Viatran IDP10-A, IDP10-V Installation, Calibration And Operations Manual

I/A Series ® Intelligent

Differential Pressure Transmitters

IDP10-A with 4 to 20 mA Output Signal

IDP10-V with 1 to 5 VDC Output Signal

Installation, Calibration, Configuration, and

3829 Forest Parkway, Suite 500

Wheatfield, NY 14120

Int’l: 1-716-629-3800

Toll Free: 1-800-688-0030

Fax: 1-716-693-9162

www.viatran.com

solutions@viatran.com

Maintenance

[1]

98MANALIDP10AV Rev. A 8/16/11

Table of Contents

Figures ........................................................................................................................................................... 4

Tables ............................................................................................................................................................ 5

1. Introduction ..................................................................................................................................... 6

General Description ......................................................................................................................... 6

Reference Documents...................................................................................................................... 6

Transmitter Identification ................................................................................................................ 6

Standard Specification ..................................................................................................................... 7

Product Safety Specifications......................................................................................................... 10

2. Installation ..................................................................................................................................... 12

Transmitter Mounting.................................................................................................................... 12

Process Mounted Transmitter .......................................................................................... 13

Pipe or Surface Mounted Transmitter .............................................................................. 13

Installation of Flow Measurement Piping ...................................................................................... 15

Filling System with Seal Liquid ....................................................................................................... 17

Positioning Housing ....................................................................................................................... 17

Positioning Display ......................................................................................................................... 17

Cover Locks .................................................................................................................................... 18

Transmitter Wiring for IDP10-A ..................................................................................................... 18

Accessing Transmitter Field Terminals ............................................................................. 19

Wiring the Transmitter to a Control Loop ........................................................................ 20

Putting Transmitter into Operation ............................................................................................... 22

Taking the Transmitter Out of Operation ...................................................................................... 22

Transmitter Wiring for IDP10-V ..................................................................................................... 23

3-Wire Connection ............................................................................................................ 23

4-Wire Connection ............................................................................................................ 23

Wiring to a Control Loop ................................................................................................... 25

Putting Transmitter into Operation ............................................................................................... 27

Taking the Transmitter Out of Operation ...................................................................................... 27

[2]

98MANALIDP10AV Rev. A 8/16/11

3. Calibration and Configuration ...................................................................................................... 28

Calibration Setup ........................................................................................................................... 28

Field Calibration Setup ................................................................................................................... 28

Bench Calibration Setup................................................................................................................. 30

General Calibration Setup .............................................................................................................. 31

Notes for Electronic Version –A and -V.......................................................................................... 32

Calibration and Configuration Using the Local Display .................................................................. 34

Calibration ......................................................................................................................... 36

IDP10-A and IDP10-V Calibration .................................................................................. 37

Zero Adjustment Using External Zero Button ................................................................... 38

Configuration .................................................................................................................... 38

IDP10-A and IDP10-V Configuration .............................................................................. 40

Re-ranging and IDP10-A or IDP10-V Transmitter .......................................................... 42

IDP10-A and IDP10-V Character Lists ............................................................................ 43

Testing the Display ......................................................................................................................... 44

Error Messages .............................................................................................................................. 45

4. Maintenance.................................................................................................................................. 47

Parts Replacement ......................................................................................................................... 47

Replacing the Electronics Module .................................................................................... 47

Removing and Reinstalling the Housing Assembly ........................................................... 48

Replacing the Sensor Assembly ........................................................................................ 48

Replacing the Terminal Block Assembly ........................................................................... 50

Rotating Process Covers for Venting ............................................................................................. 50

Index ........................................................................................................................................................... 52

[3]

