Page 1

V600

PNEUMATIC INTERNAL VIBRATORS

OPERATING MANUAL

We reserve the right to improve, modify or withdraw specifications or products without notice or obligation.

MODEL V628 V635 V645 V655 V665 V675 V685 V6105 V6140 V6160

Head Diam. (mm)

28 35 45 55 65 75 85 105 140 160

Head Length (mm)

234 278 285 316 327 366 395 395 508 508

Frequency (VPM)

18000 18000 17000 17000 18000 18000 17000 13500 10000 10000

C/F Force (N)

1440 1924 3500 6050 9301 14851 22184 22304 32460 49347

Air Consumption (l/min)

500 608 736 820 1018 1218 1600 2100 2880 3750

Weight (kgs)

4.4 6 8 9 10 15 19 23 35 41.5

Radius of Effectiv. (cm)

16 20 25 38 44 50 55 65 95 105

S P Level (dB)

104.5 107.2 113 109 113 112.1 109 112.2 115 115

Vibration (M.sec2)

3.2 3 2.74 4.5 4.4 2.24 3.1 4.4 4.8 4.8

Air Pressure (psi)

87

Sound and Vibration readings taken 1 metre from the poker head

Air Consumption established with supplied pressure of 6 bar

IMPORTANT NOTICE

Vibrators and vibrating equipment can be dangerous if not used correctly.

1. DO NOT hold steel vibrating heads when running.

2. DO NOT stand or sit on vibratory equipment when running.

3. USE ONLY for the purpose intended.

4. USE ONLY when pneumatic hoses and fittings are securely tightened.

5. ALWAYS wear ear protectors.

Page 2

General Safety

For your personal protection and safety of others around you on site, please read and ensure you fully understand the following safety information. It is the responsibility of the operator to fully understand how to operate

this equipment safely. If you are not sure consult your supervisor.

Points to remember are:

1. Keep unauthorised personnel at a safe distance from the work area.

2. Personal Protective Equipment (PPE) must be worn by the operator whenever this equipment is being

used, i.e. Safety goggles, gloves, ear defenders, dust mask and steel toe capped footwear. Always protect skin from contact with concrete.

3. Ensure that the compressor does not exceed 90 psi.

4. Never dismantle or tamper with any seals or covers fitted. Always check the vibrator thoroughly before

use for condition and safety. If any parts are damaged or missing do not use the vibrator until it is repaired or replaced.

5. The air supply must be switched off before any work is carried out on the vibrator. To prevent accidental

starting of the vibrator, it must be disconnected from the air supply.

6. The vibrator should never be left running out of concrete as it will become extremely hot and internal parts

will be damaged. Caution must be exercised when touching the vibrator head.

7. When the vibrator is not used for long periods of time, store it in a clean, dry and protected environment.

It must be hung up with the head upwards and the control handle open to allow moisture etc. to escape

from the vibrator.

8. Some vibration from vibrator is transmitted through the flexible hose to the operator’s hands. The hose

should not be held within 1 metre from the head of the vibrator at any time. Operational exposure time

may need limiting if fingers become effected.

9. Do not operate the vibrator when you are feeling unwell, tired or when under the influence of alcohol or

drugs.

2

ATTENTION Never use a high pressure compressor.

Page 3

3

General Maintenance

1. Vibrators are delivered without lubrication. Ensure to add oil before starting the vibrator.

2. Before connecting the vibrator, ensure the air line is clean from any water or dirt it may contain.

3. Refill lubricator after every four hours of use with 20/30 S.E.A. non-detergent oil.

4. To start the vibrator it may be necessary to tap the vibrator’s hardened nosepiece onto a firm surface.

5. After use, hang the vibrator with the head upwards and leave the control handle open to drain out of any

water or dirt.

