VHF Z4 Original Operating Instructions

Original Operating

Instructions

Z4

Originalbetriebsanleitung

Instrucciones de uso originales

Mode d’emploi d’origine

Istruzioni d’uso originali

dentalportal.info

Contents

EN 3

1 Welcome 5

About this document 5

Used symbols 5

Structure of safety notes 5

2 General safety instructions 6

3 Operating regulations 8

Intended use 8

Controlling the mac hine through software 8

Maintenance and cleaning 8

Spindle 8

Unattended operation 8

Transportation and storage 9

4 Machine overview 10

Front side of the machine 10

Rear side of the machine 10

Touchscreen 11

Working chamber door 11

Working chamber 11

Multi-purpose drawer 12

Required computer hardware software 12

Sound emission 12

Location of the identification plate serial number 13

Technical data 14

5 Installing the machine 15

Checking the scope of delivery 15

Choosing the installation site 16

Establishing the electric connection 18

Removing the transport lock 18

Checking the tool magazines in the drawer 18

CAD computer network integration 19

Internal CAM computer 19

Preparing the machine and CADcomputer 19

Accessing the CAM computer 20

Integrating the CAD with the CAM/ CNC software 24

6 Operation: Preparing jobs 31

Starting the machine 31

Starting the machine with a tool in the collet chuck 32

Shutting down the machine 33

If there is no connection to the CAM computer 33

Opening closing the working chamber door 34

Opening closing the multi-purpose drawer 35

The user interface on the touchscreen 36

The Home section of the touchscreen 36

The Jobs section of the touc hscreen 37

The Toolssection of the user interface 38

Exchanging the cooling liquid and cleaning the tank 38

Emptying the strainer basket 38

Exchanging or filling in the cooling liquid 39

Managing tools 41

Color codes of the tool magazines 41

Inserting and exchanging tools 41

Mounting exchanging tool magazines 43

Mounting removing blanks 46

7 Operation: Executing jobs 47

Overview 47

Starting jobs via the touchscreen 47

Aborting machining 49

Job interruptions and job abortions 49

How to proceed in case of a job interruption 50

How to proceed in case of a machine malfunction 50

How to proceed in case of a tool breakage 50

How to proceed in case of a power failure 50

Emergency opening of the working chamber door 51

Removing the back panel cover 52

Emergency opening of the multi-purpose drawer 52

8 Maintenance and do-it-yourself 53

Basic maintenance 53

Maintenance section 53

Preventive maintenance 53

Where to get service? 53

Definition of wear parts 53

Using the maintenance section 54

List of all maintenance tasks 55

Performing maintenance tasks 55

Leaving the Maintenance section 56

Cleaning the working chamber 57

Cleaning the collet chuck 58

Cleaning the nozzle plate 60

Cleaning the collet chuck of the blank holder 60

Rinsing the cooling liquid circuit 62

Exchanging the carbon filter 63

Cleaning the housing 64

Exchanging the main fuse 64

Calibrating the axes 65

Replacing the tool magazine inserts 65

Exchanging the coupling of the cooling liquid tank 66

Exchanging the view window wiper 67

Updating the software and firmware 68

Original Operating Instructions:Z4

Version: 12/5/2018

EN 4

Updating the firmware of the machine 68

Updating DentalCAM DentalCNC 68

Maintenance table 69

9 Disposal 71

Disposing of the cooling liquid 71

Disposing of the machine 71

10 Troubleshooting 72

Index 75

Contents

Original Operating Instructions:Z4

Version: 12/5/2018

Welcome

EN 5

1 Welcome

Thank you for your purchase of this Z4 dental

machine. The machine is delivered to you with pride

and confidence. It was produced using the latest techniques and strict quality control.

These operating instructions were prepared to help

you understand all functions of your new dental

machine. It should also help you keep the machine in

good conditions so that you may enjoy many hours of

productive work.

You may find updates to this document at:

dentalportal.info – search for

About this document

This document is designed and released for the

following groups/ individuals:

Authorized resellers

n

Authorized service technicians

n

Used symbols

Instructions

Single or general instruction

1.

Numbered action step

Result

Z4

Information to make work more efficient

Important information without any danger for

people or objects

Additional information

Structure of safety notes

SIGNAL WORD

Type and source of hazards

Further explanations and consequences when

ignoring the hazard.

Instructions to avoid the hazard.

The following signal words may be used:

DANGER

DANGER indicates a hazardous situation which will

result in death or serious injury.

WARNING

WARNING indicates a hazardous situation which can

result in death or serious injury.

Additional symbols

Cross reference

List (first level)

n

List (second level)

1.

Numbered image labels

CorrectorDo this

IncorrectorDo not let this happenorDont

do this

CAUTION

CAUTION indicates a hazardous situation which can

result in minor or moderate injury.

NOTICE

NOTICE indicates a situation which can lead to physical damage of the product or in the surrounding

areas.

Original Operating Instructions:Z4

Version: 12/5/2018

EN 6

Z4 – General safety instructions

2 General safety

instructions

DANGER

Incorrect operation of the machine

Before

machine, read

machine.

If it is unclear how to operate the machine in any

way, do not use the machine and contact customer service.

Ensure that every user has access to the operating

instructions.

Instruct every user on safe and proper machine

handling.

Danger to life due to an electric shock

ficantly.

Do not remove the housing of the machine.

Only have qualified electricians work on any electric equipment.

Ensure that an operational Residual Current

Device/ Ground Fault Circuit Interrupter is

installed on the electric circuit of the machine.

Run power cables so that they cannot be damaged by sharp edges.

Before

cables for damage.

Before

the machine at the main power switch.

diately and prevent it from being restarted:

n

n

n

Replace damaged cables with original manufacturers spare parts.

Never perform any troubleshooting while the

machine is operating.

Only have authorized service technicians repair

the machine.

installing, maintaining and operating the

documents provided with the

all

If you come into contact with electrically

charged parts, you can suffer from an electrical shock. Water increases the risk signi-

switching on the machine, check power

unplugging the power cable, switch off

In the following cases, disconnect the

machine from the electrical source imme-

When machine connections or electric cables are

damaged

When water is leaking

Before

you check or run electric cables

Do not touch the machine and especially the

cables with wet or damp hands.

