Page 1

Technical Note 411

Valco Instruments Co. Inc.

Implementation of the

Digital Valve Interface (DVI)

NOTE: This technical note replaces the DVI man ual, and includes all the information except a schematic

drawing. Call Valco if a copy of the schematic is required.

The V alco Digital V alv e Interface (D VI) is an electronic controller which uses CMOS integ rated circuitry

to convert low power logic level signals or contact closures into pneumatic pulses for the operation of

Valco two position air actuated valves. The DVI has two solenoids which correspond to the two positions of the actuator, with the output air supplied through the one which is activ ated. The input signal

determining which solenoid is activated may be sent manually with the toggle switch on the front panel,

or the DVI can be connected to a data system’s timed outputs for automated valve switching.

The input signal to the D VI causes the interface circuitry to provide a two second pulse to the designated

solenoid, driving the air actuator and valve to the indicated position. Upon removal of the first signal

and application of a second, a two second pulse from the other solenoid drives the actuator to the other

position. The result is that air pressure is applied to the actuator only during switching, eliminating the

possibility of side-loading, misalignment, or other problems which can arise when torque is continuously applied to the valve. This “pulsed operation” procedure mimics valve switching by hand while

providing the advantages of powered, automated operation.

The D VI also has leads to connect a remote LED position readout, for situations in which its o wn LEDs

are out of sight inside an instrument or in a different building. In addition, two contact closures are

provided for signalling the time of sample injections or for starting other devices, such as a gradient

programmer or data system.

Installation

The Digital Valve Interface can be easily installed by the user with the following items supplied:

