Page 1

Series 8116/8118

16-/18-Meter Earth Station Antenna

Installation and Operation Guide

Manual Part No.42S183D

April 2004

Page 2

Notice

All Rights Reserved

The information contained in this document is proprietary to ViaSat, Inc.

This document may not be reproduced or distributed in any form without

the consent of ViaSat, Inc.

The information in this document is subject to change without notice.

ViaSat, Inc. assumes no responsibility for any errors that may appear in

this document and does not warranty any specific application.

Any product names mentioned herein are used for identification purposes

only, and may be trademarks and/or registered trademarks of their

respective companies.

In all correspondence with ViaSat, Inc. regarding this publication, please

refer to:

Publication Number: 42S183D

Copyright ® 2002 ViaSat, Inc.

All rights reserved. No part of this book may be reproduced in any form

or by any means without permission in writing from ViaSat, Inc.

Page 3

____________________________________________________________________________________________

TABLE OF CONTENTS

NOTE

For a further or more detailed breakdown of section

contents, refer to the title page of each section.

SECTION 1

1-1

1-1

1-3

1-4

SECTION 2

2-1

2-1

2-1

2-2

2-2

2-3

2-4

2-4

2-5

2-5

2-9

2-10

2-10

2-10

2-12

2-13

2-14

2-15

2-17

2-21

2-22

2-24

2-32

2-32

2-33

2-33

GENERAL INFORMATION

Introduction to Manual

Description

Wind Load Options

Specifications

LOWER MOUNT INSTALLATION PROCEDURES

General

What to do About Visible Loss or Damage

What to do About Concealed Damage

How to Inventory Equipment Received

How to Return Equipment

General Mechanical Safety Summary

Emergency Plan

General Electrical Safety Summary

Resuscitation

Recommended Tools and Equipment

Recommended Installation Sequency

Recommended Torque Values

Site Preparation

Assembly of Lower Mount

Azimuth Bearing Ring Assembly

Leg Installation

Bottom Skin Plate Installation

Mezzanine Installation (Optional)

Ships Ladder Assembly and Installation (Optional)

Middle and Top Skin Plate Installation

Torquing Lower Mount Fasteners

Door Assembly and Installation

Grouting Baseplate and Skin Plate to Foundation

Hot Weather Grouting

Cold Weather Grouting

Grouting Procedures

____________________________________________________________________________________________

42S183D

SERIES 8116/8118 16/18-METER EARTH STATION ANTENNA iii

Page 4

TABLE OF CONTENTS

____________________________________________________________________________________________

SECTION 3

UPPER MOUNT INSTALLATION PROCEDURES

3-1

3-1

3-1

3-14

3-19

3-22

3-22

3-23

3-29

3-29

3-29

3-30

General

Azimuth Drive Anchor Installation

Rotating Frame Installation

Azimuth Drive Installation

Elevation Drive Installation

Hub Assembly and Installation

Hub Assembly

Hub Installation

Installing Guardrails and Ladders

Ladders Installation

Guardrails Installation

Miscellaneous Platform Hardware

SECTION 4

INSTALLATION OF REFLECTOR, SPARS,

SUBREFLECTOR, AND FEED

4-1

4-1

4-1

General

Installation of Reflector

Installation of Panel Mounting Ring and Optional LNA

Enclosure

4-4

4-15

4-23

4-29

4-31

4-37

4-37

4-40

Installation of 18M Truss Assemblies

Installation of 16M Truss Assemblies

Installation of Panels

Final Alignment of Panels

Installation of Spars and Subreflector

Installation of Model 8118 Feed

Installation of Feed

Installation of Waveguide

SECTION 5

OPERATION

5-1

5-1

5-1

5-2

5-5

General

Satellite Pointing Procedure

Feed Polarization

Subreflector Adjustment

Azimuth Sector Change Procedure

____________________________________________________________________________________________

iv

SERIES 8116/8118 16/18-METER EARTH STATION ANTENNA 42S183D

Page 5

TABLE OF CONTENTS

____________________________________________________________________________________________

SECTION 6

6-1

6-1

6-1

6-1

6-2

6-5

6-5

SECTION 7

7-1

7-1

7-1

APPENDIX A

APPENDIX B

APPENDIX C

MAINTENANCE

General

Periodic Maintenance

Weekly Maintenance

Monthly Maintenance

Bi-Monthly Maintenance

Yearly Maintenance

Corrosion Protection

OPTIONS

General

Feed Options

Lightning Protection

INSTALLATION CHECKLIST WITH MANUAL PAGE

REFERENCES

MECHNCIAL ALIGNMENT SPECIFICATION AND REPORT

FOR 16/18-METER LIMITED MOTION ANTENNA

(479820A)

CONTOUR ALIGNMENT SPECIFICATION AND RECORD

FOR 16/18-METER ANTENNA (479821B)

____________________________________________________________________________________________

42S183D

SERIES 8116/8118 16/18-METER EARTH STATION ANTENNA v

Page 6

Page 7

SECTION 1

1-1 Introduction to Manual

1-1 Description

1-3 Wind Load Options

1-4 Specifications

GENERAL INFORMATION

42S183D Series 8116/8118 16-/18-Meter Earth Station Antenna

Page 8

Page 9

____________________________________________________________________________________________

SECTION 1 GENERAL INFORMATION

INTRODUCTION TO

MANUAL

DESCRIPTION

This manual contains information needed to properly install,

operate, and maintain the 16-/18-Meter (16/18M) Earth Station

Antenna. This section contains general information on the 16/18M

antenna. Sections 2 through 4 contain information pertaining to

16/18M antenna installation. Sections 5 and 6 contain information

pertaining to operation and maintenance. Section 7 describes the

different configurations available for the 16/18M antenna.

Appendix A contains a complete antenna installation checklist with

page references for the detailed procedures. Appendix B and

Appendix C contain mechanical and contour alignment

specifications and report information for the antenna, respectively.

All warnings and cautions should be reviewed before any

procedures are performed. Failure to do so may result in personal

injury or equipment damage.

Periodic maintenance and corrosion protection procedures are

contained in Section 5. For replacing components of the antenna,

refer to the installation and assembly drawings contained in

Sections 2, 3, and 4.

