Page 1

Valco Instruments Co. Inc.

Helium Purifier and

Nitrogen Purifier

Instruction Manual

For item numbers:

HP2

HP2-220

NP2

NP2-220

I-23572HP2

I-23572NP2

Introduction

Specifications ................................................................................................ 1

Theory of Operation ...................................................................................... 2

Power Supply Requirements ......................................................................... 2

Installation and Operation

Installation ..................................................................................................... 3

Activation ....................................................................................................... 3

Operation....................................................................................................... 3

Removing the HP2 or NP2 from the System ................................................. 4

Routine Maintenance

Replacing the Getter Cartridge ....................................................................... 5

Disposing of Spent Getter Cartridges ............................................................. 5

Technical Drawings ............................................................................................... 6

Warranty .............................................................................................................10

HP2w.p65

Rev. 1/11

Printed in USA

Valco Instruments Co. Inc.

800

·

367

·

8424 sales

·

688

·

·

688

9345 tech

·

8106 fax

713

713

valco@vici.com

VICI International

Schenkon, Switzerland

·

41 · 925

·

Int + 41

·

41 · 925

Int + 41

info@vici.ch

6200 phone

·

6201 fax

Page 2

Introduction

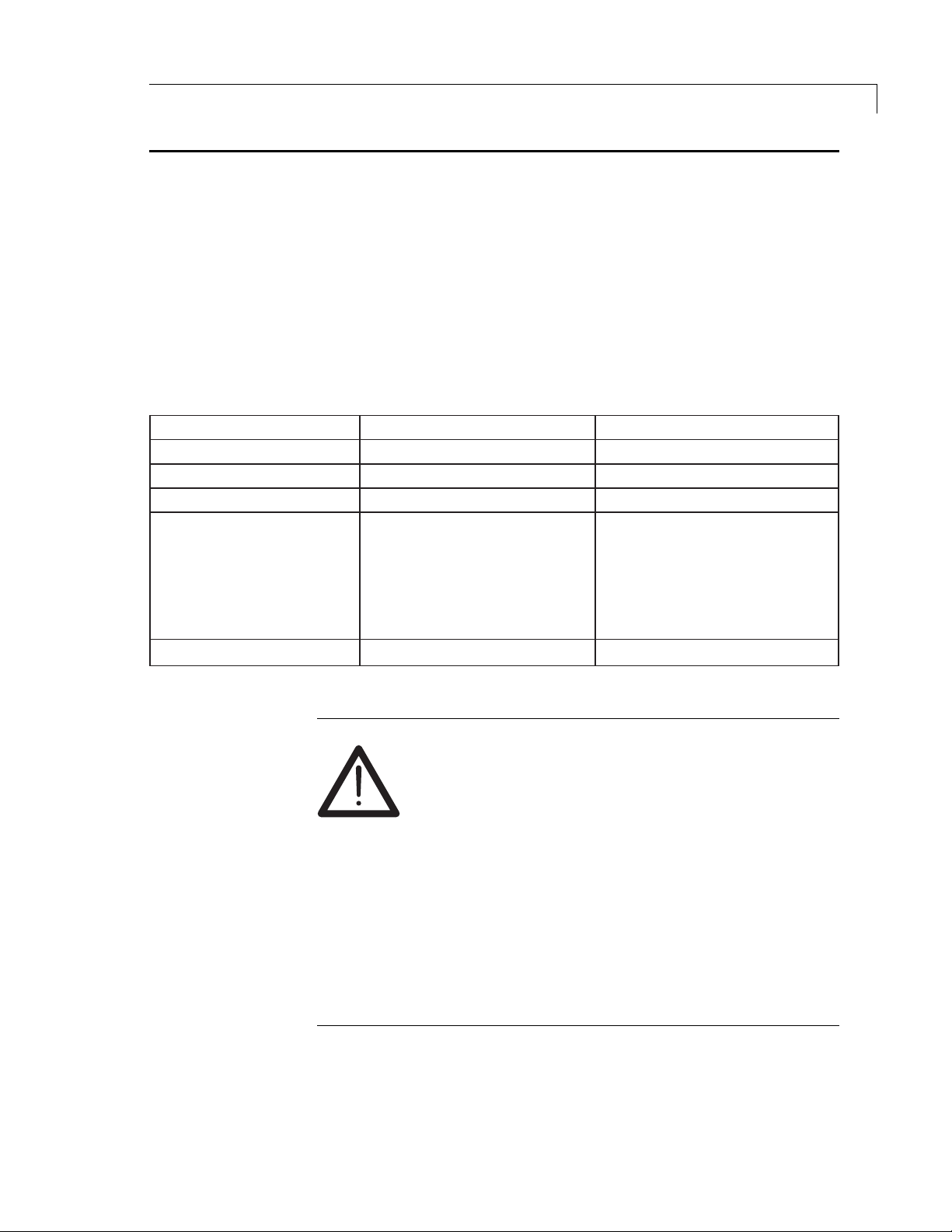

Specifications

1

The Valco Helium Purifier (HP2) and Nitrogen Purifier (NP2) provide “pointof-use” carrier gas purification to sub-ppm levels of gaseous impurities.

Designed originally for the Valco Trace Gas Analysis system with its Helium

Ionization Detectors, the Helium Purifier provides point-of-use ultrahighpurity helium for use in any chromatographic application requiring highquality helium or other noble gas (Ar, Ne, Kr, Xe). The Nitrogen Purifier was

