Page 1

Valco Instruments Co. Inc.

Introduction

Description and Operating Principles ............................................................ 1

Safety Notes and Information........................................................................ 2

Components of the Detector System ............................................................ 3

System Requirements................................................................................... 4

Installation

General Precautions...................................................................................... 6

Mounting the Detector on the GC ................................................................. 6

Pulser Module Installation ............................................................................. 6

Gas Connections........................................................................................... 7

Installing and Purging the Gas Regulator .............................................. 7

Installing and Purging the Helium Purifier.............................................. 8

Connecting the Discharge Gas to the Detector..................................... 8

Detector Electrical Connections .................................................................... 9

Initial Po wer-Up ........................................................................................... 10

Capillary Column Connection ...................................................................... 11

Pac ked Column Connection ........................................................................ 11

Testing for Leaks ......................................................................................... 12

Pulsed Discharge Detector

Models D-4-I-TQ-R

and D-4-I-TQI-R

Instruction Manual

Mode Selection and Setup

Helium Ionization Mode............................................................................... 13

Selective Photoionization Mode................................................................... 13

Troubleshooting

High Background Current............................................................................ 15

Low Sensitivity ............................................................................................ 15

No Peaks..................................................................................................... 15

High Noise Level ......................................................................................... 16

Performing a Hydrogen Leak Test ............................................................... 16

Warranty ............................................................................................................ 17

Detector Performance Log ................................................................................. 18

Valco Instruments Co. Inc.

800

·

367

·

·

688

·

688

8424 sales

·

9345 tech

·

8106 fax

713

713

valco@vici.com

Valco International

Schenkon, Switzerland

Int + 41 · 41 · 925

Int + 41 · 41 · 925

vici@vici.com

·

6200 phone

·

6201 fax

d4_therm.P65

© 2002 Rev . 1/02

Printed in USA

Page 2

Introduction

Description and Operating Principle

1

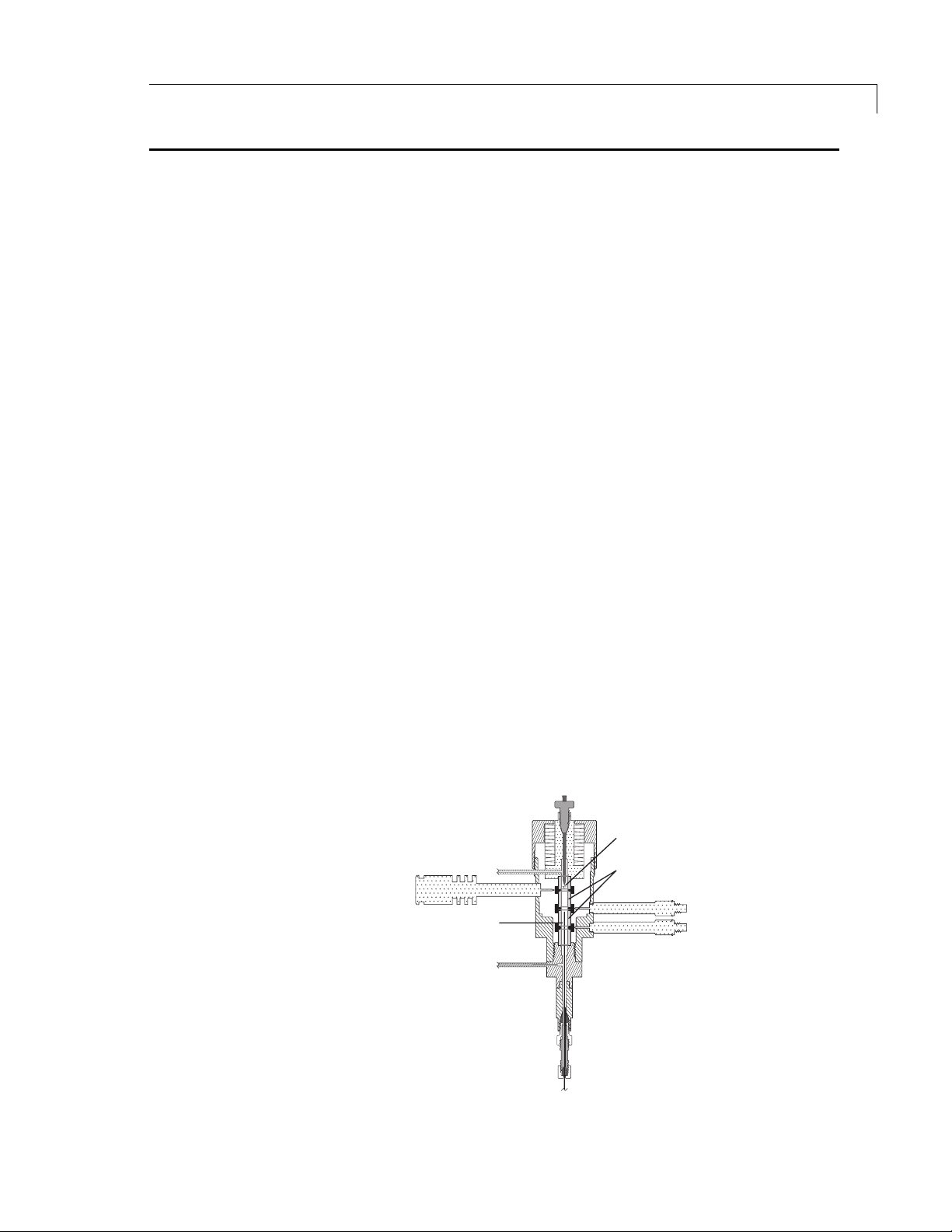

The PD-D-4-I-TQI-R and PD-D-4-I-TQ-R are non-radioactive pulsed discharge

ionization detectors (PDIDs) optimized for ThermoFinnigan GCs. A schematic

representation of the basic D4 detector is shown in Figure 1.