1. One plug-in transformer

2. One remote 10 pin flat cable (5 feet long) for interfacing with a data system

3. 5 feet of 1/8" plastic tubing for the air supply

4. The necessary fittings for air line installation

Mounting

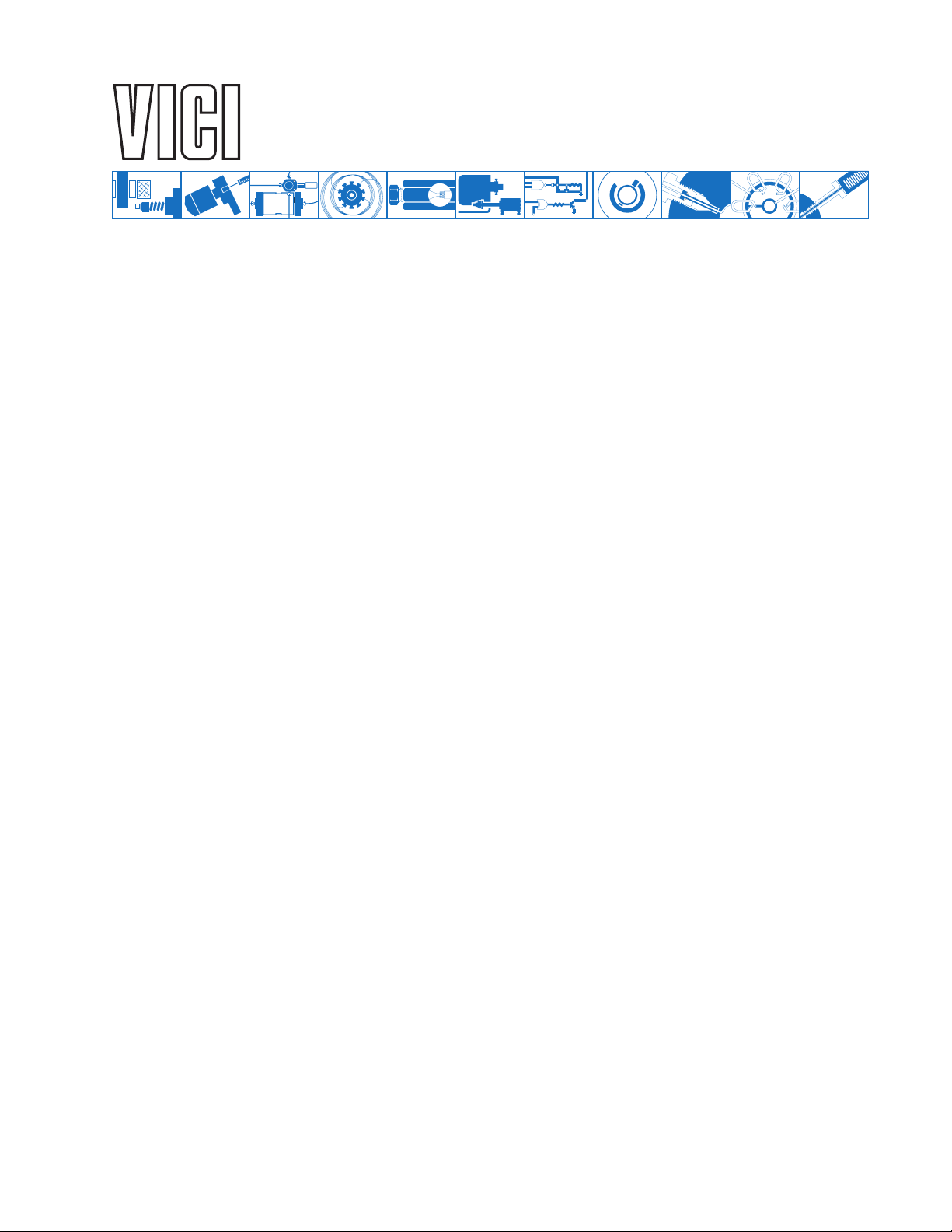

Mounting dimensions are shown in Figure 1. The D VI f eatures a two-sided f ace/mounting plate which

is factory-installed for mounting on the left side of the instrument panel. Howe ver , its design allows the

option of removing four screws and the hex nut on the switch and re-installing the plate for mounting on

the right side.

Page 2

1.75”

BLACK

LOAD

RELAY

1.8” 3” 4”

2”

RED

BLUE

1.35”

2.75”

