ViaSat Series 8345 Installation Manual

Series 8345

4.5-Meter Prime Focus Motorized Antenna

Installation Manual

Manual 42S199F

March 2003

Table of Contents

Table of Contents

Table of Contents .................................................................................................. iii

List of Figures ......................................................................................................... v

List of Tables .......................................................................................................... vi

Safety Summary ...................................................................................................vii

General Information ........................................................................................... 1-1

1.1 Introduction .............................................................................................................1-1

1.2 Description ...............................................................................................................1-1

1.3 Stability During High Winds.................................................................................1-2

2.1 General......................................................................................................................2-1

2.2 What to do About Visible Loss or Damage .........................................................2-1

2.3 What to do About Concealed Damage ................................................................2-1

2.4 How to Inventory Equipment Received ..............................................................2-2

2.5 How To Return Equipment ...................................................................................2-2

2.6 General Mechanical Safety Summary ..................................................................2-3

2.6.1 Emergency Plan.......................................................................................................2-3

2.7 General Electrical Safety Summary ......................................................................2-4

2.7.1 Resuscitation ............................................................................................................2-4

2.8 Recommended Tools And Equipment.................................................................2-5

2.9 Recommended Installation Sequence...................................................................2-6

2.10 Recommended Torque Values ..............................................................................2-6

2.11 Assembly of Mount.................................................................................................2-8

2.11.1 Adjustment of Eccentric Cam Followers ...........................................................2-21

2.11.2 Installation of Azimuth Actuator........................................................................ 2-21

2.11.3 Installation of Azimuth Stabilizer Assembly ....................................................2-22

2.11.4 Installation of Elevation Actuator.......................................................................2-22

2.11.5 Installation of Hub Support Brackets .................................................................2-23

2.12 ASSEMBLY OF REFLECTOR.............................................................................. 2-25

42S199F iii

Table of Contents

2.12.1 Installation of Feed................................................................................................2-32

2.12.2 Installation of C-Band Feed .................................................................................2-32

2.12.3 Installation of Ku-Band Feed...............................................................................2-38

2.13 Technical Drawings ..............................................................................................2-43

Operation.............................................................................................................. 3-1

3.1 General......................................................................................................................3-1

3.2 Satellite Pointing Procedure ..................................................................................3-1

3.3 Focal Length Inspection And Adjustment...........................................................3-1

3.3.1 Adjustment Procedure ...........................................................................................3-2

3.4 Equipment Required For Transmit Patterns .......................................................3-3

Maintenance......................................................................................................... 4-1

4.1 General......................................................................................................................4-1

4.2 Periodic Maintenance .............................................................................................4-1

4.2.1 Weekly Maintenance ..............................................................................................4-1

4.2.2 Monthly Maintenance ............................................................................................4-2

4.2.3 Bi-Monthly Maintenance........................................................................................4-2

4.2.4 Yearly Maintenance ................................................................................................4-4

4.3 Corrosion Protection...............................................................................................4-5

