ViaSat 8016 Installation And Operation Manual

Model 8016

11-Meter Earth Station

Antenna Installation

Installation and Operation Guide

Manual Part No. 42S132E

August 2004

Notice

All Rights Reserved

Model 8016 11-Meter Earth Statio

Installation and Operation Guide

n Antenna Installation

Table of Contents

Table of Contents

Table of Contents .................................................................................................. iii

List of Figures ........................................................................................................ vi

List of Tables ......................................................................................................... vii

Safety Summary ..................................................................................................viii

1 General Information ...................................................................................... 1-1

1.1 Introduction.............................................................................................................1-1

1.2 Mount Description .................................................................................................1-1

1.3 Reflector Description..............................................................................................1-4

2 Installation Procedures.................................................................................. 2-1

2.1 General.....................................................................................................................2-1

2.2 What to do About Visible Loss or Damage ........................................................2-1

2.3 What to do About Concealed Damage................................................................ 2-1

2.4 How to Inventory Equipment Received .............................................................2-2

2.5 How to Return Equipment.................................................................................... 2-2

2.6 General Mechanical Safety Summary..................................................................2-3

2.6.1 Emergency Plan ...................................................................................................... 2-4

2.7 General Electrical Safety Summary......................................................................2-4

2.7.1 Resuscitation ...........................................................................................................2-4

2.8 Recommended Tools and Equipment .................................................................2-4

2.9 Fastener Information..............................................................................................2-6

2.10 Recommended Installation Sequence..................................................................2-7

2.11 Site Preparation.......................................................................................................2-8

2.12 Assembly of Reflector, Spars, and Subreflector .................................................2-9

2.12.1 Installation of Trusses and Intercostals.............................................................2-10

2.12.2 Installation of the Spars and Subreflector.........................................................2-12

2.12.3 Truss Alignment ...................................................................................................2-13

2.12.4 Installation of Reflector Panels ...........................................................................2-14

2.12.5 Reflector Alignment ............................................................................................. 2-34

42S132E iii

Table of Contents

2.12.6 Subreflector Alignment .......................................................................................2-37

2.13 Mount Installation................................................................................................2-39

2.13.1 Elevation Actuator Installation...........................................................................2-39

2.13.2 Erection of Antenna Mount ................................................................................2-39

2.13.3 Installation of Azimuth Actuator – Model 8133, 120° Travel.........................2-41

2.13.4 Installation of Azimuth Actuator - Model 8133, 180° Travel .........................2-42

2.14 Grouting Baseplate to Foundation.....................................................................2-79

2.14.1 Hot Weather Grouting.........................................................................................2-80

2.14.2 Cold Weather Grouting ....................................................................................... 2-80

2.14.3 Grouting Procedures............................................................................................2-81

2.15 Assembly and Installation of Mount Platform................................................. 2-82

2.16 Reflector Installation ............................................................................................2-83

2.17 Typical Feed Installation .....................................................................................2-85

2.17.1 Installation of Subreflector to Subreflector Mounting Frame .......................2-86

2.18 Installation of Reflector Hub Cover...................................................................2-91

2.19 Installation of Feed Waveguide..........................................................................2-91

2.20 Electrical Installation............................................................................................ 2-91

2.21 Corrosion Protection After Installation.............................................................2-92

3 Operation......................................................................................................... 3-1

3.1 General.....................................................................................................................3-1

3.2 Satellite Pointing Procedure..................................................................................3-1

3.2.1 Elevation Pointing .................................................................................................. 3-1

3.2.2 Azimuth Pointing...................................................................................................3-1

3.2.3 Signal Peaking Procedure......................................................................................3-2

3.3 Subreflector Adjustment........................................................................................3-3

4 Maintenance.................................................................................................... 4-1

4.1 General.....................................................................................................................4-1

4.2 Periodic Maintenance ............................................................................................4-1

4.2.1 Weekly Maintenance..............................................................................................4-1

4.2.2 Monthly Maintenance............................................................................................4-1

4.2.3 Bi-Monthly Maintenance.......................................................................................4-2

4.2.4 Quarterly Maintenance..........................................................................................4-2

42S132E iv

Table of Contents

4.2.5 Yearly Maintenance................................................................................................4-3

4.3 Corrosion Protection .............................................................................................. 4-4

4.3.1 Touch-up Painting of Non-Reflective Surfaces ..................................................4-4

4.3.2 Touch-Up Painting of Reflective Surfaces ..........................................................4-5

4.3.3 Fasteners ..................................................................................................................4-6

5 Options............................................................................................................. 5-1

5.1 General.....................................................................................................................5-1

5.1.1 De-Icing Options.....................................................................................................5-1

5.1.2 Lightning Protection Option.................................................................................5-1

5.2 Feed Options ...........................................................................................................5-2

42S132E v

Table of Contents

List of Figures

Figure 1-1. Typical Antenna System....................................................................................................1-2

Figure 2-1. 11-Meter Reflector Assembly, 516469B .........................................................................2-17

Figure 2-2. 11-Meter Ku-band Reflector, Subreflector, and Spar

Installation, 723959-5001x01 ........................................................................................................2-22

Figure 2-3. 11-Meter Motorized Hub Assembly, 514326G.............................................................2-28

Figure 2-4. 11-Meter Reflector and Subreflector Alignment ..........................................................2-38

Figure 2-5. Model 8020-120 Mount Installation Assembly, 517098C............................................2-44

Figure 2-6. Model 8020-180 Mount Installation Assembly, 517097C............................................2-50

Figure 2-7. Model 8020-120 Mount Structure Assembly, 477697D ............................................... 2-56

Figure 2-8. Model 8020-180 Mount Structure Assembly, 476309D ............................................... 2-59

Figure 2-9. Model 8132-1 Elevation Actuator Assembly, 511956B................................................ 2-62

Figure 2-10. Model 8133-1 (1 HP) Azimuth Actuator Assembly, 477503C..................................2-64

Figure 2-11. Model 8133-1 (5 HP) Azimuth Actuator Assembly, 480239D..................................2-66

Figure 2-12. Model 8133-180 (1 HP) Azimuth Actuator Assembly, 477506D..............................2-68

Figure 2-13. Model 8133-180 (5 HP) Azimuth Actuator Assembly, 482052E ..............................2-74

Figure 2-14. Location of Grouting......................................................................................................2-79

Figure 2-15. Hoisting Reflector and Spars ........................................................................................2-85

Figure 2-16. Hoisting Feed..................................................................................................................2-86

Figure 2-17. Model 8009A-C-4P Feed Installation, 514687B ..........................................................2-87

Figure 2-18. Model 8009A-C-4PC Feed Installation, 517525A.......................................................2-89

Figure 2-19. Polarization Drive Assembly, 1017724_002...............................................................2-93

Figure 2-20. 9/11-Meter Hub Cover Installation Drawing, 521988A ...........................................2-98

Figure 2-21. Feed and Waveguide Installation – 9-Meter C-band 4P, 550847A........................2-101

Figure 3-1. Feed, Reflector, and Subreflector Distances ...................................................................3-5

Figure 3-2. Typical Antenna Patterns for Various Subreflector Positions .....................................3-6

Figure 5-1. Lightning Protection Installation, 9/11-Meter Antenna System, 517224....................5-3