developed for use with our Electron Capture Detector.

Gases purified

Max. operating pressure

Max. operating temperature

Max. flow rate

Impurities removed

Impurities not removed

Helium Purifier

(HP2)

He, Ne, Ar, Kr, Xe, Rn

1000 psig

400°C

1 liter/min

Outlet impurities less than 10 ppb

O, H2, O2, N2, NO, NH3, CO, and

H

2

, based on 10 ppm total inlet

CO

2

impurities. Other impurities

removed include CF

and hydrocarbons such as CH

He, Ne, Ar, Kr, Xe, and Rn

, CCl4, SiH4,

4

4

Outlet impurities less than 10 ppb

H

based on 10 ppm total inlet impurities.

Other impurities removed include

CF

He, Ne, Ar, Kr, Xe, Rn, CH

Nitrogen Purifier

(NP2)

He, Ne, Ar, Kr, Xe, Rn, N

1000 psig

400°C

1 liter/min

O, H2, O2, NO, NH3, CO, and CO2,

2

, CCl4, SiH4, and hydrocarbons

4

WARNING!

This product is

not for use with oxygen

oxygen or gases with a significant proportion of

oxygen. The purifier’s gettering alloy is

at operating temperature

. Use with significant

amounts of oxygen can result in combustion of the

material, potential damage to the surrounding area,

and possible injury.

2

, and N

4

– either pure

pyrophoric

2

In no event shall Valco Instruments Co. Inc. be liable

for any direct, indirect, special, incidental, or consequential damage, whether based on contract, tort,

or any other legal theory and whether advised of the

possibility of such damages.

Page 3

Introduction

2

Theory of Operation

The purification substrate in the Valco purifiers is a non-evaporable

gettering alloy, with a nominal composition of zirconium, vanadium, and

iron. This alloy must be heated so that the oxide layers on the particle

surface are eliminated. This process must be performed under a vacuum or

in at atmosphere of helium (for the HP2) or nitrogen (for the NP2).

Although the gettering alloy will purify even at ambient temperatures, raising

the temperature vastly improves the life span and efficiency of the alloy.

However, the elevated temperature causes hydrogen generation, which is

trapped only at temperatures below 250°C. Therefore the Valco purifiers

have been designed to operate at a fixed temperature gradient which yields

a long life span and high efficiency and insures that any hydrogen generated will be trapped.

