Page 1

Analytical

Components

Systems

&

Pulsed Discharge Detector

Model D-4-I

Quick Reference Guide

General Precautions:

• Never run the detector without discharge gas. To insure a continuous supply of discharge gas, always

change the gas bottle when it reaches 500 psi.

• Never bake out a column while it is connected to the detector.

• Detector lifetime is shortened in the Ar/Kr PID mode. To maximize detector lifetime, turn off the discharge

power when the GC is not actually analyzing samples.

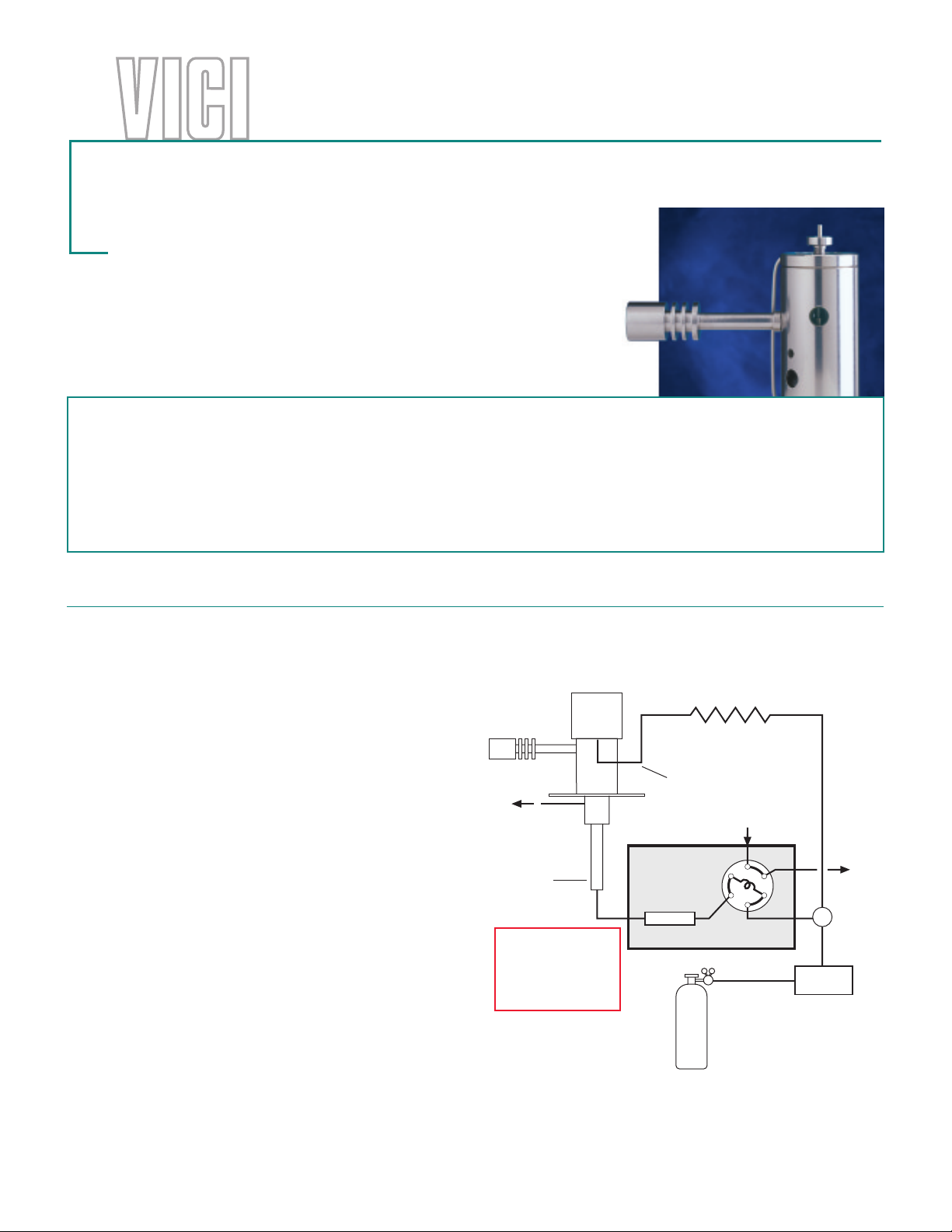

Gas connections

Detector performance is adversely affected by the

presence of impurities in the gas stream. To minimize

the chance of this occurring:

1. Always use the helium purifier.

2. Never use copper or plastic tubes,

even before the helium pur ifier.

3. Never use flow controllers containing

polymers or lubricant.

4. Never use pipe fittings or teflon tape

downstream of the purifier.

You will need:

• Helium

99.9999% purity (“six nines”)

Air Liquide part number:

• Gas regulator

Ultrahigh purity, with stainless steel

diaphragm

Valco part number:

•

Valco Helium Purifier

(included with the detector system)

Valco part number:

• Stainless steel tubing and

Fittings with gold ferrules

(consult the Valco catalog)

• Restrictor

(included with the detector system)

Valco part number:

ValGas 4

TGA-422-580

HP2

TGA-R-30F60P

VENT

COLUMN

INLET

Leave column inlet

plugged until flow

rate is set. (See

“Initial Power-Up”

on next page.)

