Page 1

Valco Instruments Co. Inc.

2 Position

Electric Actuator

Instruction Manual

P. O. Box 55603, Houston, TX 77255

(713) 688-9345

•

Sales toll-free (800) 367-8424

Fax (713) 688-8106

MAN-2EA

Rev. 9/12

Printed in USA

Page 2

Table of Co ntents

1. GENERAL DESCRIPTION............................................................................... 1

2. MANUAL USE OF THE 2 POSITION VALVE ACTUATOR .............................. 2

3. CONTROLLING THE ACTUATOR WITH A COMPUTER................................3

3.1 Using a Relay Output

3.2 Using a Logic Level Output

3.3 Using the Output from the Actuator

3.31 Inject Contact Closure

3.32 Positive Position Feedback

4. INSTALLING A VALVE ON AN ACTUATOR....................................................5

4.1 Preparing a M anual Valco Valve for Mounting on an Actuator

4.11 Disas sembly of a Manual W or UW Type Valve

4.12 Removing the Handle or Knob from a Valve on a Standoff

4.13 Removing the Handle f rom a P Type Valve

4.14 Removing the Handle from a U Type Valve

4.2 Installation of a Valve With Closemount Hardware

4.3 Installation of a Valve With a Standoff

5. VALVE ALIGNMENT.......................................................................................11

5.1 Visually Checking the Alignment

5.2 Chromatographic Symptoms of Misalignment

5.21 Loss of Flow or Blocked Flow

5.22 Multiple Peaks or Doublets

5.3 Causes of Misalignment

5.31 Removal of the Valve from the Actuator for Mounting

5.32 Shock from Heavy or Continuous Use

5.4 Alignment Procedure

6. ACTUATOR MODIFICATIONS ....................................................................... 14

6.1 Adjusting the Actuator Stroke

6.2 Actuator Conversion

6.21 Disassembly

6.22 Installation of the New Crank Assembly

6.23 Flag Adjustment

7. TECHNICAL DRAWINGS...... .. .. .. .. .... .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .... .. .. .. .. .. .. .. .. .. .. .20

8. WARRANTY............... .. .. .. .... .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .... .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .25

Page 3

1. GENERAL DESCRIPTION

Valco 2 position valves are widely used in a variety of sample injection and

switching applications. Rotating them to the desired position can be done

manually, but is best done automatically with either the Valco 2 Position Air

Actuator or the Valco 2 Position Electric Actuator described in this manual. For

most laboratory uses, especially where a laboratory computer is available for

contr ol bu t com pres sed a ir i s not , t he Valco 2 Position Elec tri c A ctua tor i s th e be st

choice.

Valco 2 Position Ele ctric Ac tuators are available in 110VAC or 220VAC models for

any 30° , 36 °, 45° , 60 °, or 90 ° Valco valve. The mod el n umb ers o f t he act u ato rs ar e

respectively E30, E36, E45, E60, and E90. (Or E30-220, etc.) An electric actuator

can be retrof itted to ex isting a ir actuate d or manu al valves and i s compat ible with

all Valco close coupling and standoff assembly hardware.

The 2 position electric actuator is a complete system, with all the necessary cables

and power cord. It consists of (a) the actuator itself, (b) a control box with LED

display, and (c) an interface cable for remote switching. The actuators are normally

suppli ed w ith a mot or/ gear train tha t moves t he val ve from Position A to Position B

in 0.56 seconds. All electric actuator models use separate line voltages (120V AC

or 220V AC, 50/60 Hz) and require no power from the chromatograph with which

they ar e u se d.

1

Page 4

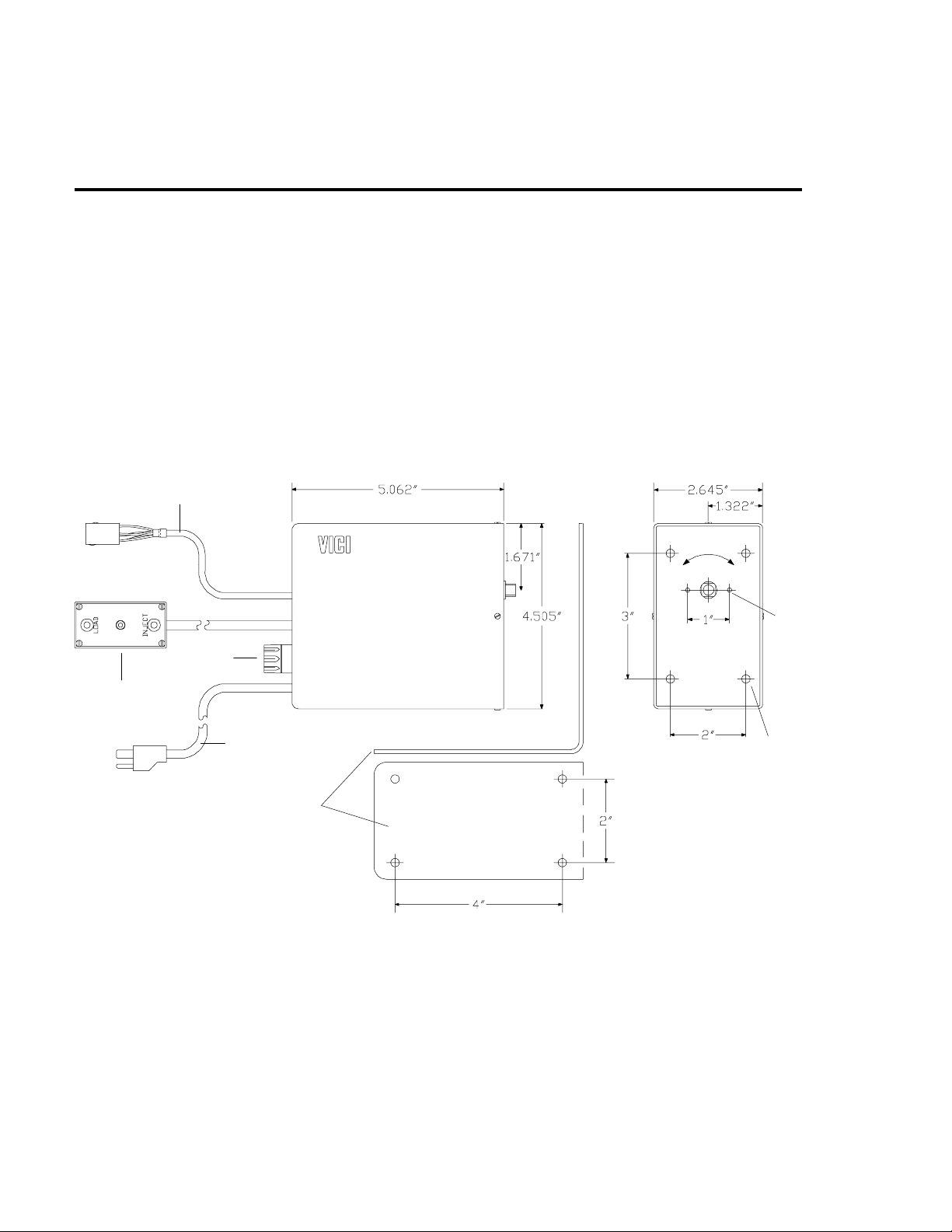

2. MANUAL USE OF THE

2 POSITION VALVE ACTUATOR

The electric actuator has a control box with a two-position, spring-loaded (normally

off) toggle switch and two LED’s which indicate the valve position. The valve can

be moved from one position to the other by manually moving the toggle switch

toward the light that is not illuminated.

REMOTE SWITCHING CABLE

(WITH 5 FOOT EXTENSION)

Valco Instruments Co. Inc.

POS B

(INJECT)

POS A

(LOAD)

HOLES FOR

CLAMP RING

SCREWS

CONTROL BOX AND

CABLE (4 F E ET )

2 AMP F USE

POWER CORD (5 FEET)

MOUNTI N G B R ACKE T

Figure 1:

Actuator dimensions

8-32 MOUNTING HOLES

(FOUR PLACES)

2

Page 5

3. CONTROLLING THE ACTUATOR

WITH A COMPUTER

The remote switching cable is used to communicate a momentary or continuous

contact closure or a negative true logic level signal from a data system, required

for automated operation of the actuator. In addition, two of the cable’s leads

supply feedback from the actuator. Since the input signal must be of 10 to 20

milliseconds duration to switch the actuator, a sub-millisecond noise spike will not

start the actuator.

