Page 1

Valco Instruments Co. Inc.

Pulsed Discharge

Detector

Model D-2-IM

Instruction Manual

Valco Instruments Co. Inc.

800

·

367

·

·

688

·

688

8424 sales

·

9345 tech

·

8106 fax

713

713

valco@vici.com

Valco International

Schenkon, Switzerland

Int + 41 · 41 · 925

Int + 41 · 41 · 925

info@vici.ch

·

6200 phone

·

6201 fax

D2-IM.p65

©2011 9/11

Printed in USA

Page 2

This page intentionally left blank for printing purposes

Page 3

Table of Contents

Introduction

System Requirements

Installation

Description and Operating Principles .......................................................................................... 1

Safety Notes and Information ................................................................................................... ...... 2

Symbols

Installation Category

Safety

Maintenance

Components of the Detector System .......................................................................................... 4

Description of Controls ..................................................................................................................... 4

Components Not Included with the Detector System .......................................................... 8

System Purity ........................................................................................................................................ 8

Specifications ....................................................................................................................................... 9

Purity Specifications ........................................................................................................................... 9

GC Column Selection ..................................................................................................................... 10

General Precautions ........................................................................................................................ 11

Mounting the Detector on the GC ............................................................................................. 11

Gas Connections .............................................................................................................................. 12

Installing and Purging the Gas Regulator ....................................................................... 12

Installing and Purging the Helium Purifier .................................................................... 13

Connecting the Discharge Gas to the Detector .......................................................... 14

Column Connection ........................................................................................................................ 14

Testing for Leaks ............................................................................................................................... 14

Electrical Connections .................................................................................................................... 15

Initial Power-Up ................................................................................................................................16

Troubleshooting High Background Current ............................................................................. 17

Checking for Leaks in the Discharge Gas Plumbing .................................................. 17

Column Bakeout Precautions ........................................................................................... 17

Warranty ..................................................................................................................................................... 18

Detector Performance Log .................................................................................................................... 19