Check the environment of the machine and all

accessible internal areas daily for leaked liquid and

remove any liquids near or in the machine immediately.

Never put any machines or devices which are

powered by electricity under the machine.

Do not put any objects onto the machine.

WARNING

Respiratory diseases when processing

harmful materials

If you inhale harmful materials during their processing,

your respiratory tracts may be damaged.

Avoid materials which damage your health.

Crushing hazard and risk of cutting injuries

through moving machine parts

Through the moving axes and the rotating spindle you

can suffer bruises and cuts.

Only use the machine when the working chamber

door is completely closed and undamaged during

machining.

Do not circumvent or deactivate safety devices of

the machine.

Check the machine regularly for damage, especially the safety devices.

Have damaged safety devices repaired by customer service only.

Use only original manufacturer’s equipment and

original spare parts in the machine.

Keep children and animals away from the

machine.

Do not remove the housing of the machine.

Service Mode: Risk of cutting injuries and

bruises as well as hazards through ejected

debris

If you operate the machine in any “Service Mode”

with the working chamber door open, the risk of

injury is increased significantly.

Operate the machine in “User“mode only unless

you have been authorized by the machines manufacturer to use other modes.

Even if you are an authorized user, use the “Service Modes” only when necessary.

While in any “Service Mode”: Do not reach

into the working chamber while the axes are

Original Operating Instructions:Z4

Version: 12/5/2018

Z4 – General safety instructions

EN 7

moving or during machining.

While in any “Service Mode”: Everyone

within reach of the machine must wear pro-

tective eye wear.

Hearing damage due to loud noise

If you are regularly exposed to loud machining noise,

you may suffer from hearing loss and tinnitus.

If loud noise cannot be avoided, wear ear

protection during machining.

CAUTION

Risk of injuries when opening or closing the

working chamber door

When you open or close the working chamber door,

the moving working chamber door may crush your

fingers. Objects on the machine may fall and cause

injuries or damage.

While the door is moving, keep both hands away

from the machine.

Do not place objects on the machine.

Health risks through constant

malpositioning if your working

environment is not sufficiently ergonomic

Over the long run, an improper or one-sided positioning can be a risk to your health.

Set up an ergonomic work environment.

Ensure the seat height and monitor position is

ideal and the lighting is sufficient.

Trip, fall and slipping hazards

Run cables in such a way that persons cannot trip over them.

Keep the working environment and installation site clean.

Risk of cutting injuries and burns

If you touch tools or sharp edges on blanks or the

machine, you may suffer from cuts. If you touch the

hot spindle body or hot tools, you may suffer from

burns.

Wear gloves when you perform manual work at

the machine or with blanks / tools.

Reduced ability to act with insufficient

lighting

In case of an insufficient lighting your judgment and /

or your precision may be reduced.

Ensure that the lighting in your working environment is sufficient.

Risk of injury in case of malfunctions caused

by insufficient maintenance

If you do not maintain the machine as required,

malfunctions may occur which can lead to injuries.

Take note of the intervals and conditions mentioned in the maintenance table in the operating

instructions. Carry out the respective maintenance

tasks accordingly.

Original Operating Instructions:Z4

Version: 12/5/2018

EN 8

Z4 – Operating regulations

3 Operating regulations

If you violate the following regulations, you may lose

your entitlement to benefits.

NOTICE

Machine damage if you violate these

regulations

If you violate the following regulations, your machine

may get damaged and/ or cause damage in the

surrounding area(s).

Thoroughly follow all instructions and information

in this section.

Intended use

The machine and the manufacturing software have

been designed for the commercial creation of dental

objects by specially trained persons. The objects

require additional work before their use on patients.

Only process materials that you can select in the

manufacturing software.

Only use the machine and manufacturing software

in a commercial environment.

Before creating jobs, verify if the objects being prepared may be utilized at the place of use according to local and/ or national regulations or other

authorized organizations or entities (e.g. professional associations, health authorities). In particular, verify if the material is approved for the

machined object type and if the object type is

designed in accordance with applicable regulations. Neither the manufacturing software nor

the machine will inform you about possible regulatory infringements, but will execute jobs in

accordance with the preferences and materials set

by the user.

Verify that each object type and each material in

your jobs are authorized manufacturing materials.

If mandated by local or national regulations, obtain

relevant authorization from the responsible organizations or entities (e.g. professional associations,

health authorities).

Only manufacture objects which correspond to

the object types that you can select in the manufacturing software. While you can import/ manufacture any other objects as well, neither the

manufacturing software nor the machine are

designed for these other objects and should not

be used in this way.

Do not manufacture implants or parts of objects

that are designed to have contact with implants.

These parts include parts of two-part abutments

which contain the connection geometry for the

implant. Do not manipulate the connection geometry of prefabricated abutments (“prefab abutments”) and you must always check finished

objects for accurate connection geometries (i.e.

that connection geometries of finished jobs have

not been damaged).

Controlling the machine through software

You control the machine through specially designed

applications which are supplied with the machine.

Always use the latest program version that officially

supports your machine.

Before installing or operating the machine, read

the documentation forthe applications.

Ensure that your CAM computer meets all system

requirements.

Maintenance and cleaning

Maintenance and cleaning is part of standard machine

usage.

Clean and maintain the machine as required. Only

then can the machine reach a long service life.

Spindle

The spindle of your machine is a high-precision instrument.

Do not use unbalanced tools at high rotational

speeds. Such an imbalance puts a great strain on

the spindle’s ball bearings, which can cause the

bearings to be damaged.

When working in the working chamber, do not

apply manual pressure against the spindle.

Unattended operation

If the machine runs unattended, the risk of material

damage is increased.

Only allow unattended operation of the machine

to occur if the following conditions are met:

The national and local laws allow it.

n

n

The working chamber of the machine is completely clean.

n

Unauthorized users cannot access the machine.

The room in which the machine is located has an

n

automatic fire detection system.