42S199F iv

Table of Contents

LIST OF FIGURES

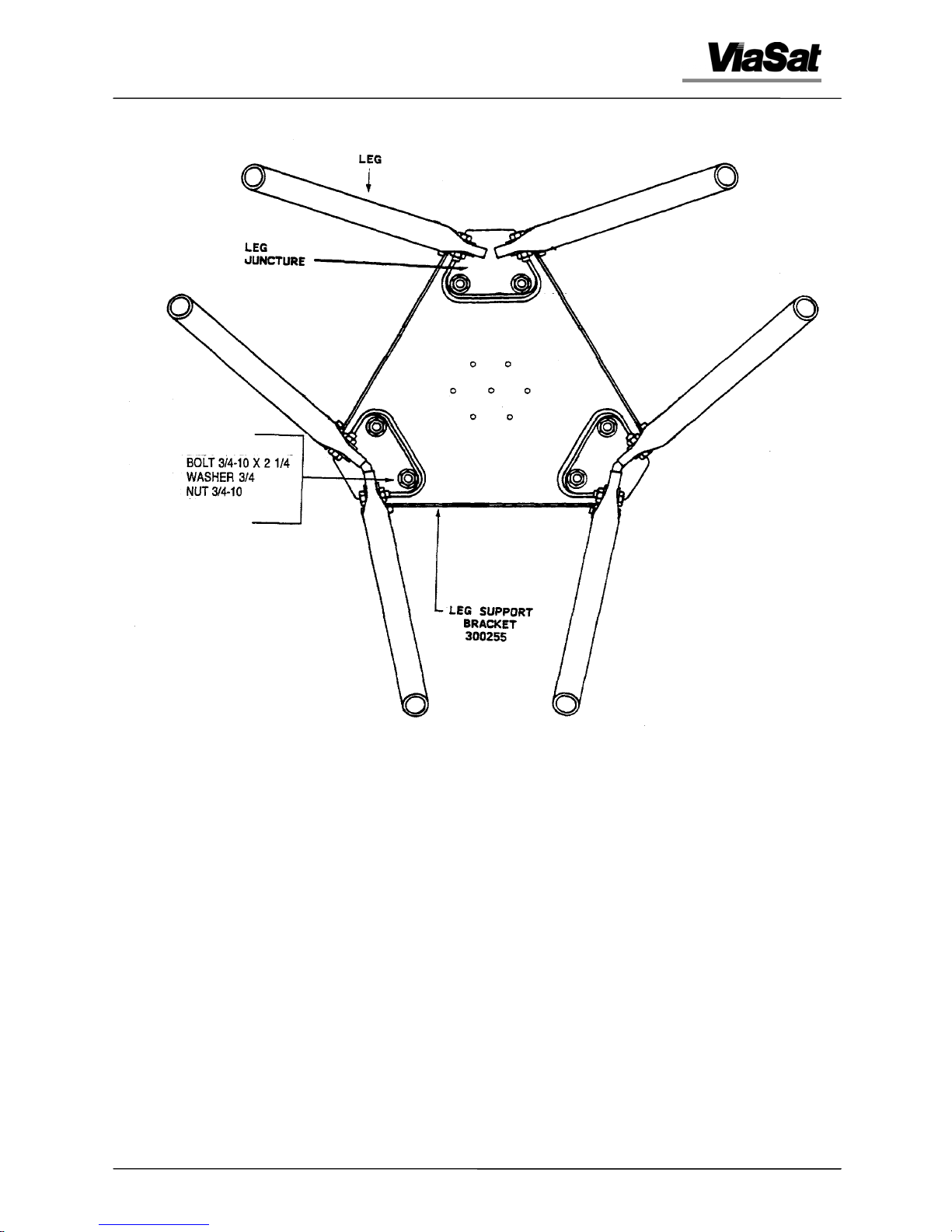

Figure 2-1. Installation of Leg Assemblies..........................................................................................2-9

Figure 2-2. Installation of Leg Support Bracket ...............................................................................2-11

