Page 1

Valco Instruments Co. Inc.

Instrumentation

Temperature Controller

Instruction Manual

P. O. Box 55603, Houston, TX 77255

(713) 688-9345

•

Sales toll-free (800) 367-8424

Fax (713) 688-8106

MAN-ITC

Rev. 8/96

Printed in USA

Page 2

Table of Co ntents

1. GENERAL DE SCRIP TION. ...... .... .... ...... .... .... .... ...... .... .... ...... .... .... ...... .... .... ...1

1.1 Standard Features

1.11 Thermocouple Sensor

1.12 Proportional Heater Power Control

1.13 Power Attenuation

1.14 Zero Crossover Power Application

1.15 Digital Temperature Setting

1.16 Compact Rugged Construction and Functional Layout

1.2 Specific ations and Model Codes

1.3 Technical Description

1.31 Thermal System Overview

1.32 ITC Block Diagram by Function

1.321 Input Amplifier

1.322 Thumbwheel Switches and D/A Converter

1.323 Differential Comparator

1.324 Heater Power Switch

1.325 Thermocouple Break Detection

1.326 Proportional Power Control

1.327 Power Attenuation

1.33 Proportional Power Control

1.34 Power Attenuation

Pag e

2. OPERATION . .... .... .... .... .... .... .... .... .... .... .... .... .... .... .... .... .... .... .... .... .... .... .... .... .10

2.1 PHYSICAL LAYOUT OF THE ITC

2.2 Thermocouples

2.3 Setpoint (Set °C)

2.4 Propor tioning Bandwidth

2.41 Bandwidth Defined

2.5 Install ation

2.6 Troubleshooting and Schematic Di agram

2.61 Situation:

PWR ON indicator fails to illuminate; instrument does nothing.

2.62 Situation:

TCPL indicator ON continuously; no power applied to heater

2.63 Situation: No power being applied to heat er ; TCPL indicator OFF.

3. WARRANTY ............... .......... ........ ........ .......... ........ ........ .......... ........ ........ .....19

4. TECHNICAL DRAWINGS .................... .............. ................ .............. .............20

Page 3

1. INTRODUCTION AND GENERAL DESCR IPTION

The Instrumentation Temperature Controller (ITC) is an isothermal temperature

controller intended for broad spectrum usage in thermal systems common to

modern analytical instrumentation. The instrument is designed to be a flexible

building block with which the user can config ure a ther mal system to suit p art icular

requi rements. Althoug h the contr oller is only a si ngle elemen t in such a sys tem,

its flexibility and performance ultimately determine the stability, reproducibility, and

accuracy of the enti re syst em.

Inasmu ch as we do no t attempt to prese nt a por tfolio o f specif ic appli cations, t his

manual is m ore gener al th an sp ecif ic. Inst ead, we ar e att empti ng t o str ike a spar k

of in tuitive understa nding a nd intere st for how the ITC functio ns. Th e ITC’s function an d relat ionsh ip to therm al syst ems ar e the mos t valuable n otion s transm itte d

by this manual. Just as there i s no appl icati on manua l for vice- grip pliers, there i s

not an application manual for the ITC. Both are basic, extremely useful devices,

whose rea l worth is det ermined by th e use r.

1.1 Standard Feat ures

1.11 Thermo couple Sen sors

The ITC utilizes thermocouple sensors fabricated from ordinary thermocouple wire.

A variety of factor s lea d to th is b eing th e bes t choi ce of senso rs:

•

Sensor junctions of very low mass can be easily fabricated. Lower mass

means quicker recognition of temperature changes.

•

Thermocouples are inherently rugged, requiring little in the way of special

handling precautions.

•

Thermocouple wire is inexpensive and readily available.

In keeping with this choice of sensors, the instrument is appropriately equipped

with:

•

Automatic reference junction compensation.

references to 0°C, regardless of ambient temperature.

•

Thermocouple break detection.

power circuitry will be disabled, and a front panel indicator illuminat ed.

•

High impedance differential input circuitry.

instrument to tolerate floating or grounded thermocouples, with high

common-mode noise immunity.

The ea se o f fabr ic atio n for sens ors compa tible wit h th e IT C is suc h th at us ers can

seriously consider making their own. (In many cases, all that is needed is a small

torch, silver solder, and a roll of thermocouple wire.)

Should the ther mocouple break, the heater

Circuitry automatically

This circuitry allows the

1

Page 4

1.12 Proportional Heater Power Control

The ITC utiliz es propor ti onal power applic ation t o minimiz e temper ature overs hoot,

and improve temperature stability about the setpoint. Controls are accessible to

the user, allowing the proportioning bandwidth (in

o

C) to be adjusted to meet

specific requirements.

1.13 Power Attenuation

Many te mperatu re co ntroll ers a re used in con junct ion wit h vari acs (var iable o utput

transformers) in order to improve temperature stability. By reducing the maximum

power available to the heater, the user is adjusting the heater "size" to suit his

particular thermal system. This is a practical, flexible solution to the problem, but

requi res two devi ces to con trol the t emperatu re, one of whi ch is heavy, ineffi cient,

and expensive.

The ITC employs a pushbutton switch so the user can attenuate the total power

available to the heater circuit. Attenuation is selectable from 0 to 90%, in increments of 1 0% .

1.14 Zero Crossing Power Application

Power is applied to the load in increments of integral half cycles, only. This

technique drastically reduces RFI/EMI normally associated with high current AC

switching.

1.15 Digital Temp erature Setting

The ITC employs a bank of three digital thumbwheel switches for temperature

setpoint selection. The setpoint is selecta ble in 1

o

increments. The most obvious

advanta ge t o thi s s che m e is 10 0% se tt i ng r epe at abi l ity.

1.16 Compact Rugged Cons tructio n and Func tional Layout

The ITC’s physical characteristics are strictly utilitarian. In all cases, rugged

construction techniques are employed, insuring that the assembled instrument is

not delivered by a freight company in kit form. The instrument is housed in an

aluminum/cycolac enclosure measuring 2.4" x 8.3" x 5.9". The top of the enclosure c an b e qu ickl y r em oved, a l low ing ac ces s to al l f u ses, e lec tr on ic s, etc.

It is worthy of note that almost all electronic components are mounted on a single

printed circuit board. This feature directly translates to simple troubleshooting

methods and minimal spare parts inventory.

2

Page 5

1.2 Product Numb ers and Spe cifications

Produc t Nu mbe rs: ITC 10 X

X corresponding to

399 for 0°C to 399°C range

999 for 0°C to 999°C range

Example:

ITC103 99: ITC, 1000 watts m aximum he ate r power, 0°C to 399°C range

Sensor Requirem ent Thermocouple; Ty pe K

Range 0° to 390°C, or 0° to 999°C, as ordered

Absolute Accurac y

±

.5% of full scale

Repeatability .5°C at constant ambient

Sensit i ti vi ty to Am bi en t Ch an ge s . 05° C per ° C c ha nge

Operati n g A mbi en t 10° t o 5 0°C

Switched AC Power 1000 watts;

zero-crossing erro r: 5V AC max.

Proportioni ng Ba ndwi dt h

±

3

°C

Proportioni ng Freque nc y 2 Hz

Setpoint 1° C increments; push button selection

Max. Power Input Requirement 10.0 amps at 117 VAC

Power Attenu ati o n 0 to 90 % in 10% i ncr eme nt s

Physical Dimensions 2.4" x 8.3" x 5.9"; weight 1 lb. 14.4 oz.

Visual I ndi c at or s

•

Power On (PWR) - illuminated whenever the instrument is plugged

into a source of 120V AC, and the PWR switch is in the ON position

•

Heater On (HTR) - illuminated whenever the controller applies

power to the heater

•

Thermocouple Fault (TCPL) - illuminates whenever thermocouple sensor

opens. (If a sensor failure is detected, heater power is automatically

interrupted, and t he HTR i ndicator will remain O FF.)

3

Page 6

1.3 Techn ical Description

A general knowledge of the ITC’s organization and operation is helpful to its

successful implementation. To facilitate understanding, three questions are posed:

1. What position does the ITC occupy in a thermal system?

2. How is the ITC organized to accomplish its task?

3. What is the most important aspect of the ITC’s organization?

These ques t io ns ar e a nswere d by Se ct ion s 1 . 31, 1.3 2, and 1 . 33, re sp ect ive ly.

