Page 1

Model 086D50

Impact Hammer

Installation and Operating Manual

For assistance with the operation of this product , contact the Division of PCB

Piezotronics, Inc.

Division toll-free 888-684-0015

24-hour SensorLineSM 716-684-0001

Fax 716-685-3886

E-mail vibration@pcb.com

Page 2

Warranty, Service, Repair, and

Return Policies and Instructions

The informati on contained in this document supersedes all similar i nformation th at

may be found elsewhere in this manual.

Total Customer Satisfaction – PCB

Piezotronics guarantees Total Customer

Satisfaction. If, at any time, for any

reason, you are not completely satisfied

with any PCB product, PCB will repair,

replace, or exchange it at no charge. You

may also choose to have your purchase

price refunded in lieu of the repair,

replacement, or exchange of the product.

Service – Due to the sophisticated nature

of the sensors and associated

instrumentation provided by PCB

Piezotronics, user servicing or repair is

not recommended and, if attempted, may

void the factory warranty. Routine

maintenance, such as the cleaning of

electrical connectors, housings, and

mounting surfaces with solutions and

techniques that will not harm the

physical material of construction, is

acceptable. Caution should be observed

to insure that liquids are not permitted to

migrate into devices that are not

hermetically sealed. Such devices should

only be wiped with a dampened cloth

and never submerged or have liquids

poured upon them.

Repair – In the event that equipment

becomes damaged or ceases to operate,

arrangements should be made to return

the equipment to PCB Piezotronics for

repair. User servicing or repair is not

recommended and, if attempted, may

void the factory warranty.

Calibration – Routine calibration of

sensors and associated instrumentation is

recommended as this helps build

confidence in measurement accuracy and

acquired data. Equipment calibration

cycles are typically established by the

users own quality regimen. When in

doubt about a calibration cycle, a good

“rule of thumb” is to recalibrate on an

annual basis. It is also good practice to

recalibrate after exposure to any severe

temperature extreme, shock, load, or

other environmental influence, or prior

to any critical test.

PCB Piezotronics maintains an ISO9001 certified metrology laboratory and

offers calibration services, which are

accredited by A2LA to ISO/IEC 17025,

with full traceablility to N.I.S.T. In

addition to the normally supplied

calibration, special testing is also

available, such as: sensitivity at elevated

or cryogenic temperatures, phase

response, extended high or low

frequency response, extended range, leak

testing, hydrostatic pressure testing, and

others. For information on standard

recalibration services or special testing,

contact your local PCB Piezotronics

distributor, sales representative, or

factory customer service representative.

Returning Equipment – Following

these procedures will insure that your

returned materials are handled in the

most expedient manner. Before returning

any equipment to PCB Piezotronics,

contact your local distributor, sales

representative, or factory customer

service representative to obtain a Return

Page 3

Materials Authorization (RMA)

Number. This RMA number should be

clearly marked on the outside of all

package(s) and on the packing list(s)

accompanying the shipment. A detailed

account of the nature of the problem(s)

being experienced with the equipment

should also be included inside the

package(s) containing any returned

materials.

A Purchase Order, included with the

returned materials, will expedite the

turn-around of serviced equipment. It is

recommended to include authorization

on the Purchase Order for PCB to

proceed with any repairs, as long as they

do not exceed 50% of the replacement

cost of the returned item(s). PCB will

provide a price quotation or replacement

recommendation for any item whose

repair costs would exceed 50% of

replacement cost, or any item that i s not

economically feasible to repair. For

routine calibration services, the Purchase

Order should include authorization to

proceed and return at current pricing,

which can be obtained from a factory

customer service representative.

Warranty – All equipment and repair

services provided by PCB Piezotronics,

Inc. are covered by a limited warranty

against defective material and

workmanship for a period of one year

from date of original purchase. Contact

DOCUMENT NUMBER: 21354

DOCUMENT REVISION: B

ECN: 17900

PCB for a complete statement of our

warranty. Expendable items, such as

batteries and mounting hardware, are not

covered by warranty. Mechanical

damage to equipment due to improper

use is not covered by warranty.

Electronic circuitry failure caused by the

introduction of unregulated or improper

excitation power or electrostatic

discharge is not covered by warranty.