The D4 utilizes a stable, lo w pow er, pulsed DC discharge in helium as the

ionization source. Elutants from the column, flowing counter to the flow of

helium from the discharge zone, are ionized by photons from the helium

discharge above. Resulting electrons are focused toward the collector

electrode by the two bias electrodes.

The principal mode of ionization is photoionization by radiation arising from

the transition of diatomic helium

He

1

+

(

∑

)

A

u

2

to the dissociative 2He(1S

1

)

ground state. This is the well-known Hopfield emission. The photon energy

from the He2 continuum is in the range of 13.5 eV to 17.7 eV.

The D4 is essentially non-destructive (0.01 - 0.1% ionization) and highly

sensitive. The response to organic compounds is linear o v er five orders

of magnitude with minimum detectable quantities (MDQs) in the low

picogram range. The response to fix ed gases is positiv e (the standing

current increases), with MDQs in the low ppb range.

Detector response is universal except f or neon, which has an ionization

potential of 21.56 eV. Since this potential is close to the energy of the

He* metastable (19.8 eV) but greater than the photon energy from the

He2 continuum, neon exhibits a low ionization efficiency and low detector

response.

When a dopant is added to the discharge gas, the D4 also functions

as a selective photoionization detector . (Suitable dopants include Ar fo r

organic compounds, Kr for unsaturated compounds , or Xe f or polyn uclear

aromatics.)

GROUND PIN

DISCHARGE REGION

HELIUM INLET

HIGH VOLTAGE

SAPPHIRE INSULATORS

BIAS ELECTRODE

CAPILLARY COLUMN

VENT

COLUMN INLET

Figure 1: Schematic of the D4 detector

COLLECTOR ELECTRODE

Page 3

Introduction

2

Helium Ionization (PDHID) Mode

The PDHID is essentially non-destructive (0.01 - 0.1% ionization) and highly

sensitive. The response to organic compounds is linear o v er fiv e orders of

magnitude with minimum detectable quantities (MDQs) in the low or sub

picogram range. The response to fix ed gases is positiv e (the standing

current increases), with MDQs in the low ppb range.

The PDHID response is universal except f or neon, which has an ionization

potential of 21.56 eV. Since this potential is close to the energy of the He*

metastable (19.8 eV) but greater than the photon energy from the He

continuum, neon exhibits a low ionization efficiency and lo w detector

response.

2

Photoionization (PDPID) Mode

Changing the discharge gas from pure helium to helium doped with argon,

krypton, or xenon changes the discharge emission profile, resulting in

resonance atomic and diatomic emissions of the rare gas added. Response

is limited to sample compounds with ionization potentials less than or equal

to the dopant gas emission energy. In this configuration, the detector is

essentially functioning as a specific photoionization detector for selective

determination of aliphatics, aromatics, and amines, as well as other species.

Since there is no lamp or window , sensitivity will not change with time.

Safety Notes and Information

CAUTION: During normal operation, the detector produces ultraviolet energy (UVA, UVB), some of which may

be emitted. Do not watch the arc without eye protection.

Symbols

HIGH VOL T A GE

V oltages presenting the risk of electric shock are present in

sever al places in the equipment. Av oid contact with hazardous live parts. Do not probe into openings or attempt to

defeat safety mechanisms .

HOT SURFA CE

The surface of the detector body may be hot while in oper ation (possibly in excess of 250°C). Caution should be

observed.

A TTENTION

Refer to the manual.

PROTECTIVE EAR TH

This internal connection provides protection against electric

shock from mains voltages and should not be remov ed.