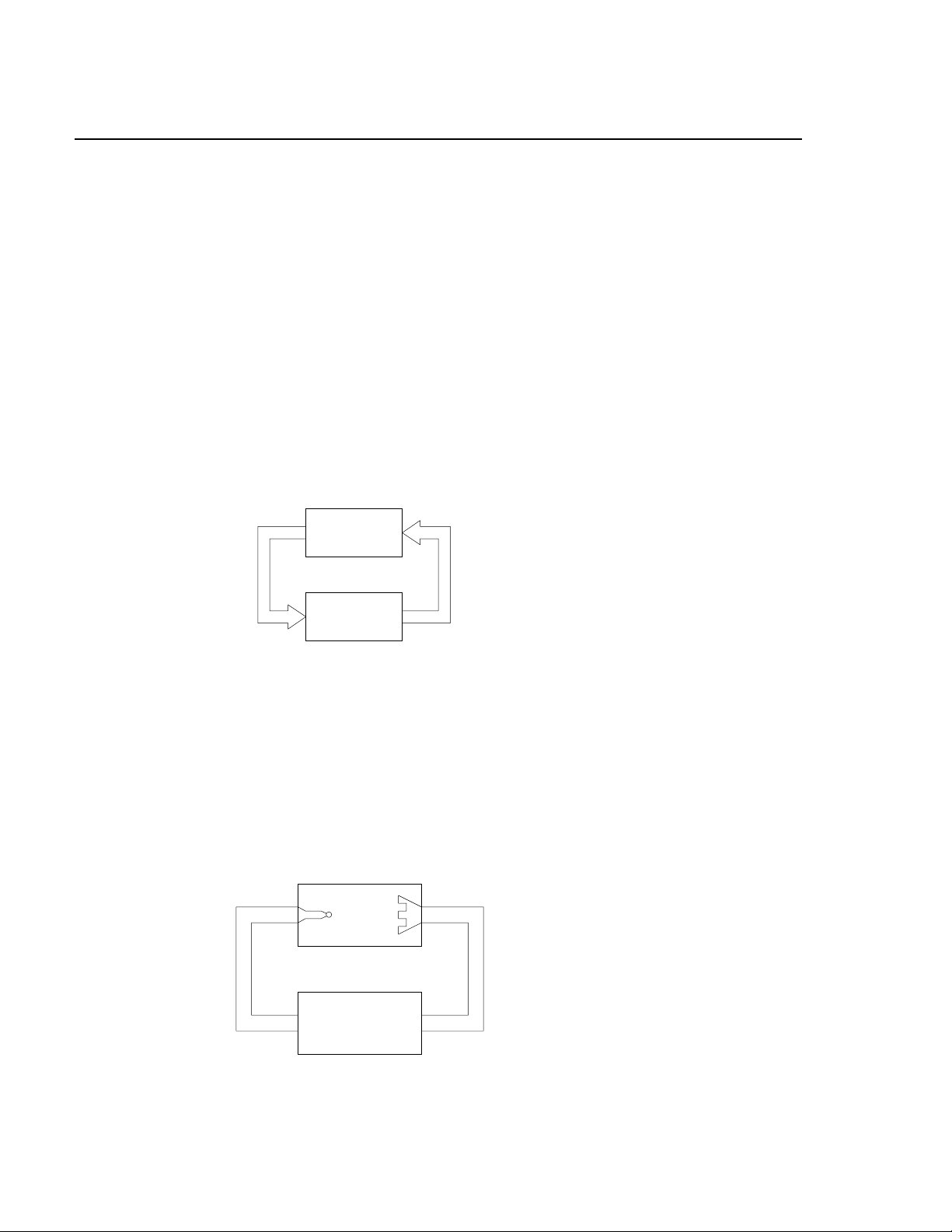

1.31 Thermal System Overview

Figure 1

depicts a generalized closed-loop control system. The system is termed

closed-loop since the controller bases its corrective actions on the actual status of

the controlled function. In an open-loop system, corrective actions are based on

anticipated stat us. Closed-loop syste ms are defi nitel y pre ferable.

CONTROLLED

FUNCTION

SENSOR

CONTROLLER

CORRECTION

ELEMENT

Figure 1

The system is compr ised of:

•

Controlled Fu nction .

•

Sensor.

•

Controller.

Appropriate to the function; level sensor, pressure transducer, etc.

Determines when corrective action is necessary, based on

Water level, air pressure, etc.

information supplied by the sens or.

•

Correction Element.

Means of adding water, increasing pressure, etc.

With slight modification, the diagram becomes appropriate to a thermal system

utili zing an ITC, as show n in

Figure 2

.

HEATED

ZONE

THERMOCOUPLE

INSTRUMENTATION

TEMPERATURE

CONTROLLER

(ITC)

HEATER

Figure 2

4

Page 7

It is readily seen that the ITC is responsible for maintaining the temperature within

the heated zone. However, proper selection and application of the thermocouple

and heater are essential if the ITC is to perform its function. (Refer to Section

2.2.)

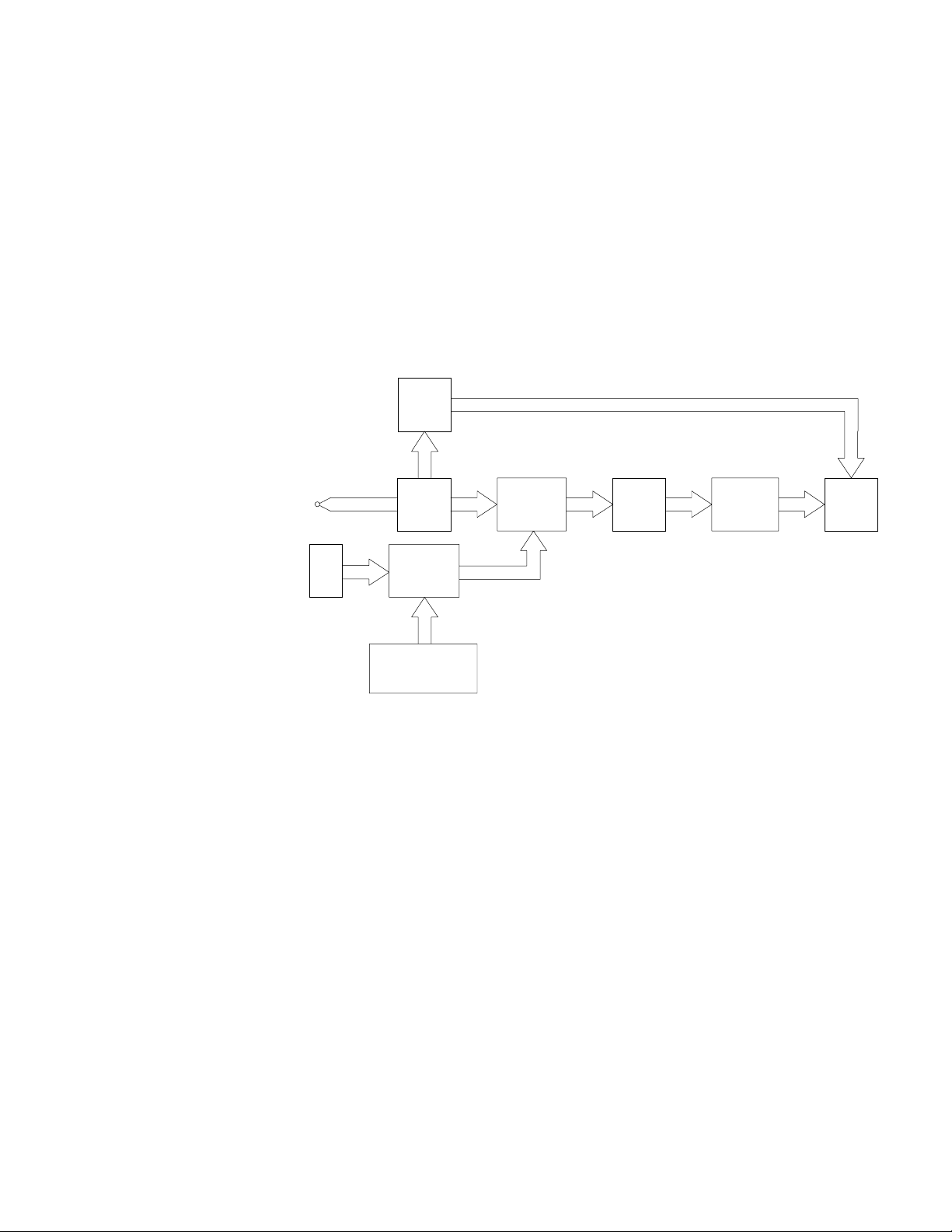

1.32 ITC Block Diagram by Function

Almost any electronic device can be described by a block diagram of its circuit

elements, each element performing something essential to the function of the

device. Indeed, such a diagram is typically the first state in its design. Further,

devices of simi lar fu nction wil l have simila r block diagrams.