Accurate temperatures at the inlet (380-400°C) and at the outlet (170190°C) are maintained with the use of a precision 24 VDC power supply.

Power Supply Requirements

As stated on the purifier, the power supply must conf orm to EN 61010-1:

Section F.2.1 Limited circuit. This section mandates that the po w er source

must be limited to 42.4 VDC or less (open circuit). In addition, the energy

must be limited by one of the following means:

• the current under any condition of load, including short circuit, is not

more than 8A measured after 1 minute of operation

rated

• the source is

condition of load

• an overload protector or circuit component opens to interrupt the

power output at a lower value than 150 VA under any condition

including short circuit

The power supply is critical for safe and pr oper operation of this unit. It is therefore recommended that the

purifer be used only with the power supply received

with it.

or set to limit its power to 150 VA under any

Page 4

Installation and Operation

This procedure describes a chromatographic installation. Although that is not

the only possible application, it is the most common. It is up to the user to

determine whether the purifier is suitable for a particular application based

upon the specifications of the purifier.

Installation

The Valco HP2 and NP2 are two part systems comprised of the purifier and

the power supply. The purifier must be installed in a vertical position to

eliminate the possibility of channeling. For best results, do not modify the

fittings or tubing lengths; small particles which might be generated by such

modifications are difficult to remove and can restrict the flow.

1. Connect the input line (tagged INLET) to a carrier gas cylinder with a

high purity regulator. (Save the caps to seal the purifier whenever you

remove it from the system.)

2. Purge the system for 15 to 30 minutes at 20 to 30 mL/min to eliminate

air from the getter material.

3

3. Connect the barrel connector of the power supply to the purifier .

4. Connect the power supply to mains (115/230 VAC). The LED on the

5. Connect the purifier output line to the chromatographic system’s carrier

Activation

When the purifier reaches operating temperature (usually in about 2½

hours) the getter will be activated. Once the getter is activated, active

gaseous impurities such as H

are captured and chemisorbed on the getter surface. Only noble gas atoms

are not affected. Once adsorbed, oxygen, carbon, and nitrogen atoms

cannot be released by the getter material even at its melting point (1400°C),

due to the formation of strong chemical bonds with the alloy atoms.

Hydrogen atoms behave quite diff erently , diffusing into the getter material

bulk more quickly than the other atoms and becoming almost uniformly

distributed within the bulk. Ho w e v er, hydrogen sorption occurs below 250°C,

achiev ed through the temperature gr adient of the trap assembl y.

CAUTION: The getter material should never be heated

when air is present.

power supply should come on to confirm power output.

gas input line using a 1/16" union (Valco Product Number ZU1).

, O2, H2O, CO, and CO2 (plus N2 for the HP2)

2

Page 5

Installation and Operation

4

Operation

Removing the HP2 or NP2 from the System

In normal operation the outside temperature of the purifier is warm, but

should not be uncomfortable to the touch. The 24 VDC po wer supply maintains the purifier trap at a constant temperature, and should be located so

that the illuminated LED can serve as a visual indicator of purifier operation.

To remove the purifier from the carrier gas line:

1. Disconnect the power supply. Disconnect the output line from the

instrument while maintaining carrier flow.

2. Allow se v er al hours f or the the getter o ven to cool. After the o ven

reaches ambient temperature, cap the output line and allow the

purifier to be pressurized for several minutes.

3. Remov e the input line and immediately cap it. This maintains a carrier

gas atmosphere on the gettering substrate, increasing its lifetime.

To reinstall, follow the instructions in the Installation section at the top of

page 3.

Page 6

Routine Maintenance

In normal usage there is no maintenance required on the purifier or power

supply. If the purifier shows signs of saturation it will need replacement.

Replacement cartridges can be ordered from Valco using the product

numbers below .

Replacing the Getter Cartridge

1. Disconnect the power supply from the purifier , but lea v e the helium

flow on.