98MANALIDP10AV Rev. A 8/16/11

Figures

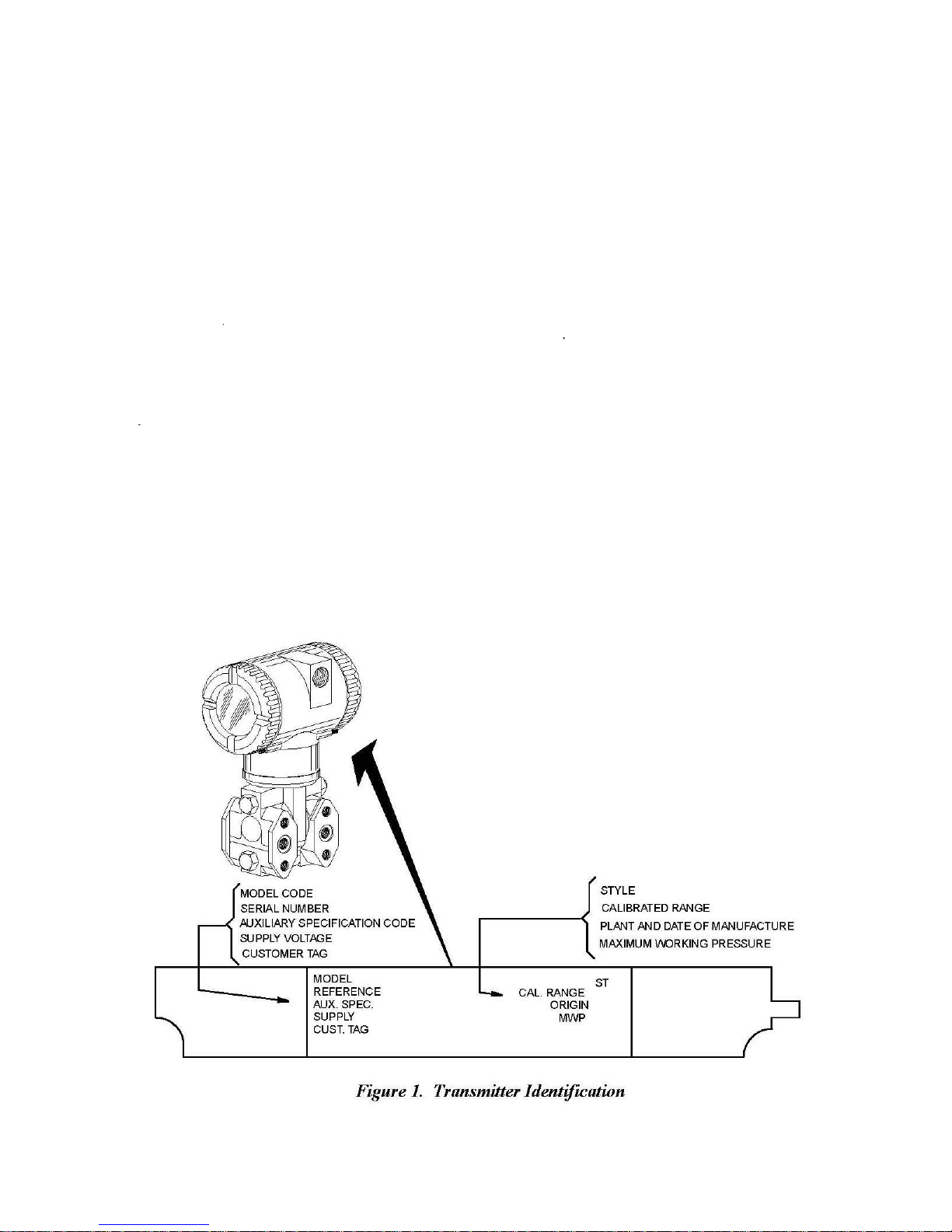

1 Transmitter Identification ...................................................................................................................... 6

