X971

Surveyor Mini Dome System

Vicon Industries Inc. does not warrant that the functions contained in this equipment will meet your requirements

or that the operation will be entirely error free or perform precisely as described in the documentation. This

system has not been designed to be used in life-critical situations and must not be used for this purpose.

Copyright © 1998 Vicon Industries Inc. All rights reserved.

Product specifications subject to change without notice.

Vicon and its logo are registered trademarks of Vicon Industries Inc.

Vicon Part No. 8006-8971-03-00 Section 1 Rev 1098

VICON INDUSTRIES INC., 89 ARKAY DRIVE, HAUPPAUGE, NEW YORK 11788

TELEPHONE: 516-952-CCTV (2288) FACSIMILE: 516-951-CCTV (2288)

TOLL FREE: 800-645-9116 UK: 44/(0) 1489-566300 INFOFAX: 800-287-1207

Dear Valued Customer:

Thank you for selecting Vicon systems and products for your

video needs.

Since Vicon’s beginning in 1967, our only business has been the

design, engineering, and production of the highest quality video systems

and equipment for use in a wide variety of security, safety, control,

surveillance, and communication applications.

We stand behind the quality and dependability of every product

with an industry leading Beneficial Use warranty.

If you are not satisfied with a Vicon product or service, I would

like to know. Your complete satisfaction is the mission of every Vicon

employee.

Sincerely,

Kenneth M. Darby

President

FCC Notice

NOTE: Complies with Federal Communications Commission Rules & Regulations Part 15, Subpart B for a

Class A digital device.

WARNING

This equipment generates and uses radio frequency energy and if not installed and used properly, that is, in

strict accordance with the manufacturer’s instruction, may cause interference to radio and television

reception. It has been type tested and found to comply with the limits for a Class A computing device in

accordance with the specification in subpart B of part 15 of the FCC rules, which are designed to provide

reasonable protection against such interference in a commercial installation. However, there is no guarantee

that interference will not occur in a particular installation. If this equipment does cause interference to radio

and television reception, which can be determined by turning equipment off and on, the user is encouraged to

try and correct the interference by one or more of the following measures:

• Reorient the receiving antenna.

• Relocate the equipment with respect to the receiver.

• Relocate the equipment away from the receiver.

• Plug the equipment into a different electrical outlet so that the equipment and receiver

are on different branch circuits.

If necessary, the user should consult the dealer or an experienced radio/television technician for additional

suggestions.

The user may find the following booklet prepared by the Federal Communications Commission helpful:

“Interference Handbook, Bulletin CIB-2”

This booklet is available from the U.S. Government Printing Office, Superintendent of Documents, Mailstop

SSOP, Washington, D.C. 20402-9328, ISBN 0-16-045542-1.

WARNING: Power must be removed from this unit before removing circuit modules or Ribbon Cables.

CAUTION: This unit contains circuit cards with integrated circuit devices that can be damaged by static

discharge. Take all necessary precautions to prevent static discharge.

Contents

INTRODUCTION...................................................................................................................1

Unpacking and Inspection.............................................................................................................................1

Inspection for Visible Damage......................................................................................................................1

Inspection for Concealed Damage ...............................................................................................................1

Housings .........................................................................................................................................................2

Drive Mechanism Assembly..........................................................................................................................2

Camera/Lens Module .....................................................................................................................................2

Lower Dome ....................................................................................................................................................2

V7UFR Fire-Resistant Shield.........................................................................................................................2

DRIVE MECHANISM ASSEMBLY .......................................................................................3

Installing the Camera/ Lens Module .........................................................................................................3

Switch Settings and Adjustments..............................................................................................................3

Setting the Service Switch ............................................................................................................................4

HOUSING INSTALLATION ..................................................................................................7

INDOOR PENDANT ..................................................................................................................8

Installation Using a Vicon Mount...............................................................................................................8

Installation Using a 1.5-inch Pipe..............................................................................................................9

DROPPED CEILING ............................................................................................10

Installation into a Dropped Ceiling ..........................................................................................................10

X971 Rev 1098 Surveyor Mini Dome System Contents • i

SOLID CEILING ............................................................................................................ 12

Installation Into a Solid Ceiling ............................................................................................................... 12

OUTDOOR PENDANT ................................................................................................ 13

Installation Using a Vicon Mount ............................................................................................................ 13

Installation Using a 1.5-inch Pipe ........................................................................................................... 14

WIRING .............................................................................................................................. 15

Installing the Cables ...............................................................................................................................17

FINAL ASSEMBLY ............................................................................................................ 19

Installing the Drive Mechanism............................................................................................................... 19

Installing the Domes ............................................................................................................................... 20

For Indoor Pendant Installations............................................................................................................. 20

For Dropped Ceiling Installations ........................................................................................................... 21

For Solid Ceiling Installations ................................................................................................................. 21

For Outdoor Pendant Installations.......................................................................................................... 21

DISASSEMBLING THE MINI DOME ................................................................................. 23

If It It Is Necessary to Remove the Trim Ring......................................................................................... 24

OPERATION ...................................................................................................................... 25

Initial Power-Up ...................................................................................................................................... 25

Verifying Proper Operation......................................................................................................................... 26

Running the Diagnostic Test ..................................................................................................................27

MAINTENANCE ................................................................................................................. 29

CARE AND CLEANING OF METALLIZED DOMES.................................................................................... 29

CARE AND CLEANING OF CLEAR ACRYLIC DOMES ............................................................................. 29

Fuse Replacement ....................................................................................................................................... 29

SHIPPING INSTRUCTIONS............................................................................................... 31

REFERENCE ..................................................................................................................... 33

ii • Contents X971 Rev 1098 Surveyor Mini Dome System

Coaxial Cable ................................................................................................................................................33

Twisted-Pair Cable .......................................................................................................................................34

1.5-inch Pipe Designation............................................................................................................................34

TECHNICAL INFORMATION .............................................................................................35

X971 Rev 1098 Surveyor Mini Dome System Contents • iii

iv • X971 Rev 1098 Surveyor Mini Dome System

List of Figures and Tables

Figure 1

Basic Surveyor Unit ...........................................................................................................................................1

Figure 2

Camera/ Lens and Ribbon Cable Assembly....................................................................................................3

Figure 3

Assembly Side View ..........................................................................................................................................3

Figure 4

Location of DIP Switches S2 and S5................................................................................................................3

Table 1

DIP Switch 5 (S5) Settings ................................................................................................................................4

Table 2

DIP Switch 2 (S2) Settings ................................................................................................................................5

Figure 5

Exploded view - Indoor Pendant and Vicon Mount ........................................................................................8

Figure 6.

Installation on a Vicon Mount ...........................................................................................................................8

Figure 7

Exploded view - Indoor Pendant and Pipe Mount ..........................................................................................9

Figure 8

Installation on a 1.5-inch Pipe ..........................................................................................................................9

Figure 9

Exploded View - Dropped Ceiling ..................................................................................................................10

Figure 10

Installation in a Dropped Ceiling ....................................................................................................................10

Figure 11

Cable Access Cap............................................................................................................................................11

Figure 12

Dropped Ceiling Mount Adjustments.............................................................................................................11

Figure 13

Exploded View - Solid Ceiling.........................................................................................................................12

Figure 14

Cable Access Cap............................................................................................................................................12

Figure 15

Exploded View - Outdoor Pendant .................................................................................................................13

Figure 16

Installation on a 1.5 inch Pipe.........................................................................................................................13

Figure 17

Exploded View - Outdoor Pendant 1.5 inch Mount ......................................................................................14

Figure 18

Installation on a 1.5 inch Pipe.........................................................................................................................14

Table 3

Required Control Signals for Specific Communication Modes ..................................................................15

Figure 19

Typical Alarm Circuit .......................................................................................................................................16

Figure 20

Typical Auxiliary Output..................................................................................................................................16

Figure 21

Customer Interface Board...............................................................................................................................17

X971 Rev 1098 Surveyor Mini Dome System List of Figures and Tables • v

Table 4

Customer Interface Board Terminal Block Definitions................................................................................ 18