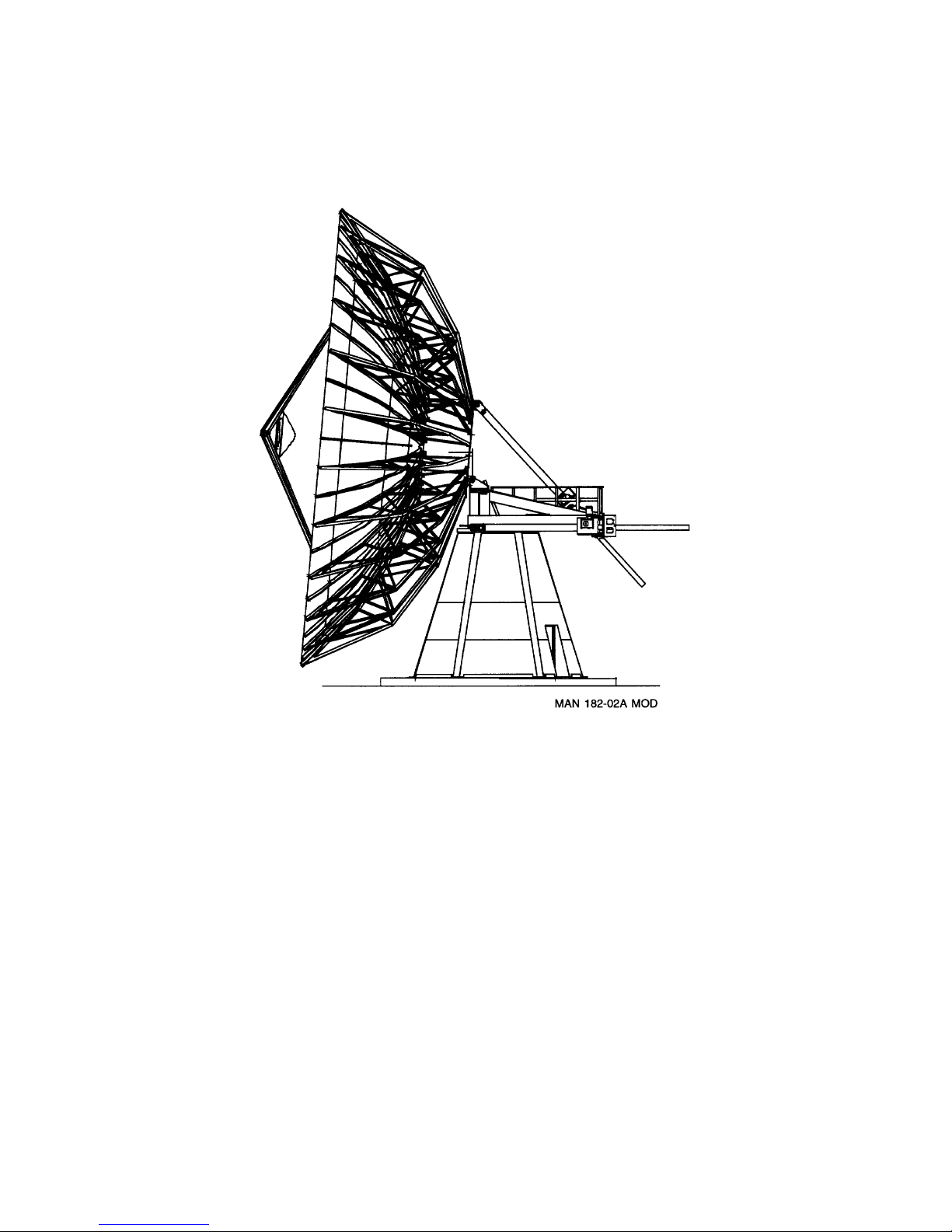

The 16/18M Earth Station Antenna provides a high-quality antenna

designed specifically for the INTELSAT-A station market. The

antenna is designed with many standard and optional features to

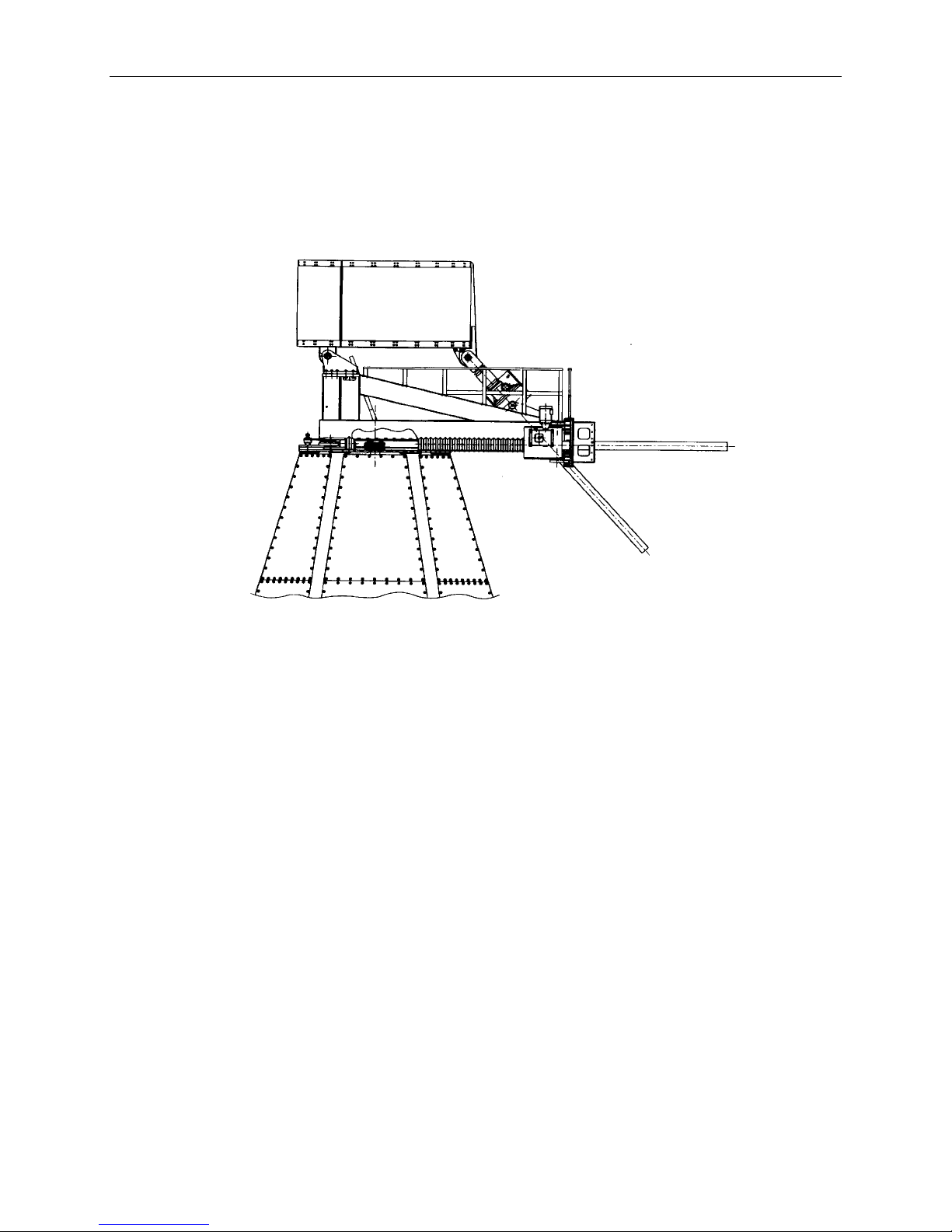

provide maximum user and application flexibility. Figure 1-1

shows an outline drawing of the 16M/18M antenna. The following

list identifies the main features of the antenna:

• Cassegrain feed for high-efficiency performance

____________________________________________________________________________________________

42S183D

SERIES 8116/8118 16-/18-METER EARTH STATION ANTENNA 1-1

• Designed for minimum maintenance

• Locked-in surface accuracy through precision tooling

• Frequency reuse feed

• Minimum site preparation required

• Full 360° azimuth travel in six over-lapping sectors

• Internal access for a clean, elegant look.

The 16/18M antenna is a Cassegrain design with a reflector and

subreflector that are shaped for maximum efficiency and low

sidelobes. The circularly polarized, four-port, frequency reuse feed

assembly includes a corrugated horn, orthomode transducer,

diplexers, and connecting waveguide. The transmit frequency

band is from 5.850 to 6.425 GHz and the receive frequency band is

from 3.625 to 4.200 GHz. All the performance specifications are

in full compliance with INTELSAT-A specifications.

Page 10

GENERAL INFORMATION

____________________________________________________________________________________________

Figure 1-1. 16-/18-Meter Motorized Antenna

____________________________________________________________________________________________

1-2

SERIES 8116/8118 16-/18-METER EARTH STATION ANTENNA 42S183D

Page 11

GENERAL INFORMATION

____________________________________________________________________________________________

The mount for both the 16- and 18-meter antennas is the same

elevation-over-azimuth pedestal. The elevation travel limits can be

set at any points between 0 and 90 degrees. The azimuth travel

range is a full 360 degrees covered in six overlapping sectors. Size

11 resolvers are supplied for position readout. Both axes are

equipped with 75 ton (667 kN) jack screws drives. As an option,

100 ton (890 kN) jack-screws can be provided to address additional

demands imposed by very high wind conditions on the 18M

antenna. Access to the drives and the reflector is gained from

inside the mount rather than from external ladders. The feed

electronics can be accessed at any elevation angle through the rear

of the hub.

The motorized package features variable-speed ac motors to

provide higher motor speeds for rapid stowing or slewing in

addition to the slow speeds required for satellite tracking. The

drives are equipped with variable-speed ac motors having a low

speed of about 0.010 degrees per second and a high speed slew rate

of about 0.1 degrees per second. The normal operational rate of

each axis is typically 0.01 to 0.015 degrees per second.

CAUTION

__________________________________________

No buildings, walls, fences, or other permanent

fixtures should be planned for installation any

closer than two meters from the antenna and

foundation envelope without consultation with

the factory.

Wind Load Options

__________________________________________

The 18-meter antenna will operate or drive to stow in winds up to

90 miles per hour (145 km/h) with the standard 75 ton (667 kN)

actuators. It will survive in any position in winds up to 105 miles

per hour (170 km/h). In the stow position (elevation axis at 90

degrees), the antenna will survive winds up to 140 miles per hour

(225 km/h). Under worst-case conditions, when the antenna is at 0

degrees elevation angle, it will take about 30 minutes to stow the

antenna using the variable speed motors. While the elevation axis

is being stowed, the azimuth axis can be turned to a more favorable

direction relative to the wind, if necessary. The azimuth axis never

needs to be stowed during adverse winds once the elevation axis is

at 90 degrees.

With the optional 100 ton (890 kN) actuators, the antenna will

operate or drive to stow in winds up to 90 miles per hour (145

km/h) but will survive in any position in winds up to 125 miles per

hour (200 km/h). In the stow position, the antenna will survive

winds up to 165 miles per hour (265 km/h).

____________________________________________________________________________________________

42S183D

SERIES 8116/8118 16-/18-METER EARTH STATION ANTENNA 1-3

Page 12

GENERAL INFORMATION

____________________________________________________________________________________________

The 16-meter antenna will operate or drive to stow in winds up to

110 miles per hour (175 km/h). It will survive in any position in

winds up to 125 miles per hour (200 km/h). In the stow position,

the antenna will survive winds up to 175 miles per hour (280

km/h).