Original Operating Instructions:Z4

Version: 12/5/2018

Z4 – Operating regulations

Transportation and storage

WARNING

Injuries caused by unsafe transportation

If you transport the machine unsafely, the machine

may slip and cause injuries.

Always transport

vidually and do not stack them.

Ensure that only trained personnel transport the

machine to and from the installation site.

Ensure that the housing of the machine is completely closed.

Always transport the machine in an upright position.

Transport and position the machine with

2people.

Before carrying an unpacked machine, install the

carrying aid that was provided with the machine

and ensure that all components are properly fixed .

unpacked

Do not use a different carrying aid

Grab unpacked machines only at the

handles of the carrying aid.

the machine when carrying it.

machines indi-

.

Do not tilt

EN 9

6.

Install the transport lock. For this, follow the corresponding steps on the supplement in reverse

order.

7.

Ensure that the housing of the machine is completely closed.

8.

Shut down the machine via the touchscreen.

9.

Switch off the machine at the main power switch.

10.

Disassemble the machine components by following the installation instructions in reverse

order.

11.

If you need to carry the machine, install the carrying aid. For this, follow the corresponding steps

on the supplement in reverse order.

12.

In case of overseas transport, take proper measures against corrosion.

Repackaging

To repack the machine after preparing its transportation or storage, the following steps are necessary:

1.

If possible, use the original packaging. If the original packaging is not available, use a packaging

of similar size and quality.

Original packaging is available from

customer service.

The supplement about the carrying aid and

transport lock is delivered with the machine.

It is also downloadable at

dentalportal.info/downloads

Ensure that the following conditions are met during the whole transport and/ or storage period:

n

Ambient temperature (storage/ transport):

between -20°C and 60°C

Relative air moisture: max. 80, non-con-

n

densing

.

Preparing transportation or storage

Before transporting or storing your machine, the

following preparations are necessary:

1.

Remove all blanks from the working chamber.

2.

Remove the tool magazine from the working

chamber.

3.

Rinse the cooling liquid system.

4.

Drain and clean the cooling liquid tank.

5.

Clean the working chamber.

2.

Pack the machine and its accessories securely.

3.

Protect the packaging against slipping. If

machines are properly packed and protected

against slipping, they may be stacked.

Original Operating Instructions:Z4

Version: 12/5/2018

EN 10

Z4 – Machine overview

4 Machine overview

With your Z4 you can process blanks of different materials to create high quality objects for the dental sector.

You can find a list of the materials which you can

process with the machine in the manufacturing software.

The machine is designed for wet machining.

During wet machining, the tools and blanks are

constantly being cooled by cooling liquid.