Figure 22

Drive to Housing Alignment ........................................................................................................................... 19

Figure 23

Exploded View - Drive Installation................................................................................................................. 19

Figure 24

Exploded View - Indoor Dome Installation.................................................................................................... 20

Figure 25

Exploded View - Outdoor Dome Installation ................................................................................................ 21

Figure 26

Drive Release Handle ...................................................................................................................................... 23

Figure 27

Trim Ring Removal.......................................................................................................................................... 24

Figure 28

Power-Up Test Screen .................................................................................................................................... 25

Figure 29

Opening Screen ............................................................................................................................................... 25

Figure 30

Main Menu ........................................................................................................................................................ 26

Table 5

Diagnostic Functions Routine........................................................................................................................ 27

Table 6

Recommended Coaxial Cable Types............................................................................................................. 33

Table 7

Recommended Individually-Shielded, Twisted-Pair Cable Types.............................................................. 34

Table 8

Applicable Wire Size ....................................................................................................................................... 35

Table 9

Surveyor Components ....................................................................................................................................38

Table 10

Surveyor Overall Dimensions ........................................................................................................................38

vi • X971 Rev 1098 Surveyor Mini Dome System

Important

Safeguards

GRAPHIC SYMBOL EXPLANATION

The lightning flash with arrowhead symbol, within an

equilateral triangle, is intended to alert the user to the

presence of uninsulated “dangerous voltage” within the

product’s enclosure that may be of sufficient magnitude

to constitute a risk of electric shock.

The exclamation point within an equilateral triangle is

intended to alert the user to the presence of important

operating and maintenance (servicing) instructions in

the literature accompanying the unit.

1. Read Instructions - All the safety and operating

instructions should be read before the video product is

operated.

2. Retain Instructions - All the safety and operating

instructions should be retained for future reference.

3. Heed Warnings - All warnings on the video product

and in the operating instructions should be adhered to.

4. Follow Instructions - All operating and use

instructions should be followed.

5. Cleaning - Step a applies to equipment that can be

disconnected from the CCTV system without seriously

jeopardizing security. Step b applies to equipment that

must operate continuously such as video switching

equipment at military installations.

a. Disconnect this video product from its power source

before cleaning. Do not use caustic, abrasive, or

aerosol cleaners. Use a damp cloth for cleaning.

b. Use a damp cloth to clean the equipment. Do not

allow moisture or liquids to enter any vents. Do not

use caustic, abrasive, or aerosol cleaners.

6. Attachments - Do not use attachments not

recommended by Vicon as they may cause hazards.

7. Water and Moisture - Do not use this video product

in any location where it may be exposed to water or

moisture. This does not apply to outdoor camera

housings, outdoor pan-and-tilt drives, and other

equipment designed for direct exposure to outdoor

environments.

8. Accessories - Do not place this video product on any

unstable surface or table. The video product may fall,

causing serious injury to a person and serious damage

to the video product. Use only with a mounting accessory

recommended by Vicon, or sold with the video product.

Any mounting of the video product should follow Vicon’s

instructions, and a mounting accessory recommended

by Vicon should be used.

9. Ventilation - If slots and openings are provided in the

cabinet, they are to provide ventilation, ensure reliable

operation and protect it from overheating. The openings

should never be blocked by placing the video product on

a rug or other similar surface. This video product should

never be placed near or over a radiator or heat register.

This video product should not be placed in a built-in

installation such as a bookcase or rack unless proper

ventilation is provided or Vicon’s instructions have been

adhered to.

10. Power Sources - This video product should be

operated only from the type of power source indicated

on the marking label. If you are not sure of the type of

power supplied to your installation site, consult your

Vicon dealer or local power company. For video

products intended to operate from battery power, or

other sources, refer to the operating instructions.

11. Grounding - This applies to video products

equipped with a 3-wire grounding-type plug, a plug

having a third (grounding) pin. This plug only fits into a

grounding-type power outlet. This is a safety feature. If

you are unable to insert the plug into the outlet, contact

your electrician to replace your obsolete outlet. Do not

defeat the safety purpose of the grounding-type plug.

X971 Rev 1098 Surveyor Mini Dome System Important Safeguards • vii

12. Power-Cord Protection - Power supply cords

should be routed so that they are not likely to be walked

on or pinched by items placed upon or against them,

paying particular attention to cords at plugs,

convenience receptacles, and the point where they exit

from the video product.

13. Outdoor Cable Grounding - If an outside cable

system is connected to the video product, be sure the

cable system is grounded so as to provide some

protection against voltage surges and built-up static

charges. Section 810 of the National Electrical Code,

ANSI/NFPA 70-1984, provides information with respect

to proper grounding of the lead-in wire to an antenna

discharge unit, size of grounding conductors, location of

antenna-discharge unit, connection to grounding

electrodes, and requirements for the grounding

electrode.

14. Lightning - For added protection for this video

product when it is not used for long periods of time,

disconnect it from its power source and from the cable

system. This prevents damage to the video product due

to lightning and power-line surges.

15. Power Lines - An outside cable system should not

be located in the vicinity of overhead power lines or

other electric light or power circuits, or where it can fall

into such power lines or circuits. When installing an

outside cable system, extreme care should be taken to

keep from touching such power lines or circuits as

contact with them might be fatal.

16. Overloading - Do not overload wall outlets and

extension cords as this can result in a risk of fire or

electric shock.

17. Object and Liquid Entry - Never push objects of

any kind into this video product through openings as

they may touch dangerous voltage points or short out

parts that could result in a fire or electric shock. Never

spill liquid of any kind on the video product.

18. Servicing - Do not attempt to service this video

product yourself as opening or removing covers may

expose you to dangerous voltage or other hazards.

Refer all servicing to qualified service personnel.

19. Damage Requiring Service - Disconnect this video

product from its power source and refer servicing to

qualified service personnel under the following

conditions. Note that step c does not apply to outdoor

camera housings, outdoor pan-and-tilt drives and other

equipment specifically designed for direct exposure to

outdoor environments.

a. When the power-supply cord or plug is damaged.

b. If liquid has been spilled, or objects have fallen into

the video product.

c. If the video product has been exposed to rain or

water.

d. If the video product does not operate normally by

following the operating instructions. Adjust only

those controls that are covered by the operating

instructions, as an improper adjustment of other

controls may result in damage and will often require

extensive work by a qualified technician to restore

the video product to its normal operation.

e. If the video product has been dropped or the cabinet

has been damaged.

f. When the video product exhibits a distinct change in

performance - this indicates a need for service.

20. Replacement Parts - When replacement parts are

required, be sure the service technician has used

replacement parts specified by Vicon or that have the

same characteristics as the original part. Unauthorized

substitutions may result in fire, electric shock, or other

hazards.

21. Safety Check - Upon completion of any service or

repairs to this video product, ask the service technician

to perform safety checks to determine that the video

product is in proper operating condition.

22. ESD Precaution - All normal precautions to avoid

component damage due to Electrostatic discharge

should be taken during installation and operation.

viii • Important Safeguards X971 Rev 1098 Surveyor Mini Dome System

Introduction

The information in this manual covers the installation, configuration and operation of the Surveyor Mini Dome

System. This system should only be installed by a qualified technician using common hand tools and

approved materials in accordance with national, state and local wiring codes.

The basic Surveyor is a compact, intelligent, high-speed Mini Dome. For programming information, refer to

the Surveyor Programming Manual X867, part number 8006-8867-01-00.

Surveyor complies with UL standard 1409, meet requirements for an FCC Class A computing device, and

comply with European Community EMC Directive 89/336. The product was subjected to the testing outlined

in European Normalization Standard EN 50081-1 (Electromagnetic Compatibility-General Emissions

Standard Part 1: Residential, Commercial and Light Industry), and EN 50082-1 (Electromagnetic

Compatibility-General Immunity Standard Part 1: Residential, Commercial, and Light Industry).

NOTE: Read all instructions before beginning any

installation.

NOTE: The following instructions are “typical”. It

may be necessary to deviate from them for

any particular installation.