SPECIFICATIONS

Function/Item Specification

General

Antenna Type Cassegrain, dual-reflector

Antenna Diameter 16 Meters

18 Meters

Reflector Construction

16-Meter Antenna 120 precision aluminum panels

18-Meter Antenna 168 precision aluminum panels

Mount Configuration Elevation-over-azimuth

Antenna Pointing Range

Azimuth 6 overlapping 90° sectors for a full 360°

Elevation 0 to 90° continuous

Antenna System Weight (Approximate)

16 Meter 124,000 lbs (56,233 kg)

18 Meter 127,000 lbs (57,594 kg)

Reflector Weight

16 Meter 39,000 lbs (17,686 kg)

18 Meter 42,000 lbs (19,047 kg)

Elevation Balance Angles

16 Meter 67°

18 Meter 69°

Drive Rates Variable over the range of:

Azimuth 0.0075 to 0.1125 degrees per second

(average)

Elevation 0.0044 to 0.0660 degrees per second

(average)

____________________________________________________________________________________________

1-4

SERIES 8116/8118 16-/18-METER EARTH STATION ANTENNA 42S183D

Page 13

GENERAL INFORMATION

____________________________________________________________________________________________

SPECIFICATIONS

Continued

Function/Item Specification

Electrical

Operating Frequency

Receive 3.625 to 4.200 GHz

Transmit 5.850 to 6.425 GHz

Feed Type Corrugated horn, frequency-reuse

Polarization Dual Circular

Gain at Midband (referenced to diplexer output ports)

Receive 55.2 + 20 log (f/4.0) dBi, 16-Meter

56.4 + 20 log (f/4.0) dBi, 18-Meter

Transmit 58.8 + 20 log (f/6.175) dBi, 16-Meter

60.1 + 20 log (f/6.175) dBi, 18-Meter

VSWR 1.25:1, Maximum

Axial Ratio

Receive 1.06:1

Transmit 1.06:1

Isolation Between Ports

Transmit 85 dB, Minimum

Receive 85 dB, Minimum

Beamwidth at Midband (nominal)

-3 dB Receive 0.32°, 16-meter

0.23°, 18-meter

-3 dB Transmit 0.21°, 16-meter

0.17°, 18-meter

First Sidelobe Level -14 dB, Maximum

Typical Antenna Noise Temperature

(Maximum @ 4 GHz referenced at output of OMT,

25°C (77°F), 50% RH, clear sky)

Elevation

5° 48

10° 41

20° 34

40° 32

60° 30

Power Handling Capability 5 kW continuous, 20 kW peak

(per port)

Feed Interface

Receive CPR-229G flange

Transmit CPR-137G flange

Voltage Requirements (actuators) 120/208V ac, 3-phase, 5-wire, 60 Hz or

220/380V ac, 3-phase, 5-wire, 50 Hz

(standard - others available)

Temperature (K)

____________________________________________________________________________________________

42S183D

SERIES 8116/8118 16-/18-METER EARTH STATION ANTENNA 1-5

Page 14

GENERAL INFORMATION

____________________________________________________________________________________________

SPECIFICATIONS

Continued

Function/Item Specification

Electrical - continued

Pointing Error 0.028° rms [with winds of 30 mi/h (48

km/h)gusting to 45 mi/h (72km/h) (1ß)]

0.040° rms [with winds of 45 mi/h

(72km/h)gusting to 60 mi/h (95 km/h)

(1ß)]

Tracking Error 0.02° rms with winds of 30 mi/h (48

km/h)gusting to 45 mi/h (72km/h)

Environmental

Feed Pressurization Leak Rate 500 cc/hr, Maximum

Feed Pressurization Relief Valve 0.5 psig

Ambient Temperature -40 to +60°C (-40 to +140°F)

Rainfall 100 mm/h (4 in/h)

Relative Humidity 0 to 100 % with condensation

Altitude Above Sea Level 0 to 10,000 feet (0 to 3048 m)

Sand and Dust As in desert regions

Salt Spray As in coastal regions

Fungi As in tropical regions

Solar Radiation 1.14 kW sq meter (360 Btu/h/sq ft)

Vertical Shock (survival) 0.1 G

Horizontal Shock (survival) 0.3 G

Earthquake Survival Per grade 11, Mercalli scale

Wind Survival (16M)

Operate Drives 110 mi/h (175 km/h)

Any Position 125 mi/h (200 km/h)

Stow Position 175 mi/h (280 km/h)

Wind Survival (18M)

Operate Drives 90 mi/h (145 km/h) (standard or optional

actuators)

Any Position 105 mi/h (170 km/h) (standard 75 ton

actuators)

125 mi/h (200 km/h) (optional 100 ton

actuators)

Stow Position 140 mi/h (225 km/h) (standard 75 ton

actuators)

165 mi/hr (265 km/h) (optional 100 ton

actuators)

________________________________________________________________

____________________________________________________________________________________________

1-6

SERIES 8116/8118 16-/18-METER EARTH STATION ANTENNA 42S183D

Page 15

SECTION 2

2-1 General

2-1 What to do about Visible Loss or Damage

2-1 What to do about Concealed Damage

2-2 How to Inventory Equipment Received

2-2 How to Return Equipment

2-3 General Mechanical Safety Summary

2-4 General Electrical Safety Summary

2-5 Recommended Tools and Equipment

2-9 Recommended Installation Sequency

2-10 Recommended Torque Values

2-10 Site Preparation

2-10 Assembly of Lower Mount

2-33 Grouting Baseplate and Skin Plate to Foundation

LOWER MOUNT INSTALLATION

PROCEDURES

42S183D Series 8116/8118 16-/18-Meter Earth Station Antenna

Page 16

Page 17

SECTION 2 LOWER MOUNT INSTALLATION PROCEDURES

GENERAL

WHAT TO DO ABOUT

VISIBLE LOSS OR

DAMAGE

WHAT TO DO ABOUT

CONCEALED

DAMAGE

This section contains general procedures for unpacking all of the

antenna hardware. This section also contains procedures for

installing the lower mount of the 16-/18-Meter Earth Station

Antenna. The installation of the upper mount (including rotating

frame, azimuth/elevation drives, hub, and optional work platform)

is contained in Section 3. The installation of the reflector, spars,

subreflector, and feed is contained in Section 4. General safety

precautions and procedures for the entire installation are also

described at the beginning of this section.

ViaSat thoroughly inspects and carefully packs all equipment

before shipment. At the time of shipment, the carrier assumes

responsibility for its safe delivery; therefore, do not return damaged

units to ViaSat. Instead, file a claim with the carrier as noted in the

paragraphs following the initial unpacking procedure given below:

1. Inspect shipping carton for visible damage.

2. Open the shipping carton.

3. Remove all packing material.

4. Inspect unit for visible damage.

5. Using packing list, check for missing items (see "How To Inventory

Equipment Received" below).

Make a note of any loss or evidence of external damage on the

freight bill or receipt, and have it signed by the carrier's agent.

Failure to adequately describe such external evidence of loss or

damage may result in the carrier refusing to honor a damage claim.

The form required to file such a claim will be supplied by the

carrier.

Concealed damage means damage which does not become

apparent until the unit has been unpacked. The contents may be

damaged in transit due to rough handling, even though the carton

may not show external damage. If you discover damage after

unpacking the unit, make a written request for inspection by the

carrier's agent within 15 days of the delivery date, then file a claim

with the carrier since such damage is the carrier's responsibility. If

you follow these instructions carefully, ViaSat guarantees its full

support of your claims to protect you against loss from concealed

damage.

____________________________________________________________________________________________

42S183D

SERIES 8116/8118 16-/18-METER EARTH STATION ANTENNA 2-1

Page 18

LOWER MOUNT INSTALLATION PROCEDURES

HOW TO INVENTORY

EQUIPMENT

RECEIVED

HOW TO RETURN

EQUIPMENT

Check off each item received against that list on the packing slip

included with the shipment, and verify that this list matches the

purchase order. If any items are missing, please notify ViaSat

immediately and return a copy of the packing slip with the missing

item(s) circled.

For a current list of telephone and email contract information

please refer to the Contact Information section of the ViaSat

internet site (http://www.viasat.com

). Select Products, Satellite

Ground Systems and Contact Us.

ViaSat’s Satellite Ground Systems division makes every

reasonable effort to ensure that all items arrive safely and in

working order. When equipment is received, which is not in

working order, return the equipment to the factory for repair or

replacement. Return the equipment according to the following

procedure. This procedure will apply whenever equipment is

returned for warranty or other services.

a) Notify ViaSat of the problem and request a Return Material

b) Tag or identify the defective equipment and note defect and

c) Reship equipment in original shipping container or use a strong

d) Package equipment using shock-absorbing material around all sides

e) Seal container securely and mark outside of container FRAGILE.

Authorization (RMA) number and shipping instructions.

circumstances, if any. If known, reference sales order, purchase

order and date equipment was received.

shipping container to protect equipment during shipment.

of equipment.

NOTE

Absence of the RMA number will cause a delay in processing

your equipment for repair. Be sure to include the RMA

number in all correspondence.

NOTE

ViaSat Inc will not accept freight collect. Be sure to ship all

items freight prepaid.

____________________________________________________________________________________________

2-2

SERIES 8116/8118 16-/18-METER EARTH STATION ANTENNA 42S183D

Page 19

GENERAL

MECHANICAL

SAFETY SUMMARY

LOWER MOUNT INSTALLATION PROCEDURES

WARNING

__________________________________________

Electrical shock from voltages used in this

system can cause injury or death. Prior to

making any electrical connections or performing

maintenance and repair, ensure power is

removed. Electrical connections should be made

only by qualified personnel in accordance with

local regulation.

__________________________________________

These are general mechanical safety precautions that are not related

to any specific procedure. They are recommended precautions that

personnel must understand and apply.

WARNING

__________________________________________

Installation or maintenance of antennas may

require persons to work at elevated work

stations. Whenever persons are working at eight

or more feet above ground and not on a guarded

platform, they should wear safety belts with at

least one, and preferably two, lanyards, with the

exception that trained and qualified persons may

work up to 25 feet (7.6m) if on an approved

ladder. In the sentence above, approved usually

means that the ladder is tied off once the person

has climbed but before work begins.

__________________________________________

____________________________________________________________________________________________

42S183D

SERIES 8116/8118 16-/18-METER EARTH STATION ANTENNA 2-3

Page 20

LOWER MOUNT INSTALLATION PROCEDURES

WARNING

__________________________________________

Overhead hazards, either because items may fall

or because a person may strike them

unintentionally, are typical around construction

sites or during installation of large antennas. It

is prudent to adopt the following rules:

1. Never stand underneath anything while it is

being hoisted.