Page 4

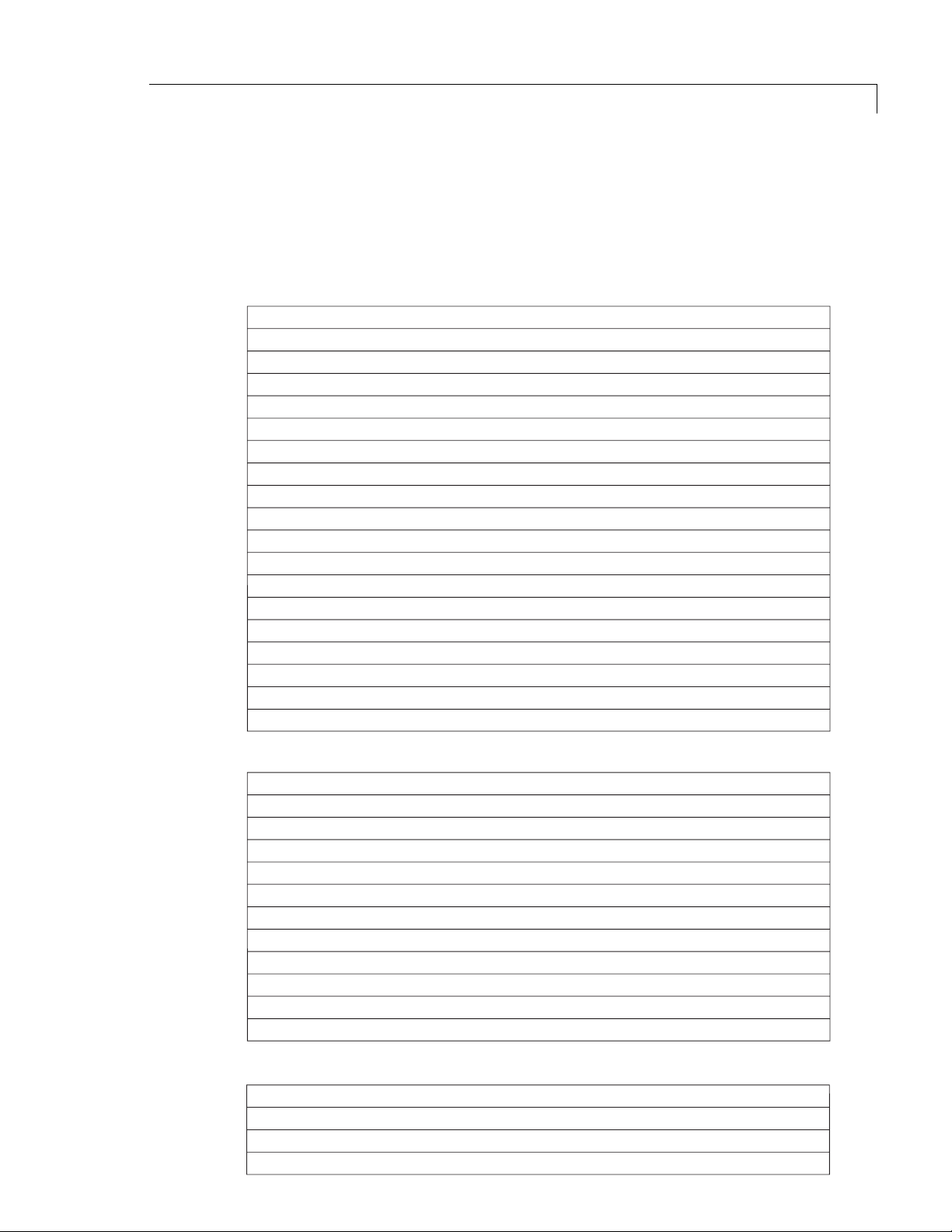

Components of the Detector System

Components of the detector systems are listed in the tables below. Chec k

the package contents to verify that e v erything is present. Contact the

factory if anything is missing or damaged. (NOTE: damaged shipments

must remain with the original packaging for freight company inspection.)

Table 1:

Components of the D-4-I-TQ-R system (Trace GC)

Description Quantity Product number

Detector cell, PDHID 1 PD-D4-I-TQI

Pulse supply module 1 PD-M2

Instruction manual 1 MAN-PDD4-TQ

ThermoFinnigan fittings kit 1 PD-KIT-TQ

Includes

Helium purifier 1 HP2

: 1/32" polyimide ferrule 5 ZF.5V

1/16" gold-plated ferrule 5 ZF1GP

Valco to TQ adapter 1 I-23913

0.25 - 0.44 mm polyimide column ferrule 5 FS.4

0.4 - 0.5 mm polyimide column ferrule 5 FS.5

1/16" bulkhead union 2 ZBU1

1/16" tee 1 ZT1

1/8" to 1/16" reducing union 2 EZRU21

1/8" external to 1/16" internal reducer 1 EZR21

1/32" external nut 1 EN.5KN

Fused silica adapter (installed) 1 IZERA1.5

Packed column adapter 1 I-23642-TQ

Restrictor, 30 cc/min @ 60 psi He 1 TGA-R-30F60P

Introduction

3

Table 3:

Components of the D-4-I-TQI-R system (Mega and 8000 Top GC)

Description Quantity Product number

Detector cell, PDHID 1 PD-D4-I-TQI

Pulse supply module 1 PD-M2

Instruction manual 1 MAN-PDD4-TQ

ThermoFinnigan fittings kit 1 PD-KIT-TQI

Includes

Helium purifier 1 HP2

Pulser power supply 1 I-23569-1

Power cord 1 I-W-17850

Description Quantity Product number

Mounting base nut 1 35001120

Electrometer 1 23468510

Silver seal 1 29015058

: 1/16" gold-plated ferrule 5 ZF1GP

1/16" bulkhead union 2 ZBU1

1/16" tee 1 ZT1

Restrictor, 30 cc/min @ 60 psi He 1 TGA-R-30F60P

Table 3:

Components not supplied by Valco (may be obtained from ThermoFinnigan)

Page 5

Introduction

4

System Requirements

Components Not Included with the Detector System

•Helium (99.999% purity) and other support gases

•Ultra high purity grade gas pressure regulator with stainless steel

diaphragm

•Any special adapters required for connection to the gas regulator

•SS tubing to go from gas supply to GC

•Flow measuring device

System Purity

Discharge/Carrier Gas Considerations

The performance of the detector is adversely affected by the presence

of any impurities in the gas streams (carrier, discharge, or dopant). We

recommend that a quality grade of helium 5.0 (99.999% pure or better)

be used at all times. Major gas suppliers off er research g rade helium

(99.9999% pure) which is particularly low in fixed gas impurities and should

give good results in a clean system, but even the highest quality carrier

gas may contain some water v apor and fixed gas impurities; hence a

helium purifier is included as part of the detector system.

must alwa ys flow through the helium purifier .

The discharge gas

Whenever a ne w batch of discharge gas is receiv ed, we recommend

performing a blank GC analysis of the gas in the PDHID mode to detect

and identify the presence of any impurities. Gas purity requirements

are specified on the next page.

T ubing

Standards of cleanliness that are suitable for many GC applications may

be totally inadequate for the sensitive PDHID/PDPID work. All surfaces that

contact the gas stream must be fused silica or stainless steel. Do not use

copper tubing or brass fittings. All tubes must be thoroughly cleaned and

baked before use.