Unpacking and Inspection

Figure 1

Basic Surveyor Unit

Inspection for Visible Damage

Immediately inspect the cartons upon delivery. On all copies of the carrier’s freight bill, make a note of any

visible damage.

Make sure the carrier’s agent (the person making the delivery) signs the note on all copies of the bill. If the

agent does not have claim forms, contact the carrier’s office.

Inspection for Concealed Damage

As soon as possible after delivery, unpack the unit and inspect it for concealed damage. Do not discard the

carton or packing materials. If the unit is damaged, contact the carrier immediately and request forms for

filing a damage claim. Make arrangements for a representative of the carrier to inspect the damaged

equipment.

If the equipment must be returned for repair, follow the Shipping Instructions at the end of this manual.

All Vicon equipment is tested and inspected before

leaving the factory. It is the carrier’s responsibility to

deliver the equipment in the same condition as it left

the factory.

X971 Rev 1098 Surveyor Mini Dome System Introduction • 1

Housings

The V7USD-V2 is the indoor Housing for the Surveyor system. It can be suspended from a piece of 1.5-inch

pipe or Vicon mount (pendant), directly to a Solid (Hard) Ceiling or into a Dropped (suspended) ceiling via a

structural grid assembly. All required installation hardware is supplied.

A plastic, color-coordinated Trim Ring is included with the Housing. This Trim Ring is used for hard and

suspended ceiling installations. It is equipped with four tabs for attachment to slots in the Housing. In

addition, four circular knockouts can be removed for attachment to a Solid Ceiling via screws.

The V7USD-W-VS is the Outdoor Housing. It is comprised of the V7USD-V2 Housing, a Sunshield, internal

Heater and Blower assembly, a modified Trim Ring and a clear Lower Outdoor Dome. An optional chrome

metallized Lower Outdoor Dome is available.

The Trim Ring for the Surveyor Outdoor Housing is specially fitted with a foam barrier for outdoor

applications. It is referred to as Trim Ring with Foam Filter. This ring provides a Housing to Lower Outdoor

Dome seal.

CAUTION: For environments subject to moisture, use the outdoor Housing.

Drive Mechanism Assembly

The V7UVS-RPX is the variable-speed Drive for the Surveyor system. Integral to the frame is a precision

pan-and-tilt-Drive assembly, a two-piece PC Board Assembly, Camera and Lens platform and Housing

mechanism latch. It provides accurate positioning for the Camera and Lens Module.

Camera/Lens Module

The Camera/Lens Module comes in two basic types; high-resolution monochrome and color. All Camera and

Lens Modules boast an extremely small and lightweight package with advanced features. These Camera

Modules offer state-of-the-art technology in a compact size.

Lower Dome

The Lower Dome is a 7.75 inch (19.7 cm) diameter unit made of acrylic plastic. There are three versions of

this dome; smoke, chrome or gold finish.

V7UFR Fire-Resistant Shield

The V7UFR Fire-Resistant Shield is a metal cover for the indoor, ceiling mounted Housing. It is constructed

of sheet aluminum with an alodine finish. This cover is required by the fire code of certain local

municipalities. It was designed to attach to the Housing top four screw holes. It can be mounted with the

Dropped Ceiling kit or into a Solid Ceiling using the same hardware.

2 • Introduction X971 Rev 1098 Surveyor Mini Dome System

Drive Mechanism Assembly

The Drive Mechanism must be fitted with the Camera/Lens Module and configured before it is installed into

the Housing. This procedure is best performed on a clean bench with common hand tools.

Installing the Camera/ Lens Module

1. Place the Drive Mechanism upside down and rotate

the Tilt Platform to a convenient working angle.

2. Slip the Camera Mounting Plate Tab into the Tilt

Platform slot. Gently rock the Mounting Plate until the

connector fits through the cutout in the Tilt Platform.

Firmly tighten the two Captive Screws.

3. Plug the Ribbon Cable connector end (without the EMI

Attenuator) into the Camera/Lens Module mating

Figure 2

Camera/ Lens and Ribbon Cable Assembly

connector in the proper orientation and latch it.

4. Plug the Ribbon Cable connector end (with the EMI

Attenuator) into the Main PC Board mating connector

and latch it.

Figure 3

Assembly Side View

Figure 4

Location of DIP Switches S2 and S5

Switch Settings and Adjustments

This section defines how to set various switches on the

Drive unit.

Refer to Figure 4 for Dip Switch location. DIP Switch 5

(S5) is used to set the communications/automatic

diagnostics mode and Camera/Lens Module type. DIP

Switch 2 (S2) is used to set the Receiver address. Each

switch is numbered from 1 to 8 and marked to indicate the

ON position.

The Mini Dome can be connected to a NOVA (VPS)

system in one of two ways:

Half Duplex: This connection type allows two-way

command flow and requires two

individually-shielded twisted-pair cables.

Simplex: This connection type allows command

flow from the CPU to the Mini Dome only.

It requires only one shielded twisted pair

from the CPU to the Housing.

X971 Rev 1098 Surveyor Mini Dome System Drive Mechanism Assembly • 3

Both formats support 4800 and 9600 baud transmission rates. Surveyor’s baud rate must match the system’s

baud rate.

NOTE: When Surveyor is to be used in a system with mixed receiver types such as the V15UVS, V1311RB,

etc., the baud rate should be set 4800 baud to ensure proper communication.

DIP Switch 5 (S5) Switch Numbers

Selection

Half duplex, 4800 baud

Simplex, 4800 baud

Half duplex, 9600 baud

Simplex, 9600 baud

**Half duplex,19200 baud

**Simplex, 19200 baud

*Vicoax Communications Mode

Automatic diagnostics

NTSC mode

PAL mode

*Applies only when DIP Switch 2 (S2) is set for Vicoax addresses.

**Supported on Rev. 0 software. "Invalid Selection" message displayed on current software.

12345678

OFF OFF OFF

ON OFF OFF n/a n/a

OFF ON OFF n/a n/a

ON ON OFF

OFF OFF ON

ON OFF ON n/a n/a

OFF ON ON n/a n/a

ON ON ON

n/a n/a n/a OFF OFF OFF OFF OFF

n/a n/a n/a ON OFF

n/a n/a

n/a n/a

n/a n/a

n/a n/a

n/a

n/a

n/a

n/a

n/a

n/a

n/a

n/a

OFF

n/a n/a

n/a n/a

n/a n/a

n/a n/a

n/a n/a

n/a n/a

n/a n/a

n/a n/a

OFF OFF

Table 1

Prior to configuration, determine

what communications mode,

Camera/Lens Module type and

Mini Dome address is required

for the CPU.

For RS-422 Mode:

1. Set switches 1, 2, and 3 on

DIP Switch 5 (S5) for the

communications/automatic

diagnostics mode as

specified in Table 1.

2. Set switches 4 - 8 on DIP

Switch 5 (S5) for the

Camera/Lens module used

as specified in Table 1.

3. Set switches 1 - 8 o 2 veyor’s address as specified in Table 2. Address 0 and 1

n DIP Switch 2 (S ) for Sur

are reserved for Vicoax mode.

4. Set the 1 position DIP Switch on the Main PC Board (located near the Ribbon Cable connector) to the ON

or OFF position. ON is for video line lock enable and OFF is for video line lock disable. The ON position

is the factory default setting set towards the Ribbon Cable Connector.

For Vicoax Mode:

1. Set switches 1, 2, and 3 on DIP Switch 5 (S5) for OFF/ON/ON, respectively, as specified in Table 1.

2. Set switches 4 - 8 on DIP Switch 5 (S5) for the Camera/Lens module used as specified in Table 1.

3. Set switches 1 - 8 on DIP Switch 2 (S2) for either Address 0 or 1 as specified in Table 2. Address 0 is

standard protocol (1902 type Vicoax) and Address 1 is extended protocol (1422 type Vicoax).

4. Set the 1 position DIP Switch on the Main PC Board (located near the Ribbon Cable connector) to the ON

or OFF position. ON is for video line lock enable and OFF is for video line lock disable. The ON position

is the factory default setting set towards the Ribbon Cable Connector.

NOTE: DIP Switches labeled ON or CLOSED and OFF or OPEN have the same meaning.