Contact Information – International

customers should direct all inquiries to

their local distributor or sales office. A

complete list of distributors and offices

can be found at www.pcb.com.

Customers within the United States may

contact their local sales representative or

a factory customer service

representative. A complete list of sales

representatives can be found at

www.pcb.com. Toll-free telephone

numbers for a factory customer service

representative, in the division

responsible for this product, can be

found on the title page at the front of this

manual. Our ship to address and general

contact numbers are:

PCB Piezotronics, I nc.

3425 Walden Ave.

Depew, NY 14043 USA

Toll-free: (800) 828-8840

24-hour SensorLine

SM

: (716) 684-0001

Website: www.pcb.com

E-mail: info@pcb.com

Page 4

1

Installation and Operating Manual

ICP® Impulse Force Test Hammer

Models: 086C01, 086C02, 086C03, 086C04, 086D05

086D20, 086D50, 086D80

Manual Number 19198

Contents:

1.0 Introduction …………………………………………… Page 1

2.0 Description ................................………………………. Page 5

3.0 Installation ...............................................……………... Page 5

4.0 Operation .........................................….……………….. Page 6

4.1 Testing ………………………………………………… Page 6

5.0 Calibration……………………………………………... Page 7

6.0 Maintenance …………………………………………… Page 8

7.0 Cautions ……………………………………………….. Page 8

8.0 Customer Service ……………………………………… Page 9

Appendix- Structure, Behavior and Calibration of Impulse-Force Test Hammers

1.0 INTRODUCTION

The ICP

®

Impulse Force Test Hammer adapts your FFT analyzer for structural behavior

testing. Impulse testing of the dynamic behavior of mechanical structures involves

striking the test object with the force-instrumented hammer, and measuring either the

resultant motion with an accelerometer or the acoustic signature with a microphone.

Structures generally respond as (1) rigid or elastic bodies, (2) finite elements, lumped

constant models, and (3) distributed parameter models conducting stress-strain (sound)

waves.

Testing the functional transfer and transactional characteristics of a mechanical structure

involves mounting the accelerometer at one location of interest, and striking the test

object with the hammer. Modal analysis and modeling involves fixing the

accelerometer(s) at one location, impacting the structure at one point, and then moving

the accelerometer(s) to other points of interest. Integration of the acceleration signal

yields velocity compliance, impedance, and mobility. The hammer impulse consists of a

nearly-constant force over a broad frequency range, and is therefore capable of exciting

all resonances in that range. The hammer, size, length, material, and velocity at impact

Page 5

2

determine the amplitude and frequency content (wave shape) of the force impulse. The

impact cap material generally determines energy content.