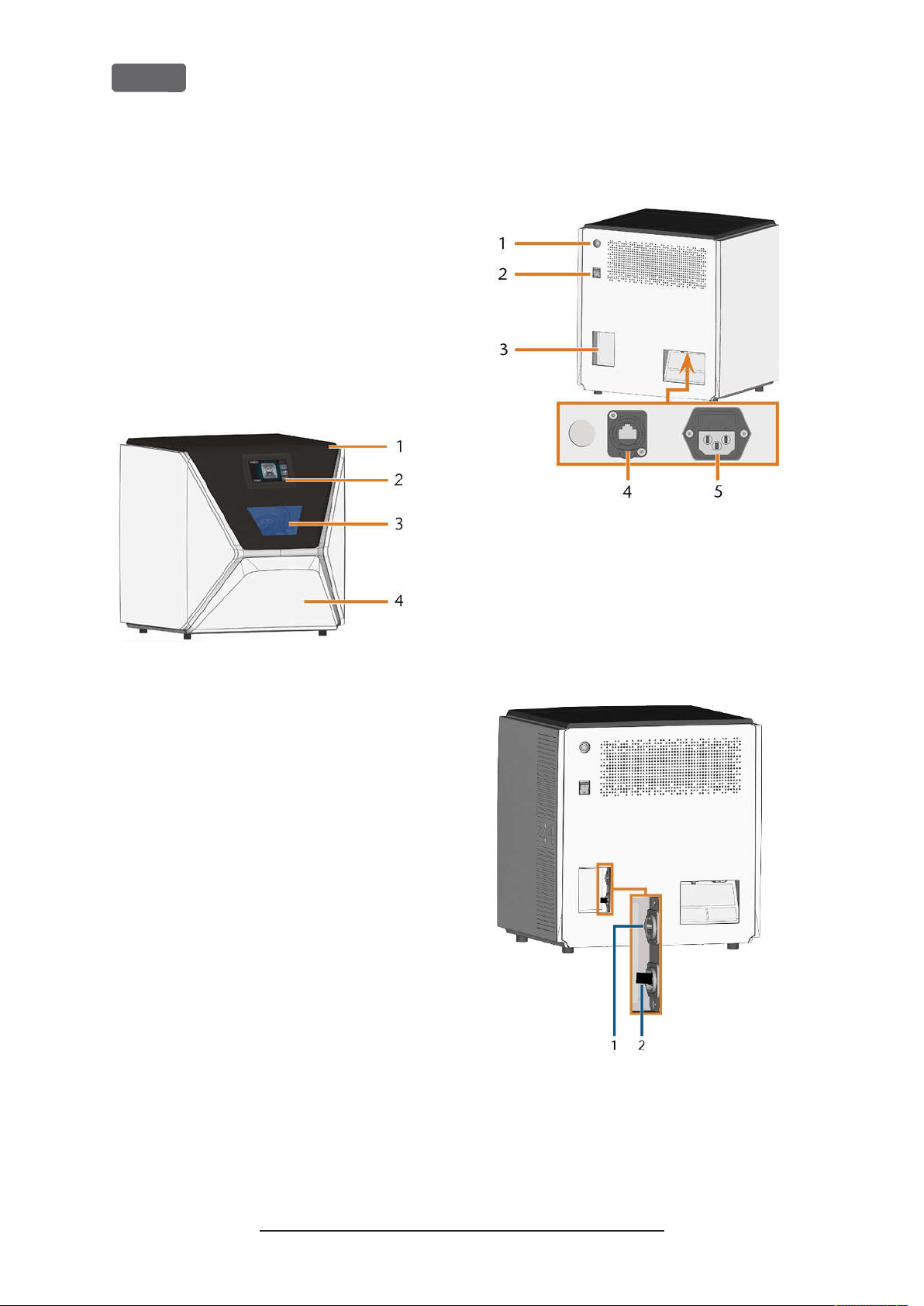

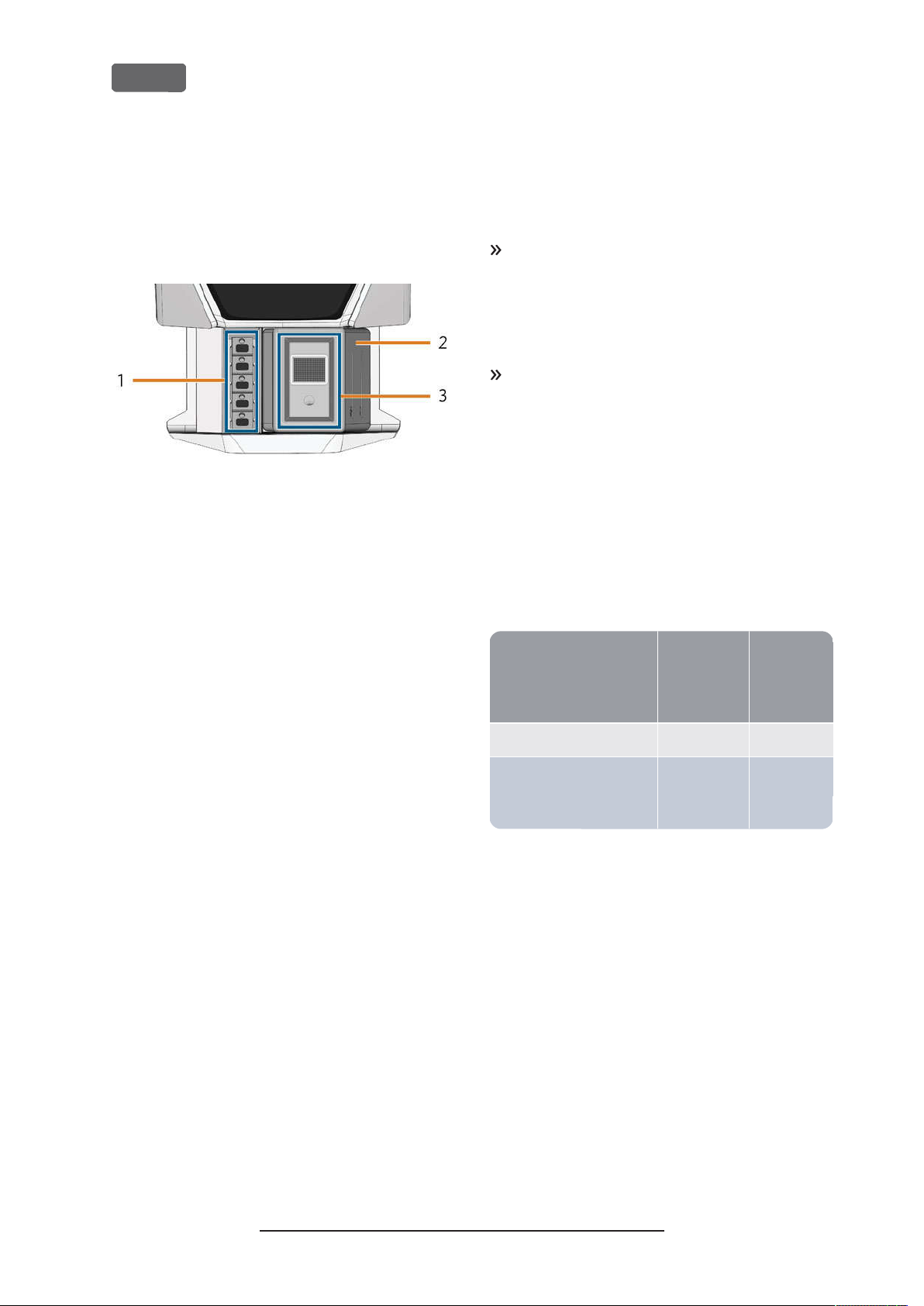

Front side of the machine

RONT SIDE OF THE MACHINE

FIG. 1 – F

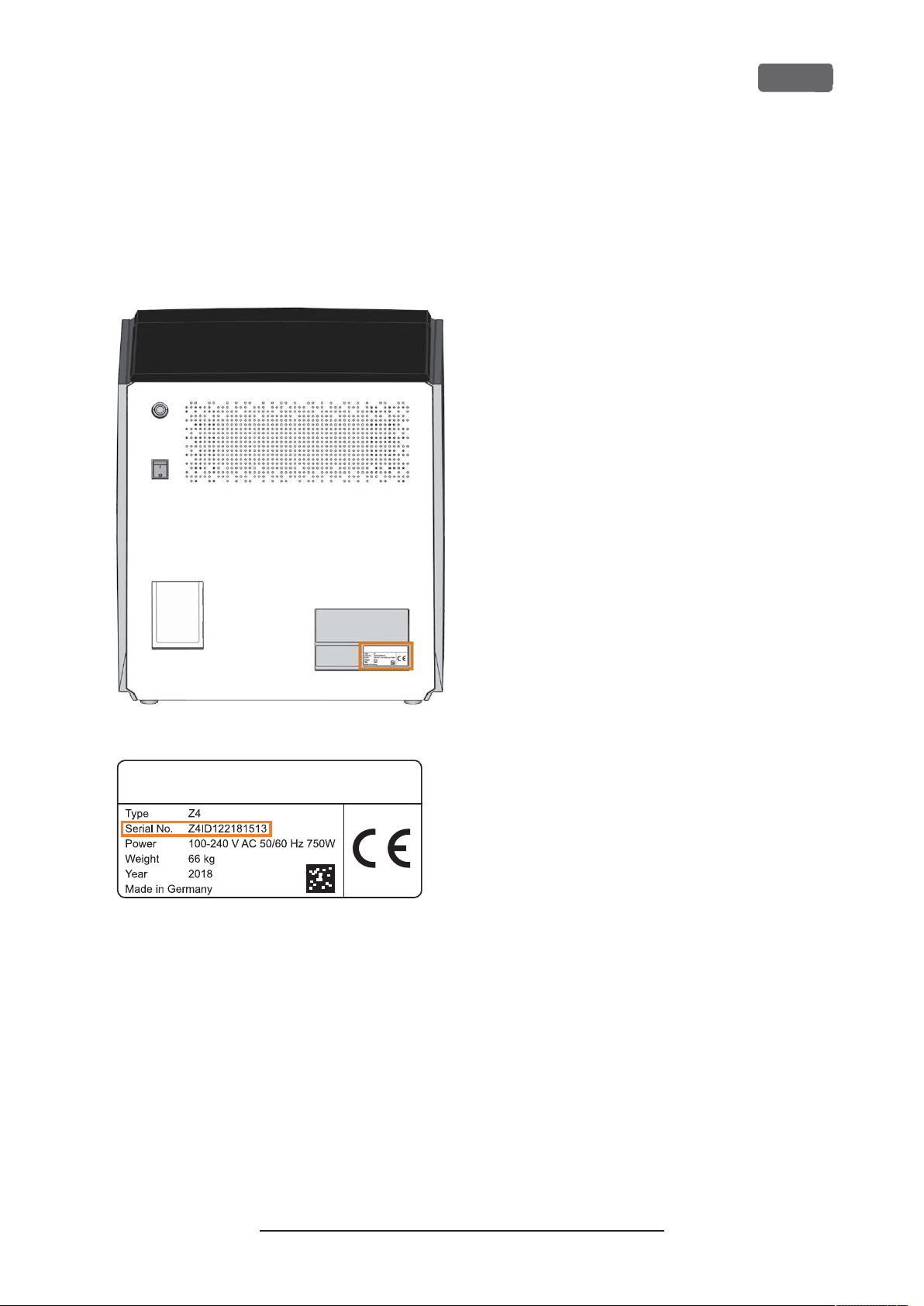

Rear side of the machine

FIG. 2 – R

EAR SID E OF THE MA CHINE

1.

Start button

2.

Main power switch

3.

CAM computer panel

4.

Network port (Ethernet RJ-45)

5.

Power connection

1.

Working chamber door

2.

Touchscreen for controlling the machine

3.

View window to the working chamber