Page 4

This page intentionally left blank for printing purposes

Page 5

Introduction

Description and Operating Principle

1

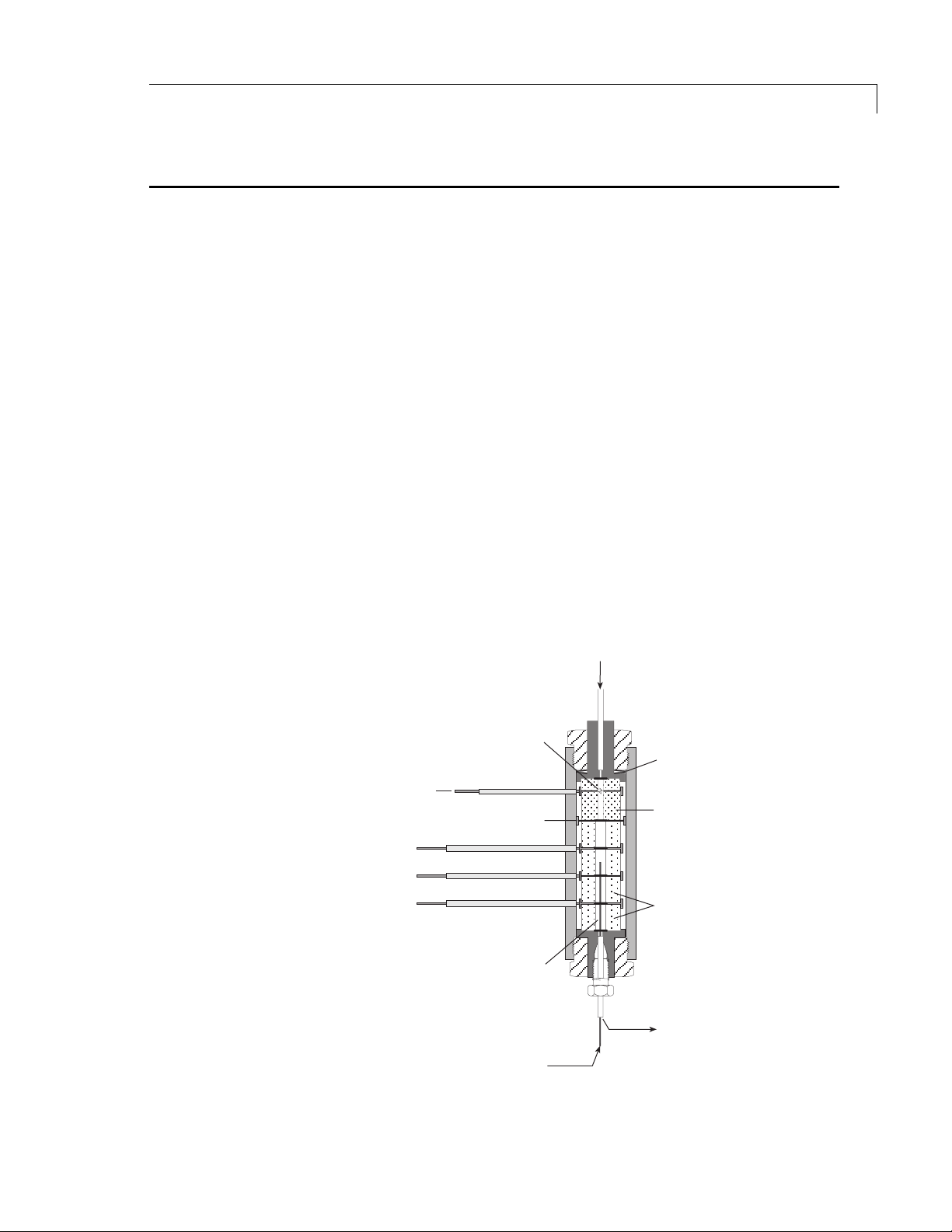

The pulsed discharge detector Model D-2-IM is a universal helium photoionization

detector optimized for trace level work with micropacked and capillary columns.

A schematic representation is shown in Figure 1.

As the name implies, a stable, low power, pulsed DC discharge in helium is utilized

as the ionization source. Elutants from the column, flowing counter to the flow of

helium from the discharge zone, are ionized by photons from the helium discharge

above. Resulting electrons are focused toward the collector electrode by the two

bias electrodes.

The principal mode of ionization is photoionization by radiation arising from the

transition of diatomic helium

This is the well-known Hopfield emission. The photon energy from the He

He

1

+

(

∑

)

A

u

2

to the dissociative 2He(1S

1

) ground state.

2

continuum is in the range of 13.5 eV to 17.7 eV.

The PDHID is essentially non-destructive (0.01 - 0.1% ionization) and highly

sensitive. The response to organic compounds is linear over five orders of

magnitude with minimum detectable quantities (MDQs) in the low or sub

picogram range. The response to fixed gases is positive (the standing current

increases), with MDQs in the low ppb range.

HELIUM INLET

DISCHARGE ZONE

SPRING WASHERS

DISCHARGE ELECTRODE

QUARTZ

GROUND

BIAS ELECTRODE

COLLECTOR ELECTRODE

BIAS ELECTRODE

INSULATOR

SAPPHIRE

INSULATORS

CAPILLARY COLUMN

VENT

COLUMN INLET

Figure 1: Schematic of the D-2-IM detector

Page 6

Introduction

2

The PDHID response is universal except for neon, which has an ionization potential

of 21.56 eV. Since this potential is close to the energy of the He* metastable

(19.8 eV ) but greater than the photon energy from the He2 continuum, neon

exhibits a low ionization efficiency and low detector response. (NOTE: Valco

makes an enhanced mode detector for neon. Consult the factory for information.)

Safety Notes and Information

Symbols

HIGH VOLTAGE

Voltages presenting the risk of electric shock are present in several

places in the equipment. Avoid contact with hazardous live parts.

Do not probe into openings or attempt to defeat safety mechanisms.

HOT SURFACE

The surface of the detector body may be hot while in operation

(possibly in excess of 250°C). Caution should be observed.

ATTENTION

Refer to the manual.

PROTECTIVE EARTH

This internal connection provides protection against electric shock

from mains voltages and should not be removed.

Installation Category

This equipment has been designed for installation category (overvoltage category)

II, pollution degree 2. It has been approved for use only in heavy industrial environments and may not be used in the residential, commercial, or light-industrial

environment.

Page 7

Introduction

Safety

This instrument has been designed and tested in accordance with the product

safety standard, EN61010. It has left the factory in a safe condition. This instruction

manual contains important information and warnings which must be followed by

the user to insure safe operation and to retain the instrument in a safe condition.

The case, chassis, and measuring terminals are connected to the protective earth

contact of the mains inlet. The instrument operates with a three-conductor power

cord having a protective earthing conductor and a plug with an earthing contact.

The mains (line) plug shall only be inserted in a socket outlet provided with a

protective earth contact. The protective action must not be negated by the use

of an extension cord without a protective conductor. Use only with an approved

mains supply cord having a rating of 2A, 250V, or greater. Do not use this equipment in a manner not specified herein.

CAUTION: During normal operation, the detector produces

ultraviolet energy (UVA, UVB), some of which may be

emitted. Do not watch the arc without eye protection.

3

Maintenance

The exterior of the instrument should be cleaned regularly with a dusting brush. If

necessary, the casing can be cleaned with a moistened cloth (99% water + 1% mild

detergent). Spirit or petroleum ether can be used to remove greasy dirt. Any other

cleaning agents can attack the plastic and painted surfaces.

Under no circumstances should the cleaning fluid get into the instrument.

Petroleum ether is flammable, and care should be taken in its use. Under no

circumstances should the detector be disassembled for cleaning. The components

of the detector are assembled with special tooling and held under considerable

force. Disassembly of the detector may present a safety hazard and will result in

its destruction.