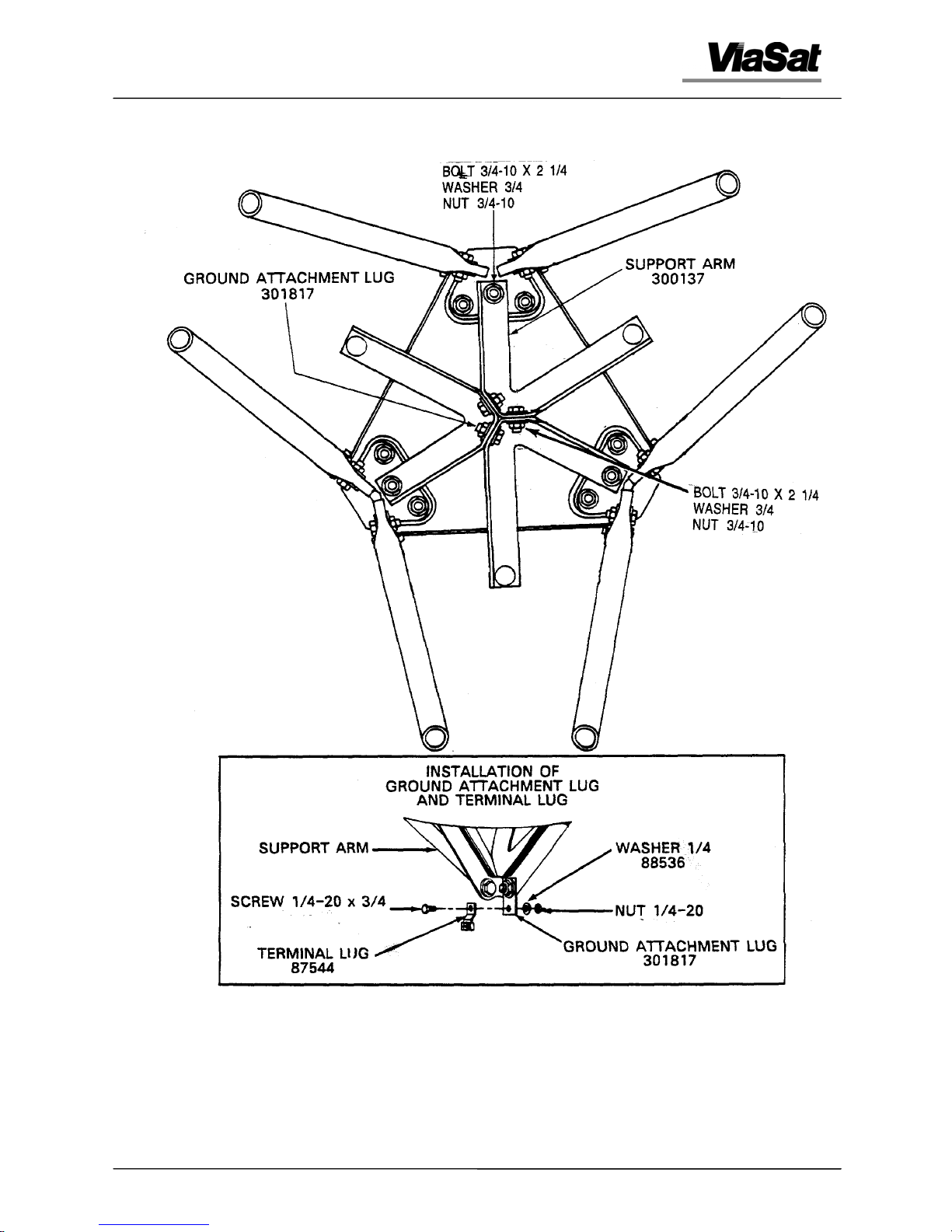

Figure 2-3. Installation of Support Arms ..........................................................................................2-12

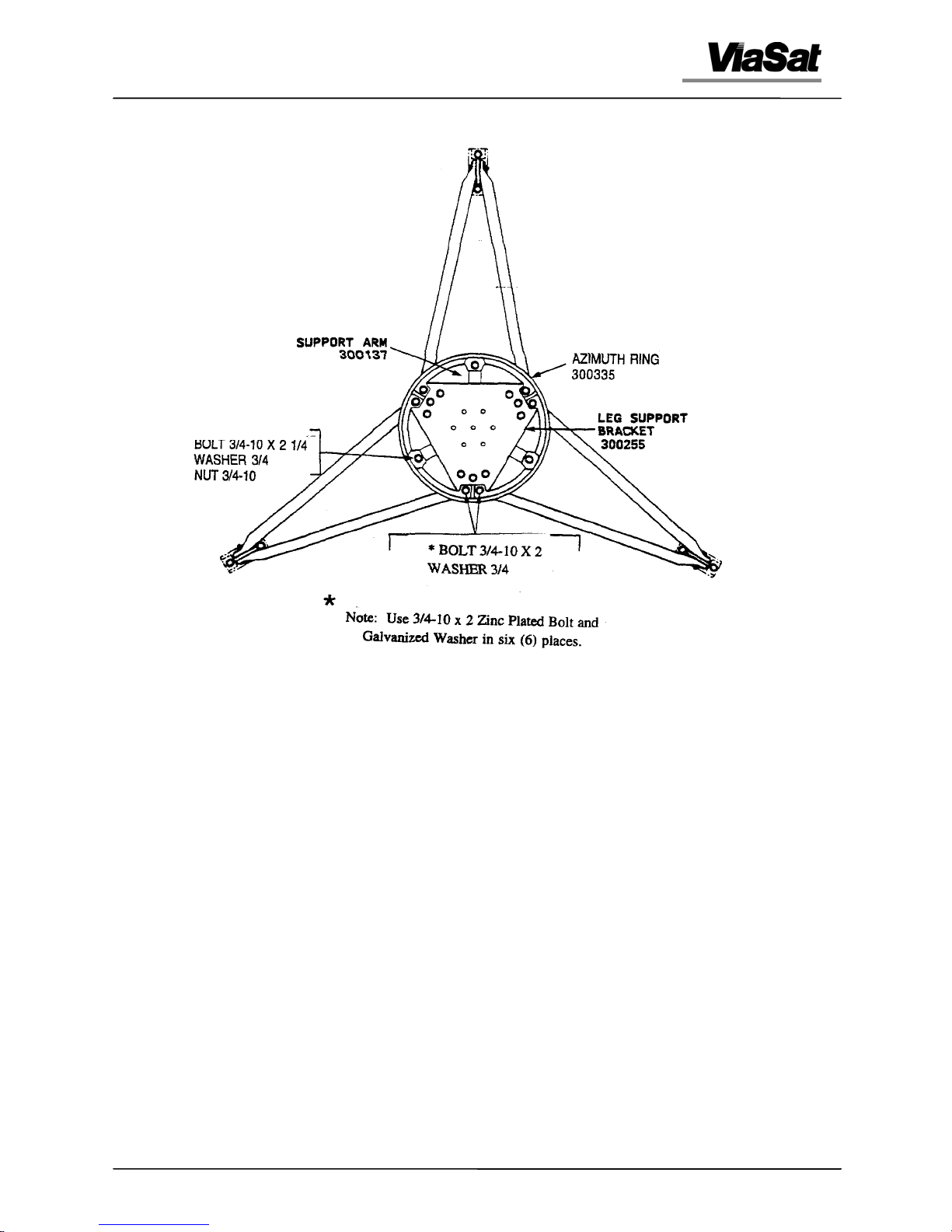

Figure 2-4. Installation of Azimuth Ring ..........................................................................................2-13