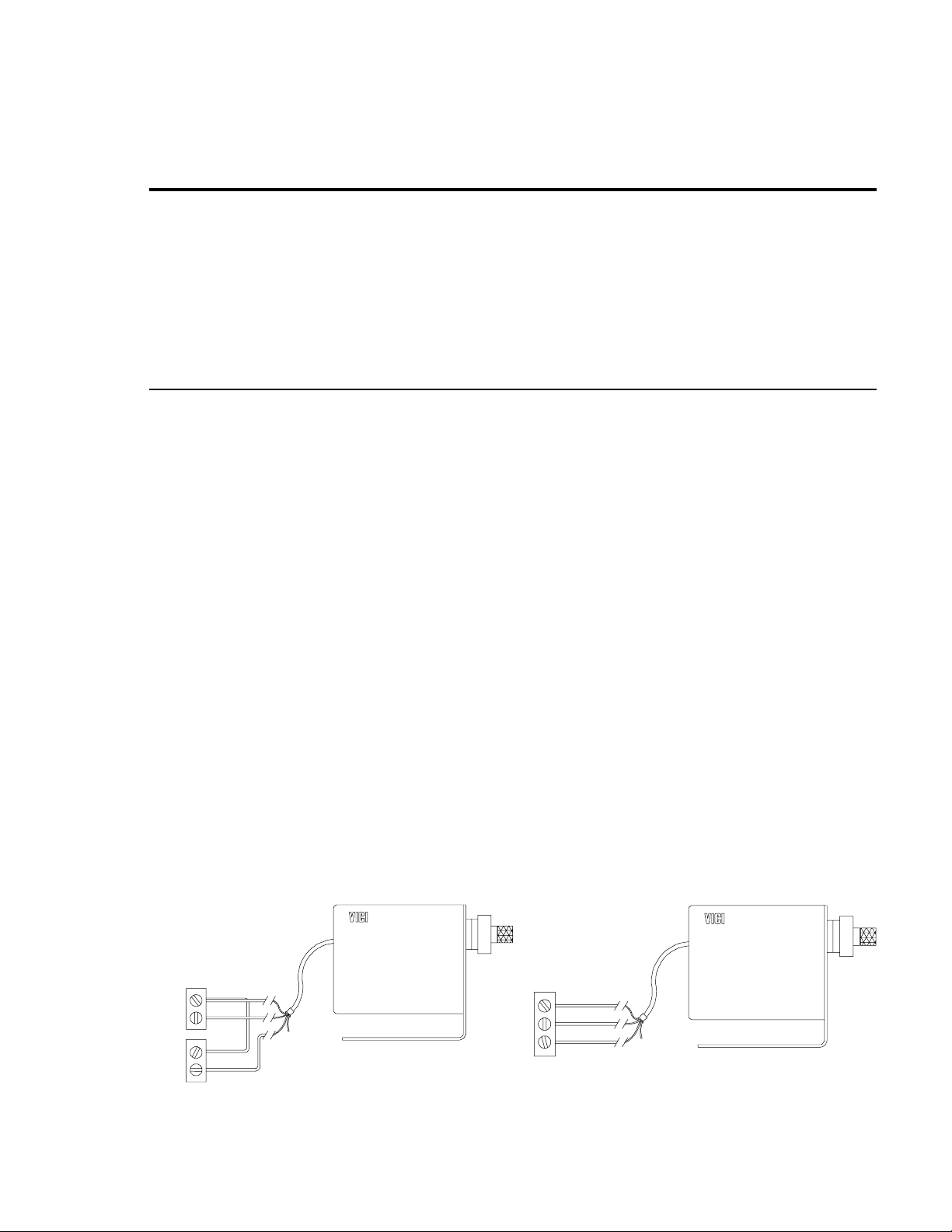

3.1 Using a Relay Output

If the data system has two relays available, then one relay can be dedicated to

each position of the actuator. This is ideal, since it allows the manual switch to

function normally. Connect the black wire (INJECT) to the normally open (NO)

terminal of the first relay and the the green wire (GROUND) to its common or logic

ground ter min al. Connect the r ed wi re ( LOAD) t o the nor mally open (NO) t er mina l

of the second relay, and connect a jumper wire from the common or logic ground

of the first relay to that of the second. (

Program the data system to energize the first relay when the valve is to be

switched to t he I N JEC T po s iti on , le avin g i t en er gi zed for only t wo o r th ree se con ds.

Likewise, at the time for LOAD, turn on the second relay for a few seconds. The

INJECT relay must be turned off before the LOAD relay is turned on, and vice

versa. If the valve will not move out of a position, it is most likely that the relay

which switched it to that position has not been turned off. When n either rel ay is

energized, the manual toggle switch can be used as described on the previous

page.

Figure 2

)

RELAY 1

GND

NO

GRD

NO

RELAY 2

GREEN

BLACK

RED

Figure 2:

If the data system has only a single double-pole relay with normally open (NO)

and normally closed (NC) terminals (

Figure 3

), connect the green wire (GROUND)

to the relay common or logic ground. Connect the black (INJECT) wire to the

normally open (NO) relay terminal and the red (LOAD) wire to the normally closed

(NC) terminal. The computer must be programmed to keep the Normally Open

(NO) relay contact engaged (ON) as long as the actuator is to be in the INJECT

position.

GREEN

GND

Dual relay connection

NO

NC

BLACK

RED

Figure 3:

Single relay connection

3

Page 6

3.2 Usi ng a Logic Level Output

If the data system uses negative true logic level output, connect the green wire

(GROUND) to the Logic Ground of the data sy stem relay. Connect the red wire

(LOAD) t o on e out put of the re lay and the bla ck wir e (INJ ECT) to th e othe r out put.

Turning the relay off will switch the actuator to LOAD and turning it on will switch it

to INJECT. If the operations are reversed, simply switch the connection of the red

and black wires.

3.3 Using the Outp ut from th e Actuator

The whi te and cl ear wires can perform either of two func tions, depen ding on the

setting of the dipswitch on the circuit board. The factory setting is for the Inject

Contact Closure mode.

3.31 Inject Co ntact Closure

In this mode, which is the factory default, the white and clear wires provide a

conta ct closur e when the ac tuator moves to the INJ ECT positio n. (The closure is

approximately two seconds long.) It may also be used to "spike" a recorder or to

start a ny d evice eq uipp ed wi th a r emo te c on t act c los ur e in pu t.

3.32 Positive Position Feedback

To change t he setti ng on th e dipswitc h, follow St eps 1-4 in Sectio n 6.21,

Conversion, Di sassem bly

for the ma nual switch ing cable. (See Draw ing 21312 , page 23. ) In this mod e, the

clear w ire carr ies a logic hi gh when the ac tuator is in the Posi tion A (LOAD) : the

white wire carries a high when the actuator in is Position B (INJECT).

. The dipswitc h is on th e boa rd next to the conn ection s

Actuator

4

Page 7

4. INSTALLING A VALVE ON AN ACTUATOR

4.1 Pr eparin g a Ma nual Valco Valve for Mo unting on an Actu ator

A manually switched 2 position valve has a handle or knob which must be removed before the valve can be installed on the actuator. Sections 4.11 - 4.14

describe the procedures for various Valco valves.

4.11 Disassembly of a Manual W or UW Type Valve

1. Rotate the knob counterclockwise so the valve is positioned properly for

later installation on the electric actuator.

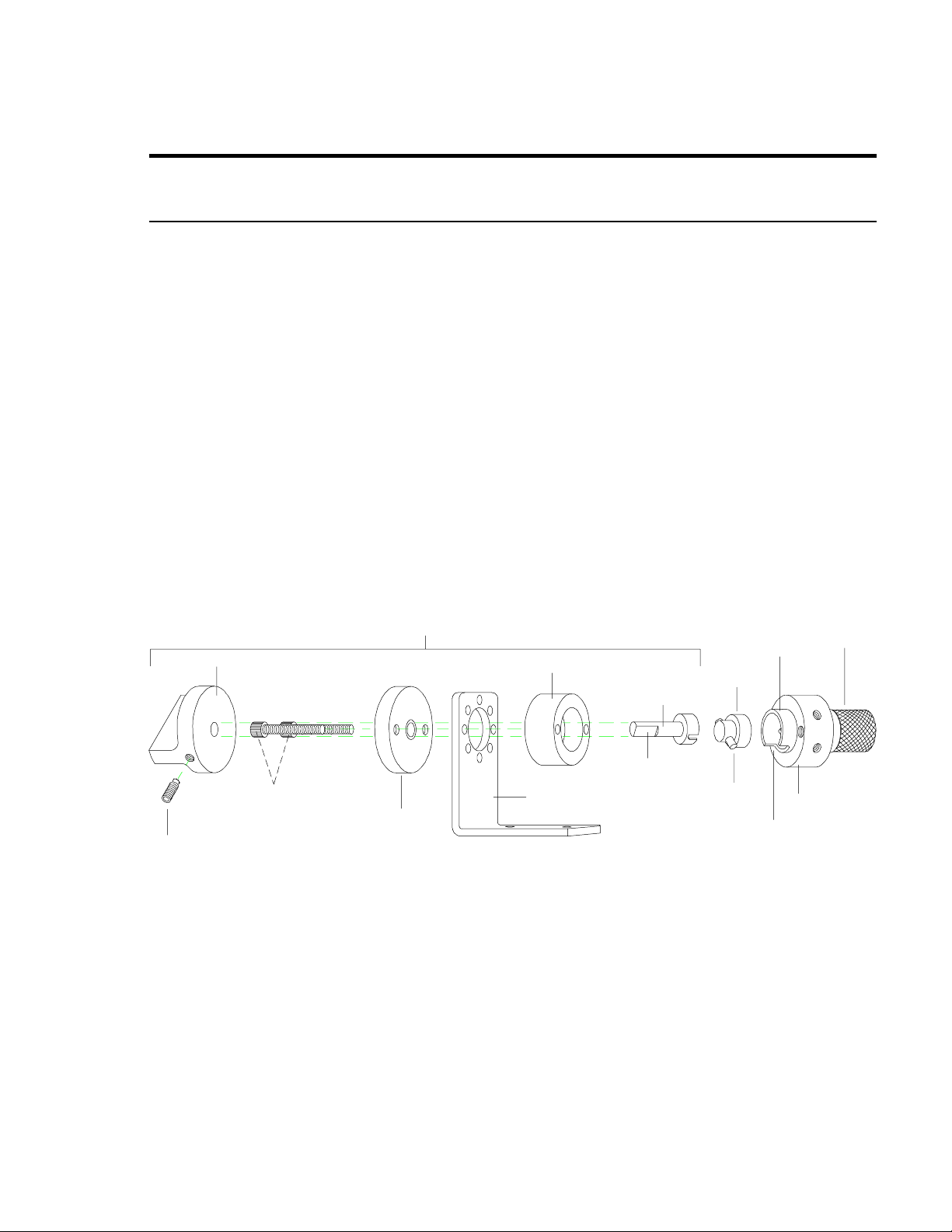

HWSC-SS8-5B/

SET-SCREW

WK/KNOB

HWSC-SC8-16

SCREWS

2. See

Figure 4

. Loosen the set-screw within the W valve knob and pull the

knob off of the manual drive shaft.

3. Using a 9/64 hex driver, unscrew the two HWSC-SC8-16/socket head

screws (8-32 x 1") until the valve comes loose from the rest of the assembly.

Keep the driver with the valve.

4. The rest of the assembly will slide easily apart, but you may wish to keep it

together for future use.

