Page 1

Valco Instruments Co. Inc.

Microvolume Thermal

Conductivity Detector

Instruction Manual

North America, South America, and Australia/Oceania contact: Europe, Asia, and Africa contact:

Valco Instruments Co. Inc.

800

·

367

·

·

688

·

688

8424 sales

·

9345 tech

·

8106 fax

713

713

valco@vici.com

VICI AG International

Schenkon, Switzerland

Int + 41 · 41 · 925

Int + 41 · 41 · 925

info@vici.ch

·

6200 phone

·

6201 fax

tcd2.p65

Rev 4/12

Printed in USA

Page 2

This page intentionally left blank for printing purposes

Page 3

Table of Contents

Introduction

Description and Operating Principle ............................................................... 1

Safety Notes and Information ........................................................................ 2

Components of the Detector System ............................................................. 3

Description of Controls and Connectors ......................................................... 4

System Requirements

Components Not Included with the Detector System ..................................... 7

System Purity................................................................................................ 7

Recommended Carrier Gas Purifiers .............................................................. 7

Carrier Gas Selection..................................................................................... 7

GC Column Selection..................................................................................... 8

Installation

General Precautions ...................................................................................... 9

Mounting the Detector on the GC................................................................... 9

Gas Connections ..........................................................................................1 0

Column Connection.......................................................................................1 2

Electrical Connections ..................................................................................1 3

Initial Pow er-Up .............................................................................................1 5

T roubleshooting

T roubleshooting Chart ...................................................................................1 7

Heater Fault Determination............................................................................1 7

Detector Fault Determination.........................................................................1 8

Maintenance

Bake Out Procedure .....................................................................................19

Disassembly and Cleaning............................................................................19

Warranty .............................................................................................................20

Detector Perf ormance Log ...................................................................................2 1

Page 4

This page intentionally left blank for printing purposes

Page 5

Introduction

Description and Operating Principle

1

The Thermal Conductivity Detector (TCD) has been one of the most popular

GC detectors since the 1950’s , second perhaps only to the Flame Ionization

Detector (FID). The principal of operation is based on the relative change in

the thermal conductivity of the gas passing across the detector filament as

components elute from the column. Heat is lost continuously by the filament

through the carrier gas to the cell wall of the detector. By measuring the

amount of current required to maintain a constant filament temperature as

gases of varying thermal conductivities cross the filament, a chromatographic signal is produced. This process is nondestructive of the sample and

is concentration dependent.

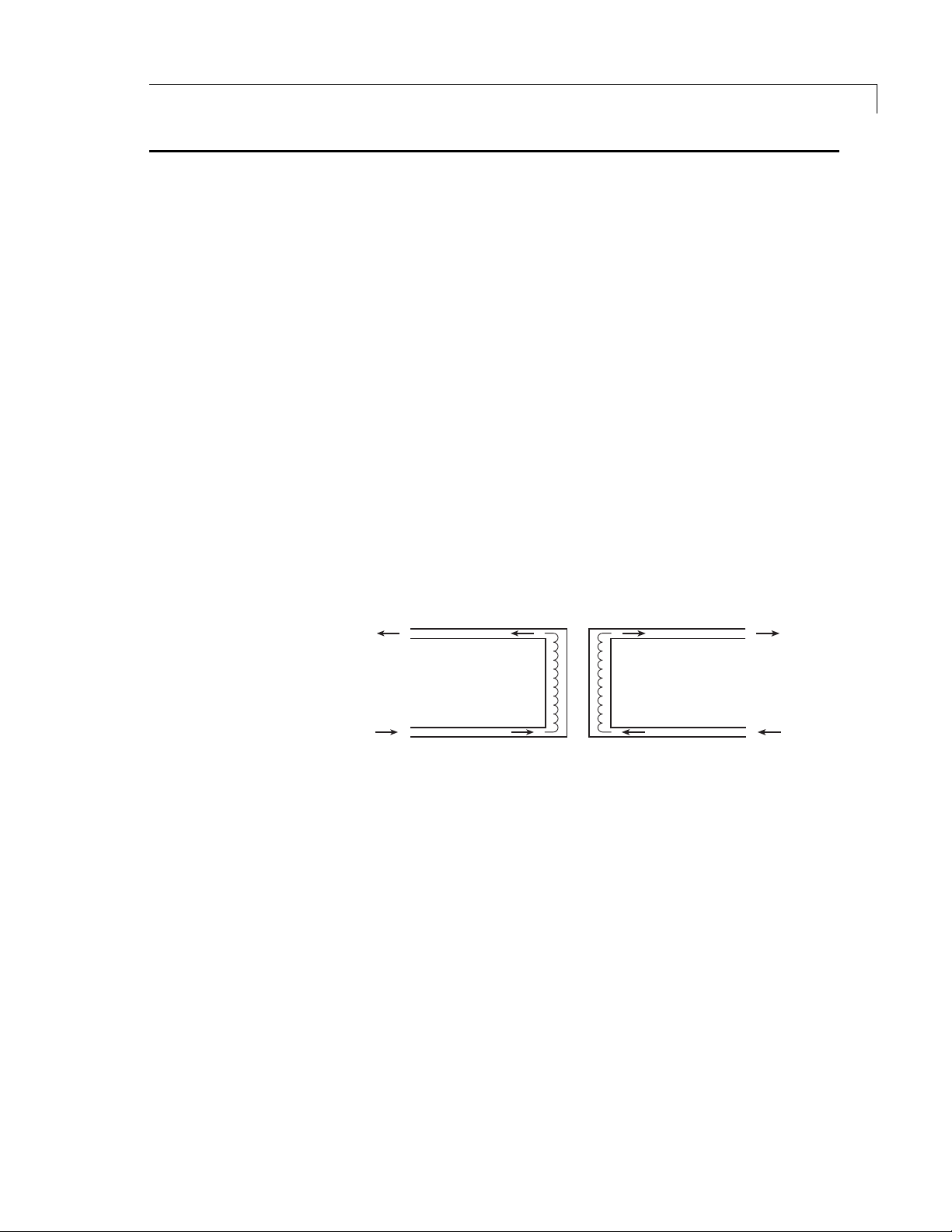

The Valco Microvolume TCD is unique in its implementation. Since changes

in conductivity are measured only by the change in current required to keep

the filament at a constant temperature, each of the two filaments can be

operated independently without referencing these changes to a matched

filament with reference gas. This constant temperature provides longer

filament life and safeguards it from the extremely high temperatures and

oxidation which can occur with high concentrations of oxidative or corrosive

components. Optional signal referencing is provided to minimize background

variables such as column bleed and temperature programming.