2. Always wear a hard hat, especially if

someone is above you.

__________________________________________

WARNING

__________________________________________

Ensure that all electrical tools and equipment

are properly grounded.

__________________________________________

Emergency Plan

Have an emergency plan. Know the procedures for obtaining firstaid and fire-fighting assistance. Plan your work and maintain good

housekeeping; the safety and quality of the product are at stake.

GENERAL

ELECTRICAL SAFETY

SUMMARY

These are general electrical safety precautions that are not related

to any specific procedure. These are recommended precautions

that personnel must understand and apply.

____________________________________________________________________________________________

2-4

SERIES 8116/8118 16-/18-METER EARTH STATION ANTENNA 42S183D

Page 21

Resuscitation

RECOMMENDED

TOOLS AND

EQUIPMENT

LOWER MOUNT INSTALLATION PROCEDURES

WARNING

__________________________________________

Avoid shorting circuits when using metal tools.

Some circuits have high current capability

which, when shorted, will flash and may cause

burns and/or eye injury.

Remove all jewelry and exposed metal objects

from body and clothing before performing

maintenance, adjustments, and/or

troubleshooting. Before working inside the

equipment, remove all power, unless power is

required to perform procedures. Do not replace

parts with power on.

Replacement of fuses or other parts must be

done using identical types and ratings.

Substitution of non-identical parts may cause

safety and fire hazards.

Servicing this equipment may require working

with protective covers removed and ac power

connected. Extreme caution must be exercised

during these procedures.

Death or severe injury may result if personnel

fail to observe safety precautions.

__________________________________________

Personnel working with or near hazardous chemicals or voltages

should be familiar with modern methods of resuscitation.

Tables 2-1 through 2-4 list the tools and equipment needed for

installing ViaSat’s 16 or 18 meter antenna. Table 2-1 is a list of

hand tools. Table 2-2 is a list of on-site requirements such as

cranes, steel chokers, and an air compressor. Table 2-3 is a list of

precision items required such as a theodolite and level. Table 2-4

is a list of installation aids, rigging, and expendable items such as

air wrenches, slings, ladders, and safety items, some of which may

be available at the site.

____________________________________________________________________________________________

42S183D

SERIES 8116/8118 16-/18-METER EARTH STATION ANTENNA 2-5

Page 22

LOWER MOUNT INSTALLATION PROCEDURES

Table 2-1. Hand Tools Required for Installation

Quantity Description

1 Set* Combination wrenches up to 1 inch size

1 Each* 3/4 inch combination wrench

1 Each* 7/8 inch combination wrench

1 Each* 1 1/16 inch combination wrench

1 Each 1 1/8 inch combination wrench

1 Each* 1 1/4 inch combination wrench

1 Each* 1 5/8 inch combination wrench

1 Each* 1 7/8 inch combination wrench

1 Each* 2 inch combination wrench

1 Each 18 inch adjustable (Crescent) wrench

1 Each 24 inch adjustable (Crescent) wrench

1 Each 24 inch pipe wrench

1 Each* 1 1/16 inch spud wrench

1 Each* 1 1/4 inch spud wrench

1 Each* 1 5/8 inch spud wrench

1 Set 3/8 inch drive ratchet, extensions, and sockets from 3/8 to 7/8

1 Set* 1/2 inch drive ratchet, extensions, and sockets from 7/16 to 1

1 Each* 3/4 inch x 1/2 inch drive socket

1 Each* 7/8 inch x 1/2 inch drive socket

1 Each* 1 1/16 inch x 1/2 inch drive socket

1 Each* 1 1/4 inch x 1/2 inch drive socket

1 Each Socket adapter, 1/2 inch female to 3/4 inch male

1 Set* 3/4 inch drive ratchet, extensions, and sockets from 7/8 to 2

1 Each* 1 1/4 inch x 3/4 inch drive socket

1 Each* 1 5/8 inch x 3/4 inch drive socket

1 Each* 1 7/8 inch x 3/4 inch drive socket

1 Each* 2 inch x 3/4 inch drive socket

1 Each Socket adapter, 3/4 inch female to 1/2 inch male

1 Each 3/4 inch drive torque wrench, 250-300 ft-lbs capacity

1 Each 3/4 inch drive torque wrench, 600 ~-lbs capacity

2 Sets Screwdrivers, flat blade and Phillips

1 Set Hex keys (Allen wrenches) up to 1/2 inch size

1 Set* Nut drivers

2 Pairs Mechanic's pliers

1 Each Wire crimping tool

2 Pairs Lineman's pliers

2 Pairs Needle-nose pliers

1 Pair 12 inch channel lock pliers

2 Pair 10 inch vise grips

1 Each 4 pound sledge hammer

1 Each 8 pound sledge hammer

1 Each 24 ounce ball peen hammer

1 Each* Rawhide hammer

2 Each Claw hammer

2 Each 1 inch bull pin

2 Each 2 inch bull pin

1 Each Small slaver bar

inch size

1/4 inch size

inch size

____________________________________________________________________________________________

2-6

SERIES 8116/8118 16-/18-METER EARTH STATION ANTENNA 42S183D

Page 23

LOWER MOUNT INSTALLATION PROCEDURES

Table 2-1. Hand Tools Required for Installation - continued

Quantity Description

2 Each Large slaver bar

2 Each Crow (wrecking) bar

1 Each Pry bar

1 Each Band cutter

1 Each Hacksaw

6 Each Hacksaw blade

1 Each Automatic center punch

1 Each Drill index, 1/16 through 1/2 inch

6 Each 3/16 inch drill bits (for panel targets)

1 Each Tap and die set up through 3/8-16 size

1 Each 12 inch machinist's flat file

1 Each 12 inch round file

3 Each 6 inch C-clamp

1 Each Wire brush, stainless steel

1 Each Grease gun with cartridges

2 Rolls Electrical tape

1 Each Angle finder or magnetic base inclinometer

1 Each 24 inch carpenter's level

1 Each 12 inch machinist's scale with square head, 1/100 graduation

1 Each Feeler gage set

1 Each 12 foot tape

1 Each 25 foot tape

1 Each Chalk line reel (full of chalk)

1 Each 1 inch putty knife

1 Each 3 inch putty knife

1 Each 4 x 12 inch finishing trowel

1 Each 6 inch pointing trowel

4 Each 3/4 - 10 shoulder eye bolts (4-6 inch)

* Doubling the quantity of this item will enable a larger crew to install the

antenna more quickly.

______________________________________________________

____________________________________________________________________________________________

42S183D

SERIES 8116/8118 16-/18-METER EARTH STATION ANTENNA 2-7

Page 24

LOWER MOUNT INSTALLATION PROCEDURES

Table 2-2. On-Site Machinery and Equipment Required for

Quantity Description

1 Each* 45 ton crane with a 100 foot boom

4 Each 15 foot steel choker, 3/4 inch wire diameter

2 Each 20 foot steel choker, 1 inch wire diameter

4 Each Small, medium, and large shackles

1 Each Electric generator [or power hook-up point]

1 Each Air compressor with hoses and fittings, 600 cfm capacity

1 Each 20 foot scaffold [Not needed if mezzanine option is included

1 Each 50 foot high platform lift or bucket truck [Optional, but very

1 Each 5 gallon bucket (for grouting)

* Adding another crane will enable a larger crew to install the antenna more

quickly. [About 20 ton capacity with as much boom as possible to be used for

assembling trusses and intercostals.]

______________________________________________________

Table 2-3. Precision Tools Required for Installation

Quantity Description

1 Each

Machinist's level, 0.005 inch/foot graduation

1 Each

Wild Heerburg T2 theodolite with tribrach

1 Each

GV01 short focus lens for T2 theodolite

1 Each

GV02 short focus lens for T2 theodolite

1 Each

GV03 short focus lens for T2 theodolite

1 Each

Battery pack and light kit for T2 theodolite

1 Each

90 degree eyepiece set for T2 theodolite

1 Each 16/18 meter reflector alignment kit [Part number 479609]

______________________________________________________

Table 2-4. Installation Aids, Rigging, and Expendable Items

Quantity Description

1 Each 6 foot step ladder

1 Each 12 foot step ladder

2 Each 50 foot extension cord

2 Each Trouble light with 25 foot cord

1 Each* Transformer with duplex receptacle, 220 Volt to 110 Volt

1 Each Q-beam spotlight, 200,000 candle-power, 120 volt

1 Each 12 volt power supply for Q-beam spotlight

2 Each Flashlight, 2 D cell battery type

6 Each Flashlight battery, D cell

1 Each* 1/2 inch drive electric impact wrench

Installation

with mount]

useful]

Required

____________________________________________________________________________________________

2-8

SERIES 8116/8118 16-/18-METER EARTH STATION ANTENNA 42S183D

Page 25

RECOMMENDED

INSTALLATION

SEQUENCY

LOWER MOUNT INSTALLATION PROCEDURES

Table 2-4. Installation Aids, Rigging, and Expendable Items

Required - continued

Quantity

1 Each * 3/4 inch drive electric impact wrench

1 Each* 1/2 inch drive air impact wrench (if a compressor is available)

1 Each* 3/4 inch drive air impact wrench (if a compressor is available)

1 Each Cordless 3/8 inch drive drill motor with charger

1 Each 7 1/4 inch circular saw

3 Each Plywood blade for circular saw

4 Each 20 foot nylon sling

4 Each 15 foot nylon sling

4 Each 10 foot nylon sling

1 Each 50 foot nylon rope (1/2 inch)

4 Each Moving quilts

4 Each Safety belt with 2 D-rings

4 Each Safety lanyard

3 Each Tool belt

3 Each Bolt bag with tool holder

4 Each Hard hat

2 Pair Safety glasses

6 Pair Ear plugs

12 Pair Cloth gloves

6 Pair Leather palm gloves

1 Each First aid kit

1 Box Garbage bags

1 Can Hand Cleaner

6 Rolls Toilet paper

1 Each Ice Chest

1 Each Water Cooler

1 Each Umbrella

* Doubling the quantity of this item will enable a larger crew to install the antenna more

quickly.