TCPL

BREAK DE-

TECTION

SENSOR

SET POIN T

SELECT

INPUT

AMP

D/A

CONVERTER

DIFFER E NT I AL

COMPARATOR

ZERO

CROSSING

SWITCH

POWER

ATTE NUATOR

HEATER

POWER

SWITCH

Are these blocks supposed

to correlate to items in

PROPORTIONAL

POWER

CONTROL

1.321 and following? Nomenclature needs to be

consistent. RC

Figure 3

The function of the ITC is to control the temperature in a heated zone. A brief

discussion of what is required to perform the function reveals the elements

conta ine d i n i ts bl ock dia gra m,

Figure 3

.

1.321 Input Amplifier

The signal supplied by the thermocouple is too small to be recognized by the other

circ uit el ement s (appr ox. 50 microvolts /

o

C). Therefore, t he si gn al m ust b e amp l ifi e d

to a us ef ul level .

1.322 Set Point Selectors and D/A Convert er

The th umbwheel sw itches provi de a means of repre senting th e desired t emperature within the heated zone. (This temperature is hereafter referred to as the

setpoint

.) The switches prov ide a digit al repres entation o f the setpoi nt, which i s

then c onverted to a more useful s ignal by mea ns of a te n-bit D/A convert er. The

D/A converter conforms to the same transfer function as the input amplifier; i.e., a

representation of 100° C by the input amplifier is identical to the D/A converter’s

repres ent a ti on of 10 0

o

C.

5

Page 8

1.323 Differential Comparator

A dif ferential comparat or is u sed to co mpare the output o f the D/ A converte r with

that of the inp ut ampl ifier. Subsequent ly, the com parator ’s output den otes whe ther

the zo ne t emp era t ur e is hi gh er or l ower tha n the se t poin t .

1.324 Heater Power Switch

In accordance with the comparator’s decision, the power circuitry will apply power

to the hea ter wh en t he zone temper atur e is below t he s etpoi nt a nd int err upt power

when i t i s ab ove th e s etp oi nt .

In strictly theoretical terms, the above four elements are all that would be required

to imp leme nt th e contr olle r’s fun ction . However, prac tical appl ica tion r equi res three

additional elements:

1.325 Thermocouple Break Detection

The most common physical malfunction in thermocouples is a break, or open

circuit. If a break occurs, the input amplifier can no longer report the zone

temperature, and usually will report the ITC’s temperature, instead. From the

preced ing d isc ussi on, one can de duce t hat t his i s a pot enti all y disa stro us s ituat ion.

However, a separate circuit is employed specifically to detect a break condition. Its

output will cause the Heater Power Switch to be disabled, and a front panel

indicator to be illuminated whenever a break occurs.

1.326 Propor tional Power Control

To this point, power application to the heater has been described as simply

"appl ied or inte rrupted ". In rea lity, this would be anal ogous to tr ying to m aintain a

dragster’s speed at 30 mph using full throttle applications only. Obviously, power

must be delivered according to the need. For this reason, the ITC employ s proportional power control, where net power is delivered to the heater according to

the difference between the setpoint and zone temperature. The proportioning

technique is discu ssed in Se ction 1.33 .

1.327 Power Attenuation

Effective heater size can be tailored to the application by proper adjustment of the

power a ttenu atio n con tro l. Exce ssive h eat er rat ings ar e oft en t he ca use o f sys tem

instability at near ambient temperatures. Proportional control and power

attenuation work hand-in-hand to produce excellent temperature stability. (Refer to

Section 2.3.)

1.328 Zero Crossing Switch

This allows the he ater to come on only if t he AC wavefor m is at zero to supp ress

noise on th e p ower li ne.

1.33 Propor tional Power Control

Alth ough t he IT C’s inpu t amp lifi er a nd D/A ci rcui tr y are acc urate and predi cta ble in

their temperature representations, they do not in themselves constitute a good

temperature controller. In a control system, the essential factor is stability. A

temperature controller is not doing its job if the zone temperature is allowed to

oscil late about the setpoint to a degree which upsets the process. In shor t, the

aim is to reduce a thermal system’s natural tendency to oscillate to a level where it

is not significant.

6

Page 9

If zone heat er p ower i s sim ply appli ed o r int err upted acc ordi ng to t he c ompara tor’s

verdict (correction required/not required) the result is wholly unacceptable. To

illustrate:

Assume that a zone is to be heated from room ambient to 75

power is applied until the temperature r eaches 75

o

, and then interrupted, the

temperature will overshoot. As the temperature settles back to 75

o

C. If 100%

o

, 100%

power will again be appli ed in an effor t to prevent the temperature from falling

below the setpoint. As a result, the temperature will overshoot again. In this

manner, the temperature will continue to oscillate about the setpoint.

As can be seen, on/off, stop/go, etc. are corrective measures that would make the

ITC unacceptable for all but the crudest applications.

The key to obtaining acceptable stability lies in applying heater power relative to

the need. Using the above example, but employing proportional control, more

reason abl e r esu l ts ar e ob t aine d:

o

While the temperature rises from ambient toward 75

continuously, just as before. However, at a poi nt just

o

, the power is reduced to 95%. As the temperature continues to rise,

70

C, power is applied

the setpoint, say

below

power is linearly reduced such that power will be applied 50% of the time

when the temperature reaches the setpoint, and only 5% when it reaches

o

. When the temperature begins to settle, the process is reversed. Heater

80

power is gradually increased as the temperature declines toward the setpoint.

As a result, the temperature will tend to stabilize at a point where the power

application is sufficient to maintai n equilibrium.

In conclusi on, the syste m’s tendency to oscil late is greatl y reduced i f some form of

proportional control is employed.

Commonly, two methods can be used to electronically control AC power: phase

proportioning, and time proportioning. With phase proportioning, some percentage

of eac h AC cyc le is appl ied to the l oad. While this method is ju st fine for power

drills, it is not acceptable for instrument use. This is due to the fact that the power

is not switched at zero-crossings. Therefore, large amounts of RFI/EMI can be

generated. (If such elec trical "no ise" is generated, it may upset the operation of

other instruments in the vicinity.) With time proportioning, the average power is

contr oll ed by divi din g time int o sp ecif ied p eri ods. Duri ng ea ch pe rio d, t he pe rcent age of power ON versus OFF time is proportional to the difference between the

setpoint and the controlled temperature. Power is switched only at AC voltage

zero-c ros s ing s, avoidi ng RFI /E M I ge ne rati o n.

Figure 4

is a graphic represent ation of time pr oport ioning as it is implemen ted in

the IT C. T he hear t of the p rocess is the propo rti oning waveform. Thi s sawtoothshaped waveform defines three important parameters of operation: lower temperature boundary, setpoint, and upper temperature boundary. The setpoint will always

be situated in the exact center of the waveform. The

represents the point below which 100% power will be applied. The

ary

temperature boundary

plie d. And, as sta ted ear li er, the

represents the point above which no power will be ap-

setpoint

denotes the point at which power will be

lower temperature bound-

upper

applied 50% of the time. Observe, also, that between the two boundary temperatures, the average applied power is linearly proportional to the difference between

the s etp oi nt an d th e actu al t em per atu re wi th in th e h eat ed zon e.

7

Page 10

1

PROPORTIONING

WAVEFORM

POWER

APPLICATIONS

CONTROLLED TEMPERATURE RISING FROM AMBIENT;

1

NOTICE POWER APPLICATION IS PROGRESSIVELY REDUCED AS T HE TEMPERATURE

RISES

OVERSHOOT; NO POWER APPLIED

2

EQUILIBRIUM;CONTROLLED TEMPERATURE HAS SETTLED AT APPROX. 40% POWER

3

TIME

2

3

102°

98°

Figure 4

The number of degrees between the upper and lower temperature boundaries is

referred to as th e

proportioning bandwidth

. Proper adjustment of the bandwidth

will further enhance temperature stability within the heated zone. Some guidelines

for adjust ment ar e found in S ectio n 2.4 .