OUTLET OUTLET

FILAMENT

A

A

FLOW

INLET

FILAMENT

B

B

FLOW

INLET

Figure 1: Unique dual filament design

Cell volume has been minimized to accommodate capillary column

chromatography and optimize the sensitivity of the detector at low flow

rates. (Carrier flow rates of 1 - 10 mL/min are recommended for best sensitivity.) Thermal stability is maintained in the detector cell to within 0.010°C

drift, giving the detector a stable, noise-free signal.

The Model TCD2 is a stand-alone system which can be easily added to

any chromatograph. It consists of a detector and a control module which

incorporates the electrometer and temperature controls. The detector cell

includes two separate filaments, capable of independent or referenced

(differential) operation. Output signal is provided as 0-1 and 0-10 volt

attenuated for chart recorders and 0-1 and 0-10 volts unattenuated for

integrators and data systems.

Page 6

Introduction

2

Safety Notes and Information

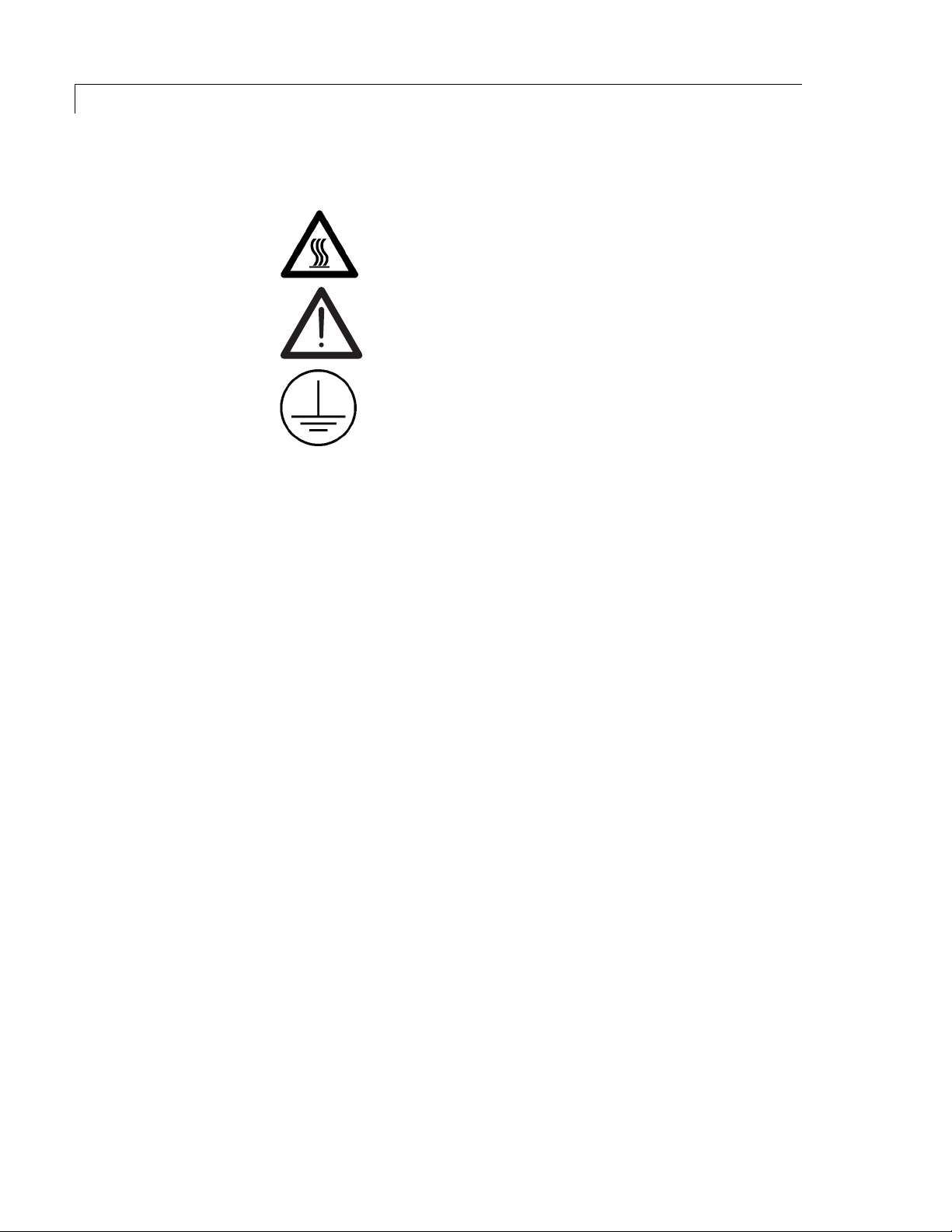

Symbols

HOT SURF AC E

The surface of the detector body may be hot while in

operation (possibly in excess of 250°C). Observe caution.

A TTENTION

Refer to the manual.

PROTECTIVE EARTH

This internal connection provides protection against electric

shock from mains voltages and should not be removed.

Installation Category

This equipment has been designed for installation category (overvoltage

category) II, pollution degree 2. It has been approved for use only in heavy

industrial environments and may not be used in the residential, commercial,

or light-industrial environment.

Safety

This instrument has been designed and tested in accordance with the

product safety standard, EN61010. It has left the factory in a safe

condition. This instruction manual contains important information and

warnings which must be followed by the user to insure safe operation and to

retain the instrument in a safe condition. The case , chassis, and measuring

terminals are connected to the protective earth contact of the mains inlet.

The instrument operates with a three-conductor power cord having a protective earthing conductor and a plug with an earthing contact. The mains

(line) plug shall only be inserted in a socket outlet provided with a protective

earth contact. The protective action must not be negated by the use of an

extension cord without a protective conductor . Use only with an appro ve d

mains supply cord having a rating of 2A, 250V, or greater. Do not use this

equipment in a manner not specified herein.

Maintenance

The exterior of the instrument should be cleaned regularly with a dusting

brush. If necessary, the casing can be cleaned with a moistened cloth

(99% water + 1% mild detergent). Spirit or petroleum ether can be used

to remove greasy dirt. Any other cleaning agents can attack the plastic

and painted surfaces.

Under no circumstances should the cleaning fluid get into the instrument.

Petroleum ether is flammab le, and care should be taken in its use .

The detector must be returned to the factory when filament replacement is

required. Call VICI Tech Support for return authorization.

Page 7

Introduction

Components of the Detector Systems

Components of the detector system are listed in T ables 1 and 2. Check the

contents of the packages to verify that everything is present. Contact the

factory if anything is missing or damaged. (NO TE: damaged shipments

must remain with the original packaging for freight company inspection.)

