ViaSat 3862 Operation And Maintenance Manual

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

Instra

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

REMOTE INSPECTION

View

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Model 3862

Autotrack Digital Controller

Operation and Maintenance Manual

Manual Part No. 1000569

January 2003

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Notice

All Rights Reserved

The information contained in this document is proprietary to ViaSat, Inc.

This document may not be reproduced or distributed in any form without

the consent of ViaSat, Inc.

The information in this document is subject to change without notice.

ViaSat, Inc. assumes no responsibility for any errors that may appear in

this document and does not warranty any specific application.

Any product names mentioned herein are used for identification purposes

only, and may be trademarks and/or registered trademarks of their

respective companies.

In all correspondence with ViaSat, Inc. regarding this publication, please

refer to the Manual Part No. on the title page.

Copyright ® 2003 ViaSat, Inc.

All rights reserved. No part of this book may be reproduced in any form

or by any means without permission in writing from ViaSat, Inc.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Table of Contents

Table of Contents

Table of Contents .................................................................................................. iii

List of Figures ......................................................................................................viii

List of Tables .......................................................................................................... ix

Safety Summary ......................................................................................................x

General Information ........................................................................................... 1-1

1.1 Introduction .............................................................................................................1-1

1.2 Contents of this Manual .........................................................................................1-1

1.3 Use of this Manual ..................................................................................................1-1

1.4 Format of this Manual ............................................................................................ 1-2

1.5 Change Recommendations ....................................................................................1-2

1.6 Description ...............................................................................................................1-2

1.6.1 Major Components .................................................................................................1-3

1.6.2 Functional Configurations .....................................................................................1-3

1.6.3 Physical Configurations .........................................................................................1-4

1.7 Specifications ...........................................................................................................1-6

1.8 Glossary of Symbols and Abbreviations..............................................................1-7

Installation............................................................................................................ 2-1

2.1 Introduction .............................................................................................................2-1

2.2 Unpacking and Inspection.....................................................................................2-1

2.2.1 Damage or Loss During Shipment .......................................................................2-1

2.3 Equipment Return................................................................................................... 2-1

2.4 Installation Procedure ............................................................................................2-2

2.4.1 General......................................................................................................................2-2

2.4.2 Chassis Slide Mounting.......................................................................................... 2-2

2.4.3 Cable Connectors ....................................................................................................2-3

2.4.4 Host Computer Interfaces....................................................................................2-16

2.4.4.1 Serial Communications ........................................................................................2-16

3862 Autotrack Controller iii

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Table of Contents

2.4.4.2 IEEE-488 Communications ..................................................................................2-16

2.4.5 Time-stamped Position and Autotrack Status Message..................................2-18

2.4.6 GPS Time-code Interface......................................................................................2-20

2.4.7 Power Input ...........................................................................................................2-20

2.5 Initial Checkout .....................................................................................................2-20

2.5.1 Initial Turn-on and Checkout..............................................................................2-21

2.5.2 Axis Position Offsets.............................................................................................2-24

Operation.............................................................................................................. 3-1

3.1 Introduction .............................................................................................................3-1

3.2 Modes of Operation ................................................................................................3-1

3.2.1 Local Pedestal Control............................................................................................3-1

3.2.2 Remote Control........................................................................................................3-2

3.2.3 Front-panel Control ................................................................................................3-2

3.3 Front-panel controls and indicators .....................................................................3-2

3.3.1 Liquid Crystal Display Indicators.........................................................................3-4

3.3.2 Data Entry ................................................................................................................3-5

3.3.3 Softkeys.....................................................................................................................3-6

3.3.4 Top Level Softkey Menu ........................................................................................3-6

3.3.5 Front-panel Operating Procedures .......................................................................3-6

3.3.6 Power Up And Down.............................................................................................3-6

3.3.7 Emergency Shutdown ............................................................................................3-8

3.3.8 Standby Mode.......................................................................................................... 3-8

3.3.9 Position Mode..........................................................................................................3-8

3.3.10 Rate Mode ................................................................................................................3-9

3.3.11 Track Mode ..............................................................................................................3-9

3.3.12 Menus .......................................................................................................................3-9

3.3.13 Softkey Axis Assignment .......................................................................................3-9

3.3.14 Secondary Modes ..................................................................................................3-10

3.3.14.1 Standby Mode........................................................................................................ 3-10

3.3.14.2 Scan Mode ..............................................................................................................3-11

3.3.14.3 Slave Mode.............................................................................................................3-11

3.3.14.4 Stow Mode .............................................................................................................3-11

3862 Autotrack Controller iv

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Table of Contents

3.3.15 Setup Menus ..........................................................................................................3-12

3.3.15.1 Servo Parameters...................................................................................................3-12

3.3.15.1.1 Digital Filter Selection ..........................................................................................3-12

3.3.15.1.2 Torque Bias Parameters........................................................................................3-14

3.3.15.1.3 Test Port Signal Selection .....................................................................................3-14

3.3.15.1.4 Step Response Test................................................................................................ 3-15

3.3.15.2 Scan Parameters ....................................................................................................3-16

3.3.15.2.1 Sector Scan..............................................................................................................3-17

3.3.15.2.2 Step Scan.................................................................................................................3-17

3.3.15.2.3 Spiral Scan ..............................................................................................................3-18

3.3.15.3 Position Parameters ..............................................................................................3-18

3.3.15.4 Limit Parameters ...................................................................................................3-19

3.3.16 Control Menus.......................................................................................................3-20

3.3.16.1 Local/remote Control...........................................................................................3-21

3.3.16.2 Autotrack Mode ....................................................................................................3-22

3.3.16.3 Steptrack Mode...................................................................................................... 3-24

3.3.16.4 AGC Channel Input..............................................................................................3-25

3.3.16.5 Digital Controller Setup Configuration Store/recall .......................................3-26

3.3.16.6 Feed Scan Selection ...............................................................................................3-28

3.3.16.7 Time And Date Set ................................................................................................3-29

3.3.16.8 Status And Command Lines................................................................................3-29

3.4 Remote operation ..................................................................................................3-30

Principles of Operation ...................................................................................... 4-1

4.1 Introduction .............................................................................................................4-1

4.2 Functional description............................................................................................4-1

4.2.1 Servo Assembly .......................................................................................................4-7

4.2.2 Synchro/resolver Assembly..................................................................................4-8

4.2.3 Operator/remote Interface Assembly................................................................ 4-10

4.2.4 Autotrack Assembly (Optional)..........................................................................4-11

4.2.5 Resolver Reference Oscillator Assembly ...........................................................4-12

4.2.6 Synchro Reference.................................................................................................4-13

4.2.7 Analog Rate Loop Assembly (Optional)............................................................4-13

3862 Autotrack Controller v

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Table of Contents

4.2.7.1 Loop Compensation..............................................................................................4-13

4.2.7.2 Differential Tach/torque Bias (dual Drive System) .........................................4-13

4.2.8 Motherboard .......................................................................................................... 4-14

4.2.9 Front Panel ............................................................................................................. 4-14

4.2.10 Front-panel Board Assembly............................................................................... 4-15

Maintenance......................................................................................................... 5-1

5.1 Introduction .............................................................................................................5-1

5.2 Preventive Maintenance.........................................................................................5-1

5.2.1 Visual Inspection.....................................................................................................5-1

5.2.2 Cleaning....................................................................................................................5-2

5.3 Test Equipment........................................................................................................5-2

5.4 Troubleshooting ......................................................................................................5-2

5.5 Alignment.................................................................................................................5-6

5.6 Repair........................................................................................................................5-6

5.6.1 Prerequisites To Removal And Installation.........................................................5-7

5.6.2 Internal Component Access................................................................................... 5-7

5.6.3 Servo, Synchro/resolver, ORI, Or Autotrack Board Removal..........................5-7

5.6.4 Servo, Synchro/resolver, ORI, Or Autotrack Board Installation .....................5-8

5.6.5 Resolver Reference Board Removal......................................................................5-8

5.6.6 Resolver Reference Board Installation .................................................................5-9

5.6.7 Power Supply Removal........................................................................................5-10

5.6.8 Power Supply Installation....................................................................................5-10

5.6.9 Power Inverter Removal ......................................................................................5-10

5.6.10 Power Inverter Installation ..................................................................................5-11

5.6.11 Optical Encoder Removal ....................................................................................5-11

5.6.12 Optical Encoder Installation ................................................................................5-12

5.6.13 Fan Assembly Removal........................................................................................5-13

5.6.14 Fan Assembly Installation....................................................................................5-13

Parts List ............................................................................................................... 6-1

6.1 Introduction .............................................................................................................6-1

6.2 Parts List and Assembly Drawings ......................................................................6-1

6.2.1 Explanation of Title Block on Parts Listing .........................................................6-1

3862 Autotrack Controller vi

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Table of Contents

6.2.2 Explanation of Parts Lists Column Headings .....................................................6-1

6.3 Ordering Parts .........................................................................................................6-2

Drawings .............................................................................................................. 7-1

7.1 Introduction .............................................................................................................7-1

7.2 Drawing Index.........................................................................................................7-1

3862 Autotrack Controller vii

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Table of Contents

LIST OF FIGURES

Figure 1.1. 3860 Digital Controller........................................................................................................ 1-2

Figure 1.2. 3860 Digital Controller Functional Configurations ........................................................1-5