1.34 Power Attenuation

In the precedi ng sect ion, pr opor tion al power co ntrol was desc ribed as the pro cess

by which the ITC applies a percentage of power proportional to the difference

between the setpoint and the controlled temperature. It is not unusual that this

technique, alone, will not yield acceptable temperature stability. Commonly, this

situation occurs when near ambient temperatures are desired of a thermal system

orig inally de signed for h igher temp eratures. Cons equently, t he heater s ize (rated

output) is much too large for system demand.

In compensating for such difficulties, laboratory personnel often employ variacs

(variable output, s tep-down transformers) to attenuate the power delivered to the

heater.

Power delivere d to the heate r can be atte nuated in incr ements of 10% by setting

the ITC’s front panel mounted ATTN pushbutton switch. This control performs

exactly the same function as the variac mentioned above. However, the method

by which the ITC performs this function differs considerably from variac operation.

Here’s how :

A variac provides a means of adjusting the voltage (and consequently, the

power) applied to the heater. The ITC varies the number of half-cycles

to be delivered by its power circuitry. For example, 100% is available

able

avail -

when the ATTN control is set to 0. I f the attenuation is changed to 4 (40%),

only six of every ten half-cycles are available for delivery to the heater. As a

result, the heater output will be 60% of its full rating.

8

Page 11

In summary, the proportioning circuitry determines the percentage of time during

which power will be applied, while the attenuati on circuitry deter mines what percenta ge o f power is t o be avai l able fo r d el ivery during t his t ime.

9

Page 12

2.

In thi s sec t ion pr ac ti cal c on si der ati on s for th e IT C ’s usage a re di scu sse d.

OPERATION

2.1 Physical layout of the ITC

Following are illustrations of the var ious models of the Instrumentation Temperature

Controller.

the ITC.

models. The numbers on the illustrations relate to the numbered parts below.

Figure 5

Figures 7

shows the front panel, and

and 8 show the back panels of the 110V AC and 220V AC

1

2

34

Figure 6

56

shows the top v iew of

A

T

T

5999

OPEN

TCPL

PWR

1

Power Switch PWR

Front mounted toggle switch controlling power to heater and power supply

circuits.

2

Power On Indi cat or

Front mounted neon indicator; illuminated whenever the power switch is in

the ON position and power supply fuse is intact.

3

Heater Power On

Front mounted neon indicator; illuminated whenever instrument applies

power to heater; will not illuminate if heater is not connected, or if broken

thermocouple is detected.

4

Thermocou ple Fault In dicator

Front mounted LED indicator; lights whenever thermocouple circuit is

broken.

ON

Figure 5:

HTR

Front panel, model ITC10

N

S

E

T

C

°

5

Heater Power Attenuation Switch

Front panel mounted bidirectional ATTN switch; denotes heater power

attenuation in increments of 10 percent.

6

Setpoint Swi t ches

Front panel mounted switches; denote controlled temperature setpoint in

7

Calibr ation Adj ustment s

Printed circuit board mounted pots; DO NOT attempt adjustment.

10

o

C.

Page 13

10

8

9

7

7

Top view, model ITC10

8

Thermocouple Connector

Figure 6:

Printed circuit board mounted connector; connect red lead of ther mocouple

to Terminal R.

9

.5 Amp Fuse

Printed circuit board mounted; fuses power supply primary circuitr y.

10

10 Amp Fuse

Printed circuit board mounted; fuses heater power circuitry.

13 11

13

THERMOCOUPLE

Y R

Figure 7:

HEATER

POWER

Back panel, model ITC10 110V AC

120V AC

10A MAX

13 12 13

THERMOCOUPLE

Y R

Figure 8:

HEATER

POWER

Back panel, model ITC10 220V AC

220V AC

10A MAX

11

Page 14

11

Heater Receptacle, 120V AC only

Rear panel mounted AC receptacle; two-wire plus ground; connects heater

via standard 16 or 18 gauge three-wire power cord (not supplied).

12

Heater Receptacle, 220V AC only

Rear panel mounted AC receptacle; two-wire plus ground; connects heater

via power cord (black and white to heater, green to ground). Power cord is

not supplied.

13

Top Cover Reta ining Scr ews

Remove these screws to gain access to inter ior of ITC.

2.2 Thermoco uples

Thermocouples, when used properly, are a very expedient and reliable means of

sensin g t empera ture. In t his sect ion, we wi ll a ttemp t to h elp the use r avoid cer tai n

genera l and s pe ci f ic pit fal ls in t her m oc oup le u sag e wi t h t he IT C.

Ther mocoup le meas uri ng junc tions are fabr icate d by jo ining two di ssimi lar met als.

A type K thermocouple is formed from chromel and alumel. In theory, the thermocoupl e is func tio nal so l ong as th e t wo meta ls r emai n in c ont act. (Th is do es i mply

that a measuring junction can be formed by twisting two wires together. We would

point out that the junction will not be suitable for any real application, however.)

Maintaining the integrity of the measuring junction is of prime importance. This

means th at for a given appl icatio n, thought mu st be given the junc tion’s maxim um

attainable temperature, corrosion resistance to its environment, and mechanical

strength.

Commercially available thermocouples are usually joined by welding. This

produc es a juncti on in whi ch the max imum temperat ure and cor rosion resi stance

properties are those of the metals themselves. For applications below 400

quite serviceable junction can be formed by twisting the bare ends of the wire

toget her, and then sec uring wit h silver sold er. For applicat ions above 400

o

C, a

o

C, t he

junction should be welded. In the case of silver soldered junctions, we would

again point out that the environment and maximum temperature must not be

harmful to the solder.

It is important to note that considerations pertaining to junction integrity are also

applicable to the

insulation

around each wire. As sta ted earl ier, a new junctio n is

formed each time the two thermocouple wires come into contact. Obviously,

unplanned junctions are to be avoided.

In matters concerning the thermocouple, measuring junction mass, thermal

conduc tivity of the contr olled mediu m and placem ent can grea tly affect con trolled

tempe ratur e st abil ity. In Sect ion 1 .32 6, an examp le was give n ill ust rati ng te mperature instability. It was pointed out that stability is obtained by supplying heater

power proportional to the need. At this point, it is important to recall that the

thermocouple is responsible for telling the controller what the need is. Most

importantly, any change in temperature must be reported without appreciable

delay. This causes instability, regardless of how craftily the correction is carried

out. This notion of minimizing delay is carried to fact by observing two rules:

12

Page 15

1. The meas uring junct ion sh ould be o f the l owest ma ss pra cticabl e for the a pplication. Simply put, the higher the mass, the more time required for the junction to

reach t h e t emp era t ure of i ts s ur ro undi n gs.

2. The measuring junction should be placed as close as possible (thermally) to

the heater. Whenever there is doubt about proper location of a thermocouple,

follow these suggestions:

a. Place the junction directly between the heater and the object to be heated,

as close to the heater as possible.

b. In a stirred air or liquid bath, place the junction immediately downstream

from the heater.

In addi tion to the mo re commo n cons iderati ons, t here are a few impor tant speci fic

notions regarding thermocouples to be used with the ITC.

•

Electrical contact.

If the measuring junction is in electrical contact with an

object, that object must be connected to AC ground. For example, this would

require a heater block to be grounded unless the ther mocouple is electrically

insulated from it. (The junction must float or be grounded.)

•

Thermocouple resistance.

The following data describes the thermocouples

normally shipped with the ITC:

ITC-K: 10 ft., 28 gauge, 40 ohm , ANSI Type K

2.3 Setpoint (Set °C)

Loosely defined, the setpoint denotes the desired temperature within the heated

zone. However, the user should be aware that the denoted setpoint is not necessarily the temperature at which the zone will stabilize.

To be more precis e, the setp oint denote s the tempera ture at whic h power will b e

applied 50% of the time. It is entirely possible that the zone will require more or

less t han 50% power to ma intain s tabilit y. As a cons equence, t he zone te mperature will settle above the setpoint if less than 50% power is required, and below

the s etp oi nt if mor e th an 50% powe r i s ne eded .

Essentially, this characteristic offset is brought about by the proportional power

control method used in the ITC, coupled with the thermal characteristics of the

user configured heated zone. Without prior knowledge of the zone’s heat input vs.

heat l oss proper ties, the only certainty is that the zone temperature will stabilize

somewhere

settl es, can be op timized by adjustment of the propo rtion ing bandwidt h. (Refer to

Section 2.4.)

within the proportioning bandwidth. Exactly

the temperature

where

13

Page 16

2.4 Propor tioni ng Ban dwidth

Current models of the ITC may have fi xed valued resistors in the trim

Note:

pot location for the bandwidth calibration. If the ITC needs fur ther calibration

they may be replaced with 10K trim pot and the following text will explain the

band width adjustments.