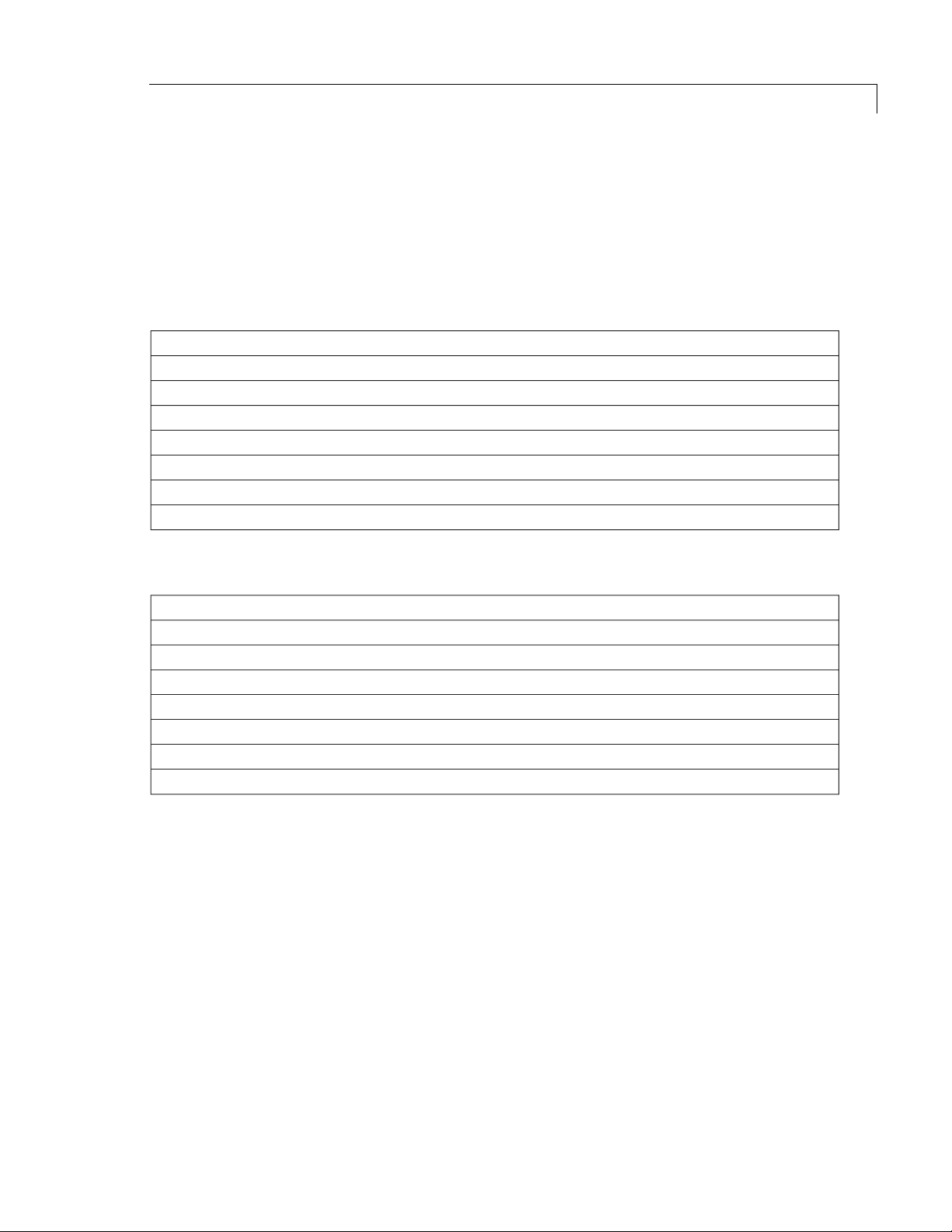

Description Quantity Product number

Detector cell, Nickel-Iron filament 1 TCD2-NIFED

Controller unit with power cord 1 TCD2-C

Includes: Cable, output 2 I-24010

1/16' zero dead volume union 2 ZU1C

Fused silica adapter for 0.53 mm ID x 0.8 mm OD capillary column 2 FS1R.8

1/16" zero dead volume nut 2 ZN1

1/16" zero dead volume ferrule 2 ZF1

3

Table 1:

Description Quantity Product number

Detector cell, Tungsten-Rhenium filament 1 TCD2-WRE

Controller unit with power cord 1 TCD2-C

Includes: Cable, output 2 I-24010

1/16' zero dead volume union 2 ZU1C

Fused silica adapter for 0.53 mm ID x 0.8 mm OD capillary column 2 FS1R.8

1/16" zero dead volume nut 2 ZN1

1/16" zero dead volume ferrule 2 ZF1

Table 2:

Components of the TCD2-NIFE system

Components of the TCD2-WRE system

Specifications

Mains (line): 115/230 V~50/60 Hz, 175 V A

Fuse: 2 A, time-delay, 5 x 20 mm

Pressure: 6.9 kPa (1 psi) operating, 6.9 MP a (1000 psi) max.

working

Maximum temperature 300°C

Heater power: 60 W max., 48 V, PWM

Output impedance: 100 Ω

Page 8

Introduction

4

Description of Controls and Connectors

Controls and connectors are indicated in Figures 2 and 4.

MAINS switch (rear panel)

Controls mains (line) voltage to the controller unit. When this s witch is

on ( | ), the unit is operational except for the detector filaments (see next

paragraph) and the detector heater will operate if connected.

FILAMENT switch and indicator

Controls power to the detector filaments; when the switch is on, current

passes through the filaments. The indicator will light e v en if the detector

is not connected to the controller.

DETECTOR TEMPERA TURE control and indicator

Sets the temperature (°C) of the detector heater block. The indicator is

steadily on when maximum power is being applied to the heater , steadily

off when no power is applied, and regularly blinking on/off when the set

temperature has been established.

Note that due to the fail-safe mechanism designed into the temperature

controller, the heater will not operate if mains po wer is applied before the

heater is connected or if the detector is too cold (< 0°C). If the heater is

disconnected with mains on, the unit must first be turned off to restore

control of the heater; if the unit is operated in a very cold environment,

the detector should first be gently warmed without power applied.

The fail-safe mechanism will also act under any condition resulting from loss

of control (

been followed and the controller will not heat the detector , there is cause

to suspect that the fail-safe mechanism has been activated. Consult the

factory or an authorized representative. Note that the maximum temperature

for operation of the TCD2 is 300°C.

FILAMENT TEMPERATURE switch

Separate 10-turn knobs control Filaments A and B. The value displa yed

corresponds to temperatures indicated in Figure 3 for nickel/iron filaments.