42S132E vi

Table of Contents

List of Tables

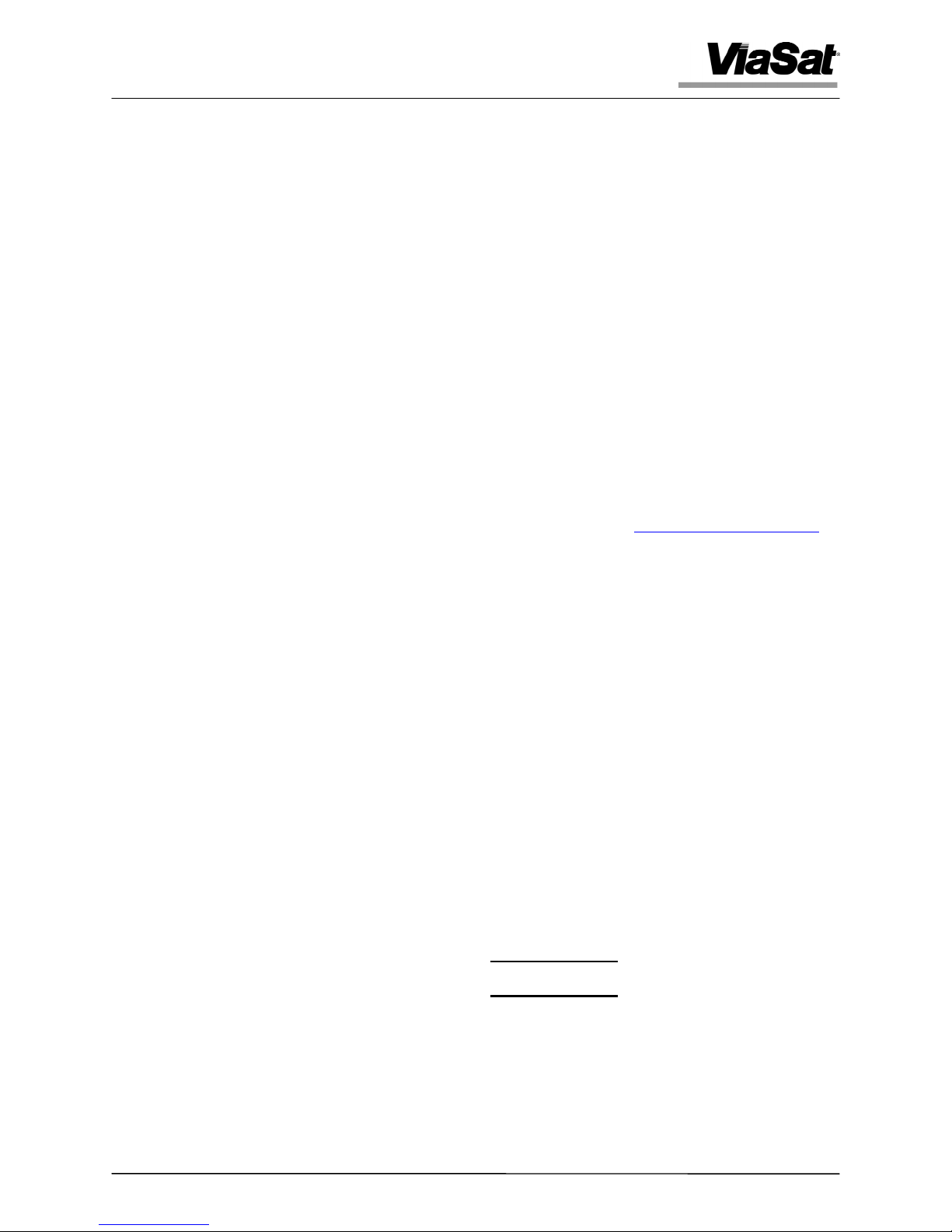

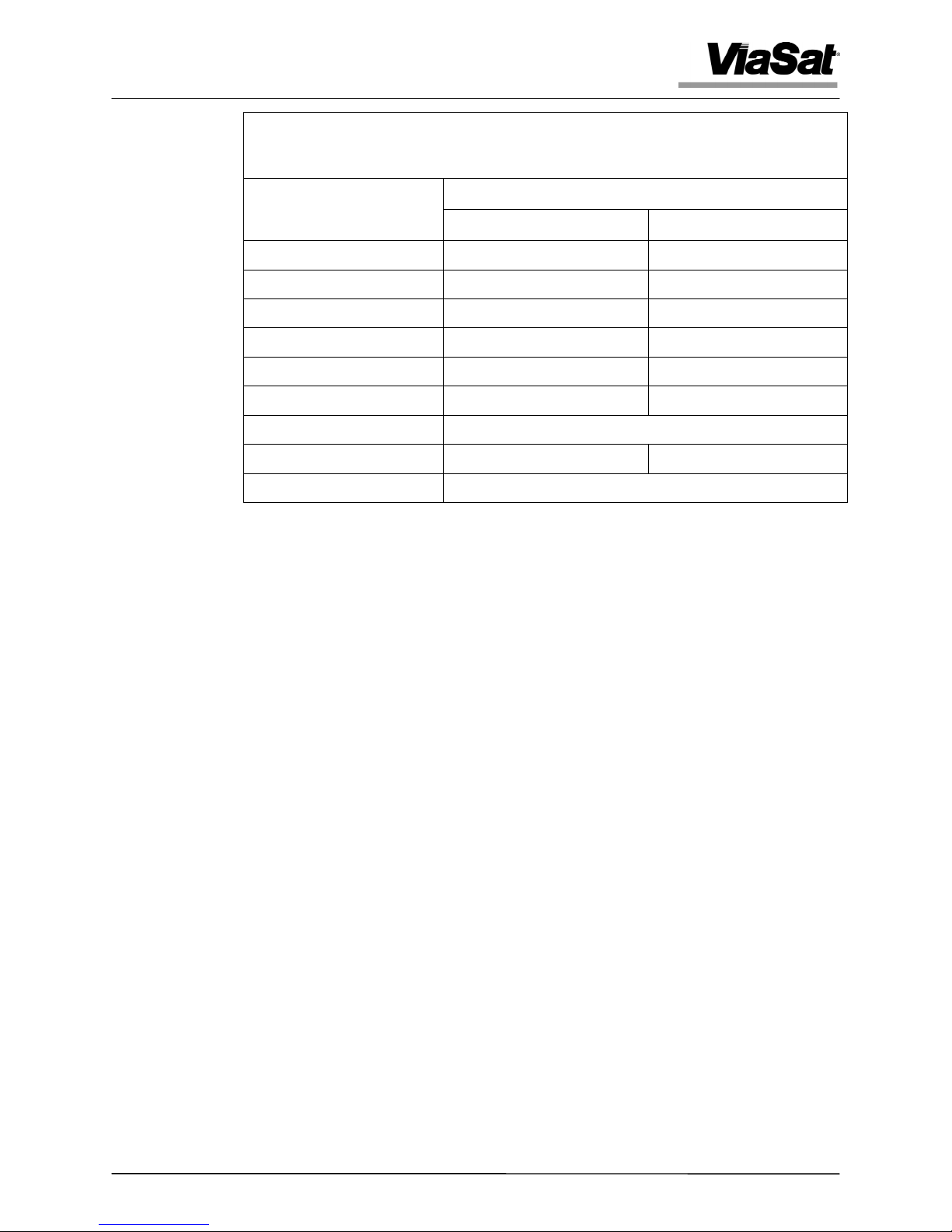

Table 1-1. Antenna Mount Configurations.........................................................................................1-1

Table 2-1. Tools and Equipment Required For Installation .............................................................2-5

Table 2-2. Torque Values For Antenna Fasteners..............................................................................2-7

Table 2-3. Panel Rough Alignment....................................................................................................2-15

Table 2-4. Final C-band Alignment Target Measurements - Sight Center

of the Middle Diamond................................................................................................................2-35

Table 2-5. Final Ku-band Alignment Target Measurements - Sight Center

of the Middle Diamond................................................................................................................2-35

Table 2-6. ViaSat 11-Meter Reflector Alignment Record................................................................2-36

42S132E vii

Table of Contents

42S132E viii

Safety Summary

SAFETY SUMMARY

Notice

Any service, adjustment, maintenance, or repair of this product must be

performed only by authorized technical service personnel.

Prior to installation and use of this product review all safety markings and instructions.

When safety precautions or important information is presented in this manual, the

information will normally be presented just prior to the point where the hazard is likely

to be encountered.

The following symbols are used throughout this manual to bring attention to practices,

procedures, and conditions important to the safety of the operator and equipment or to

obtaining desirable results from the equipment.

This symbol warns of electrical shock hazards

to personnel. Failure to comply with the

NOTE

instructions of such a warning may result in

severe injury or death resulting from electrical

shock.

This symbol warns of non-electrical hazards to

personnel. Failure to comply with the

instructions of such a warning may result in

severe injury or death.

This symbol warns of hazards to equipment.

Failure to comply with the instructions of such

a caution may result in damage or destruction

of equipment.

This symbol is used to bring attention to

installation grounding requirements.

Notes are used to provide clarification, or to

alert the reader of possible erroneous results,

which may occur if a procedure is not

followed as written.

42S132E ix

Safety Summary

42S132E x

Chapter 1 - General Information

1.1 Introduction

This manual contains information needed to properly install, operate, and

maintain ViaSat's 11-Meter (11M) Earth Station Antenna. The antenna is

eleven meters in diameter. It provides high quality receive/transmit and

receive-only capabilities for both domestic and international C-band or Kuband applications. The antenna consists of an 11M-shaped reflector, a

shaped subreflector, and a linearly or circularly polarized feed on a highstrength structural steel elevation-over-azimuth mount. The mount's stiff,

rugged construction provides the pointing accuracy needed for proper

operation under adverse wind conditions.

Chapter 1

General Information

This chapter of the manual contains general descriptions and specifications

on the mount, reflector, feed, and subreflector. Chapters 2 through 4 contain

information pertaining to antenna installation, operation, and maintenance.

All warnings and cautions should be reviewed before any procedures are

performed. Failure to do so may result in personal injury or equipment

damage.

ViaSat, Inc. makes every effort to ensure that the information contained

herein is correct and complete.

1.2 Mount Description

The 11M reflector can use either of two mounts, the Model 8020-120 and the

Model 8020-180 mounts. The mount configurations are described in Table

1-1.

Table 1-1. Antenna Mount Configurations

Mount Required Components Description

Model 8020-120 Model 8084-120 Foundation

Model 8132-M,-1,-2 Elevation Actuators

180° Total Azimuth Coverage, in

Three Overlapping 120° Sectors

Model 8133-M,-1,-2 Azimuth Actuators

Model 8020-180 Model 8084-180 Foundation

Model 8132-M,-1,-2 Elevation Actuators

Model 8133-180 Azimuth Actuators

42S132E 1-1

180° Continuous Azimuth

Coverage

Chapter 1 - General Information

Optional 120° and 180° mounts are available with precise orthogonal

alignment between the azimuth and elevation axes; typically used for TT&C

applications.

The Model 8020-120 and Model 8020-180 Mounts provide two-axis

(elevation-over-azimuth) adjustment for pointing the antenna. In the

elevation-over-azimuth configuration, the antenna rotates about two axes, a

vertical azimuth axis and a horizontal elevation axis. Pointing to a

geostationary satellite requires that the antenna be moved to a specific angle

about the azimuth axis, then to a specific angle about the elevation axis. The

42S132E 1-2

Figure 1-1. Typical Antenna System

Chapter 1 - General Information

required sighting angles for any satellite are given in look-up tables which

are readily available.

The mount consists of a 20-foot-tall structural tube that is supported at the

top by two diagonal leg braces, which extend to the rear of the antenna. The

bottom of the tube is supported by a pivot bearing and is driven at the

ground level location by the azimuth actuator. The elevation actuator is

located atop the structural tube and behind the reflector hub. The actuator

locations are very convenient to access for maintenance.

Grounding cables are provided to ensure system electrical grounding

between the antenna reflector and the antenna mount structure. Tapped

holes are provided in the mount base plates for attachment to a suitable

foundation grounding system.

Included as optional equipment on the mount is a ladder and work platform

assembly. These components provide safe and convenient access to the feed

electronics inside the antenna hub and to the elevation drive motor for

servicing and inspection. The ladder and platform are designed to be fully

compatible with OSHA specifications.