Page 8

Introduction

4

Description Quantity Product number

Detector cell, PDHID D2 Mini ionization 1 PD-D2-IM

Pulse supply module 1 PD-M2

Includes: Cable, controller to pulse supply 1 I-23477

Controller unit with power cord 1 PD-C2

Includes: Cable, computer (unattenuated) output 1 I-23136

Helium purifier, miniature version 1 HPM

Helium purifier, standard 1 HP2

Instruction manual 1 MAN-PDD-M

Fittings kit 1 PD-KIT-IM

Includes: 1/16" gold-plated ferrule 5 ZF1GP

Cable, recorder (attenuated) output 1 I-23483

1/32" Vespel ferrule 5 ZF.5V

Fused silica adapter, 40 mm to 1/32" 5 FS.4

Fused silica adapter, 50 mm to 1/32" 5 FS.5

1/16" union 2 ZU1MS6

1/16" tee 1 ZT1

Restrictor, 10 cc/min @ 60 psi He 1 TGA-R-10F60P

Table 1:

Components of the D-2-IM system

Components of the Detector System

Components of the detector system are listed in Table 1. Check the contents of

the packages to verify that everything is present. Contact the factory if anything is

missing or damaged. (NOTE: damaged shipments must remain with the original

packaging for freight company inspection.)

Description of Controls

Controls and connectors are indicated in Figure 2.

MAINS switch

Controls mains (line) voltage to the controller unit. When this switch is on ( | ),

the unit is operational except for the pulse supply (see the next paragraph). The

detector heater will operate (if connected) and high voltage is present on the bias

cables.

DISCHARGE switch and indicator

Controls power to the pulse supply module. When the switch is on and the module

is connected, high voltage is generated by the unit and is present at the detector

electrodes. The indicator will not light if the detector is in the standby mode, or if

the pulse supply is not connected to the controller. The indicator flashes until the

discharge has been established, then glows steadily.

Page 9

Introduction

TEMPERATURE control and indicator

Sets the temperature (°C) of the detector heater block. The indicator is steadily on

when maximum power is being applied to the heater, steadily off when no power

is applied, and regularly blinking on/off when the set temperature has been

established.

Note that due to the fail-safe mechanism designed into the temperature controller,

the heater will not operate if mains power is applied before the heater is connected

or if the detector is too cold (< 0°C). If the heater is disconnected with mains on,

the unit must first be turned off to restore control of the heater; if the unit is

operated in a very cold environment, the detector should first be gently warmed

without power applied.

The fail-safe mechanism will also act under any condition resulting from loss of

control (e.g., over-heating, RTD failure, etc.). If proper procedures have been

followed and the controller will not heat the detector, there is cause to suspect that

the fail-safe mechanism has been activated. Consult the factory or an authorized

representative. Note that the maximum temperature for operation of the

PD-D2-IM is 400°C.

5

Heater control may be lost during periods of fast

electrical transients. The unit will self-recover.

MODE switch

Not used with this detector, since it is in the PDHID mode at all times.

RANGE switch

Determines the full-scale range of the electrometer: 100 nA @ 1X or 10 nA @ 10X.

CURRENT switch

Sets the standing current in PDECD mode. Not used with this detector, since it is in

the PDHID mode at all times.

ATTENUATION control

Determines the attenuation factor for the recorder output.

ZERO push button

Offsets the output signal to zero volts by a measurement of the standing current.

The offset is applied to the output when the button is released. Once set, the

offset is not changed unless the unit is re-zeroed or the mode is changed. To

remove any applied offset and restore the unit to an un-zeroed condition, toggle

the MODE or RANGE switch. The function of this control is duplicated by an

external logic connection; see UNATTENUATED OUTPUT on page 7.

Display

Indicates standing current. In the un-zeroed PDHID mode, the display indicates the

instantaneous signal current in nA. After zeroing, the display indicates the standing

current by which the signal is offset.

Page 10

Introduction

6

TEMPERATURE

CONTROL

TEMPERATURE

INDICATOR

DISCHARGE

INDICATOR

DISCHARGE

SWITCH

160

120

80

200

240

40

DETECTOR TEMP .

400

DISCHARGE

280

MODE

SWITCH

PDECD

RANGE

SWITCH

1X

CURRENT

SWITCH

INCREASE

320

360

PDHID

MODE

10X

RANGE

DECREASE

CURRENT

PULSED DISCHARGE CONTROLLER

2

1

V ECD

nA HID

DISPLAY

16

8

4

ATTENUATION

6432

ZERO

128

256

512

1024

ATTENUATION

CONTROL

ZERO PUSH

BUTTON

HEATER

OUTPUT

PULSE

SUPPLY

HEATER

VALCO INSTR UMENTS CO . INC .

115/230V ~ 175VA MAX

ATTEN

PULSE

SUPPLY

+

SHIELD

ATTENUATED

OUTPUT

MODEL PD-C2

50/60 Hz

OUTPUTS

-

UNATTEN

10V-SHIELD

1V

COM

ZERO

UNATTENUATED

OUTPUT

MAINS INPUT

T2.0A

250V

MAINS

INPUT

WARNING: FOR CONTINUED PROTECTION AGAINST FIRE

HAZARD, REPLACE FUSE WITH SAME TYPE AND RATING.

ATTENTION: UTILISER UN FUSIBLE DE RECHANGE DE MÊME TYPE.