NOTE: Address 256 is the same as address 0 by setting all switches to OFF.

Setting the Service Switch

Refer to Figure 2 for Service Switch location. It is a two position toggle switch, located at the base of unit

having positions RUN and SERVICE. RUN enables normal operation with the Mask installed and SERVICE

enables normal operation with the Mask removed. Verify that it is set to the RUN position.

4 • Drive Mechanism Assembly X971 Rev 1098 Surveyor Mini Dome System

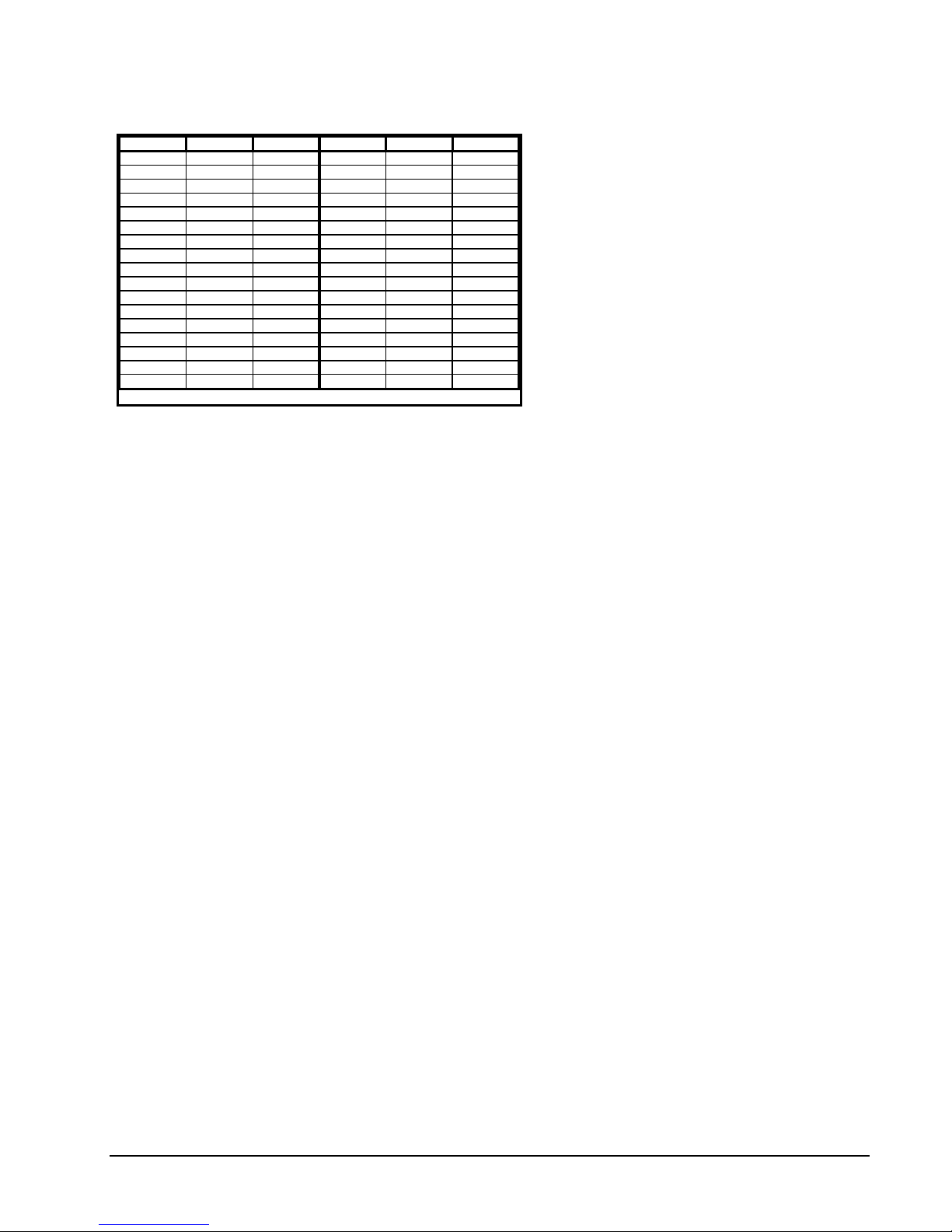

DIP SWITCH 2 (S2) ADDRESS SELECTION

XXX

X

X

XXXXX

X

X

XXX

X

X

XXX

X

X

X

X

XXX

X

X

XXXXX

X

X

XXX

X

X

X

XXXXX

X

X

X

XXXXX

X

XXXXX

X

X

X

X

X

X

X

XXX

X

X

X

XXX

X

XXX

X

X

X

XXX

X

X

XXX

X

X

X

X

XXX

X

X

XXXXX

X

X

XXX

X

X

XXX

X

X

X

X

XXX

X

X

X

XXXXX

XXX

XXX

X

XXX

XXXXX

XXX

X

XXXXX

X

X

XXXXX

X

XXX

X

XXX

XXX

X

XXX

X

X

XXX

X

XXX

X

X

X

XXXXX

XXX

X

XXX

X

XXX

X

XXXXX

X

XXX

X

XXXXX

X

X

XXXXX

X

X

X

X

XXX

X

X

X

X

XXXXX

X

X

X

X

XXXXX

X

X

XXXXX

X

XXX

X

XXXXX

XXX

X

XXXXX

X

X

XXX

X

XXXXX

X

X

X

XXXXXXX

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

XXX

X

X

X

X

X

X

X

X

XXX

X

X

X

X

XXX

X

X

XXX

X

X

X

X

X

X

X

X

X

XXX

X

X

X

X

XXX

X

X

XXX

X

XXX

X

XXX

XXX

X

XXX

X

X

XXX

X

XXX

X

X

X

XXXXX

X

X

X

X

X

X

X

X

XXX

X

X

X

X

XXX

X

X

XXX

X

X

X

X

XXX

X

X

X

XXX

X

X

X

X

X

XXX

X

X

X

XXXXX

X

X

X

XXX

X

X

X

XXX

X

X

X

X

X

XXX

X

X

X

XXXXX

X

X

X

XXX

X

X

X

X

XXXXX

X

X

X

X

XXXXX

X

X

XXXXX

X

X

X

X

X

X

X

X

X

XXX

X

X

X

X

XXX

X

X

XXX

X

X

X

X

XXX

X

X

X

XXX

X

X

X

X

X

XXX

X

X

X

XXXXX

X

X

X

XXX

X

X

X

XXX

X

X

X

X

X

XXX

X

XXXXX

SWITCHES SWITCHES SWITCHES

12345678#12345678#12345678

#

* Vicoax Mode, standa rd pr ot ocol

0

X * Vicoax Mode, extended prot ocol

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

X

XX

XX

XXX

XX

XX X

XXX

XXXX

XX

XX X

XX X

XXX X

XXX

XX X X

X XXX

XXXXX

XX

XX X

XX X

XXX X

XXX

XX X X

XXX X

XXXX X

XXX

XX XX

XX XX

XXX XX

XXXX

XX X XX

X XXXX

XXXXXX

XX

XX X

XX X

XXX X

XXX

XX X X

XXX X

XXXX X

XXX

XX X X

XX X X

X

XX

X

XX

XX

XXX

X

XX

XX

XX X

XX

XXX

XXX

XXXX

X

XX

XX

XX X

XX

XXX

XX X

XXX X

XX

XXX

XXX

XX XX

XXX

XXXX

XXXX

XXXXX

XX

XX

XX X

XX

XX X

XX X

XXX X

XX

XXX

XXX

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

X

150

151

152

153

154

155

156

157

158

159

160

161

162

163

164

165

166

167

168

169

170

171

DIP Switch 2 (S2) Settings

Table 2

172

173

174

175

176

177

178

179

180

181

182

183

184

185

186

187

188

189

190

191

192

193

194

195

196

197

198

199

200

201

202

203

204

205

206

207

208

209

210

211

212

213

214

215

216

217

218

219

220

221

222

223

224

225

226

227

228

229

230

231

232

233

234

235

236

237

238

239

240

241

242

243

244

245

246

247

248

249

250

251

252

253

254

255

XX X

XX X

XX X

XX X

XXX

XXX

XXX

XXX

XXXX

XXXX

XXXX

XXXX

X

XX

XX

XX

XX

XX

XX

XX

XX

XXX

XXX

XXX

XXX

XX

XX

XX

XX

XX X

XX X

XX X

XX X

XXX

XXX

XXX

XXX

XXXX

XXXX

XXXX

XXXX

XX

XX

XX

XX

XXX

XXX

XXX

XXX

X

X

XX

XX

XX

XX

X

XX

XX

XX

XX

XX

XX

XX

XX

XXX

XXX

XXX

XXX

X971 Rev 1098 Surveyor Mini Dome System Drive Mechanism Assembly • 5

NOTES

6 • Drive Mechanism Assembly X971 Rev 1098 Surveyor Mini Dome System

Housing Installation

Housing installation is a simple process. Choose the installation type based on the supplied components.