COARSE ZER O control

Once filament temperature has been applied, the Coarse Zero knob makes

coarse adjustments of the zeroing voltage supplied for establishing the

baseline zero on both the strip chart output and the integrator outputs.

FINE ZERO control

Once coarse adjustments have been made, the Fine Zero control is used to

make fine adjustments in the output signals.

A TTENU ATION control

The Attenuation control determines the attenuation of the signal for the chart

output.

RECORDER switch

The Recorder switch selects which signal is directed to the chart output.

The choices are A, B, or A - B (or A minus B, which is conventional

differential operation with the B channel representing the reference.)

The selected output signal is displayed in the LCD displa y.

e.g.

, over-heating, RTD failure, etc.). If proper procedures have

Page 9

Figure 2: Front panel controls

Introduction

5

400

350

300

250

200

150

ACTUAL TEMPERATURE IN °C

100

50

0

012345678910

FILAMENT TEMPERATURE KNOB SETTING

Figure 3: Actual filament temperature vs. filament temperature knob settings

Page 10

Introduction

6

MAINS POWER connector

For connection to 115/230 V A C source.

CHART OUTPUT connector

Normally connected to a strip chart recorder. This output has an attenuated

range of 0-1 volt and 0 - 10 volts, with the signal scaled by the attenuation

factor set on the front panel. The output also has an internal signal reference

(-) at zero volts. For best noise performance, the shield (earth) and signal

reference (-) should not be connected together .

UNA TTENUA TED OUTPUT connector

Normally connected to a data acquisition system or other recording means.

For convenience, full-scale 0 - 1V and 0 - 10V outputs are provided, with an

internal signal reference (-) at zero volts. For best noise performance, the

shield (earth) and signal reference (-) should not be connected together.

DETECTOR connector

For connection to the detector control and heating system.

NOTE: These terminals are for connection only to

equipment having no accessible live parts.

UNATTENUATED

OUTPUT

CONNECTORS

CHART OUTPUT

CONNECTOR

CONNECTOR

Valco Instruments Co. Inc.

MODEL TCD2-C

115/230

175VA MAX.

CHART

A

Made in USA by

Valco Instruments Co. Inc.

OUTPUTS

SERIAL NO.MODEL NO.

MAINS

T2.0A

B A-B

250V

Figure 4: Rear panel connectors

MAINS SWITCHMAINS POWER

DETECTOR

DETECTOR

CONNECTOR

Page 11

System Requirements

Components Not Included with the Detector System

•Carrier gas (99.999% purity is recommended)

•Ultra high purity grade gas pressure regulator with stainless steel

diaphragm (recommended)

•Any special adapters required for connection to the gas regulator

•Flow measuring device

•Flow regulating device

System Purity

Since detection of low concentrations depends in part on the purity of the

carrier, the purest carrier available must be used in order to achieve the

lowest possible detection limit. To maintain carrier purity, extra care must be

taken to assure that the delivery system is clean and free of leaks. Use

stainless steel tubing (cleaned to removed manufacturing solvents) instead

of nylon or PTFE tubing, which can diffuse contaminants into the carrier.

7

Recommended Carrier Gas Purifiers

The Valco Helium Purifer (product number HP2) and Nitrogen Purifer (product

number NP2), which utilize a rare earth gettering alloy to effectively remove

contaminants, are recommended for ppm level analysis of permanent gases.

For other applications, economical and convenient VICI Mat/Sen purifiers are

appropriate. Order the P300-1 for nitrogen, P200-1 for hydrogen, or the

P100-1 for helium and other inert carrier gases.

Carrier Gas Selection

The detector’s response to a component is based upon the difference

between the thermal conductivities of the component and the carrier gas: the

greater the difference, the greater the response. The table below shows

thermal conductivities for a variety of light gases.

Hydrogen 45.9

Helium 36.9

Neon 11.8

Methane 8.6

Oxygen 6.6

Air 6.4

Nitrogen 6.4

Carbon monoxide 6.2

Water 4.5

Argon 4.5

Carbon dioxide 4.2

As an example, note in the table that the thermal conductivity of hydrogen is

46 and helium is 37, while nitrogen is only 6 and argon is even lower at 4.

Since the largest difference in thermal conductivity yields the best response,

detection of small amounts of hydrogen is better done with argon or nitrogen

carrier than with helium.

Page 12

System Requirements

8

GC Column Selection

Howev er, while nitrogen as a carrier yields e xcellent response to hydrogen,

the response to oxygen and carbon dioxide is diminished compared to the

levels that could be achieved with helium or hydrogen. Argon would yield

poor response to carbon dioxide and water , but w ould be adequate for other

components.

There is no absolute “best choice” of carrier gas. For any situation, the choice

must take into account all of the parameters involved: column

characteristics, components of interest and their concentrations, safety

considerations, carrier cost, etc.

Cell volume has been minimized to accommodate capillary , megabore, and

micropacked columns, and to optimize the sensitivity of the detector at low

flow rates. However, standard pack ed columns may also be used if sensitivity is not an issue.

2 13⁄16"

5

5

⁄8"

1

1

⁄4"

3"

6"

1

1

⁄2"

1"

Figure 5: Detector assembly mounting dimensions

Page 13

Installation

General Precautions

9

The detector is usually mounted on top of the GC column oven. The power

cord for the controller is 1.8 m (6') long; the detector cable and the signal

output cables (attenuated and unattenuated) are 1.2 m (4') long.

•Do not turn the unit on until the carrier gas is flowing through the detector .

•Do not shut off or disconnect the carrier gas when the detector is hot,

even if the unit is turned off . Turn off the power switch on the back of the

controller and allow the detector to cool down naturally before disconnecting or shutting off the carrier gas.

•Position the controller unit where the mains switch on the rear panel can

be reached easily .