Given that the controlled temperature is reasonably accurate, stability becomes a

most important measure of system performance. Perfect stability is obtained by

applying the exact amount of power required to offset a system’s demand. In

addition, the power must be applied

Think about thi s. Theor etical n otions l ike "exact" and "ins tantaneo us" soon reveal

the me ani ng of t he term, "opti mum".

In attempting to achieve optimum stability, we assume that the user will experiment

with t h e proport ion i ng ban dw id th ad jus tme nt po t . (Refer to Sec t ion 2. 1, i tem 7 . ) In

keeping with this assumption, we offer the following explanation of bandwidth

adjustment.

2.41 Bandwidth Defined

Rigorously defined, bandwidth is the peak to peak value of the proportioning waveform, expres sed in degre es centigrade. The ba ndwidth pot con trols the heig ht of

the wavefor m. More impor tantl y, t he heigh t deter mines the slope of the diagon al.

In

Figure 9

6° bandwidth. In each case, the controlled temperature is depicted 1 below the

peak height of the waveform. Notice that the resulting power applications are

differen t. In fact, power is applied twice as l ong in the 3° example as in the 6°

example. This is due to the slope of the diagonal, and, as we shall see, is a very

usefu l t hi ng t o re memb er.

, two waveforms are shown: one with 3° bandwidth, and the other with

instantaneously whenever a d emand occ urs.

The important thing to notice in

changes within the bandwidth, the resulting change in heater power is dependent

on the slope of the diagonal. More specifically, the

power is controlled by the slope of the diagonal.

If, in each case, the temperature falls 1° (1° excursion), the resulting changes in

applied power are dramatically different. In the 3° example, ap plication ch anges

from 33- 1/3% to 66- 2/3%. The same 1 excursion in a 6° bandwidth causes

application to change from 16- 2/3% to 33- 1/3% per degree and 16- 2/3% per

degree, respectively. By observation, increasing the bandwidth decreases the

amount of ch an ge i n averag e ap pl i ed pow er for a g iven cha ng e in t em per atu re.

How does all this relate to stability improvement? Well, assuming that a stability

problem ex ist s, it may be attr ibutabl e to excessi ve heater power. By this, we mea n

that the heater is simply too powerful for the application. The situation usually

results from designing the system to heat quickly and operate over a broad

tempe rature range. The pr oblem is chara cterized by the contro lled temper ature’s

tendency to spend most of the time above the bandwidth, occasionally falling into

its upper reaches. The temperature will not stay within the bandwidth because

14

Figure 9

is that as the controlled temperature

rate of change

in applied

Page 17

POWER AP PLI CATIONS

3

°

TIME

6

°

CONTROLLED TEMP

1° EXCURSION

POWER AP PLI CATIONS

CONTROLLED TEMP

1° EXCURSION

CONTROLLED TEMP

EXCURSION TEMP

Figure 9

power is i nc rease d too ab rupt ly, quickly dr ivi ng th e temper ature up, out of re ach. If

the heater size cannot be reduced, the bandwidth must be increased. Doing so

will decrease the rate of change in applied power, hopefully increasing stability.

Always allow ten to fifteen minutes after making each adjustment before making

another. This will allow the system enough time to reveal whether or not further

adjustment is required.

As a consequence of increasing the bandwidth, the user should be aware that the

controlled temperature is usually shifted upward, as well. This notion is most easily understood by noting the position of the 1% power point before and after adjustment. Remember that the system will still require the same average power to

maint ain a given temp erat ure. There fore, as t he bandwi dth is i ncre ased, the given

power point shifts upward, carrying with it, the controlled temperature.

Note that the controlled temperature shifts upward only if it was originally trying to

stabilize above the setpoint (50% power point). There usually is no stability

problem when the temperature is settling below the setpoint. However, we will

point out that in this situation, the temperature will shift downward when bandwidth

is increased.

The valu e of th e ba ndwi dt h ( i n ° C) ca n be de termined by t h e fol low ing met h od:

1. Reduce the setpoint temperature until the HTR indicator is OFF continuously. Make note of this temperature.

2. Increase the setpoint until t he HTR indicator is ON continuously. Make note

of this temperature.

3. Determine the difference between the two temperatures. This value is the

bandwidth.

15

Page 18

2.5 Installation

The following discussion is intended to assist you in the initial installation of an

ITC. It is assumed that you have read the foregoing portions of this manual.

Check the instrument for shipping damages. Open the instrument and check for

loose components. There shouldn’t be any. In the event that damage is noted,

notif y th e carr ier imme diate ly. Valco a ssumes no r espo nsib ilit y for dam age in cur red

in shipment.

Assuming no damage is seen, perform the following checkout. You will need an

ordinary incandescent light or other resistive load that provides indication of when

power is applied.

1. Connect the load to the ITC. In 110V models, a receptacle (labeled P1) is

provided which accepts ordinary three-wire appliance plugs. The 220V uses a

cinch socket.

2. Connect t h e in st r ume nt t o a su it abl e s our ce of 12 0V AC.

3. Set the set poin t and at tenuati on switc hes to 0 . Swi tch th e instr ument o n. The

TCPL indicator should illuminate momentarily. (The instrument is determining

whether or not its thermocouple is OK.) The HTR indicator should be OFF.

4. After allowing the instrument to warm up for a few minutes, increase the

setpoint until the HTR indicator flashed with a 50/50 duty cycle. The setpoint

shoul d a ppr oxima te t he am b ien t temp era t ur e.

5. Hold the thermocouple’s measuring junction firmly in one hand. Since your

skin temperature is usually 10° above ambient (and subsequently, the setpoint),

the HT R i ndi c at or sho ul d c eas e f l as hing .

6. Increase the setpoint until the HTR indicator is ON continuously. (Try 50°.)

Change the power attenuation switch to 9. The HTR indicator should flicker faintly.

Progressively decrease the ATTN setting, noting that the HTR indicator "brightness" increases at each position. When the ATTN switch is at zero, the HTR indicator should be ON continuously, with no visible flickering.

Regarding the zone heater specifications, care should be taken to avoid exceeding

the ITC’s specifications for switched power. The ITC10 will switch loads up to

1000 watts. If you attempt to exceed this rating, the instrument will probably sacrifice its f uses and/or p ower tr iac.

The present ITC power circuitry is intended to switch resistive loads only. This

means that inductive loads, such as electric motors, solenoids, and especially

variacs cannot be switched successfully.

Damage may result if inductive loads are used.

Always use three-wire power connections for the instrument, as well as heater

connection. (Ref. Section 2.2.) It is important that the heater block, etc. be

16

Page 19

connec t ed t o AC gr ou nd . Failure t o d o so may c aus e a s ho ck haz ar d, or co ntr ol le r

malfu nctio n, or bo th.

Locate the ITC where it will not be subjected to abrupt changes in ambient

tempe ratu re. This w i ll im pr ove the c ont r ol led t emp era tur e s tab i lit y.

When installing the thermocouple, be sure to observe electrical restrictions noted

in Sect ion 2.2 .

Actual installation consists of, first, thinking about what must be done, then

connec ting the heater, and finally inserting the ther mocouple. After this is done,

turn it ON and play with the system. Notice whether or not corrections need to be

made in such areas as thermocouple location, bandwidth adjustment, etc. Enjoy!

(If you’re not enjoying yourself, cal l us. We’ll try t o help in any way we can.)

2.6 Troubleshooting and Schematic Diagram

Troubleshooting the ITC is straightforward, in most cases. The device can be

though t of as being di vided in to two sections ; ins trumenta tion an d power cir cuitr y.

Problems with the power circuitry are the most easily identified, and can be

handled with a minimum of electronics experience. Isolation and repair of malfuncti ons in th e instrum entation circuitr y require sophistic ated test equipment an d

extensi ve el ec t ron ic s expertise. For this r eas on, i t i s rec omm e nded t hat th e fa ctory

be con sul te d w he n t he foll owi ng pr oc edur es ar e of no he l p.

2.61 Situation: PWR ON indicator fails to illuminate; instrument does

nothing.

A 1/2 amp fu se i s em ployed t o fuse th e ins trum ent’s DC p ower s uppl y. If this fus e

is blown, the PWR ON indicator will not illuminate, and the instrument will not

perfor m any fun cti ons. The f use is l ocate d at the le ft re ar c or ner of t he en clos ure.

(Refer to

fact ory.