Three mounting kits are provided for the four possible installation types.

INSTALLATION TYPES

Indoor Pendant Dropped Ceiling Solid Ceiling Outdoor Pendant

The Pendant Mounting Kit labeled FOR FREE HANGING INSTALLATION ONLY includes:

The Dropped or Solid Ceiling Mounting Kit labeled FOR CEILING INSTALLATION ONLY includes:

The Outdoor Pendant Accessory Kit labeled FOR FREE HANGING INSTALLATION ONLY includes:

DESCRIPTION QUANTITY

Cylindrical Spacer 1

Nut, 1.5-inch 1

Cotter pin 1

Set screw, 1/4-20 x 3/16 inch 2

DESCRIPTION QUANTITY

Bracket, L-shaped 2

Bracket, T-shaped 2

Long Caddy bar with clips

Screw, No. 8-32 x 3/8 in. 12

Lock washer, No. 8 4

Flat washer, No. 8 4

Cable access cap 1

DESCRIPTION QUANTITY

Spacer 1

Screw, 8-32 x 3/8 4

Screw (tamperproof), 8-32 x 3/8 (optional) 4

Key, 8-32 (tamperproof) 1

Set screw, 1/4-20 x 3/16 inch 2

Locking nut, 1.5 inch 11-1/2 pt. 1

O-ring, 1.85 inch i.d. x 0.210 inch th. 1

Cotter pin, 3/4 inch L x 3/32 inch dia. 1

Retainer ring, 8-32 4

Setscrew, socket head, 1/4-20 4

4

X971 Rev 1098 Surveyor Mini Dome System Housing Installation • 7

INDOOR PENDANT

The Indoor Pendant mounts in two configurations: Vicon Mount or 1.5-inch Pipe Mount. Both use standard

1.5-inch NPT threaded pipe and can be attached to a wall (vertical surface) or a ceiling (horizontal surface).

Installation Using a Vicon Mount

Vicon mounts are supplied with the correct 1.5-inch

NPT threaded pipe. The pipe features a 0.125-inch

(0.3 cm) hole at the mounting end. This hole is used

for Cotter Pin installation as a mechanical safety.

NOTE: Early version mounts did not have the drilled

hole. Contact Vicon for a free warranty

replacement or drill the hole as described

above.

1. Install the mount in accordance with the

Installation Manual included with the mount.

2. Install a Set Screw in each hole of the Spacer

flush with the inside surface.

3. Slide the Spacer up to the bottom of the mount

and tighten the Set Screws to hold it in place.

4. Slide the Housing up the Pipe followed by the

1.5-inch Lock Nut, tabs facing upward, screwed

Figure 5

Exploded view - Indoor Pendant and Vicon Mount

onto the threads and hand tighten.

5. Rotate the Housing clockwise until it is firmly

tightened against the Spacer.

6. Insert the Cotter Pin through the Pipe hole from

the outside. Spread the ends of the pin against

the Pipe inner surface. In the rare event that the

Lock Nut loosens, it will stop against the Cotter

Pin.

Figure 6.

Installation on a Vicon Mount

8 • Housing Installation X971 Rev 1098 Surveyor Mini Dome System

Figure 7

Exploded view - Indoor Pendant and Pipe Mount

Figure 8

Installation on a 1.5-inch Pipe

Installation Using a 1.5-inch Pipe

This installation is similar to the Vicon mount. The pipe

can be fastened to any surface or support providing

sufficient strength and area for the Mini Dome.

1. Inspect the end of the pipe and remove any burrs on

the inside diameter.

2. Drill a 0.125-inch (0.3-cm) hole through the mounting

end 0.125 (0.3-cm) above the end.

3. Install a Set Screw in each hole of the Spacer flush

with the inside surface.

4. Slide the Spacer up the pipe a few inches and tighten

one Set Screw just enough to secure it.

CAUTION: Exposing more than 3/16 inch (0.5 cm) of

threads from the bottom of the Lock Nut

5. Slide the Housing up the pipe followed by the Lock

Nut screwed onto the threads three full turns (no

more than 3/16-inch) and lower the Housing to rest

on the Lock Nut.

6. Insert the Cotter Pin through the pipe hole from the

outside. Spread the ends of the pin against the pipe

inner surface. In the rare event that the nut loosens,

it will stop against the Cotter Pin.

7. Back the Lock Nut down counter-clockwise until it

rests on the Cotter Pin. Loosen the Set Screw and

lower the Spacer to the top of the Housing.

8. Press down firmly on the Spacer and tighten both Set

Screws firmly.

9. Rotate the Housing clockwise until it is firmly

tightened against the Spacer.

can cause damage to the wiring and

prevent the Drive Mechanism from

seating and locking properly.

X971 Rev 1098 Surveyor Mini Dome System Housing Installation • 9

p

g

DROPPED CEILING

Mounts in the grid frame between the dropped and true ceiling space. A complete mounting kit is provided

and includes a Cable Access Cap which allows connection to two sizes of conduit pipe.

Installation into a Dropped Ceiling

The Housing is attached to the Mounting Bracket

Assembly and then installed into the Dropped Ceiling.

A typical Dropped Ceiling consists of tiles 2 x 2-foot

(0.61 x 0.61-m) or 2 x 4-foot (0.61 x 1.22-m) size tiles

hung in a metal frame and suspended by wires.

There are sufficient adjustments on the assembly to

produce a tight and concentric fit within the tile

opening.

The Cable Access Cap is included in the mounting kit

to permit the installation of a strain relief type or

Conduit fitting installed into it. This cap provides two

different diameter holes; 1.062 inch (2.7 cm) and

0.875 inch (2.2 cm) for a 0.75 inch (1.9 cm) and a 0.5

inch (1.3 cm) standard fitting, respectively. If the 0.75

(1.3 cm) standard fitting is used, simply remove the

knockout.

1. Remove a ceiling tile from the desired location

and two additional adjacent tiles for workspace.

2. Cut a 12-1/8-inch (30.8 cm) diameter hole in one

removed ceiling tile.

3. Route all cabling to the space above the tile.

4. Secure the cut Ceiling Tile to the space where

the Housing is to be installed.

5. Insert the legs of the Cable Access Cap into the

top opening of the Housing.

6. Fold the two legs over to secure the Cable

Access Cap in place.

Figure 9

Ex

loded View - Dropped Ceilin

Figure 10

Installation in a Dropped Ceiling

10 • Housing Installation X971 Rev 1098 Surveyor Mini Dome System

Figure 11

Cable Access Cap

Figure 12

Dropped Ceiling Mount Adjustments

7. Install the Conduit fitting.

8. Attach a T Bracket to an L Bracket using two

screws, flat washers and lock washers. Repeat

on the remaining brackets.

9. Slide two sections of a Caddy Rail through the

base of a T Bracket. Rotate the Caddy Rail Clips

so the open end is facing downward. Repeat with

the remaining Caddy Rail sections.

10. Install the remaining screws into the threaded

holes of the T Brackets. Snug them to hold Caddy

Rail position.

11. Attach a Mounting Bracket assembly to each pair

of threaded holes on the Housing top using two

Screws and Lock Washers.

