Page 1

Technical Data Sheet

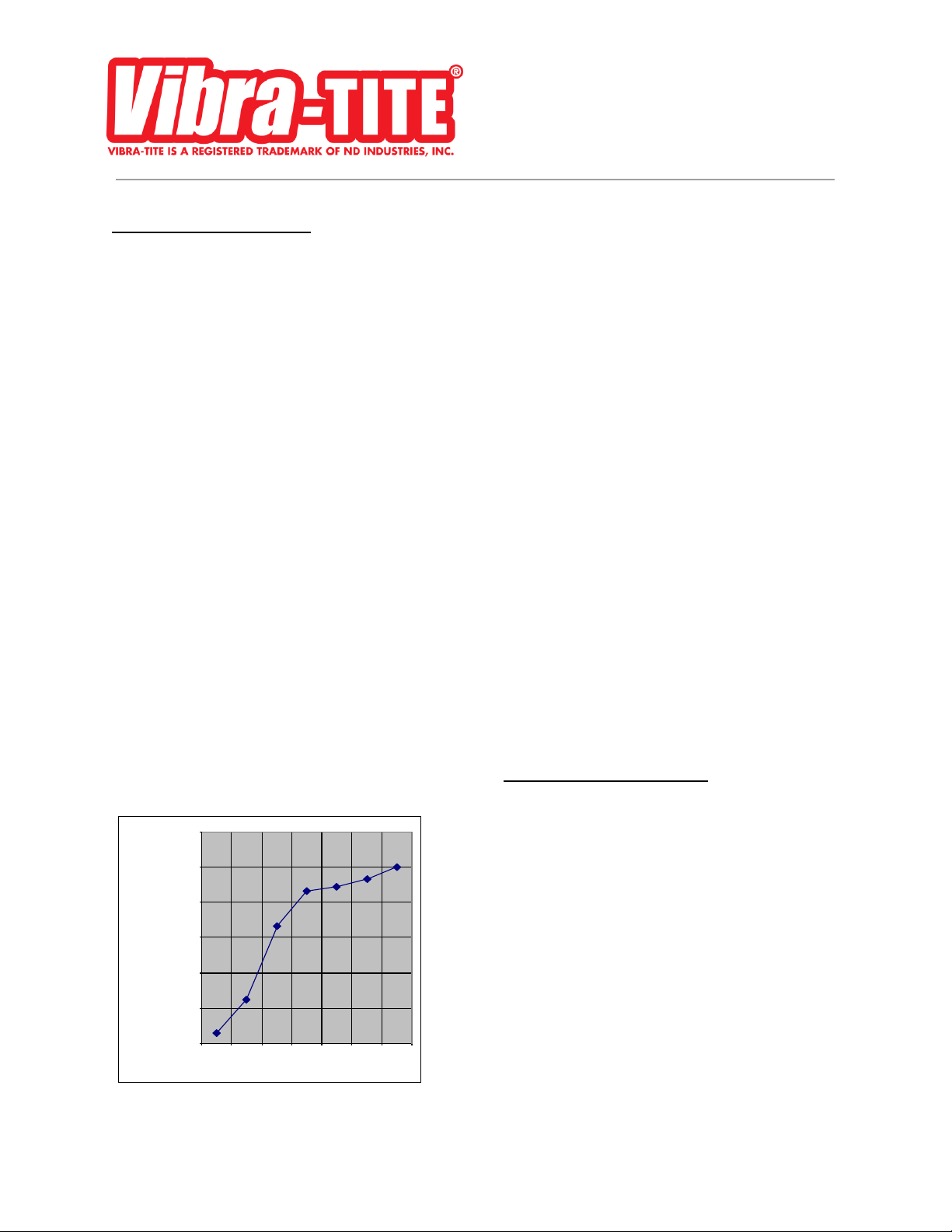

0%

20%

40%

60%

80%

100%

120%

5 min 10 min 30 min 2 hr 4 hr 8 hr 24 hr

Cur e Ti me

% of Ful l

St ren gth

Vibra-Tite® 548

Retaining Compound

September 2012

Product Description

Vibra-TITE 548 is a medium viscosity, quick curing,

high strength anaerobic retaining compound. VibraTITE 548 is used for tight-clearance, and slip-fit

metal applications. The product performs on

aluminum, steel, plated, stainless steel, and special

alloy parts. Vibra-TITE 548 exhibits good

temperature and solvent resistant. Vibra-TITE 548

can be used to create an air-tight seal on cylindrical

assemblies. This product cures rapidly on all metal

surfaces.

Typical Applications

Locks shaft and hubs together for gears,

bearing, bushings

Bonds pins, adaptors, plugs

Properties of Uncured Material

Chemical Type Anaerobic

Appearance Green

Toxicity Low

Solids 100%

Viscosity 450-600 cPs

Specific Gravity 1.1

Typical Curing Performance

Cure Speed

The cure rate depends on temperature and substrate.

The graph below shows the shear strength developed

with time on steel pins and collars.

Performance of Cured Material

Typical Values

Fixture Time 2-5 min @ 72oF

Full Cure Time 24 hrs @ 72oF

Temperature Range -60oF to 350oF

(-51oC to 177 oC)

Shear Strength

Cold rolled steel 15 min cure >1800 psi

Cold rolled steel 24 hr cure >3260 psi

Aluminum >1000 psi

Static shear strength was measured on cylindrical

parts with a 0.002” diametrical clearance.

Environmental and Fluid Resistance

(Shear strength values)

Typical Values

Heat age 100%

Engine oil@ 150oC 95%

Brake fluid @ 150oC 90%

ATF @ 150oC 90%

50/50 water/

ethylene glycol @ 120oC 92%

Water @ 100oC 92%

Gasoline @ 25oC 100%

Diesel fuel @ 25oC 100%

Ethyl Alcohol @25oC 75%

General Information

Storage

Product should be stored in a cool and dry location at

temperatures between 14°F (-10°C) to 86°F (30°C).

Shelf life is 2 years from date of manufacture when

stored at 72±8°F (22±4°C).

Note

The data are furnished for information only and are

believed to be reliable. We cannot assume

responsibility for the results obtained by others over

whose methods we have no control. It is

recommended that the product be tested in the

application for which it is to be used.

Loading...

Loading...