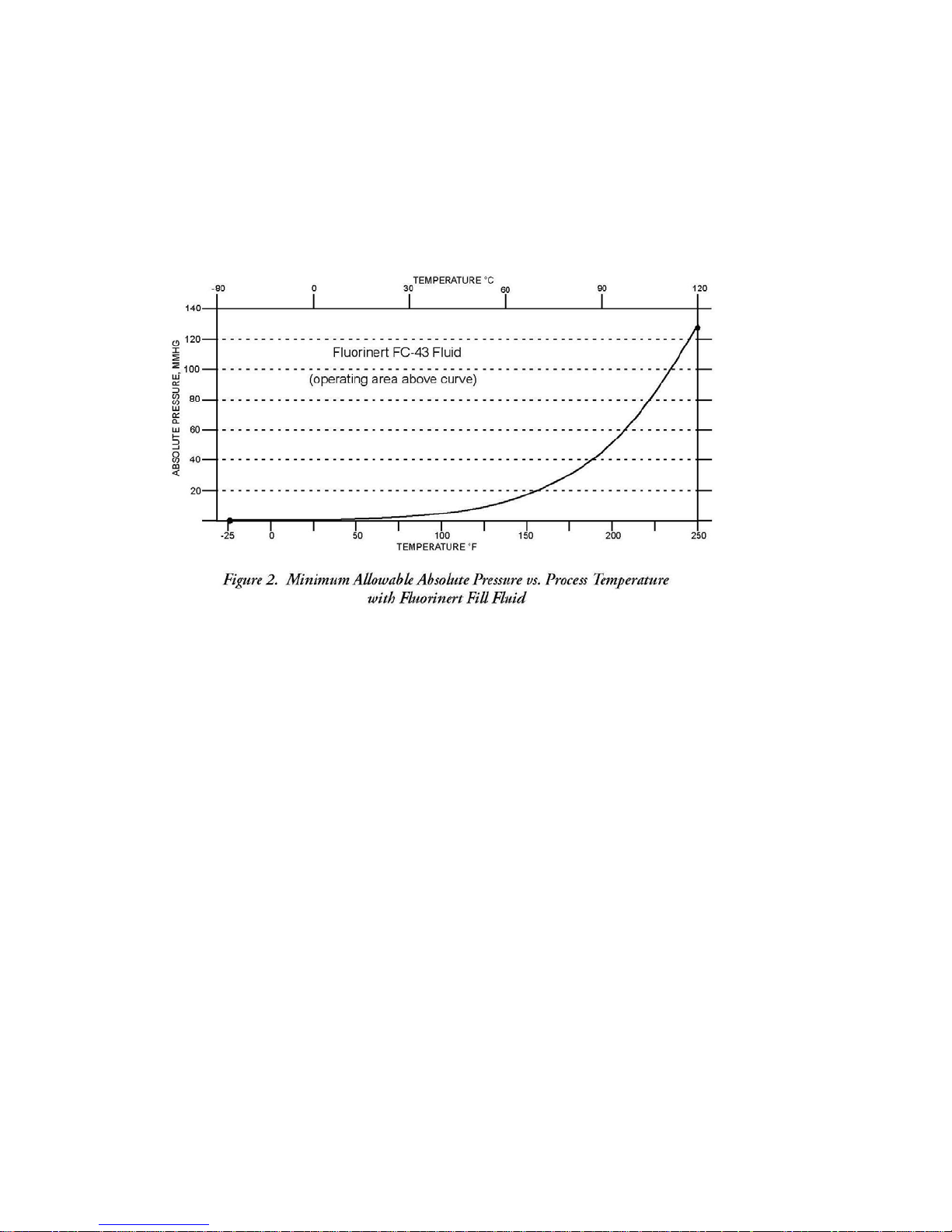

2 Minimum Allowable Absolute Pressure vs. Process Temperature w/Fluorinert Fill Fluid ................... 9

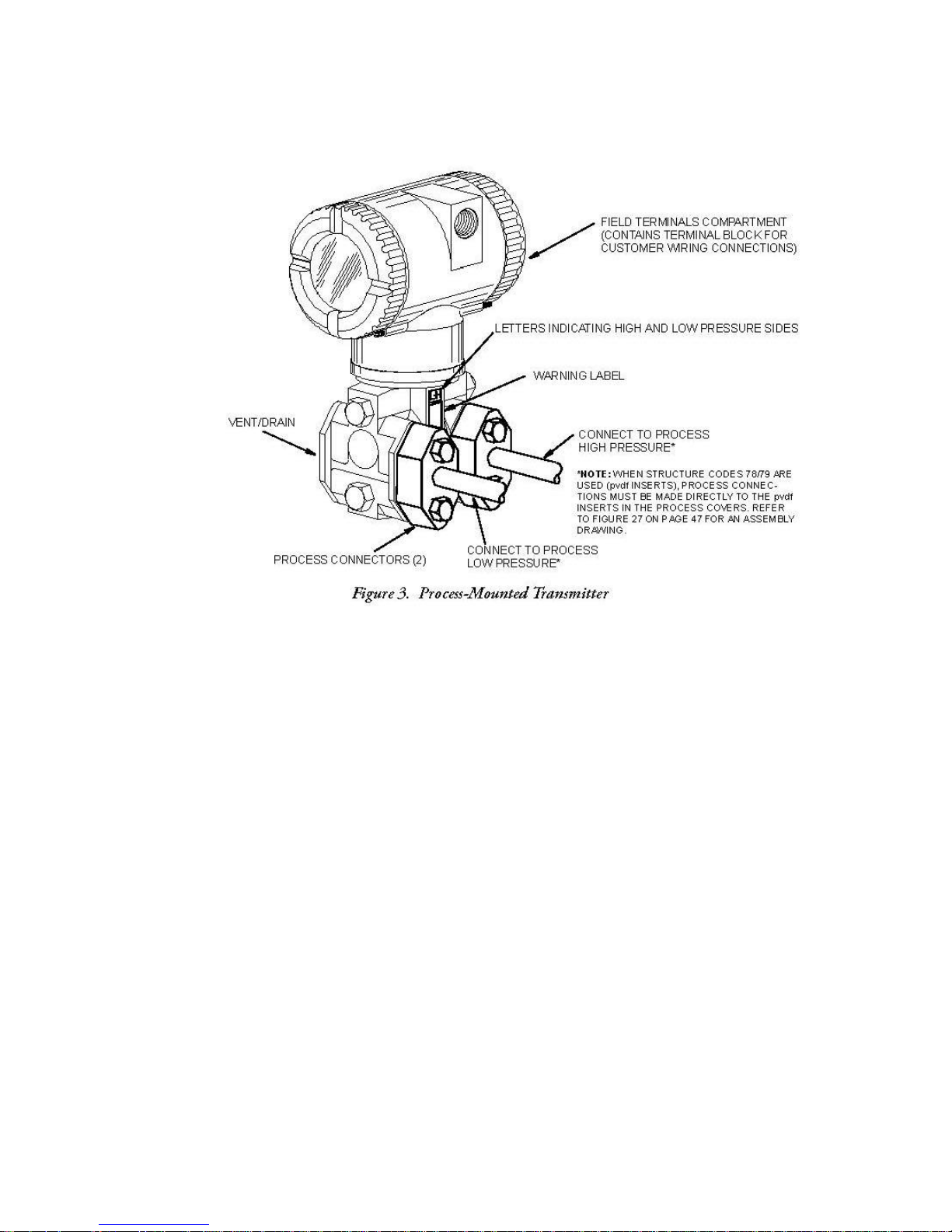

3 Process Mounted Transmitter ............................................................................................................ 13