Description

______________________________________________________

In order to ensure proper and trouble-free installation, the following

installation sequence is recommended:

1. Site Preparation (contained in manual #42S182)

2. Assembly of Lower Mount (contained in this section)

3. Assembly of Upper Mount (contained in Section 3)

4. Installation of Reflector (contained in Section 4)

5. Assembly of Spars and Subreflector (contained in Section 4)

6. Installation of Feed, Spars, and Subreflector (contained in Section 4)

7. Electrical Installation (contained in manual #42S197)

Appendix A provides a checklist with manual page number

references. The checklist follows the recommended sequence listed

above.

____________________________________________________________________________________________

42S183D

SERIES 8116/8118 16-/18-METER EARTH STATION ANTENNA 2-9

Page 26

LOWER MOUNT INSTALLATION PROCEDURES

RECOMMENDED

TORQUE VALUES

The following list contains the recommended torque values for all

antenna fasteners.

__________________________________________

Do not torque any fasteners until specifically

directed to torque a fastener. As fasteners are

installed, tighten finger tight only.

__________________________________________

1 1/4-inch Fasteners 1100 ft-lbs (1491 Nm)

1-inch Fasteners 600 ft-lbs (813 Nm)

3/4-inch Fasteners 260 ft-lbs (353 Nm)

5/8-inch Fasteners 150 ft-lbs (203 Nm)

1/2-inch Fasteners 76 ft-lbs (103 Nm)

3/8-inch Fasteners 31 ft-lbs (42 Nm)

5/16-inch Fasteners 24 ft-lbs (33 Nm)

1/4-inch Fasteners 9 ft-lbs (12 Nm)

SITE PREPARATION

Refer to 16-/18-Meter Earth Station Antenna Site Preparation

Technical Manual #42S182 for information needed to properly

locate and install the foundation for the 16-/18-Meter (16/18M)

Earth Station Antenna.

ASSEMBLY OF

LOWER MOUNT

The following procedure describes the complete assembly of the

lower mount for the 16- or 18-meter antenna. The completed

lower and upper mount assembly is identified in Figure 2-1. A

crane will be required during the entire assembly of the 16- or 18meter antenna. (The crane is required during the entire installation

process except for the site preparation and electrical installation.)

CAUTION

____________________________________________________________________________________________

2-10

SERIES 8116/8118 16-/18-METER EARTH STATION ANTENNA 42S183D

Page 27

LOWER MOUNT INSTALLATION PROCEDURES

Figure 2-1. Completed Mount Assembly With Hub

____________________________________________________________________________________________

42S183D

SERIES 8116/8118 16-/18-METER EARTH STATION ANTENNA 2-11

Page 28

LOWER MOUNT INSTALLATION PROCEDURES

Azimuth Bearing Ring

Assembly

The platform plate is assembled on the ground and then installed

on the top of the mount after the columns are erected during the

frame installation procedure. Assemble the azimuth bearing ring

assembly in accordance with the following procedure.

__________________________________________

The following assemblies weigh from 870 lbs

(395 kg) to 9300 lbs (4218 kg). Use extreme care

when hoisting these assemblies into position.

__________________________________________

__________________________________________

Mount damage can occur if the platform plates

are not properly aligned. Ensure proper

alignment is maintained as described in the

following procedure.

__________________________________________

1. Block up 2 piece tapped plate (item 3 in Figure 2-2) with ends 0.125

inches apart forming a hexagon (access underneath for installation of

top skin mounting angle is required).

2. Using hoist set 2 piece mounting plate (item 2 in Figure 2-2) in place

rotating ends 60° from ends of item 3.

3. Using hoist set 2 piece top plate (item 1 in Figure 2-2) in place rotating

ends 60° from ends of item 2 and item 3.

4. Secure all three layers together through bolt holes indicated in Figure 22 using screws and washers (items 100 and 101). Note that only 6 bolts

are used in one segment of the hexagon. This is where the azimuth drive

pivot frame is installed at a later time.

5. Torque bolts to 600 ft-lbs (813 Nm).

6. Attach six top skin mount angles (item 8 in Figure 2-3) to underside of

azimuth bearing ring assembly using screw, two flat washers, and nut

(items 102, 103 and 104 in Figure 2-3). Hand tighten nuts.

The azimuth bearing ring assembly is now ready to be set on

top of the columns in accordance with the next procedure.

WARNING

CAUTION

NOTE

____________________________________________________________________________________________

2-12

SERIES 8116/8118 16-/18-METER EARTH STATION ANTENNA 42S183D

Page 29

LOWER MOUNT INSTALLATION PROCEDURES

Leg Installation

The leg assembly must be properly aligned and installed for all

assemblies to properly fit together. Install the legs and associated

frame assemblies in accordance with the following procedure.

WARNING

__________________________________________

The following assemblies weigh from 135 lbs

(61 kg) to 15355 lbs (16965 kg). Use extreme

care when hoisting these assemblies into position.

__________________________________________

1. Install one hex nut (item 100, Figure 2-3) on each of the 24 leg anchor

bolts (six sets of four) and one hex nut (item 104) on each of 38 skin

bottom angle anchor bolts. Locate top of the nut 1-inch above the pad.

2. Place one flat washer (items 101 or 103, Figure 2-3) on each hex nut.

3. Using hoist, lift leg (item 1) into position over one set of column anchor

bolts (weight = 2790 lbs, 1265 kg).

4. Align column bottom plate holes with anchor bolts so the column leans

inward toward center of mount and secure with four flat washers and

nuts (item 100 and 101). Hand tighten nuts.

5. Using ladder remove hoist from leg.

6. Install remaining 5 legs as described in steps 3 through 5.

7. Attach hoist to azimuth bearing ring assembly (item 2).

8. Lift azimuth bearing ring assembly to rest on top of 6 legs.

9. Align azimuth bearing ring assembly corner holes with holes in top

mounting plate of legs. (It may be necessary to lower some of the legs

using nuts on leg base in order to properly align the holes.)

10. Secure azimuth bearing ring assembly to top plate of legs with screw,

two flat washers, and nut (item 102, 103, and 104). Hand tighten.

11. Remove hoist from azimuth bearing ring assembly.

12. Torque azimuth bearing ring assembly bolts to 1100 ft-lbs

(1491 Nm). Azimuth bearing ring assembly bearing mounting surface

(top of item 2 in Figure 2-2) should be leveled now by adjusting leg

anchor nuts up or down as required.

____________________________________________________________________________________________

42S183D

SERIES 8116/8118 16-/18-METER EARTH STATION ANTENNA 2-13

Page 30

LOWER MOUNT INSTALLATION PROCEDURES

Bottom Skin Plate

Installation

The bottom skin angles, door skin angles, lower skin tees, lower

door tees, lower skins, and lower door skins (items 3, 4, 5, 7, 11,

and 13 in Figure 2-3) are installed prior to installation of the

optional mezzanine and stairway.

1. Attach lower skin tee (item 5, Figure 2-3) to inside surface of lower

skin (item 11) with bolt, two flat washers, and nut (item 105, 103, and

104). Hand tighten. (Five of these assemblies are required.)

2. Lift lower skin into position on outside of two legs which do not have

the foundation bolt pattern for the access door between the legs.

3. Align plate side holes with holes in leg and secure to leg with bolt, two

flat washers, and nut (item 105, 103, and 104) in each skin plate side

hole. Hand tighten.

4. Install bottom skin angle (item 3) on skin bottom angle anchor bolts

using the following procedure.

a. Align holes in vertical leg of bottom skin angle with holes in

bottom skin.

b. Secure angle to skin with bolt, two flat washers, and nut (item

105, 103, and 104).

c. Secure angle to anchor bolts using washer and nut (item 103

and 104).

d. Hand tighten fasteners.

5. Remove hoist from bottom skin plate.

6. Install remaining four bottom skin plates as described in steps 1 through

5.

7. Attach lower door tee (item 7) to inside surface of lower door skin (item

13) with bolt, two flat washers, and nut (item 105, 103, and 104). Make

sure slanted side of skin is to the right.

8. Attach lower door tee in the same manner as step 7 except place angled

side of lower door skin on the left side.

9. Lift left lower door skin assembly into position on outside of left leg.

10. Align plate angled side holes with holes in leg and secure to leg with

bolt, two flat washers, and nut (item 105, 103, and 104) in each skin

plate side hole. Hand tighten.

11. Install door skin angle same as step 4 above.

12. Install right lower door skin assembly as described in steps 9, 10, and

11.

____________________________________________________________________________________________

2-14

SERIES 8116/8118 16-/18-METER EARTH STATION ANTENNA 42S183D

Page 31

LOWER MOUNT INSTALLATION PROCEDURES

Mezzanine

Installation (Optional)

The optional mezzanine is installed at this time to aid in attaching

the top skin plates and aligning the azimuth bearing ring assembly.