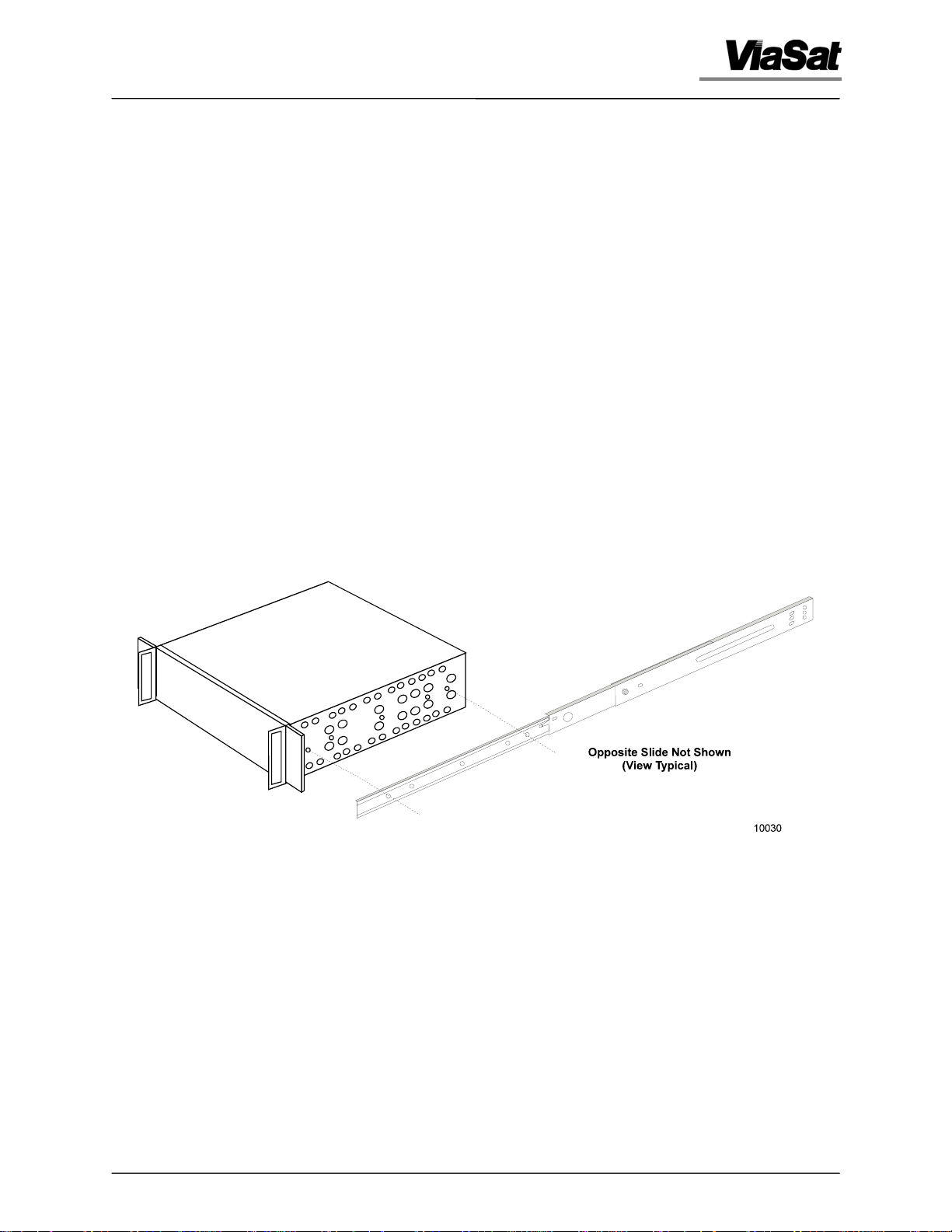

Figure 2.1. Typical Slide Mounting ......................................................................................................2-2

Figure 2.2. Typical Rear-panel Connector Interface..........................................................................2-6

Figure 3.1. 3860 Digital Controller Front Panel.............................................................................3-3

Figure 3.2. LCD Controls And Indicators .......................................................................................3-5

Figure 3.3. Top Level Softkey Menu.................................................................................................3-7

Figure 3.4. Softkey Axis Assignment ...............................................................................................3-9

Figure 3.5. Secondary Modes............................................................................................................3-10

Figure 3.6. Servo Parameters ...............................................................................................................3-13

Figure 3.7. Scan Parameters ..............................................................................................................3-16

Figure 3.8. Position Parameters........................................................................................................3-19

Figure 3.9. Limit Parameters.............................................................................................................3-20

Figure 3.10. Control Menus...............................................................................................................3-21

Figure 3.11. Local/remote Control Selection ...............................................................................3-22

Figure 3.12. Autotrack Mode Parameters..........................................................................................3-23

Figure 3.13. Steptrack Mode Parameters ..........................................................................................3-24

Figure 3.14. AGC Channel Input Parameters ..............................................................................3-25

Figure 3.15. Digital Controller Setup Configuration Store/recall..........................................3-27

Figure 3.16. Feed Scanner Control...................................................................................................3-28

Figure 3.17. Time And Date Set .......................................................................................................3-29

Figure 4.1. 3860 Digital Controller Block Diagram, Single-chassis Configuration ........................4-3

Figure 4.2. 3860 Digital Controller Block Diagram, Two-chassis Configuration...........................4-5

Figure 4.3. Servo Assembly Block Diagram ........................................................................................4-7

3862 Autotrack Controller viii

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Table of Contents

Figure 4.4. Synchro/resolver Assembly Block Diagram ...................................................................4-9

Figure 4.5. Operator/remote Interface Assembly Block Diagram.................................................4-10

Figure 4.6. Autotrack Assembly Block Diagram ..............................................................................4-12

LIST OF TABLES

Table 1-1. Series 13000 Pedestal Technical Specifications .................................................................1-4

Table 1-2. Environmental Specifications.............................................................................................1-5

Table 4-1. Position Data Package Electrical Interface .......................................................................4-4

Table 4-2. Gearmotor Electrical Interface ...........................................................................................4-6

Table 5-1. Tools and Test Equipment..................................................................................................5-1

Table 5-2. Periodic Maintenance Chart ...............................................................................................5-2

Table 5-3. Routine Inspection ...............................................................................................................5-2

Table 5-4. Consumable Materials List .................................................................................................5-6

Table 5-5. Troubleshooting Chart ........................................................................................................5-7

Table 5-6. Finish Repair Consumable Materials ................................................................................ 5-9

Table 7.1. Drawing Index......................................................................................................................7-1

3862 Autotrack Controller ix

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Safety Summary

SAFETY SUMMARY

These are general safety precautions that are not related to

any specific procedure. These are recommended precautions

that personnel must understand and apply.

WARNING

Use care when using metal tools that circuits are not shorted.

Some circuits have high current capacity which, when shorted,

will flash and may cause burns and/or eye injury.

Remove all jewelry and exposed objects from body and

clothing before performing maintenance, adjustments, and/or

troubleshooting. Before working inside equipment, remove all

power, unless power is required to be on to perform

procedures. Do NOT replace parts or modules with power

ON.

Servicing this equipment requires working with the equipment

while AC power is applied. Extreme caution must be

exercised during these procedures.

RESUSCITATION

Personnel working with or near hazardous chemicals or voltages should be

familiar with modern methods of resuscitation.

USE SAFETY-APPROVED EQUIPMENT

When cleaners are being applied, approved explosion-proof lights, blowers,

and other equipment shall be used. Ensure that firefighting equipment is

readily available and in working order. Keep cleaners in special

polyethylene bottles or in safety cans and in minimum quantities. Discard

soiled cloths into safety cans.

3862 Autotrack Controller x

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Chapter 1 - General Information

General Information

1.1 Introduction

This manual provides general operation and maintenance

instructions for the Series 3860 Digital Controller. This manual

includes optional equipment and features that may not be present

in all configurations.

1.2 Contents of this Manual

This manual consists of the following chapters:

Chapter 1

Chapter 1 General Information

Chapter 2 Installation

Chapter 3 Operation

Chapter 4 Principles of Operation

Chapter 5 Maintenance

Chapter 6 Parts List

Chapter 7 Drawings

1.3 Use of this Manual

This manual is divided into chapters, each with a specific purpose. The Table

of Contents lists all chapters and paragraphs with their titles and page

numbers. Illustrations, tables, and diagrams are provided to support the text.

Lists of illustrations and tables indicate their numbers, titles, and page

numbers. Abbreviations, phrases, and words appear in the text exactly as

they appear on the equipment.

3862 Autotrack Controller 1-1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Chapter 1 - General Information

1.4 Format of this Manual

Paragraph headings of this manual are formatted to indicate subordination of

subject matter as follows:

1.1 Primary Heading

1.1.1 First Subordinate

1.1.1.1 Second Subordinate

1.1.1.1.1 Third Subordinate

1.1.1.1.1.1 Fourth Subordinate

1.5 Change Recommendations

Submit recommendations concerning changes to ViaSat.