2. Allow at least two hours for the purifier to cool.

3. Using a thin-edged screwdriver or knif e, remo v e the two hole plugs

from the side of the unit and one from the top.

Do not open or modify the trap assembly .

For an HP2:

For an NP2:

I-23572HP2

I-23572NP2

5

4. The side holes allow access to the two screws which secure the trap.

With a 5/32" allen wrench, turn each screw counterclockwise one to

two rotations.

5. If the trap is still too hot to the touch, allow more cooling time. If it can

be handled, pull it out through the hole in the top of the unit.

6. Disconnect the output line at the fitting, and cap it to allow the trap to

pressurize.

7. Hav e a second cap at the ready. Disconnect the input line at the

fitting, and cap it immediately .

8. Insert the new trap, making sure the insulation and f eed-through hole

plug are snug against the top of the trap. Push the trap assembly

down until the feed-through hole plug is resting on the top of the unit.

9. Tighten both allen screws, making sure the trap does not mov e .

10. Snap in the feed-through hole plug, and both the side hole plugs .

11. Ref er to the Installation section at the top of page 3 to get the

system back in operation.

Disposing of Spent Getter Cartridges

Obtain a return authorization number from VICI by emailing tga@vici.com or

calling 800-367-8424. The packaged getter cartridge should be clearly

marked “Traps for Disposal”.

Page 7

6

Technical Drawings

Enclosure Assembly................................................ Drawing 23575 Page 7

Secondary Assembly .............................................. Drawing 23579 Page 8

Final Assembly HP2/NP2 ........................................ Drawing 23580 Page 9

Page 8

Technical Drawings

7

REVISIONS

NEW DWG. GETTER REDESIGN (HP2) ECN #4015 17DEC97 S.WERNERA

LTR DESCRIPTION DATE INITIATED

B ECN# 4908 CHANGE ITEM 7 TO 1" WIDE (1.5") 24SEP99 JDURR

1

1

1

1

4

QTY

VALCO #

HWSC-PL4-4

I-23541-02

I-23541-01

I-23577

I-23578

PARTS LIST

DESCRIPTION

SCREW, PHMS: 4-40 X 1/4 LG

INSULATION, FRONT: HP2*NP2

INSULATION, REAR: HP2*NP2

ENCLOSURE: COVER, HP2/NP2

ENCLOSURE: OVEN, HP2/NP2

321

4A

ITEM

4B

2

.041

2

1

1

1.00'

CI608104

I-E-FELT

HWSC-SC10-48

TAPE: HIGH TEMP 1" WIDE, 100' ROLL

SCREW, SHCS: 10-32 X 3" LG, SS

U-FELT SERIES MICROFIBER 3/4" TH

6

7

8

2

1

2

HWSP-1169

I-23574-01

I-23574-02

HEATER BLOCK-A: HP2*NP2 COMPLETE

HEATER BLOCK-B: HP2*NP2 COMPLETE

SPACER: #10*1 1/8, 5/16 OD, SS

10

9

1

4

HWNUT-HEX#10-5

I-21208-48

HWSO-1751

HWJAX-10

HEATER: CARTRIDGE 42W, 24V 6" X 3/8

NUT, HEX: 10-32 X 5/16 SS

STANDOFF: 10-32*1/2, 5/16 OD, SS

JACK: POWER, PANEL SLOT MT, .1 ID PIN

14

15

121311

*

4A

1.5" X 4.0"

*

14

15

8

ASSEMBLED PROFILE

9

10

11

12

13

4B

6

7

11

10

ENSURE CLOSE PARALLEL FIT OF AND

SO THERE ARE ABOUT 2 THREADS SHOWING ~ .050

LOCK THREADED SPACERS TOGETHER WITH PLIERS

WHEN ADJUSTING FOR THREAD GAP

ASSEMBLE AS SHOWN:

1

63

THIS DOCUMENT AND THE INFORMATION WHICH IT CONTAINS SHALL NOT BE USED, EXPLOITED

OR SOLD, AND SHALL NOT BE REVEALED OR DISCLOSED TO OTHERS WITHOUT THE EXPRESSED

WRITTEN PERMISSION OF VALCO. THIS DOCUMENT SHALL REMAIN THE PROPERTY OF VALCO

AND SHALL BE RETURNED UPON DEMAND.