12. Lift the entire assembly into the ceiling through an

adjacent grid space. Adjust the Caddy Rails, as

necessary, to seat the clips properly. Align the

clips to attain a proper “X” position.

13. Slide the Housing along the T Brackets and tighten

the screws to attain a proper “Y” position.

14. Slide the Housing within the T Bracket slots and

tighten the screws to attain a flush fit with the

ceiling.

X971 Rev 1098 Surveyor Mini Dome System Housing Installation • 11

SOLID CEILING

The Surveyor mounts in a Solid Ceiling cutout and is supported by the Trim Ring. There are four knockout

holes on the Trim Ring which must be removed prior to installation. The installer must supply mounting

screws and verify ceiling strength for this installation.

Installation Into a Solid Ceiling

Before starting, route all cabling from the control

equipment to this location.

The Cable Access Cap is included in the Mounting

Kit and is installed to permit the installation of a strain

relief type or Conduit fitting into it. This cap provides

two different diameter holes; 1.062 inch (2.7 cm) and

0.875 inch (2.2 cm) for a 0.75 inch (1.9 cm) and a 0.5

inch (1.3 cm) standard fitting, respectively. If the

0.75 (1.3 cm) standard fitting is used, simply remove

the knockout.

1. Insert the legs of the cap through the top opening

of the Housing.

2. Fold the two legs over to secure the cap in place.

3. Install the Conduit fitting.

4. Cut a 12-1/8-inch (30.8 cm) diameter hole at the

desired location in the solid ceiling.

5. Remove the four knockouts on the Trim Ring.

Figure 13

Exploded View - Solid Ceiling

Figure 14

Cable Access Cap

6. Stabilize the Housing and position the Trim Ring

over the Housing lower rim. Push up on the Trim

Ring inner edge firmly and, using the other hand,

push down on the Trim Ring outer edge. A single

snapping sound will verify that the latch has been

properly seated. Repeat on the remaining three

latches.

7. Lift the Housing up into the ceiling, through the

previously cut hole, and attach with four screws.

12 • Housing Installation X971 Rev 1098 Surveyor Mini Dome System

OUTDOOR PENDANT

The Surveyor Outdoor Pendant version mounts in two configurations: Vicon mount or 1.5 inch Pipe mount.

Both configurations use standard 1.5-inch NPT threaded pipe and can be attached to a wall or a ceiling. This

mount is exactly an Indoor Pendant version with an exterior Sunshield and Lower Outdoor Dome for

environmental protection.

The Housing is furnished with an Accessory Kit which includes tamperproof hardware for areas where the

Mini Dome is within easy tampering reach. See Installation Types at the beginning of this section.

Installation Using a Vicon Mount

Vicon mounts are supplied with the correct 1.5-inch NPT

threaded pipe. In addition, the Pipe features a 0.125inch (0.3 cm) hole at the mounting end. This hole is used

for Cotter Pin installation as a mechanical safety.

NOTE: Early version mounts did not have the drilled

hole. Contact Vicon for a free warranty

replacement or drill the hole as described above.

1. Install the mount in accordance with the Installation

Manual included with the mount.

2. Install a Set Screw in each hole of the Spacer flush

with the inside surface.

3. Slide the Spacer up to the bottom of the mount and

tighten the Set Screws to hold it in place. Then slide

the O-ring up the Pipe to the bottom of the Spacer.

4. Slide the Sunshield up the Pipe followed by the

Figure 15

Exploded View - Outdoor Pendant

Housing. Install the 1.5 inch Lock Nut, tabs facing

upward, up the Pipe and hand tighten to support the

Housing.

5. Rotate the Housing clockwise until it is just touching

the O-ring. Then rotate the Housing one half turn to

assure a firm, watertight seal.

Figure 16

Installation on a 1.5 inch Pipe

X971 Rev 1098 Surveyor Mini Dome System Housing Installation • 13

CAUTION: Overtightening the Lock Nut will damage

the Housing and deform the O-ring,

causing the Housing to leak.

6. Insert the Cotter Pin through the Pipe hole from the

outside. Spread the ends of the pin against the Pipe

inner surface. In the rare event that the Lock Nut

loosens, it will stop against the Cotter Pin.

Installation Using a 1.5-inch Pipe

This installation is similar to the Vicon mount. The

pipe can be fastened to any surface or support

providing sufficient strength and area for the Mini

Dome.

1. Inspect the end of the Pipe and remove any

burrs on the inside diameter.

2. Drill a 0.125-inch (0.3-cm) hole through the

mounting end 0.125 (0.3-cm) above the end.

3. Install a Set Screw in each hole of the Spacer

flush with the inside surface.

4. Slide the Spacer up the pipe a few inches

followed by the O-ring to hold it in place.

5. Slide the Sunshield up the Pipe followed by

the Housing and hold in place. Install the 1.5inch Lock Nut, tabs facing upward, to expose

no more then 3/16 inch (0.5 cm) of Pipe below

the nut.

Figure 17

Exploded View - Outdoor Pendant 1.5 inch Mount

Figure 18

Installation on a 1.5 inch Pipe

CAUTION: Exposing more than 3/16-inch (0.5

cm) of pipe can cause damage to

wiring and prevent proper seating

6. Insert the Cotter Pin through the Pipe hole

from the outside. Spread the ends of the pin

against the Pipe inner surface. In the rare

event that the Lock Nut loosens, it will stop

against the Cotter Pin.

7. Back the Lock Nut down counter-clockwise

until it rests on the Cotter Pin. Loosen the Set

Screw and lower the Spacer to the top of the

Housing.

8. Press down firmly on the Spacer and tighten

both Set Screws firmly.

9. Rotate the Housing clockwise until it is firmly

tightened against the Spacer.

and locking of the Drive

Mechanism.

14 • Housing Installation X971 Rev 1098 Surveyor Mini Dome System

Wiring

The types of wires that need to be installed are power, video, control, auxiliary outputs and alarm inputs. All

wiring cables enter the Housing through the top hole via the Cable Access Cap, Vicon mount or 1.5-inchPipe, depending upon the mounting method used. Refer to the Technical Information section for all electrical

requirements.

Power cables carry 24 VAC power and are usually a two-conductor type ranging in size from 20 to 12 AWG.

The power source should be a Class 2 indoor/dry or Class 3 outdoor/ wet rated type. The leads should be

connected to Terminal Block 2 (TB2), pin 1 [H - (hot)] and pin 2 [N - (neutral)]. Also, connect an 18 AWG wire

from TB1-8 (SHLD) to a solid earth ground (ex. water pipe). The size of the two-conductor cable depends on

indoor/outdoor application and cable distance as shown in the Technical Information Section.

Video cables carry the composite video signal and uses coaxial cable. The type of cable depends on the

cable distance as shown in the Reference Section. In Vicoax mode the video signal also carries the Control

signals.

Control cables carry RS-422 format digital signals and require individually-shielded twisted-pair sets. The

type of cable depends on the cable distance and number of wire pairs within a cable as shown in the

Technical Reference Section. There can be a maximum of four Control cables (twisted-pair sets), depending

on the mode selected, Simplex or Half-Duplex or chained through the Mini Dome. The Mini Dome has the

capability of being “daisy chained” to any other RS-422 format device, including another Mini Dome. It can

receive the signal and retransmit it to another device. See Table 3 below.

Note: If the Surveyor is not being connected in a daisy chain fashion, place a short jumper wire between TB1-

8 (SHLD) and TB1-10 (RIN-).

COMMAND IN (CIN): A signal from the CPU that causes some function to occur in the Mini Dome.

RESPONSE OUT (RO): A signal from the Mini Dome to the CPU in response to a COMMAND IN signal or

triggered by an alarm input.

COMMAND OUT (CO): A signal from the CPU that is received and retransmitted by the Mini Dome to

another RS-422 device.

RESPONSE IN (RIN): A signal from another RS-422 device received and retransmitted by the Mini Dome to

the CPU.