1.6 Description

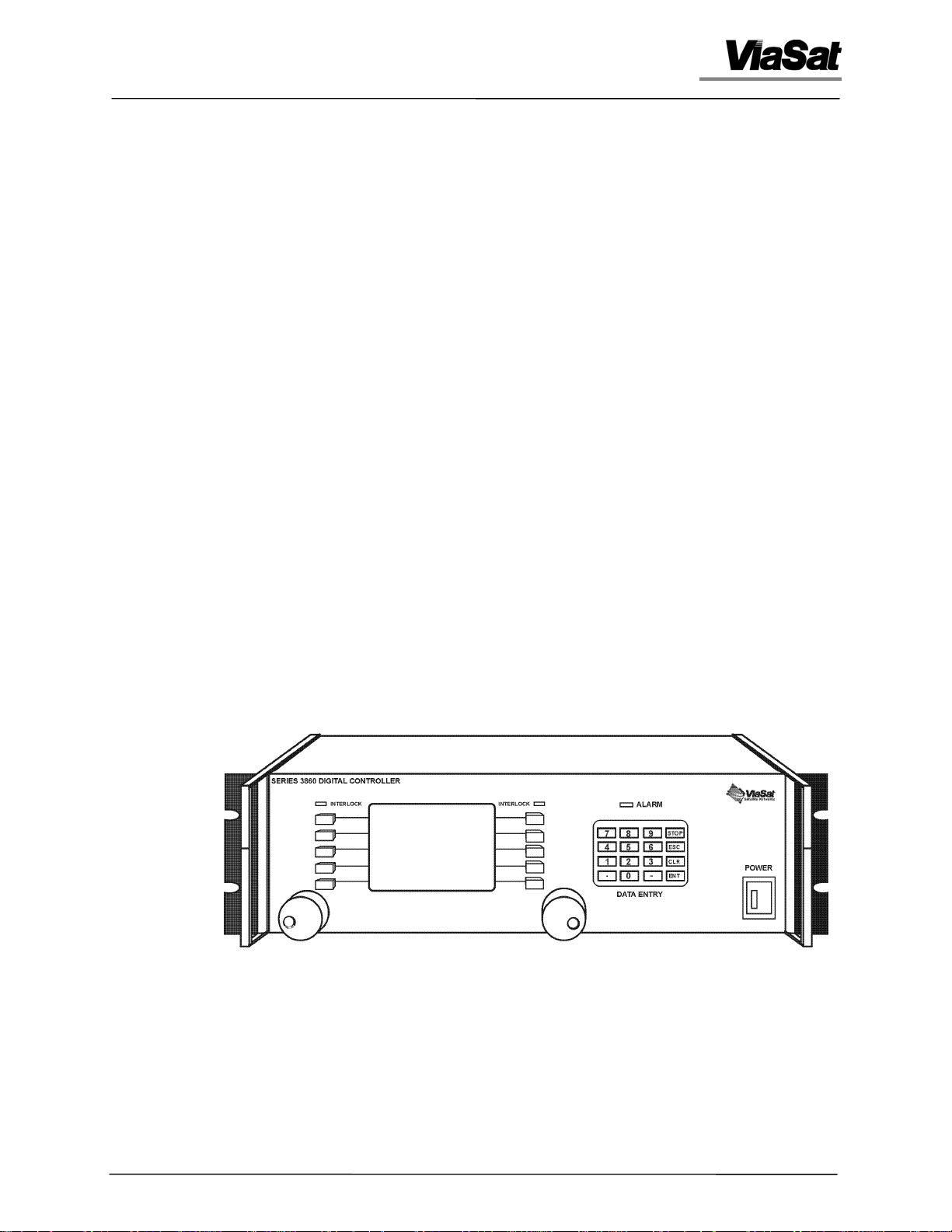

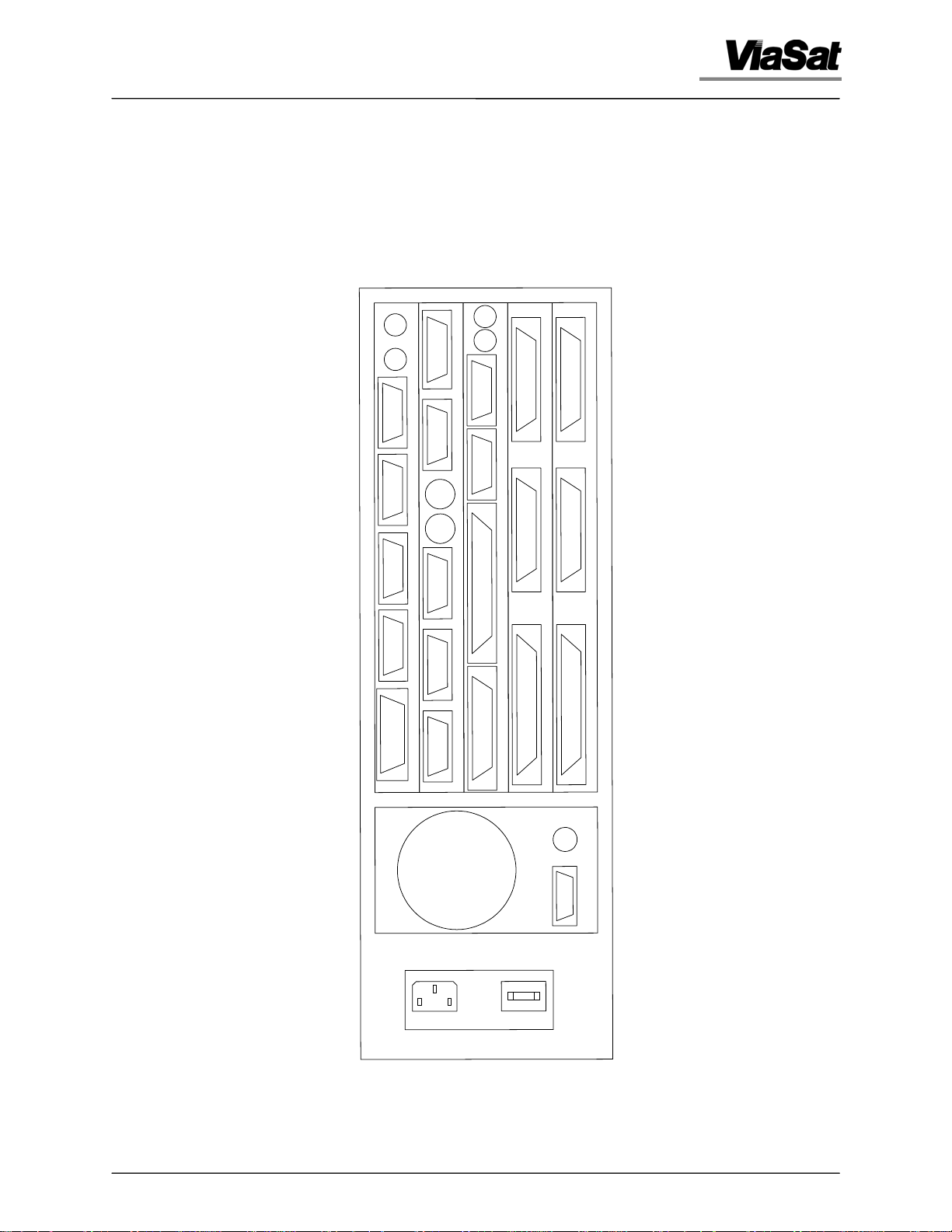

The Series 3860 of Digital Controllers (Figure 1.1) provide antenna pedestal

or positioner control in tracking, communications, and microwave

instrumentation applications. These controllers implement full digital servo loop

control and compensation in several control modes suitable for use with two-axis

pedestals and may be adapted for use with positioners having up to eight axes. The

controllers are available in a variety of physical and functional configurations to

provide maximum flexibility for any given application.

(NOTE: This illustration shows the single-chassis version.)

Figure 1.1. 3860 Digital Controller

3862 Autotrack Controller 1-2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Chapter 1 - General Information

1.6.1 Major Components

The Digital Controller is made up of several components combined in

modular fashion to provide the desired functions and physical configuration.

Each block or module performs a unique function. For applications not

requiring a particular function, the assembly or module providing that

function may be excluded from the controller. The following are the principal

components of the Digital Controller (see Chapter 4 for detailed descriptions

of each):

• Servo Assembly

• Synchro/Resolver Assembly

• Operator/Remote Interface Assembly

• Autotrack Assembly (Optional)

• Resolver Reference Assembly

• Analog Servo Rate Loop Assembly (Optional)

• Front Panel Assembly

• Motherboard Assembly

• DC Power Supply

1.6.2 Functional Configurations

The Model 3861 Manual Controller provides basic operator control of the

pedestal. This controller is equipped with a Servo Assembly and a

Synchro/Resolver Assembly and includes the enclosures and/or interfaces

appropriate to the physical configuration selected. The Model 3861 operates

using an indoor control panel or an external computer and remote interface.

The Model 3862 Autotrack Controller includes the Autotrack Assembly

which allows operation with automated tracking systems. The automated

tracking (Autotrack) function requires input of both a signal strength and a

tracking video signal from the receiver. The Autotrack function can be used

with a wide variety of feeds and is compatible with ViaSat Satellite Networks

ESCAN and MONOSCAN tracking feeds and the associated digital

demodulation techniques.

The Model 3863 Steptrack Controller is equipped with steptrack capability

which allows operation with step tracking subsystems. The steptrack

function is contained within the Operator/Remote Interface Assembly or

within a computer subsystem equipped with the PC Interface Module. The

steptrack function requires an automatic gain control (AGC) signal from a

receiver and may be used with a wide variety of feeds.

3862 Autotrack Controller 1-3

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Chapter 1 - General Information

1.6.3 Physical Configurations

The unit may be provided with all components housed in either one or two

rack-mounted chassises as shown in Figure 1.2.

A single-chassis configuration is used in most systems. Using the singlechassis requires that all electrical control cables extend from the pedestal into

the control room and be connected directly to the 3860.

Two-chassis configurations are used in large pedestal systems where it is

possible to mount a rack-mounted chassis within the base extension. The

two-chassis configuration greatly reduces the length and number of

electrical control cables from the pedestal into the control room by placing

the functional modules that interface to the pedestal within the pedestal

equipment. The second chassis provides the operator controls and indicators.

The two chassises are functionally connected by a full-duplex fiber optic link.