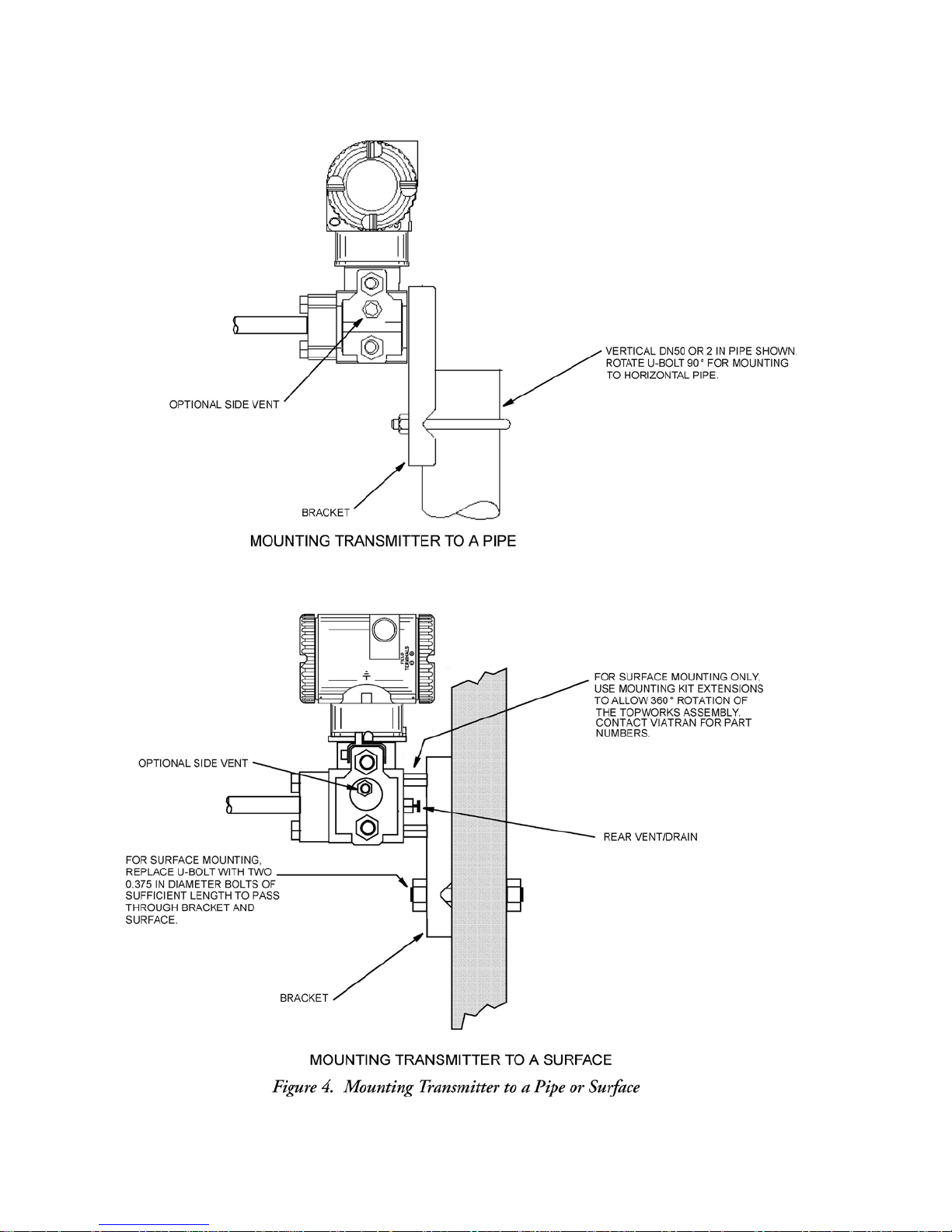

4 Mounting Transmitter to a Pipe or Surface ........................................................................................ 14