5. Proceed to Section 4.2 for c losemount assembly, or Sec tion 4.3 if the valve

will go on a standoff before being installed on the actuator.

KNOB ASSEMBLY

WSB/SHAFT

BEARING

PLATE

Figure 4:

WSH/SHAFT HOUSING

STANDARD

ANGLE

BRACKET

WDS/MANUAL

DRIVE

SHAFT

FLAT

FACE

W or UW type valve with knob assembly

WD/DRIVER

ROTOR

PIN

COLLAR

CUTOUT

VALVE

BODY

PRE-LOAD

ASSEMBLY

4.12 Removing th e Hand le or K nob from a Valve on a S tandof f

1. Rotate the knob counterclockwise so the valve is positioned properly for

later installation on the electric actuator.

2. See

Figure 5

. Simply pull the handle or knob, with the manual handle

adapter and retainer, off of the standoff tube.

3. Proceed to Section 4.3.

5

Page 8

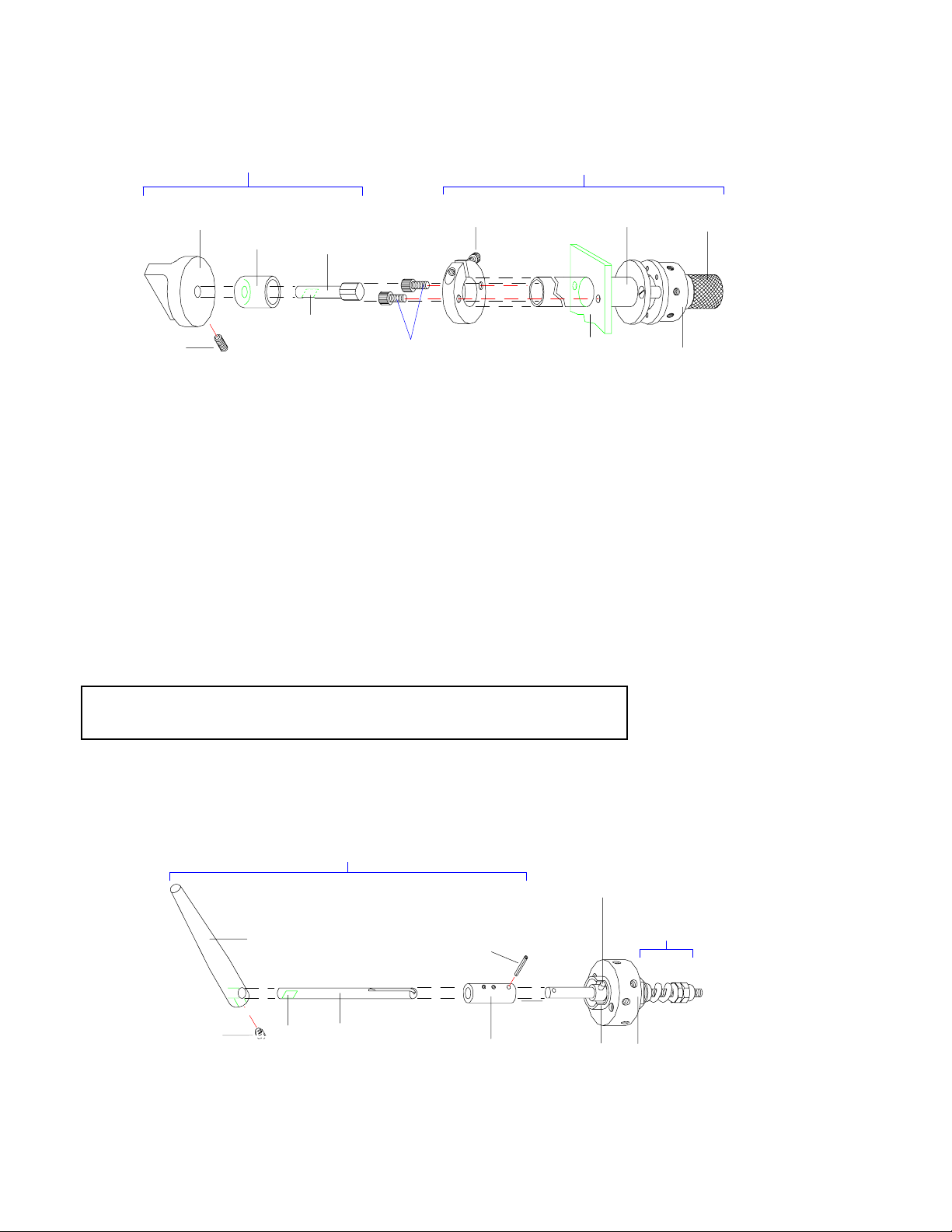

KNOB ASSEMBLY

STANDOFF ASSEMBLY (Length varies)

WITH VALVE ATTACHED

HWSC-SS8-5B/

SET-SCREW

WK/KNOB

RETAINER

MHA/MANUAL

HANDLE

ADAPTER

FLAT FACE

Figure 5:

HWSC-SC6-8B/

SCREW

SCREWS

FOR CR2

(NOT SUPPLIED)

Manual valve on a standoff

STANDOFF

OPTIONAL

MOUNTING

BRACKET OR

OVEN WALL

4.13 Removing the Handle from a P Type Valve

These types of valves have a 1-1/8" metal rotor shaft that connects to the handle.

1.Rotate the knob counterclockwise so the valve is positioned properly for

later installation on the electric actuator.

2.See

Figure 6

. Remove the black handle by sliding its shaft out of the

coupling.

3.Place the coupling in a bench vise with the side with only one hole facing

up. Use a hammer and punch to remove the roll pin which connects the

coupling to the valve rotor shaft. Pull the coupling off of the shaft.

PRE-LOAD

ASSEMBLY

VALVE

BODY

CAUTION: Do not hold the valve body in the vise when removing t he

coupling. Valve damage will result.

4.Proceed to Section 4.2 for closemount assembly, or S ection 4.3 if the valve

will go on a standoff before being installed on the actuator.

HANDLE ASSEMBLY

ROTOR

PIN

HWSC-SS10-3B/

SET-SCREW

SVH/

STANDARD

HANDLE

FLAT

FACE

Figure 6:

ROLL

PIN

SHAFT

COUPLING

P Type valve with an SVH handle

(Varies with valve type)

CUTOUT

SPRING HARDWARE

VALVE

BODY

6

Page 9

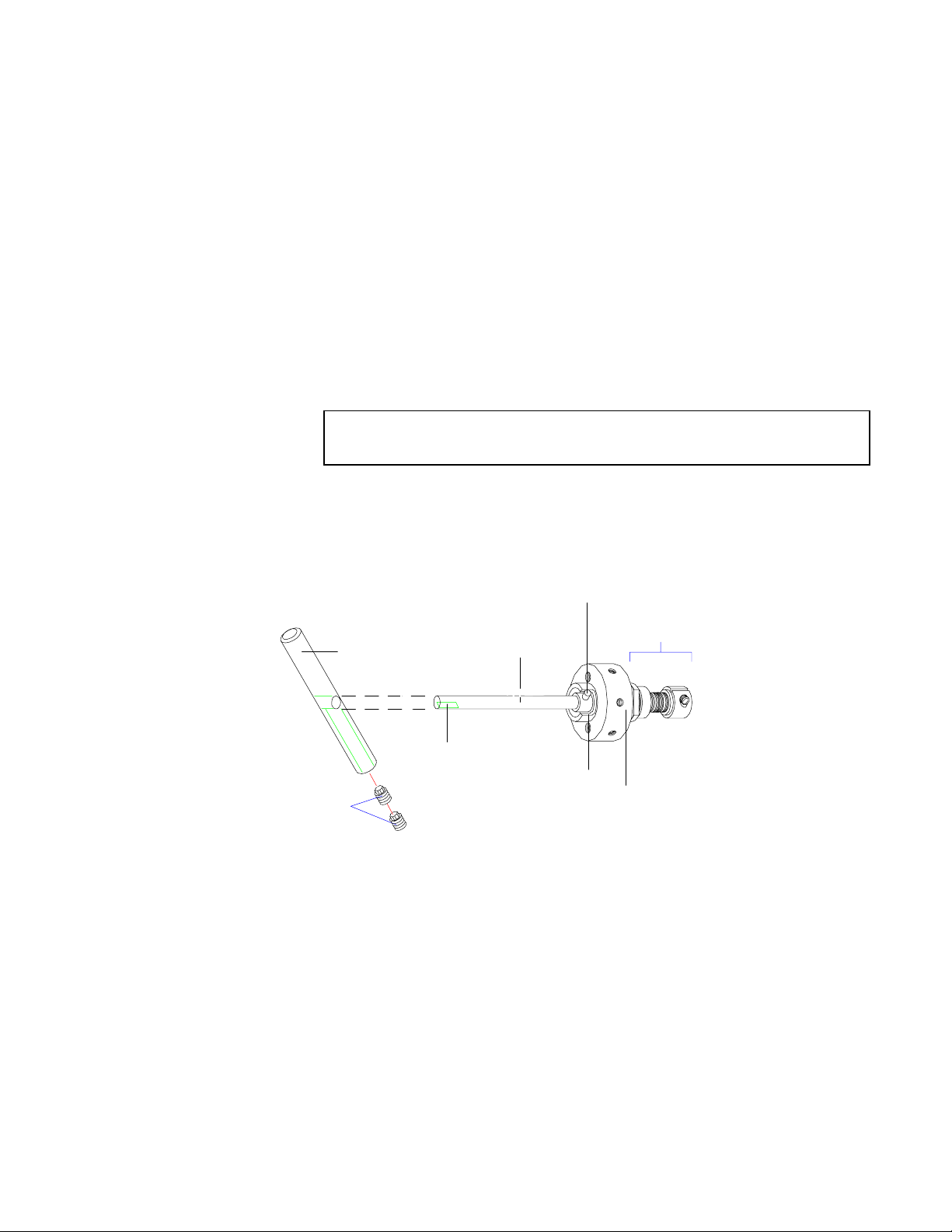

4.14 Removing the Handle from a U Type Valve

In addition to removing the handle, it is necessary to cut the 3" shaft of the manual

U Type valve to ap proxim at el y 1" .