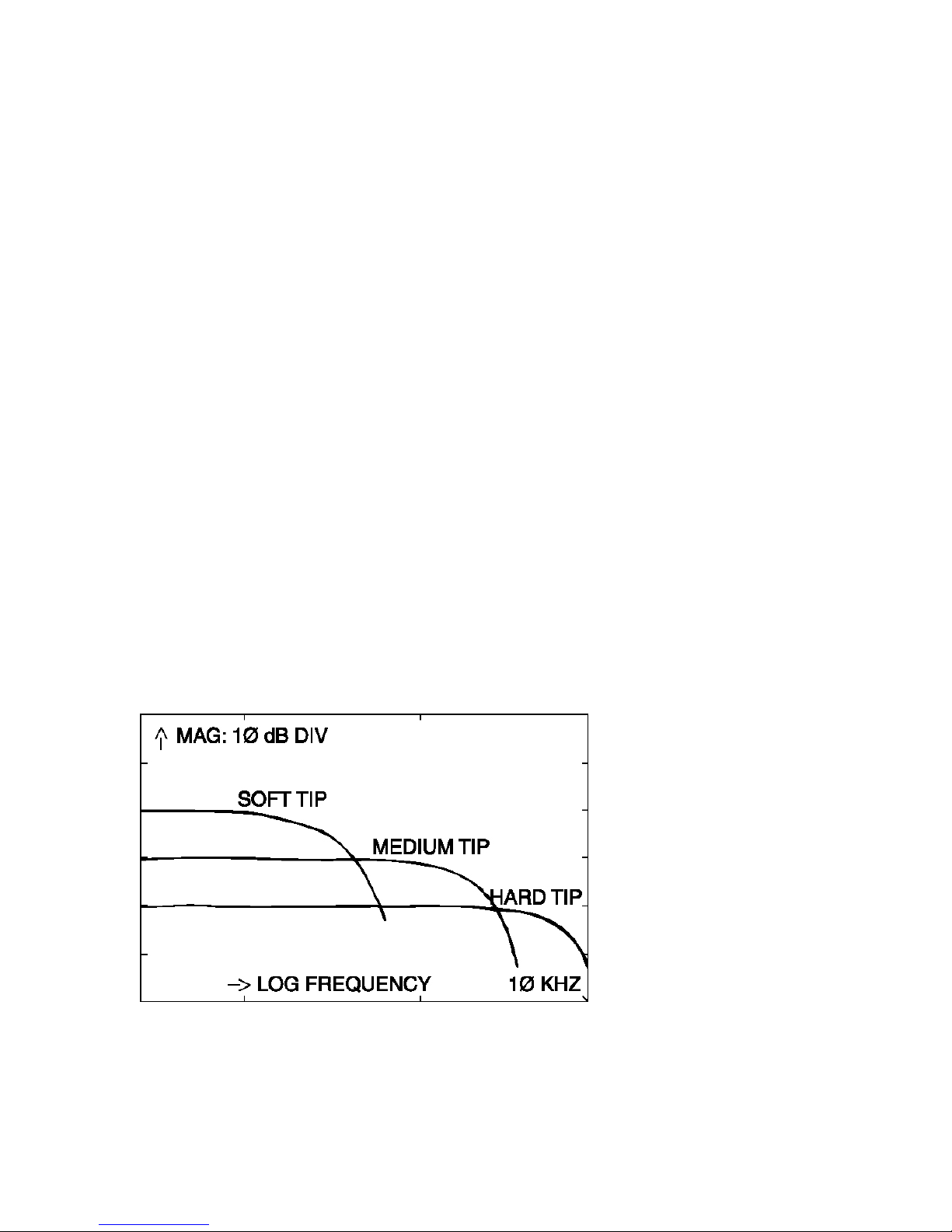

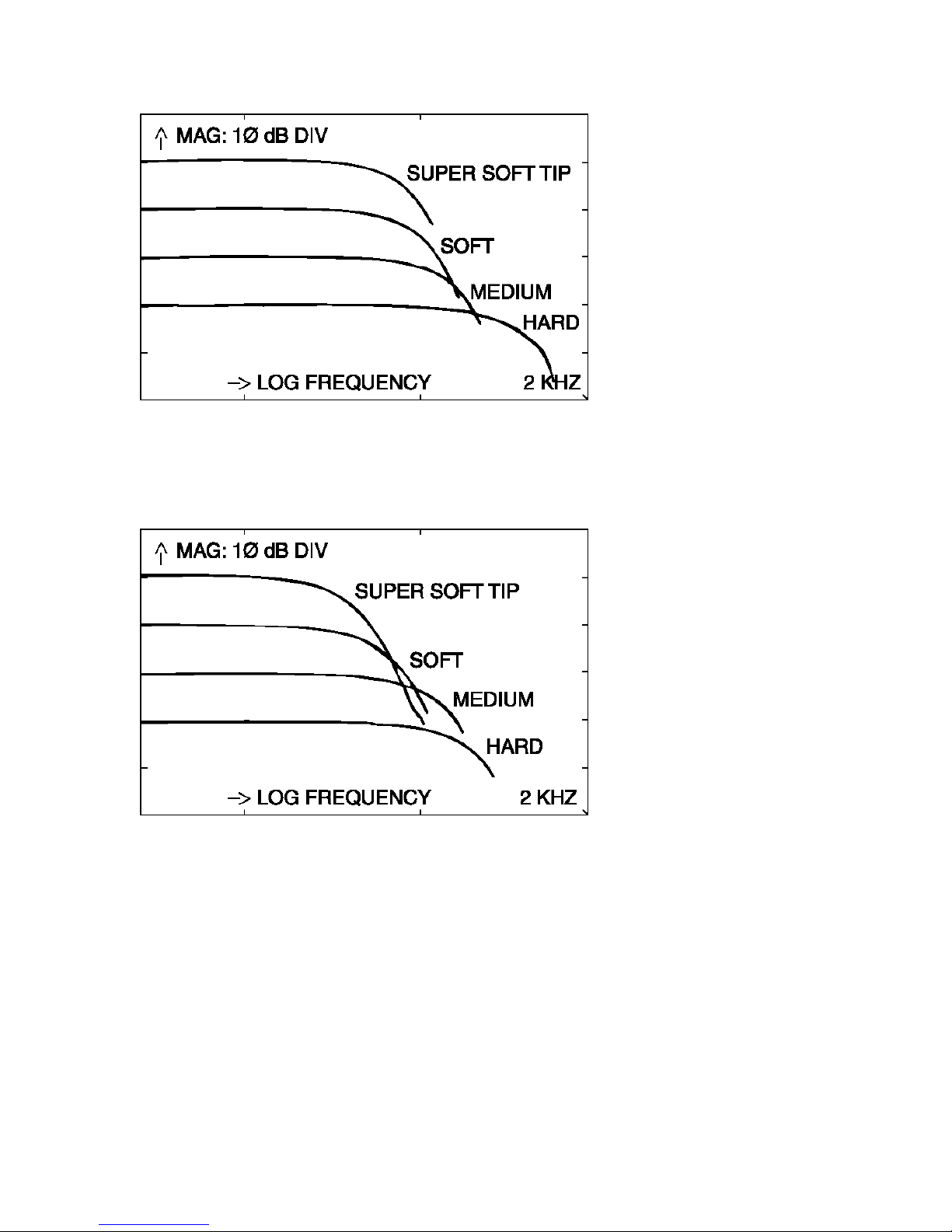

Hammer model selection involves determining the size and mass of the hammer structure

which will provide the force amplitude and frequency content required for proper

excitation of the structure under test. Each hammer’s corresponding frequency response

plots indicate the frequency content of the force impulse that can be achieved using the

variety of supplied tips. An extender mass, supplied with most hammers, allows further

tuning by concentrating more energy at lower frequencies.

Large, heavy structures like locomotive frames, tanks, and bridges require an

instrumented sledgehammer; small structures like compressor blades often require minihammers. Some very large structures may require a massive mechanical ram

instrumented with a force-sensing impact head.

All sensors in this system are classified as ICP® (Integrated Circuit Piezoelectric), low

impedance, voltage-mode sensors. Microelectronic, built-in amplifiers standardize

sensitivities within a few percent of nominal value, which is adequate for most dynamic

applications.

PCB® impulse hammers are available in nine different models, including an

automatically-actuated unit (Model 086C09) that is not included in this manual. These

hammers range in size from the mini-impulse hammer to the 12 lb sledgehammer.

Spectrum of impulse signals from different hammer structures (hard, medium and soft

impact tips) are below:

Model 086C01

Page 6

3