The Model 8132-M Elevation Actuator (manual drive), the Model 8132-1

(single speed) and Model 8132-3 Elevation Actuator (variable speed) will

provide elevation coverage of 0-degree to 90-degrees.

The Model 8133-M Azimuth Actuator (manual drive), the Model 8133-1

(single speed) and Model 8133-3 (variable speed) Azimuth Actuator will

provide azimuth coverage of 180-degrees through three available 120-degree

overlapping sectors. The selecting of alternate sectors can be accomplished

within two hours by moving the azimuth actuator to an alternate position on

the foundation. These actuators are used only with the Model 8020-120

Mount.

The Model 8133-180-1 Azimuth Actuator (single speed drive) and the Model

8133-180-3 (variable speed drive) provide continuous azimuth coverage of

180° and must be used with the Model 8020-180 Continuous Azimuth

Coverage Mount. These actuators are used only with the Model 8020-180

Mount.

Manual drive elevation and azimuth actuators are operated manually or with

an auxiliary power source such as a drill motor. Motor drive actuators may

also be operated manually if required.

The Model 8084-180 and Model 8084-120 foundations are an essential part of

the antenna installation. The foundation should be oriented so that the

desired pointing angles can be achieved and accurately maintained under

maximum wind loads.

The antenna mount is designed to safely support the antenna in winds up to

125 mi/h (201 km/h). The pointing accuracy of the installed antenna is

42S132E 1-3

Chapter 1 - General Information

determined by the stiffness of the mount, the antenna, and the foundation. It

is recommended that the foundation be designed for a maximum tilt of

0.15 degrees when the 125 mi/h (201 km/h) wind loads are applied to the

antenna. It is imperative that competent engineering assistance be engaged

to assure that the foundation is properly designed for the local site conditions

and building codes. The contractor does not imply or warrant that the

foundation design shown as typical on ViaSat drawings is appropriate for

any particular locality or site condition.

The Model 8084-120 Foundation Kit includes thirty-two foundation anchor

bolts and an anchor bolt location template. The template accurately locates

the three main foundation plates for the mount and three foundation plate

locations for the azimuth actuator positions.

The Model 8084-180 Foundation Kit includes twenty foundation anchor bolts

and an anchor bolt location template. The template accurately locates the

three main foundation plates for the mount and one foundation plate for the

azimuth actuator.

A true north-south reference line for the purpose of foundation orientation

may be established by reference to: (1) a magnetic compass heading

(corrected for declination or variation), (2) a survey from registered

benchmarks, or (3) a sighting of Polaris (North Star). This line is used to

position the foundation pad and to establish the heading of the foundation

anchor bolt pattern. The survey should be done by a qualified surveyor.

The Models 8020-120 and Model 8020-180 Mounts have been designed in

accordance with the American Institute of Steel Construction (AISC)

specifications for Design, Fabrication and Erection of Structural Steel

Buildings as presented in the Manual of Steel Construction, eighth edition

(copyright 1980).

1.3 Reflector Description

The reflector, in combination with its shaped subreflector and feed system, is

optically designed to yield high efficiency. The reflector consists of 48

precision stretch-formed aluminum panels. The panels are bolted together in

the field to form a surface of revolution.

Each reflector assembly consists of a central hub assembly, to which are

attached the radial trusses, intercostals, and the reflector panels. Ample

space is provided inside the hub for mounting of redundant low-noise

amplifiers (LNAs) and switching equipment. The hub has an access cover on

the rear surface for convenient service and inspection of the feed electronics.

Each reflector panel is aligned independently to ensure accuracy. The radial

trusses support the panels and are locked together using the intercostals.

42S132E 1-4

Chapter 1 - General Information

The hub assembly includes a machined plate for attaching the inner row of

panels. All the panels are stretch-formed and have rigid back structures that

are riveted into place.

The reflector panels are finished with a high reflectance white paint applied

over a chromate conversion coating. (Other colors are available as options.)

This special paint diffuses solar radiation to minimize subreflector heating

from the reflector. The remainder of the equipment is primed and painted

with two coats of gloss enamel.