Install the mezzanine in accordance with the following procedure

and Figure 2-4.

NOTE

Leave all fasteners hand tight until directed to

torque fasteners.

CAUTION

__________________________________________

The mezzanine is designed for a live load

(personnel and tools) of 200 lbs per square foot

(976 kg per square meter) or a concentrated load

of 300 lbs (136 kg).

__________________________________________

1. Attach hoist to floor support beam A (item 1, Figure 2-4).

2. Lift support beam into position between legs directly opposite from

door opening.

3. Align two slotted holes with leg bracket holes and secure with two

bolts, four flat washers, two oversized flat washers, and two nuts (items

100, 102, 103, and 101) at each end of support beam. Hand tighten.

4. Remove hoist from mezzanine support beam.

5. Install floor support beam F (item 5) in next clockwise position,

(viewing from top of mount assembly) using steps 1 through 4.

6. Install floor support beam C (item 2).

7. Install floor support beam D (item 6).

8. Install floor support beam E (item 3).

9. Install floor support beam B (item 4).

10. Lift stairway header beam (item 8) into position between support beam

(item 1) and stairway opening beam (item 7) which will be installed

next.

11. Secure stairway header beam with two bolts, four flat washers, and two

nuts (item 104,102, and 101) at beam A. Hand tighten.

12. Attach hoist to stairway opening beam (item 7).

____________________________________________________________________________________________

42S183D

SERIES 8116/8118 16-/18-METER EARTH STATION ANTENNA 2-15

Page 32

LOWER MOUNT INSTALLATION PROCEDURES

13. Lift stairway opening beam into position between beams B and F.

14. Align four holes in end plates with holes in beams B and F and secure

with screw, two flat washers, and nut (item 104, 102, and 101). Hand

tighten. Install remaining two sets of bolts, flat washers, and nuts

between stationary header beam and stairway opening beam.

15. Attach hoist to right floor support beam (item 9).

16. Lift right floor support beam into position between stairway opening

beam and support beam C on right side of mount (viewing inward from

door opening).

17. Align two end plate holes with holes in stairway opening beam and

secure with two screws, four flat washers, and two nuts (item 104, 102,

and 101).

18. Align end clip plate (item 11) with four holes each in right floor support

beam and support beam C.

a. Secure end clip plate in place using screw, two flat washers

and nut (item 104, 102, and 101) eight places.

b. Torque four bolts securing end clip plate to right floor support

to 260 ft lbs (353 Nm).

c. Hand tighten the bolts securing the end clip plate to support

beam C.

19. Remove hoist from right floor support beam.

20. Install left floor support beam (item 10) to stairway opening beam and

support beam E on left side of mount (viewing inward from door

opening) using steps 15 through 18.

21. Attach hoist to center floor beam (item 12).

22. Lift center floor beam into position between stairway opening beam and

support beam D. Slide end plate holes on center support beam over

studs at each end. (The center support beam is a removable beam to

allow for equipment installation and removal.)

23. Remove hoist from center support beam.

____________________________________________________________________________________________

2-16

SERIES 8116/8118 16-/18-METER EARTH STATION ANTENNA 42S183D

Page 33

LOWER MOUNT INSTALLATION PROCEDURES

Ships Ladder

Assembly and

Installation (Optional)

The optional ships ladder is first assembled on ground, then hoisted

into position and installed in the mount. Perform the following

procedures to assemble and install the ships ladder (refer to Figure

2-5).

ASSEMBLY OF SHIPS LADDER

1. Position stringers side by side with left hand stringer (item 1, Figure 2-

5) on left side and right hand stringer (item 2) on the right side. Lay

stringers flat with flanges upward.

2. Turn left hand stringer on edge with flanges toward right hand stringer.

3. Position one tread (item 11) inside stringer flanges and align hole in

tread with hole in stringer at nearest end of stringer.

a. Secure tread to stringer with screw, two flat washers, and nut

(item 100, 101, and 102).

b. Align slot in tread with hole in left hand stringer.

c. Secure tread with screw, two flat washers, and nut (item 100,

101, and 102).

d. Align slot in tread with hole in right hand stringer.

e. Secure tread with screw, two flat washers, and nut (item 100,

101, and 102).

f. Hand tighten fasteners.

NOTE

Assure that rough surface of tread will be up when the top end

of stringer is raised to mezzanine floor.

4. Turn right hand stringer (item 2) on edge with flanges toward left hand

stringer.

5. Align hole in tread with hole in right hand stringer.

a. Secure tread to stringer with screw, two flat washers, and nut

(item 100, 101, and 102).

b. Align slot in tread with hole in left hand stringer.

c. Secure tread with screw, two flat washers, and nut (item 100,

101, and 102).

d. Hand tighten fasteners.

6. Repeat steps 3 and 5 for all fourteen tread locations.

____________________________________________________________________________________________

42S183D

SERIES 8116/8118 16-/18-METER EARTH STATION ANTENNA 2-17

Page 34

LOWER MOUNT INSTALLATION PROCEDURES

7. Install top mount (item 3) between right hand and left hand stringer at

end of stringers which will be raised to join with the mezzanine floor.

a. Secure with screw, two flat washers, and nut (item 103, 104,

and 105) at both ends of top mount.

b. Hand tighten fastener.

8. Attach bottom mount (item 4) to bottom end of both stringers using

bolt, two flat washers, and nut (item 103, 104, and 105) through slotted

hole in bottom mount. Hand tighten.

9. Position right hand stanchion (item 10) on outside of the right hand

stringer just above the top tread.

10. Align holes in right hand stanchion with right stringer. Secure two

places using screw, two flat washers, and nut (item 100, 101, and 102).

Hand tighten.

11. Repeat step 9 and 10 just above the tenth tread, and the first tread.

12. Position left hand stanchion (item 9) on outside of left hand stringer just

above the tenth tread.

13. Repeat step 10.

14. Repeat step 12 and 13 just above the fifth tread and the first tread.

15. Position left handrail (item 5) inside of and on top of the three left hand

stanchion.

16. Align holes in handrail with stanchion and secure three places with

screw, two flat washers, and nut (item 100, 101, and 102). Hand

tighten.

17. Position left hand kneerail (item 7) on inside of left hand stanchion and

secure three places with screw, two flat washers, and nut (item 100, 101

and 102). Hand tighten.

18. Repeat step 15 on right side using right handrail (item 6) inside the four

right hand stanchions.

19. Repeat step 16 four places.

20. Repeat step 17 on right side using right hand kneerail (item 8) secure

four places.

21. Torque all 3/8-inch fasteners in treads, stanchions, handrails, and

kneerails to 31 ft-lbs. (42 Nm).

____________________________________________________________________________________________

2-18

SERIES 8116/8118 16-/18-METER EARTH STATION ANTENNA 42S183D

Page 35

LOWER MOUNT INSTALLATION PROCEDURES

SHIPS LADDER INSTALLATION

1. Attach hoist to ships ladder (see Figure 2-5).

2. Lift ships ladder into position in the stair opening (across the mount

from door opening).

3. Align three top mount holes at top of ladder with stairway header beam

holes.

4. Secure three places with screw, two flat washers, and nut (item 103,

104, and 105). Hand tighten.

5. Mark position on concrete where two holes on stair bottom mount meet

concrete floor.

6. Remove three bolts, washers, and nuts that secure ships ladder to

stairway header beam and lift ships ladder away from marked concrete

area.

7. Drill two 3/4-inch by 4-inch deep holes into concrete at marked

locations.

8. Insert expansion bolt (item 106) into expansion bolt holes and remove

nut and washer. (Retain these for use in step 10.)

9. Place ships ladder back in position and repeat step 4.

10. Secure bottom mount angles to concrete using the two nuts and washers

removed in step 8.

11. Level tread plate and torque bolts in slotted hole of bottom mount angle

to 260 ft-lbs (353 Nm).

12. Torque bolts in top of ships ladder to 260 ft-lbs (353 Nm).

13. Remove hoist from ships ladder.

14. Attach hoist to mezzanine guard rail (item 21, Figure 2-4).

15. Lift guard rail into position on mezzanine stairway opening beam.

16. Align guard rail bottom plate holes with holes in stairway opening beam

four places on each guard rail bottom plate.

17. Secure guard rail bottom plate to stairway opening beam with screw,

two flat washers, and nut (item 104, 102, and 101) 16 places.

18. Remove hoist from mezzanine guard rail.

____________________________________________________________________________________________

42S183D

SERIES 8116/8118 16-/18-METER EARTH STATION ANTENNA 2-19

Page 36

LOWER MOUNT INSTALLATION PROCEDURES

The grating may be lifted into place by hand or with the crane.

The stair landing grating and corner gratings weigh 20 lbs (9

kg) each and the center gratings weigh 100 lbs (45 kg) each.

MEZZANINE GRATING

1. Attach hoist to stair landing grating (item 13, Figure 2-4).

2. Lift grating into position on mezzanine at head of stairs.

The grating hold-down will be installed after the top skins are

installed and all fasteners in mount have been torqued.

3. Remove hoist from grating.

4. Attach hoist to corner grating C (item 15).

5. Lift grating to position on mezzanine at right side (facing inward from

door).

6. Remove hoist from grating.

7. Attach hoist to corner grating D (item 19).

8. Lift grating into position on mezzanine at right side (facing inward from

door).

9. Remove hoist from grating.

10. Attach hoist to corner grating A (item 17).

11. Lift grating into position on mezzanine at left side (facing inward from

door).