OTHERWISE SPECIFIED

TOLERANCES UNLESS

THREAD GAP

OF

I-23575

SHEET

23575

C

SIZE DRAWING NO.

Valco Instruments Co., Inc.

HP2/NP2

SCALE

S.WERNER 17DEC97

S.WERNER

DRAWN

DESIGNED

USA PROJECTION

CHECKED

FILE NAME SUB-DIR

23575 HP2

23579

NEXT ASSY.

FRACTIONS DEC. ANGLES

ENCLOSURE: SUB-ASSY:

1

DATE

.X.1

.XX.01

.XXX.005

1/64"

APPROVED

3

Page 9

Technical Drawings

8

REVISIONS

ECN# 4015 NEW DWG. 17DEC97 S.WERNERA

LTR DESCRIPTION DATE INITIATED

5JUN00 JDURR

ECN# 5161 ADD SERIAL TAG INFO

B

5

1

4

VALCO # QTY.

I-23575

I-23542 1

HWSC-PL6-6 4

HW-1658

HW-7603 2

I-TAG73T1-795 1

I-23572HP2 1

DESCRIPTION

TAG: 1*2" METALIZED

TRAP TUBE ASSY: COMPLETE, HP2

FEET: RUBBER, STICK-ON

HOLE PLUG: 1/2"

SCREW,PHMS: 6-32 X 3/8 LG

BASE: GAS PURIFIER HP2/NP2

ENCLOSURE: ASSY. HP2/NP2

7

5

6

234

1

ITEM

*

1

OF

I-23579

SHEET

2

4

SIZE DRAWING NO.

23579

C

Valco Instruments Co., Inc.

SECONDARY HP2/NP2

SCALE

S.WERNER 17DEC97

S.WERNER

DRAWN

DESIGNED

CHECKED

NEXT ASSY.

USA PROJECTION

FILE NAME SUB-DIR

23579 HP2

I-23580

ENCLOSURE: ASSY.

7

1

63

DATE

.X.1

.XX.01

.XXX.005

1/64"

THIS DOCUMENT AND THE INFORMATION WHICH IT CONTAINS SHALL NOT BE USED, EXPLOITED

OR SOLD, AND SHALL NOT BE REVEALED OR DISCLOSED TO OTHERS WITHOUT THE EXPRESSED

WRITTEN PERMISSION OF VALCO. THIS DOCUMENT SHALL REMAIN THE PROPERTY OF VALCO

AND SHALL BE RETURNED UPON DEMAND.

APPROVED

FRACTIONS DEC. ANGLES

OTHERWISE SPECIFIED

TOLERANCES UNLESS

3

6

*

NITROGEN MODELS USE I-23572-02

Page 10

MNL-HP2

1991 REV.7/98

C

Printed in USA

Technical Drawings

9

HP2

23580NONE

C

SIZE DRAWING NO.

OF

SHEET

REVISIONS

ECN #4015 NEW DWG.GETTER REDESIGN (HP2)

ECN #5161 SHOW SERIAL TAG

LTR DESCRIPTION DATE INITIATED

A 17DEC97 S.WERNER

B 5JUN00 JDURR

INLET

GETTERING

MATERIAL

HELIUM

NITROGEN PURIFIER

INSTRUCTION MANUAL

HELIUM PURIFIER and

Valco Instruments Co. Inc.

vici@vici.com

Web site www.vici.com

Fax Int + 41 41 925 6201

Phone Int + 41 41 925 6200

P.O. Box 55603, Houston Tx. 77255

Valco International Schenkon, Switzerland

General email: valco@vici.com Tech support email: tech@vici.com

(713) 688-9345 Sales toll-free (800) 367-8424 Fax (713) 688-9348

Valco Instruments Co., Inc.