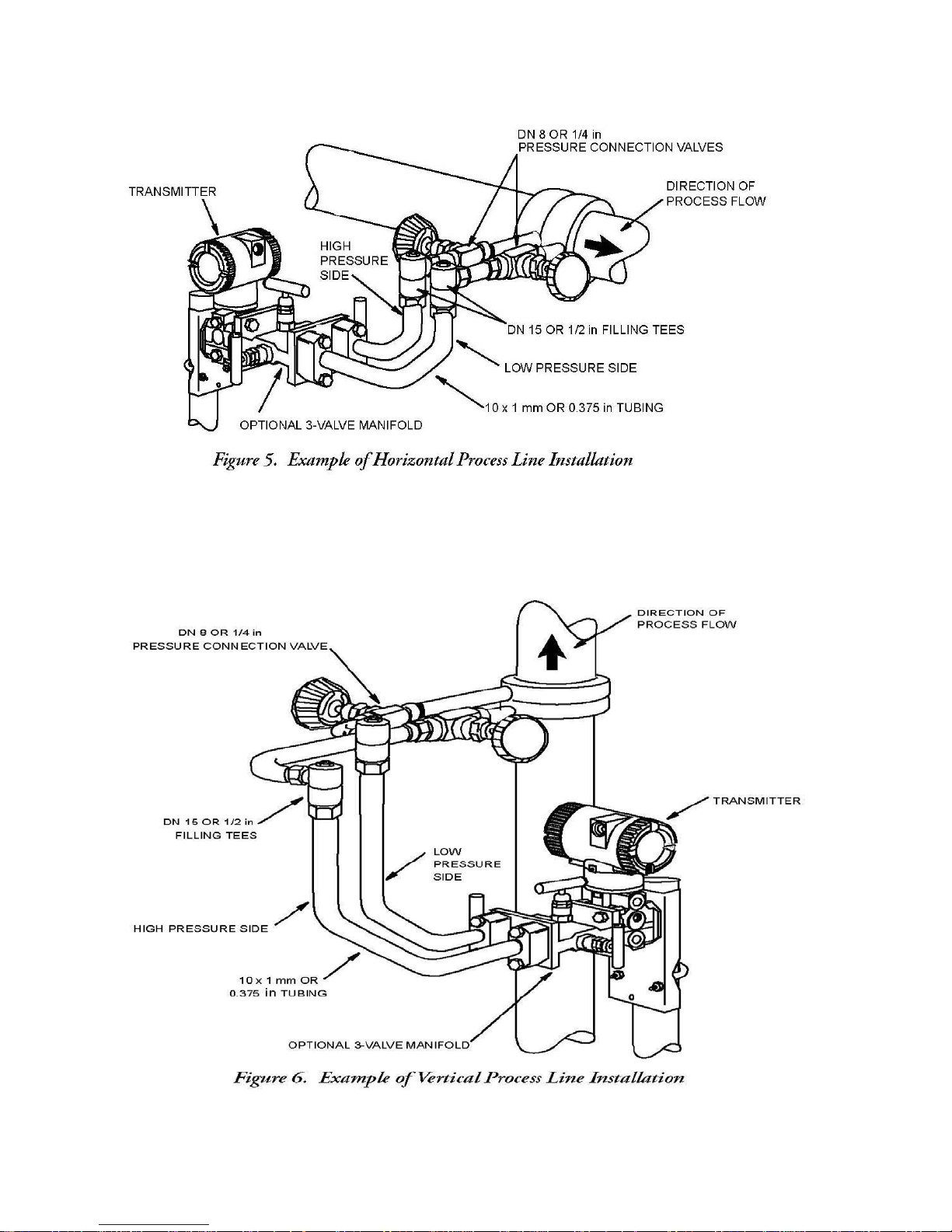

5 Example of Horizontal Process Line Installation ................................................................................. 16

6 Example of Vertical Process Line Installation ..................................................................................... 16

7 Positioning Display .............................................................................................................................. 18

8 Accessing Field Terminals ................................................................................................................... 19

9 Identification of Field Terminals ......................................................................................................... 19

10 Supply Voltage and Loop Load ............................................................................................................ 20

11 Loop Wiring ......................................................................................................................................... 21

12 Wiring Several Transmitters to a Common Power Supply .................................................................. 22

13 Identification of Field Terminals .......................................................................................................... 23

14 Three-Wire Connection ....................................................................................................................... 24

15 Four-Wire Connection ......................................................................................................................... 24

16 Loop Wiring ......................................................................................................................................... 25

17 Wiring Several Transmitters to a Common Power Supply (Four-Wire) .............................................. 26

18 Field Calibration Setup ........................................................................................................................ 30

19 Calibration Setup of Electronic Equipment ......................................................................................... 30

20 Bench Calibration Setup ...................................................................................................................... 31

21 Local display Module ........................................................................................................................... 34

22 Top Level Structure Diagram ............................................................................................................... 35

23 Calibration Structure Diagram ............................................................................................................. 37

24 Configuration Structure System .......................................................................................................... 40

25 Display Test Segment Patterns ............................................................................................................ 44

26 Replacing the Sensor Assembly ........................................................................................................... 49

27 Replacing the Sensor Assembly (Code 78/79 pvdf Inserts) ................................................................. 49

28 Sensor Cavity Venting and Draining .................................................................................................... 51

[4]

98MANALIDP10AV Rev. A 8/16/11

Tables

1 Electrical Safety Specifications .............................................................................................................. 11

2 Calibration Menu ................................................................................................................................... 36

3 IDP10-A and IDP10-V Configuration Menu ........................................................................................... 38

4 Alphanumeric Character List ................................................................................................................. 43

5 Numeric Character List .......................................................................................................................... 43

6 Error Messages ...................................................................................................................................... 45

[5]

98MANALIDP10AV Rev. A 8/16/11

1. Introduction

General

The IDP10-A and IDP10-V Differential Pressure Transmitters measure the difference between two

pressures applied to opposite sides of a silicon strain gauge microsensor within

This microsensor converts differential pressure to a change in

converted to a 4 to 20 mA or 1to 5 VDC signal

of differential pressure. The

the same two wires

The transmitters are often used for measuring fluid flow across a primary device such as an orifice

Description

that

supply power to the transmitter

measurement

the

sensor assembly.

resistance.

proportional

signal for the IDP10-A is transmitted to remote receivers over

to differential pressure or to the square root

electronics.

The resistance change is then

plate, but can also be used for other types of differential pressure measurements such as liquid level,

interface level, or density measurements.

Reference

This document contains descriptions and instructions for transmitter installation, configuration,

calibration, and

Documents

maintenance.

Transmitter

See Figure 1 for transmitter data plate contents. When the transmitter is powered, the firmware

revision is shown on the top line of the display.