2.62 Situat ion : TCPL ind icat or ON con ti nuously; no p ower appl ied to

heater

When t he TC PL in dica tor is O N con tinuo usly, the in str ument thi nks an ope n cir cui t

has developed in the thermocouple. As a consequence, the ITC will refuse to

apply power to the heat er. The t hermo couple is co nnected t o the i nstru ment by a

barrier strip, designated B1. (Refer to

tions are snug. As a second consideration, be cer tain that proper connection to

AC ground is made in any case where the thermocouple measuring junction

contacts metal. If this is not done, the TCPL circuit can sometimes be fooled into

beli eving there is a malf unction. As a fin al considera tion, dis connect the th ermocoupl e, and check i t for elect rical c ontinui ty. If the problem is not locat ed, consul t

the fact ory.

Figure 6

, Item 10.) If the ITC persists in blowing this fuse, consult the

Figure 6

, Ite m 9.) Be cer t ai n t he se co nnec -

17

Page 20

2.63 Situation: No power being applied to heater; TCPL indicator OFF.

In this situation, the HTR indicator remains OFF. The power triac is protected

against continuous current overload with a 10 amp fuse. (Refer to

11.) If this fuse is blown, no power is available to the heater circuitry. In addition

to replacing a blown fuse, consider what may have caused the overload. The

heater and/or power triac may have developed a short circuit. This sort of occurrence i s us ual ly acc ompan ied by bu rn ed wi rin g. Be cer ta in tha t the heate r doe sn’ t

exceed the power rating for the ITC (1000 watts).

It is the case that the situation described above can occur without blowing the

fuse. If this occurs, consid er whet her or not the load i s induct ive. Rememb er that

such loads cannot be switched with the ITC’s present circuitry.

The appropriate schematic diagram is supplied in this section. Should you require

any explan at io n o f th e c ir cui try, p l ea se con tac t the fac tory.

Figure 6

, Item

18

Page 21

3.

WARRANTY

This L imited Warran ty gives the Bu yer speci fic legal rights, and a Buyer may a lso

have othe r r i gh ts t h at var y form state t o s ta t e.

For a period of 365 calendar days from the date of shipment, Valco Instruments

Company, Inc. (hereinafter Seller) warrants the goods to be free from defect in

mater ial and w orkmanshi p to the o riginal purchaser. During the warrant y period,

Seller agrees to repair of replace defective and/or nonconfor ming goods or parts

without charge for material or labor OR at seller’s option demand return of the

goods and tender repayment of the price. Buyer’s exclusive remedy is repair or

replacement of defective and nonconforming goods OR at Seller’s option repayment o f t he p r ic e.

SELLER EXCLUDES AND DISCLAIMS ANY LIABILITY FOR LOST PROFITS,

PERSONAL INJURY, INTERRUPTION OF SERVICE, OR FOR CONSEQUENTIAL INCIDENTAL OR SPECIAL DAMAGES ARISING OUT OF, RESULTING

FROM, OR RELATING I N ANY MANNER TO THESE GOODS.

The Limited Warranty dose not cover defects, damage or nonconformity resulting

from abuse, misuse, neglect, lack of reasonable care, modification or the attachment of improper devices to the goods. This Limited Warranty does not cover

expendabl e items. This warr anty is VOID w hen repai rs are perfor med by a non author ized ser vice cent er or rep resentati ve. If you have any problem loc ating an

authorized service center or representative, please call or write Customer Repairs,

(713) 688-9345, Valco Instruments Company, Inc., P.O. Box 55603, Houston, Texas

77255. At Seller’s option, repairs or replacements will be made on site or at the

factor y. If repairs or re plac ement s are t o be made at the fact or y, Buyer s hall r etur n

the goods prepaid and bear all the risks of loss until delivered to the factory. If

Seller returns the goods, they will be delivered prepaid and Seller will bear all risks

of loss until delivery to Buyer. Buyer and Seller agree that this Limited Warranty

shall be governed by and construed in accordance with the laws of the State of

Texas.

THE WARRANTIES CONTAINED IN THIS AGREEMENT ARE IN LIEU OF ALL

OTHER WARRANTIES EXPRESSED OR IMPLIED, INCLUDING THE WARRANTIES OF MERCHAN TABILITY AND FITNESS FOR A PARTICULAR PUR POSE.

This Limited Warranty supercedes all prior proposals or representations oral or

written and constitutes the entire understanding regarding the warranties made by

the Seller to Buyer. This Limited Warranty may not be expanded or modified

except i n wr it in g s ign ed by t he p arties h ere t o.

19

Page 22

4.

Assembly Drawing..... .............. .............. .............. .............. ............ ....... Drawing 21556 Page 21

Assembly Broad Drawing ............ .............. .............. .............. .............. . Drawing 22218 Page 22

Schematic – ITC Board ............. .............. .............. ............ .............. ..... Drawing 22219 Page 23

Board Conversion.... ............ .............. .............. .............. ............ ........... Drawing 21647 Page 24

TECHNICAL DRAWINGS

20

Page 23

110V VERSION

4

3

(ON BOTTOM)

1A

220V VERSION ONLY

*

3

4

9

18

4

7

8

13

*

17

(FROM BOTTOM

12

OF ENCLOSURE)

16

5

15

BLACK

GREEN

14

GREEN

WHITE

BLACK

WHITE

9

(GREEN/YELLOW 220V)

(BLUE 220V)

(BROWN 220V)

1

Valco Instruments Co., Inc.

INSTRUMENTATION TEMPERATURE CONTROLLER

PWR

ON HTR

11

LTR DESCRIPTION

A

ITC BD. ASSY. REV. M,N

B

19

2

4

YELLOW RED

34

OPEN

TCPL

6

-

A

T

T

0

N

+

10

+

++

993

---

S

E

T

C

18

20

Instrumentation

Temperature Controller

Instruction Manual

Valco Instruments Co. Inc.

18

SEE NOTE 2

NOTE: FOR 220V MODEL.

*

ITEM

1

2 PCB ASSY: ITC 10 AMP

3

4

5

6

7

*

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

REF

*

REMOVE ITEM 13 AND DRILL MOUNTING HOLES USING DRILL TEMPLATE A-21819.

INSTALL CINCH SOCKET #S304-AB WITH COVER PLATE ITEM 20 (A-21820).

WIRE SCHEDULE

WIRE (PCB)

TERMINAL (SOCKET)

BLACK (HOT)

WHITE (NEUT.)

GREEN (GND)

MODIFY PCB PER DRAWING A-21647

INCLUDE I-T304PCCT PLUG

ENCLOSURE C-21527 REV. G

C

ECN #2050 CLARIFY DWG

D

ECN #4668 CLARIFY 220V VERSION

ENCLOSURE: ITC, 10 AMP.

STANDOFF: 4-40*1/4, THREADED, NYLON

SCREW,PLMS: 4-40*1/4 lg,PANHD,PH,SS

STANDOFF: 4-40*1/4 SWAGE THREADED

SWITCH ASSY: ITC TEMP.CTRL. (399 DEG.C)

POWER-CORD: GREY 6' 18/3 SVT

STRAIN-RELIEF: SRR-10, HEYCO#: 5P-4 1147

LUG: FEMALE SLIP-ON, 16-14 AWG

THERMOCOUPLE-ASSY: 10'2 (ITC) K TYP

FEET: RUBBER STICK-ON

NUT, HEX: #4-40 UNC, STAINLESS

RECEPTACLE: POWER OUTLET BLACK

WIRE: 14 AWG TEFLON BLACK CSA SPEC

WIRE: 14 AWG TEFLON GREEN CSA SPEC

WIRE: 14 AWG TEFLON WHITE CSA SPEC

TUBING: HEAT SHRINK 1/4" ID.