42S132E 1-5

Chapter 1 - General Information

42S132E 1-6

!"#$%&'()(*(+,-%#..#%/0,(1'02&34'&-(

Installation Procedures

2.1 General

:"/-(2"#$%&'( 20,%#/,-( $'02&34'&-(;0'( 4,$#2</,=(#,3(/,-%#../,=(%"&( 77*>&%&'(

#,%&,,#( -?-%&>@( ( A&,&'#.( -#;&%?( $'&2#4%/0,-( #,3( $'02&34'&-( #'&( #.-0(

3&-2'/B&3@(

C/#6#%( %"0'04=".?( /,-$&2%-( #,3( 2#'&;4..?( $#2<-( #..( &D4/$>&,%( B&;0'&(

-"/$>&,%@((E%(%"&(%/>&(0;(-"/$>&,%F(%"&(2#''/&'(#--4>&-('&-$0,-/B/./%?(;0'(/%-(

-#;&(3&./G&'?H(%"&'&;0'&F(30(,0%('&%4',(3#>#=&3(4,/%-(%0(C/#6#%@((+,-%F(;/.&(

#( 2.#/>( I/%"( %"&( 2#''/&'( #-( ,0%&3( /,( %"&( $#'#='#$"-( ;0..0I/,=( %"&( /,/%/#.(

4,$#2</,=($'02&34'&(=/G&,(B&.0IJ(

Chapter 2

7@( +,-$&2%(-"/$$/,=(2'#%&(;0'(G/-/B.&(3#>#=&@(

)@( K$&,(%"&(-"/$$/,=(2'#%&@(

8@( L&>0G&(#..($#2</,=(>#%&'/#.@(

5@( +,-$&2%(4,/%(;0'(G/-/B.&(3#>#=&@(

M@( N-/,=($#2</,=( ./-%F( 2"&2<(;0'(>/--/,=(/%&>-(O-&&( PQ0I( :0( +,G&,%0'?( 9D4/$>&,%(

L&2&/G&3P(B&.0IR@(

2.2 What to do About Visible Loss or Damage

S#<&(#(,0%&(0;(#,?(.0--(0'(&G/3&,2&(0;(&T%&',#.(3#>#=&(0,(%"&(;'&/="%(B/..(0'(

'&2&/$%F( #,3( "#G&( /%( -/=,&3( B?( %"&( 2#''/&'U-( #=&,%@( ( V#/.4'&( %0( #3&D4#%&.?(

3&-2'/B&(-42"( &T%&',#.( &G/3&,2&( 0;(.0--(0'( 3#>#=&( >#?('&-4.%(/,(%"&( 2#''/&'(

'&;4-/,=(%0("0,0'(#(3#>#=&(2.#/>@((:"&(;0'>('&D4/'&3(%0(;/.&(-42"(#(2.#/>(I/..(

B&(-4$$./&3(B?(%"&(2#''/&'@(

2.3 What to do About Concealed Damage

!0,2&#.&3(3#>#=&(>&#,-(3#>#=&(I"/2"(30&-(,0%(B&20>&(#$$#'&,%(4,%/.(%"&(

4,/%( "#-( B&&,( 4,$#2<&3@( ( :"&( 20,%&,%-( >#?( B&(3#>#=&3( /,( %'#,-/%(34&( %0(

'04="( "#,3./,=F(&G&,( %"04="(%"&( 2'#%&(>#?( ,0%(-"0I( &T%&',#.( 3#>#=&@((+;(

?04( 3/-20G&'( 3#>#=&(#;%&'( 4,$#2</,=(%"&( 4,/%F( >#<&( #(I'/%%&,( '&D4&-%( ;0'(

/,-$&2%/0,(B?(%"&(2#''/&'U-(#=&,%(I/%"/,(7M(3#?-(0;(%"&(3&./G&'?(3#%&F(%"&,(;/.&(

#(2.#/>( I/%"( %"&(2#''/&'(-/,2&(-42"(3#>#=&( /-( %"&( 2#''/&'U-('&-$0,-/B/./%?@( ( +;(

?04(;0..0I(%"&-&(/,-%'42%/0,-(2#'&;4..?F(C/#6#%(=4#'#,%&&-(/%-(;4..(-4$$0'%(0;(

?04'(2.#/>-(%0($'0%&2%(?04(#=#/,-%(.0--(;'0>(20,2&#.&3(3#>#=&@(

(

5)678)9( )*7(

!"#$%&'()(*(+,-%#..#%/0,(1'02&34'&-(

2.4 How to Inventory Equipment Received

!"&2<( 0;;( "(/%&>( '&2&/G&3(#=#/,-%( %"#%( ./-%(0,( %"&($#2</,=( -./$(/,2.43&3(

I/%"( %"&(-"/$>&,%F( #,3( G&'/;?(%"#%( %"/-(./-%( >#%2"&-(%"&( $4'2"#-&( 0'3&'@(( +;(

#,?(/%&>-(#'&(>/--/,=F($.&#-&(,0%/;?(C/#6#%(/>>&3/#%&.?(#,3('&%4',(#(20$?(0;(

%"&($#2</,=(-./$(I/%"(%"&(>/--/,=(/%&>O-R(2/'2.&3@(

2.5 How to Return Equipment

C/#6#%( 6#%&../%&( W&%I0'<-( >#<&-( &G&'?( '&#-0,#B.&( &;;0'%( %0( &,-4'&( %"#%( #..(

/%&>-( #''/G&( -#;&.?( #,3( /,( I0'</,=( 0'3&'@( ( X"&,( &D4/$>&,%( /-( '&2&/G&3F(

I"/2"(/-(,0%(/,(I0'</,=(0'3&'F('&%4',(%"&(&D4/$>&,%(%0(%"&(;#2%0'?(;0'('&$#/'(

0'('&$.#2&>&,%@((L&%4',(%"&(&D4/$>&,%(#220'3/,=(%0(%"&(;0..0I/,=($'02&34'&@((

:"/-($'02&34'&(I/..(#$$.?(I"&,&G&'( &D4/$>&,%( /-( '&%4',&3(;0'(I#''#,%?(0'(

0%"&'(-&'G/2&-@(

#@( W0%/;?( C/#6#%( 6#%&../%&( W&%I0'<-( 0;( %"&( $'0B.&>( #,3( '&D4&-%( #( L&%4',(

S#%&'/#.(E4%"0'/Y#%/0,( OLSER(,4>B&'(#,3( -"/$$/,=( /,-%'42%/0,-@(V0'(#(

24''&,%(./-%( 0;( %&.&$"0,&(#,3(&>#/.( 20,%#2%( /,;0'>#%/0,('&;&'(0,(!0,%#2%(

+,;0'>#%/0,(-&2%/0,(0;(%"&(C/#6#%(/,%&',&%(-/%&(O"%%$JZZIII@G/#-#%@20>R@((

B@( :#=(0'(/3&,%/;?(3&;&2%/G&(&D4/$>&,%(#,3(,0%&(3&;&2%(#,3(2/'24>-%#,2&-F(/;(

#,?@( ( +;( <,0I,F( '&;&'&,2&( -#.&-( 0'3&'F( $4'2"#-&( 0'3&'F( #,3( 3#%&(

&D4/$>&,%(I#-('&2&/G&3@(

2@( L&-"/$(&D4/$>&,%(/,(0'/=/,#.(-"/$$/,=(20,%#/,&'(0'(4-&(#(-%'0,=(-"/$$/,=(

20,%#/,&'(%0($'0%&2%(&D4/$>&,%(34'/,=(-"/$>&,%@(

3@( 1#2<#=&( &D4/$>&,%( 4-/,=( -"02<*#B-0'B/,=(>#%&'/#.( #'04,3( #..( -/3&-( 0;(

&D4/$>&,%@(

&@( 6&#.(20,%#/,&'(-&24'&.?(#,3(>#'<(04%-/3&(0;(20,%#/,&'(VLEA+[9@(

NOTE

C/#6#%(I/..(,0%(#22&$%(;'&/="%(20..&2%@((\&(-4'&(%0(-"/$(#..(/%&>-(

;'&/="%($'&$#/3@(

WARNING

Electrical shock from voltages used in this system can cause

injury or death. Prior to making any electrical connections or

performing maintenance and repair, ensure power is removed.

Electrical connections should be made only by qualified

personnel in accordance with local regulation.

(

5)678)9( )*)(

!"#$%&'()(*(+,-%#..#%/0,(1'02&34'&-(

2.6 General Mechanical Safety Summary

:"&-&(#'&( =&,&'#.( >&2"#,/2#.(-#;&%?( $'&2#4%/0,-( %"#%(#'&(,0%( '&.#%&3( %0(#,?(

-$&2/;/2($'02&34'&@((:"&?(#'&('&20>>&,3&3($'&2#4%/0,-(%"#%($&'-0,,&.(>4-%(

4,3&'-%#,3(#,3(#$$.?@(

WARNING

Installation or maintenance of antennas may require persons

to work at elevated work stations. Whenever persons are

working at eight or more feet above ground and not on a

guarded platform, they should wear safety belts with at least

one, and preferably two, lanyards, with the exception that

trained and qualified persons may work up to 25 feet (7.6 m) if

on an approved ladder. In the sentence above, approved

usually means that the ladder is tied off once the person has

climbed but before work begins.

CAUTION

Assembly and installation of the reflector should only be done

during fair weather and low wind conditions.

WARNING

Overhead hazards, either because items may fall or because

a person may strike them unintentionally, are typical around

construction sites or during installation of large antennas. It is

prudent to adopt the following rules:

1. Never stand underneath anything while it is being hoisted.

2. Always wear a hard hat if someone is above you.

WARNING

Ensure that all electrical tools and equipment are properly

grounded.

(

5)678)9( )*8(

!"#$%&'()(*(+,-%#..#%/0,(1'02&34'&-(

2.6.1 Emergency Plan

Q#G&(#,( &>&'=&,2?( $.#,@((],0I(%"&( $'02&34'&-( ;0'( 0B%#/,/,=(;/'-%*#/3(#,3(

;/'&*;/="%/,=( #--/-%#,2&@(( 1.#,(?04'( I0'<(#,3(>#/,%#/,( =003("04-&<&&$/,=H(

%"&(-#;&%?(#,3(D4#./%?(0;(%"&($'0342%(#'&(#%(-%#<&@(

2.7 General Electrical Safety Summary

:"&-&( #'&( =&,&'#.( &.&2%'/2#.( -#;&%?( $'&2#4%/0,-( %"#%( #'&( ,0%( '&.#%&3( %0( #,?(

-$&2/;/2($'02&34'&@((:"&-&(#'&('&20>>&,3&3($'&2#4%/0,-(%"#%($&'-0,,&.(>4-%(

4,3&'-%#,3(#,3(#$$.?@(

WARNING

Avoid shorting circuits when using metal tools. Some circuits

have high current capability which, when shorted, will flash

and may cause burns and/or eye injury.

2.7.1 Resuscitation

1&'-0,,&.(I0'</,=(I/%"( 0'( ,&#'( "#Y#'304-(2"&>/2#.-( 0'(G0.%#=&-(-"04.3(B&(

;#>/./#'(I/%"(>03&',(>&%"03-(0;('&-4-2/%#%/0,@(

Remove all jewelry and exposed metal objects from body and

clothing before performing maintenance, adjustments, and/or

trouble-shooting. Before working inside the equipment,

remove all power, unless power is required to perform

procedures. Do not replace parts with power on.

Replacement of fuses or other parts must be done using

identical types and ratings. Substitution of non-identical parts

may cause safety and fire hazards.

Servicing this equipment may require working with protective

covers removed and ac power connected. Extreme caution

must be exercised during these procedures.

Death or severe injury may result if personnel fail to observe

safety precautions.