The operator interface components include the keypad, display screen,

position knobs, and power switch on the front panel. The unit chassis is 5.25

inches high and can be mounted in a standard, 19-inch-wide equipment rack.

All of the Series 3860 Digital Controller's printed wiring boards provide

direct cabling access through integral connector plates on the unit's rear

panel. A fan in the rear panel provides cooling for the enclosure.

3862 Autotrack Controller 1-4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Chapter 1 - General Information

Figure 1.2. 3860 Digital Controller Functional Configurations

3862 Autotrack Controller 1-5

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Chapter 1 - General Information

1.7 Specifications

Equipment characteristics and specifications are provided in Tables 1.1 and

1.2.

Table 1.1. Physical and Electrical Specifications

Characteristic Specification

Dimensions

Height 5.25 in. (133.35 mm)

Depth 18.00 in. (457.20 mm)

Width 19.00 in. (482.60 mm)

Weight 20 lb nominal

Input Power Requirements

Voltage 110V ac at 150W or 220V ac at 150W

Frequency 47 to 440 Hz

Host Communication Interface Serial Link

Selectable Media RS-422, RS-232, or IEEE-488

Communication Rate 9600 Baud

Controls and Indicators

Display High contrast LCD display

Mode Selection Menu-driven function keys plus full numeric

keypad

Axis Position Controls Analog position knobs and joystick for 2 axes

Status Displays Up to 32 optically isolated and 32 TTL lines to

report various system functions

Servo Functions Digital servo compensation with four user-

selectable servo loop bandwidths. Typically two

axes can be configured to control up to eight

pedestal or positioner axes

Pedestal Control Modes Standby, Rate (Slew), Position, Autotrack, Slave,

Remote and Scan

Pedestal Position Feedback Six independent synchro/resolver to digital

converters channels

3862 Autotrack Controller 1-6

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Chapter 1 - General Information

Table 1.2. Environmental Specifications

Characteristic Specification

Ambient Temperatures

Operation -0°C to +40°C (+32°F to +104°F)

Storage -20°C to +60°C (-4°F to +140°F)

Relative Humidity 0% to 95%, without condensation

Altitude

Operation 10,000 feet

Storage 50,000 feet

Cooling Fan cooling

Shock and Vibration Normal benchtop handling and commercial

shipping

1.8 Glossary of Symbols and Abbreviations

The following list defines symbols and abbreviations used in this manual.

Symbol or

Abbreviation

ABS automatic beam switching

ac alternating current

ACQTIM acquire time

A/D analog-to-digital

ADC analog-to-digital converter

AGC automatic gain control

AMPL amplitude

AUTOTRK autotrack

AUTODV auto diversity

AZ azimuth

Definition

BIT built-in test

BKMODE backup mode

C celsius

CHANN channel

CMD, CMND command

3862 Autotrack Controller 1-7

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Chapter 1 - General Information

Symbol or

Abbreviation

Definition

COMPSN compensation

CONFIG configuration

DAC digital-to-analog converter

dc direct current

DISABL disable

EL elevation

F fahrenheit

FDSCAN feed scan

FNTPNL front panel

Hz hertz

I/O input/output

kHz kilohertz

LCD liquid crystal display

LCL local

LED light-emitting diode

LCLRMT local/remote

LNCHAC launch angle

LOWTRK low track

mA milliampere

mm millimeter

MAXANG maximum angle

MINANG minimum angle

MLTPTH multipath

NS PWR noise source power

NVRAM nonvolatile RAM

ORI operator remote interface

PC personal computer

PED pedestal

PID proportional/integral/derivative

POS, POSN position

POSERR position error

POSMEM position memory

POSNFL, PFLT position filter

3862 Autotrack Controller 1-8

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Chapter 1 - General Information

Symbol or

Abbreviation

POSTIM position time

PSTART position start

PWB printed wiring board

PWR power

RAM random-access memory

RATEFL, RFLT rate filter

RCALL recall

RCVR receiver

RF radio frequency

ROM read-only memory

RTEMEM rate memory

RTETIM rate time

RUNSTP run step response

SECT sector

Definition

STAT status

STPRSP step response

STEPTR step track

STPSZE step size

TESTPT test point

THRHLD threshold

TIM DUR time duration

TQBIAS, TQB torque bias

TRAVL travel

TTL transistor-transistor logic

V volts

W watts

3862 Autotrack Controller 1-9

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Chapter 1 - General Information

Blank

3862 Autotrack Controller 1-10

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Chapter 2 - Installation

Chapter 2

Installation

2.1 Introduction

This chapter provides instructions and guidelines for installing the Series

3860 Digital Controller and for reshipment and storage as required.

2.2 Unpacking and Inspection

While unpacking, carefully compare bill of lading with equipment received.

Inspect for transit damage. If equipment is missing, carefully check and sift

through packing material to confirm. If errors are confirmed, notify ViaSat

and carrier as soon as possible.

2.2.1 Damage or Loss During Shipment

When equipment is damaged or lost in transit, the delivering transportation

company is required by law to make notation of damage or loss on the

freight bill. The carrier, not the shipper, should be charged with all damage

or loss. If damage or loss during shipping occurs, contact the carrier of the

equipment. Save the shipping carton. The carrier's inspector must examine

the carton and complete an inspection report.

2.3 Equipment Return

ViaSat makes every reasonable effort to ensure that all items arrive safely and

in working order. When equipment is received, which is not in working

order, return the equipment to the factory for repair or replacement. Return

the equipment according to the following procedure. This procedure will

apply whenever equipment is returned for warranty or other services.

a) Notify ViaSat of the problem and request a Return Material

Authorization (RMA) number and shipping instructions. For a

current list of telephone and email contact information refer to

Contact Information section of the ViaSat internet site

(http://www.viasat.com).

b) Tag or identify defective equipment and note defect and

circumstances, if any. If known, reference sales order, purchase order,

and date equipment was received.

c) Reship equipment in original shipping container or use a strong

shipping container to protect equipment during shipment.

3862 Autotrack Controller 2-1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Chapter 2 - Installation

d) Package equipment using shock-absorbing material around all sides

of equipment.

e) Seal container securely and mark outside of container FRAGILE.

2.4 Installation Procedure

2.4.1 General

The 3860 Digital Controller indoor configuration is shipped fully assembled

and is designed to be installed in a standard 19-inch panel width equipment

rack. The unit should be mounted on chassis slides or angle chassis supports.

The controller is cooled by forced air flowing through one side and the rear

panel of the unit. The mounting location should be selected to avoid blocking

the side panel's air flow or access to the rear-panel cable connections. The

unit should not be installed adjacent to other high-heat-producing units.

2.4.2 Chassis Slide Mounting

Two captive nuts (6-32) are provided on each chassis side panel for

attachment of chassis slides. The nut pattern matches standard chassis slides.

A typical example of slide mounting is shown in Figure 2.1.