Dismantling and Re-assembly Instructions

1. Replacement of Vane and Rotor

Hold housing (4) in a vice and unscrew nosepiece (1A) - right-hand thread. Remove from the vice and by

angling downwards the rotor is free to drop into the hand ensuring not to cause damage. The parts should

be cleaned and examined . If the nosepiece shows signs of excessive wear, then it should be replaced (see

point 4). Vanes must be a snug sliding fit in the rotor and fitted so that the vane cuts-out face away from the

milled slot in the rotor. Adjust length of vane to 0.1 - 0.15mm shorter than the rotor.

Re-assembly is opposite to the above, but the following should be observed:

1. Lightly oil running faces of the rotor.

2. Insert rotor so that the exhaust holes are in opposite end to the nosepiece.

3. Fit a new ‘O’ ring or fibre washer (2) onto the nosepiece (1A).

Note

Some models (V665-V6105) have nosepieces (1) and separate front closure plates (3). Dismantling is similar

to the above and these two parts are available as spares.

2. Removal of Rear Body, Rear Closure Plate and Hoses

Cut exhaust hose clip (16), pull off exhaust hose (15) from exhaust body (17). Unscrew exhaust body (17)

from lubricator/handle (39/30), then pull out handle to expose hose clip (10). Cut hose clip (10) to release inlet

hose (11) from the handle. Hold housing (4) in a vice and unscrew rear body (12) - left-hand thread, removing

complete with exhaust hose (15). If the hose is to be replaced then unscrew hose sleeve (13), pull out hose

(15) from rear body (12) and remove hose protection spring (14) - only on models V675 - V6105. Using inlet

hose (11) pull out rear closure plate (7), locking ring (8) and inlet hose connector (9). All parts should be

cleaned and the rear closure plate (7) examined for signs of wear (see point 4).

3. Re-assembly

Rear closure plate (7), inlet hose fitting (9) and inlet hose (11) should be inserted into the housing as an assembly, ensuring that the plate is kept square to the housing (4) and pushed onto the housing shoulder. Slide

new locking ring (8) over inlet hose (11) and locate behind rear closure plate (7). If necessary, fix exhaust

hose (15) into rear body (12), insert hose protection spring (14) - only models V675 - V6105, and clamp with

hose sleeve (13). The assembly can then be screwed onto the housing (4) ensuring that a new ‘O’ ring or

fibre washer (2) is fitted. Adjust hose lengths so that the inlet hose (11) protrudes approximately 65mm from

the exhaust hose (15). Slide new clips (10 & 16) onto respective hoses (11 & 15). Pass inlet hose (11)

through exhaust body (17) and fit onto inlet hose connector (18) using hose clip (10). Screw exhaust body

(17) onto control handle (30). Push exhaust hose (15) onto exhaust body (17) and fit hose clip (16).

4. Wear Criterion

The optimum condition of the vibrator turbine assembly to produce maximum speed and therefore power is

determined by the total air gap of the rotor. Ideally this should be between 0.06 - 0.13mm and a total gap

greater than 0.20mm greatly impairs the performance. The length of the rotor is 129.00 - 129.02mm when

assembled at the factory and if worn below 128.70mm, it should be replaced.