Figure 2-5. Tightening Sequence for Pedestal..................................................................................2-14

Figure 2-6. AZ/EL Assembly, 4.5 Meter Motorized (Sheet 1 of 5), 482045B ...............................2-16

Figure 2-7. Assembly and Adjustment of Rib and Panel Brace..................................................... 2-26

Figure 2-8. Template Installation .......................................................................................................2-27

Figure 2-9. Tapered Pins .....................................................................................................................2-28

Figure 2-10. Placing the Template onto the Panel ...........................................................................2-30

Figure 2-11A. Stringing the Reflector ...................................................................................2-30

Figure 2-11B. Locating the Strings for Rib Adjustment.................................................................. 2-30

Figure 2-12. Feed and Feed Housing Assembly (C-Band) .............................................................2-33

Figure 2-13. Attachment of Spars to Support Brackets...................................................................2-33

Figure 2-14. Installation of Feed Housing and Orthomode Transducer ......................................2-34

Figure 2-15. Installation of LNAs/LNBs ..........................................................................................2-36

Figure 2-16. Installation of LNA/LNB Cover ..................................................................................2-37

Figure 2-17. Feed Window Installation.............................................................................................2-39

Figure 2-18. Feed and Feed Housing Assembly (Ku-Band)........................................................... 2-40

Figure 2-19. Attachment of Spars to Support Brackets...................................................................2-40

Figure 2-20. Installation of Feed Housing, OMT and LNAs/LNBs..............................................2-41

Figure 2-21. Installation of LNA/LNB Cover ..................................................................................2-42

Figure 2-22. Motorized 4.5-Meter Ku-Band Feed Installation (Sheet 1 of 3), 367733 .................2-44

Figure 2-23. Motorized 4.5-Meter Ku-Band Feed Assembly (Sheet 1 of 10), 367730..................2-47

Figure 3-1. Focal Length Inspection and Adjustment....................................................................... 3-2

42S199F v

Table of Contents

LIST OF TABLES

Table 2-1. Tools and Equipment Required For Installation .............................................................2-5

Table 2-2. Torque Values For Antenna Fasteners (High Strength Grade 5 Zinc or Galvanized

Steel).................................................................................................................................................. 2-6

Table 2-3. Torque Values For Antenna Fasteners (Stainless Steel) .................................................2-7

42S199F vi

Safety Summary

SAFETY SUMMARY

Notice

Any service, adjustment, maintenance, or repair of this product must be

performed only by authorized technical service personnel.

Prior to installation and use of this product review all safety markings and instructions.

When safety precautions or important information is presented in this manual, the

information will normally be presented just prior to the point where the hazard is likely

to be encountered.

The following symbols are used throughout this manual to bring attention to practices,

procedures, and conditions important to the safety of the operator and equipment or to

obtaining desirable results from the equipment.

This symbol warns of electrical shock hazards

to personnel. Failure to comply with the

NOTE

instructions of such a warning may result in

severe injury or death resulting from electrical

shock.

This symbol warns of non-electrical hazards to

personnel. Failure to comply with the

instructions of such a warning may result in

severe injury or death.

This symbol warns of hazards to equipment.

Failure to comply with the instructions of such

a caution may result in damage or destruction

of equipment.

This symbol is used to bring attention to

installation grounding requirements.

Notes are used to provide clarification, or to

alert the reader of possible erroneous results,

which may occur if a procedure is not

followed as written.

42S199F vii

Notice

All Rights Reserved

The information contained in this document is proprietary to ViaSat, Inc.

This document may not be reproduced or distributed in any form without

the consent of ViaSat, Inc.

The information in this document is subject to change without notice.

ViaSat, Inc. assumes no responsibility for any errors that may appear in

this document and does not warranty any specific application.

Any product names mentioned herein are used for identification purposes

only, and may be trademarks and/or registered trademarks of their

respective companies.

In all correspondence with ViaSat, Inc. regarding this publication, please

refer to the Manual Part No. on the title page.

Copyright ® 2003 ViaSat, Inc.

All rights reserved. No part of this book may be reproduced in any form

or by any means without permission in writing from ViaSat, Inc.