DETECTOR

INPUT: 15V MAX. CAT

FUSE MAINS

ELECTROMETER

BIAS-B

BIAS-A

SWITCH

Figure 2: Controls and connections

on front (top) and back panels of the control module

Page 11

Introduction

ATTENUATED OUTPUT connector

Normally connected to a strip chart recorder. This output has an unattenuated

range of 0 - 10V, and an internal signal reference (-) at zero volts. For best noise

performance, the shield (earth) and signal reference (-) should not be connected

together. The signal from this output is scaled by the attenuation factor set on the

front panel.

UNATTENUATED OUTPUT connector

Normally connected to a data acquisition system or other recording means. For

convenience, a full-scale 0 - 10V output and a 1/10 scale 0 - 1V output are provided,

with an internal signal reference (-) at zero volts. For best noise performance, the

shield (earth) and signal reference (-) should not be connected together. The

internal impedance of these outputs is 1000 ohms. The connection marked ZERO

is a low-true, 5V logic-level input which duplicates the function of the front-panel

ZERO; connection of this input to COM through either a relay contact or logic gate

is equivalent to pressing the ZERO button.

HEATER OUTPUT connector

For connection to the detector heating system.

ELECTROMETER INPUT cable

For connection to the collector electrode of the PD detector. The full-scale input

current is determined by the RANGE switch. Input voltages in excess of 15 VDC

may result in damage to the electrometer.

7

BIAS A, B OUTPUT cables

For connection only to the bias electrodes of the PD detector in the manner

described on page 15 under the heading “Electrical Connections”. These outputs

supply high voltages when power is applied to the unit, and caution should be

observed when connecting or disconnecting these cables.

NOTE: These terminals are for connection only to

equipment having no accessible live parts. Insulation

of external circuits to which these are connected must

meet the requirements of EN61010 for 220 VDC working

voltage.

Page 12

8

System Requirements

Components Not Included with the Detector System

System Purity

• Helium (99.999% purity) and other support gases

• Ultra high purity grade gas pressure regulator with stainless steel diaphragm

• Any special adapters required for connection to the gas regulator

• Flow measuring device

Discharge/Carrier Gas Considerations

The performance of the detector is adversely affected by the presence of any

impurities in the gas streams (carrier, discharge, or dopant). We recommend that a

quality grade of helium 5.0 (99.999% pure or better) be used at all times. Major gas

suppliers offer research grade helium (99.9999% pure) which is particularly low in

fixed gas impurities and should give good results in a clean system, but even the

highest quality carrier gas may contain some water vapor and fixed gas impurities;

hence a helium purifier is included as part of the detector system. The discharge

gas must always be run through the helium purifier.

Whenever a new batch of discharge gas is received, we recommend performing

a blank GC analysis of the gas in the PDHID mode to detect and identify the

presence of any impurities. Gas purity requirements are specified in the next

section.

Tubing

Standards of cleanliness that are suitable for many GC applications may be totally

inadequate for the sensitive PDHID work. All surfaces that contact the gas stream

must be glass or stainless steel. Do not use copper tubing or brass fittings. All

tubes must be thoroughly cleaned and baked before use.

Flow Controllers

The use of valves or flow controllers in which the gas stream is exposed to any

polymer-based packing or lubricating material is to be particularly avoided.

Pressure Regulators

We recommend commercial “ultra-pure” grade regulators with stainless steel

diaphragms. Regulators with diaphragms made of neoprene or other elastomers

should never be used.

Page 13

Specifications

Mains (line): 115/230 V~50/60 Hz, 175 VA

Fuse: 2 A, time-delay, 5 x 20 mm

Pressure: 6.9 kPa (1 psi) operating, 6.9 MPa (1000 psi) max.

Max temperature: 400°C

Heater power: 60 W max., 48 V, PWM

Sensitivity

Range

System Requirements

9

working

10X range: 1.0 V/nA

1X range: 0.1 V/nA ± 1%*

10X: 10 nA full-scale

1X: 100 nA full-scale*

Noise

1X: 20 fA/√Hz (referred to the input), 0.1 - 10 Hz*

10X: 5 fA/√Hz (referred to the input), 0.1 - 10 Hz

Risetime: 10 msec, 10% = 90%*

Output impedance: < 1 Ω , attenuated

*Controller only, PDHID mode, 10 V unattenuated output

Purity Specifications

Helium (discharge and carrier gas) must have a minimum purity of 99.999%, with

< 20 ppm Ne impurity. For trace analysis of fixed gases, we strongly recommend

99.9999% purity He with < 0.5 ppm Ne.

1 KΩ, unattenuated, 1 V, 10 V

Page 14

System Requirements

10

GC Column Selection

To prevent detector contamination, we strongly

recommend disconnecting the column from the

detector during column bakeout procedures.

The PD-D2-IM is optimized for micropacked (1/16" and smaller) and capillary /PLOT

columns. The column tubing must be thoroughly cleaned and baked before the

column is packed. Even when the best care is taken in column tubing cleaning and

in the support and stationary phase selection, a new column will often bleed

compounds, resulting in a considerable increase in the detector baseline. This

initial bleed will usually be reduced to acceptable levels after the column is

conditioned with clean carrier gas flow for several hours at the recommended

bakeout temperature.