2.8 Recommended Tools and Equipment

:#B.&()*7(./-%-(%"&(%00.-(#,3(&D4/$>&,%('&D4/'&3(;0'(&;;/2/&,%(#,3(20,G&,/&,%(

/,-%#..#%/0,@(

(

5)678)9( )*5(

!"#$%&'()(*(+,-%#..#%/0,(1'02&34'&-(

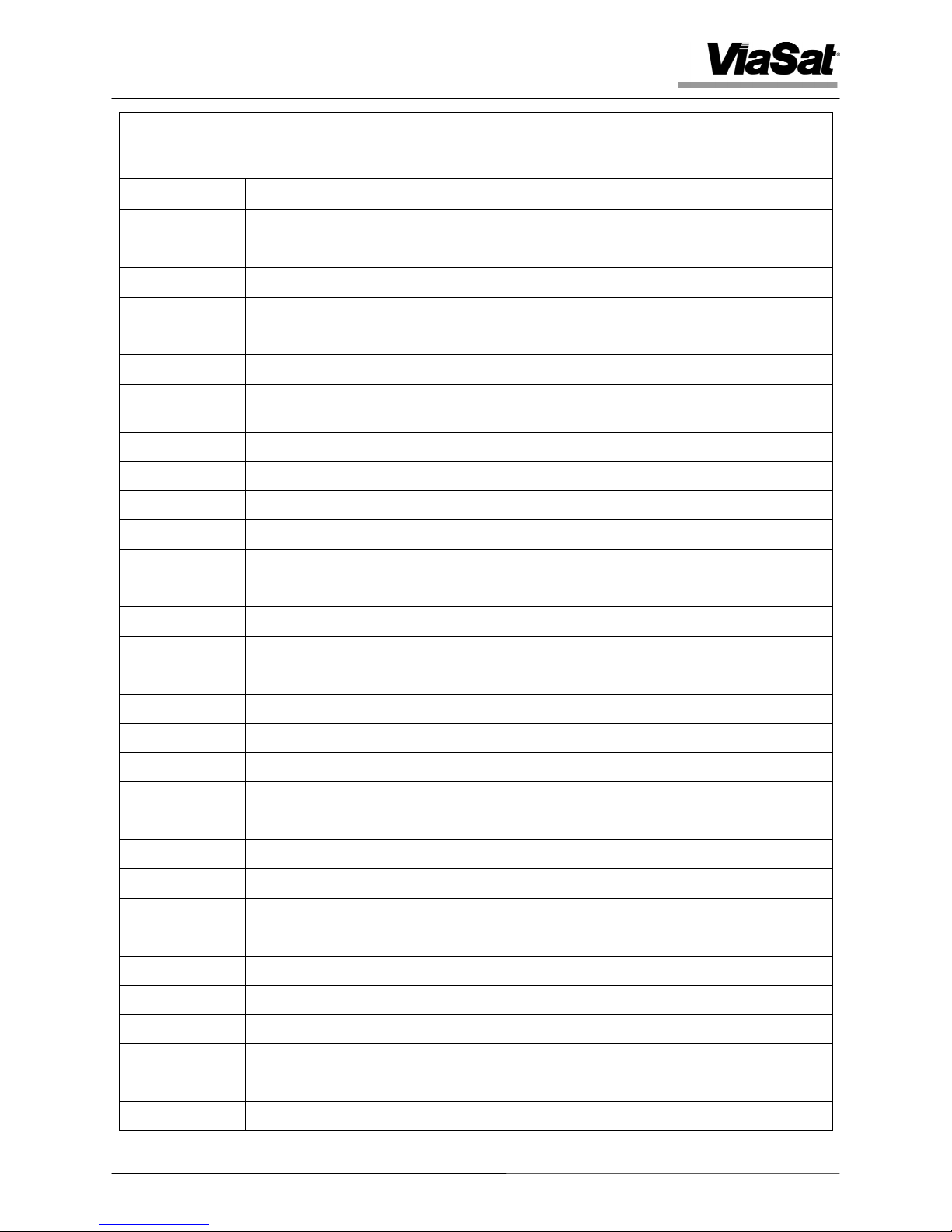

!"#$%&'()*&&!++$,&"-.&/01234%-5&6%0127%.&8+7&9-,5"$$"52+-&

^4#,%/%?( _&-2'/$%/0,(

7(6&%( 602<&%F(8Z`*/,2"(3'/G&F(/,2.43/,=(8*/,2"(&T%&,-/0,(

7(6&%( 602<&%F(8Z5*/,2"(3'/G&F(/,2.43/,=(8*/,2"(&T%&,-/0,(

7(6&%( !0>B/,#%/0,(I'&,2"&-(4$(%0(7(MZ`*/,2"(-/Y&(

7(9#2"( 602<&%F(7(7MZ7a*/,2"(-/Y&F(5*/,2"(.0,=H(4-&3(;0'(%4',/,=(#,2"0'(B0.%(,4%-(

7(9#2"( 602<&%F(7(MZ`*/,2"(-/Y&F()*/,2"(.0,=(

7(9#2"( 602<&%F(7(7Z)*/,2"(-/Y&(

5(9#2"( 6%'#$-F(,?.0,F(8b(;&&%(.0,=F(>/,/>4>(2#$#2/%?(Mbbb($04,3-("F(20>$.&%&(I/%"(

./;%/,=('/,=(#,3(#%%#2">&,%("00<-(

7(9#2"( Q0/-%F(.&G&'*0$&'#%&3(2#B.&(0'(2"#/,H()*%0,(>/,/>4>(2#$#2/%?(

)(9#2"( _'/;%($/,F(.#'=&(-/Y&(;0'(#./=,/,=(7*/,2"("0.&-(

)(9#2"( _'/;%($/,F(.#'=&(-/Y&(;0'(#./=,/,=(8Z`*(#,3(7Z)*/,2"("0.&-(

7(9#2"( \#..($&&,("#>>&'F()5*04,2&(

7(9#2"( 7b*;00%(-%&$.#33&'(

7(9#2"( )M*;00%(&T%&,-/0,(-%&$.#33&'(

7(9#2"( :0'D4&(I'&,2"F(abb(;%*.B(

7(9#2"( :0'D4&(I'&,2"F(a(%0(cM(;%*.B(

)(9#2"( X'&,2"F(-$43F(7(MZ`*/,2"(-/Y&(

7(9#2"( S#..&%F('#I"/3&(

7(9#2"( L0$&F(Mb*;00%F(8Z`*/,2"(>#,/.#(0'(,?.0,H(4-&3(;0'(%/&(./,&(

7(9#2"( [&G&.(O-$/'/%(0'(B4BB.&R(

7(9#2"( [&G&.F(-4';#2&(

a(9#2"( !.#>$F(`*/,2"F(!*%?$&(

7(9#2"( 62'&I3'/G&'F(d)($"/../$-(

7(9#2"( 62'&I3'/G&'F(>&3/4>F(-%'#/="%(-.0%(

7(9#2"( A#4=&F(%"/2<,&--('#,=&-(;'0>(b@b7b(%0(b@b8b(/,2"(

7(9#2"( A'&#-&(=4,(I/%"(2#'%'/3=&-(

7(9#2"( !'#,&F(#$$'0T/>#%&.?()b*%0,-(I/%"(#(`b*;00%(B00>(

7(9#2"( E,=.&(;/,3&'(0'(>#=,&%/2(B#-&(/,2./,0>&%&'(

7(9#2"( L0..(0;(>#-</,=(%#$&(0'(342%(%#$&(

7(9#2"( @)M(3/#@(;/.&(

7(9#2"( 7@b(/,2"(;.#%(;/.&(

7(9#2"( _&B4''/,=(%00.(

(

5)678)9( )*M(

!"#$%&'()(*(+,-%#..#%/0,(1'02&34'&-(

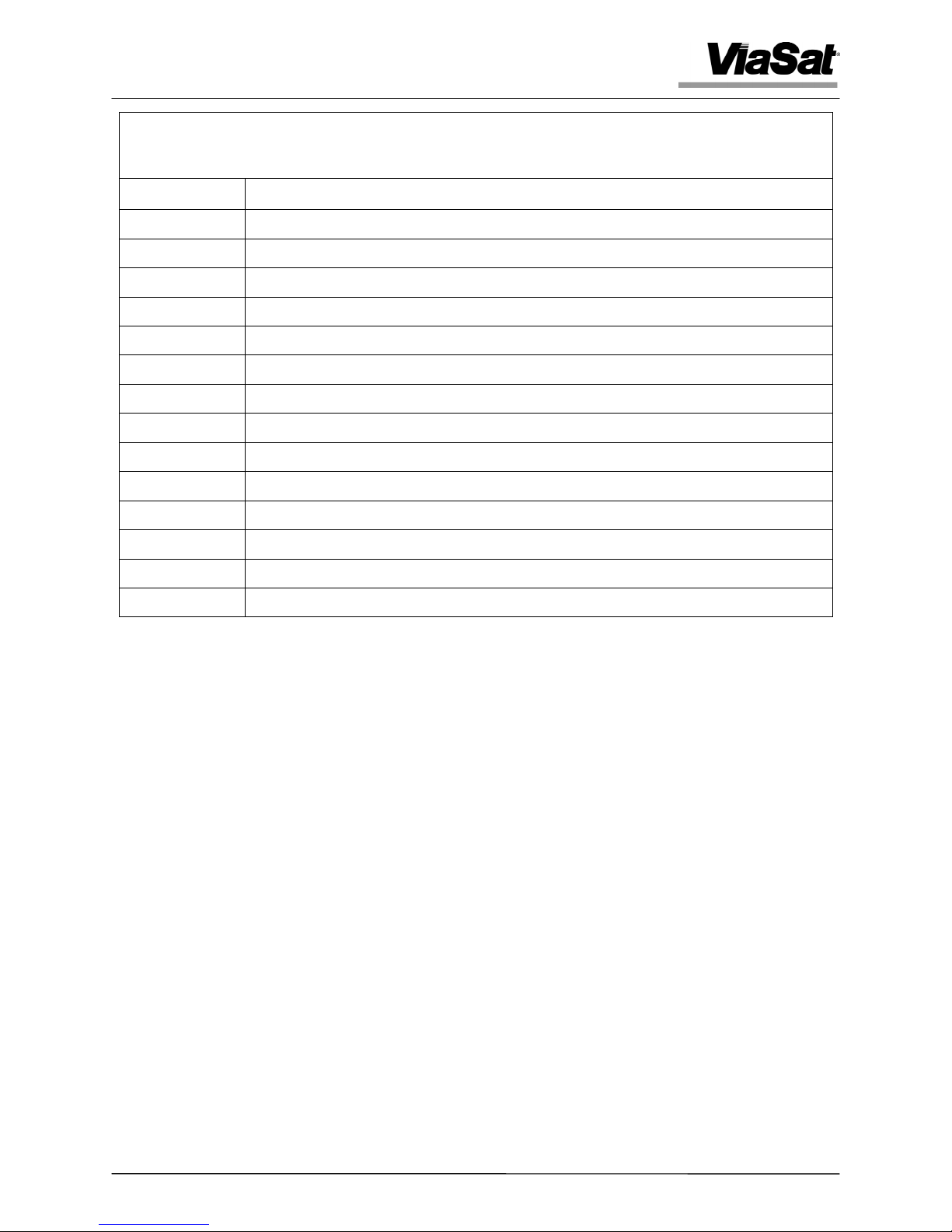

!"#$%&'()*&&!++$,&"-.&/01234%-5&6%0127%.&8+7&9-,5"$$"52+-&

^4#,%/%?( _&-2'/$%/0,(

8(9#2"( 8Z7a*/,2"(3'/..(B/%(

7(9#2"( 8Z`*/,2"(3'/..(>0%0'(

7(9#2"( 8Z5*/,2"(3'/..(>0%0'(

7(9#2"( 7bb*;00%($0I&'(20'3(

7(9#2"( 7`*/,2"(>#2"/,&(-2#.&(

7(9#2"( :"&030./%&(OI/.3(:)R(

7(6&%( 6"0'%(;024-(.&,-(OACb7*ACb5R(

7(9#2"( L/="%(#,=.&(&?&$/&2&(

7(9#2"( \#%%&'?(./="%(</%(

7(9#2"(( ^*\&#>(-$0%(./="%(O;0'('&;.&2%0'(#3e4-%>&,%R(

7(9#2"( 1'?(B#'(

7(6&%( 6>#..Z>&3/4>Z.#'=&(E..&,(I'&,2"&-(

7(9#2"( 1.4>(B0B(#,3(-%'/,=(

7(9#2"( \#,3(24%%&'(

(

2.9 Fastener Information

E..( %"'&3( ;#-%&,&'-( #'&( =#.G#,/Y&3F( E6:S( E8)MF( "/="*-%'&,=%"F(

"&T#=0,#.*"( -2'&I-( O&D4/G#.&,%(%0( 6E9(A'#3&(MR( 0'(-%#/,.&--( -%&&.@( (:"&(

#,2"0'(B0.%-(4-&3(/,(%"&(;04,3#%/0,(#'&(>#3&(0;(6E9(A'#3&(M(-%&&.(0'(B&%%&'@(

9#2"(;#-%&,&'(>4-%(B&(20''&2%.?(%/="%&,&3(#%(;/,#.(#--&>B.?(%0(&,-4'&(%"#%(/%(

I/..(2#''?(/%-(3&-/=,(.0#3(I/%"04%(I0'</,=(.00-&(4,3&'(G/B'#%/0,(#,3(I/..(,0%(

#..0I( -./$$#=&( 0'( -&$#'#%/0,( 0;( e0/,&3( >&>B&'-@( ( :"4-F( %"&( -%'42%4'#.(

/,%&='/%?( #,3( $0/,%/,=( #224'#2?(0;( %"&( %0%#.( #,%&,,#(-?-%&>( 3&$&,3-(4$0,(

%"&($'0$&'(/,-%#..#%/0,(0;(D4#./%?(;#-%&,&'-@(

:"/-(>#,4#.( -$&2/;/&-( %"&('&D4/'&3(%0'D4&(G#.4&(;0'(/,-%#..#%/0,( 0;( #..(>#e0'(