Blank Page

Chapter 1 - General Information

1.1 Introduction

This manual contains information needed to properly install, operate, and

maintain the Series 8345 4.5-meter (4.5M) Prime Focus Motorized Antenna.

Section 1 contains general information on the Series 8345M Prime Focus

Motorized Antenna. Chapters 2 through 4 contain information pertaining to

Series 8345 4.5M Prime Focus Motorized Antenna installation, operation, and

maintenance. All warnings and cautions should be reviewed before any

procedures are performed. Failure to do so may result in personal injury or

equipment damage.

1.2 Description

Chapter 1

General Information

The Series 8345 4.5M Prime Focus Motorized Antenna is designed for quick

and easy installation and provides cost effective, high performance for a wide

range of applications combining the following features:

• Ease of Installation

• Minimum maintenance design

• Minimum shipping and installation costs design

• Minimum site preparation requirements

• Full satellite arc coverage from any location in the contiguous United

States (2° to 90° continuous elevation: 180° continuous azimuth)

• Elevation-over-azimuth Mount for ease of operation

• Interchangeable stamped reflector panels for consistent surface accuracy

• Protected environment for LNAs/LNBs

• Ku-band compatible

The motorized elevation-over-azimuth mount provides the 4.5-meter antenna

with ease of operation and high pointing accuracy. The mount provides

continuous pointing satellite arc coverage from any location in the United

States. Pointing of the antenna is rapid and accurate. 2° to 90° continuous

elevation is provided for maximum pointing capability. 360° in 3

overlapping 180° continuous sectors precludes alignment of the foundation

42S199F 1-1

Chapter 1 - General Information

to a specific heading, thereby eliminating the possibility of installation errors

associated with foundation centerlines.

The parabolic reflector consists of twelve precision stretch stamped steel

panels for consistent surface accuracy. The twelve panels are uniform and

completely interchangeable, resulting in handling convenience, lower

shipping costs and easy installation. Once a foundation has been prepared,

three people can install the antenna in one day.

The mount load frame weight is approximately 250 lbs. A

minimum of three people shall be used to manually place the

load frame on the azimuth ring. An optional hoisting device

may also be used during installation.

Each of the optional feeds offered with the Series 8345 4.5M Prime Focus

Motorized Antenna provides consistent high quality and unusual economy

in a mid-sized antenna system. The Ku-band feed provides dual

polarization, receive only capability in the 10.9 to 12.75 GHz range. The Cband feed provides dual polarization, receive-only capability in the 3.7 to 4.2

GHz range. Both are available in motorized polarization versions. Also

available are Ku-band receive-transmit versions.

NOTE

1.3 Stability During High Winds

The reflector mount and motorized actuators are designed to withstand high

winds. The azimuth and elevation actuators will drive the antenna in an

85 mi/hr wind at any orientation with no ice.

The antenna will survive 110 mi/hr winds at any orientation with no ice.

Antenna survival at 125 mi/hr winds from any direction with no ice is also

achievable by driving the elevation axis to a 90° stow position.

42S199F 1-2

Chapter 2 - Installation

2.1 General

This chapter contains procedures for unpacking and installing the Series 8345

4.5M Prime Focus Motorized Antenna. General safety precautions and

procedures are also described.

ViaSat thoroughly inspects and carefully packs all equipment before

shipment. At the time of shipment, the carrier assumes responsibility for its

safe delivery; therefore, do not return damaged units to ViaSat. Instead, file a

claim with the carrier as noted in the paragraphs following the initial

unpacking procedure given below:

Chapter 2

Installation

1. Inspect shipping carton for visible damage.

2. Open the shipping carton.

3. Remove all packing material.

4. Inspect unit for visible damage.

5. Using packing list, check for missing items (see "How To Inventory Equipment

Received" below).

2.2 What to do About Visible Loss or Damage

Make a note of any loss or evidence of external damage on the freight bill or

receipt, and have it signed by the carrier's agent. Failure to adequately

describe such external evidence of loss or damage may result in the carrier

refusing to honor a damage claim. The form required to file such a claim will

be supplied by the carrier.

2.3 What to do About Concealed Damage

Concealed damage means damage which does not become apparent until the

unit has been unpacked. The contents may be damaged in transit due to

rough handling, even though the carton may not show external damage. If

you discover damage after unpacking the unit, make a written request for

inspection by the carrier's agent within 15 days of the delivery date, then file

a claim with the carrier since such damage is the carrier's responsibility. If

you follow these instructions carefully, ViaSat guarantees its full support of

your claims to protect you against loss from concealed damage.

42S199F 2-1

Chapter 2 - Installation

2.4 How to Inventory Equipment Received

Check off each item received against that list on the packing slip included

with the shipment, and verify that this list matches the purchase order. If

any items are missing, please notify ViaSat immediately.