4.

Multi-purpose drawer

FIG. 3 – CAM

COMPUTER PANEL

1.

HDMI 1.4b port

2.

USB 2.0 port with WiFi device

Original Operating Instructions:Z4

Version: 12/5/2018

Color Status

Z4 – Machine overview

EN 11

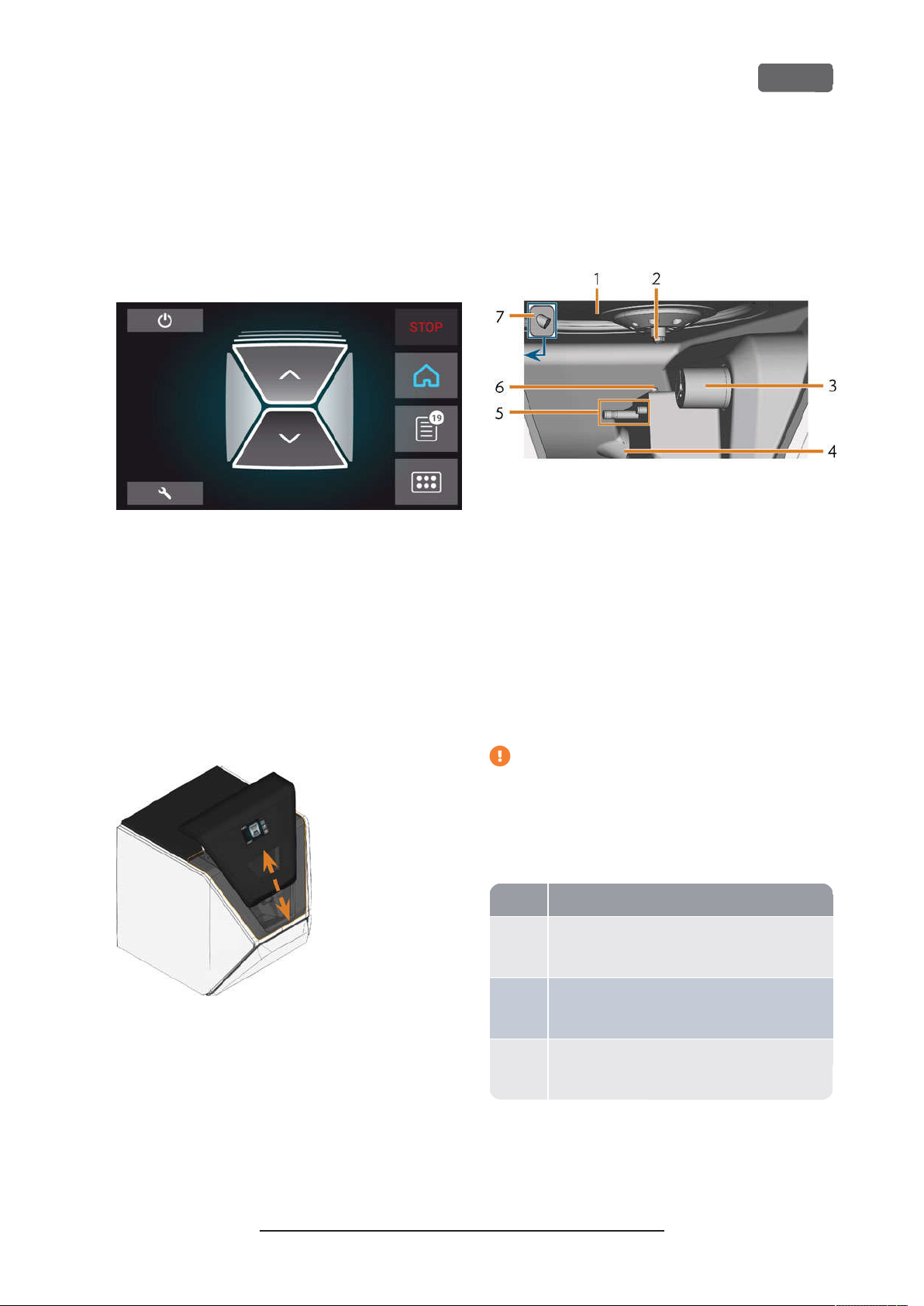

Touchscreen

The screen in the working chamber door of your

machine responds to touch. You can use it to operate

the machine by selecting icons on the user interface

and to receive information about jobs, tools and the

machine status.

