original shipping carton or its equivalent for maximum protection.

4. Mark the R.A. number on the outside of the carton on the shipping label.

12 •••• Shipping Instructions X986-03-02 Rev 1101 Roughneck V900 Dome Cameras

Reference

Coaxial cables used to route video signals to and from the unit must meet the video recommendations in this section.

Caution: Careful selection of the proper cable is essential to obtain the best performance from this

equipment. Vicon assumes no responsibility for poor performance when cables other than those

recommended are installed. In all cases, coaxial cable impedance should be 75 ohms.

Materials

Use only cable with a pure copper center conductor. Do not use cable with either a copper-plated steel or an aluminum

center conductor because these do not transfer signals effectively in the frequency range used in CCTV networks. A

center conductor with low DC resistance is required for effective CCTV operation. Solid-core bare copper conductor is

best suited to video applications, except where flexing occurs. If the coaxial cable will be subjected to flexing during

normal use, select a cable with a stranded center conductor. The preferred dielectric material is cellular (foam)

polyethylene. It has better electrical characteristics than solid polyethylene, but is more vulnerable to moisture. Therefore,

use only solid polyethylene dielectric cable with a heavy exterior insulation in applications subject to moisture. The shield

must be copper braid providing 95% or better coverage.

Cable Types

The most commonly used cable types are RG-59/U and RG-11/U. Each is actually a family of cables with widely varying

electrical characteristics, some of which are not suitable for CCTV applications. Choose a cable type by referring to the

characteristics and maximum distances listed below. The maximum distance for best picture refers to the distance

between the camera and the unit The characteristics of the cables in this table should be used as a guideline when

cables other than Belden are used. Materials and construction must follow the guidelines above. Note that “BC” refers to

bare copper and “TC” refers to tinned copper.

Recommended Coaxial Cable Types

Cable

Type

Belden

Type No.

Alpha

Type No.

West Penn

Type No.

Type

Center

Conductor

Type Shield and

% Coverage

DC

Resistance

ohms per

1000 feet

(km)

RG-11/U 8213 9847 811,4811 14 Solid BC BC braid (95%) 2.6 (8.5)

RG-6/U 9248 9804C 806,4806 18 Solid BC Foil + 61% TC

braid (100%)

RG-59/U 8281 9803 815 20 Solid BC 2 TC braids (96%) 9.9 (32.5)

RG-59/U 9259 ---- 816 22 Stranded

BC

RG-59/U 9659 ---- ---- 22 Stranded

BC

BC braid (95%) 15.0 (49)

BC braid (95%) 15.0 (49)

7.5 (24.6)

Picture Quality vs Cable Length

Picture Quality

Maximum

Cable Run*

ft (m)

RG-59/U RG-6/U RG-11/U

Usable picture 1100 (350) 1500 (450) 2400 (750)

Clean picture 820 (250) 1000 (300) 1600 (500)

Best picture 400 (120) 530 (160) 820 (250)

* For longer cable runs, refer to the Product Specifications for Video Amplifiers.

X986-03-02 Rev 1001 Roughneck V900 Dome Cameras Reference •••• 13

Technical Information

ELECTRICAL

Input Voltage:

17 to 34 VDC (24 VDC nominal), nonisolated.

Power Consumption:

Current Rating:

Maximum Operating

Distance: Without Heaters

With Heaters

Heat Equivalent:

Note: These figures represent the conversion of 100% of the electrical energy to heat.

Connectors:

Video: BNC on pendant cable or special video screw terminal supplied.

Heaters: one 2-pin connector and one 3-pin connector.

Radio Frequency

Emission Rating:

European Community

(CE) Standard:

EN 50082-1 generic immunity.

Safety Standard:

Camera/Lens

14 to 25 VAC (24 VAC nominal), nonisolated.

13 W without heaters.

30 W with heaters.

0.9 A without heaters.

1.25 A with heaters.

Voltage Wire

Gauge

24 VAC 550

24 VDC 390

Voltage Wire

24 VAC 400

24 VDC 280

0.7 btu/min (0.19 kg-cal/min) without heaters.

1.7 btu/min (0.43 kg-cal/min) with heaters.

Actual percentage of heat generated will be less and will vary from product to product.

These figures are provided as an aid in determining the extent of cooling required for

an installation.

Power: 3-pin screw terminal.

FCC Class A.

EN 50081-1 generic emissions.

UL 2044.

20 18 16 14 12

859

(168)

(119)

20 18 16 14 12

(122)

(85)

(262)

609

(186)

Gauge

625

(191)

438

(134)

ft (m)

1375

(419)

975

(297)

ft (m)

1000

(305)

700

(213)

2200

(1671)

1576

(480)

1600

(488)

1120

(341)

3438

(1048)

2438

(743)

2500

(762)

1750

(533)

X986-03-02 Rev 1001 Roughneck V900 Dome Cameras Technical Information •••• 15

Specifications:

Refer to Table 3.