SCREW,SMS : #4*3/8 LG, PL, SS

TAG: SERIAL, ALL ELEC. DEVICES

MANUAL: OPERATION, ITC

PLATE, ADAPTER 220V ITC PLUG

SCREW,PLMS: 6-32 X 3/8 LG

NUT, KEP: #6-32

PLUG: 4 PIN CABLE

SOCKET-MOUNT: 4 PIN PANEL

POWER CORD: "SCHUKO" PLUG

DESCRIPTION

1

2

3

REVISIONS

PARTS LIST

POWER CORD 220V

I-W-17800

BRN

HOT

BLU

NEUT

YEL/GRNGND

23

25

4

ENCLOSURE

DATE APPROVED

20FEB89

22FEB89

8AUG94

22MAR99

VALCO #

I-21527

I-22218

HWSO-4050

HWSC-PL4-4

HWSO-1650-2

I-21280-02

I-W-CS-21

HWSRR-10

HWLUG-4218B

I-21014-01

HW-1658

HWNUT-HEX#4

HW-OUTLET

I-W-14-BLACK

I-W-14-GREEN

I-W-14-WHITE

I-STUBE.250

HWSC-SM4-6

I-21988

MANUAL:ITC

I-21820

HWSC-PL6-6

HWNUT-KEP#6

I-T304PCCT

I-T304SAB

I-W-17800

J DURR

J DURR

QTY

.333

.333

.333

.125

1

1

3

9

3

1

1

1

6

1

4

1

1

4"

4"

4"

6

1

1

1

2

2

1

1

1

24

21

21

I

N

V

S

a

T

lc

R

o

In

U

M

s

tr

E

u

N

m

T

e

n

A

t

s

T

C

IO

o

N

.

, In

T

c

E

.

M

P

E

R

A

T

U

R

E

C

O

N

T

R

O

L

L

E

R

NOTE 2

ADJUST HEIGHT OF COVER

BY TURNING SCREW

1B

22

FINAL ASSY

THIS DOCUMENT AND THE INFORMATION WHICH IT CONTAINS SHALL NOT BE USED, EXPLOITED

OR SOLD, AND SHALL NOT BE REVEALED OR DISCLOSED TO OTHERS WITHOUT THE EXPRESSED

WRITTEN PERMISSION OF VALCO. THIS DOCUMENT SHALL REMAIN THE PROPERTY OF VALCO

AND SHALL BE RETURNED UPON DEMAND.

TOLERANCES UNLESS

OTHERWISE SPECIFIED

FRACTIONS DEC. ANGLES

1/64"

APPROVED

DRAWN

R.B.D. / M.C.

DESIGNED

CHECKED

FILE NAME

21556

.XX.01

.XXX.005

63

.X.1

1

ITC ASSY. 10 AMP

DATE

2/20/94

REV. M,N,P

2/20/89

SUB-DIR

\ITC\

USA PROJECTION

1

432

Valco Instruments Co., Inc.

ITC10399-220

SIZE DRAWING NO.SCALE

C

ITC10399

21556---

SHEET

OF

Page 24

22

*

*

*

ITEM

PCB

T1

F1

F2

TP1-10

CO1

CO2

C03,4

CO5,6

Z1

Z2-4

Z5

Z6

Z7

S1,5

S2-4

S6

S7

TR1

C1,2

C3,4,14

C5,6,8-10,

15,16

C7

C11

C12,13

RN1

RN2,3

Q1

Q2,3

SW1

L1,2

L3

BR1

VR1

VR2

D1

R1

R2

R3

R4

R5,7

R6

R8A

R8B

R9,R10

R11

R12

MT1-6

SC1-6

KN1-6

FC1-4

R13-14

PCB ASSY: ITC 10 AMP

TRANSFORMER 115/230V DSC4-24

FUSE: 10AMP 3AG

FUSE: 3AG SLO BLO 1/2 AMP (TYPE 313.5)

TERMINAL: HOLLOW USECO

CONN: 20 PIN HEADER, ANSLEY

CONN: 2 POSITION BLOCK

CONN: 2 PIN MOLEX

CONN: DIALIGHT

IC: K TYPE THERMOCOUPLE CONDITIONER

IC: COMPARATOR ( DUAL )

IC: DUAL TYPE D FLIP-FLOP

IC: DECIMAL CTR/DIVIDER. RCA OR MOT

IC: OPTO-TRIAC MOC3011

SOCKET: DIP, 14 PIN LOW PROFILE

SOCKET: DIP, 8 PIN, LOW PROFILE

SOCKET: DIP, 16 PIN, LOW PROFILE

SOCKET: DIP, 6 PIN, LOW PROFILE

TRIAC: T0220, 400V 15AMP

CAP: ELECT, 220uF 35V, AXIAL LEAD

CAP: TANTAL, 4.7MF 35V

CAP: CERAMIC, .022uF 50V, .250 LEADS

CAP: CERAMIC, 27 PF 50V

CAP: MONO CERAMIC, .22 uF 50V, .2"LEADS

CAP: TANTAL, 1MF 35V

RES NET: 10 K, 16 PIN DIP, DISCRETE

RES NET: 100 K, 16 PIN DIP, DISCRETE

TRANSISTOR: NPN, T093, DARLINGTON

TRANSISTOR: PNP, TO93, DARLINGTON

SWITCH: TOGGLE DPDT-RPC-N-P-S

LAMP: NEON, RED (9001-52-C-03-2RN)

LED: RED, WITH MOUNT (9001-52-C-03-2RN)

RECTIFIER BRIDGE

IC: VOLTAGE REGULATOR, -12V TO220

IC: VOLTAGE REGULATOR, 12V, TO220

DIODE: SILICON SIGNAL

RES: 100, 5%, 1/2W

RES: 1.27 K, 1%, 1/4W

RES: 2.2 MEG, 5%, 1/4W

RES: 10, 1%, 1/4W

RES: 10 K, 5%, 1/4W

RES: 953, 1%, 1/4W

RES: 10.0 K, 1%, 1/4W

RES: 715, 1%, 1/4W

POT: 10 K, TRIM, SHORT CT9W

RES: 100 K, 5%, 1/4W

RES: 1 K, 5%, 1/4W

MALE TABS

SCREW,PLMS: 6-32 X 1/4 LG, SS

NUT, KEP: #6-32 UNC

FUSE CLIP: PCB MOUNT (102080)

FOR 110V MODELS-WIRE:BUSS, UNINSULATED,.025 DIA,22 AWG

FOR 220V MODLES - RES, 237 K, 1%, 1/4W

DESCRIPTION

* R6,R8A,R8B MAY BE SUBSTITUTED BY TRIM POTS.

VALCO #

I-PCB22217

I-X-DSC4-24

HWFUSE-10A

HWFUSE-.5A

HW-2010B

I-T6092027

I-T4888-6

I-T09641021

I-TCM21-3

I-ICAD595AQ

I-ICLM358

I-IC4013

I-IC4017

I-IC3011

I-TDS-14-LP

I-TDS-8-LP

I-TDS-16-LP

I-TDS-6-LP

I-Q4015L5

I-CE227-35AL

I-CT475-35

I-CC223-50

I-CC270-50

I-CC224-50

I-CT105-35

I-RN761-3-10K

I-RN761-3-100K

I-QMPSA13

I-QMPSA65

I-SW-MTM206

I-LAMP-R

I-LED550-01

I-D-VE28

I-IC7912

I-IC7812

I-D1N914

I-R521000

I-R111271

I-R512204

I-R1110R0

I-R511002

I-R119530

I-R111002

I-R117150

I-RTP103

I-R511003

I-R511001

HW-607

HWSC-PL6-4

HWNUT-KEP#6

HWFUSECLIP-1

I-W-BUSS-1

I-R112373

1 EA

1 EA

1 EA

1 EA

10 EA

1 EA

1 EA

2 EA

2 EA

1 EA

3 EA

1 EA

1 EA

1 EA

2 EA

3 EA

1 EA

1 EA

1 EA

2 EA

3 EA

7 EA

1 EA

1 EA

2 EA

1 EA

2 EA

1 EA

2 EA

1 EA

2 EA

1 EA

1 EA

1 EA

1 EA

1 EA

1 EA

1 EA

1 EA

1 EA

2 EA

1 EA

1 EA

1 EA

2 EA

1 EA

1 EA

6 EA

6 EA

6 EA

4 EA

.75" EA

QTY

2 EA

NOTE: INSTALL TR1 AS SHOWN

.15

.35

.35"

FC1

FC3

MT3

SC3

KN3

F1

F2

MT4

SC4

KN4

MT5

SC5

KN5

MT6

SC6

KN6

CO3

CO5 CO6

SW 1

LTR

A

B

C

TR1

MT1

MT2

SC1

SC2

N1

KN2

FC2

FC4

Z7

S7

+

+

CO4

R13 R14

L1

L2

INSTALL JUMPERS FOR R13 & R14 (110V MODELS)

INSTALL R13 & R14 ON 220V MODELS

REFER TO DWG 21647

NEXT ASSY

21556

REVISIONS

SHEET

INITIATED

J DURR

I-22218

J DURR

REPLACE R9A,R9B FOR TRIM POT 10K (R9)

DESCRIPTION

ECN #1805 UPDATE PER REV. P BOARDS

ECN #2145 CHG R2 TO 1.27K WAS 2.2K

Z5

S5

THIS DOCUMENT AND THE INFORMATION WHICH IT CONTAINS SHALL NOT BE USED, EXPLOITED

OR SOLD, AND SHALL NOT BE REVEALED OR DISCLOSED TO OTHERS WITHOUT THE EXPRESSED

WRITTEN PERMISSION OF VALCO. THIS DOCUMENT SHALL REMAIN THE PROPERTY OF VALCO

AND SHALL BE RETURNED UPON DEMAND.