2.5 How To Return Equipment

ViaSat's Satellite Ground Systems division makes every reasonable effort to

ensure that all items arrive safely and in working order. When equipment is

received, which is not in working order, return the equipment to the factory

for repair or replacement. Return the equipment according to the following

procedure. This procedure will apply whenever equipment is returned for

warranty or other services.

a) Notify ViaSat of the problem and request a Return Material

Authorization (RMA) number and shipping instructions.

For a current list of telephone and email contact information

please refer to the Contact Information section of the ViaSat

internet site (http://www.viasat.com). Select Products and

Technologies, Satellite Ground Systems and Contact Us.

b) Tag or identify defective equipment and note defect and circumstances, if

any. If known, reference sales order, purchase order, and date equipment

was received.

c) Reship equipment in original shipping container or use a strong shipping

container to protect equipment during shipment.

d) Package equipment using shock-absorbing material around all sides of

equipment.

e) Seal container securely and mark outside of container FRAGILE.

WARNING

Electrical shock from voltages used in this system can cause

injury or death. Prior to making any electrical connections or

performing maintenance and repair, ensure power is removed.

Electrical connections should be made only by qualified

personnel in accordance with local regulation.

42S199F 2-2

Chapter 2 - Installation

2.6 General Mechanical Safety Summary

These are general mechanical safety precautions that are not related to any

specific procedure. They are recommended precautions that personnel must

understand and apply.

WARNING

Installation or maintenance of antennas may require persons

to work at elevated work stations. Whenever persons are

working at eight or more feet above ground and not on a

guarded platform, they should wear safety belts with at least

one, and preferably two, lanyards, with the exception that

trained and qualified persons may work up to 25 feet if on an

approved ladder. In the sentence above, approved usually

means that the ladder is tied off once the person has climbed

but before work begins.

Overhead hazards, either because items may fall or because a

person may strike them unintentionally, are typical around

construction sites or during installation of large antennas. It is

prudent to adopt the following rules:

1. Never stand underneath anything while it is being hoisted.

2. Always wear a hard hat, especially if someone is above you.

Ensure that all electrical tools and equipment are properly

grounded.

2.6.1 Emergency Plan

Have an emergency plan. Know the procedures for obtaining first-aid and

fire-fighting assistance. Plan your work and maintain good housekeeping;

the safety and quality of the product are at stake.

WARNING

WARNING

42S199F 2-3

Chapter 2 - Installation

2.7 General Electrical Safety Summary

These are general electrical safety precautions that are not related to any

specific procedure. These are recommended precautions that personnel must

understand and apply.

WARNING

Avoid shorting circuits when using metal tools. Some circuits

have high current capability which, when shorted, will flash

and may cause burns and/or eye injury.

Remove all jewelry and exposed metal objects from body and

clothing before performing maintenance, adjustments, and/or

troubleshooting. Before working inside the equipment, remove

all power, unless power is required to perform procedures. Do

not replace parts with power on.

2.7.1 Resuscitation

Personnel working with or near hazardous chemicals or voltages should be

familiar with modern methods of resuscitation.

Replacement of fuses or other parts must be done using

identical types and ratings. Substitution of non-identical parts

may cause safety and fire hazards.

Servicing this equipment may require working with protective

covers removed and ac power connected. Extreme caution

must be exercised during these procedures.

Death or severe injury may result if personnel fail to observe

safety precautions.

42S199F 2-4

Chapter 2 - Installation

2.8 Recommended Tools And Equipment

Table 2-1 lists the tools and equipment required for efficient and convenient

installation.

Table 2-1. Tools and Equipment Required For Installation

Quantity Description

1 Set Combination wrenches 1/4-inch to 1 1/2-inch size including 15/16-inch

2 Each Alignment pins 1/8-inch and 1/2-inch taper

1 Each 3/4-inch spud wrench

1 Each 3 lb. hammer

1 Each Pry bar

1 Each Band cutter

1 Each 12-foot stepladder

1 Each 6-foot stepladder

1 Each Torque wrench, 7-9 ft-lbs (9-12 Nm)

1 Each Torque Wrench, 15-20 ft-lbs (20-27 Nm) 1/4-inch to 3/8-inch drive

1 Each Torque wrench, 150 ft-lbs (203 Nm)

1 Each Torque wrench, 250-300 ft-lbs (333-400 Nm) 3/4-inch drive

1 Each Small Allen wrench set

1 Each Medium Allen wrench set

1 Each Large Allen wrench set

1 Each 1/2-inch Allen wrench

1 Each Torpedo level

1 Set Electrical tools (screw drivers, nut drivers, pliers, crimp tool, line-man pliers, needle

nose pliers, channel lock pliers)