Models 086C02, 086C03, 086C04

Model 086D05

Page 7

4

Model 086D20

Model 086D50

Page 8

5

Model 086D80

2.0 DESCRIPTION

The hammer consists of an integral, ICP® quartz force sensor mounted on the striking end

of the hammer head. The sensing element functions to transfer impact force into electrical

signal for display and analysis. It is structured with rigid quartz crystals and a built-in,

micro-electronic, unity gain amplifier. The cable is connected to the end of the handle for

convenience, and to avoid connector damage in the event of a “miss hit.”

The ICP® sensor operates over a standard two-wire cable from a PCB® power unit. For

reasons of safety, the easily-repairable ribbon wire cable is intended to be the weak link

in larger hammer design. The ICP® power unit supplies constant current excitation to the

sensor over the signal lead and AC couples the output signal. Many FFT

analyzer/computer systems have ICP® power supply built in.

The hammer is a single, integral unit. Laser-welded construction of the sensor element

insures reliable operation in adverse environments. The mechanical assembly is locked

together with a structural epoxy adhesive so it should not be taken apart except at the

factory.

The striking end of the hammer has a threaded hole for installation of a variety of impact

tips. The tip functions to transfer the force of impact to the sensor, and protects the sensor

face from damage. Tips of different stiffness allow you to vary the pulse width and

frequency content of the force.