OPERATING AND MAINTENANCE INSTRUCTIONS

Models V 628, 635, 645, 655, 665, 675, 685 & 6105

Page 4

4

Models V 628, 635, 645, 655, 665, 675, 685 & 6105

Page 5

5

Ref. Description Qty. V628 V635 V645 V655 V665 V675 V685 V6105

1

Nosepiece 1 - - - - 16265 3551 1602 16246

1A

* 1part Nosepiece / FC plate 1 16310 16206 16216 16227 - - - -

2

* ‘O’ Ring 2 16314 779 1808 2126 16268 2330 1600 16251

3

* Front Closure Plate 1 - - - - 16260 16230 16380 16240

4

Housing 1 16301 16201 16211 16221 16261 16231 16381 16241

5

Rotor 1 16302 16202 16212 16222 16262 16232 16382 16242

6

* Vane 1 16303 16203 16213 16223 16263 16233 16383 16243

7

* Rear Closure Plate 1 16304 16204 16214 16224 16264 16234 16384 16244

8

* Locking Ring 1 16307 16134 7704 7663 16267 7688 - 16252

9

Inlet Hose Connector 1 - - 5521 16225 16225 16235 16245 16245

10

Inlet Hose Clip 2 16313 137 137 5456 5456 5211 5211 5211

11

* Inlet Hose 1 46073 788 788 1583 1583 540 540 540

12

Rear Body 1 16306 2622 7701 1576 16266 3553 1601 16247

13

Hose Sleeve 1 - 2623 1730 1582 1582 1604 1604 1604

14

Hose Protection Spring 1 - - - - - 1479 1479 1479

15

Exhaust Hose 1 171 2021 7985 1584 1584 541 541 541

16

* Exhaust Hose Clip 1 Bandit 3679 2392 75 75 76 76 76

17

Exhaust Body 1 16040 10225 10224 10223 10223 10222 10222 10222

18

Inlet Hose Connector 1 16311 10588 10588 10221 10221 10219 10219 10219

30

Steel Handle Complete 1 16120 16120 16120 16120 16120 16120 16120 16120

31

* Rubber Gland 1 81 81 81 81 81 81 81 81

32

* Gauze Filter 1 156 156 156 156 156 156 156 156

33

Q / R Coupling 1 2512 2512 2512 2512 2512 2512 2512 2512

34

* ‘O’ Ring 2 2273 2273 2273 2273 2273 2273 2273 2273

35

Handle Shaft 1 2261 2261 2261 2261 2261 2261 2261 2261

37

Twist Grip 1 2260 2260 2260 2260 2260 2260 2260 2260

38

Adaptor 1 16042 16042 16042 16042 16042 16042 16042 16042

39

Lubricator Complete 1 10270 10270 10270 10270 10270 10270 10270 10270

40

Lubricator Tube 1 10289 10289 10289 10289 10289 10289 10289 10289

41

‘O’ Ring 1 10273 10273 10273 10273 10273 10273 10273 10273

42

Lubricator Body 1 10271 10271 10271 10271 10271 10271 10271 10271

43

‘O’ Ring 1 2524 2524 2524 2524 2524 2524 2524 2524

44

Oil Filler Screw 1 2265 2265 2265 2265 2265 2265 2265 2265

46

Felt 9 2520 2520 2520 2520 2520 2520 2520 2520

47

Bleed Wire 1 2521 2521 2521 2521 2521 2521 2521 2521

Opt.

Rubber Nosepieces 1 - 16208 16218 16229 19145 3611 - -

Spare Parts

* Most frequently needed parts

Page 6

6

OPERATING AND MAINTENANCE INSTRUCTIONS

Models V6140 & V6160

General Maintenance

1. Vibrators are delivered without lubrication. Before using the vibrator ensure to add 20/30 S.E.A. nondetergent oil.

2. Before connecting the vibrator, ensure the air line is clean from any water or dirt it may contain.

3. These models do not have any oil reservoir thus it is essential to use an air line lubricator.

4. To start the vibrator it may be necessary to tap the vibrator’s hardened nosepiece onto a firm surface.

5. After use, it is important that the vibrator is filled with 60ml of oil and run for 30sec. before storage.

Then hang the vibrator with the head upwards and the on/off valve open to drain out of any water or dirt.

Dismantling and Re-assembly Instructions

1. Replacement of Vane and Rotor

Hold housing (3) in a vice and unscrew nosepiece (1) - right-hand thread. Remove front plate (7) using 16mm

extractor. This allows the rotor (5) and vane (4) to be removed for inspection for wear and damage. Vanes

must be a snug sliding fit in the rotor and fitted so that the vane cuts-out face away from the milled slot in the

rotor. Adjust length of vane to 0.1 - 0.15mm shorter than the rotor.