FIG. 4 – A

SECTION OF THE US ER INTERFA CE

Working chamber door

The working chamber door locks the working

chamber and protects the user from injuries during

operation.

The working chamber door is operated by electricity.

You can open and close the door via the touchscreen

or with DentalCNC. You cannot open the door when

the machine is switched off or while the axes are

moving.

Working chamber

You can mount blanks and insert tools into the

working chamber. This is where the blanks are

processed.

FIG. 6 – W

Colors of the working chamber lighting

ORKING CHAMBER

1.

Bellow/Nozzle plate

2.

Spindle with collet chuck for picking up tools

3.

Blank holder (with collet chuck); Rotational axis A

4.

Outlet for the cooling liquid

5.

Tool magazine holder

6.

Measuring key

7.

Webcam

FIG. 5 – W

ORKING CHAMBER DO OR

If the working chamber lighting is insufficient,

provide additional lighting.

The machine illuminates the working chamber in

different colors. The color will change depending on

the state of the machine. You will find the colors and

respective machine status in the following table:

White The machine is ready for operation.

You can open the working chamber door.

Blue The machine is operating.

Theworking chamber door is locked.

Red A machinemalfunction has occured.

Theworking chamber door is locked.

Original Operating Instructions:Z4

Version: 12/5/2018

A-weighted

EN 12

Z4 – Machine overview

Multi-purpose drawer

The multi-purpose drawer contains the cooling liquid

tank and up to 5 tool magazines. You can unlock the

multi-purpose drawer via the touchscreen and then

pull it out manually.

FIG. 7 – M

ULTI-PURPOSE DRAWER

1.

Space for tool magazines

2.

Cooling liquid tank

3.

Cover of the cooling liquid tank with strainer basket

Required computer hardware

software

This machine is designed for an integrated CAD/

CAM workflow which allows you to manufacture

restaurations with the following components:

The touchscreen of the machine

n

A machine internal CAM computer running

n

DentalCAM DentalCNC (manufacturing software)

An external CAD computer*running a supported

n

CAD application

*

Sound emission

The actual sound emission of the machine varies

heavily depending on the manufacturing material and

the machining conditions.

If the machine is exceptionally loud, check the following operating conditions:

Cleanliness of the blank holder

n

Condition of the tools

n

Quality of the blanks

n

If loud noise cannot be avoided, wear ear protection during machining.

Sound measurement

Measuring conditions:

n

Processed material: IPS e.max (block, C14)

Tool status: new

n

Measured value: sound pressure level (distance:

n

1m)

Measurement according to ISO 3746, survey

n

method 3

Established sound emission:

A-weighted

Operating condition

sound pres-

sure level

Processing 81.8 dB(A) 92.3dB(A)

All other operating condi-

<70 dB(A) –

tions (tool change, movement of the axes etc.)

sound

power

level

*

not provided

You can use the touchscreen for standard operation

and basic maintenance.

If you do not use an integrated CAD/ CAM workflow,

you will need to access Windows®on the CAM

computer during standard operation to directly work

with DentalCAM DentalCNC.

Original Operating Instructions:Z4

Version: 12/5/2018

Z4 – Machine overview

Location of the identification plate

serial number

The identification plate of the machine contains identifying information such as the serial number. You can

find the identification plate and machine serial

number at the following location:

EN 13

OCATION OF THE ID ENTIFICATIO N PL ATE(MARKED ORA NGE

FIG. 8 – L

ERIAL N UMBER ON THE IDE NTIFICATION PL ATE(MARKED

FIG. 9 – S

ORANG E

)

)

Original Operating Instructions:Z4

Version: 12/5/2018

EN 14

Z4 – Machine overview

Technical data

Base system

Dimensions: (W/D/H):

n

Footprint: approx.400x 305 mm

Housing fully closed: approx.471x 522x 507mm

Housing fully open: approx.471x 737x 608mm

Weight: approx.66 kg

n

4-axis mechanism

n

Rotational axis A: +190° to -10°

n

Working chamber

n

Complete housing of the working chamber

Working chamber lighting with different colors to indic-

ate the machine state

Webcam for video transmissions to customer service

Integrated compressed air production

n

Permitted ambient temperature/ air moisture:

n

Ambient temperature (storage/ transport): between

-20°C and 60°C

Ambient temperature (operation): between 10°C and

32°C

Relative air moisture: max. 80, non-condensing

Spindle SFZ 170P

Asynchronous spindle rotating up to 100,000 rpm

n

Nominal power under continuous operation (S1): 170 W

n

Nominal power under uninterrupted periodic operation

n

(S6): 220 W

Peak power (P

n

Hybrid ceramic ball bearing

n

2-fold bearing

n

Pneumatic collet chuck Ø 3mm

n

Sealing air

n

Standard blank holder

For mounting blocks with round shafts

n

Maximum number of blocks per job: 1

n

n

Maximum block dimensions: 40x 20x 20mm (L/D/H)

Supports designated abutment holders

n

Tool magazine

Removable (5 provided)

n

Maximum tools in magazine: 6

n

Maximum tool length: 35 mm

n

Automatic tool change with compressed air monitoring

n

n

Automatic tool length measurement and tool breakage monitoring via a measuring key