Identifica

tion

[6]

98MANALIDP10AV Rev. A 8/16/11

Span Limits

A

Standard

Span and Range Limits

Span Limit

Elevated Zero and

Standard (B7 steel), Option "-B2" (17-4 PS ss), Option

“-D3” or “-D7”(c)

Specifications

Code

0.12 and 7.5 kPa (0.5 and 30 inH2O) -7.5 and +7.5 kPa (-30 and +30 inH2O)

B

C

D

E

Negative values

Positive values indicate

For

applications requiring

range limits

of the

Transmitter Configuration

0.87 and 50 kPa (3.5 and 200 inH2O) -50 and +50 kPa (-200 and +200 inH2O)

7.0 and 210 kPa (28 and 840 inH2O) -210 and +210 kPa (-840 and +840 H2O)

0.07 and 2.1 MPa (10 and 300 psi) -0.21 and +2.1 MPa (-30 and +300 psi)

0.7 and 21 MPa (100 and 3000 psi) -0.21 and +21 MPa (-30 and +3000 psi)

of

differential pressure indicate

high side of

Suppressed Zero

an

transmitter

∆

P

low side of

sensor

at the

elevated

or

suppressed zero,

can not be exceeded.

Bolting

Material

higher

sensor

at the

higher

pressure.

the

maximum span

Maximum Static

Over-range Pressure

Rating(a,e)

MPa

25

Range Limits

∆

P

pressure.

and the upper and

and

Psi

3625

lower

Proof

MPa

100

Pressure

Rating(b)

14500

Psi

Option “B1” (316 ss) or Opti on "-D5"(c) 15 2175 60 8700

Option AS-B7M (B7M) 25 3625 100 14500

Option “-D1”(c) 16 2320 64 9280

Option “-D2”, “-D4”, "-D6", or "-D8"(c,d) 10 1500 40 6000

(a) Either side can be at the higher pressure during over-range.

(b)

Meets ANSI/ISA

(c)-D1 = DIN

-D2 = DIN Double ended

-D3 = DIN

-D4 = DIN Double ended

-D5 = DIN

-D6 = DIN Double ended

-D7 = DIN

-D8 = DIN Double ended

(d)Limited

(e)When

maximum over-range is 2.1 MPa (300 psi) and temperature limits are -7 and +82°C (20 and 180°F).

to

Structure Codes

Standard S82.03-1988.

Single

ended

Single

ended

Single

ended

Single

ended

operating temperatures ranging

NOTE

Static pressure zero shift

zero

output at nominal

!

CAUTION

1.

Exceeding

degrading its

2. The

the

maximum over-range pressure

performance.

transmitter

process cover

process cover

process cover

process cover

process cover

process cover

process cover

process cover

78/79 are

for

all calibrated spans

with M10 bolting.

with M10 bolting

with 7/16 in bolting.

with 7/16 in bolting.

with 7/16 in 316

with 7/16 in 316

with 7/16 in 17-4

with 7/16 in 17-4

from 0 to 60 °C (32 to 140°F)

used (pvdf inserts

operating static pressure.

could be nonfunctional

[7]

ss

bolting.

ss

bolting.

ss

bolting.

ss

bolting.

in the Hi and Lo

can be

eliminated

can

cause damage

after application

side process covers),

by

readjusting

to the transmit

of the proof pressure

the

the

ter

.

98MANALIDP10AV Rev. A 8/16/11

Influence

Operative Limits

Sensor Body Temperature

pvdf Inserts

-7 and +82°C (20 and 180°F)

Electronics

Temperature

With LCD

Display

-40 and +85°C (-40 and +185°F)(a)

Relative Humidity

0 and 100%

Supply Voltage

IDP10-A 11.5 and 42 VDC(b)

Output Load

IDP10-A 0 and 1450 Ohms

Mounting Position

No Limit

Output Signal

4 to 20 mA dc linear, 4 to 20 mA dc square root, or 1 to 5 VDC, software selectable,

locally configurable using pushbuttons on the transmitter.

Zero and Span

Adjustable

moisture sealed pushbutton

housing

Adjust

at the

cover.

ments

transmitter using

assembly allows local resetting

the

local display.

An optional

of

zero

external se

lf-contained

without removing

Field Wiring Reversal

Accidental reversal

limited to 1 A or

1

A will

not

block assembly

less

damage

and

of

field wiring will

by

active

current limiting or loop

the

electronics

module or

external instruments

not

damage

in the loop.

the

sensor

transmitter, provided

the current is

resistance. Sustained currents

but could

damage

the terminal

of

Mounting

The

piping. It can

using

any

“Positioning Housing”

of four

NOTE

Position effect zero

output after installa

Adjustable

The transmitter

setting

an 80% input step

Operative

Pos

ition

transmitter

can be mounted in any orientation. It can be

also

be mounted

an optional mounting

desired

position for

access

on

different positions

shift for all

tion.

Damping

response

of 0.00 (none), 2, 4, or 8,

as defined

Limits

directly

bracket.

to

adjustments, display,

page

13. The

at 90°

increments. See “Positioning Display”

calibrated spans

time is

normally

seconds, whichever is greater,

in

ANSI/ISA

to a

The

vertical

housing

display

1.0

second

S51.1.

supported

or

horizontal

pipe or

can be rotated up to one

can

also

can be

or the

or conduit

be rotated in the

eliminated

connections.

by re

electronically

for a 90%

by the

process

surface mounte

full

turn to

See

housing

on

page

adjusting

adjustab

recovery

to any

13.

zero

le

from

d

Silicone Fill Fluid

Fluorinert Fill Fluid

(a)

Display updates are slowed

(b) 11 V dc with optional

-46 and +121°C (-50 and +250°F)

-29 and +121°C (-20 and +250°F)

IDP10-V 9 to 15.5 VDC

IDP10-V 10 MegOhms

and

readability decreased below temperatures

shorting block (AS code

[8]

of -20 °C (-4°F).