1. Rotate the knob counterclockwise so the valve is positioned properly for

later installation on the electric actuator.

2. See

two

Figure 7

set screws within the handle.

. Remove the handle by using a 1/8 hex driver to unscrew the

3. Take all the fittings out of the valve. Cover all the ports with mas king tape

so that no debris can enter the ports.

4. Clamp the end of the shaft,

not the valve body

, in a bench vise. Carefully

cut the valve shaft to a length of 1" or less with a hack saw. Be sure not to

let the valve fall and become damaged.

CAUTION: Do not ho ld the val ve b ody in th e v ise wh en c ut ti ng the

shaft. Valve damage will result.

5. Proceed to Section 4.3.

ROTOR P IN

SPRING HARDWARE

UHT/

HANDLE

SHAFT

(Varies with valve type)

HWSC-SS1/4F-4B

SET-SCREWS

FLAT FACE

Figure 7:

CUTOUT

VALVE

BODY

U Type valve with UTH handle

7

Page 10

4.2 Installation of a Valve With C losemount Hardware

If the electric actuator has been specified for use with closemount hardware, it will

be received from the factory with the CR4/clamp ring already affixed to the

actuator. The clamp ring is attached to the actuator with a two HWSC-SC86TDH/modified socket head screws (8-32 x 3/8").

CAUTION: Do not use screws longer than 1/2" to attach clamp rings to

electric actuators. They will interfere with internal moving parts and

damage the actuator.

1.Plug in the electric actuator and put it into the LOA D position (indicated by a

red light in the LOAD position) on the control box. The valve will have been

rotated to the counterclockwise position before the knob or the handle was

removed, so they should now be in the same relative rotational position.

CAUTION: The valve and the actuator must be in corresponding

rotational positions before assembly. If they are not, t he valve or

actuator may be damaged when operated.

2.Place the slotted coupling over the driver (

(

Figure 6 and 7

) and engage the rotor pin.

Figure 8

) or the valve shaft

3.The actuator is shipped with the CR41/closemount standoff mounted in the

CR4/clamp ring. Remove the CR41 from the CR4 and attach it to the valve

body with the two HWSC-SC6-10NT/modified socket head screws (6-32 x

5/8"). (Only one is used for a P-Type 10 port valve.) The CR41 must be

oriented so that the valve cutout is visible through the long slot on its side.

4.Press the flange of the CR41/closemount standoff into the CR4/clamp ring

on the actuator, making sure that the square driver of the actuator engages

the squared hole of the slotted coupling. (It may be eas ier to put the slotted

CLOSEMOUNT STANDOFF

PRE-LOAD

TAB

ASSEMBLY

VALVE

BODY

SQUARE

DRIVER

CR4/

CLAMP

RING

HWSC-SC6-8B/

SCREW

HWSC-SC8-12TDH/

SCREWS

CR41/CLOSEMOUNT

STANDOFF

SLC/SLOTTED-

COUPLING

ROTOR

PIN

WD/DRIVE

CUTOUT

ROTOR

HWSC-SC6-10NT/

SCREWS

Figure 8:

Valve on actuator with closemount hardware

8

Page 11

coupling on the square driver of the actuator first. However, make sur e that

the driver doesn’t get cocked.) The CR41/closemount standoff should end

up flush against the CR4/clamp ring.

5.Tighten the HWSC-SC6-8B/screw (6-32 x 5/8") in the clamp ring with a

7/64 hex driver.

6.Align the valve and actuator according to the

in Section 5.4.

CAUTION: If the valve and actuator are not properly aligned, the slots

on the valve rotor and the ports in the valve body will not align properly.

The flow of sample may be blocked, and other problems may result.

4.3 Installation of a Valve With a S tandoff

If the electric actuator has been specified for use with a standoff, it will arrive from

the factory with the CR3/clamp ring already on the actuator. The clamp ring is

attached to the actuator with two HWSC-SC8-8B/socket head screws (8-32 x 1/2") .

CAUTION: Do not use screws longer than 1/2" to attach clamp rings to

electric actuators. They will interfere with internal moving parts and

damage the actuator.

1.Plug in the electric actuator and put it into the LOA D position (indicated by a

red light in the LOAD position) on the control box. The valve will have been

rotated to the counterclockwise position before the knob or the handle was

removed, so they should now be in the same relative rotational position.

CAUTION: The valve and the actuator must be in corresponding

rotational positions before assembly. If they are not, t he valve or electric actuator may be damaged when operated.

Alignment Procedure

found

HWSC-SC8-8B/

SQUARE

DRIVER

CR3

CLAMP

RING

SCREW

HWSC-SC8-8B/

SCREWS

SCREWS

(NOT

PRO-

Figure 9:

STANDOFF ASSEMBLY (Lengths vary)

HWSC-SC6-8B/

SCREW

CR2/

CLAMP

RING

STANDOFF

OPTIONAL

MOUNTING

BRACKET

OR OVEN WALL

Valve on actuator with a standoff

STANDOFF

DRIVE SHAFT

CUTOUT

ROTOR

PIN

WD/DRIVER

ROTOR

TAB

PRE-LOAD

ASSEMBLY

VALVE

BODY

HWSC-SC6-

10NT/

9

Page 12

2. Remove the CR2/clamp ring from the standoff and mount it on the oven

wall. (Screws are not provided for this pur pose.) Slide the standoff through

the CR2/clamp ring on the oven wall or bracket. (The standoff requires an

11/16" clearance hole.)

3. Firmly press the end of the st andoff into the CR3/clamp ring mounted on the

actuator, making sure that the square driver of the actuator engages the

squared hole of the standoff drive shaft. Position the entire assembly so

that the entire valve body cutout is visible.

4. Tighten the screw in the CR3/clamp ring.

5. Align the valve and actuator according to the

in Section 5.4.

CAUTION: If the valve and actuator are not properly aligned, the slots

on the valve rotor and the ports in the valve body will not align properly.

The flow of sample may be blocked, and other problems may result.

7. Position the standoff in the CR2/clamp r ing and tight en the clamp ring screw

to secure the standoff in place.

Alignment Procedure

found

10

Page 13

5. VALVE ALIGNMENT

When the valve arrives from the factory installed on the actuator, it is accurately

aligned and ready to use. However, every time the clamp ring on the actuator is

loosen ed to re adjust or remove the va lve from th e actuat or, the valve and actu ator

alignment

rotor al ign pro pe r ly.

5.1 Vis ually Checking the Alig nment

It is important to note that the actuator actually drives only the rotor within the

valve body, and that the valve or valve/standoff assembly remain stationary with

respect to the actuator. To check the alignment, cycle the actuator from one

position to the other and observe the location of the rotor pin. The rotor pin should

come to rest against both sides of the cutout in the valve body.

show th e rotor pi n in both po sitions ( LOAD and IN JECT). In

pin contacts one side of the c utout but does not touch the other side, indica ting

that the valve needs to be aligned. (See Section 5.4,

Figure 11

actuator stroke must be adjusted. (See Section 6.1,

.)

Stroke

be checked to be sure that the internal ports and slots on the

must

, the pin does not touch the cutout on either side, indicating that the

Figure 12

shows the pin properly contacting both sides of the cutout.

Figures 10-12

Figure 10

, the rotor

Ali gnment Proced ure

Adjusting the Actuator

.) In

END OF ROTOR PIN

IN EITHER POSITION

CUTOUT

VALVE

BODY

Figure 10

Adjust alignment

END OF ROTOR PIN

IN EITH E R PO S IT IO N

CUTOUT CUTOUT

VALVE

BODY

END OF ROTOR PIN

IN EITHER POSITION

Figure 11

Adjust stroke

Proper al ig nme nt

VALVE

BODY

Figure 12

11

Page 14

5.2 Chromatographic Symptoms of Misalignment

5.21 Loss of Flow or Blo cked Flow

When the rotor does not rotate completely or accurately, the ports of the valve may

not intersect the engravings on the valve rotor. This can cause a loss of flow at

outlet s or a blockag e of flow at inlets .

5.22 Multipl e Peaks or Doublets

In some configurations, the engraving may not be aligned properly even though

flow is not eliminated. Some engravings are very small or very large, and

inaccu rate alignment can cause what appear to be multiple injections due to the

sweeping action of the rotor.

5.3 Caus es of Misalig nment

5.31 Removal of th e Valve from the Act uator for M ounti ng

To mount valv es throu gh a bracket or oven wall , the val ve and stan doff asse mbly

must be separated from the actuator. Any time the clamp ring screw has been

loosened, the alignment of the valve after replacement on the actuator

checked, an d r ea li gned as ne ce ssa r y.

must

be

NOTE: To reduce the possibility of having to realign after installation,

before removing the valve from the actuator:

Closemount:

where it lines up with the slot in the stainless clamp ring on the actuator.

Standoff:

lines up wit h the sl ot in t he bla ck anod ize d c la mp r i ng on t h e ac tu ato r. Do

not remove the valve from the standoff assembly.

When t hi s ma r k i s l in ed up w it h t he sl ot on re ass embly, the fact or y ali gn men t

will be approximately reproduced as long as the valve and the actuator remain i n th ei r o r ig inal po si tio ns.

Whenever the valve and standoff assembly is removed from the actuator and

replaced, be certain that the assembly is inserted into the actuator as far as

possible (approximately 3/8 inch) to achieve complete driver coupling.

5.32 Shock from Heavy or Conti nuous Use

Occasionally, when valves are used in applications requiring a high-duty cycle,

wear or shock may cause the valve mounting screws or the clamp ring screw to

loosen . This al lows the valve to overth row and may resul t in misalig nment. The

most obvious symptom is movement observed in the valve or valve/standoff

assembly, which normally would not move when the valve is actuated.