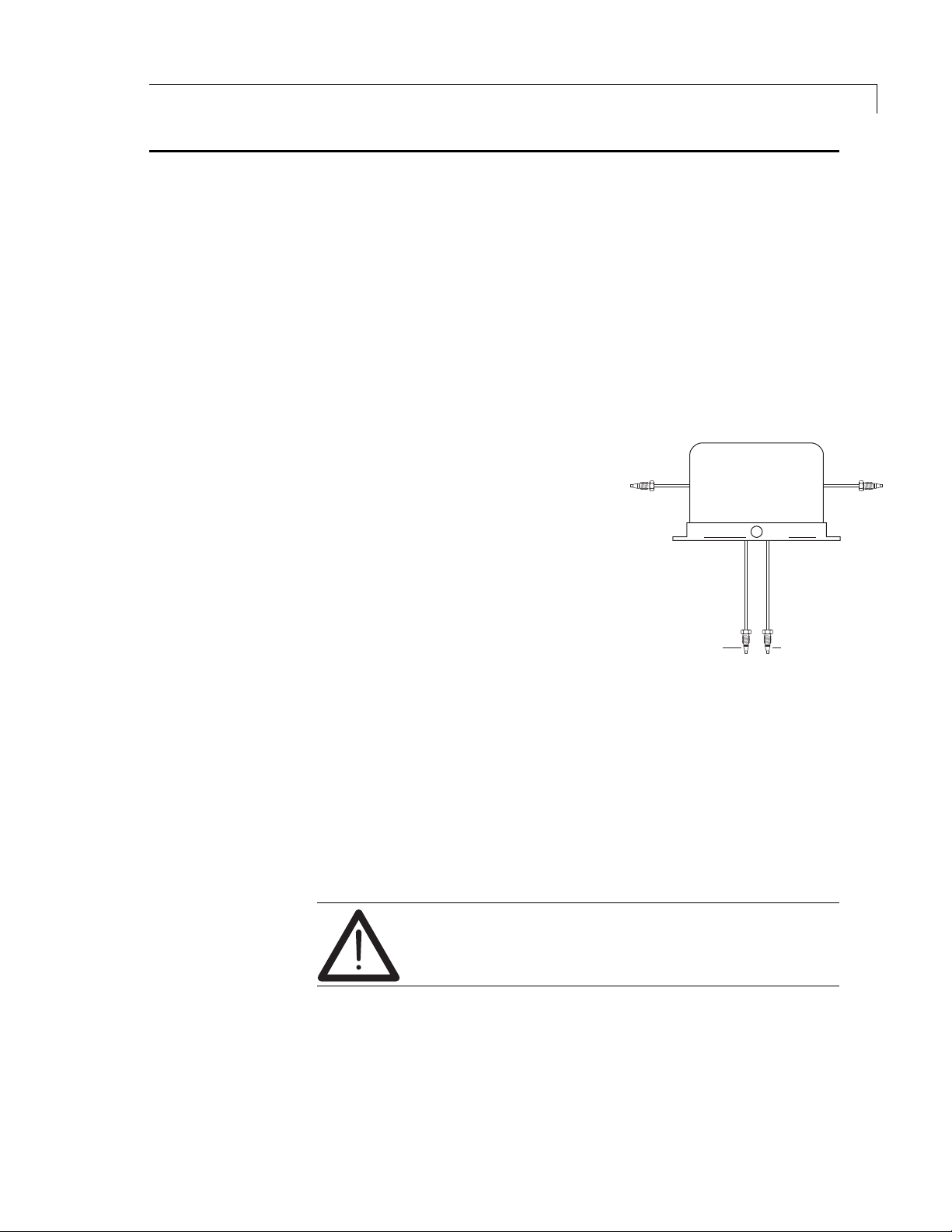

Mounting the Detector on the GC

V ertical Mounting

The detector has no particular orientation

requirements, but it should have adequate

thermal isolation from the column oven and

injection port. Most GCs have an existing

opening which will allow the TCD2 to sit

vertically on top of the column oven with the

column inlet extending into the oven. If you

are replacing an existing detector , you can

usually just remove it and set the TCD2 in its

place. If not, use a drill or chassis punch to

drill a hole of the proper size, and set the

detector in position.

While trying to match base plate mounting holes to every GC on the market

is impractical, we have located the mounting holes so that at least two of

them will coincide with existing holes on the GC. (Refer to Figure 5.)

Orient the detector to allow for easy cable and gas connections . The inlet

lines installed into the detector must enter the column oven and permit

column connection. Temperature loss between the column outlet and the

detector should be minimized to prevent possible condensation of the

sample.

CHANNEL

A

VENT

CHANNEL

A

INLET

(gold ferrule)

Figure 6: Detector connections

CHANNEL

B

VENT

CHANNEL

B

INLET

(stainless ferrule)

CAUTION: Do not mount the detector near the column

oven cool-down vents.

Horizontal Mounting

Some older GCs have access to the column oven through the side of the

GC. This does not present a prob lem as far as oper ation of the TCD2 is

concerned. Drill a hole at the appropriate location, orient the detector for

convenient connection, and mark the position of the mounting holes. Drill the

mounting holes and secure the detector to the side of the GC with four sheet

metal screws (not supplied).

Page 14

Installation

10

Gas Connections

Remember these three points discussed earlier: (1) all surfaces that contact

the gas stream must be glass or stainless steel; (2) do not use copper tubing

or brass fittings; and (3) all tubes must be thoroughly cleaned and baked

before use. The installation instructions below assume that the detector

carrier will be supplied from a nearby cylinder. If your installation is different,

you may need to modify the instructions appropriately. Consult the VICI

catalog or vici.com for any fittings and tubing required.