SB-11

98MANALIDP10AV Rev. A 8/16/11

Sensor

Fill Fluid

Silicone

Oil (DC 200), or Fluorinert (FC-43).

Minimum Allowable Absolute Pressure vs. Process Temperature

With

Silicone Fill

With Fluorinert

Fluid

Fill

Fluid

At

full vacuum:

Refer

to

Figure

Up to 121°C (250°F)

2.

Power-Up

Less

electronic

Elec

trical

Field wires

electronics housing. Leads

terminal

environmental,

plugged

Process Connections

IDP10

number of optional

Supply

Time

than 2.0

seconds

damping rate to the

Connections

enter through PG 13.5 or 1/2 NPT threaded

block

with metal plug

transmitters

Current

for output to

final measured variable

terminate under

in the

field

terminal compartment. To maintain RFI/EMI,

and

explosion proof ratings,

(provided), inserted

are

connected

process connectors

reach approximately

screw terminals

unused conduit connection

to

five

to the

process via

.

3.5

mA,

and then at the

value.

full

entrances

turns.

and

on either

washers

side

on the

must

of the

be

a 1/4 NPT thread or any one of a

Power supply must be capable of providing 22 mA current for the IDP10-A and 3 mA

current for the IDP10-V. Ripple of up to 2 V pp (50/60/100/120 Hz) is tolerable, but

instantaneous voltage must remain within specified range.

[9]

98MANALIDP10AV Rev. A 8/16/11

Electrical Ground

The transmitter

compartment and an

To

minimize galvanic corrosion, place

washer

and

(ground) the

trans

Test Po

mitter

ints

The banana plug receptacles (designated CAL) can be used to check transmitter output of

the IDP10-A. Measurements should be 100 to 500 mV dc for 0 to 100% transmitter

output. Refer to Figure 9.

Conne

is equipped

loose washer

shield

at the

.

cti

ons

with an internal ground connection within the

external

ground

on the

external

field enclosure

connection

the

wire lead

ground

at the

or terminal

screw.

base

If

shielded cable

only. Do not ground the

of the

between

field

electronics

the captive

is

used,

shield

at the

wiring

housing.

earth

HHT Terminals

As

the top terminal

PC20, HART Communicator, or IFDC.

Approximate

Without

With

Process

With Optional 316

Process Wetted

Diaphragm:

Covers

and

is blocked, this transmitter does

Mass

Process Connectors

3.5 kg (7.8 lb)

Connectors 4.2 kg (9.2 lb)

ss

Housing Add 1.1 kg (2.4 lb)

Materials

316L

Process Connections:

ss,

Co-Ni-Cr,

Hastelloy

316

ss,

not

communicate

C, gold plated 316L

carbon

steel, Hastelloy

with the HHT, PC10,

ss,

Monel, or tantalum

C, Monel, or

pvdf inserts

Product Safety

To

prevent possible explosions

protection, observe applicable wiring practices. Plug unused

provided

!

To maintain IEC IP66 and NEMA Type 4X protection, the unused conduit opening

must be

T

urn

as

possible

!

DANGER

metal pipe plug,

WARNING

plugged.

covers

until O-ring

(at

Specifications

and to maintain

which engages

In addition, the threaded

contacts housing;

least

1/4 turn).

explosion proof,

dust-ignition proof

conduit

a minimum of

housing covers

five

full threads.

must be

installed.

then continue to hand tighten

[10]

98MANALIDP10AV Rev. A 8/16/11

opening

as

with the

much

C

NOTE

1.

These transmitters have

listed

in Table 1. For

approvals and

2.

Wiring

are

restrictions

provided

certifications,

in the

Testing

Types of

and

CSA intrinsically safe for Class I,

Division 1, Groups A, B, C, and D; Class

II, Division 1, Groups E, F, and G; Class

III, Division 1.

CSA explosion proof for Class I, Division

1, Groups B, C, and D; Dust ignition

proof for Class II, Division 1, Groups E,

F, and G; Class III, Division 1.

CSA for Class I, Division 2, Groups A, B,

C, and D; Class II, Division 2, Groups F

and G; Class III, Division 2.

Area

Laborator

y,

Protection,

Classification

been

detailed

designed

information or status of testing

to meet the

electrical safety description

contact Viatran.

required to maintain

“Transmitter

Wiring”

electrical certification

section

of

this

document on

Table 1. Electrical Safety Specifications

Application Condition

Connect per CD 0629. Temperature

Class T4A at 40°C (104°F) and T3C at

85°C (185°F) maximum ambient.

IDP10-V only.

Temperature Class T6 at 80°C (176°F),

and T5 at 85°C (185°F) maximum

ambient.

Connect to source not exceeding 42.4

V. Temperature Class T6 at 40°C

(104°F) and T4A at 85°C (185°F)

maximum ambient. IDP10-V only.

laboratory

of the transmitter

page

Electrical

s

Design Code

15.

Safety

FM intrinsically safe for C l a s s I, Division

1, Groups A, B, C, and D; Class II,

Division 1, Groups E, F, and G; Class III,

Division 1.