1

63

.X.1

1/64"

THIS DOCUMENT AND THE INFORMATION WHICH IT CONTAINS SHALL NOT BE USED, EXPLOITED

OR SOLD, AND SHALL NOT BE REVEALED OR DISCLOSED TO OTHERS WITHOUT THE EXPRESSED

WRITTEN PERMISSION OF VALCO. THIS DOCUMENT SHALL REMAIN THE PROPERTY OF VALCO

AND SHALL BE RETURNED UPON DEMAND.

FRACTIONS DEC. ANGLES

OTHERWISE SPECIFIED

TOLERANCES UNLESS

4

SERIAL NO.

HP-XXXXX

MADE IN U.S.A BY

VALCO INSTRUMENTS CO INC.

MODEL NO.

HP2

.XX.01

FINAL ASSY.:

.XXX.005

DATE

APPROVED

HP2/NP2

SCALE

S.WERNER 17DEC97

S.WERNER

DRAWN

DESIGNED

USA PROJECTION

CHECKED

FILE NAME SUB-DIR

23580 HP2

FINAL ASSY

2

1

111

I-23579

I-W-17600

PARTS LIST

DESCRIPTIONITEM VALCO # QTY

1

3

POWER SUPPLY , 24VDC PS24VDC-CE

OVEN ASSY, GETTER

MANUAL, HP2 I-MNL-HP2

LINE CORD, IEC 320 TYPE

4

123

FOR 220 VAC MODELS USE I-17850

*

*

Page 11

10

Warranty

This Limited Warranty gives the Buyer specific legal rights, and a Buyer

may also have other rights that vary from state to state. For a period of 365

calendar days from the date of shipment, Valco Instruments Company, Inc.

(hereinafter Seller) warrants the goods to be free from defect in material

and workmanship to the original purchaser. During the warranty period,

Seller agrees to repair or replace defective and/or nonconforming goods or

parts without charge for material or labor, or, at the Seller’s option, demand

return of the goods and tender repayment of the price. Buyer’s exclusive

remedy is repair or replacement of defective and nonconforming goods, or,

at Seller’s option, the repayment of the price.

Seller excludes and disclaims any liability for lost profits, personal

injury, interruption of service, or for consequential incidental or

special damages arising out of, resuiting from, or relating in any

manner to these goods

This Limited Warranty does not cover defects, damage, or nonconformity

resulting from abuse, misuse, neglect, lack of reasonable care, modification,

or the attachment of improper devices to the goods. This Limited Warranty

does not cover expendable items. This warranty is VOID when repairs are

performed by a nonauthorized service center or representative. For information about authorized service centers or representatives, write Customer

Repairs, Valco Instruments Company, Inc, P.O. Box 55603, Houston, Texas

77255, or phone (713) 688-9345. At Seller’s option, repairs or replacements will be made on site or at the factory. If repairs or replacements are

to be made at the factory, Buyer shall return the goods prepaid and bear all

the risks of loss until delivered to the factory. If Seller returns the goods,

they will be delivered prepaid and Seller will bear all risks of loss until

delivery to Buyer. Buyer and Seller agree that this Limited Warranty shall

be governed by and construed in accordance with the laws of the State of

Texas.

The warranties contained in this agreement are in lieu of all

other warranties expressed or implied, including the warranties

of merchantability and fitness for a particular purpose.

This Limited Warranty supercedes all prior proposals or representations oral

or written and constitutes the entire understanding regarding the warranties

made by Seller to Buyer. This Limited Warranty may not be expanded or

modified except in writing signed by the parties hereto.

Loading...

Loading...