Page 15

Installation

General Precautions

11

The detector is usually mounted on top of the GC column oven. The cabling as

supplied requires the discharge module to be located within 0.6 m (2') of the

detector and the controller to be within 1 m (3.5') of the detector and discharge

module. The power cord for the controller is 1.8 m (6') long, and the signal output

cables (attenuated and unattenuated) are 1.2 m (4') long.

• Do not use plastic/polymer or copper tubes for gas handling and inter-

connectons. Use only stainless steel tubing with Valco gold-plated ferrules.

• Do not turn the unit on until the helium discharge gas is flowing through the

detector.

• Do not shut off or disconnect the discharge gas when the detector is hot, even

if the unit is turned off. Turn off both power switches (front and back of the

controller) and allow the detector to cool down naturally before disconnecting

or shutting off the discharge gas.

• Do not cover the unit with materials or devices which would restrict air

circulation.

• Position the controller unit where the mains switch on the rear panel can

be reached easily.

Mounting the Detector on the GC

Vertical Mounting

Most GCs have an existing opening which will allow the PDD to sit vertically on top

of the column oven with the column inlet tube extending into the oven. The vent

tube can either extend into the oven or be carefully bent near the base to remain

outside the oven. If you are replacing an existing detector, you can usually just

remove it and set the PDD in its place. If not, use a drill or chassis punch to drill a

hole of the proper size, and set the detector in position.

While trying to match the mounting holes of the base plate to every GC on the

market is impractical, we have located the mounting holes so that at least two of

them will coincide with existing holes on the GC. If you had to drill a new hole to

mount the PDD, you will have to drill new mounting holes as well. Orient the

detector to allow for easy cable and gas connections.

Horizontal Mounting

Some older GCs have access to the column oven through the side of the GC. This

does not present a problem as far as operation of the PDD is concerned. Drill a

hole at the appropriate location, orient the detector for convenient connection, and

mark the position of the mounting holes. Drill the mounting holes and secure the

detector to the side of the GC with four sheet metal screws (not supplied).

Page 16

Installation

12

Gas Connections

Remember these three points discussed earlier: (1) all surfaces that contact the

gas stream must be glass or stainless steel; (2) do not use copper tubing or brass

fittings; and (3) all tubes must be thoroughly cleaned and baked before use. The

installation instructions below assume that the detector discharge will be supplied

from a nearby cylinder of helium of the proper purity. If your installation is different, you may need to modify the instructions appropriately. A number of Valco

fittings have been supplied in the fittings kit to handle different situations.

Figure 3 illustrates gas connections for a typical PD-D2-IM detector system.

Since the distance from the helium supply to the GC varies from installation to

installation, we do not supply tubing to go from that point to the GC.

TGA-R-10F60P

RESTRICTOR

(10 mL/min minimum)

DISCHARGE GAS

INLET

TEE

(ZT1)

HELIUM

PURIFIER

DISCHARGE GAS

(99.999% He)

VENT

COLUMN

INLET

COLUMN INJECTOR

GAS CHROMATOGRAPH

Figure 3: Gas connections for a PD-D2-IM system

Installing and Purging the Gas Regulator

1. Make sure the on/off valve on the helium cylinder is completely closed. Screw

the CGA fitting nut of the regulator into the helium cylinder. Go beyond fingertight, but do not tighten the nut all the way – some leakage is required for the

purging operation.

2. Turn the output pressure regulating knob completely counterclockwise.

3. Open the cylinder on/off valve slightly and quickly close it again.

4. Adjust the tightness of the regulator connecting nut to allow a pressure reduction of ~690 kPa/sec (100 psi/sec). With a new bottle, the gauge should start

out at about 14 MPa (2000 psi).

5. When the pressure drops into the 1.4 - 3.4 MPa (200 - 500 psi) range, open the

cylinder on/off valve slightly and quickly close it again.

6. Repeat Step 5 eight or ten times to be certain that all the air is purged. On the

final purge, tighten the regulator connecting nut very securely as the pressure

approaches the 2.1 - 3.4 MPa (300 - 500 psi) range.

7. Open the cylinder valve to pressurize the regulator once again. Close the valve

and observe the needle of the high pressure gauge for 15 minutes. If it doesn’t

move, there is no critical leak on the high pressure side of the regulator.

Page 17

EZR21

Installation

13

CAUTION: Never use leak detecting fluids on any part of

this system.

Installing and Purging the Helium Purifier

1. If the pressure regulator has a 1/8" male cone-type outlet port, install the Valco

1/8" external to 1/16" internal reducer (EZR21); if it has a 1/4" male cone-type

outlet port, install the Valco 1/4" external to 1/16" internal reducer (EZR41). For

other regulator outlet fittings, a wide variety of Valco adapters are available.

2. Remove the cap from the inlet tube of the Valco helium purifier and insert the

tube fitting into the 1/16" reducer port. (Keep the outlet tube capped.) Use a

1/4" wrench to turn the nut one-quarter turn past the point where the ferrule

first starts to grab the tubing. Do not remove the fitting. When made up

properly, it should be leak-tight.