FM explosion proof for Class I, Division

1, Groups B, C, and D; Dust ignition

proof for Class II, Division 1, Groups E,

Connect per CD 0629. Temperature

Class T4A at 40°C (104°F) and T4 at

85°C (185°F) maximum ambient.

IDP10-V only.

Temperature Class T6 at 80°C (176°F),

and T5 at 85°C (185°F) maximum

ambient.

F, and G; Class III, Division 1.

FM nonincendive for Class I, Division 2,

Groups A, B, C, and D; Class II, Division

2, Groups F and G; Class III, Division 2.

Connect to source not exceeding 42.4

V. Temperature Class T6 at 40°C

(104°F) and T4A at 85°C (185°F)

maximum ambient. IDP10-V only.

F

[11]

98MANALIDP10AV Rev. A 8/16/11

2. Installation

The following material provides information and procedures for installing the IDP10-A and

IDP10-V Differential Pressure Cell Transmitter.

!

CAUTION

To

avoid damage

impact

Use a suitable

wrench

NOTE

to the

or

stamping device,

thread

sealant

transmitter sensor,

on the

on all connections.

do not

trans

mit

use

any impact

ter

.

devices, such as

an

Transmitter

The

transmitter

vertical

or

horizontal

NOTE

1. If the transmitter is not

Figure

2. The

transmitter should

draining into the

threaded

connections.

Mounting

can be

supported

pipe or

4,

readjust zero

conduit

by the

surface using

installed

output to

be mounted

field wiring

process

compartment can

piping

the optional mounting

in the

eliminate

so

as shown

vertical

the

that any

position

position zero

moisture condensing

exit

in

Figure

bracket shown

as shown

through one of the two

3, or mounted to a

in

Figure

in

Figure

effect.

or

4.

3 or

[12]

98MANALIDP10AV Rev. A 8/16/11

Pr

ocess-

Mo

unted Transmitter

Figure 3 shows

the

transmitter

mounted to and supported by the

process

piping.

Pipe

To mount the

Option -M).

Referring

proor 2-in pipe. To mount to a

Figure

to a

360° rotation of the to

when the

or

Surface Mounted

transmitter

to

Figure

vided.

wall using

Mount the transmitter with mounting

4. The mounting

the U-bolt mounting

transmitter is

to a pipe or

4,

secure

bracket

p-

works assembly.

mounted to a

Transmitter

surface, use

the mounting

horizontal

pipe, turn U-bolt 90 from the position

can

also

holes.

surface as shown

the Optional Mounting Set (Model Code

bracket

be

Mounting kit

This

used

provides

to the

bracket

for

transmitter using

to a

vertical

wall

mounting by

extensions

better

access

in

Figure

4.

the two

or

horizontal,

securing

are

available

to the rear vent/drain

screws

shown

the

bracket

to

allow

DN 50

in

[13]

98MANALIDP10AV Rev. A 8/16/11

[14]

98MANALIDP10AV Rev. A 8/16/11

Installation of Flow

Figure

The

ment,

(for a

If the

lines

transmitter

flow,

(or

ter, the

mounted

tees.

Tighten drain

nector bolts to a torque of 61 N m (45 lb ft).

Note that the high and

the

With

5 and

Figure 6 show typical installations

transmitters

except

seal

liquid).

process fluid being measured

must be

the

lines are filled

water) is

tees

vertically (as shown).

side

of the

medium-viscosity seal liquids

NOTE

1. With a horizontal line,

the line.

of line.

2. With a

3. For liquid or steam

the

4. For gas

the

transmi

5. Viatran recommends the use of snubbers in installations prone to high levels of

flow

are

for

gas flow

filled

must be mounted

added to the

must be at the

plugs

sensor above

vertical

pressure connections

flow

pressure connections

tter should be mounted below the

pulsations.

Measurement

shown below

without a

with a

However,

suitable seal

below

with

water

lines

through the

same elevation (as shown

If a

and optional vent

low pressure sides

the

warning label as shown

with

line,

flow

flow,

without a

seal

with

the

level

of the

seal liquid),

must not

liquid

the

level

to protect the

filling tees.

seal

liquid

screws

of the transmitter

and/or

pressure connections

gas flow

should be upwards.

the

at the pipe.

liquid, the

at the pipe; for gas

long transmitter

without a

transmitter should

pressure connections

and with

come

in

(see procedure

of the

pressure connections

transmitter

in

is

not

to 20 N m (15 lb ft). Tighten the four

transmitter should

pressure

Piping

horizontal

filling tees

contact

To

prevent

Figure

required, elbows

in

Figure

at the pipe

seal

liquid,

be mounted lower than

flow

with a

and

vertical process

in the

with the

in next

from the hot

5) and the

are identified

lines, larger valve sizes should

connections.

transmitter,

section).

unequal

can be

3.

should

connections

be mounted

seal

liquid, the

pipes.

at the pipe

lines

at the pipe. With stea

steam.

heads

transmitter

by an L-H

be at the side of

(usual

to the

In such a

used

should be at

above

trans

the

transmitte

case,

The

seal

on the transmit

must be

in

place

process

marking

arrange-

be used.

mitter

the

m

liquid

of the

con-

on

top

r

-

[15]

98MANALIDP10AV Rev. A 8/16/11

[16]

98MANALIDP10AV Rev. A 8/16/11

Loading...

Loading...