OPERATIONAL

Tilt and Horizontal

Adjustment:

2 axis adjustment, pan and tilt.

MECHANICAL

Application:

Indoor and outdoor models.

Mounting:

Ceiling or wall.

Dimensions:

Height: 4.8 in. (122 mm).

Total Diameter: 6.12 in. (155 mm).

Dome Diameter: 3.5. in. (89 mm).

Weight:

Approximately 4 lb (1.8 kg).

Construction:

Indoor Base/Cover: sand cast aluminum.

Outdoor Base/Cover: permanent mold cast aluminum.

Dome: polycarbonate plastic.

Finish:

Base/Cover: painted light gray.

Dome: clear.

ENVIRONMENTAL

Operating Temperature

Range:

Outdoor: 14 to 140° F (-10 to 60° C).

Operating Humidity:

Up to 95% relative, noncondensing.

Storage Temperature

Range:

-40 to 150° F (-40 to 65° C).

Storage Humidity:

Up to 90% relative, noncondensing.

Wind Load:

Outdoor: Heavy rain or snow driven by winds up to 80 mph.

16 •••• Technical Information X986-03-02 Rev 1101 Roughneck V900 Dome Cameras

Ratio

>50 dB

>50 dB

(AGC off)

>48 dB

(AGC off)

(AGC off)

>48 dB

>48 dB

(AGC off)

(AGC off)

Table 3

BLC AGC Signal-to-Noise

Synchronization Electronic Iris

Camera Specifications

On/Off,

selectable

− −

− −

On/Off,

(0.03)

selectable

1/250, 1/500,

1/60–1/100,000,

linear or 1/60, 1/100,

Automatically

Line lock (24 VAC)

(sec)

Internal 1/60 – 1/100,000

Internal 1/60 – 1/100,000

(0.03)

−

−

selectable

1/60–1/100,000

1/1000, 1/2000,

1/400,1/10,000,

selected

−

−

••

• 17

1/60–1/100,000

selectable

DIP switch

selectable

DIP switch

Lens Specifications

(TV lines) fc (lux)

Resolution Sensitivity

Color 480 0.28 (3) Internal (24 VDC)/

Mono 580 0.0028

Mono 580 0.0028

Mono

NTSC

EIA/CCIR

1/3” CCD,

2:1 interlace, EIA

Model Image Device Color/

V900-2.8HB-24 1/3” CCD,

V900-358HB-24/

2:1 interlace,

2:1 interlace,

V900-358-24C

V900-2.9HC-24 1/4” CCD,

Color 460 0.04 (0.4)* Internal/Line lock

Color 460 0.04 (0.4)* Internal/Line lock

1/3 CCD,

1/3” CCD,

NTSC/PAL

2:1 interlace,

2:1 interlace,

V900358HC-24/

V900-358HC-24C

V900-358HC-AI-24/

V900-358HC-AI-24C

NTSC/PAL

* At 40 IRE.

(mm) Horizontal Vertical

Model Focal Length Field-of-View

V900-2.8HB-24 2.8 120° -

V900-2.9HC-24 2.9 69° -

V900-358HB-24/24C 3.5-8 varifocal with manual iris 77.6° - 35.4° 57.6°- 26.6°

V900-358HC-24/24C 3.5-8 varifocal with manual iris 77.6° - 35.4° 57.6°- 26.6°

V900-358HC-AI-24/24C 3.5-8 varifocal with autoiris 77.6° - 35.4° 57.6°- 26.6°

X986-03-02 Rev 1001 Roughneck V900 Dome Cameras Technical Information •

Vicon Industries Inc.

Corporate Headquarters

89 Arkay Drive

Hauppauge, New York 11788

631-952-CCTV (2288) 800-645-9116

Fax: 631-951-CCTV (2288)

Infofax: 800-287-1207

!

Vicon Europe

Headquarters

Brunel Way

Fareham, PO15 5TX

United Kingdom

44/(0) 1489/566300

Fax: 44/(0) 1489/566322

Brussels Office

Planet II - Unit E

Leuvensesteenweg 542

B-1930 Zaventem

Belgium

322 712 8780

Fax: 322 712 8781

Far East Office

Unit 5, 17/F, Metropole Square

8 On Yiu Street, Shatin

New Territories,

Hong Kong

(852) 2145-7118

Fax: (852) 2145-7117

Internet Address: www.vicon-cctv.com

Loading...

Loading...