Flow Controllers

The use of valves or flow controllers in which the gas stream is exposed

to any polymer-based packing or lubricating material is to be particularly

avoided.

Pressure Regulators

We recommend commercial “ultra-pure” g rade regulators with stainless steel

diaphragms. Regulators with diaphragms made of neoprene or other

elastomers should never be used.

Page 6

Gas Specifications

Introduction

5

edoMrotceteD

DIHDPDIPDP-rADIPDP-rKDIPDP-eX

sagegrahcsiD

sagreirraC

Any gas including He which has an ionization potential greater than 12 eV

**

Any gas including He which has an ionization potential greater than 11 eV

**

muileHeHnirA%2eHnirK%5.1eHnieX%8.0

muileH*****

Purity Specifications

•Helium (discharge and carrier gas) must have a minimum purity of

99.999%, with < 20 ppm Ne impurity . For tr ace analysis of fix ed gases,

we strongly recomment 99.9999% purity He with < 0.5 ppm Ne.

•Ar-PDPID mode: 2% ± 0.2% Ar in 99.999% He balance

•Kr-PDPID mode: 1.5% ± 0.1% Kr in 99.999% He balance

•Xe-PDPID mode: 0.8% ± 0.2% Xe in 99.999% He balance

Page 7

6

Installation

General Precautions

•Do not use plastic/polymer or copper tubes for gas handling and

interconnectons. Use only stainless steel tubing with V alco gold-plated

ferrules.

•Do not turn the unit on until the helium discharge gas is flowing through

the detector.

•Do not shut off or disconnect the discharge gas when the detector is hot,

even if the unit is turned off. Turn off the discharge power switch and

allow the detector to cool down naturally before disconnecting or shutting

off the discharge gas.

•Do not cover the unit with materials or devices which would restrict air

circulation.

Mounting the Detector on the GC

1. Remove the FID flame tip .

2. Install the PDD on the FID heater block. Make sure you interpose the

silver seal.

3. Tighten the nut to secure the detector.

Pulser Module Installation

1. Mount the pulser module on the GC as shown below.

2. Connect +24VDC power to the pulser module from the GC .

TO PNEUMATIC

MODULE

BIAS

GAS

INLET

ELECTROMETER

DETECTOR

MOUNTING NUT

p

u

ls

e

d

d

is

c

h

a

r

g

e

m

o

d

u

le

PULSED DISCHARGE

MODULE

D

R

A

C

D

D

P

PDD CONTROL

CARD

Figure 3: Mounting the detector on the GC

Page 8

Gas Connections

Remember these three points discussed earlier: (1) all surfaces that contact

the gas stream must be fused silica or stainless steel; (2) do not use copper

tubing or brass fittings; and (3) all tubes m ust be thoroughly cleaned and

baked before use . The installation instructions below assume that the

detector discharge gas will be supplied from a nearby cylinder of helium

of the proper purity . If your installation is diff erent, y ou may need to modify

the instructions appropriately . A number of Valco fittings hav e been supplied

in the fittings kit to handle different situations.

Figure 4 illustrates gas connections for the D-4-I-TQ-R detector system.

Since the distance from the helium supply to the GC varies from installation

to installation, we do not supply tubing for that purpose.

VENT

COLUMN

INLET

TGA-R-30F60P

RESTRICTOR

(30 mL/min minimum)

DISCHARGE GAS

INLET

SAMPLE IN

(or blank)

EPC

HPM

TEE

(ZT1)

HELIUM

PURIFIER

ELECTRONIC

PNEUMATIC

CONTROL

VICI

MINIATURE

HELIUM

PURIFER

(recommended)

VENT

Installation

DISCHARGE GAS

(99.999% He)

7

COLUMN

GAS CHROMATOGRAPH

Figure 4: Gas connections for a D-4-I-TQ-R system

Installing and Purging the Gas Regulator

1. Make sure the on/off valve on the helium cylinder is completely closed.

Screw the CGA fitting nut of the regulator into the helium cylinder . Go

beyond finger-tight, but do not tighten the n ut all the way – some leakage

is required for the purging operation.

2. Turn the output pressure regulating knob completely counterclockwise.

3. Open the cylinder on/off valve

4. Adjust the tightness of the regulator connecting nut to allow a pressure

reduction of ~690 kPa/sec (100 psi/sec). With a ne w bottle, the gauge

should start out at about 14 MPa (2000 psi).

5. When the pressure drops into the 1.4 - 3.4 MPa (200 - 500 psi) range,

open the cylinder on/off valve slightly and quic kly close it again.

6. Repeat Step 5 eight or ten times to be certain that all the air is purged.

On the final purge, tighten the regulator connecting nut very securely as

the pressure approaches the 2.1 - 3.4 MPa (300 - 500 psi) range.

slightly

and quickly close it again.

Page 9

Installation

8

7. Open the cylinder valve to pressurize the regulator once again. Close the

valve and observe the needle of the high pressure gauge f or 15 minutes.

If it doesn’t move, there is no critical leak on the high pressure side of the

regulator.

CAUTION: Never use leak detecting fluids on any part

of this system.

Installing and Purging the Helium Purifier

1. If the pressure regulator has a 1/8"

the Valco 1/8" e xternal to 1/16" internal reducer (EZR21); if it has a

1/4"

male

cone-type outlet port, install the V alco 1/4" e xternal to 1/16"

internal reducer (EZR41). For other regulator outlet fittings , a wide

variety of Valco adapters is available.