3. Turn the output pressure regulating knob clockwise until the gauge registers

345 KPA (50 psi).

4. Allow five minutes for equilibration, then turn the regulating knob all the way

counterclockwise.

5. Observe the needle of the output pressure gauge for 15 minutes. There will be

a slight initial drop, but if it doesn’t move after that, consider that all the connections are tight.

6. If necessary, use an electronic leak detector to locate any leaks. If a leak

detector is not available, tighten all the fittings (including the output pressure

guage), and repressurize the system for another test.

CAUTION: Never use leak detecting fluids on any part of

this system.

7. Upcap the outlet tube of the purifier and purge the system for 15 to 30 minutes

at 60 - 80 mL/min to eliminate air from the purifier getter material.

Page 18

Installation

14

Connecting the Discharge Gas to the Detector

1. If you are supplying the GC from the helium purifier, use the Valco tee (ZT1).

Otherwise, use one of the Valco 1/16" unions (ZU1) to connect the outlet tube

of the purifier to the inlet of the supplied discharge gas restrictor (TGA-R-10F60P).

2. Connect the outlet end of the restrictor to a flow measuring device and adjust

the helium pressure to obtain a flow of and ~10 mL/min for the PD-D2-IM.

3. After setting the flow rate, connect the outlet of the restrictor to the discharge

gas inlet tube at the top of the detector.

Column Connection

The type of column used will determine the parts needed to connect the column.

If a metal capillary or micropacked column is the column of choice, then a packed

column adapter (I-23642-D2-IM) is required. This inlet provides a 1/16" fitting detail

for external connection of the column to the detector with the appropriate ferrule

or fused silica adapter. The same adjustability is offered for column insertion depth

using this adapter.

If a fused silica capillary column is used, the outlet end of the column is inserted

directly into the column at an insertion depth of 7 cm. Instructions below are for

the use of fused silica capillary column.

1. Make a mark on the column 7 cm from the end.

2. Remove the knurled nut and plug from the column inlet manifold at the bottom

of the detector. Slide the nut over the end of the column, followed by the

appropriate column ferrule (FS.4 or FS.5, or ZF.5V for megabore).

3. Insert the column through the column inlet manifold at the bottom of the

detector. Slide it in until the mark is flush with the surface of the knurled nut,

and secure the column by tightening the knurled nut fingertight only.

Testing for Leaks

It is critical for the system to be leak-tight, and an additional check at this point can

save many headaches later on. To test for leaks:

1. Cap the vent outlet tube.

2. Pressurize the entire system with helium to 138 kPa (20 psi).

3. If the system does not hold pressure, check all the fittings with an electronic

helium leak detector. DO NOT use leak detecting liquids.

4. Tighten fittings as required. (Further leak testing is described on page 17 in the

section entitled “Checking for Leaks in the Discharge Gas Plumbing”).

Page 19

Electrical Connections

1. Referring to Figure 4 as necessary, connect the bias and electrometer cables

as follows: the BIAS-B cable to the top electrode (closest to the discharge

electrodes), the electrometer cable (ELECT) to the middle, and the BIAS-A

cable to the bottom electrode.

2. Connect the high-voltage cable from the detector to the pulse supply, and

connect the pulse supply cable between the back of the controller and the

pulse supply. Connect the heater cable from the detector to the back of the

controller.

Installation

15

CAUTION: Do not use a wrench to tighten the SMC

connectors on the bias and electrometer cables.

Connections should be fingertight only.

RECORDER

DISCHARGE

MODULE

ATTENUATED

OUTPUT

SHIELD

+

RED

BLACK

GREEN

WHITE

HIGH

VOLTAGE

HEATER CABLE

FROM DETECTOR

CONTROLLER

(Rear panel)

RED

BLACK

WHITE

GREEN

BROWN

BLUE

ORANGE

YELLOW

0 - 10 V

Common

0 - 1 V

Shield

COM

SET

BIAS-B

ELECT.

BIAS-A

UNATTENUATED

OUTPUT

AUTO

ZERO

COMPUTER OR

INTEGRATOR

Figure 4: Electrical connections

Page 20

Installation

16

Initial Power-Up

1. If it is not already there, set the MODE switch on the front of the controller to

PDHID.

2. Set the discharge gas flow as specified in on page 14 in the section entitled

“Connecting the Discharge Gas to the Detector”.

CAUTION: Always make sure that discharge gas is flowing

before powering up the detector.

3. Apply power to the helium purifier.

4. Turn on the MAINS switch located on the back of the controller.

5. Set the detector temperature to 100°C with the TEMPERATURE control k nob.

Allow time for the detector and helium purifier to reach temperature.

6. Turn on the DISCHARGE switch, located on the front of the controller. The

discharge should start within five minutes. (Once a system has been up and

running, the discharge will start within a few seconds.)

In a clean system, the discharge will have a peach/pink color. A purple discharge

indicates impurities and/or leaks in the discharge gas stream.