1 Set 3/8-inch drive ratchet set

1 Each Grease gun with cartridges

1 Each 1/2-inch drive ratchet set with 15/16-inch socket and 3/4-inch deep well socket

1 Each 3/4-inch drive ratchet with a 1 1/8-inch, 1 1/4-inch, 1 1/2-inch, 1 7/8-inch sockets

and 6-inch extension

1 Each Angle finder or magnetic base inclinometer

1 Each 1/4-inch diameter drill

1 Each 1/2 hp drill motor

42S199F 2-5

Chapter 2 - Installation

2.9 Recommended Installation Sequence

In order to ensure proper and trouble-free installation, the following

installation sequence is recommended:

1. Assembly of Mount

2. Assembly of Reflector

3. Installation of Feed

2.10 Recommended Torque Values

The following list contains the recommended torque values for all 4.5M

antenna fasteners. Refer to Table 2-2 for galvanized fasteners and Table 2-3

for stainless steel fasteners.

CAUTION

Do not torque any fasteners until specifically directed to torque

a fastener. As fasteners are installed, tighten finger tight only.

Table 2-2. Torque Values For Antenna Fasteners

(High Strength Grade 5 Zinc or Galvanized Steel)

Fastener Size Torque (ft-lb) tolerance ±10%

1/4-20 6 (8 Nm)

5/16-18 15 (20 Nm)

3/8-16 30 (40 Nm)

1/2-13 75 (100 Nm)

3/4-10 250 (except as noted) (333 Nm)

1-8 600 (except as noted) (813 Nm)

42S199F 2-6

Chapter 2 - Installation

Table 2-3. Torque Values For Antenna Fasteners (Stainless Steel)

Fastener Size Torque (ft-lb) tolerance ±10%

1/4-20 6 (8 Nm)

5/16-18 12 (16 Nm)

3/8-16 20 (26 Nm)

1/2-13 45 (60 Nm)

3/4-10 130 (except as noted) (173 Nm)

NOTE

The required torque value for the foundation anchor bolts is

100 lb-ft (136 Nm).