Communication mode Command In (CIN) Response Out (RO) Command Out (CO) Response In (RI)

Simplex

Half Duplex

Simplex, Chained

Half Duplex, Chained

Required Control Signals for Specific Communication Modes

X

XX

XX

XXXX

Table 3

X971 Rev 1098 Surveyor Mini Dome System Wiring • 15

Alarms are electronic TTL (transistortransistor logic) type inputs that are driven

by a dry contact type switch. The switch

has two states, open and closed. For

example, in Figure 19, a door switch can

activate an alarm when connected to a Mini

Dome alarm input. These signals require

an unshielded twisted pair cable. As a

guideline (under normal conditions), the

cable should be 22 AWG for a 1000 foot

(305 m) distance The states correspond

Figure 19

Typical Alarm Circuit

to defined TTL designations as follows:

PEN = HIGH

CLOSED = LOW

where: HIGH = 5 VDC

LOW = < 1 VDC

Since dry contact switches are normally defined in terms of their inactive or “normal” state, the following holds

true: NORMALLY CLOSED (NC) = ACTIVE HIGH (OPEN)

NORMALLY OPEN (NO) = ACTIVE LOW (CLOSED)

The “active” state can be programmed through the Mini Dome menu system. Alarm signals can be

programmed for their status (enabled/disabled), active level definition (high/low), action/reset function (none,

preset, aux on, aux off or tour), acknowledgement mode (automatic/manual) and report status (yes/no).

Auxiliary outputs are electronic open

collector type outputs which drive external

devices In Figure 20, a light can be turned

on and off when an auxiliary signal is

connected to a relay. Auxiliary signals can

be programmed for their active level

definition (high/low), power-on state

definition (on/off) and output type definition

(momentary or latching). For this example

the output must be defined as Active Low

(NO) and latching.

Each output can drive a relay at about 35

volts and 100 mA typical. There can be a

maximum of eight auxiliary outputs and

eight alarm inputs (twisted-pair sets).

Connect the DC voltage required for the

relay drive coil to TB3, pins 9 and 10. The

positive (+) side goes to pin 9, Common

Figure 20

Typical Auxiliary Output

and the negative (-) side goes to pin 10,

Ground. The relay drive IC will switch

negative connection (Ground) to the

appropriate output. In addition, the relay can be used as a set of dry contacts for a Normally Open device

input.

O

NOTE: For more information on auxiliary outputs refer to Vicon Technical Bulletin TB5156, “Application of

Open Collector Relay Outputs”.

16 • Wiring X971 Rev 1098 Surveyor Mini Dome System

Installing the Cables

WARNING: Disable the 24 VAC power to

prevent installer injury and

damage to the unit.

1. Route all cables into the top of the Mini

Dome through the electrical Conduit/Cable

Access Cap, Vicon mount or 1.5-inch Pipe.

Pull approximately 10 ft (3 m) of cable

through the Housing to allow convenient

wiring on a workbench.

2. Route all cables through the Customer

Interface Board’s Cable Clamp.

3. Remove terminal blocks TB1, TB2, TB3 and

TB4 from the Customer Interface Board by

pulling each straight out.

4. Strip approximately 8 inches (20 cm) of

Figure 21

Customer Interface Board

5. Strip approximately 0.25 inch (0.6 cm) of insulation off of each power, alarm and auxiliary wire.

6. Install a BNC male connector to the video (coaxial) cable.

7. Make all wiring connections to the terminal blocks as shown in Figure 21 and with reference to Table 4

and Table 8. In simplex configuration, the COMMAND IN + (CI+) and COMMAND IN - (CI-) terminals

must be connected. If the Surveyor is daisy-chained, the COMMAND OUT + (CO+) and COMMAND OUT

- (CO-) terminals must also be used. The response lines RO+, RO-, RIN+, and RIN- are used for HalfDuplex configuration only.

jacket off each Control cable. Then strip

approximately 0.25 inch (0.6 cm) of

insulation off of each Control cable wire.

WARNING: If Vicoax mode is being used, DO NOT wire TB1 for RS-422 mode, as this will cause the Mini

Dome program to lock up upon power-up.

8. Pull the cables back through the top of the Housing until approximately 12 inches (30.5 cm) of each cable

remains in the Housing.

9. Reinstall the terminal blocks TB1, TB2, TB3 and TB4 into to the Customer Interface Board at the proper

block frames.

WARNING: Failure to install the terminal blocks into the correct frames can cause damage to the CPU and

other electrical components in the Housing upon power-up.

10. Install the video BNC cable connector to the Customer Interface Board’s mating BNC connector.

11. Remove the screws from the Strain Relief Clamps and conveniently insert all wires. Screw the clamps

loosely back onto the board and pivot each Strain Relief Ring for optimum positioning. Conveniently

route the wires to their individual connections, leaving an approximate 3 inch (7.5 cm) loop in each wire.

Tighten the Strain Relief clamp screws. Pull the remainder of the cable back through the top of the

Housing until the wiring comfortably passes directly from the Cable Clamp to the top of the Housing.

X971 Rev 1098 Surveyor Mini Dome System Wiring • 17

TERMINAL BLOCK/

PIN NUMBER CONNECTOR LABEL SIGNAL NAME

POWER INPUT CONNECTOR (TB2)

TB2-1

TB2-2

TB2-3

H

N

G

Hot

Neutral

Ground

ALARM INPUT CONNECTOR (TB4)

TB4-10

TB4-9

TB4-8

TB4-7

TB4-6

TB4-5

TB4-4

TB4-3

TB4-2

TB4-1

GND

GND

ALM 8

ALM 7

ALM 6

ALM 5

ALM 4

ALM 3

ALM 2

ALM 1

Ground

Ground

Alarm 8

Alarm 7

Alarm 6

Alarm 5

Alarm 4

Alarm 3

Alarm 2

Alarm 1

RELAY OUTPUT CONNECTOR (TB3)

TB3-10

TB3-9

TB3-8

TB3-7

TB3-6

TB3-5

TB3-4

TB3-3

TB3-2

TB3-1

GND

RCOM

RY8

RY7

RY6

RY5

RY4

RY3

RY2

RY1

Ground

Relay Common

Relay 8

Relay 7

Relay 6

Relay 5

Relay 4

Relay 3

Relay 2

Relay 1

COMMAND INPUT/OUTPUT CONNECTOR (TB1)

TB1-10

TB1-9

TB1-8

TB1-7

TB1-6

TB1-5

TB1-4

TB1-3

TB1-2

TB1-1

RIN-

RIN+

SHLD

CO-

CO+

RO-

RO+

SHLD

CIN-

CIN+

Response in -

Response in +

Shield

Command out -

Command out +

Response out -

Response out +

Shield

Command in -

Command in +

Table 4

Customer Interface Board Terminal Block Definitions

18 • Wiring X971 Rev 1098 Surveyor Mini Dome System

Final Assembly

Final assembly is the last step before power-up and test. Final assembly is comprised of installing the preassembled Drive Mechanism into the Housing, installing the Lower Dome(s) and attaching a Trim Ring. Final

assembly varies in method, depending upon the Housing installation type used. This procedure is performed

on the installed Housing with common hand tools. Refer to Figures 22 and 23 before beginning.

Installing the Drive Mechanism

1. Rotate the Pan Drive Gear until its arrow is

aligned with the Drive Unit upper arrow. Refer

to Figure 22.

2. Align the Drive Unit lower arrow with the

Housing label “FRONT.”

3. Maintaining the arrow alignment, guide the

Drive Mechanism up into the Housing. Push up

against the Housing spring pressure until it

snaps into place.

Figure 22

Drive to Housing Alignment

CAUTION: It is necessary to hear a definite

snap. Verify that the rim of the Drive

is approximately flush with rim of the

Housing and centrally positioned

within the Housing to prevent

accidental Drive Mechanism

dropout.

4. Place the RUN/SERVICE switch to the RUN

position.

Figure 23

Exploded View - Drive Installation

X971 Rev 1098 Surveyor Mini Dome System Final Assembly • 19

Installing the Domes

There are three possible domes to be installed, a Mask, a Lower Dome and a Lower Outdoor Dome. The

following is brief description of each Dome. Refer to the Introduction Section of this manual for a detailed

description. Perform Steps 1 and 2 on all installations and proceed to the remaining Steps for a particular

installation.