DISCHARGE GAS

COLUMN

GAS CHROMATOGRAPH

(99.9999% He)

TGA-R-30F60P

RESTRICTOR

(30 mL/min minimum)

DISCHARGE GAS

INLET

SAMPLE

IN

HELIUM

PURIFIER

VENT

TEE

(ZT1)

Page 2

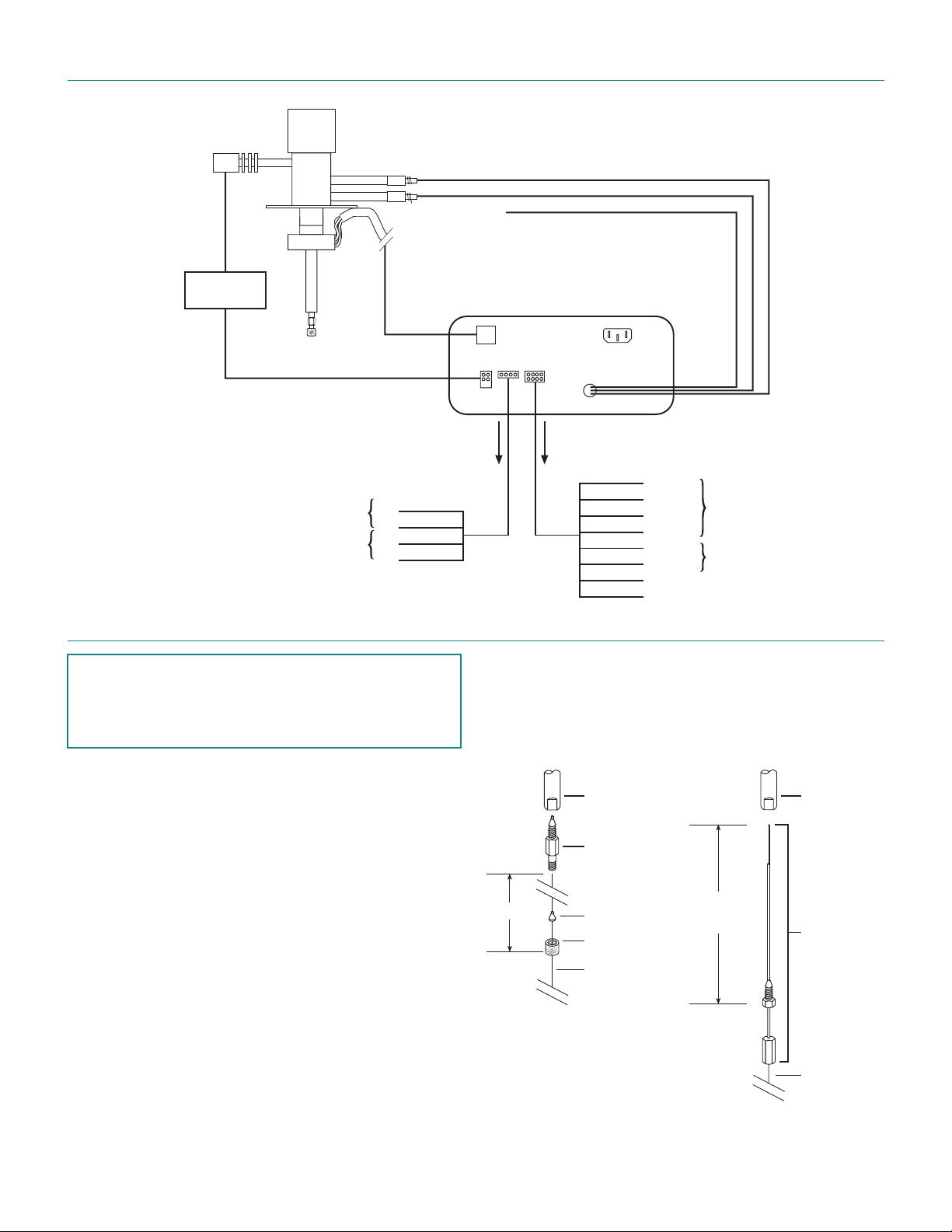

Electrical Connections

HIGH

VOLT AGE

PULSER

MODULE

(no connection)

HEATER CABLE

FROM DETECTOR

BIAS-B

ELECTROMETER

BIAS-A

CONTROLLER

(Rear panel)

RECORDER

ATTENUATED

OUTPUT

SHIELD

+

–

RED

BLACK

GREEN

WHITE

Initial Power-Up

Caution:

•

Always make sure that discharge gas is

flowing before heating and powering up

the detector.

1. Before installing the column, set the gas flow to

30 ml/min (measured at the detector vent). Let it

flow for 15 minutes so that all air is purged from the

helium purifier.