7. Check the detector standing/background current, indicated in the LED DISPLAY

on the controller, and record it in the Detector Performance Log on the last page

of this manual. The optimum detector background current is 0.5 to 1.5 nA. The

initial value may be higher, but as the detector bakes out at its operating

temperature, the background current should decrease to the optimum value.

8. The recommended detector temperature is 20°C above the column temperature, with a minimum of 100°C. Set the detector to the operating temperature

required for the intended analysis. When the detector has reached the set

temperature, read and record the standing current.

9. Install the column as described on page 14, leaving the oven at ambient

temperature. Start carrier flow, then read and record the standing current.

The difference between this reading and the one previous is the ionization of

the combined impurities in and eluting with the carrier gas. The smaller the

difference, the better the quality of the gas exiting the column.

10. Set the column oven to the temperature required for the intended analysis.

When the oven reaches the set temperature, read and record the standing

current.

The difference from the previous reading is the ionization of the column

bleed. The smaller the difference, the better the column is conditioned.

NOTE: Some stationary phases will have a higher bleed than others, but

are still suitable for this detector. However, the lower the bleed, the lower

the chances of contaminating the detector cell.

Page 21

From this point, the standing current should be observed and logged after any

system change. In addition, logging the standing current (with and without the

column) on a regular basis is an effective monitor of system integrity (leaktightness and cleanliness). We also recommend tracking the internal standard

(quantity on column/area count) for sensitivity continuity.

Troubleshooting High Background Current

If the background current does not drop below 2 nA even after a 12 hour bakeout,

there is either a leak in the system or the column effluent is not clean. To see if the

high background current is due to the column:

1. Make sure the controller is in the un-zeroed condition. (Refer to the discussion

about the ZERO push button on page 5.)

2. Completely disconnect the column from the column inlet tube, leaving the inlet

open.

3. Watch the detector standing/background current, indicated in the controller

DISPLAY. If the current remains high, then either the system has a leak in the

discharge gas supply line or the discharge gas has impurities in it. Proceed to

the next section, “Checking for Leaks in the Discharge Gas Plumbing”. If the

current decreases dramatically, then either the carrier gas supply has leaks

and/or contaminants, or the column is the source of contamination and needs

a bakeout. Read the “Column Bakeout Precautions” below before proceeding.

Installation

17

Checking for Leaks in the Discharge Gas Plumbing

Leaks can be detected with hydrogen. A small lecture bottle of hydrogen with a

regulated flow of 10-15 mL/min through a small outlet tube is all that is required.

(This method can only be used to detect leaks on the discharge gas side of the

plumbing and between the column and detector inlet.)

1. Make sure the controller is in its un-zeroed condition. (Refer to the discussion

about the ZERO push button on page 5.)

2. Hold the hydrogen outlet tube at a fitting connection for ten seconds while

monitoring the standing current display on the controller.

3. If the current remains the same, proceed to the next fitting. If the current

increases, there is a leak at that connection. Tighten the fitting and test it again,

repeating as necessary until there is no change in the standing current.

4. Repeat the test for every fitting in the discharge gas plumbing.

5. Reinstall the column according to the instruction on page 14. When the

standing current reaches an acceptable level, the detector is ready for use.

Proceed to the next chapter, “Mode Selection and Setup”. If the current stays

high, use this method to check for leaks at the column/detector connection.

Column Bakeout Precautions

To prevent detector contamination, we strongly recommend disconnecting the

column from the detector during column bakeout procedures.

When the column in reinstalled after bakeout (refer to page 14 if necessary), the

standing current should be at an acceptable level. If you have exhausted these

troubleshooting methods and the standing current is still high, consult the factory.

Page 22

18

Warranty

This Limited Warranty gives the Buyer specific legal rights, and a Buyer may also

have other rights that vary from state to state. For a period of 365 calendar days

from the date of shipment, Valco Instruments Company, Inc. (hereinafter Seller)

warrants the goods to be free from defect in material and workmanship to the

original purchaser. During the warranty period, Seller agrees to repair or replace

defective and/or nonconforming goods or parts without charge for material or

labor, or, at the Seller’s option, demand return of the goods and tender repayment

of the price. Buyer’s exclusive remedy is repair or replacement of defective and

nonconforming goods, or, at Seller’s option, the repayment of the price.

Seller excludes and disclaims any liability for lost profits, personal injury,

interruption of service, or for consequential incidental or special damages

arising out of, resuiting from, or relating in any manner to these goods

This Limited Warranty does not cover defects, damage, or nonconformity resulting

from abuse, misuse, neglect, lack of reasonable care, modification, or the attachment of improper devices to the goods. This Limited Warranty does not cover

expendable items. This warranty is VOID when repairs are performed by a

nonauthorized service center or representative. For information about authorized

service centers or representatives, write Customer Repairs, Valco Instruments

Company, Inc, P.O. Box 55603, Houston, Texas 77255, or phone (713) 688-9345.

At Seller’s option, repairs or replacements will be made on site or at the factory.

If repairs or replacements are to be made at the factory, Buyer shall return the

goods prepaid and bear all the risks of loss until delivered to the factory. If Seller

returns the goods, they will be delivered prepaid and Seller will bear all risks of loss

until delivery to Buyer. Buyer and Seller agree that this Limited Warranty shall be

governed by and construed in accordance with the laws of the State of Texas.