-%'42%4'#.(;#-%&,&'-@((L&;&'(%0(:#B.&()*)(;0'(%"&(-$&2/;/2(%0'D4&(G#.4&-(;0'("(

;#-%&,&'@(

(

5)678)9( )*a(

!"#$%&'()(*(+,-%#..#%/0,(1'02&34'&-(

!"#$%&'('*&&!+701%&:"$1%,&8+7&;-5%--"&8",5%-%7,&

:0'D4&(O;%*.BR(%0.&'#,2&(f7bg(

V#-%&,&'(6/Y&(

(

A#.G#,/Y&3( 6%#/,.&--(

7Z5*)b( h(O7)(W>R( a(O`(W>R(

MZ7a*7`( 7`(O)5(W>R( 7)(O7a(W>R(

8Z`*7a( 8b(O5b(W>R( )b(O)a(W>R(

7Z)*78( cM(O7bb(W>R( 5M(Oab(W>R(

hZ7a*7)( 77b(O75h(W>R( (

MZ`*77( 7Mb(O)b8(W>R( (

8Z5*7b( )ab(O&T2&$%(#-(,0%&3R(O8M8(W>R(

E,2"0'(\0.%-( 55b(OMha(W>R( (

7*`( abb(O&T2&$%(#-(,0%&3R(O`78(W>R(

NOTE

:"&( '&D4/'&3( %0'D4&( G#.4&( ;0'( %"&( ;04,3#%/0,( #,2"0'( B0.%-(

>#?( ,0%( B&( #224'#%&.?( #2"/&G&3( B?( %"&( %4',*0;*%"&*,4%(

>&%"03@((V0'(%"&-&(B0.%-F(#,(#224'#%&(%0'D4&(G#.4&(0;(5bb(%0(5Mb(

;%*.B(OM8b(%0(abb(W>R(/-('&D4/'&3@(

2.10 Recommended Installation Sequence

+,( 0'3&'( %0( &,-4'&( $'0$&'( #,3( %'04B.&*;'&&( /,-%#..#%/0,F( %"&( ;0..0I/,=(

/,-%#..#%/0,(-&D4&,2&(/-('&20>>&,3&3J(

7@( 6/%&(1'&$#'#%/0,(

)@( E--&>B.?(0;(L&;.&2%0'F(6$#'-F(#,3(64B'&;.&2%0'(

8@( E--&>B.?(0;(S04,%(#,3(E2%4#%0'-(

5@( A'04%/,=(\#-&$.#%&(%0(V04,3#%/0,(

M@( L&;.&2%0'(+,-%#..#%/0,(

a@( V&&3(#,3(X#G&=4/3&(+,-%#..#%/0,(

c@( 9.&2%'/2#.(+,-%#..#%/0,(

`@( [/>/%(6I/%2"(E3e4-%>&,%(1'02&34'&@(

(

5)678)9( )*c(

!"#$%&'()(*(+,-%#..#%/0,(1'02&34'&-(

:"&(#B0G&(-&D4&,2&(/-(3&-/=,&3(%0(>/,/>/Y&(2'#,&(4-#=&(%/>&@((

:"&(2'#,&(/-(0,.?('&D4/'&3(;0'(/%&>-(M(#,3(c@(

:0( /,-%#..( ;&&3( #,3( #--02/#%&3( "#'3I#'&F( #( )M*;00%( &T%&,-/0,( .#33&'( /-(

'&D4/'&3(%0(&,%&'( %"&( '&;.&2%0'@((E.I#?-(I&#'( -0;%( -0.&(-"0&-(I"&,(I0'</,=(

/,-/3&( %"&( '&;.&2%0'@((:"&( /,-%#..#%/0,(-&D4&,2&( >#?( B&(#.%&'&3(B?(-$&2/#.( 0'(

4,4-4#.(0,*-/%&(20,-/3&'#%/0,-@(

:"&(#--&>B.?( $'02&34'&-( $'&-&,%&3( /,( %"/-(2"#$%&'(#'&(B#-&3(

0,( %"&( #--4>$%/0,(%"#%( #( $0I&'&3(./;%/,=(3&G/2&( 0;(#3&D4#%&(

-/Y&( #,3( 2#$#2/%?(/-( 4-&3H( %"&'&;0'&F(%"&($'02&34'&-(=/G&,( 30(

,0%('&;.&2%(20,-/3&'#%/0,(0;(./>/%#%/0,-( /,(./;%/,=(#,3("#,3./,=(

&D4/$>&,%( %"#%( >/="%( B&( &,204,%&'&3( #%( #,?( -$&2/;/2(

/,-%#..#%/0,( -/%&@( ( +;( #( -4/%#B.&( 2'#,&( /-( ,0%( #G#/.#B.&F( /%( /-(

$0--/B.&( %0( #--&>B.&( %"&( &,%/'&( #,%&,,#( I/%"04%( "&#G?(

"0/-%/,=( &D4/$>&,%F( $'0G/3&3( -4;;/2/&,%( >#,$0I&'( /-(

#G#/.#B.&( #,3( #( -4/%#B.&( &.&G#%&3( I0'<( $.#%;0'>( 2#,( B&(

$'0G/3&3( -0( %"#%(%"&( '&;.&2%0'(>#?( B&(#--&>B.&3( /,($.#2&( 0,(

%0$(0;(%"&(>04,%@(

NOTE

NOTE

Do not attempt to erect the antenna in winds exceeding 25

mi/h (40 km/h). Injury to personnel or damage to antenna

may result if erection is attempted in high winds.

After the panels are installed on the reflector assembly, the

reflector is very susceptible to moving during windy conditions.

Ensure the reflector is properly tied down until the reflector is

completely secured on the mount.

2.11 Site Preparation

L&;&'(%0(77*S&%&'( 9#'%"( 6%#%/0,(E,%&,,#(6/%&(1'&$#'#%/0,( :&2",/2#.( S#,4#.(

d5)6787(;0'(/,;0'>#%/0,(,&&3&3(%0($'0$&'.?(.02#%&(#,3(/,-%#..(%"&(;04,3#%/0,(

;0'(%"/-(#,%&,,#(-?-%&>@(

WARNING

CAUTION

(

5)678)9( )*`(

!"#$%&'()(*(+,-%#..#%/0,(1'02&34'&-(

2.12 Assembly of Reflector, Spars, and Subreflector

:"&( ;0..0I/,=( $'02&34'&( 3&-2'/B&-( %"&( 20>$.&%&( #--&>B.?( 0;( %"&( '&;.&2%0'(

I"/2"(/,2.43&-(%"&('&;.&2%0'("4BF(%'4--&-F(/,%&'20-%#.-F(-$#'-F(-4B'&;.&2%0'F(#,3(

$#,&.-@( ( !#'&;4..?( -%43?( V/=4'&-( )*7F( )*)F( #,3( )*8( %0( 4,3&'-%#,3( "0I( %"&(

20>$.&%&('&;.&2%0'(/-(#--&>B.&3@((V/=4'&()*7(-"#..(B&(4-&3(;0'(%"&(77S(!*B#,3(

#,%&,,#(#,3(V/=4'&()*)(;0'(%"&(77S(]4*B#,3(#,%&,,#@(1&';0'>(%"&(;0..0I/,=(

$'02&34'&(%0(#--&>B.&(%"&('&;.&2%0'J(

!.&#,./,&--(0;(%"&($'&2/-/0,(>#%/,=($#'%-(%"#%(>#<&(4$(%"&('&;.&2%0'(#--&>B.?(

/-(&--&,%/#.(%0($'0$&'(;/%(#,3('&;.&2%0'(-4';#2&(#224'#2?@((V0'(%"/-('&#-0,F(0,.?(

'&>0G&(%"&('&;.&2%0'($#'%-(;'0>(%"&/'(2'#%&-(0'($#..&%-(#-('&D4/'&3@(

E--&>B.&(%"&('&;.&2%0'(0,(%"&(='04,3(B?(%"&(;0..0I/,=(-%&$-@((\&;0'&(-%#'%/,=(

%"&(#--&>B.?F(G&'/;?(%"&(;0..0I/,=J(

7@( 9T#>/,&(5`('&;.&2%0'($#,&.-(#,3()5(%'4--&-(/,(%"&/'(2'#%&-@((+3&,%/;?(&/="%(

-$#'($#,&.-(;0'( %"&( -4B*'&;.&2%0'(-$#'(>04,%/,=(%#B(#%%#2"&3( %0(%"&( -$#'(

%'4--&-@(( +3&,%/;?(;04'(-$#'( %'4--&-( B?(%"&(-$#'(-4$$0'%(2.&G/-( I&.3&3(%0(

%"&(%'4--@( ( 9T#>/,&(%"&("4B(#,3( ,0%&( %"&(0'/&,%#%/0,(0;( %"&( -$#'(%'4--&-(

O-&&(V/=4'&()*7R@(

)@( !.02<I/-&( #,3( 204,%&'2.02<I/-&( /-( #-( 0B-&'G&3( B?( #( $&'-0,( .00</,=(

30I,(0,%0(%"&(;'0,%(0;(%"&('&;.&2%0'(I"/.&(%"&("4B(/-($0-/%/0,&3(I/%"(/%-(

'&#'(-/3&(%0I#'3-(%"&(='04,3@(

8@( :"&( 3'#I/,=-( /,2.43&3( /,( %"/-( >#,4#.( #'&( &T#>$.&-( 0;( '&;.&2%0'(

#--&>B./&-(I/%"(>0%0'/Y&3($0.#'/Y#%/0,(3'/G&-(#,3(,0(3&*/2&(-?-%&>@(

5@( :"&(B#-/2('&;.&2%0'(#--&>B.?(-&D4&,2&(/-J(

#@( +,-%#..(%'4--&-(#,3(/,%&'20-%#.-(

B@( +,-%#..(-$#'-(#,3(-4B'&;.&2%0'(

2@( E./=,(%'4--&-(

3@( +,-%#..('&;.&2%0'($#,&.-(%0(%'4--&-(

&@( E./=,($#,&.-(

;@( :/="%&,(;#-%&,&'-@(

(

5)678)9( )*h(

!"#$%&'()(*(+,-%#..#%/0,(1'02&34'&-(

If it is necessary to walk inside the reflector during assembly,

be sure to walk on the portion of the reflector closest to the

hub. Avoid putting weight on unsupported parts of the

reflector panels. Wear clean soft sole shoes or socks only.