Figure 2.1. Typical Slide Mounting

3862 Autotrack Controller 2-2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Chapter 2 - Installation

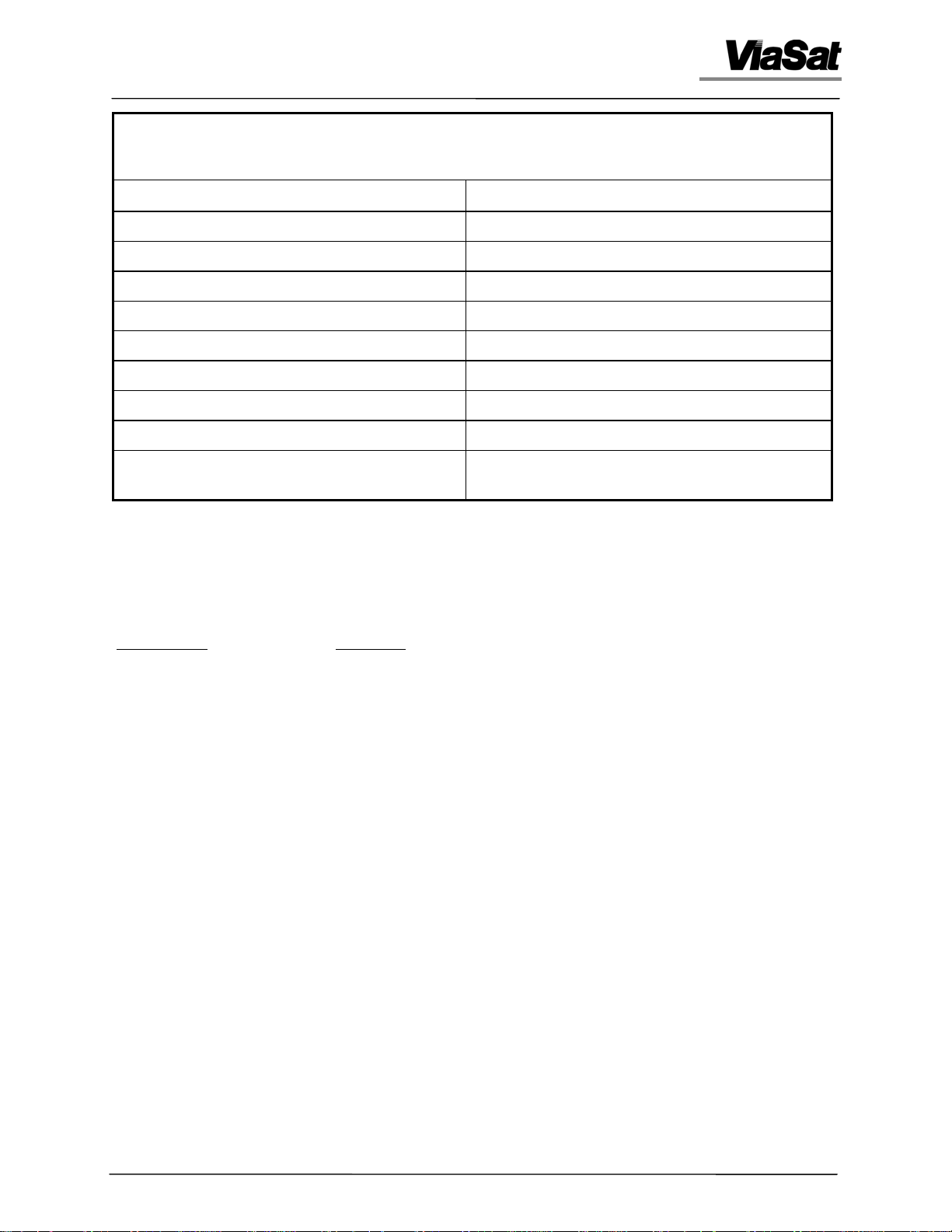

2.4.3 Cable Connectors

External cables connect directly to each component assembly on the digital

controller's rear panel. Each connector is identified by a reference designation

permanently marked on the rear panel (see Figure 2.2). A list of rear-panel

connectors with functional descriptions is provided in Table 2.1. Tables 2.2

through 2.22 provide pinout information for each connector excluding the

fiber-optic connectors. For units purchased as part of an integrated system,

refer to the appropriate system cabling diagram for cable connections.

Avoid shorting signal lines together or to chassis when

attaching cables. Equipment damage can result from failure to

observe this precaution.