2. Remove the cap from the inlet tube of the V alco helium purifier and insert

the tube fitting into the 1/16" reducer port. (Keep the outlet tube capped.)

Use a 1/4" wrench to turn the nut one-quarter turn past the point where

the ferrule first starts to grab the tubing. Do not remov e the fitting. When

made up properly , it should be leak-tight.

3. Turn the output pressure regulating knob clockwise until the gauge

registers 345 KPA (50 psi).

4. Allow five minutes f or equilibration, then turn the regulating knob all the

way counterclockwise .

5. Observe the needle of the output pressure gauge for 15 minutes. There

will be a slight initial drop, but if it doesn’t mo v e after that, consider that all

the connections are tight.

6. If necessary , use an electronic leak detector to locate any leaks. If a

leak detector is not availab le, tighten all the fittings (including the output

pressure guage), and repressurize the system for another test.

male

cone-type outlet port, install

CAUTION: Never use leak detecting fluids on any part

of this system.

7. Upcap the outlet tube of the purifier and purge the system for

15 to 30 minutes at 60 - 80 mL/min to eliminate air from the purifier

getter material.

Connecting the Discharge Gas to the Detector

1. If you are supplying the GC from the helium purifier, use the Valco

ZT1 tee. Otherwise , use one of the Valco 1/16" unions (ZU1) to connect

the outlet tube of the purifier to the inlet of the supplied discharge gas

restrictor (TGA-R-30F60P).

2. Connect the outlet end of the restrictor to a flow measuring device. Adjust

the helium pressure to 60 psi to obtain a continuous flow of ~30 mL/min.

3. After setting the flow rate, connect the outlet of the restrictor to the

discharge gas inlet tube (labelled “INLET”) which comes out the side

of the detector.

Page 10

Detector Electrical Connections

CAUTION: Do not use a wrench to tighten the SMC

connectors on the bias and electrometer cables.

Connections should be finger tight only .

1. Referring to Figure 5 as necessary, connect the BIAS cable to the top

electrode and the electrometer cable (ELECT) to the bottom electrode.

2. Connect the high-voltage cable from the detector to the pulse supply.

Installation

9

BIAS CABLE

PULSER

MODULE

ELECTROMETER CABLE

ELECTROMETER

BOARD

Figure 5: Schematic of electrical connections

Page 11

Installation

10

Initial Power-Up

CAUTION: Always make sure that dischar ge gas is

flowing before heating and powering up the detector.

1. Before installing the column, set the gas flow to 30 ml/min (measured at

the detector vent). Let it flo w f or 15 min utes so that all air is purged from

the helium purifiers.

2. Plug in the helium purifiers and turn on the GC.

3. Set the detector temperature to 100°C and allow time for the detector and

helium purifiers to reach the set temperature.

4. Plug 24 VDC into the pulser module (PD-M2).

5. Turn on the discharge.

CAUTION: During normal operation, the detector produces ultraviolet energy (UVA, UVB), some of which may

be emitted. Do not watch the ar c without ey e protection.

6. Check the standing/background current, and record it in the Detector

Perf ormance Log on the last page of this manual. Optimum range is

1.0 to 2.5 nA at 100°C. Low er current indicates a clean, leak-free system.

7. The recommended detector temperature is 20°C above the column

temperature, with a minimum of 100°C . Set the detector to the operating

temperature required for the intended analysis. When the detector has

reached the set temperature, read and record the standing current.

8. Install the column as illustrated on page 11, leaving the oven at ambient

temperature. Start carrier flow, then read and record the standing current.

The difference between this reading and the one pre vious is the ionization

of the combined impurities in and eluting with the carrier gas. The smaller

the difference, the better the quality of the gas e xiting the column.

9. Set the column oven to the temperature required f or the intended

analysis. When the ov en reaches the set temperature, read and record

the standing current.

The difference with the previous reading is the ionization of the column

bleed. The smaller the difference, the better the column is conditioned.

NOTE: Some stationary phases will have a higher bleed than others , b ut

are still suitable for this detector. How e ver, the lo wer the b leed, the lo w er

the chances of contaminating the detector cell.

From this point, the standing current should be observed and logged after

any system change. In addition, logging the standing current (with and

without the column) on a regular basis is an effective monitor of system

integrity (leaktightness and cleanliness). We also recommend tracking the

internal standard (quantity on column/area count) for sensitivity continuity.

Page 12

14.5 cm/

Capillary Column Connection

If the capillary column adapter is installed in the column inlet:

1. Make a mark on the column 14.5 cm from the end.

COLUMN

INLET

CAPILLARY

COLUMN

ADAPTER

(IZERA1.5)

COLUMN

FERRULE

NUT

CAPILLARY

COLUMN

2. Remove the knurled nut and plug from the capillary column adapter in the

column inlet at the bottom of the detector. Slide the nut ov er the end of

the column, followed b y the appropriate column ferrule (FS.4 or FS .5, or

ZF.5V for megabore).

3. Seat the ferrule in the detail of the column adapter and begin sliding the

column through the capillary column adapter and into the column inlet.

4. Get the nut started on the threads and tighten it until you feel it contact

the ferrule, then back off half a turn. Slide the column into the column

inlet until the mark is flush with the surface of the knurled nut, and secure

the column in the adapter by tightening the knurled nut

If the capillary column adapter has been removed, reinstall it:

1. Unscrew the liner as far as it will go, then screw the fitting body into the

column inlet fingertight.

Installation

finger tight only

11

.