Material allocation through color code

n

Automatic tool magazine recognition

n

): 340 W

max

Removable

Dishwasher-safe

Flow sensor for monitoring the flow of the cooling liquid

n

Connections

Power connection: 100 – 240 V AC, 50/60 Hz including

n

glass fuse T6,3A L250V

Network port

n

RJ-45

Speed: 10BASE/100BASE-TX/1000BASE-T (Auto-sensing)

Internal CAM computer

Processor:

n

Intel® Atom™ E3950

4 cores

1.60 – 2.00 GHz

RAM: 8GB DDR3L-SDRAM

n

Graphic:

n

GPU: Intel® HD Graphics 505

Display Interface: HDMI1.4b up to 3840x 2160 at

1

30Hz

LAN: Intel®I211 GbE LAN controllers (RJ-45)

n

Audio: not available

n

USB 2.0 interface with WiFi device

n

1

wired to the CAM computer panel of the machine

2

wired to the connection panel of the machine

1

2

WiFi

Standards: IEEE 802.11 ac

n

n

Data rate:

802.11 ac: downlink up to 867Mbps, uplink up to

867Mbps (20/40MHz)

802.11 a/b/g/n/ac: downlink up to 300Mbps, uplink up

to 300Mbps (20/40MHz)

Encryption:

n

64-bit WEP

128-bit WEP

WPA2-PSK

WPA-PSK

Operating frequency: 2.4 GHz/5 GHz

n

Cooling liquid system for wet machining

Cooling liquid: Drinking water

n

n

Integrated cooling liquid tank

Maximum amount of cooling liquid: 2 l

Integrated filter

Original Operating Instructions:Z4

Version: 12/5/2018

Z4 – Installing the machine

5 Installing the machine

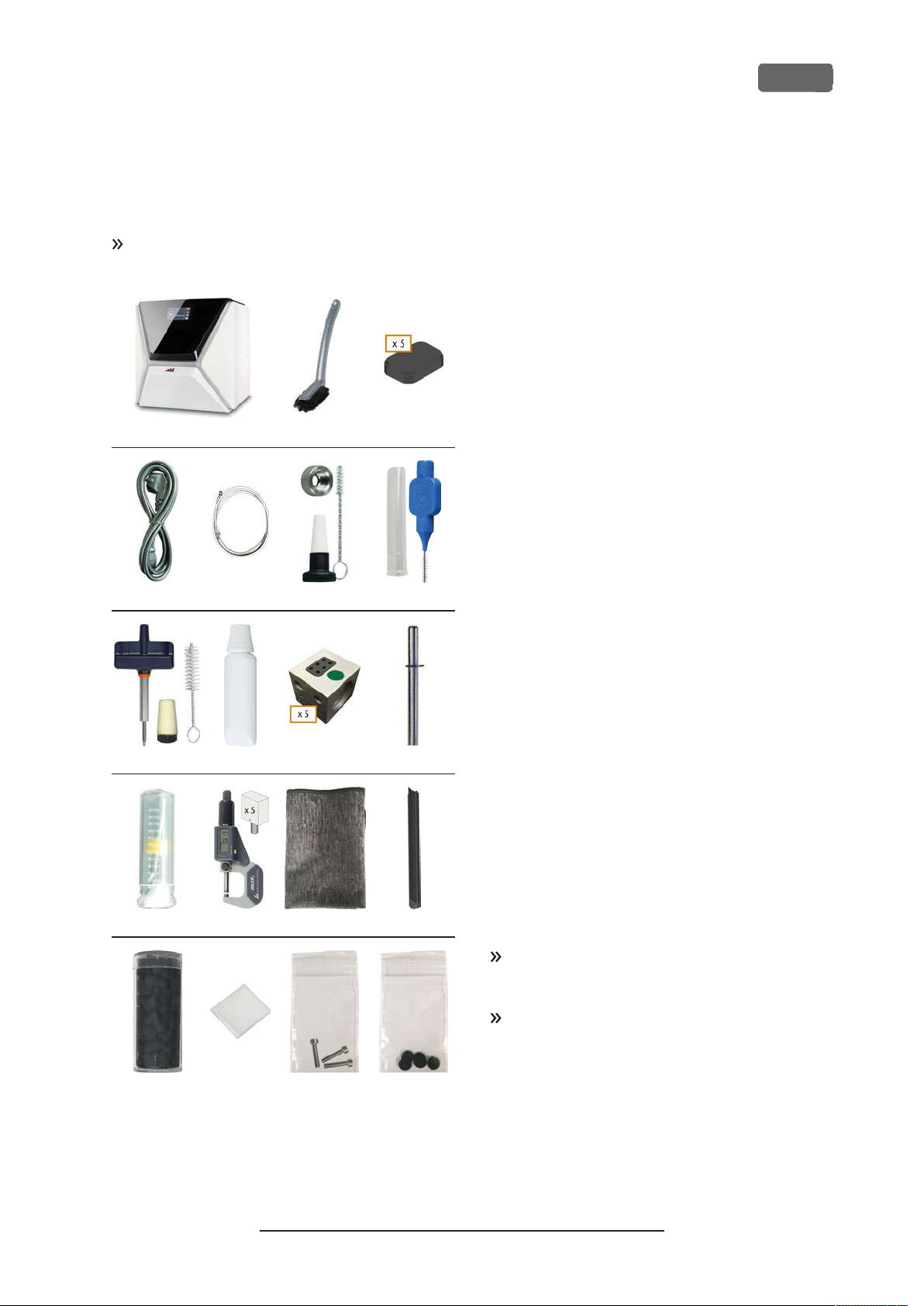

Checking the scope of delivery

Unpack the machine and ensure that you have

received the following items:

1 2 3

4 5 6 7

1.

1x Machine Z4

2.

1x Cleaning brush

3.

5x Tool magazine inserts

4.

1x Power cable

5.

1x Ethernet network cable(type: straight)

6.

1x Spindle service set

7.

1x Interdental brush(for cleaning the nozzle plate)

8.

1x Blank holder service set

9.

1x Tube of collet chuck grease (for spindle, blank

holder, tool magazine holder)

10.

5x Tool magazines (in the drawer)

11.

1x Measuring pin

12.

1x Drill bit for tool positions (2.8 mm)

13.