CAUTION

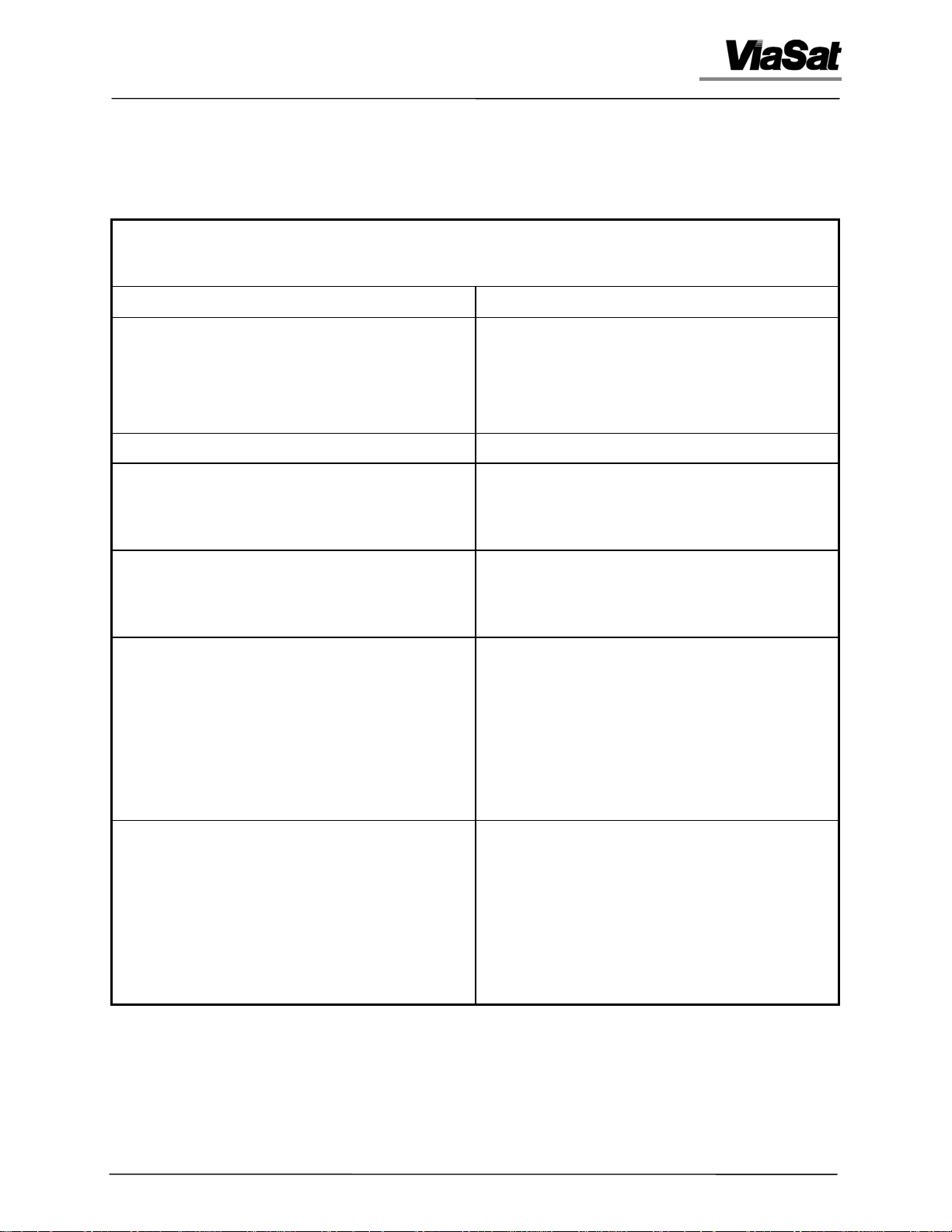

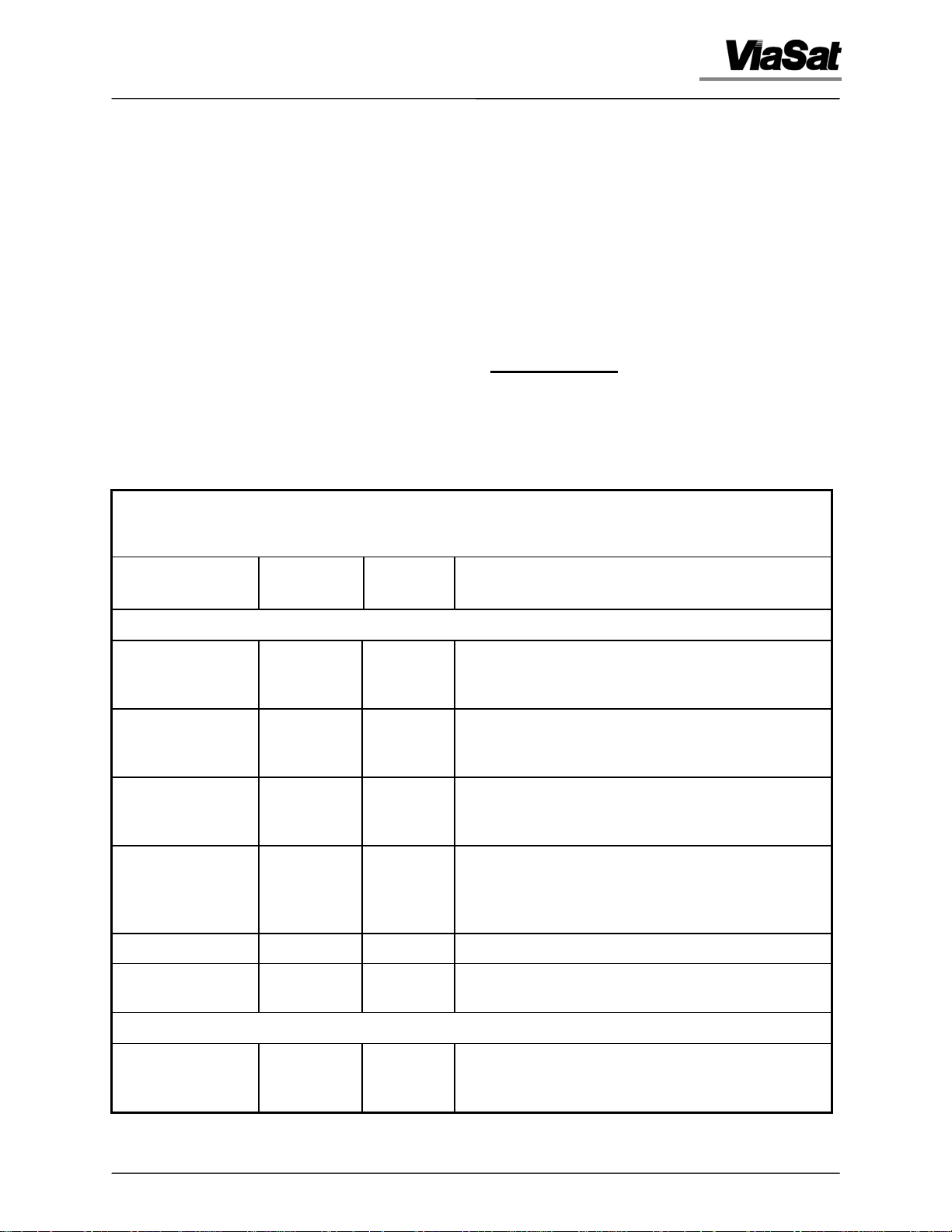

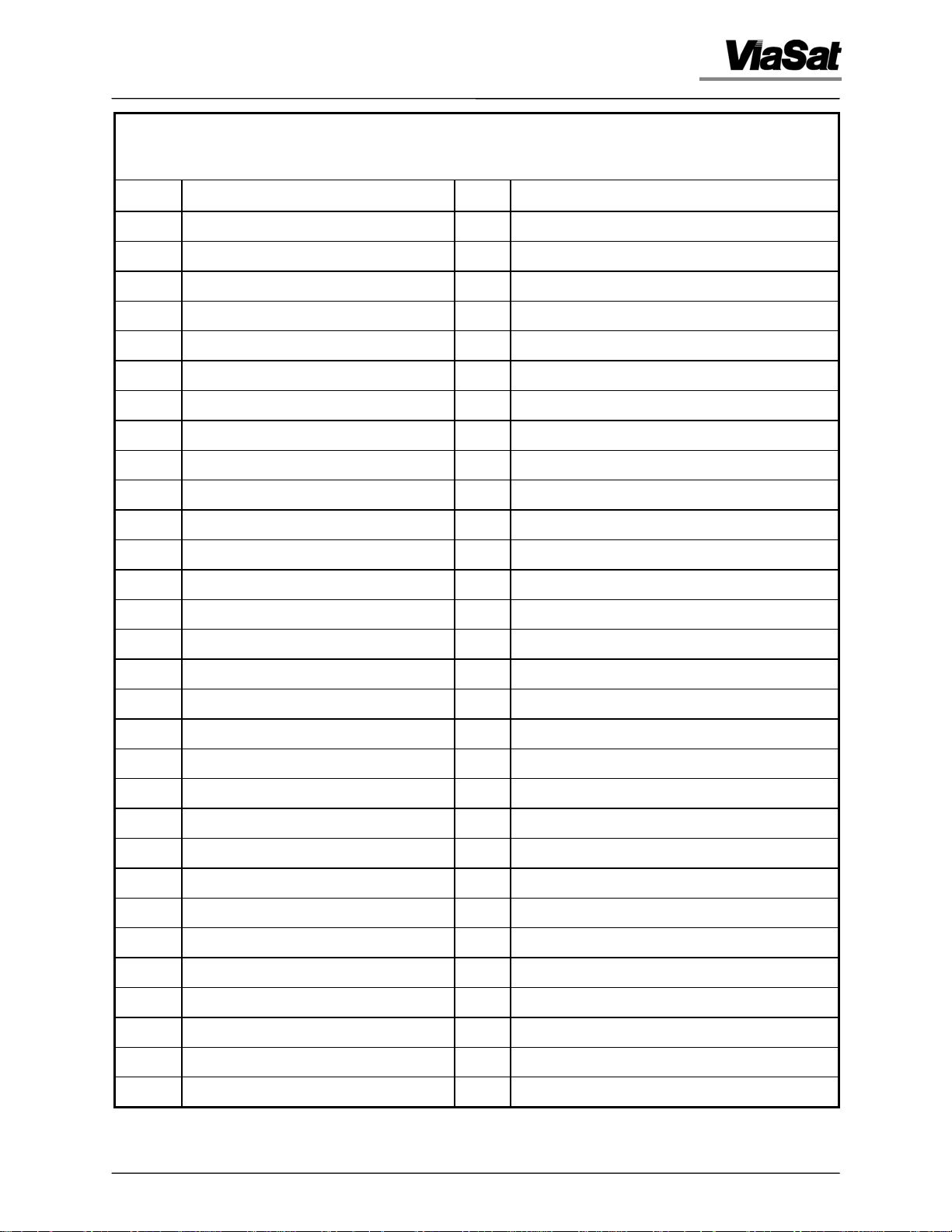

Table 2.1. 3860 Digital Controller Rear-panel Connectors

Function

Reference

Designation

Connector

Type

Interface Description

Servo Assembly

Analog I/O J101 DB25

Male

Digital I/O J102 DB62

Female

Serial Link 1 J103 DB9

Male

Serial Link 2 J104 DB9

Male

Fiber-optic Receiver J105 ST This type ST connector is a fiber-optic command link.

This connector provides tachometer signal input and

command voltage to power amplifiers. Refer to

Table 2.2 for pin assignments.

This connector provides contact closure input and

relay driver output. Refer to Table 2.3 for pin

assignments.

This connector is the main command/status link to

the operator/remote interface board. Refer to Table

2.4 for pin assignments.

This connector is the RS-422/RS-232 auxiliary/local

control data link. Refer to Table 2.5 for pin

assignments. Refer to paragraph 2.4.6 for a

description of the GPS Time-code interface.

Fiber-optic

Transmitter

J106 ST This type ST connector is a fiber-optic status

reporting link.

Synchro/Resolver Assembly

Synchro/Resolver

Interface

3862 Autotrack Controller 2-3

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

J201 DB37

Female

This connector provides interface to resolvers or

synchros for axis position feedback or slave input.

Refer to Table 2.6 for pin assignments.

Chapter 2 - Installation

Table 2.1. 3860 Digital Controller Rear-panel Connectors

Function

Digital I/O J202 DB44

Auxiliary TTL I/O J203 DB44

Reference

Designation

Connector

Type

Female

Female

Operator/Remote Interface Assembly

IEEE-488 Remote

Interface

External Joystick J302 DB9

Analog Signals J303 DB9

Serial Port 1 J304 DB9

J301 IEEE-488

Female

Male

Male

Male

Interface Description

This connector provides contact closure sensing

inputs and relay driver outputs. Refer to Table 2.7

for pin assignments.

This connector is a configurable 32-bit TTL level I/O.

Refer to Table 2.8 for pin assignments.

This rear-panel connector provides a parallel data

interface conforming to IEEE-488-1978. Refer to Table

2.9 for pin assignments.

This connector provides connection to the table top

joystick used for az/el rate control. Refer to Table

2.10 for pin assignments.

This connector provides for AGC input for steptrack

operation. Refer to Table 2.11 for pin assignments.

This connector is the main command/status link to

the servo board. Refer to Table 2.12 for pin

assignments. Refer to paragraph 2.4.5 for a

description of the ouput data.

Serial Port 2 J305 DB9

Male

Fiber-optic Serial

Receiver

Fiber-optic Serial

Transmitter

J306 BNC This BNC connector is a fiber-optic status reporting

J307 BNC This BNC connector is a fiber-optic command link.

This connector is the link to the system computer.

Refer to Table 2.13 for pin assignments.

link.

Autotrack Assembly (Optional)

Receiver 1 and 2

Video and AGC

Receiver 3 and 4

Video and AGC

Receiver 5 and 6

Video and AGC

Channel 7 AGC J404 ST This type ST connector provides AGC input.

Channel 7 Video J405 ST This type ST connector provides tracking video

J401 DB9

Male

J402 DB9

Male

J403 DB9

Male

This connector is the receiver interface containing

signal strength and tracking video. Refer to Table

2.14 for pin assignments.

This connector is the receiver interface containing

signal strength and tracking video. Refer to Table

2.15 for pin assignments.

This connector is the receiver interface containing

signal strength and tracking video. Refer to Table

2.16 for pin assignments.

input.

3862 Autotrack Controller 2-4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Chapter 2 - Installation

Table 2.1. 3860 Digital Controller Rear-panel Connectors

Function

Feed Scanner

Interface

Serial Link 1 J407 DB9

Reference

Designation

J406 DB9

Connector

Type

Male

Male

Analog Rate Loop Assembly (Optional)