Extra care should be taken to protect the painted panel

surface.

C/#6#%F( +,2@( =4#'#,%&&-( %"&( #,%&,,#( -$&2/;/2#%/0,-F( $'0G/3&3(

%"#%( %"&( '&;.&2%0'( #--&>B.?( $'02&34'&( /-( $&';0'>&3( B?( #,(

/,-%#..#%/0,(2'&I(%'#/,&3(#,3(#$$'0G&3(B?(C/#6#%F(+,2@(

L&;&'(%0(V/=4'&()*7(;0'(%"&(/,-%#..#%/0,(3&%#/.-(#,3($#'%-(./-%-@((:"&('&;&'&,2&3(

/%&>(,4>B&'-(/,(%"&(;0..0I/,=($'02&34'&-(#='&&(I/%"(V/=4'&()*7@(

CAUTION

NOTE

NOTE

Q4B( >#?( 3/;;&'( B#-&3( 0,( ;&&3( 0$%/0,-( -&.&2%&3@( ( Q0I&G&'F(

/,-%#..#%/0,(-&D4&,2&(#,3(/,-%'42%/0,-(I/..('&>#/,(%"&(-#>&@(

2.12.1 Installation of Trusses and Intercostals

7@( L&>0G&("4B(#--&>B.?(O/%&>(87(/,(V/=4'&()*7R(;'0>($#2<#=/,=(#,3($.#2&(

/,( 4$'/="%( $0-/%/0,( 0,(-%#B.&( I003&,(B.02<-( 0'( %/>B&'-@(( L#/-&( %"&("4B(

#--&>B.?( #%( .&#-%( `( /,2"&-( #B0G&( %"&( ='04,3( ;0'( I0'</,=( 2.&#'#,2&@((

OL&;&'(%0(V/=4'&()*8(;0'("4B(#--&>B.?(/,;0'>#%/0,@R(

CAUTION

When assembling the reflector on the ground, the trusses

should be installed by alternating from one side of the reflector

to the other. This will prevent an unbalanced load that could

cause the assembly to tip over.

)@( [02#%&(%"&(e#2<(>04,%(&#'(0,("4B(O/%&>(8(/,(V/=4'&()*8R@(

(

5)678)9( )*7b(

!"#$%&'()(*(+,-%#..#%/0,(1'02&34'&-(

+,( %"&( ;0..0I/,=( -%&$-F( -&24'&( "#'3I#'&( ;/,=&'( %/="%( 4,.&--(

3/'&2%&3(0%"&'I/-&@(

8@( E%%#2"( -%'4%(O/%&>( 7cR(#%( ;/'-%( 2.02<I/-&( $0-/%/0,(#B0G&( e#2<(>04,%( &#'@((

6&24'&(-%'4%(I/%"(0,&(B0.%(O/%&>()MRF(%I0( I#-"&'-(O/%&>()cRF(#,3(0,&(,4%(

O/%&>()aR@(

5@( E%%#2"( %'4--(O/%&>()8R(%0("4B(4-/,=(0,&(B0.%( O)MRF( %I0(I#-"&'-( O)cRF(#,3(

0,&(,4%( O)aR( #,3(%0(-%'4%(4-/,=(;04'( B0.%-( O/%&>()`RF( &/="%(I#-"&'-( O/%&>(

8bRF(#,3(;04'(,4%-(O/%&>()hR@(

M@( E%%#2"( ,&T%(2.02<I/-&(-%'4%(#,3( %'4--( #--&>B./&-( #-(3&-2'/B&3(/,(-%&$-(8(

#,3(5@(

a@( +,-%#..(%0$(/,,&'(/,%&'20-%#.(O/%&>(7`R(B&%I&&,(%I0(%'4--(#--&>B./&-(4-/,=(

%I0(B0.%-(O/%&>()`RF(;04'(I#-"&'-(O/%&>(8bRF(#,3(%I0(,4%-(O/%&>()hR@(

NOTE

c@( +,-%#..( B0%%0>(/,,&'( /,%&'20-%#.(O/%&>(7hR( B&%I&&,(%'4--(-%'4%( #--&>B./&-(

4-/,=(%I0(B0.%-(O/%&>()`RF(;04'(I#-"&'-(O/%&>(8bRF(#,3(%I0(B0.%-(O/%&>()hR@(

`@( +,-%#..( %0$( >/33.&( /,%&'20-%#.( O/%&>( )bR( B&%I&&,( %I0( %'4--( #--&>B./&-(

4-/,=(%I0(B0.%-(O/%&>()`RF(;04'(I#-"&'-(O/%&>(8bRF(#,3(%I0(,4%-(O/%&>()hR@(

h@( E%%#2"( ,&T%(2.02<I/-&(-%'4%(#,3( %'4--( #--&>B./&-( #-(3&-2'/B&3(/,(-%&$-(8(

#,3(5@((:"&,(/,-%#..(/,%&'20-%#.-(#-(3&-2'/B&3(/,(-%&$-(a(%"'04="(`@(

7b@( E%%#2"( -%'4%(O/%&>(7cR( #%(,&T%(2.02<I/-&( $0-/%/0,@( (6&24'&(-%'4%(I/%"(0,&(