Make temporary registration marks on the face of the valve

Make t emp ora r y reg is t rati on mar ks on t he s t an dof f tub e wher e i t

12

Page 15

5.4 Alignment Procedure

1. After determining that alignment is necessary, actuate the valve to the

position in which the rotor pin is against the stop.

2. Loosen the clamp ring screw slightly. This will allow the actuator to complete

its travel if it was being stopped by the end of the valve rotor travel. The

valve body will rotate slightly.

3. Tighten the clamp ring screw and cycle the actuator to the other position.

The pin should come to rest against the stop. If it does not, repeat the

procedure. If after several attempts the pin still does not contact the stop in

both positions, see Section 6.1,

Adjusting the Actuator Stroke.

13

Page 16

6. ACTUATOR MODIFICATIONS

6.1 Adjusting the A ctuator Stroke

If for any reason the actuator will not rotate the valve rotor completely, or if you

have reason to believe that the actuator is stroking too far, refer to the direc tions

below to adjust the actuator for slightly more or less rotation than is supplied by

the factory.

Because of differing amounts of play designed into the com ponents, the actuator

stroke

different mounting hardware than it originally received at the factory: i.e., a standoff

assembly used with an actuator that originally had closemount hardware, or

closemount hardware used with an actuator originally supplied with a standoff

assembly.

Valve alignment should always be checked before adjusting the actuator stroke to

confirm that the rotor pin is not contacting either side of the cutout. Since it is

difficult to see whether the stroke is too great, adjust the stroke by very small

increments so that you can stop as s oon as the rotor pin just contacts both s ides

of the cutout.

NOTE: This adjustment cannot make a 36° actuator into a 60° actuator. To do

that, see Section 6.2,

be checked any time that the actuator is refitted to operate with

must

Actuator Conversion

.

1.Step the actuator to the LOAD position. Remove the valve and its mounting

hardware from the actuator.

For a closemount valve, (Figure 8

loosen the HWSC-SC6-8B/socket head screw (6- 32 x 5/8") in the stainless

CR4/clamp ring. Pull off the valve and its attached black-anodized

CR41/closemount standoff. With a 9/64 hex driver remove the two HWSCSC8-6TDH/modified socket head screws ( 8-32 x 3/8") which hold the clamp

ring to the actuator.

For a valve on a standoff, (Figure 9

loosen the HWSC-SC8-8B/socket-head screw (8-32 x 5/8") in the black

anodized CR3/clamp ring on the actuator. Pull off the standoff with the valve

attached. The same hex driver will remove the two HWSC-SC8-6/sockethead screws (8-32 x 3/8") which hold the clamp ring to the actuator.

2.

Unplug the actuator

SC8-6/screws (8-32 x 3/8") which hold the black right angle mounting

bracket to the actuator body. (See

3.Remove the four HWSC-PL4-4/screws (4-40 x 1/4") holding the outer

cover and pull the cover back 1 to 2 inches. It may be necessary to

remove the two strain reliefs labeled REMOTE SWITCHING and

MANUAL SWITCHING.

120V AC 50/60 HZ.

. Use a 9/64 hex driver to remove the four HWSC-

Do not remove

, page 9) use the 7/64 hex driver to

, page 10) use the 9/64 hex driver to

Figure 13

)

the bottom strain relief labeled

4-40 X 1/4 "

SCREWS

Figure 13:

cover screws

8-32 x 3/8"

SCREWS

Bracket and

14

Page 17

GEARSHAFT

END OF GEARSHAFT CRANK

CROSS-

LINK

BOTTOM OF

ELECT RIC

ACTUATOR

(With bracket

removed)

6x32 LOCKING CAP SCREW

Figure 14:

GEARSHAFT

CRANK

PIN

NYLON

WASHER

FRONT OF

ELECT R IC

ACTUATOR

(Installed 90°

from usual

position)

Actuator stroke adjustment

4. Temporarily install the mounting bracket at 90° from normal (see

ADJUST MENT

HOLE

FRONT OF

BRACKET

Figure 12

so that the adjustment hole is accessible.

5. Put the clamp ring back on and attach the valve or valve/standoff assembly.

Plug in the actuator power cord and align the valve as nearly as possible, as

described in Section 5.4,

Alignmen t Procedure

.

)

6.

Unplug the power cord.

BOTTOM VIEW

7. Use a 7/64 hex driver to loosen the 6-32 cap

screw on the gearshaft crank. (

8. Use a screwdriver to

crank pin. (

Figure 15

slightly

) To

Figure 14

move the gearshaft

increase

rotate it slightly (1/16 turn) in the direction which

has the

resistance. To

most

decrease

rotate it in the direction which has the

tance.

)

the stroke,

the stroke,

resis-

least

MAXIMUM

EDGE

SIDE VIEW

Figure 15:

Gearshaft crank pin

MINIMUM

EDGE

9. Lock the 6-32 cap screw on the gearshaft.

10. Plug in the power cord. Cycle the valve several times and check the

alignment. If the valve rotation is still incorrect, loosen the gear s haft crank

screw and readjust the gear shaft crank pin to set rotation correctly.

11. When the rotation is correct, unplug the power cord and reassemble the

electric actuator and valve with all the parts in proper orientation.

12. Realign the valve as described in Section 5.4,

Alignment Procedure

.

15

Page 18

6.2 Actuator Conversion

In situations wher e a serviceable Valco two pos ition ac tuator has been relegated to

the shelf because it rotates the wrong number of degrees, it makes economic

sense to restore it to useful service by converting it to the desired rotation. This

can be accomplis hed by following the proc edure in this section.

You will need one of the following:

For P Type valves

with coil spring hardware:

No. of ports Description Product No.

3 port 90 degree crank ass embly I-21826-90

4 port 90 degree crank ass embly I-21826-90

6 port 90 degree crank ass embly I-21826-90

8 port 90 degree crank ass embly I-21826-90

10 port 60 degree crank assembly I-21826-60

12 port 60 degree crank assembly I-21826-60

For new W and UW Type valves

with preload assembly:

No. of ports Description Product No.

3 port 90 degree crank ass embly I-21826-90

4 port 90 degree crank ass embly I-21826-90

6 port 60 degree crank ass embly I-21826-60

8 port 45 degree crank ass embly I-21826-45

10 port 36 degree crank assembly I-21826-36

12 port 30 degree crank assembly I-21826-30

CAUTION: Before performing any operations on the actuator,

make sure

Figure 16:

the ac tu ato r powe r c or d is un pl ug ged.

6.21 Disassembly

1.Step the actuator to the LOAD position. Remove the valve and its mounting

hardware from the actuator.

For a closemount valve, (Figure 8

loosen the HWSC-SC6-8B/socket-head screw ( 6-32 x 5/8") in the stainless

CR4/clamp ring. Pull off the valve and its attached black-anodized

CR41/closemount standoff. With a 9/64 hex driver remove the two HWSCSC8-6TDH/modified socket head screws which hold the clamp ring to the

actuator.

, page 8) use the 7/64 hex driver to

Crank

assembly

For a valve on a standoff, (Figure 9

loosen the HWSC-SC8-8B/socket-head screw (8-32 x 5/8") in the black

anodized CR3/clamp ring on the actuator. Pull off the standoff with the valve

attached. The same hex driver will remove the two HWSC-SC8-6/sockethead screws (8-32 x 3/8") which hold the clamp ring to the actuator.

16

, page 9) use the 9/64 hex driver to

Page 19

2.

Unplug the actuator

. Use a 9/64 hex driver to remove the four HWSC-SC86/screws (8-32 x 3/8") which hold the black right-angle mount ing bracket to

the actuator. (

Figure 13

)

3. Use a pair of pliers to compr ess and remove the top two cable strain relief

devices from the actuator cover. They are at the points marked REMOTE

SWITCHING and MANUAL SWITCHING. Once they are out, pull them apart

and remove them from the cables to allow the cables to travel freely through

the holes in the cover.

4. Remove the four 4-40 x 1/4" slotted-head screws which secure the actuator

cover to the front casting. Slide the cover back far enough to allow the wiring

connectors to be pulled from the circuit board. Make careful note of their

location for reattachment later. Now remove the cover completely.

SHAFT CRANK

6-32 SCREW IN

SHAFT CRANK

GEARBOX

SQUARE

DRIVE SHA F T

FRONT CASTING

TRIANGULAR

CASTING

ALIGNM ENT

SLEEVES

Figure 17:

Identification of actuator parts

CIRCUIT BOARD

FLAG

OPTICAL SENSOR

REMOTE SWITCHING

CABLE

MANUAL SWITCHING

CABLE

MOTOR

MOTOR BR AK E

RELEASE

5. Place the actuator in front of you so that the square black motor is down

and away, and the front casting with the square valve drive shaft extending

through it is facing you. Use the 9/64 hex driver to remove the four 8-32 x

1" socket-head screws at the corners of the casting, observing that two of

these screws must pass through small sleeves which align this front casting

and the triangular casting. As the front casting is removed, the sleeves may

come with it or they may stay with the triangular casting. Locate and retain

both alignment sleeves.

6. Swing the entire crank assembly to one side, away from the body of the

actuator, and slide the triangular casting off of t he crank assembly. (

)

18

Figure

7. The shaft crank is threaded on to the output shaft extending from the gearbox. (See

Figure 19

) Since simply trying to unscrew the shaft crank will

only turn the output shaft instead, it is necessary to first break it loose by

placing the 1/2" open end or the adjustable crescent wrench on the shaft

crank and applying a shar p counterclockwise snap to break it loose. Once it

has been freed, it is an easy matter to unscrew it the rest of the way by

hand.

17

Page 20

CRANK ASSEMBLY

SHAFT CRANK

ORIENT

SHAFT

CRANK SLOT

TOW ARD THIS

OUTPUT SH AF T

GEAR BOX

TRIANGULAR CASTING

Figure 18:

Removal of triangular

Figure 19:

Shaft crank at one o’clock

cast ing

6.22 Installation of the New Crank Assembly

1. Screw the shaft crank of the new crank assembly onto the output shaft.

Once the threads have bottomed out, use the open end or adjustable

wrench to apply a sharp clockwise snap to lock it in position.