TOLERANCES UNLESS

OTHERWISE SPECIFIED

FRACTIONS DEC. ANGLES

.X.1

1/64"

.XX.01

.XXX.005

APPROVED

DRAWN

M.CHIU 1/11/89

DESIGNED

CHECKED

FILE NAME SUB-DIR

22218 \ITC\

DATE

Z1

TP10

S1

Z2

S2

C12

C14

+

+

+

C13

R

8

B

Z4

S4

A

R9

Z6

R10

S6

63

1

PCB ASSY: ITC

REV M,N,P

DO NOT SCALE DRAWING

SCALE

USA PROJECTION

Z3

S3

C

1

6

R

N

3

Valco Instruments Co., Inc.

SIZE DRAWING NO.

B

DATE

2/28/89

4/5/94

22SEP94

REV P BOARDS ONLY

DRILL FEEDTHRUS

OUT AT THIS

LOCATION.

JUMPER LAND ON

BOTTOM OF BOARD

TO BRIDGE HOLE.

22218---

OF

Page 25

CO2

R

Y

+12V

C9

.022uf

953

FRONT END

R6

BANDWIDTH ADJ.

98

11

-12V

RN3 100K

3

+

Z3

1

2

358

6

/

-

2

RN2

100K

8

+

C14

4.7uf

-12V

RN2

100K

10

1

9

RN3

100K

10

R12 1K

RN3

100K

7

+12V

.022uf

C8

R7 10K

-12V

C10

.022uf

TCPL TEMP.

- 100V

TP1

Z1

R5 10K

13

14

-ALM

-IN

7

+IN

-V

1

2

5

AD

6

3

595

10

4

COUNT

8

11

FB

+V

9

12

V0

+ALM

THERMOCOUPLE FAULT

L3

16 1

RN1

Q3

10K

A65

215

Q2

RN1

10K

A65

Q1

A13

+12V

R2 2.2K

Z7

R1

1

MOC

2

3011

3

100

4

5

6

VOLT. READING

+5V

-5V

TP2

REF.

RN3

100K

.22uf

C11

6

2

5

1

73

4

16 1

215

3

COMPARE

RN2

100K

13

RN2

100K

1

100K

6

-

8

Z3

1

/

358

+

4

5

-12V

-12V

RN3

2

+12V

RN2

100K

15

6

1

/

Z2

+

5

+

C12

1MF

16

7

7

+

C13

1MF

-12V

6

11

R8A

RN2

10K

100K

R8B

715

-12V

RN3

100K

14

(NOT INSTALLED)

10

8

9

4

LTR DESCRIPTION DATE

A REPLACE R9A,B FOR TRIM POT 10K(R9) 3/1/89

ECN #2050 UPDATE DRAFTING STANDARDSB 4AUG94

ECN #3334 CORRECT SCHEMATICC

2

2

358

7

14

3

RN2

100K

TP4

TP5

10.00V DC

REFERENCE

VOLTAGE

+12V

R10 10K

REVISIONS

7AUG96

R3

2.2Meg

+12V

R4

10

3

2

27pF

-

Z2

1

/

+

-12V

TP3

8

2

358

4

C7

HEAT

1

D1

1N914

18

19

20

J DURR

J DURR

FRONT PANEL

CONTROLS

TEMPERATURE

SELECTOR

10K

INITIATED

23

.022uf

C15

RN3

100K

413

+12V

-

8

Z4

1

2

358

220V

+

/

1

+

324

VR2

7812

+

C2

C6

.022uF

VR1

.022uF

7912

C5

C1

220V

R11

100K

+-

BR1

ZERO CROSSING

100K

RN3

125

+12V

10K

TP9

+12V

+

C4

4.7MF

TP8

C3

+

4.7MF

9

R

6

-

Z4

1

2

358

/

+

5

T1 DSC4-24

5

6

7

8

-12V

7

1

2

3

4

TP6

7.21V DC

R13

*

*

CUT

*

JUMP

*

CUT & JUMP FOR

*

220V MODLES

POWER SUPPLY

** R13, R14 - 220V

MODLES ONLY

JUMP FOR 110V MODELS

F2 .5A

SW1

F1 10A

L1

TO LOAD

HEAT

TP7

+12V

RN1

.022uf

10K

MT6

MT5

MT4

C16

HOT

BLACK

NEUTR.

WHITE

GND

GREEN

314

Q4015L

R14

**

MT2

B

H

G

L

O

N

A

T

D

C

K

TR1

L2

MT3

MT1

N

W

G

E

H

R

U

I

E

T

T

E

RE

N

Z6

4017

4

7

Q3

Q2

Q0

3

1

Q4

Q5

5

16

+12

Q6

Q7

12

NC

10

Q7

CK

9

14

Q8

6

8

Q9

11

13

EN

15

2

RES

Q1

ATTENUATOR

Z5

6

S

RES

2

C

Q

D

5

4013

14

13

12

1

C

Q

P

O

W

E

R

I

N

12

4

11

10

9

8

7

3

5

RN1

10K

413

RN1 10K

512

RN2

100K

THIS DOCUMENT AND THE INFORMATION WHICH IT CONTAINS SHALL NOT BE USED, EXPLOITED

OR SOLD, AND SHALL NOT BE REVEALED OR DISCLOSED TO OTHERS WITHOUT THE EXPRESSED

WRITTEN PERMISSION OF VALCO. THIS DOCUMENT SHALL REMAIN THE PROPERTY OF VALCO

AND SHALL BE RETURNED UPON DEMAND.

TOLERANCES UNLESS

OTHERWISE SPECIFIED

FRACTIONS

1/64"

APPROVED

DRAWN

M.CHIU

DESIGNED

CHECKED

FILE NAME

22219

.XX.01

.XXX.005

63

ANGLES

DEC.

.X.1

1

DATE

1/16/89

SUB-DIR

\ITC\

10

2

3

5

6

4

8

7

9

11

12

13

14

15

16

17

1

CO1

BOARD ASSY. I-22218

Valco Instruments Co., Inc.

SCHEMATIC

ITC REV P

USA PROJECTION

SIZE DRAWING NO.SCALE

1

ATTENUATOR

9

SELECTOR

8

6

5

7

C

3

4

2

N/C

22219---

C

SHEET

OF

Page 26

ADD JUMPER

LTR DESCRIPTION

A

ITC BD. REV M,N

ECN #1808 NEW DWG

B

C

ECN #2050 SHOW NEW VER. W/R13 & R14

ASSY-22218

SCH-22219

BD-22217

AW-160

REV-N

CUT

DATE APPROVED

21FEB89

15APR94

8AUG94

J DURR

J DURR

COMPONENT SIDE

MT6

SC6

KN6

SW 1

CO3

CO5

R13

L1

CO4

CO6

R14

L2

COMPONENT SIDE

NOTE: INSTALL R13 AND R14 ON BOARD FOR 220V VERSION.

(237K 1% 1/4W I-R112373)

THIS DOCUMENT AND THE INFORMATION WHICH IT CONTAINS SHALL NOT BE USED, EXPLOITED OR SOLD, AND SHALL NOT BE REVEALED OR DISCLOSED TO OTHERS

WITHOUT THE EXPRESSED WRITTEN PERMISSION OF VALCO. THIS DOCUMENT SHALL REMAIN THE PROPERTY OF VALCO AND SHALL BE RETURNED UPON DEMAND.

USA

FILE NAME

SUB-DIR

\ITC\

SCALE

SHEET OF

APPROVED DATE

DRAWN

R.B.D.

DESIGNED

---

8/22/9021647

DRAWING NO.

A

TOLERANCES UNLESS

OTHERWISE SPECIFIED

+-1/64"

21647

DEC.FRACTIONS

.X.1

.XX.01

.XXX.005

63

ANGLES

+- 1

Valco Instruments Co., Inc.

O

PCB CONVERSION, ITC

110V TO 220V

24

Loading...

Loading...