B0.%(O/%&>()MRF(%I0(I#-"&'-(O/%&>()cRF(#,3(0,&(,4%(O/%&>()aR@(

77@( E%%#2"( -$#'( %'4--(O/%&>())R(%0("4B(4-/,=(0,&(B0.%(O)MRF(%I0(I#-"&'-(O)cRF(

#,3( 0,&(,4%( O)aR( #,3( %0(-%'4%( 4-/,=(;04'( B0.%-(O/%&>( )`RF( &/="%( I#-"&'-(

O/%&>(8bRF(#,3(;04'(,4%-(O/%&>()hR@(

7)@( +,-%#..( %0$( /,,&'( /,%&'20-%#.( O/%&>( 7`R( #,3( -$#'( %'4--( B'#2&( O/%&>( 85R( %0(

-$#'(%'4--(4-/,=(B0.%(O/%&>(88RF(%I0(I#-"&'-(O/%&>(8bRF(#,3(,4%(O/%&>()hR@((

6&&(V/=4'&()*7F(6"&&%(5@(

78@( +,-%#..( %0$(/,,&'(/,%&'20-%#.( O/%&>(7`R(%0(0%"&'( %'4--( 4-/,=( B0.%(O/%&>()`RF(

%I0(I#-"&'-(O/%&>(8bRF(#,3(,4%(O/%&>()hR@(

75@( +,-%#..( B0%%0>( /,,&'(/,%&'20-%#.( O/%&>()7R( #,3(.&;%( "#,3(-$#'(%'4--( B'#2&(

O/%&>( ))R( %0(%'4--( OI/%"04%( -$#'( %#BR(4-/,=( B0.%(O/%&>( 88RF(%I0( I#-"&'-(

O/%&>(8bRF(#,3(,4%(O/%&>()hR@(

7M@( +,-%#..( B0%%0>( /,,&'(/,%&'20-%#.( O/%&>(7hR( %0( 0%"&'(%'4--( 4-/,=( B0.%(O/%&>(

)`RF(%I0(I#-"&'-(O/%&>(8bRF(#,3(,4%(O/%&>()hR@(

(

5)678)9( )*77(

!"#$%&'()(*(+,-%#..#%/0,(1'02&34'&-(

7a@( +,-%#..(%0$(04%&'(/,%&'20-%#.(O/%&>()bR(B&%I&&,(%I0(%'4--(#--&>B./&-(4-/,=(

%I0(B0.%-(O/%&>()`RF(;04'(I#-"&'-(O/%&>(8bRF(#,3(%I0(,4%-(O/%&>()hR@(

7c@( E%%#2"( ,&T%(2.02<I/-&(-%'4%(#,3( %'4--( #--&>B./&-( #-(3&-2'/B&3(/,(-%&$-(8(

#,3( 5@( ( :"&,( /,-%#..( /,%&'20-%#.-( #,3( '/="%( "#,3( -$#'( %'4--( B'#2&( #-(

3&-2'/B&3(/,(-%&$-(7)(%"'04="(7a@(

7`@( E%%#2"( ,&T%( ;04'( 2.02<I/-&( -%'4%( #,3( %'4--( #--&>B./&-( #-( 3&-2'/B&3( /,(

-%&$-( 8( #,3( 5@( ( E;%&'( "( -%'4%( #,3( %'4--( #--&>B.?( /-( /,-%#..&3F( /,-%#..(

/,%&'20-%#.-(#-(3&-2'/B&3(/,(-%&$-(a(%"'04="(`@(

7h@( E%%#2"( ,&T%( 2.02<I/-&( -%'4%( #,3( -$#'( %'4--( #--&>B./&-( #-( 3&-2'/B&3( /,(

-%&$-(7b(#,3(77@((:"&,(/,-%#..(/,%&'20-%#.-(#-(3&-2'/B&3(/,(-%&$-(a(%"'04="(

`@(

)b@( E%%#2"( ,&T%( ;/G&( 2.02<I/-&( -%'4%( #,3( %'4--( #--&>B./&-( #-( 3&-2'/B&3( /,(

-%&$-( 8( #,3( 5@( ( E;%&'( "( -%'4%( #,3( %'4--( #--&>B.?( /-( /,-%#..&3F( /,-%#..(

/,%&'20-%#.-(#-(3&-2'/B&3(/,(-%&$-(a(%"'04="(`@(

)7@( E%%#2"( ,&T%( 2.02<I/-&( -%'4%( #,3( -$#'( %'4--( #--&>B./&-( #-( 3&-2'/B&3( /,(

-%&$-(7b(#,3(77@((:"&,(/,-%#..(/,%&'20-%#.-(#-(3&-2'/B&3(/,(-%&$-(a(%"'04="(

`@(

))@( E%%#2"( ,&T%( ;/G&( 2.02<I/-&( -%'4%( #,3( %'4--( #--&>B./&-( #-( 3&-2'/B&3( /,(

-%&$-( 8( #,3( 5@( ( E;%&'( "( -%'4%( #,3( %'4--( #--&>B.?( /-( /,-%#..&3F( /,-%#..(

/,%&'20-%#.-(#-(3&-2'/B&3(/,(-%&$-(a(%"'04="(`@(

)8@( E%%#2"( ,&T%( 2.02<I/-&( -%'4%( #,3( -$#'( %'4--( #--&>B./&-( #-( 3&-2'/B&3( /,(

-%&$-(7b(#,3(77@((:"&,(/,-%#..(/,%&'20-%#.-(#-(3&-2'/B&3(/,(-%&$-(7)(%"'04="(

7a@(

)5@( E%%#2"(.#-%(%I0(2.02<I/-&(-%'4%(#,3(%'4--(#--&>B./&-(#-(3&-2'/B&3(/,(-%&$-(

8( #,3( 5@( ( E;%&'( "( -%'4%( #,3( %'4--( #--&>B.?( /-( /,-%#..&3F( /,-%#..(

/,%&'20-%#.-(#-(3&-2'/B&3(/,(-%&$-(a(%"'04="(`@(

2.12.2 Installation of the Spars and Subreflector

6%43?( V/=4'&( )*7F(-"&&%( 8(%0( 4,3&'-%#,3("0I( %"&(-4B'&;.&2%0'( #,3( -$#'-(;/%(

%0=&%"&'@((1'02&&3(I/%"(%"&(#--&>B.?(#220'3/,=(%0(%"&(;0..0I/,=($'02&34'&-J(

7@( E--&>B.&( ;04'(-$#'-(O/%&>(7aR(%0(%0$(-$#'(;/%%/,=( O/%&>(7MR(I/%"(`(-2'&I-(

O/%&>(`RF(7a(I#-"&'-(O/%&>(hRF(#,3(`(,4%-(O/%&>(7bR@(

)@( E%%#2"( %"&( -4B'&;.&2%0'( -4$$0'%( ;'#>&( O/%&>( aR( %0( %"&( >04,%/,=( ;'#>&(

O/%&>(cR(4-/,=(%"'&&(-2'&I-(O/%&>(`RF(-/T(I#-"&'-(O/%&>(hRF(#,3(%"'&&(,4%-(

O/%&>(7bR(/,(%"&(%"'&&(#3e4-%/,=(-.0%-@(

8@( E%%#2"( %"'&&( %"'&3( '03-(O/%&>(7)R(%0(%"&(;'#>&-(O/%&>-(a( #,3(cR(4-/,=(

&/="%(I#-"&'-(O/%&>(hR(#,3(&/="%(,4%-(O/%&>(7bR(0,("('03@(

(

5)678)9( )*7)(

!"#$%&'()(*(+,-%#..#%/0,(1'02&34'&-(

5@( [/;%( %"&(;'#>&( #--&>B.?( 4$(%0( %"&(-$#'(#--&>B.?@( ( E%%#2"(%"&( >04,%/,=(

;'#>&(O/%&>(cR(%0(%"&(-$#'-(4-/,=(;04'(-2'&I-(O/%&>(`RF(&/="%(I#-"&'-(O/%&>(

hRF(#,3(;04'(,4%-(O/%&>(7bR@(

M@( 6&%( %"&( -4B'&;.&2%0'( O/%&>( MR( 20,2#G&( -/3&( 4$( 0,( #( $#33&3( -4';#2&( ;0'(

$'0%&2%/0,@(

a@( +,-%#..( #(,4%( O/%&>(78R( #,3(#( I#-"&'(O/%&>( 77R(0,%0( "(%"'&3( -%43(

O/%&>(75R(#$$'0T/>#%&.?(7@M(/,2"&-(i8@`(2>j(;'0>(%"&(&,3F(#,3(-2'&I(%"&(

-#>&(&,3(0;("(-%43(/,%0(0,&(0;(%"&(>#2"/,&3(B0--(0,(%"&(-4B'&;.&2%0'@(

c@( +,-%#..(#(,4%(O/%&>(78R(0,%0("(%"'&3(-%43(O/%&>(75R(#$$'0T/>#%&.?(8(

/,2"&-(ic@a(2>j(;'0>(%"&(;'&&(&,3F(#,3($.#2&(#(I#-"&'(O/%&>( 77R(0G&'(%"&(

&,3(0;(%"&(-%43(#,3(0,%0(%"&(,4%@(

`@( [/;%(%"&(-4B'&;.&2%0'(4$(%0(%"&(-4$$0'%(;'#>&(#,3(/,-&'%(%"&(-%43-(/,%0(%"&(

20''&-$0,3/,=( "0.&-( /,( %"&( ;'#>&@( 6&24'&( %"&( -4B'&;.&2%0'( 4-/,=( %"'&&(

I#-"&'-(O/%&>(77R(#,3(%"'&&(,4%-(O/%&>(78R@(

h@( !"0<&(#(,?.0,(-%'#$(#'04,3(%"&(-$#'(#--&>B.?(%0$(;/%%/,=(#,3(#%%#2"(/%(%0(

%"&(./;%/,=("00<(0;(%"&(2'#,&@(

7b@( Q0/-%( %"&( -$#'( #,3( -4B'&;.&2%0'(#--&>B.?(/,%0(%"&('&;.&2%0'(#,3(#./=,(%"&(

.0I&'(&,3(0;("(-$#'(I/%"(%"&(#%%#2">&,%(%#B(0,(#(-$#'(%'4--@(E%%#2"(%"&(

-$#'-(%0(%"&(%'4--(%#B-(#-(-"0I,(/,(V/=4'&()*7F(-"&&%()F(4-/,=(;04'(-2'&I-(

O/%&>()MRF(&/="%(I#-"&'-(O/%&>()cRF(#,3(;04'(,4%-(O/%&>()aR@(

77@( :0'D4&(#..(%"&(;#-%&,&'-(4-&3(/,(%"&(#--&>B.?(#,3(/,-%#..#%/0,(0;(%"&(-$#'-(

#,3( -4B'&;.&2%0'( %0( %"&( G#.4&-( 20''&-$0,3/,=( %0( %"&( 20''&2%( -/Y&-( #-(

/,3/2#%&3(/,(:#B.&()*)@(

2.12.3 Truss Alignment

7@( +,-%#..( %"&(%"&030./%&( >04,%/,=(B'#2<&%(0,%0( %"&( $#,&.( >04,%/,=( '/,=( /,(

%"&("4B(4-/,=(%"'&&(8Z`(/,2"(-2'&I-@(+%(I/..(0,.?(>04,%(0,&(I#?(34&(%0(

%"&(30I&.($/,-@((

)@( +,-%#..( %"&( %"&030./%&( 0,%0( %"&( >04,%/,=( B'#2<&%@( [&G&.( %"&( %"&030./%&(

0G&'( /%-( %"'&&( ;&&%( 4-/,=( #,( 7`*/,2"( >#2"/,&( -2#.&F( >&#-4'/,=( 7a@`Mb(

/,2"&-(i5)@chh(2>j(4$(;'0>(%"&($#,&.(>04,%/,=('/,=@(O6&&(V/=4'&()*5@R(

8@( k&'0(%"&(#Y/>4%"(-2#.&(0;(%"&(%"&030./%&(I"/.&(.00</,=(#%(%"&(2&,%&'(0;(%"&(

>04,%/,=(B0.%(0;(%"&(;/'-%(%'4--(%0(%"&("4B@(

5@( 6&%( ( %"&( %"&030./%&( &.&G#%/0,( #,=.&( %0( cMl*57U*M8P@( V024-( 0,( %"&( 7Z5P(

3/#>&%&'( =#=&( "0.&(/,( %"&( %0$( 0;(%"&( &,3($.#%&( 0,(%"&( %'4--@(E3e4-%( %"&(

%'4--( .#%&'#..?( #,3( G&'%/2#..?( -0( %"#%( %"&( =#=&( "0.&( /-( 2&,%&'&3( 0,( %"&(

%"&030./%&(%&.&-20$&(2'0--"#/'-@(:/="%&,(%"&(>04,%/,=(-2'&I-(;0'(%"&(%'4--(

#%(%"&("4BF(#,3(%"&( -2'&I-(I"/2"(#%%#2"(%"&(04%&'(3/#=0,#.(B'#2&-(%0(%"&(

%'4--@((

(

5)678)9( )*78(

Loading...

Loading...