13 cm/

2. While using a 1/8" wrench to prevent rotation of the liner (the part with the

seat for the column ferrule), use a 1/4" wrench to tighten the body of the

adapter until the ferrule has sealed. The liner

3. Proceed to Step 1 above.

Packed Column Connection

T o pre vent detector contamination, we strongly

recommend disconnecting the column from the

detector during column bakeout procedures.

COLUMN

INLET

The D4 is optimized for pack ed columns . The column tubing must be

thoroughly cleaned and baked before the column is pac ked. Even when

the best care is taken in column tubing cleaning and in the support and

stationary phase selection, a new column will often bleed compounds,

PACKED

COLUMN

ADAPTER

(I-23642-TQ)

resulting in a considerable increase in the detector baseline. This initial

bleed will usually be reduced to acceptable levels after the column is

conditioned with clean carrier gas flow for sev er al hours at the

recommended bakeout temperature.

1. Loosen and remove the knurled nut and plug of the capillary column

adapter, (or remov e the column ferrule and the column if one has been

installed).

will deform

if it rotates.

PACKED

COLUMN

2. Use a 1/8" wrench to hold the liner – that part of the adapter in which the

column ferrule sits. While the 1/8" wrench k eeps the liner from rotating,

use a 1/4" wrench on the fitting body to loosen the adapter 1/2 turn.

Page 13

Installation

12

3. Set aside the 1/8" wrench and completely remove the adapter from the

column inlet.

4. Screw the packed column adapter into the column inlet b y hand.

caution

with a 1/4" wrench, using an additional wrench on the flats of the column

inlet to support the detector.

5. Connect the 1/8" column to the packed column adapter with the EZR U21

reducing union supplied in the fittings kit.

, as the tip of the adapter is very fragile. Then tighten the adapter

Testing for Leaks

It is critical for the system to be leak-tight, and an additional check at this

point can save many headaches later on. To test for leaks:

1. Cap the tube and pressurize the entire system with helium to 138 kPa

(20 psi).

2. If the system does not hold pressure, check all the fittings with an

electronic helium leak detector.

3. Tighten fittings as required.

Exercise

CAUTION: Never use leak detecting fluids on any part

of this system.

An alternative leak testing method is descibed on page 16. NOTE: A leak

upstream from the column will not cause an immediate baseline change.

There must be time allowed for the h ydrogen to pass through the column.

Page 14

Mode Selection and Setup

Helium Ionization Mode

If the instructions at the top of page 11 were properly executed, the column

should already be properly positioned. Since there ma y be some v ariation

in the flow rate f or the diff erent types of capillary columns, the user ma y w ant

to optimize the column position within ± 2.0 mm. DO NOT insert the column

more than 15 cm.

With this flow configuration, only pure helium passes through the discharge

region, minimizing the chance of discharge electrode contamination through

contact with the eluting sample. How e ver, if v ery high concentrations of

organic compounds are introduced for extended periods of time, the y could

diffuse into the discharge region and contaminate the electrodes. Under

normal chromatographic use with capillary columns, such contamination is

negligible even o v er extended periods.

Selective Photoionization Mode

13

Since the pulsed discharge detector is essentially a windowless helium

photoionization detector, changing the discharge gas from pure helium

to helium doped with argon, krypton, or xenon changes the discharge

emission profile. This results in a change in the photon energy due to

additional resonance atomic emissions and diatomic emissions from the

rare gas added. Thus a single detector can be operated in any of the

three photoionization detector (PID) modes: Ar-, Kr-, or Xe-PID.

Doped helium is used rather than other pure gases in order to retain the

benefits of the helium: namely, its transparency for Ar, Kr, an Xe resonance

radiation and its efficient cooling of the electrodes. An y prob lems associated

with the presence of a window between the photon source and the ionization

chamber are eliminated. In most applications in v olving current commercial

PIDs, analyte condensation and decomposition on the window attenuate the

lamp energy , necessitating frequent cleaning and recalibr ation.

Custom gas blends for the pulsed discharge detector are a v ailab le from

leading gas suppliers at special prices. Alternatively, they may be formulated on the spot by using appropriate fixed restrictors to mix appropriate

amounts of pure helium and pure dopant through a tee. Since all gas

streams must pass through a Valco purifier, the second option requires

an additional purifier for each dopant. This may still be more cost eff ectiv e

than requesting a custom blend of the more expensiv e Kr or Xe; since the

typical flow rate required for the pure dopant rare gas is about 0 . 3 - 1 mL/min,

a small lecture bottle can last for a long time. In either case, the total discharge gas flow rate should be the same as specified in “Gas Connections”

on page 7.

Page 15

Mode Selection and Setup

14

Ar-PDPID

Changing the discharge gas from helium to a mixture of 2% argon in

helium changes the photon energy level from the 17 - 13.5 eV r ange to the

11.8 - 9.8 eV range. The argon emission consists of resonance radiation

at 11.8 eV and 11.6 eV and the diatomic Ar2 emission in the range of

9.2 - 10.3 eV. Except for fix ed gases and a f ew organic compounds like

CH4 (IP = 12.5 eV), CH3CN (IP = 12.2 eV) and some fluro-chloro hydrocarbons, the majority of organic compounds have ionization potentials

lower than 11.8 eV. Thus the Ar-PDPID is nearly univ ersal, lik e the flame

ionization detector, b ut without the risks associated with the presence of

an open flame and hydrogen.

Kr-PDPID

The recommended proportion is 1.4% Kr in He as the discharge gas.

The krypton emission consists principally of resonance lines at 10.6 eV

and 10.1 eV. The Kr-PDPID can detect compounds with IP < 10.6 eV,

which includes unsaturated and cyclic hydrocarbons, alcohols, aldeh ydes ,

organic acids, esters, etc.