The warranties contained in this agreement are in lieu of all other warranties

expressed or implied, including the warranties of merchantability and fitness for

a particular purpose.

This Limited Warranty supercedes all prior proposals or representations oral or

written and constitutes the entire understanding regarding the warranties made by

Seller to Buyer. This Limited Warranty may not be expanded or modified except in

writing signed by the parties hereto.

Page 23

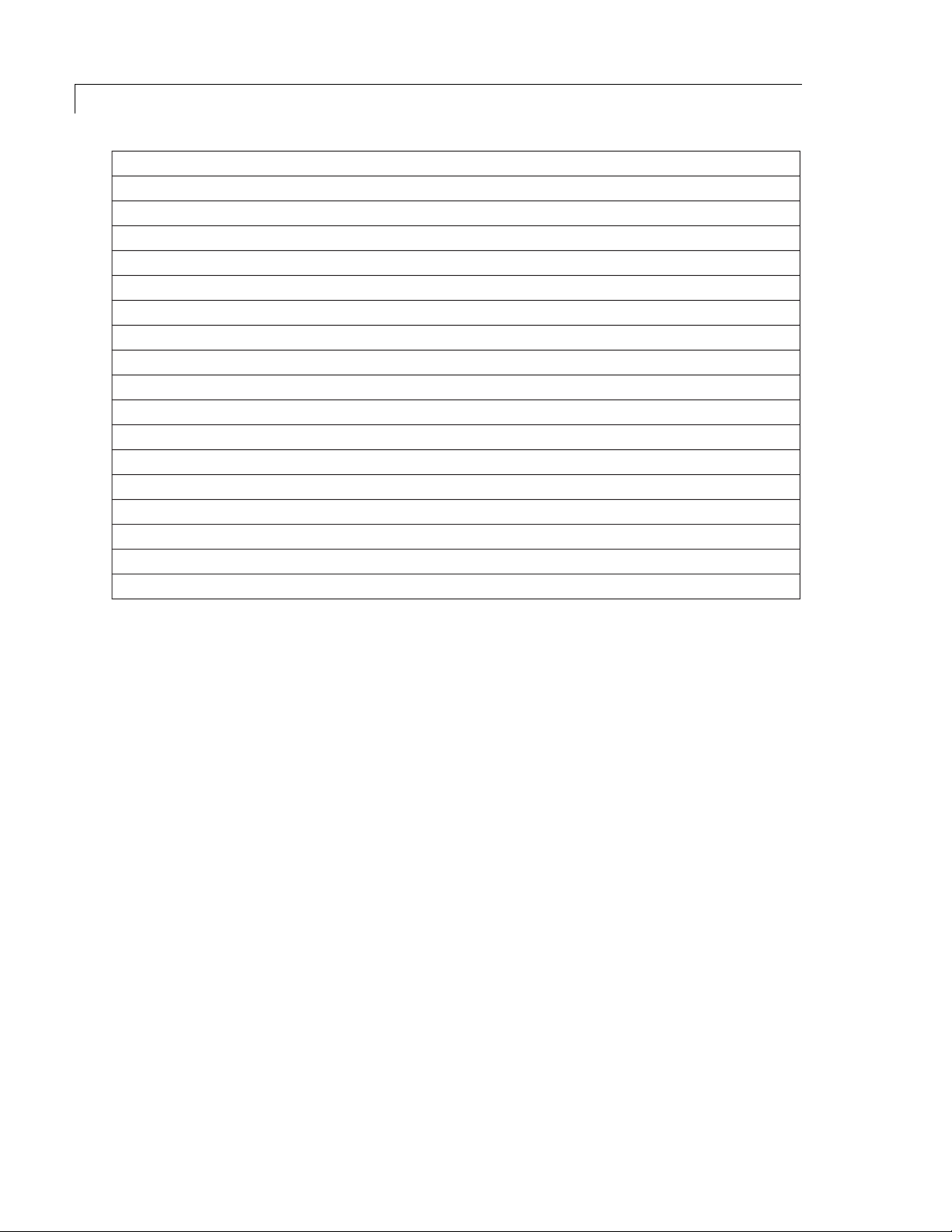

Detector Performance Log

In addition to the occasions indicated in the Comments area of the table below, (see Initial Power-Up, page

16), the standing current should be observed and logged after any system change. Logging the standing

current (with and without the column) on a regular basis is also an effective monitor of system integrity

(leaktightness and cleanliness). To check sensitivity continuity, we recommend tracking the internal standard

(quantity on column/area count). Additional log pages can be downloaded from the support/manuals section

of www.vici.com.

19

Detector Model: Serial Number: Date of purchase:

Date

Operator Column

D-2-I M

Detector

temp

(°C)

Initial power-up (IPU) 100

IPU, detector to analysis temp

IPU, column installed Ambient

IPU, column to analysis temp

temp

(°C)

Noise

level

SampleComments

Standing

current

(nA)

Loading...

Loading...