2. Turn the actuator around so that the motor is toward you and locate the

small button in the center of the round motor casting. While pushing this

button to release the brake, use the wrench on the shaft crank to rotate the

output shaft until the slotted end of the shaft crank is oriented toward the

screw hole at one o’c lock.

(

Figure 19

)

CRANK

ASSEMB LY

SHOWN

DASHED

3. With its countersunk recesses for the alignment

sleeves facing you, slide the triangular casting

onto the crank assembly from the back side.

4. Position the triangular casting over its mounting

holes, making sure that the crank assembly is

pivoted to the left. (

Figure 20

) Put the alignment sleeves in their recesses in the triangular

casting.

5. Reinstall the front casting. It is helpful t o get all

four screws started before tightening any of

them.

18

TRIANGULAR

CASTING

Figure 20:

Triangular casting in place

with crank assembly pivoted to left

RECESSES

FOR

ALIGNMENT

SLEEVES

Page 21

6.23 Flag Adjustment

As not ed above, the shaf t crank screws o nto the threaded o utput s haft exte nding

from the gearbox. On the opposite end of this shaft is a thin metal "flag" which

operates in conjunction with two optical sensors to signal th e motor to start and

stop. (

Figure 17

in corr ect rel ation ship to the newly in stal led cran k asse mbly.

1. With the 1/4" open-end wrench, reach between the circuit board and the

gearbox and loosen the hex head screw that holds the flag in position in

front of the sensors.

2. From the same viewpoint previously described (motor down and away, casting in front), position the flag at three o’clock. Partially tighten the screw so

that the flag stays in place but can still be moved.

3. Turn t he actuator cover so that the writing is upside down and slide it on the

actuator far enough to allow the connectors to be plugged back onto the

board. The manual switching cable has six wires, while the remote switching

cable has only five. They connect to the same row of eleven pins, with the

six wire connector closest to the motor. (See

lead which supplies power goes on wit h the green wire to the outside. Plug

in the actuator.

Caution: The following steps describe adjustments which require the

use of metal tools in close proximity with electrical circuits. Checking

the result of the adjustments requires that the actuator be plugged in,

but remember to unplug the actuator before further adjustments are

made.

) For the actuator to function properly, this flag must be positioned

Figure 17

.) The three wire

4. Step the actuator from position to position two or three times. Look through

the adjustment hole (

crank assembly are parallel. They should look like

crank virtually hidden behind the other arm. If they do,

tighten the screw which secures the flag, and proceed to Step 5 in Section

6.1,

Adjusting the Actuator Stroke

step.

5.

Unplug the actuator.

move the flag

it

slightly

6. Plug the actuator in and repeat Steps 4 and 5 until proper adjustment is

achieved.

7. Proceed to Step 5 in Section 6.1,

slightly

toward 12 o’clock.

Figure 21:

Move flag to

6 o’cl ock

Figure 14

If the arms are off in the direction of

toward 6 o’clock. If they are off as in

) in the front casting to see if the arms of the

Figure 23

unplug the actuat or,

. If they do not, proceed to the next

Adjusting the Actuator Stroke

Figure 22:

Move flag to

12 o’cl ock

Figure 23:

Proper

adjust ment

, with the shaft

Figure 21

Figure 22

, move

.

,

19

Page 22

7. TECHNICAL DRAWINGS

Electric Actuator Assembly – 110V AC . ............ ......... Drawing 21307 Page 21

Electric Actuator Assembly – 220V AC . ............ ......... Drawing 21612 Page 22

Electric Actuator Board Assembly..... ............ ............. Drawing 21312 Page 23

Schematic – Electric Actuator Assembly –

110V AC........ .............. ............ .............. .............. ...Dr awing 21313 Page 24

20

Page 23

220V VERSION-SEE DWG: 21612

SET ROTATION +3 DEG

YEL

FROM MOTOR

GRY

BLK

54312

BLACK

- GO TO INJECT

*

I-21307-60

I-21307-90

I-21358-60-110

I-21358-90-110

SHIELD

GREEN

RED

- GO TO LOAD

- COMMON

{

CONTACT

CLOSURE

I-21307-36

I-21307-45

I-21307-30 I-21358-30-110 30

I-21358-36-110

I-21358-45-110

REMOTE INTERFACE CONNECTIONS

WHITE

-

HI-POT COMPLETE ASSY 1500V, 1 MIN.

DASH

DASH SCHEDULE

8

9

WHT

GRN

BLK

17

1

1

12

5

6

2

18

7

60

90

21307 \EA\

CHECKED

FILE NAME SUB-DIR

DESIGNED

SCALE

USA PROJECTION

SIZE DRAWING NO.

C

21307---

SHEET

OF

ITEM 1

ANGLE

36

45

FRACTIONS DEC. ANGLES

OTHERWISE SPECIFIED

TOLERANCES UNLESS

APPROVED

DRAWN

DJM 6/24/88

1/64"

.XXX.005

.XX.01

.X.1

DATE

63

1

2 POS 110V

ACTUATOR: ELECTRIC

Valco Instruments Co., Inc.

I-21307

.125

NOTE: INSTALL ITEMS 15 AND 16 AFTER ITEM 3

THIS DOCUMENT AND THE INFORMATION WHICH IT CONTAINS SHALL NOT BE USED, EXPLOITED

OR SOLD, AND SHALL NOT BE REVEALED OR DISCLOSED TO OTHERS WITHOUT THE EXPRESSED

WRITTEN PERMISSION OF VALCO. THIS DOCUMENT SHALL REMAIN THE PROPERTY OF VALCO

AND SHALL BE RETURNED UPON DEMAND.

3

VICI

SEE CONNECTION DETAIL

NOTE: AFFIX TAG TO REAR OF COVER

AFTER S/N, MODEL, AND VOLTS

AFFIX SERIAL TAG TO FRONT CASTING

NO CONNECTION

GREEN

ARE RECORDED

*

I-21307-90-GSS USE THESE PARTS ONLY

*

151413121110987654321

CONTROLLER ASSY: 2PEA

SOCKET: 6 POSITION, 24 GAUGE- PANDUIT

CABLE ASSY: REMOTE, 2PEA, 1 FT

CONN: 6 PIN MALE MOLEX

STRAIN RELIEF: SRR-10

SCHEMATIC B-21313REF ---- --

VIEW WITH DIMENSIONS C-21364REF ---- --

VALVE INSTALLATION (CL MOUNT) B-21446REF ---- --

STRAIN RELIEF: .375 SR 2M-4 HEYCO16

SCREW,PLMS: 6-32 X 1/4 LG,PL,SS17 HWSC-PL6-4 1

TY-WRAP: TYTON 1/8 X 4" T18R18 HWTYWRAP-2 1

16

15

10

15

13

BLACK

RED

REAR VIEW

5

4

1

2

SHIELD

WHITE

6

3

INJECT

LOAD

*

*

SPACER: #8 X 1" ALUM.

SCREW, SHCS: 8-32 X 1-1/4 LG

SCREW, PLMS: 4-40 X 1/4 LG

BRACKET: 2PEA

SCREW, SHCS: 8-32 X 3/8 LG

TAG: 1 X 2" METALIZED (3000/PKG)

*

PCB ASSY: 2PEA, 110V

ENC. ASSY: 2PEA, 110V

CABLE ASSY: REMOTE INTERFACE (2-P)

*

BASE & MOTOR ASSY: 2PEA

ITEM DESCRIPTION VALCO # QTY

H ECN #9472 UPDATE TO REV U PCB 10/05/07

J ECN #10466 UPDATE GND LOC. (ADD ITEM 17) 09/10/08

G ECN #4470 ADD CHANGES FOR GSS ITEMS 11/03/98

ECN #3268 CORRECT WIRE COLOR/FUNCTIONF

LTR DESCRIPTION DATE APPROVED

14

11

PARTS LIST

REVISIONS

4

HWSRR-10

HWSR2M-4

I-T03061062

I-21791-01

I-21360

I-T100F24-6

VICI

INJECT

LOAD

Valco Instruments Co., Inc.

Made in USA by

120 VAC 50/60 HZ 220 VA

EXX EA2XXXXX

SERIAL NO.MODEL NO.

I-TAG73T1-795

HWSC-SC8-6B

111111114412211

HWSC-PL4-4

I-21308

HWSC-SC8-20B

I-21361

HWSP-8527

I-21710-01

I-21312-01

SEE DASH SCHEDULE

1

R.S.S.

JDURR

JDURR

07/01/96

20JUL94ECN #2000 ADD CSA SPEC AND TAGE

JDURR

JDURR

21307 21

Page 24

110V VERSION-SEE DWG: 21307

SET ROTATION +3 DEG

YEL

FROM MOTOR

GRY

BLK

54312

SHIELD

BLACK

GREEN

RED

- GO TO INJECT

- GO TO LOAD

- COMMON

{

CLOSURE

I-21612-36

I-21612-45

I-21612-60

I-21612-90

I-21358-36-220

I-21358-45-220

I-21358-60-220

I-21358-90-220

REMOTE INTERFACE CONNECTIONS

WHITE

-

CONTACT

I-21612-30 I-21358-30-220 30

HI-POT COMPLETE ASSY 1500V, 1 MIN.

DASH

DASH SCHEDULE

8

9

17

GRN

WHT

BLK

12

5

1

6

2

18

7

60

90

21612 \EA\

DESIGNED

CHECKED

FILE NAME SUB-DIR

SCALE

USA PROJECTION

SIZE DRAWING NO.

C

21612---

ITEM 1

ANGLE

36

45

FRACTIONS DEC. ANGLES

OTHERWISE SPECIFIED

TOLERANCES UNLESS

APPROVED

DRAWN

JDURR 4MAY07

DATE

2 POS 220V

AND SHALL BE RETURNED UPON DEMAND.