Analog I/O J501 DB25

Female

Analog I/O J502 DB25

Male

Analog I/O J503 DB25

Female

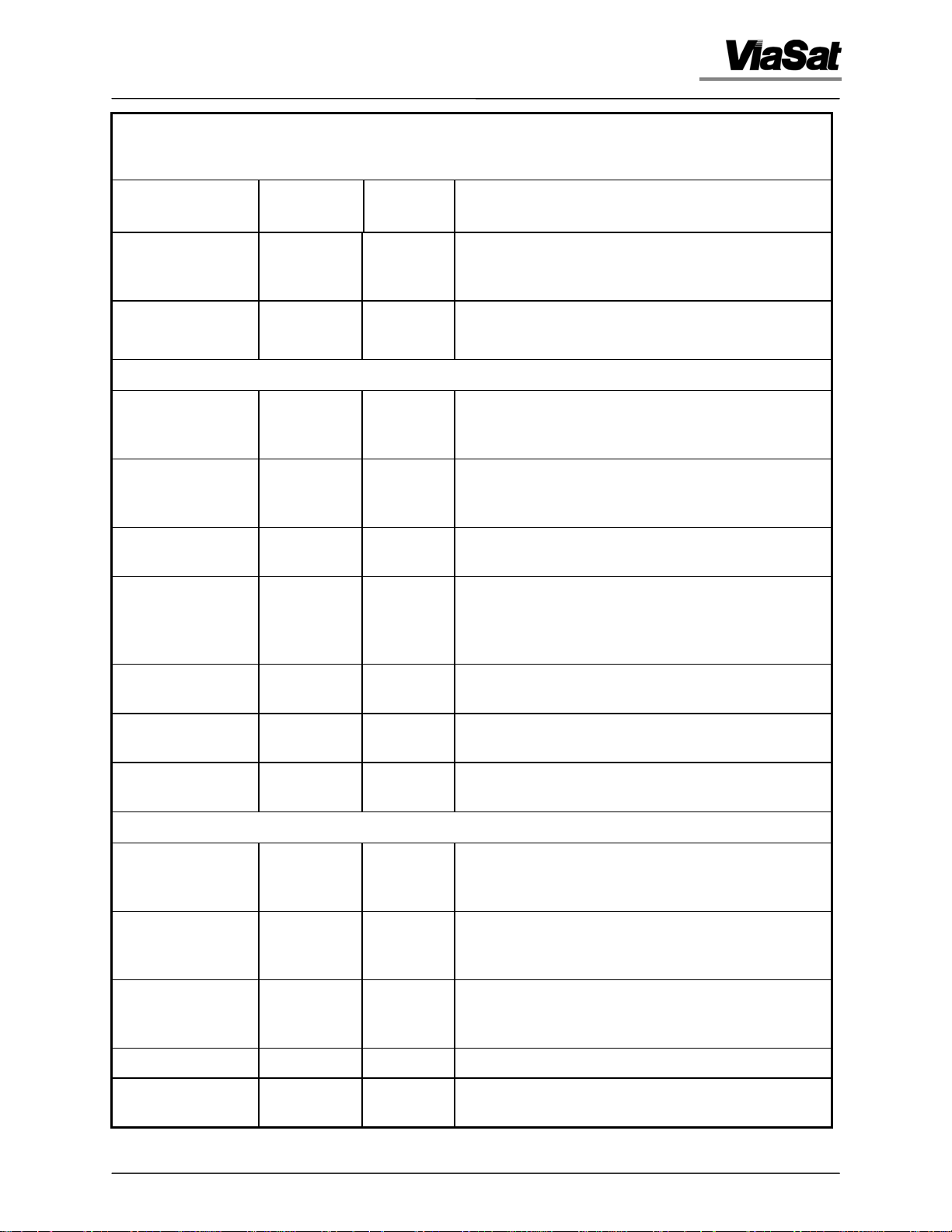

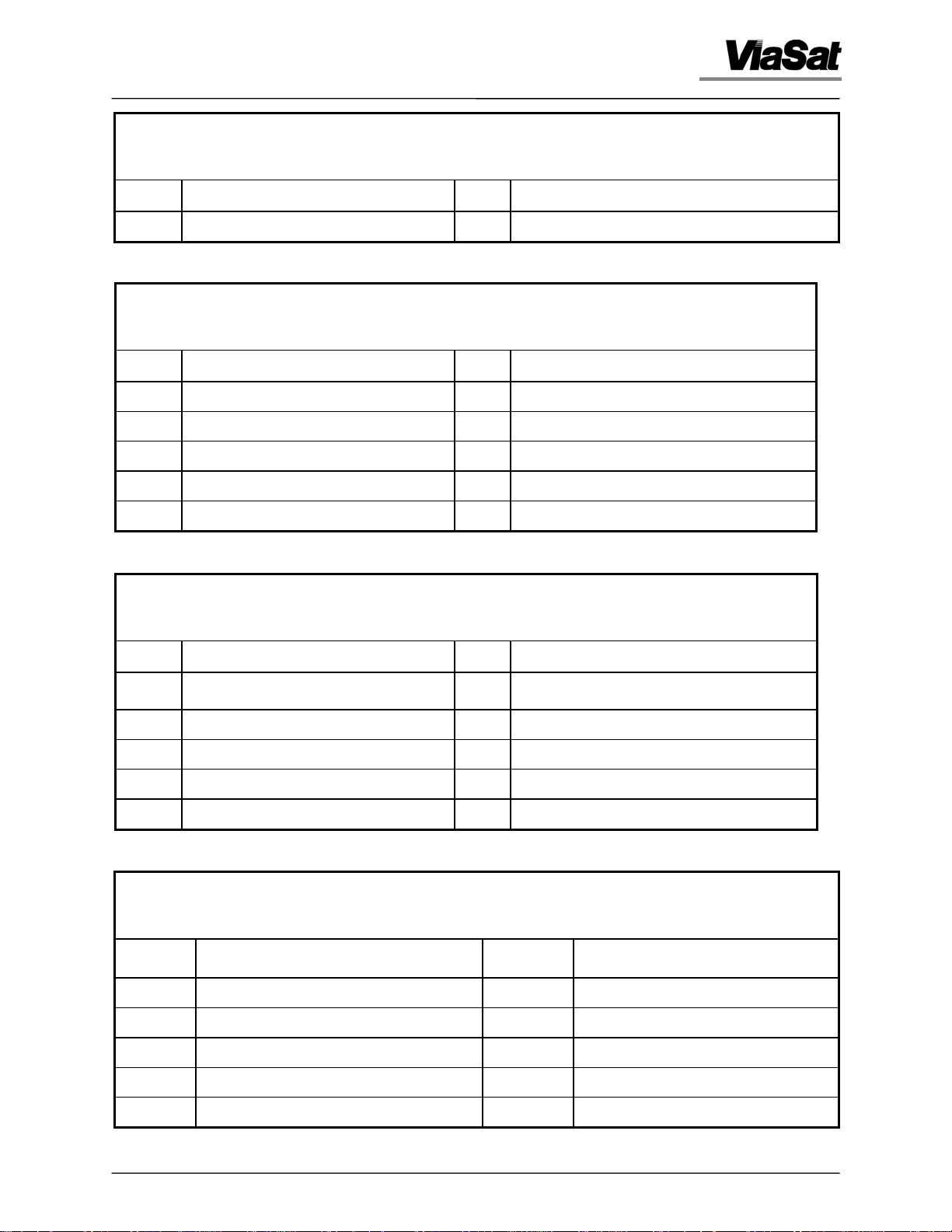

Table 2.2. Pin Functions for J101, Analog I/O

Interface Description

This connector provides feed scan driver output.

Refer to Table 2.17 for pin assignments.

This connector is the command/status link to the

servo board. Refer to table 2.18 for pin assignments.

This connector provides input rate command from

the position loop. Refer to Table 2.19 for pin

assignments.

This connector provides tachometer signal input and

command to power amplifiers. Refer to Table 2.20 for

pin assignments.

This connector provides major test points. Refer to

Table 2.21 for pin assignments.

Pin Function Pin Function

1 GND 14 DAC6

2 AZZ TACH LO 15 DAC5

3 AGND 16 DAC4

4 AGND 17 DAC3

5 + 15 V 18 DAC2

6 Not Connected 19 DAC1

7 - 15 V 20 AMP_OUT (Test Point)