2. Plug in the helium purifier.

3. Install the column as illustrated at right.

4. Turn on the MAINS switch on the back of the

controller. Set the MODE switch on the front

panel of the controller to PDHID.

5. Set the detector temperature and allow time for

the detector and helium purifier to reach the set

temperature.

6. Turn on the DISCHARGE switch on the front panel

of the controller.

TO

11.4 cm

TO COMPUTER

OR INTEGRATOR

RED

BLACK

WHITE

GREEN

BROWN

BLUE

ORANGE

YELLOW

COLUMN

INLET

CAPILLARY

COLUMN

ADAPTER

(IZERA1.5)

COLUMN

FERRULE

NUT

CAPILLARY

COLUMN

0 - 10 V

Common

0 - 1 V

Shield

COM

SET

UNATTENUATED

OUTPUT

AUTO

ZERO

9.8 cm

(set at the

factory)

COLUMN

INLET

PACKED

COLUMN

ADAPTER

(I-23642-D4RU)

The discharge should start within five minutes. In a

clean system, the discharge will have a peach/pink color.

A purple discharge indicates leakage or impurities in the

system.

7. Check the standing/background current on the

controller display. Optimum current is 1.0 - 2.5 nA.

PACKED

COLUMN

Page 3

Troubleshooting

•

High Background Current

Disconnect the column

and cap the column inlet

Pink

Check

discharge

color

•

Low Sensitivity

Check background current

with column removed and

column inlet plugged

Purple/

blue

Do a hydrogen leak test

(described on last page)

Baseline current falls to

normal range (£ 2.5 nA)

Baseline current is still high

(> 2.5 nA)

Leaks in the fittings of the

PDD plumbing

Leaks inside the detector

cell itself

No detectable leaks.

The detector isn’t leaking.

Check for column bleed

and/or leaks in the GC setup.

Tighten leaking fittings

Consult

Valco

Possible bad carrier gas

or empty He bottle. Install

a new bottle.

Baseline current falls to

normal range (£ 2.5 nA)

Baseline current is still high

(> 2.5 nA)

Baseline current falls to

normal range (£ 2.5 nA)

Baseline current is still high

(> 2.5 nA)

Baseline current falls to

normal range (£ 2.5 nA)

Baseline current is still high

(> 2.5 nA)

Consult

Valco

Consult

Valco

Consult

Valco

Sensitivity is in

acceptable range

High background current

(> 2.5 nA)

Refer to “Troubleshooting:

High Background Current”

•

No Peaks

Normal background current

(£ 2.5 nA)

Reinstall column and check

background current

Background current

increases

Background current

remains in normal range

If the background current is stable but there are no peaks:

1. Check column flow.

2. Check the column insertion position (11.4 cm for

capillary columns, 8.9 cm for packed columns).

3. If there are still no peaks, check to make sure that

the GC is actually making an injection.

4. If there are still no peaks, consult Valco.

Check column inlet for

leaks. Tighten fittings.

Check column position

according to drawing on

page 2, and run a sample.

Background current

remains high

Background current

drops to normal range

Sensitivity is in

acceptable range

Sensitivity is still

too low

Remove column and

condition it, then run

a sample

Run

a sample

Remove column and

bake detector at

300°C for four hours.

Install column and run

a sample.

Sensitivity is still

too low

Sensitivity is in

acceptable range

Sensitivity is still

too low

Sensitivity is in

acceptable range

Sensitivity is still

too low

Consult

Valco

•

High Noise Level

If the noise level is high:

1. See if it improves with the GC fan turned off.

2. Check the column insertion position (11.4 cm for

capillary columns, 8.9 cm for packed columns).

3. If the noise level is still high, do a hydrogen leak test

(described on the next page).

4. If there are no leaks found, or leaks are found and

repaired and the noise is still high, consult Valco.

Page 4

Hydrogen Leak Test

A hydrogen leak test allows you to pinpoint loose fittings

and leaks inside the detector.

1. Connect a length of plastic tubing to a regulated

hydrogen bottle. Establish a flow of 5 -10 ml/min.

2. Hold the hydrogen outlet tube at a fitting connection for ten seconds while monitoring the

baseline. (Flip the mode switch to PDECD and

back to PDHID to un-zero the baseline.)

If the baseline stays the same, that connection is

leak-free. If the baseline goes up, you have

located a leak.

3. Tighten the fitting and test it again, repeating as

necessary until every connection has passed the

ten second test.

4. If the current remains high, hold the hydrogen

outlet close to the detector.

tube into any detector holes.)

detector is indicated, contact Valco.

(Do not insert the

If a leak in the

Valco Instruments Co. Inc. Valco International

tel: 800 367-8424

fax: 713 688-8106

valco@vici.com

tel: Int + 41 41 925-6200

fax: Int + 41 41 925-6201

vici@vici.com

Printed in USA © 2003

VICI® and Cheminert

are registered trademarks of

Valco Instruments Co. Inc. and VICI AG

7/03

®

Loading...

Loading...