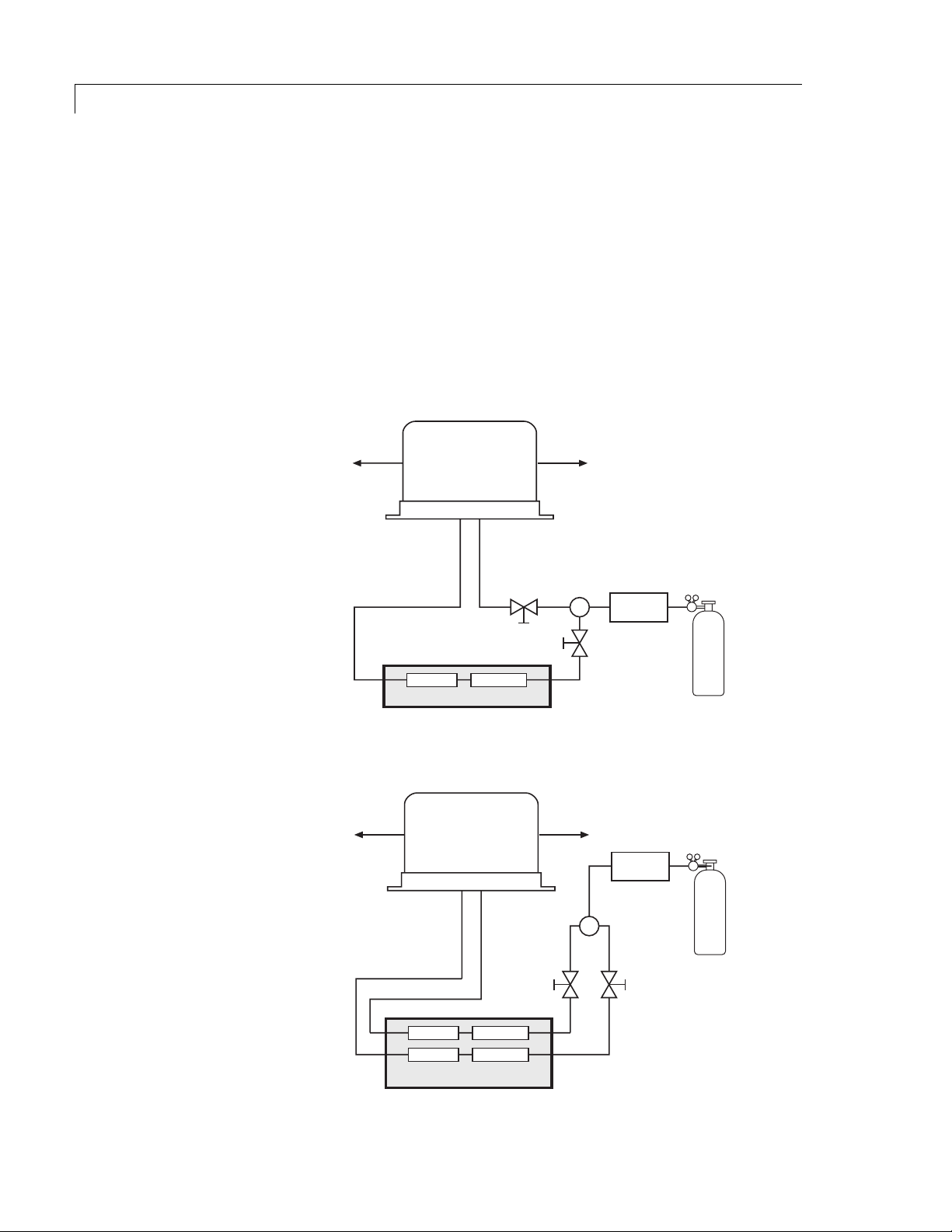

The figures below illustrates gas connections for a typical TCD2 detector

system, in referenced and unreferenced modes. Since the distance from the

carrier supply to the GC varies from installation to installation, we do not

supply tubing to go from that point to the GC.

CHANNEL

A

VENT

CHANNEL

B

VENT

DETECTOR

CHANNEL A

INLET

(gold ferrule)

COLUMN INJECTOR

CHANNEL B

INLET

(stainless ferrule)

FLOW

CONTROLLERS

TEE

(ZT1)

GAS CHROMATOGRAPH

Figure 7: Referenced mode (A - B)

CHANNEL

A

VENT

DETECTOR

CHANNEL

B

VENT

PURIFIER

CARRIER GAS

(99.999% purity)

PURIFIER

CHANNEL A

INLET

(gold ferrule)

COLUMN INJECTOR

COLUMN INJECTOR

CHANNEL B

INLET

(stainless ferrule)

GAS CHROMATOGRAPH

Figure 8: Unreferenced mode

TEE

(ZT1)

CARRIER GAS

(99.999% purity)

FLOW

CONTROLLERS

Page 15

Installation

Installing and Purging the Gas Regulator

1 . Make sure the on/off valve on the helium cylinder is completely closed.

Screw the CGA fitting nut of the regulator into the helium cylinder . Go

beyond finger-tight, but do not tighten the nut all the way – some leakage

is required for the purging operation.

2 . Turn the output pressure regulating knob completely counterclockwise.

11

EZR21

3. Open the cylinder on/off valve

4 . Adjust the tightness of the regulator connecting nut to allow a pressure

reduction of ~690 kPa/sec (100 psi/sec). With a ne w bottle, the gauge

should start out at about 14 MPa (2000 psi).

5 . When the pressure drops into the 1.4 - 3.4 MP a (200 - 500 psi) range,

open the cylinder on/off valve slightly and quickly close it again.

6 . Repeat Step 5 eight or ten times to be certain that all the air is purged.

On the final purge, tighten the regulator connecting nut very securely as

the pressure approaches the 2.1 - 3.4 MPa (300 - 500 psi) range.

7 . Open the cylinder valve to pressurize the regulator once again, then close

it and observe the high pressure gauge needle for 15 minutes. If it doesn’t

move, there is no critical leak on the high pressure side of the regulator .

CAUTION: Never use leak detecting fluids on an y part of

this system.

slightly

and quickly close it again.

Installing and Purging a Purifier

1. If the pressure regulator has a 1/8"

the Valco 1/8" external to 1/16" internal reducer (EZR21); if it has a 1/4"

male

cone-type outlet port, install the V alco 1/4" e xternal to 1/16" internal

reducer (EZR41). F or other regulator outlet fittings , a wide variety of V alco

adapters are available.

2. Remove the cap from the inlet tube of the V alco helium purifier and insert

the tube fitting into the 1/16" reducer port. (Keep the outlet tube capped.)

Use a 1/4" wrench to turn the nut one-quarter turn past the point where the

ferrule first starts to grab the tubing. Do not remo ve the fitting. When

made up properly , it should be leak-tight.

3. T urn the output pressure regulating knob clockwise until the gauge

registers 345 KPA (50 psi).

male

cone-type outlet port, install

4. Allow five minutes for equilibration, then turn the regulating knob all the

way counterclockwise.

5. Observe the needle of the output pressure gauge for 15 minutes. There

will be a slight initial drop, but if it doesn’t move after that, consider that

all the connections are tight.

6. If necessary, use an electronic leak detector to locate any leaks . If a

leak detector is not available, tighten all the fittings (including the output

pressure guage), and repressurize the system for another test.

7. Upcap the outlet tube of the purifier and purge the system for 15 to 30

minutes at 60 - 80 mL/min to eliminate air from the purifier getter material.

Page 16

Installation

12

Column Connection

T o prevent detector contamination, we strongly recommend disconnecting the column from the detector during

column bakeout procedures.

Referenced mode

In the referenced mode, the column is connected to the Channel A inlet, and

the carrier gas stream is split and used as a reference in channel B. The gas

flow rate from both channels must be the same (flow balanced). This mode

of operation provides the best baseline stability and the least background

noise.

Unreferenced mode

In the unreferenced mode, Channels A and B are used independently. One

column connects to the Channel A inlet, and the other to Channel B. The

carrier gas must be the same for both channels.

It is also possible to use only one channel with the other capped off, as long

as the filament temperature control knob of the unused channel is set to

zero.

The unreferenced mode has certain limitations: there is a possibility of

detector cross-talk (interference) if compound concentrations exceed 1%,

and baseline drift and background noise are greater than with the referenced

mode.