Xe-PDPID

The recommended proportion is 0.8% Xe in He as the discharge gas. The

xenon emission consists principally of resonance lines at 9.6 eV and 8.4 eV,

and can detect compounds with IP < 9.6, like aromatics, ethers, alcohols ,

aldehydes, etc.

In addition to the specific compounds named in the three paragraphs

above, certain important inorganic compounds like ammonia, hydrogen

peroxide, arsenic trichloride, hydrogen sulfide , arsine, phosphine , nitric

oxide, carbon disulfide etc. can be selectively detected using the

appropriate photoionization mode.

Each dopant gas requires an additional helium purifier, which must be

purged and conditioned in the same manner as the purifier installed on

the discharge gas supply. If y ou are using more than one dopant, we

recommend use of a Valco multiposition stream selection valve so that no

fittings have to be disconnected. Not only is this convenient, it keeps the

system closed, minimizing chances of contamination. When changing from

one dopant to another, allo w at least one hour f or the old gas to be purged

from the system.

Page 16

Troubleshooting

High Background Current

Disconnect the column

Pink

Check

discharge

color

Purple/

blue

Low Sensitivity

Check background current

with column removed and

column inlet plugged

High background current

(> 2 nA)

Refer to “Troubleshooting:

High Background Current”

and cap the column inlet

Do a hydrogen leak test

(described on next page)

Normal background current

£ 2 nA)

(

Reinstall column and check

background current

Background current

increases

Background current

remains in normal range

Baseline current falls to

normal range (< 2.0 nA)

Baseline current is still high

(> 2.0 nA)

Leaks in the fittings of the

PDD plumbing

Leaks inside the detector

cell itself

No detectable leaks.

The detector isn’t leaking.

Check for column bleed

and/or leaks in the GC setup.

Tighten leaking fittings

Consult

Valco

Possible bad carrier gas or

empty He bottle. Install a new

bottle.

Check column inlet for

leaks. Tighten fittings.

Check column position

according to drawing on

p. 11, and run a sample.

Baseline current falls to

normal range (< 2.0 nA)

Baseline current is still high

(> 2.0 nA)

Baseline current falls to

normal range (< 2.0 nA)

Baseline current is still high

(> 2.0 nA)

Baseline current falls to

normal range (< 2.0 nA)

Baseline current is still high

(> 2.0 nA)

Background current

remains high

Background current

drops to normal range

Sensitivity is in

acceptable range

Sensitivity is still

too low

Consult

Consult

Consult

Remove column and

condition it, then run

a sample

Run

a sample

Remove column and

bake detector at

300°C for four hours.

Install column and run

a sample.

Valco

Valco

Valco

15

Sensitivity is in

acceptable range

Sensitivity is still

too low

Sensitivity is in

acceptable range

Sensitivity is still

too low

Sensitivity is in

acceptable range

Sensitivity is still

too low

No Peaks

If the background current is stable but there are no peaks:

1. Check column flow .

2. Check the column insertion position (14.5 cm for capillary columns,

3. If there are still no peaks, check to make sure that the GC is actually making

4. If there are still no peaks, consult Valco.

13.0 cm for pack ed columns).

an injection.

Consult

Valco

Page 17

Troubleshooting

16

High Noise Level

If the noise lievel is high:

1. See if it improves with the GC f an turned off .

2. Check the column insertion position (14.5 cm for capillary columns,

13.0 cm for pack ed columns.)

3. If the noise level is still high, do a hydrogen leak test, described below .

4. If there are no leaks found, or leaks are found and repaired and the noise

level is still high, consult Valco.

Performing a Hydrogen Leak Test

A hydrogen leak test allows you to pinpoint loose fittings and leaks inside

the detector.

1. Connect a length of plastic tubing to a regulated hydrogen bottle.

Establish a flow of 5-10 ml/min.

2. Hold the hydrogen outlet tube at a fitting connection for ten seconds while

monitoring the baseline.

3. Tighten the fitting and test it again, repeating as necessary until every

connection has passed the ten second test.

4. If the current remains high, hold the hydrogen outlet close to the detector .

(Do not insert the tube into any detector holes.)

indicated, contact Valco.

NOTE: This method may also be used to test for leaks in other parts of the

system, but remember – a leak upstream from the column will not cause an

immediate baseline change. There m ust be time allow ed f or the h ydrogen to

pass through the column.

If a leak in the detector is

Page 18

Warranty

17

This Limited W arranty giv es the Buy er specific legal rights, and a Buy er

may also hav e other rights that vary from state to state. For a period of 365

calendar days from the date of shipment, Valco Instruments Company, Inc.

(hereinafter Seller) warrants the goods to be free from defect in material

and workmanship to the original purchaser. During the warranty period,

Seller agrees to repair or replace defective and/or nonconforming goods or

parts without charge for material or labor, or, at the Seller’s option, demand

return of the goods and tender repayment of the price. Buyer’s exclusive

remedy is repair or replacement of defective and nonconforming goods, or,

at Seller’s option, the repayment of the price.