Re-assembly is opposite to the above, but the following should be observed:

1. Lightly oil running faces of the rotor.

2. Insert rotor so that the exhaust holes are in opposite end to the nosepiece.

3. Fit a new ‘O’ ring (2) onto the nosepiece (1).

2. Removal of Rear Body

Undo nut (36) and remove handle (35), then undo nut (24) and clamp nut (21). You can then unscrew rear

body (6) - left hand thread. Should the rear plate (8) need to be removed, this can be pressed out. You will

need to remove the rotor first from the vibrator to do this.

Re-assembly is opposite to the above, but in order to refit the clamp nut (21), you will need to use M12

female extractor to slightly stretch the inlet hose (17) to line up the thread with the hole in the tube. Once

the clamp nut has been fitted, the rest of the handle can be assembled.

3. Removal of Bush

Hold handle tube (34) in a vice and unscrew nut (10) - right-hand thread. Unscrew locking nut (13) - left hand

thread, the tube will now separate from the rubber bush (14). To fit a new bush (14), replace the locking nut

(13) and push new bush into place. Then place tube with the new bush into the rear body (6) and refit nut (10).

4. Wear Criterion

The optimum condition of the vibrator turbine assembly to produce maximum speed and therefore power is

determined by the total air gap of the rotor. Ideally this should be between 0.06 - 0.13mm and a total gap

greater than 0.20mm greatly impairs the performance. The length of the rotor is 110.00mm when assembled

at the factory and if worn below 109.70mm, it should be replaced.