To make column connection as convenient as possible, each TCD is

shipped with two V alco 1/16" unions (Product No . ZU1C) complete with

nuts and ferrules (Product Nos. ZN1 and ZF1). Also included are two fused

silica adapters (FSR1.8) for use with .53 mm ID wide bore capillary columns

(.8 mm OD). Ref er to the information below to determine the correct V alco

fitting for use with other columns.

Column Connection Fittings

Packed Columns

A 1/16" packed column requires only the ZU1C which comes with the TCD .

For 1/8" columns, order a ZR U21.

ZU1C

Used with 1/16" column

ZRU21

Used with 1/8" column

Page 17

Packed Columns with Swagelok®-type Female Nut

The connection of these columns is similar to that for standard packed

columns, but requires a union which adapts the f emale nut to the Valco

fitting.

Installation

13

Used with 1/16" column

Capillary Columns

Connection of these columns requires the use of the ZU1C with the appropriate fused silica adapter. For a .53 mm ID x .8 mm OD column, use the

FSR1.8 supplied with the TCD. For other sizes , use this table to determine

the proper adapter:

Column size

.32 mm ID x .5 mm OD

.25 mm ID x .4 mm OD

< .2 mm ID

Testing for Leaks

It is critical for the system to be leak-tight, and an additional check at this

point can save man y headaches later on. To test for leaks:

1. Insure that both outlets are capped.

2. Pressurize the entire system with helium to 138 kPa (20 psi).

3. If the system does not hold pressure, check all the fittings with an

electronic helium leak detector. DO NO T use leak detecting liquids .

Electrical Connections

EZU1

Adapter required

FS1R.5

FS1R.4

FS1R.2

EZRU21

Used with 1/8" column

ZU1C with fused silica adapter

Before connecting the detector cable to the control

module, make sure that the control module power cord is

unplugged.

1. The heater and filament connections from the detector to the rear panel of

the controller are made up in one cable. After making sure that the control

module power cord is not plugged in, connect this detector cable to the

connector on the control module. The cab le connector should be firmly

seated by turning the coupling ring clockwise until the detent is felt.

For best detector performance, the cable and connector

should not be allowed to move while measurements are

being made. If the cable is disconnected, exercise care

to keep the connecting pins in each connector clean.

Page 18

Installation

14

2. Connect the data output(s). The A / B / A - B outputs are used with an

integrator or PC-based data acquisition system; the chart output is for a

strip chart recorder. P olarities and full scale range are indicated in the

figure below . (Set the recorder/D AQ f or the same voltage scale .)

3. Connect the main power cord.

RED (+10V)

BLACK ()

WHITE (+1V)

RED (+10V)

BLACK ()

WHITE (+1V)

220V

ATTENUATED STRIP

CHART OUTPUT

CABLES FOR A, B,

and AB

CHANNEL

A

Valco Instruments Co. Inc.

MODEL TCD2-C

115/230

175VA MAX.

A

CHART

MODEL NO.

Valco Instruments Co. Inc.

OUTPUTS

SERIAL NO.

MAINS

T2.0A

250V

B A-B

CHANNEL

B

DETECTOR

INLET

A

INLET

B

Figure 9: Electrical connections

Page 19

Initial Power-Up

Since the TCD is a concentration-dependent detector , the lower the flo w

rate through the detector, the higher the sensitivity. Column diameter will

determine the optimum column flow rate.

The microvolume TCD is designed f or the low er flow rates typical f or capillary

columns, and achieves best sensitivity at rates below 10 ml/min. Since the

filaments are maintained at constant temperature, the detector can be

operated at extremely low flow rates (less than 0.5 ml/min) without damage

to the filaments.

A - B referenced mode

Flow Rate Settings

1. Measure the column flow at the detector’s Channel A out. The optimum

flow rate is in the range of 4 - 20 mL/min, with the actual rate dependent

on the type of column used.

2. Measure the reference gas flow at Channel B out. It should be as close as

possible to the GC column flow . Use a fixed flow restrictor or a good

quality flow controller to match the the carrier gas and reference gas flows.

Installation

15

3 . Once the flows have been established, make sure the filament switch and

the main power switch are in the OFF position, and plug the power cord

into an AC main outlet.

Initial Conditioning

4. T urn on the control module main power s witch and set the detector

temperature to 220°C.

5. T urn on the filament power s witch and set both filament temperature knobs

at 8.0.

6. Condition the detector by allowing it to bake at these settings for at least

12 hours.

Temperature Settings

7. After the initial bakeout period, set the detector temperature at 100°C or at

the column temperature plus 30°, whichev er is higher.

8. Set the filament temperatures at least 50° and as much as 100° higher

than the detector temperature. Refer to Figure 3 on page 5, which

outlines the relationship between the filament temperature knob settings

and the actual filament temperature.

Detector sensitivity increases as the temperature differential between the

detector and the filaments increases, but filament life decreases as its

temperature increases. Thus, the detector temperature should be set as

low as possible, determined by the boiling point of the highest boiling

component of the sample.

9. Once all temperatures are set, allow plenty of time for the system to

equilibrate, evidenced b y a stable baseline . Typical equilibration time for

going from a cold start-up to 130°C detector temperature is approximately

five hours. Detector temperature changes take much longer to equilibrate

than do filament temperature changes.

Page 20

Installation

16

The test chromatogram accompanying your TCD was obtained under the

following conditions:

Sample: ~100 ppm blend in Helium balance

Sample volume: 250 µl

Column: 10' x 1/16" x 0.040" molecular sieve 5Å micropacked

Column flow: 6 mL/min

Reference flow: 6 mL/min

Column temperature: 65°C

Detector temperature: 100°C

Filament temperature: 230°C (a setting of 5.0)

Carrier gas: Helium

Balancing the Channels

The LCD display indicates the signal lev el from the recorder/chart output.

10. Set the recorder switch to A, and use the coarse and fine controls for

Channel A to adjust the signal level to about 300 mv.

11. Set the recorder switch to B and repeat the same process to adjust the

signal level to about 200 mv.

12. Set the recorder switch to A-B. The display should read about 100 mv. If

the signal levels drifts below zero, readjust the A & B channels.

The detector is now ready for analytical use.

Balancing the Channels

10. Use the zero (or shunt) setting on the recorder to set the true zero on the recorder.

11. Set the Recorder switch to A, and use the coarse and fine zero controls

for Channel A to bring the recorder pen on scale and to a position

approximately 1-2 cm abov e zero.

12. Set the Recorder switch to B, and repeat the same process, bringing the

pen to a position

13. Set the Recorder switch to A - B, and observe the recorder pen position.

It should be above the true zero position, but below the position for

Channel A. If the pen drifts below z ero , readjust the A and B channels .

The detector is now ready for analytical use.