8 ADC10 21 MUX_OUT (Test Point)

9 ADC9 22 ADC4

10 ADC8 23 ADC3

11 ADC7 24 ADC2

12 ADC6 25 ADC1

13 ADC5

3862 Autotrack Controller 2-5

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Chapter 2 - Installation

E

T

O

M

E

R

/

R

O

T

A

R

E

P

O

D

D

R

R

A

O

B

E

C

A

F

R

E

T

N

I

7

0

3

J

6

0

3

J

5

0

3

J

4

0

3

J

3

0

3

J

D

A

R

O

A

B

O

K

B

C

A

O

V

R

T

R

E

O

T

S

U

A

7

0

4

J

6

0

4

J

5

0

4

J

4

0

4

J

3

0

4

J

D

R

E

A

/

O

R

H

C

N

Y

S

6

0

1

J

5

0

1

J

4

0

1

J

3

0

1

J

2

0

1

J

T

O

A

B

R

R

E

V

L

O

S

E

R

P

O

G

O

O

L

L

A

N

A

2

0

2

J

3

0

2

J

3

3

6

3

1

3

0

5

J

1

0

5

J

2

0

3

J

2

0

4

J

2

1

0

0

5

2

J

J

1

1

0

3

J

N

A

F

0

1

J

1

0

4

J

1

J

2

J

R

T

E

U

C

W

P

A

O

N

I

P

Figure 2.2. Typical Rear-panel Connector Interface

3862 Autotrack Controller 2-6

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Chapter 2 - Installation

Table 2.3. Pin Functions for J102, Digital I/O

Pin Function Pin Function

1 Pull-Up For CNTRL Output Lines 32 Not Connected

2 GND 33 Not Connected

3 GND 34 Not Connected

4 GND 35 Not Connected

5 GND 36 Not Connected

6 GND 37 Not Connected

7 External Pull-Up 38 Not Connected

8 Not Connected 39 Cmnd01

9 STAT16 40 Cmnd02

10 STAT15 41 Cmnd03

11 STAT14 42 Cmnd04

12 STAT13 43 Cmnd05

13 STAT12 44 Cmnd06

14 STAT11 45 Cmnd07

15 STAT10 46 Cmnd08

16 STAT09 47 Not Connected

17 STAT08 48 Not Connected

18 STAT07 49 Not Connected

19 STAT06 50 Not Connected

20 STAT05 51 Not Connected

21 STAT04 52 Not Connected

22 STAT03 53 Not Connected

23 STAT02 54 Not Connected

24 STAT01 55 Not Connected

25 Not Connected 56 Not Connected

26 Not Connected 57 Not Connected

27 Not Connected 58 Input Pull-Up For Stat09 - Stat16 Lines

28 Not Connected 59 Not Connected

29 Not Connected 60 Input Pull-Up For Stat08 - Stat01 Lines

30 Not Connected 61 Not Connected

3862 Autotrack Controller 2-7

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Chapter 2 - Installation

Table 2.3. Pin Functions for J102, Digital I/O

Pin Function Pin Function

31 Not Connected 62 Not Connected

Table 2.4. Pin Functions for J103, Serial Link 1

Pin Function Pin Function

1 GND 6 +RX1 RS-422

2 TX1 RS-232 7 Not Connected

3 –TX1 RS-422 8 RX1 RS-232

4 –RX1 RS-422 9 +TX1 RS-422

5 GND

Table 2.5. Pin Functions for J104, Serial Link 2

Pin Function Pin Function

1 CTS2 RS-232 6 +RX2 RS-422

2 TX2 RS-232 7 Not Connected

3 –TX1 RS-422 8 RX2 RS-232

4 –RX1 RS-422 9 +TX2 RS-422

5 GND

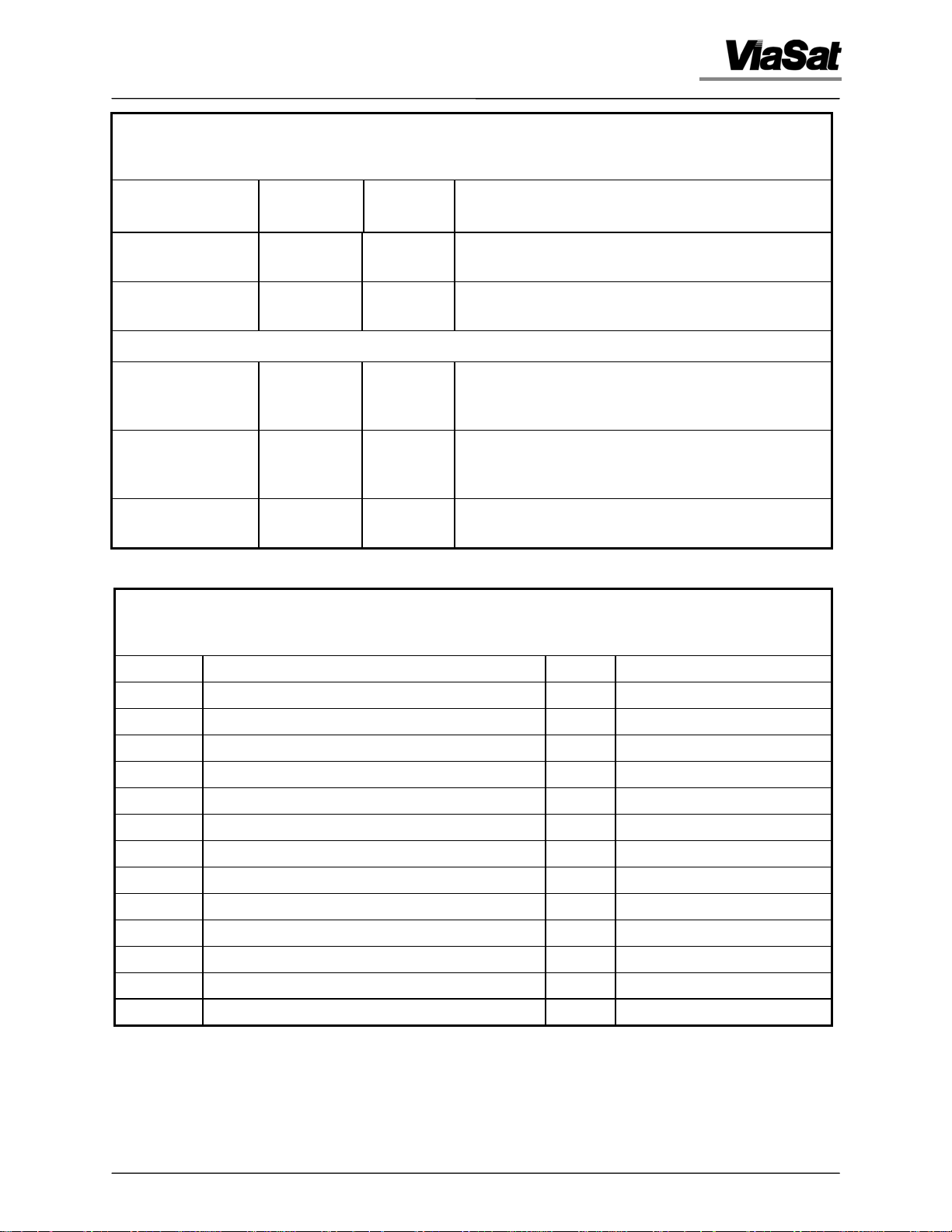

Table 2.6. Pin Functions for J201, Synchro/Resolver Interface

Pin Function Pin Function

1 Resolver Reference – 20 Resolver Reference +

2 Not Connected 21 S64 (Channel 6 Lead S4)

3 S63 (Channel 6 Lead S3) 22 S62 (Channel 6 Lead S2)

4 S61 (Channel 6 Lead S1) 23 Not Connected

5 S54 (Channel 5 Lead S4) 24 S53 (Channel 5 Lead S3)

3862 Autotrack Controller 2-8

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Chapter 2 - Installation

Table 2.6. Pin Functions for J201, Synchro/Resolver Interface

Pin Function Pin Function

6 S52 (Channel 5 Lead S2) 25 S51 (Channel 5 Lead S1)

7 Not Connected 26 S44 (Channel 4 Lead S4)

8 S43 (Channel 4 Lead S3) 27 S42 (Channel 4 Lead S2)

9 S41 (Channel 4 Lead S1) 28 Not Connected

10 S34 (Channel 3 Lead S4) 29 S33 (Channel 3 Lead S3)

11 S32 (Channel 3 Lead S2) 30 S31 (Channel 3 Lead S1)

12 Not Connected 31 S24 (Channel 2 Lead S4)

13 S23 (Channel 2 Lead S3) 32 S22 (Channel 2 Lead S2)

14 S21 (Channel 2 Lead S1) 33 Not Connected

15 S14 (Channel 1 Lead S4) 34 S13 (Channel 1 Lead S3)

16 S12 (Channel 1 Lead S2) 35 S11 (Channel 1 Lead S1)

17 Not Connected 36 Not Connected

18 Not Connected 37 Synchro Reference

19 Synchro Reference +

Standard Channel Designations:

Channel 1 — Azimuth Coarse

Channel 2 — Azimuth Fine

Channel 3 — Elevation Coarse

Channel 4 — Elevation Fine

Channel 5 — Azimuth Slave

Channel 6 — Elevation Slave

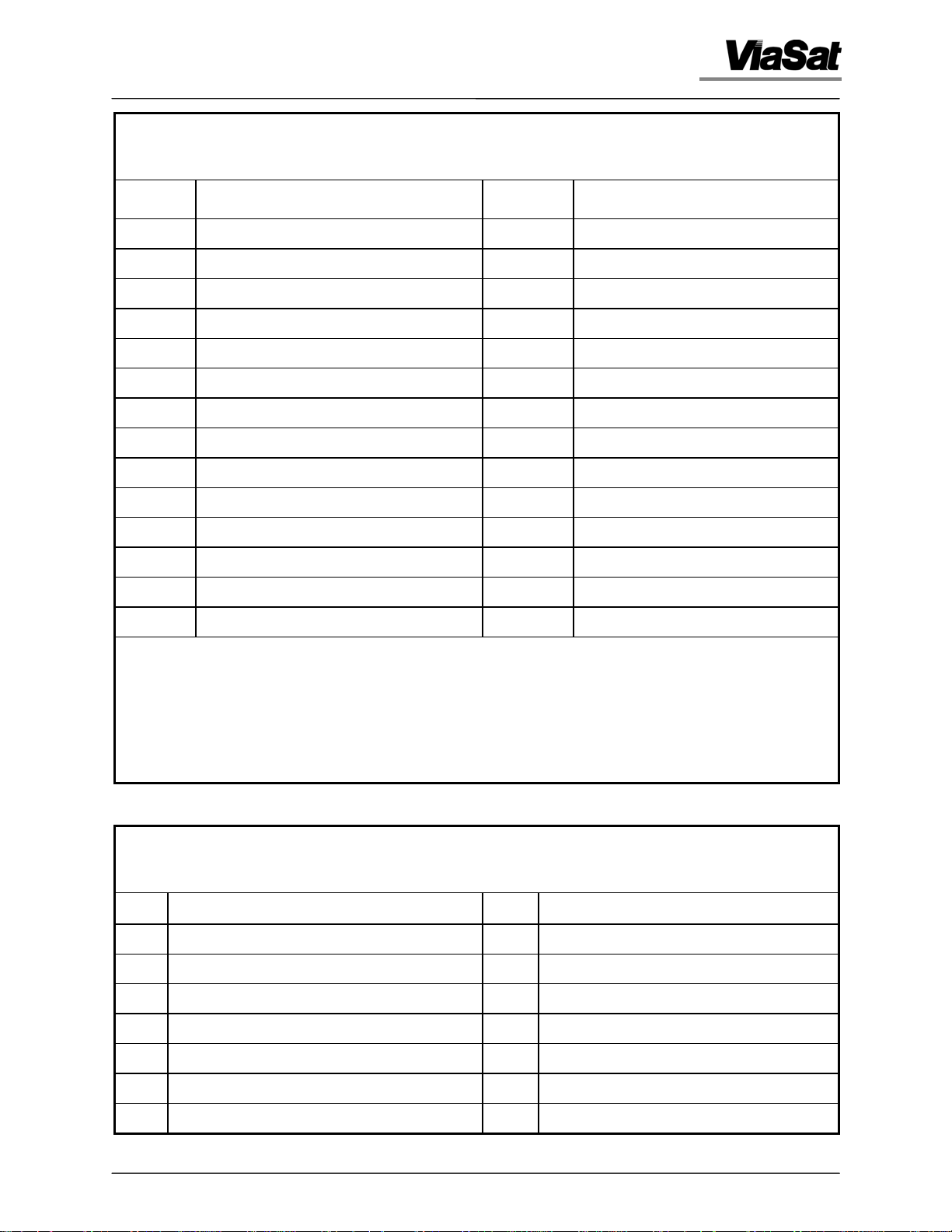

Table 2.7. Pin Functions for J202, Digital I/O

Pin Function Pin Function

1 STAT21 23 STAT31

2 STAT17 24 CMND17

3 CMND10 25 CMND19

4 CMND12 26 CMND21

5 CMND14 27 CMND23

6 CMND16 28 STAT25

7 STAT30 29 STAT27

3862 Autotrack Controller 2-9

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...