Mask: 7.25 inch (18.4 cm) diameter black opaque unit which attaches to the base of the

Drive Mechanism magnetically, equipped with a Lanyard, and rotates with the Drive

Mechanism.

Lower Dome: 7.75 inch (19.7 cm) diameter chrome, gold or gray opaque unit that attaches to the

base of the Housing with clips and maintains a fixed position.

Lower Outdoor Dome: 11.3 inch (28.7 cm) diameter clear acrylic plastic unit that attaches to the base of the

Housing with screws and maintains a fixed position.

NOTE: The Accessory Kit comes with tamperproof hardware, in addition to standard hardware, for the

mounting of the Lower Outdoor Dome.

CAUTION: Use care when handling all domes to prevent damage. Refer to the Handling Domes Section

of this manual.

1. Locate the Lanyard inside the Mask. Connect the spring clip on the end of the Lanyard to the mating

latch on the inside of the Drive. Verify that the spring clip is firmly fastened.

2. Place the Mask onto the lower rim of the Drive Mechanism and rotate it until the magnetic latches snap

into place. Verify that the Camera Lens is in sight through the Mask slot.

For Indoor Pendant Installations

3. Align the four Lower Dome metal clips with the four

Trim Ring slots and push the Lower Dome upward into

the cutouts until it snaps into place on all four metal

clips.

Figure 24

Exploded View - Indoor Dome Installation

20 • Final Assembly X971 Rev 1098 Surveyor Mini Dome System

For Dropped Ceiling Installations

3. Stabilize the Housing and position the Trim Ring over the Housing lower rim. Push up on the Trim Ring

inner edge firmly and, using the other hand, push down on the Trim Ring outer edge. A single snapping

sound will verify that the latch has been properly seated. Repeat this action on all four latches.

4. If necessary, readjust the “Z” (vertical) position of the Housing to seat the Trim Ring flush against the

ceiling tile. Firmly tighten all bracket adjustment screws. Refer to Figure 12.

5. Align the four Lower Dome metal clips with the four Trim Ring slots and push the Lower Dome upward

into the cutouts until it snaps into place on all four metal clips.

For Solid Ceiling Installations

3. Align the four Lower Dome metal clips with the four Trim Ring slots and push the Lower Dome upward

into the cutouts until it snaps into place on all four metal clips.

For Outdoor Pendant Installations

3. Stabilize the Housing and position the Trim Ring

with Foam Filter over the Housing lower rim.

Push up on the Trim Ring inner edge firmly and,

using the other hand, push down on the Trim

Ring outer edge. A single snapping sound will

verify that the latch has been properly seated.

Figure 25

Exploded View - Outdoor Dome Installation

Outdoor Dome. Insert either the Modified Standard Screws or the Modified Tamperproof Screws

provided into the holes from the outside surface.

5. Press a Retainer Ring around the groove on the screw to hold in place. Repeat this on all four holes.

6. Locate the four threaded holes in the Trim Ring with Foam Filter. Align the four screws in the rim of the

Dome with the four threaded holes and screw them in. Use the tamperproof key provided to tighten the

tamperproof screws.

Repeat this action on all four latches.

4. Locate the four holes in the rim of the Lower

X971 Rev 1098 Surveyor Mini Dome System Final Assembly • 21

NOTES

22 • Final Assembly X971 Rev 1098 Surveyor Mini Dome System

Disassembling the Mini Dome

The Mini Dome can be easily disassembled by simply removing the domes and Drive Mechanism. The

Housing and cabling remains intact during disassembly. It is not necessary to disable the 24 VAC power.

Perform Step 1 for a particular installation type and continue with the remaining steps for all installation types.

1. For Indoor Pendant and Dropped and Solid Ceiling Installations:

Gently pull down the Lower Dome outside edge, with two hands, until all metal clips snap out of place.

1. For Outdoor Pendant Installations:

Remove the four screws from the Outdoor Lower Dome and lower. Use tamperproof key, if necessary.

2. Verify that the Green LED is not illuminated. If it is, place the RUN/SERVICE switch to the RUN position.

Gently pull the Mask down until the magnetic latches snap out of place. The Red LED should illuminate.

CAUTION: Failure to verify illumination of the Red LED and position of the RUN/SERVICE switch prior to

removal of the Mask can cause injury to the technician and damage to the unit.

3. Disconnect the spring clip on the

end of the Lanyard from the

mating latch on the inside of the

Drive.

4. Slowly rotate the Drive until the

arrow on the Drive lower rim

aligns with the arrow on the

Housing inside edge. Verify that

the Drive Release Handle is

visible through the slot behind

the Camera/Lens Module.

5. Support the Drive with one hand

and insert the supplied Removal

Tool into the slot as shown in

Figure 26, “A”.

6. Latch the Removal Tool onto the

Drive Release Handle and pull

downward until the spring

latches disengage as shown in

Figure 26, “B”. The Drive will

release.

7. Carefully lower the Drive while

releasing the Drive Release

Figure 26

Drive Release Handle

Handle.

X971 Rev 1098 Surveyor Mini Dome System Disassembling the Mini Dome • 23

If It It Is Necessary to Remove the Trim Ring

1. Insert a small flat blade

screwdriver behind one of

the four slots on the Trim

Ring inner edge as shown in

Figure 27. Gently pull down

on the screwdriver while

pulling down on the Trim

Ring outer edge until it

becomes unseated. Repeat

this on the remaining three

latches.

2. With all four latches

unseated, pull straight down

on the Trim Ring outside

edge, with two hands, until it

snaps out of place.

Figure 27

Trim Ring Removal

24 • Disassembling the Mini Dome X971 Rev 1098 Surveyor Mini Dome System

Operation

Following the complete installation and setup of the Mini Dome, it is necessary to perform initial power-up

testing and verify proper operation. If the Surveyor fails to power-up correctly, a built-in diagnostic test can be

run to assist in troubleshooting. When initial power-up has been completed and verified, Surveyor can be

setup and operated in a normal fashion using a Vicon remote operator keypad, NOVA (VPS) unit or through a

PC running Protech software.

Initial Power-Up

Setup an appropriate monitor within the vicinity of

the Mini Dome. Connect the video out cable to an

appropriate monitor. Power-on the monitor and

verify that no signal is displayed.

1. Verify that the RUN/SERVICE Switch is in the

RUN position. If not, place it in the RUN

position and replace the Mask. No LEDs

should be illuminated.

2. Switch the 24 VAC power on to the Mini Dome.

Figure 28

Power-Up Test Screen

Figure 29

Opening Screen

The monitor displays the power-up test screen

(Figure 28) for the duration of testing and then

switches to the Surveyor opening screen

(Figure 29). When Surveyor is powered-up,

information is displayed to confirm current DIP

Switch settings.

3. This test displays the status of the functions

pan, tilt, zoom, focus and the integrity of the

memory (NVRAM). If any test fails, “FAIL”

displays in place of “OK.”

4. Upon completion of these tests, the Drive

Mechanism moves slightly, to find its home

position. It pans a few degrees and returns to

its original pan position then tilt a few degrees

and find its original tilt position. Upon

completion of homing, the Mini Dome is ready

to verify proper operation.

NOTE: The Drive Mechanism always returns to the

pan and tilt coordinates it was initially

powered-up with.

X971 Rev 1098 Surveyor Mini Dome System Operation • 25

Verifying Proper Operation

Setup a remote keypad via RS-422 or a V1902VCT Vicoax Control Transmitter via composite video to the

Mini Dome. Power-on the control device and verify that it boots up. Setup the control device for operation

with the Mini Dome in accordance with its Installation and Operation Manual.

For a Vicon model V1300X-RVC or V1300X-DVC use the following procedure to access Surveyor

programming:

1. Slide the keypad’s PGM-RUN switch to the PGM position.

2. Press the PP ENTER key; the PRESET LED displays a blinking 0.

3. Press the 9 and 4 numeric keys in that order.

4. Press the PP ENTER key again. The

PRESET LED display remains with the

number 94 and the monitor displays the

Surveyor Main Menu, as shown in Figure

30.