12. Remove hoist from grating.

13. Attach hoist to corner grating B (item 18).

14. Lift grating into position on mezzanine at left side (facing inward from

door).

15. Remove hoist from grating.

16. Attach hoist to center grating A (item 14).

17. Lift grating into position on mezzanine at center (by stairway).

NOTE

NOTE

____________________________________________________________________________________________

2-20

SERIES 8116/8118 16-/18-METER EARTH STATION ANTENNA 42S183D

Page 37

Middle and Top Skin

Plate Installation

LOWER MOUNT INSTALLATION PROCEDURES

18. Remove hoist from grating.

19. Attach hoist to center grating C (item 20).

20. Lift grating into position on mezzanine at center (near doorway).

21. Remove hoist from grating.

22. Attach hoist to center grating B (item 16).

23. Lift grating into position on mezzanine at center (mezzanine center).

24. Remove hoist from grating.

After the optional mezzanine, stairway, and grating installation is

complete, install the middle and top skins as follows.

WARNING

__________________________________________

The following assemblies weigh approximately

1525 lbs (692 kg) each. Use extreme care when

hoisting these assemblies into position.

__________________________________________

1. Attach upper skin tee (item 6, Figure 2-3) to top surface of middle

mount skin (item 10) at seven places with bolt, two flat washers, and

nut (item 105, 103, and 104). Hand tighten.

2. Lift middle mount skin into position on outside of two legs which do

not have the door opening between them.

3. Align plate side holes with holes in leg (eight holes in each leg) and

secure with bolt, two flat washers, and nut (item 105, 103, and 104).

4. Secure middle mount skin to lower skin tee at nine places using bolt,

two flat washers, and nut (item 105, 103, and 104). Hand tighten.

5. Repeat steps 1 through 4 on four more middle mount skins.

6. Attach upper skin tee (item 6) to inside top surface of middle door

mount skin (item 12) at seven places with bolt, two flat washers, and

nut (item 105, 103, and 104). Hand tighten.

7. Lift middle door mount skin into position using hoist. Locate between

two legs where door will be located.

8. Repeat step 3.

____________________________________________________________________________________________

42S183D

SERIES 8116/8118 16-/18-METER EARTH STATION ANTENNA 2-21

Page 38

LOWER MOUNT INSTALLATION PROCEDURES

9. Secure the middle door mount skin to the lower door tee, two places

each side of door opening, using bolt, two flat washers, and nut (item

105, 103, and 104). Hand tighten.

10. Lift upper mount skin into position using hoist. Locate between two

legs.

11. Align plate side holes with holes in leg (thirteen holes in each leg) and

secure with bolt, two flat washers, and nut (item 105, 103, and 104).

Hand tighten.

12. Secure the upper mount skin to the upper skin tee at seven places with

bolt, two flat washers, and nut (item 105. 103 and 104). Hand tighten.

13. Secure the upper mount skin to the top skin mount angles, four places,

with bolt two flat washers, and nut (item 105, 103 and 104). Hand

tighten.

14. Repeat steps 10 through 13 for remaining five upper mount skin panels.

Torquing Lower

Mount Fasteners

The mount is torqued from the top down in order to secure

everything together prior to grouting the base. Perform the

following procedures to properly torque all mount fasteners.

1. Loosen all nuts securing bottom skin mount angles to foundation by a

couple turns (this will allow the skin to be pulled tight from the top

down).

Do not loosen nuts securing legs to foundation.

2. Tighten fasteners holding bearing ring assembly plate together to 600

ft-lbs (813 Nm).

3. Tighten fasteners securing bearing ring assembly to top mounting plate

of legs to 600 ft-lbs (813 Nm).

4. Tighten bearing ring assembly plate to top skin mount angle fasteners to

600 ft-lbs (813 Nm).

5. Tighten upper mount skin to leg fasteners to 600 ft-lbs (813 Nm).

Tighten from top down.

6. Tighten upper mount skin plate to upper skin tee fasteners to 600 ft-lbs

(813 Nm).

7. Tighten middle mount skin panels to upper mount skin tee fasteners to

600 ft-lbs (813 Nm).

NOTE

____________________________________________________________________________________________

2-22

SERIES 8116/8118 16-/18-METER EARTH STATION ANTENNA 42S183D

Page 39

LOWER MOUNT INSTALLATION PROCEDURES

8. Tighten middle mount skin panels to leg fasteners to 600 ft-lbs

(813 Nm). Tighten from top down.

9. Tighten middle mount skin panels to lower skin tee fasteners to 600 ftlbs (813 Nm).

10. Tighten lower mount skin panels to lower skin tee fasteners to 600 ftlbs (813 Nm).

11. Tighten lower mount skin panel to leg fasteners to 600 ft-lbs

(813 Nm). Tighten from top down.

12. Tighten lower mount skin panel to bottom skin angle fasteners to 600

ft-lbs (813 Nm).

13. Ensure bottom nuts on leg base are snug against plate.

14. Tighten top nuts on leg base to 1100 ft-lbs (1491 Nm).

15. Ensure bottom nuts on bottom skin angle are snug against angle.

16. Tighten top nuts on bottom skin angle to 150 ft-lbs (200 Nm).

17. Tighten mezzanine guard rail to stair opening beam fasteners to 260 ftlbs (353 Nm).

18. Tighten ships ladder to stair stringer support beam fasteners to 260

ft-lbs (353 Nm).

19. Tighten stair stringer to stair to right mount fasteners to 260 ft-lbs

(353 Nm).

20. Tighten bottom mount to floor fasteners to 150 ft-lbs (203 Nm).

21. Tighten bottom mount to stringer fasteners to 260 ft-lbs (353 Nm).

22. Tighten all mezzanine edge beam to leg fasteners to 260 ft-lbs

(353 Nm).

23. Install mezzanine grating hold downs (item 105 Figure 2-4) in

accordance with the following procedure.

a. Space hold down approximately two feet (61 cm) apart (in

each direction) with a minimum of two per grating.

b. Transfer holes to mezzanine beams using a tap for 1/4-20

screws.

c. Install each hold down with one socket head cap screw (item

106).

____________________________________________________________________________________________

42S183D

SERIES 8116/8118 16-/18-METER EARTH STATION ANTENNA 2-23

Page 40

LOWER MOUNT INSTALLATION PROCEDURES

Door Assembly and

Installation

After the mount is torqued the mount door and frame should be

assembled and then installed from the inside of the mount in accordance

with the following procedures.

1. From inside mount, place right door skin (item 14, Figure 2-3) with

small end pointing toward door opening and short flange on floor and

turned toward outside of door.

2. From inside mount, locate left door skin (item 15) on floor with small

end pointing toward door opening and short flange on floor and turned

opposite from the flange in step 1 above.

3. Locate top door skin (item 16) across the narrow end of left and right

door skins. The long flange should be placed on the floor and end

flanges overlapping on outside of door skins.

4. Secure top door skin to left and right door skins in two places each side

using screw, two flat washers, and nut (item 108, 109, and 110).

5. Install one door side channel (item 18) on right door skin.

6. Secure door side channel in six places using screw, two flat washers,

and nut (item 108, 109, and 110). Torque to 31 ft-lbs

(42 Nm).

7. Install one door side channel (item 18) on left door skin.

8. Repeat step 6.

9. Locate door top channel (item 17) on upper door skin.

10. Secure door top channel four places using screw, two flat washers, and

nut (item 108, 109, and 110). Torque to 31 ft-lbs (42 Nm).

11. With one person on each side of door assembly (item 111), lift

assembly and slide it onto the door side channels until door frame top

covers door top channel.

NOTE

Make sure that the door will open inward when erected in the

door opening.

12. Check that door frame rails are touching right and left door skins and

completely hitting door side channels.

13. Check that top door frame rail is touching top door skin and hitting

door top channel.

14. With door frame and side skin panels still laying on the ground, drill

two holes in top of door frame and door top channel and secure door

frame in place using self tapping screw (item 106).

15. With door frame and skin panel still laying on the floor, drill two pilot

holes equally spaced through top door frame and top door channel

using drill bit (item 107, Figure 2-3) and secure with self tapping

screws (item 106).

____________________________________________________________________________________________

2-24

SERIES 8116/8118 16-/18-METER EARTH STATION ANTENNA 42S183D

Page 41

LOWER MOUNT INSTALLATION PROCEDURES

16. Drill one pilot hole near bottom of each side door frame and install self

tapping screws (item 106).

NOTE

These two screws will be removed at a later procedure.

17. Set door assembly and side skins up in a vertical position.

18. Position bottom of right and left floor skins on doorway anchor bolts.

19. Secure with nut and flat washer (item 100 and 101, Figure 2-3), one on

each side. Hand tighten.

20. Align holes in right and left door skins with holes in lower and middle

door skin panels.

21. Secure in place, ten places on each side of door frame assembly, using

bolt, two flat washers, and nut (item 105, 103, and 104).

22. Secure top door skin, four places, using bolt, two flat washers, and nut

(item 105, 103, and 104).

23. Remove two self tapping screws installed at step 16.

24. Adjust door side skins to provide an equal gap between door and door

frame along sides and across the top.

25. Torque door side skin to lower door skin and middle door skin fasteners

to 260 ft-lbs (353 Nm).

26. Torque door top skin to middle door skin fasteners to 260 ft-lbs

(353 Nm).

27. Torque door side skin to doorway anchor bolts to 1100 ft-lbs

(1491 Nm).