42S199F 2-7

Chapter 2 - Installation

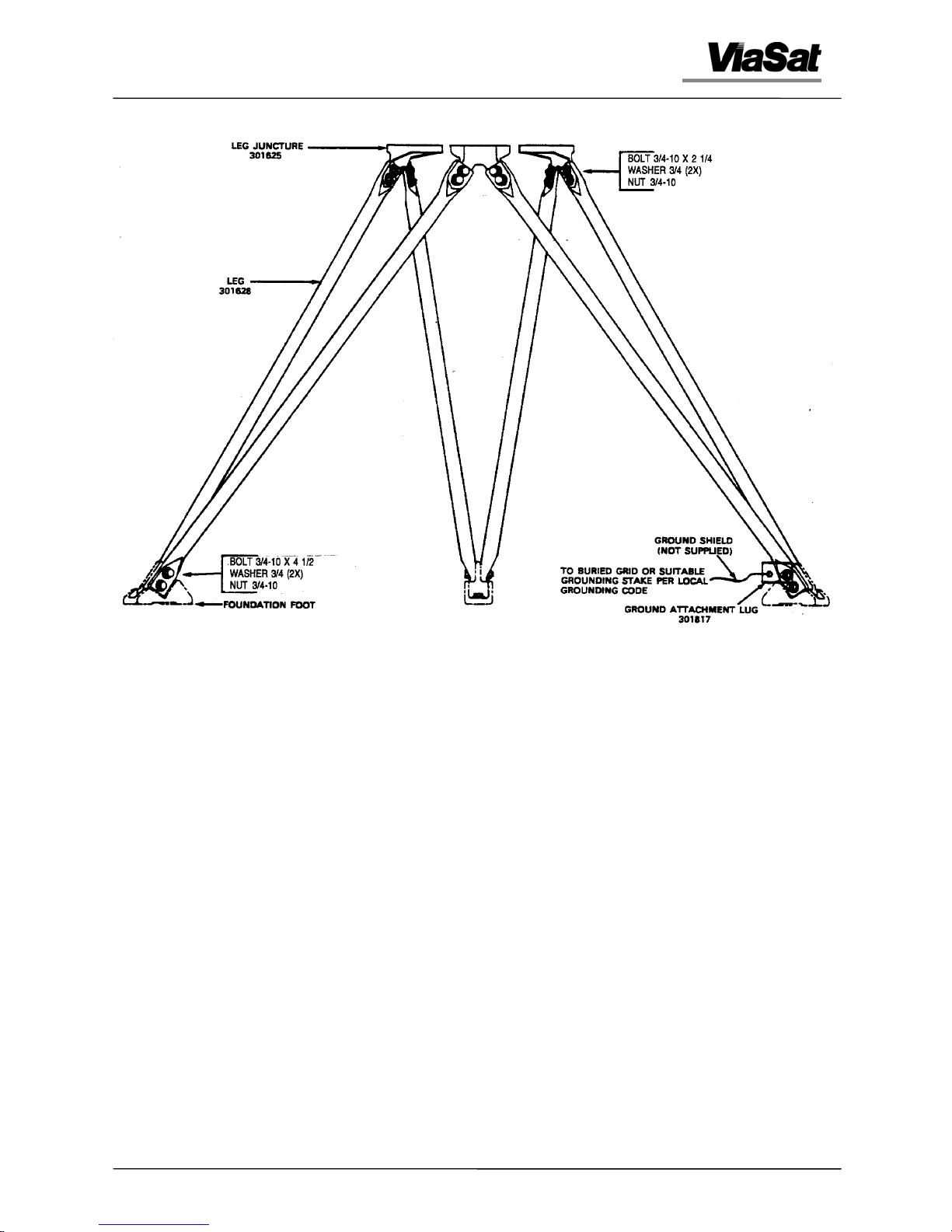

2.11 Assembly of Mount

The following procedure provides instructions for assembling the Series 8345

elevation-over-azimuth mount. Three foundation feet are supplied with each

foundation kit. (See foundation instructions for installation of feet.)

Before proceeding, be sure that the ground cable has been

attached to a foot of the foundation according to local

grounding codes. (See NOTES in Figures 2-2, 2-3, or 2-4.)

For the following procedure tighten all fasteners in steps 1

through 8 only finger tight, then follow step 9 (a through e) for

tightening sequence.

NOTE

NOTE

1. As shown in Figure 2-1, place one end of a leg onto a leg

juncture maintaining proper orientation of bend in leg.

Bolt in place with 3/4-10 x 2 1/4-inch bolt, washer, and

nut in two places. Repeat this operation with each of the

six legs and three leg junctures.

42S199F 2-8

Chapter 2 - Installation

Figure 2-1. Installation of Leg Assemblies

2. Attach two leg assemblies to each foundation foot and bolt the two leg ends to

the foundation foot using 3/4-10 x 4 1/2-inch bolt, washer, and nut in six places.

At one foundation foot, install a ground attachment lug to the leg ends before

bolting the leg ends to the foundation foot. Then ground antenna according to

local grounding codes.

3. As shown in Figure 2-2, position the leg support bracket, flanges down, on top of

the previously assembled leg junctures. Bolt leg support bracket in place at the

two inboard holes of each leg juncture using 3/4-10 x 2 1/4-inch bolt, washer,

and nut in six places.

4. Attach short extension of each support arm to the center hole at the underside of

each leg juncture using 3/4-inch bolt, washer, and nut in three places. Refer to

Figure 2-3.

5. Before fastening the support arms together, install a ground attachment lug to

the support arm at one of the center locations. Then attach a terminal lug to the

ground attachment lug using 1/4-20 x 3/4-inch screw, washer, and nut. This

will be used later to ground the antenna feed/LNBs.

42S199F 2-9

Chapter 2 - Installation

6. Bolt the three support arms together at the center using 3/4-10 x 2 1/4-inch bolt,

7. Position the azimuth ring on top of the leg support bracket and bolt in place at

8. As shown in Figure 2-4, bolt the long extension of each support arm to the

9. Using the following sequence, as shown in Figure 2-5, torque all 3/4-inch

washer, and nut in three places.

the outboard holes using 3/4-10 x 2-inch bolt and washer in six places. Refer to

Figure 2-4.

azimuth ring using 3/4-10 x 2-inch bolt, washer, and nut in three places.

fasteners to 250 ft-lbs (333 Nm).

a. Torque the two inboard bolts of each leg juncture.

b. Torque the six outboard bolts of each leg juncture which connect the azimuth

ring to the leg junctures.

NOTE

Using a carpenters level, make sure that the azimuth ring

remains level during steps c and d.

c. Torque the two bolts at each foot.

d. Torque two bolts at the upper end of each leg.

e. First, snug all bolts in the support arms to ensure that there is no binding of the

arms at any connecting point; then torque all nine bolts in the support arms.

42S199F 2-10

Chapter 2 - Installation

Figure 2-2. Installation of Leg Support Bracket

42S199F 2-11

Chapter 2 - Installation

Figure 2-3. Installation of Support Arms

42S199F 2-12

Chapter 2 - Installation

Chapter 2 - Installation

Figure 2-4. Installation of Azimuth Ring

42S199F 2-13

42S199F 2-13

Loading...

Loading...