3.0 INSTALLATION

The hammer is assembled and locked together with structural adhesive at the factory.

Tips and extender mass install at opposite ends of the hammer via 10-32 threaded studs

(see chapter 4.1 TESTING for hammer/tip extender selection). Cable connections are

illustrated in the system drawing and are generally made via BNC connectors.

Page 9

6

Sensors install and connect according to detail procedures described in specific sensor

manuals. Some common installation methods include stud mount, Petro-wax,

cyanoacrylate adhesive, and magnetic. The method used depends on test conditions and

user preference.

In general, sensors connect to the ICP® power unit at the jack labeled "XDCR." The jack

labeled "SCOPE" is connected to the readout device (FFT analyzer/computer). Consult

ICP® Power Unit Operating Guide for proper installation and operating procedures.

4.0 OPERATION

1. With cables supplied, connect the hammer to a power unit, and then to your analyzer,

as shown in the system and power unit operation guide.

2. Tighten the cable connectors securely by hand to insure good electrical contact.

3. Switch power on, and wait a minute or two for the sensor amplifier to turn on, and for

the coupling capacitor to fully charge.

4. Check the power unit meter for normal operation (meter pointer pointing in green

area).

5. If meter pointer points in the red area, look for shorted cables or connections. If meter

pointer points in the yellow area, look for open cables or connections.

Connect accelerometer(s) in similar manner referring to the appropriate operating guides

for the accelerometer(s) and power unit. When all power unit meters indicate normal

operation (green), proceed with tests, following all sensor, power unit, and analyzer

operating instructions.

4.1 TESTING

To test the behavior of your structure, and to tailor the frequency bandwidth of the force,

follow the following procedures:

1. Strike the test object with the hammer and process the results. Always take several

averages to reduce the effects of spurious noise. CAUTION: Never impact without a

hammer tip properly installed on the sensor element. In the case of the 086D80, the

sensor element is pre-installed with a steel tip.

2. Check the measured results for signal quality (adequate signal-to-noise), no overloads

(overload lights or sharp flattening of time history peaks), and no double impacts.

3. Analyze results for frequency content, and check to insure that the reasonably flat

portion of the force spectrum is sufficient to cover the structural resonances present in the

acceleration spectrum. Often signal energy is sufficient to excite structural resonances at

Page 10

7

20 dB below initial low frequency force levels.

4. Change hammer tips and/or mass to modify its behavior if necessary:

a. For higher frequency response, use a stiffer tip and no extender.

b. For better low frequency response, use a softer tip and install the extender.

c. To increase motion signal energy, increase impact velocity and/or hammer

mass.

IMPORTANT: When using the Model 086D80 Mini Impact Hammer with the Model

084A17 Hammer Handle, best results are achieved when also using the Model 084Al3

Extender Mass. The Model 084Al7 is designed for use in frequency ranges lower than

those reached when using the Model 084Al4 Handle Cable Assembly. The use of the

Model 084Al3 Extender Mass improves the low frequency content of the force input to

the structure, and improves the “feel” of the hammer by offsetting any effective mass

added to the handle base by an attached cable.

5. Repeat steps 1 and 4 until adequate results are obtained.

Generally speaking, the impact tips affect the hammer impulse frequency content, and the

extender affects the signal energy level. Frequency content and energy level are

interrelated, so both will be affected by different hammer structures. Hammer velocity at

impact will also affect both. In general, massive structures with lower stiffness require

the use of the extender and soft impact tip to adequately excite low frequency resonances.

During testing, occasionally check and tighten the electrical and mechanical connections.

Repeated impacting tends to loosen them, which may result in erratic and noisy signals.

Although modal tuning has done much to eliminate this possibility, bouncing (multiple

impacts) or penetration may still occur when using too heavy a hammer on too light a

structure, or section of a structure. This will appear as an oscillatory component

superimposed on the spectrum in your data. Reject such data. Some skill and practice

may still be required when testing lighter structures.