Figure 1: Mounting dimensions

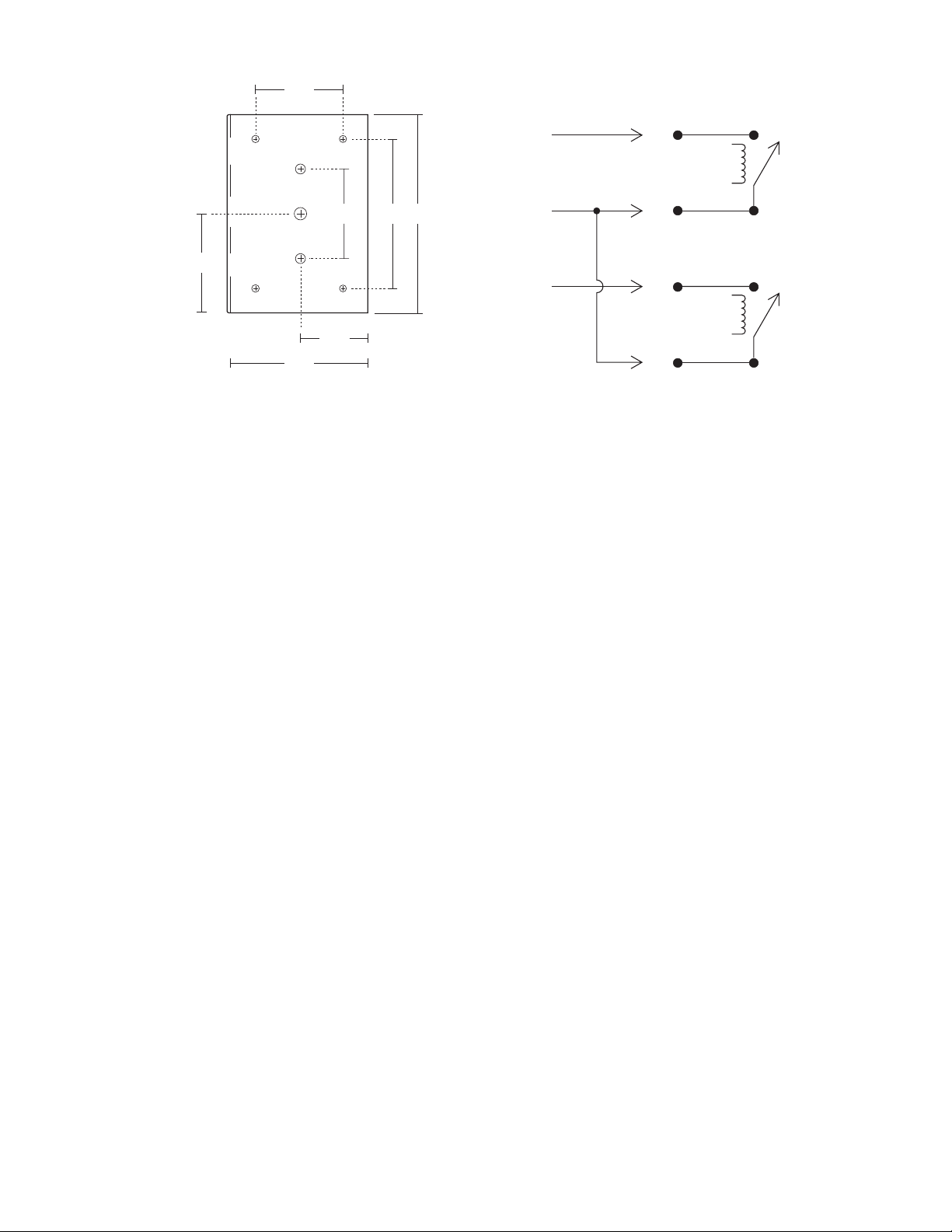

Figure 2: Relay connections

INJECT

RELAY

Basic Connections

1. Connect the air lines betw een the DVI and the air actuator as shown in Figure 3 on the back page.

2. Connect the air supply line to a regulated source of compressed air or nitrogen. (60-80 psi recommended, 100 psi maximum)

3. Connect the tr ansformer to the DVI as indicated, and plug it in.

Manual Operation

No additional installation is required for use of the three position switch on the front panel of the DVI.

The manual switch will override automatic operation unless the operation is controlled by a single

double throw relay.

Automatic Operation

The D VI can be controlled b y one doub le throw relay, two single throw relays, or remote negative true

logic. The input signals to the DVI can be continuous or as short as fifty milliseconds. Any unused

wires should be taped or tied out of the way.

One relay operation (double throw)

1. Connect the BLACK (LOAD) wire from the DVI to the Normally Closed (N.C.) relay contact.

2. Connect the RED (ground) wire to the Common (Com/Grnd) relay contact.

3. Connect the BLUE (INJECT) wire to the Normally Open (N.O.) relay contact.

Two relay operation

1. Connect the RED (ground) wire from the DVI to the common of both relays.

2. Connect the BLACK (LOAD) wire to the Normally Open (N.O.) contact of the relay designated for

the LOAD position.

3. Connect the BLUE (INJECT) wire to the Normally Open (N.O.) contact of the relay designated for

the INJECT position.

Page 3

Operation by Remote Negative True Logic

1. Connect the RED (logic g round) wire from the DVI to the logic ground of the timing device . (Consult

its manual as necessary.)

2. Connect the BLACK (LOAD) wire from the DVI to the output chosen for the LOAD position.

3. Connect the BLUE (INJECT) wire from the DVI to the output chosen for the INJECT position.

Use of Remote LEDs

1.Connect the positive (+) leg of the LEDs to the grey wire of the interface cable.

2. Connect the other legs from the LEDs to the VIOLET wire for the LO AD indicator and to the GREEN

wire for the INJECT indicator.

INPUT (LOAD)

CONTACT CLOSURE 2

LED DRIVE +

LED 2 (LOAD)

INPUT (INJECT)

LED 1 (INJECT)

CONTACT CLOSURE 1

CONTACT CLOSURE 2

LOGIC GROUND

CONTACT CLOSURE 1

BLACK

WHITE

GREY

VIOLET

BLUE

GREEN

YELLOW

ORANGE

RED

BROWN

NOTE:

ALL INPUTS ARE 5 VOLT NEGATIVE TRUE LOGIC

1.

INPUTS REQUIRE .5 MILLIAMPERES DRIVE

2.

INPUTS MUST HAVE A CLOSURE TO LOGIC GROUND - (RED) TO ACTUATE

3.

DIGIT AL V AL VE

INTERF ACE (D VI)

CONNECTION FOR

LOAD POSITION

VALCO TWO POSITION

AIR ACTUATOR

CONNECTION FOR

INJECT POSITION

POWER SUPPLY

TRANSFORMER

Figure 3: D VI connections

North America, South America, and Australia/Oceania contact: Europe, Asia, and Africa contact:

®

Valco Instruments Co. Inc.

P. O. Box 55603

Houston, TX 77255

Sales toll-free (800) 367-8424

Technical help

Fax (713) 688-8106

(713) 688-9345

valco@vici.com

®

VICI AG International

Parkstrasse 2

CH-6214 Schenkon

Switzerland

Phone (Int + 41 + 41) 925-6200

Cheminert® and VICI® are registered trademarks of Valco Instruments Co . Inc. and VICI AG

Fax (Int + 41 + 41) 925-6201 info@vici.ch

AIR IN

(100 psi MAX)

TN-411 8/04

Loading...

Loading...