1/64"

.XXX.005

.XX.01

.X.1

63

1

ACTUATOR: ELECTRIC

Valco Instruments Co., Inc.

.125

THIS DOCUMENT AND THE INFORMATION WHICH IT CONTAINS SHALL NOT BE USED, EXPLOITED

OR SOLD, AND SHALL NOT BE REVEALED OR DISCLOSED TO OTHERS WITHOUT THE EXPRESSED

WRITTEN PERMISSION OF VALCO. THIS DOCUMENT SHALL REMAIN THE PROPERTY OF VALCO

INSTALL 15 AND 16 AFTER 3

15

3

VICI

SEE CONNECTION DETAIL

NOTE: AFFIX TAG TO REAR OF COVER

AFTER S/N, MODEL, AND VOLTS

AFFIX SERIAL TAG TO FRONT CASTING

NO CONNECTION

GREEN

ARE RECORDED

*

I-21307-90-GSS USE THESE PARTS ONLY

151413121110987654321

18

17 HWSC-PL6-4 1

TY-WRAP: TYTON 1/8 X 4" T18R HWTYWRAP-2 1

SCHEMATIC B-21313REF ---- --

VIEW WITH DIMENSIONS C-21364REF ---- --

VALVE INSTALLATION (CL MOUNT) B-21446REF ---- --

STRAIN RELIEF: .375 SR 2M-4 HEYCO16

SCREW, HHMS: 632_1/4 LG, PL, HD,SS

CONTROLLER ASSY: 2PEA

SOCKET: 6 POSITION, 24 GAUGE- PANDUIT

CABLE ASSY: REMOTE, 2PEA, 1 FT

CONN: 6 PIN MALE MOLEX

STRAIN RELIEF: SRR-10

16

10

15

13

BLACK

RED

REAR VIEW

5

4

1

2

SHIELD

WHITE

6

3

INJECT

LOAD

SPACER: #8 X 1" ALUM.

SCREW, SHCS: 8-32 X 1-1/4 LG

SCREW, PLMS: 4-40 X 1/4 LG

BRACKET: 2PEA

SCREW, SHCS: 8-32 X 3/8 LG

TAG: 1 X 2" METALIZED (3000/PKG)

PCB ASSY: 2PEA, 220V

ENC. ASSY: 2PEA, 220V

CABLE ASSY: REMOTE INTERFACE (2-P)

ITEM DESCRIPTION VALCO # QTY

BASE & MOTOR ASSY: 2PEA

F ECN #9472 UPDATE TO REV U PCB 10/05/07 JDURR

G ECN #10466 UPDATE GROUND WIRING 5/20/08 RSS

E

CORRECT WIRE COLOR/FUNCTION ECN# 3268

LTR DESCRIPTION DATE INITIATED

A

B

C

D

ECN #109

REVISE DRAWING TO SHOW VALCO P/N

ECN #2000 UPDATE PER NEW P.C.B.

ADD PROPER GROUNDING ECN# 2524

14

11

PARTS LIST

DELETE CR3 AND HWSC-SC8-8B

REVISIONS

4

VICI

INJECT

Valco Instruments Co., Inc.

Made in USA by

220 VAC 50/60 HZ 220 VA

EXX-220 EA2XXXXX

SERIAL NO.MODEL NO.

HWSRR-10

HWSR2M-4

I-T03061062

I-21791-01

I-21360

I-T100F24-6

I-TAG73T1-795

HWSC-SC8-6B

I-21308

I-21361

HWSC-PL4-4

HWSC-SC8-20B

HWSP-8527

I-21710-220

I-21312-02

SEE DASH SCHEDULE

4-2-92 DJM

7/20/94 J DURR

12/11/89

SHEET

OF

I-21612

LOAD

J DURR10/27/95

111111115412211

1

J DURR07/01/96

2161222

Page 25

*

~

3.

5.1.4.

6.

MATERIALS AND PROCESSES MUST BE RoHS COMPLIANT

CAPACITOR C5 LEADS TO BE SOLDERED INTO THE

LOCATIONS MARKED "C5"

FOR 220 VOLT AC UNITS: CUT & JUMP

FOR -TM MODELS- CHANGE U3 TO I-IC3011

I-21312-01

I-21312-02

PN:

AS INDICATED, INSTALL APPROPRIATE C5 CAP.

DASH SCHEDULE

MODEL:

110V

220V

I-CM206-250

I-CM687-400

CAP (C5)

HS 1,2

SC1-6

ST1,2,3

SW1

RLYI

FT

TUBING: HEAT SHRINK #19 AWG, TFE

TAPE: DOUBLE-SIDE/FOAM,3M,216 IN/EA

CUT LENGTH WISE IN HALF

STANDOFF: 4-40_1.00, F/F,HEX

SCREW,PLMS: 4-40*1/4 lg,PANHD,PH,SS

J1

J4,J5

J3

J2

HEADER: 11 POSITION, PANDUIT

HEADER: 3 PIN, UNSHROUDED, .9L, SAMTEC

CONN: 3 PIN W/RAMP, MOLEX

CONN: SOCKET STRIP, 3 PIN, SIP, GOLD

RELAY: HAMLIN #HE3621A0500 I-RY-HAMLIN 1

NOTES:

2.

SCREWS SC4, 5, 6, TO BE INSTALLED AFTER BOARDS

ARE REMOVED FROM CARRIER.

APPLY LOCTITE 242 ON THE TIP OF ALL SCREWS

BEFORE ASSEMBLY.

RN4

RN3

RN2

RES NET: 330, 6 PIN SIP, COMMON

RES NET: 1K, 8 PIN SIP, DISCRETE

R4

R5

RN1

RES: 10K, 5%, 1/4W

RES: 1K, 5%, 1/4W

CUT OFF ALL EXPOSED LEADS

FROM BACK OF PC BOARD.

OPPOSITE SIDE

R1, R2

R3

DES

RES: 330, 5%, 1/4W

RES: 39, 5%, 1/4W (REEL)

DESCRIPTION VALCO # QTY

OPPOSITE SIDE

SC3

ST3

J3

J3

C1

1

2

C2

NOTE ORIENTATION

OF OS1

PARTS LIST CONTINUED

D1

JUMP

OF OS2

D2

I-PD-EA2C54R(X)

J1

OPPOSITE SIDE

CUT

NOTE ORIENTATION

SKT1

OPPOSITE SIDE

ST2

SC2

F 2A 250V

U

L

W

SA

OPPOSITE

SIDE

OPPOSITE SIDE

SC1

ST1

2) DO NOT SOLDER X1 (CRYSTAL) TO THE PC BOARD GROUND

PLAIN

AW 132

REV U

PCB

(*FOR 220V UNITS)

1) ELEVATE THE CRYSTAL (X1) SLIGHTLY ABOVE THE PC BOARD,

NOT MORE THAN .062" (1/16")

ST3

ENGAGE

J2 & J3

SECURE C5 TO BOARD

W/ SMALL AMOUNT

OFSILICONE (I-RTV) ON

NEAR AND FAR SIDE

OPPOSITE SIDE

OPPOSITE SIDE

SC5

J5

SKT2

PCB

+

-

OPPOSITE SIDE

C5

OPPOSITE SIDE

C5

J1

OPPOSITE SIDE

J4

ST2

OPPOSITE SIDE

SC6

NOTE PIN 1

F1 AND FS1 OPPOSITE SIDE

SILICONE (I-RTV) ON THE EDGE

OF THE FUSE AND THE FUSE HOLDER

ST1

FS1

APPLY A SMALL AMOUNT OF

HWSO-2334

I-TAPE-D/S FOAM

HWSC-PL4-4

I-STUBE #19

3

3

2"

6

1"

21312 EA

CHECKED

FILE NAME SUB-DIR

DESIGNED

JDURR 2APR07

RSIMPSON

SCALE

USA PROJECTION

SIZE DRAWING NO.

B

21312---

SHEET

I-T26510032

1I-SW-76SD01SWITCH: DIP DPDT GRAYHILL #76DS01

2

APPROVED

DRAWN

DATE

PCB ASSY: 2PEA

I-TTSW-103-19-S-S

I-TSSW-103-01-S-S

1

1

FRACTIONS DEC. ANGLES

1/64"

.XXX.005

.XX.01

.X.1

1

Valco Instruments Co., Inc.

I-RN750-61-331

I-RN750-83-473

I-T100-11

1

1

OTHERWISE SPECIFIED

TOLERANCES UNLESS

I-R511002

I-R511001

I-RN750-83-102

I-RN750-83-22R0

1RES NET: 47K, 8 PIN SIP, DISCRETE

1

1

1

1RES NET: 22, 8 PIN SIP, DISCRETE

THIS DOCUMENT AND THE INFORMATION WHICH IT CONTAINS SHALL NOT BE USED, EXPLOITED

OR SOLD, AND SHALL NOT BE REVEALED OR DISCLOSED TO OTHERS WITHOUT THE EXPRESS

WRITTEN PERMISSION OF VALCO. THIS DOCUMENT SHALL REMAIN THE PROPERTY OF VALCO

AND SHALL BE RETURNED UPON DEMAND.

PN: FOR -TM. UNITS - I-21312-01-TM, -02-TM

63

I-R513300

I-R5139R0

2

1

****

***

**

*

PN: FOR 110V. UNITS - I-21312-01

PN: FOR 220V. UNITS - I-21312-02 (SEE NOTE 4)

OS1, OS2 ARE HEAT SENSITIVE AND NEED TO BE HAND SOLDERED TO

THE BOARD.

PN: I-21312 - ASSEMBLED PCB (EXCLUDING - C5 CAP)

D1, D2 REPLACE W/WIRE JUMPERS.

USE CURRENT REV.