28. Drill five pilot holes equally spaced through inside right door frame and

door side channel using drill bit (item 107).

29. Secure door frame to side channel using self tapping screw (item 106).

30. Repeat step 28 and 29 along inside left door frame.

31. From outside door, drill two pilot holes, equally spaced, through top

door frame and top door channel using drill bit (item 107).

32. Secure door frame to top door channel with self tapping screw (item

106).

33. From outside door, repeat step 28, 29, and 30.

____________________________________________________________________________________________

42S183D

SERIES 8116/8118 16-/18-METER EARTH STATION ANTENNA 2-25

Page 42

LOWER MOUNT INSTALLATION PROCEDURES

Figure 2-2. Azimuth Bearing Ring Assembly, 483183

____________________________________________________________________________________________

2-26

SERIES 8116/8118 16-/18-METER EARTH STATION ANTENNA 42S183D

Page 43

LOWER MOUNT INSTALLATION PROCEDURES

Figure 2-3. 16/18-Meter Mount Assembly (Sheet 1 of 3), 483184A

____________________________________________________________________________________________

42S183D

SERIES 8116/8118 16-/18-METER EARTH STATION ANTENNA 2-27

Page 44

LOWER MOUNT INSTALLATION PROCEDURES

Figure 2-3. 16/18-Meter Mount Assembly (Sheet 2 of 3), 483184A

____________________________________________________________________________________________

2-28

SERIES 8116/8118 16-/18-METER EARTH STATION ANTENNA 42S183D

Page 45

LOWER MOUNT INSTALLATION PROCEDURES

Figure 2-3. 16/18-Meter Mount Assembly (Sheet 3 of 3), 483184A

____________________________________________________________________________________________

42S183D

SERIES 8116/8118 16-/18-METER EARTH STATION ANTENNA 2-29

Page 46

LOWER MOUNT INSTALLATION PROCEDURES

Figure 2-4. 16/18-Meter Mezzanine Installation, 512020

____________________________________________________________________________________________

2-30

SERIES 8116/8118 16-/18-METER EARTH STATION ANTENNA 42S183D

Page 47

LOWER MOUNT INSTALLATION PROCEDURES

Figure 2-5. 16/18-Meter Stairway Installation, 483185

____________________________________________________________________________________________

42S183D

SERIES 8116/8118 16-/18-METER EARTH STATION ANTENNA 2-31

Page 48

LOWER MOUNT INSTALLATION PROCEDURES

GROUTING

BASEPLATE AND

SKIN PLATE TO

FOUNDATION

Hot Weather Grouting

Grout is used between the concrete foundation surface and the six

base plates to ensure a rigid, load-bearing connection between the

mount and the foundation. Grout may also be placed between the

concrete foundation and the bottom bracket on the bottom skin

plates to ensure rigidity but is not required structurally. Standard

shipments include enough grout for the six base plates only. It is

important that the grout manufacturer's instructions be followed.

These instructions are packaged with the grout. For convenience,

the essentials of the procedure are repeated as follows:

The grout must completely fill all locations (see Figure 2-6).

Verify that each anchor bolt nut will have no less than two threads

above the nut. The normal ambient temperature range for good

"early-strength" grouting is 55°F to 80°F (13°C to 27°C). When

temperatures at the job site are outside this range, the procedures

given here must be modified to compensate for the high or low

temperature. If the temperature is outside the range, perform one

of the following procedures before proceeding to the grouting

procedure.

Temperatures above 80°F (27°C) accelerate hardening of the grout,

reducing the time that the grout remains workable after mixing;

therefore, it is necessary that either procedures be used which

permit placing of the grout more quickly, or the available working

time increased by cooling the mixture and the mount base plates.

If the first approach is taken, it is suggested that grout be mixed for

each base plate separately and poured immediately. Mixing time

could be reduced to one minute by use of an electric drill and

mixing blade made of steel rod.

If the second approach is taken, grout working time may be

increased by use of cold materials, cool foundation, and base

plates. This approach involves the use of cold or iced water in the

mix to keep the as-mixed temperature of the grout under 70°F

(21°C), preferably between 50°F (10°C) and 55°F (13°C).

In either case, the following practices are recommended:

1. Store bags of grout in as cool a place as practicable, but at least in the

shade. Avoid exposing the bags to dampness or rain.

2. Give extra attention to saturating the concrete foundation for 24 hours

before grouting. Heat and wind cause rapid evaporation; therefore, the

concrete should be wet liberally and frequently to prevent drying.

Consider the use of windbreaks and sunshades to maintain saturation.

3. Cool the base plates while saturating the foundation by covering the

plates with wet cloths and allowing evaporation to cool them.

____________________________________________________________________________________________

2-32

SERIES 8116/8118 16-/18-METER EARTH STATION ANTENNA 42S183D

Page 49

LOWER MOUNT INSTALLATION PROCEDURES

Cold Weather

Grouting

Temperatures below 55°F (13°C) slow the hardening process and

keep the grout in a flowable state long enough to permit settlement

and bleeding. Although grouting may be successfully

accomplished at ambient temperatures as low as 45°F (7°C), the

rate of strength gain (hardening) is slow and the required time onsite may be excessive. To minimize the curing time, it is

recommended that the grout, mixing water, and mount base plates

be warmed to accelerate the curing process. The following

procedure is suggested:

1. Store bags of grout in a sheltered place so that the material will be at

least above freezing, but preferably above 45°F (7°C).

2. Measure the temperature of the base plate and foundation by placing a

thermometer on the surface and covering it with a piece of dry

insulation or dry rags. If the temperature is above 55°F (13°C)

minimum, proceed with grouting following the grouting

procedures. If the temperature is below 55°F (13°C), warm the base

plate and foundation to bring the temperature above the

minimum, using the following methods:

a. Base plates may be warmed by use of infrared heat lamps or by

building a small enclosure around the base plate and

introducing heat from a convenient source. Warm the mixing

water as necessary to provide mixed grout at a temperature of

60°F (15°C) or above, but avoid use of water hotter than 90°F

(32°C).

b. After installing grout, maintain the temperature of the in-place

grout at 50°F (10°C) or above for a minimum of three hours to

ensure adequate grout hardness for final tightening of the anchor

bolt nuts.

NOTE

Grout will not harden unless the temperature is maintained

above freezing. The minimum temperature is 40°F (4°C).

Grouting Procedures

Perform the following procedure to grout base plates to foundation

first. Then, grout bottom skin plates to foundation using the

following procedure.

1. Wash work surface with water. Keep surface saturated with water for at

least 24 hours prior to grouting.

NOTE

Grouting must be completed within 10 minutes after mixing.

____________________________________________________________________________________________

42S183D

SERIES 8116/8118 16-/18-METER EARTH STATION ANTENNA 2-33

Page 50

LOWER MOUNT INSTALLATION PROCEDURES

2. Pour grout into a five gallon bucket (0.019 cubic meter) or equivalent

mixing container and slowly add water. Stir the mix and add grout or

water as required to obtain a good paste.

Be sure to mix enough grout to complete each pad (or bottom

plate) at one time. Once the grout begins to set, new grout will

not bond to the old grout.

3. Starting on one side of each base plate, use a small strip of wood to

work the grout between base plate and foundation. It is important that

the grout be worked from one side to the other to prevent air from being

trapped under each plate. Once the area under the plate is full of grout,

smooth the edges around each plate for best appearance.

4. Immediately after the grout is installed, cover all exposed grout with

clean wet rags (do not use burlap). Keep the rags moist for at least two

hours.

NOTE

____________________________________________________________________________________________

2-34

SERIES 8116/8118 16-/18-METER EARTH STATION ANTENNA 42S183D

Page 51

LOWER MOUNT INSTALLATION PROCEDURES

____________________________________________________________________________________________

42S183D

SERIES 8116/8118 16-/18-METER EARTH STATION ANTENNA 2-35

Figure 2-6. Location of Grouting

Page 52

Page 53

SECTION 3

UPPER MOUNT INSTALLATION

PROCEDURES

3-1 General

3-1 Azimuth Drive Anchor Installation

3-1 Rotating Frame Installation

3-14 Azimuth Drive Installation

3-19 Elevation Drive Installation

3-22 Hub Assembly and Installation

3-29 Installation Guardrails and Ladders

42S183D Series 8116/8118 16-/18-Meter Earth Station Antenna

Page 54

Page 55

____________________________________________________________________________________________

SECTION 3 UPPER MOUNT INSTALLATION PROCEDURES

GENERAL

AZIMUTH DRIVE

ANCHOR

INSTALLATION

ROTATING FRAME

INSTALLATION

This section contains procedures for installing the upper mount

hardware. This hardware includes the rotating frame,

azimuth/elevation drives, hub, and work platform of the

16-/18-Meter Earth Station Antenna. The installation of the lower

mount is contained in Section 2 and the installation of the reflector,

spars, subreflector, and feed is contained in Section 4. General

safety precautions and procedures for the entire installation are

described in Section 2 and should be reviewed before proceeding

with these procedures.

Perform the following procedure to install the azimuth drive

anchor. This should be accomplished prior to installing the

rotating frame (azimuth frame and alignment assembly).

1. Determine center of optimum azimuth sector to locate azimuth drive

anchor (item 2 in Figure 3-1). See Figure 3-1, Sheet 2.

2. Install azimuth drive anchor to azimuth frame and alignment

assembly (item 4) using 2 azimuth anchor spacer plates (item 25), 2