Seller excludes and disclaims any liability for lost profits, personal

injury, interruption of service, or for consequential incidental or

special damages arising out of, resuiting from, or relating in any

manner to these goods

This Limited Warranty does not cover defects, damage, or nonconformity

resulting from abuse, misuse, neglect, lack of reasonable care, modification,

or the attachment of improper devices to the goods. This Limited Warranty

does not cover expendable items. This warranty is VOID when repairs are

performed by a nonauthorized service center or representative. For information about authorized service centers or representatives, write Customer

Repairs, Valco Instruments Company, Inc, P.O. Box 55603, Houston, Texas

77255, or phone (713) 688-9345. At Seller’s option, repairs or replacements

will be made on site or at the factory. If repairs or replacements are to be

made at the factory, Buyer shall return the goods prepaid and bear all the

risks of loss until delivered to the factory. If Seller returns the goods, the y

will be delivered prepaid and Seller will bear all risks of loss until delivery to

Buyer. Buyer and Seller ag ree that this Limited Warranty shall be governed

by and construed in accordance with the laws of the State of Texas.

The warranties contained in this agreement are in lieu of all

other warranties expressed or implied, including the warranties

of merchantability and fitness for a particular purpose.

This Limited W arranty supercedes all prior proposals or representations oral

or written and constitutes the entire understanding regarding the warranties

made by Seller to Buyer. This Limited Warranty may not be expanded or

modified except in writing signed by the parties hereto.

Page 19

18

Detector Performance Log

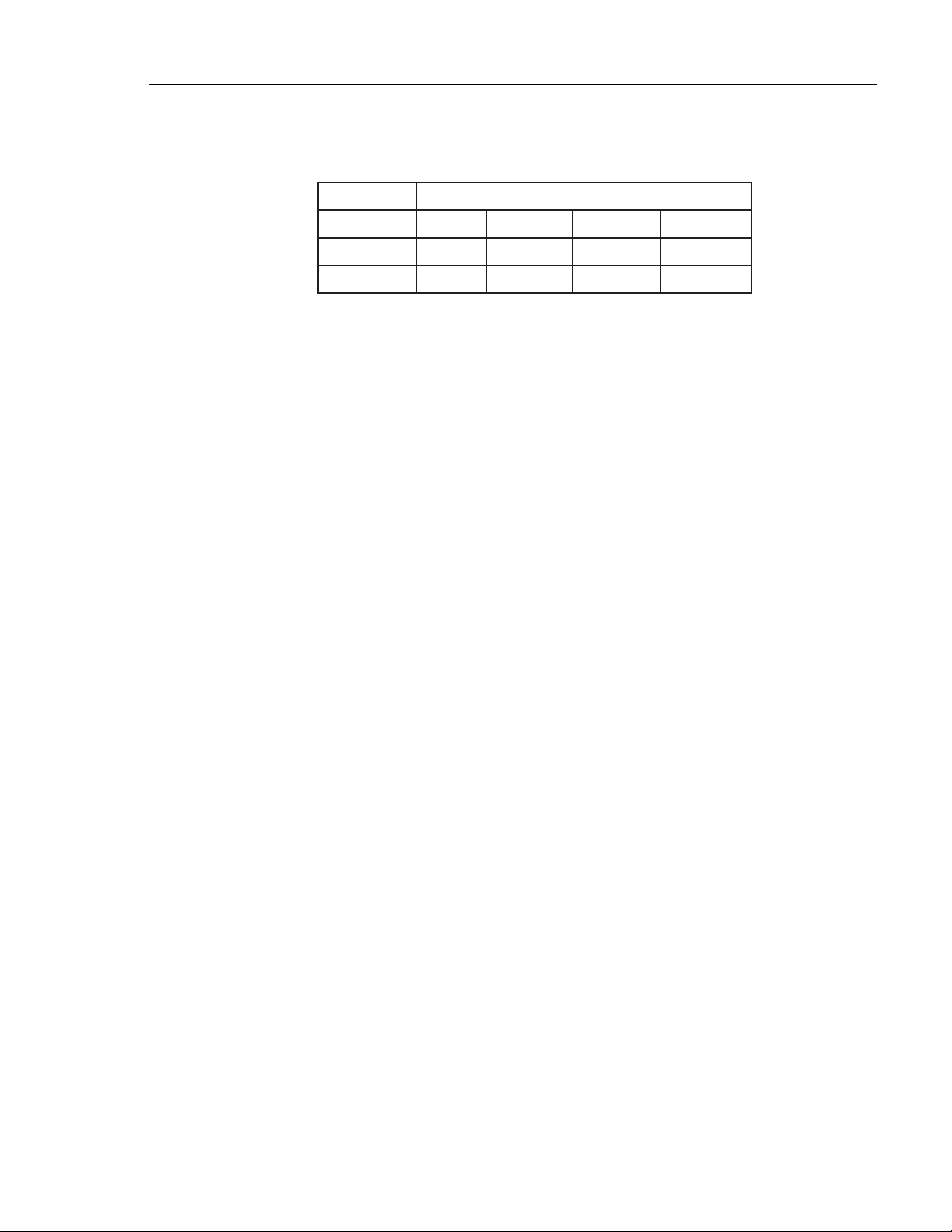

In addition to the occasions indicated in the Comments area of the table below (see

Initial Pow er-Up

page 10), the standing current should be observed and logged after any system change. Logging

the standing current (with and without the column) on a regular basis is also an effective monitor of

system integrity (leaktightness and cleanliness). To check sensitivity continuity , we recommend

tracking the internal standard (quantity on column/area count). Additional log pages can be do wnloaded from the support/manuals section of www.vici.com.

Detector Model: Serial Number: Date of purchase:

Date

Operator Column

D-4-I-TQ-R

Detector

temp

(°C)

Initial power-up (IPU) 100——

IPU, detector to analysis temp — —

IPU, column installed Ambient —

IPU, column to analysis temp —

temp

(°C)

Noise

level

SampleComments

Standing

current

(nA)

,

Loading...

Loading...