C10 CAP: MONO CERAMIC, .22 uF 50V, .2"LEADS 1

I-CC224-50

UNTIL NEXT ASSY

*

C7

C5 CAP: MYLAR, 20uf 250V

C4 CAP: CERAMIC, .01uF 1000V

C6 CAP: CERAMIC, .005uF 1KV 1

C8,C9 CAP: CERAMIC, 12PF 50V 2

CAP: TANTAL, .47MF, 35V

I-CT474-35

SEE DASH SCHED

I-CC103-1K

I-CC502-1K

I-CC120-50

NOT INSTALLED

C2 CAP: TANTAL, 4.7MF, 35V

C3 CAP: ELECT, 220uF, 35V, RADIAL LEAD 1

C1,C11 CAP: MONO CERAMIC, .01uF 50V, .1" LEADS 2

I-CT475-35

I-CE227-35RL

I-CC103-50-1

F1 FUSE: 2AMP, TR5, PC MOUNT

T1 TRANSFORMER: 110/220V, 12V SEC, PC MOUNT

SKT1 SOCKET: DIP, 18 PIN LOW PROFILE

SKT2 SOCKET: DIP, 6 PIN, LOW PROFILE 1I-TDS-6-LP

I-TDS-18-LP 1

HWFUSEHOLD-5

HWFUSE-2A-TR5

I-X-DSW-212

H1 & H2

SLEEVE, 2 PLCS

****

***

D1, D2 WIRE: BUSS, UNINSULATED,.025 DIA,22 AWG

X1 CRYSTAL: 16 MHZ, LOW PROFILE

D3 DIODE: SILICON SIGNAL

Q1 TRIAC: 4AMP-600V, ISO, T0-220, txt

BR1 RECTIFIER BRIDGE: 2A, 50V, 4 PIN DIP 1

Q2,Q3 TRANSISTER: SIGNAL, NPN, TO92

I-Q2N4401

I-W-BUSS-1

I-ICTIL139SENSOR: OPTICAL REFLECTIVE (OPB742)OS1,2 2

I-Q6004L4

I-D3N253

I-XTAL-6

I-D1N914

**

U2 1

I-IC78L05IC: VOLTAGE REGULATOR, 5V, T092

PCB PCB: ELECT. ACT. 2 POS., (CSA)

DES DESCRIPTION VALCO # QTY

PARTS LIST

I-PCB21311

F1

RoHS

MFG TO

SPECS

LTR DESCRIPTION DATE APPROVED

AC

AD

AE

ECN #15146 REMOVE D1, D2, REPLACE W/WIRE JUMPERS

ECN #10916 ADD ASSEMBLY NOTE FOR CRYSTAL (X1) and ADD

ECN #11066 ADD NOTE TO INDICATE HEAT SENSITIVE PARTS. &

NOTE CONCERNING APPLICATION OF ITEM FT TO ASSEMBLY

REMOVE LW1, 2, 3

REVISIONS

03/31/09 BILL S

07/21/09 C. PRATCHER

10/05/10 RSS

OF

1I-IC3082IC: OPTO-TRIAC ZERO CROSSINGU3

1FS1 FUSE HOLDER: TR5, PC MOUNT

1

1

1

1

1

1

1

1

2

1

2

1I-PD-EA2F54R(X)**PROGRAMMED DEVICE: 2P EA I-ICPIC16F54U1

1

23

21312

Page 26

MOTOR ASSEMBLY

CHASSIS GROUND

.005uF

JUMPERS

DSW-212

1

2

7

8

+

220uF 35V

C3

1J43

2

AC-NEUT

C6

3

6

BR1

2A

PWR CONFIG

240 120

4

T1

5

F1

AC-HOT

OPB-742

E

C

K

SP1 ST1

J5

7

3

2

1

20uF 250V

.01uF 1KV

C4

330

R2

C5

1

3

MOC-3082

R3

39

AC-HOT

2

Q1

330

R1

4

6

U3

2

1

2N44O1

Q3

2N4401

R5 1K

1N914

HE3612A0500

3

4

8

RN3:4

47K

RN2:3

1K

5

RN2:4

1K

Q2

+5

D3

2

RLY1

1

22

RN1:4

8

7

JMP1

3

RN1:2

RN1:3

22

22

45678

OPB-742

OS2

A

RN3:3

47K

R4

10K

6

9

678

RB3

RB2

RB1

RB0

16C54

GND

PIC

5

RB7

RB6

RB5

RB4

13

101112

C8

P

1

F

16MHz

RN1:1

X1

22

2

1212

P

F

OS1

C

AKE

+5

6

+5

234

1

TOCK1

MCLR

RA2

RA3

VCC

+5

14

OSC2

OSC1

15

C9

U1

RA0

RA1

18

17

16

3

1

RN3:2

RN3:1

47K

47K

4

2

1

3

D2

D1

*

*

+5

1

2

RN4 330

3

4

5

6

RN2:1

1K

+5

2

4

RN2:2

1K

21313 EA

DESIGNED

CHECKED

FILE NAME SUB-DIR

JDURR/BOB S 4APR07

BOB S

SCALE

USA PROJECTION

SIZE DRAWING NO.

B

FRACTIONS DEC. ANGLES

OTHERWISE SPECIFIED

APPROVED

DRAWN

1/64"

.XXX.005

.XX.01

.X.1

DATE

1

21312 REV U

SCHEMATIC: 2 POS ACTU.

Valco Instruments Co., Inc.

TOLERANCES UNLESS

THIS DOCUMENT AND THE INFORMATION WHICH IT CONTAINS SHALL NOT BE USED, EXPLOITED

OR SOLD, AND SHALL NOT BE REVEALED OR DISCLOSED TO OTHERS WITHOUT THE EXPRESSED

WRITTEN PERMISSION OF VALCO. THIS DOCUMENT SHALL REMAIN THE PROPERTY OF VALCO

AND SHALL BE RETURNED UPON DEMAND.

63

VALID FOR REF U PCB'S

3

2

1

J2

J3

3

2

1

.01uF 50V

C1

+ C2

4.7uF 35V

IN

78L05

GND

U2

OUT

+ C7

.47uF 35V

.22uF

.001uF

+5

C10

C11

*

3.

JMP1 SHOULD BE JUMPERED FOR THE

CONTINOUS RELAY CONTACT MODE.

D1, D2 REPLACE W/WIRE JUMPERS.

1.

2.

OUTPUT SELECT SWITCH IS SHOWN

IN THE "DIGITAL OUT" POSITION.

THE "RELAY OUT" POSITION IS

WHEN THE ROCKER IS UP

TOWARDS THE OUTSIDE EDGE

OF THE PC BOARD.

4

76DS01

NOTE:

6

3

1

SW1

2

5

4

3

5

2

1

6

LOAD_IN

INJECT_IN

789

LED_SRC

INJECT_LED

10

LOAD_LED

11

J1

LTR DESCRIPTION DATE APPROVED

WHT

RELAY/LOAD INDICATOR

INTERFACE CABLE

SHLD

RELAY/INJECT INDICATOR

RED

GRN

LOAD INPUT

GND

BLK

INJECT INPUT

ORG

BRN

INJECT INPUT

LOAD INPUT

BLU

YEL

MANUAL CONTROL BOX

LOAD INDICATOR

INJECT INDICATOR

ECN #9472 UPDATE TO REV U PCBJ

ECN #15146 REMOVE D1, D2, REPLACE W/WIRE JUMPERSK

GRN

RED

REVISIONS

24

SHEET

OF

21313---

21313

10/05/07

10/05/10

RSS

RSS

Page 27

8. WARRANTY

This Limited Warranty gives the Buyer specific legal rights, and a Buyer may also

have othe r r i gh ts t h at vary fr o m st at e to s t ate.

For a period of 365 calendar days from the date of shipment, Valco Instruments

Company, Inc. (hereinafter Seller) warrants the goods to be free from defect in

mater ial and w orkma nship to th e or igin al pu rchase r. Repaired parts are wa rrant ed

for 90 days. During the warranty period, Seller agrees to repair or replace

defective and/or nonconforming goods or parts without charge for material or labor,

or, at the Seller’s option, demand return of the goods and tender repayment of the

price. Buyer’s exclu sive remed y is re pair or r eplac ement o f defecti ve and nonco nforming goods, or, at Seller’s option, the repayment of the price.

SELLER EXCLUDES AND DISCLAIMS ANY LIABILITY FOR LOST PROFITS,

PERSONAL INJURY, INTERRUPTION OF SERVICE, OR FOR CONSEQUENTIAL INCIDENTAL OR SPECIAL DAMAGES ARISING OUT OF, RESULTING

FROM, OR RELATING IN ANY MANNER TO THESE GOODS.

This Li mited Warranty does not cover de fects, damage, or nonconform ity resul ting

from abuse, misuse, neglect, lack of reasonable care, modification, or the attachment of improper devices to the goods. This Limited Warranty does not cover

expendable items. This warranty is VOID when repairs are performed by a

nonauthorized ser vice center or represe ntative. For infor mation about authorized

service centers or representatives, call or write Customer Repairs, Valco Instruments Company, Inc, P.O. Box 55603, Houston, Texas 77 255. ph(713) 688 -9345

At Se ller’s opt ion , r epair s or repl acemen ts will be m ade on si te or at the fa ctor y. If

repairs or replacements are to be made at the factory, Buyer shall return the

goods prepaid and bear all the risks of loss until delivered to the factory. If Seller

returns the goods, they will be delivered prepaid and Seller will bear all risks of

loss u nt il d el iver y t o Buy er. Buyer an d Se ll er agr ee t hat thi s L imi ted Warr ant y sh al l

be gover ne d by an d c ons tr ue d in ac c ord an ce wit h th e l aws o f t he Stat e of Texas.

THE WARRANTIES CONTAINED IN THIS AGREEMENT ARE IN LIEU OF ALL

OTHER WARRANTIES EXPRESSED OR IMPLIED, INCLUDING THE

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE.

This Limited Warranty supersedes all prior proposals or representations oral or

writ ten and cons titute s the entire un derstand ing regar ding the warra nties made by

Seller to Bu yer. This Limited Warranty may not b e expand ed or m odi fied exc ept i n

writing signed by the parties hereto.

25

Loading...

Loading...