Page 7

7

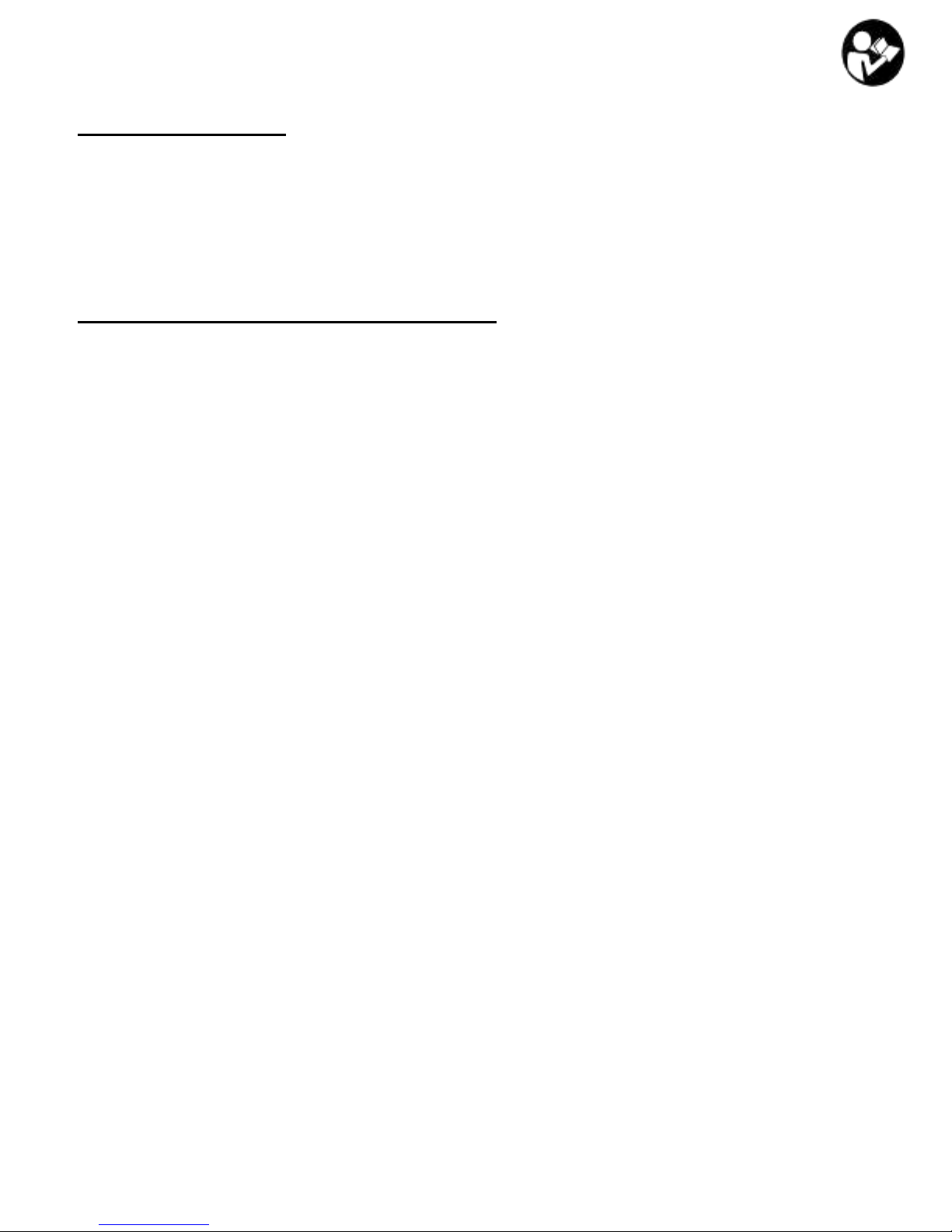

Ref. Description Qty. V6140 V6160 Ref. Description Qty. V6140 V6160

1

* Nose piece 1 7500 16393

24

Lock Nut 1 1564 1564

2

‘O’ Ring 2 1534 16395

25

Cover 1 16430 16430

3

Housing 1 7501 16388

27

Slide Valve 1 46155 46155

4

Vane 1 16353 16394

28

Rear Inlet Body 1 16432 16432

5

Rotor 1 7503 16389

29

Exhaust Banjo Fitting Assy 1 16429 16429

6

Rear Body 1 1533 16390

Exhaust Banjo Sleeve 1 16433 16433

7

* Front Closure Plate 1 7502 16392

Exhaust Banjo Inlet 1 16434 16434

8

* Rear Closure Plate 1 7504 16391

30

External Circlip 1 16180 16180

9

Inlet Hose Connector 1 1528 1528

31

‘O’ Ring 2 16181 16181

10

Nut (bush support tube) 1 1539 1539

32

Banjo Spindle 1 16431 16431

11

Front Spacer 1 1542 1542

33

Handle Clamp Assy 2 16355 16355

12

Rear Spacer 1 1544 1544

Tube (flexible handle) 2 1555 1555

13

Nut (rear body) 1 1538 1538

Clamp Collar 2 16367 16367

14

Bush (shock absorbing) 1 1540 1540

Hex Head Screw 2 16373 16373

15

Sealing Ring Rear 1 1541 1541

Hex Nyloc Nut 2 16374 16374

16

‘O’ Ring 1 2330 2330

M8 Plain Washer 2 46017 46017

17

* Inlet Hose 1 2021 2021

34

Support Tube Assy 1 16363 16363

18

Quick Release Joint 1 1654 1654

Bush Support Tube 1 1536 1536

19

* Rubber Gland 1 81 81

Rigid Exhaust Tube 1 16364 16364

20

* Gauze Filter 1 156 156

35

Flexible Handle Assy 2 1657 1657

21

Exhaust Shield Clamp Nut 1 16428 16428

Flexible Handle Connector 2 1556 1556

22

Exhaust Deflector 1 1646 1646

36

Hex Nyloc Nut Thin Type 4 1559 1559

23

Hose Fitting 1 1636 1636

37

M14 Plain Washer 4 16372 16372

Spare Parts

1 2 4 3 6 2

5 8 7

32

9

11 10 12 14

16

15

13

34 17

200

450

1536 Bush Support Tube

22

23

20 21 19 18

24

25

28

31

29

30

27

33

35 36 37

V6160

V6140

* Most frequently needed parts

Page 8

2 CHAPEL ROAD, PORTSLADE, BRIGHTON, BN41 1PF ENGLAND

Tel. +44(0) 1273 430977 Fax. +44 (0) 1273 430978

Web. www.vibtec.com E-mail. sales@vibtec.com

Loading...

Loading...