PCB's newest ICP® power units providing greater than 10 volts positive signal range

(three x 9 volt batteries) prevent undetected overloads in the power unit. Distortion,

undershoot, and oscillation of the impulse time history as viewed on the analyzer display

is caused by ringing of the analyzer's anti-aliasing filters, which is their normal behavior.

To view the correct impulse waveform, switch the analyzer to a high-frequency range.

5.0 CALIBRATION

Calibration involves testing the functional transfer behavior (sensitivity) of the sensor

structure in controlled transactions and environments.

Different hammer structures have different sensitivities, because the test structure

experiences a force greater than the crystal-sensing elements. The force of impact on the

Page 11

8

test structure is a function of the total mass of the hammer, while the force on the crystals

is a function of only the mass behind them (the impact tip is in front of the crystalsensing element). Their differences, which depend on the ratio of the tip mass to the head

mass, is automatically compensated for when the hammer is properly calibrated, since

the extender mass is behind the sensing element. When used, it results in a slight

increase in voltage sensitivity (as shown on calibration certificate). Each hammer

structure can be easily calibrated to ensure the most accurate data.

A hammer can be calibrated by hitting a freely-suspended mass instrumented with a

quartz reference accelerometer. According to Newton's second law of motion, at any

instant in time, the force experienced by the mass is simply the mass multiplied by the

measured acceleration. On a storage oscilloscope, dividing the peak output signal of the

hammer (mV) by the mass (lb or kg), times the peak acceleration (g), gives the hammer

sensitivity directly in mV/lb or mV/kg.

Calibration on a FFT analyzer produces the same result as a function of frequency. Since

the transfer function of a mass behaving as a rigid body is a consistent (1/M) ratio, the

force and the acceleration signals produces a calibration constant (ideally 1/M) for each

discrete frequency. The effects of a non-modally tuned hammer will be readily apparent

when performing this calibration.

The mass, pendulously suspended or placed on a piece of foam rubber, will behave as a

rigid body. Hitting such an instrumented mass is also a good way of checking the normal

operation of the hammer and instruments prior to testing. This procedure builds

confidence in data results.

6.0 MAINTENANCE

The sealed construction of the sensing element and the bonded construction of the

hammer preclude field maintenance. Should service be required, first replace the cables

(cables are often the source of trouble) and test operation again. If necessary, return the

unit to the factory with a note describing the problem.

7.0 CAUTIONS

Although hammers are very rugged in construction, damage can result from misuse.

When observed, the following precautions can ensure long life and accurate data.

1. Do not attempt to dismantle sensor element from hammer structure. All service should

be performed at the factory.

2. Never generate more than 5 times the rated impact force range with any hammer.

Generally, observe the force rating for five volts output. Excessive impact force may

destroy the built-in miniature electronics.

Page 12

9

3. Never strike an object without an impact tip properly installed in front of the forcesensing element. Damaging the precision-lapped surface of the hammer sensor can affect

its behavior.

4. During testing, periodically check and tighten tip, extender and cable connections to

ensure continued proper operation. Machined flats in the tips and extender facilitate

tightening and removal.

5. Do not apply voltage to unit without constant current protection.

6. Do not apply more than 20 mA of current.

7. Do not exceed 30 volts supply voltage.

8. Do not subject units to temperatures above 250 degrees F (121 degrees C).

8.0 CUSTOMER SERVICE

PCB Piezotronics guarantees Total Customer Satisfaction. If, at any time, for any

reason, you are not completely satisfied with any PCB product, PCB will repair, replace,

or exchange it at no charge. You may also choose, within the warranty period, to have

your purchase price refunded. Contact PCB Vibration Division Customer Service

personnel by calling toll-free in the USA at 1-888-684-0013 or outside the USA at 716684-0001, or send an email to vibration@pcb.com

PCB offers to all customers, at no charge, 24-hour phone support. This service makes

product or application support available to our customers, day or night, seven days a

week. When unforeseen problems or emergency situations arise, call the PCB 24-Hour

Sensorline at (716) 684-0001, and an application specialist will assist you.

3425 Walden Avenue, Depew, New York 14043-2495 USA

USA Toll Free Phone: 888-684-0013

International Phone: 716-684-0001 Fax: 716-685-3886

E-mail: vibration@pcb.com Website: www.pcb.com

Page 13

Page 14

Loading...

Loading...