Balancing the Channels

10. Connect the output cable to the A connector, and use the coarse and fine

zero controls for Channel A to bring the baseline signal on scale and to a

position approximately 100 mV abov e zero.

11. Move the output cable to the B connector, and use the coarse and fine

zero controls for Channel B to bring the baseline to a position half as far

above zero as for Channel A (the value of A minus B).

12. Move the output cable to the A - B connector, and observe the baseline

signal. It should be above the true zero position. If the signal drifts below

zero, readjust the A and B channels .

The detector is now ready for analytical use.

using LCD Display

using Recorder/Chart Output

half

as far above zero as the pen for Channel A.

using Unattenuated Outputs

Single filament mode

The basic procedures and temperature settings described for referenced

mode operation can also be applied to operation in the single filament or

independent mode. Both channels must have the same carrier gas; you

cannot use helium carrier in one channel and nitrogen in the other. Also be

aware of the possibility of detector cross-talk when components elute from

the columns in concentrations greater than 1%.

Page 21

Troubleshooting

Troubleshooting Chart

Problem Possible Cause Refer to page:

No signal Main or filament power switch off 4

Filament temperature too low 4

Fuse blown 3

Output cable in the wrong connector 1 4

Signal reversed Signal wires reversed 14

Noisy signal Dirty system or leaking fittings 7, 13, 19

Bad flow controller in system 1 5

Cell/filament differential too small 1 5

Filament damaged 2

Cannot zero the signal Recorder/Int. not zeroed 16

V oltage incompatibility 14

Main or filament power switch off 4

17

Excessive drift* Block temperature not stabilized 1 5

Heater fault 17

Cell doesn’t heat properly Heater/sensor cable unplugged/

heater fail safe mechanism 1 7

Heater fault 17

Fuse blown 3

For technical assistance from V alco Instruments, call (713) 688-9345 or email tech_usa@vici.com.

*T ry referenced mode , page 12

Heater Fault Determination

The heater control circuit is designed to disable itself in the event of a fault

such as over-temperature , shorted heater, short/open temperature sensor,

etc. Once disab led, circuit operation is restored b y turning off the controller,

disconnecting and reconnecting the detector cable, and then turning the

controller back on.

connected to the controller, the heater circuit will not operate until mains

power is removed, the detector connected, and mains power restored.

Under normal circumstances, the amber temperature indicator light will flash

once after mains power is applied, before control is established. If the light

fails to flash, it indicates that a fault has been detected or (less likely) the

heater supply fuse has failed.

E.g.

, if mains power is applied before the detector is

Page 22

Troubleshooting

18

Detector Fault Determination

Electrical faults in the detector are most easily discovered by making

resistance measurements between pins of the detector cable connector . The

table below shows the pin numbering and connections for the detector cable

(view into pins). Nominal resistance values (in ohms) at 25°C are shown.

Unshaded boxed without numbers represent open circuits, and should in no

case be blow 1 MΩ. Resistance values given should be within ±10% of the

nominal values.

Pin

1

2

3

4

5

6

8

9

11

12

13

23 4

0

5

25

25

6

108

89

0

11 12

25

25

13014

50

Page 23

Maintenance

Cleaning the Enclosure

Bake Out Procedure

19

The exterior of the instrument should be cleaned regularly with a dusting

brush. If necessary, the casing can be cleaned with a moistened cloth

(99% water + 1% mild detergent). Spirit or petroleum ether can be used

to remove greasy dirt. Any other cleaning agents can attack the plastic

and painted surfaces.

Under no circumstances should the cleaning fluid get into the instrument.

Petroleum ether is flammab le, and care should be tak en in its use.

Under normal conditions, the TCD requires no routine maintenance.

Howev er, if the detector is exposed to chemicals which may condense or

polymerize within the detector and adversely affect performance, the detector

cell can be baked out at elev ated temperatures (up to 300°C). Inert carrier

gas flow (other than hydrogen, oxygen, or air) should be maintained during

the reconditioning procedure. Filament temperature should also be increased

to approximate the setpoint of the bake out temperature.

If a 24 hour bake out is not sufficient to remove the contamination, the unit

must be returned to be factory for disassembly and cleaning.

Page 24

20

Warranty

This Limited W arranty giv es the Buyer specific legal rights, and a Buy er

may also have other rights that vary from state to state. For a period of 365

calendar days from the date of shipment, Valco Instruments Company, Inc.

(hereinafter Seller) warrants the goods to be free from defect in material and

workmanship to the original purchaser. During the warranty period, Seller

agrees to repair or replace defective and/or nonconf orming goods or parts

without charge for material or labor , or, at the Seller’ s option, demand return

of the goods and tender repayment of the price. Buy er’ s e xclusiv e remedy is

repair or replacement of defective and nonconf orming goods, or, at Seller’ s

option, the repayment of the price.

Seller excludes and disclaims any liability for lost profits, personal

injury, interruption of service, or for consequential incidental or special

damages arising out of, resuiting from, or relating in any manner to

these goods

This Limited W arranty does not cov er defects , damage, or nonconformity

resulting from abuse, misuse, neglect, lack of reasonable care, modification,

or the attachment of improper devices to the goods. This Limited W arranty

does not cover e xpendable items. This w arranty is V OID when repairs are

performed by a nonauthorized service center or representative. For information about authorized service centers or representatives, write Customer

Repairs, Valco Instruments Company, Inc, P.O. Box 55603, Houston, Texas

77255, or phone (713) 688-9345. At Seller’ s option, repairs or replacements

will be made on site or at the factory . If repairs or replacements are to be

made at the factory , Buyer shall return the goods prepaid and bear all the

risks of loss until delivered to the factory. If Seller returns the goods, they

will be delivered prepaid and Seller will bear all risks of loss until delivery to

Buyer. Buy er and Seller agree that this Limited Warranty shall be go verned

by and construed in accordance with the laws of the State of Texas.

The warranties contained in this agreement are in lieu of all

other warranties expressed or implied, including the warranties

of merchantability and fitness for a particular purpose.

This Limited W arranty supercedes all prior proposals or representations oral

or written and constitutes the entire understanding regarding the warranties

made by Seller to Buyer . This Limited W arranty ma y not be e xpanded or

modified except in writing signed by the parties hereto.

Page 25

Detector Performance Log

21

Detector Model: Serial Number: Date of purchase:

Date

Operator Filament

TCD2

Detector

temp

(°C)

Initial power-up (IPU) 100——

IPU, detector to analysis temp — —

IPU, column installed Ambient —

IPU, column to analysis temp —

temp

(°C)

Noise

level

SampleComments

Detector

flow

AB

Loading...

Loading...