1x Calibration set: 1 micrometer, 5 blanks for manufacturing test and calibration specimen

14.

1 x Microfiber cloth

15.

1 x View window wiper

16.

1 x Container with activated carbon pellets

17.

1 x Fine filter

18.

3 x Fixing screw for the collet chuck of the blank

holder

19.

5 x Tool magazine caps

EN 15

8 9 10 11

12 13 14 15

16 17 18 19

Not depicted:

This document

n

1 x Carrying aid for transporting the machine

n

1 x Transport lock in the working chamber

n

1 x Supplement about removing the carrying aid

n

and transport lock

1 x Transport protection cover in the multi-pur-

n

pose drawer

n

1 x Allen key for the tool magazine release screw

1 x Allen key for the holder of the view window

n

wiper

Store the measuring pin and the calibration set

safely near the machine. Customer service will

need them for maintenance.

Keep the packaging of the machine, the carrying

aid and the transport lock for future transports.

Original Operating Instructions:Z4

Version: 12/5/2018

EN 16

Z4 – Installing the machine

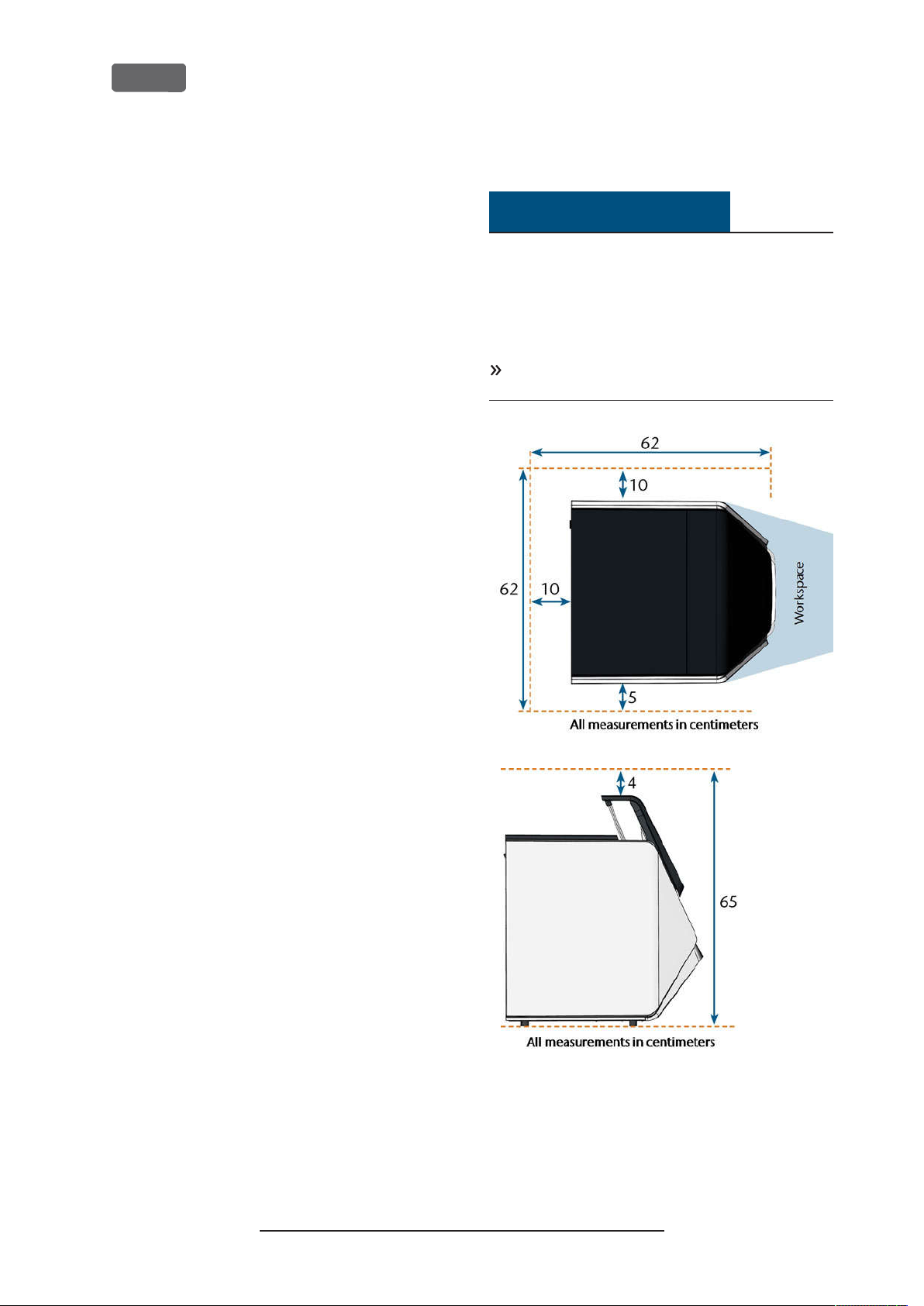

Choosing the installation site

The installation site must meet the following criteria:

n

Firm and even surface, must be able to carry the

weight of the machine (66 kg)

Minimum required space: 620 x 620 x 650 mm

n

(W/D/H)

Ambient temperature (storage/ transport):

n

between -20°C and 60°C

Ambient temperature (operation): between

n

10°C and 32°C

Relative air moisture: max. 80, non-con-

n

densing

Machine location must be dust-free

n

Alternating current source with 100 – 240 V AC,

n

50/60 Hz

An operational Residual Current Device/ Ground

n

Fault Circuit Interrupter on the electric circuit of

the machine

Access to the internet and local computer net-

n

work via cable/ WiFi

Distances to maintain

NOTICE

Damaging of the machine if safety

distances are not maintained

If you do not maintain the safety distances, the

movable parts of the housing can collide with

obstacles when being opened and get damaged. If

the ventilation openings are covered, the machine

may overheat and get severely damaged.

Ensure that the following safety distances are

always maintained.

FIG. 10 – D

ISTA NCES TO MAINTAIN

Original Operating Instructions:Z4

Version: 12/5/2018

Z4 – Installing the machine

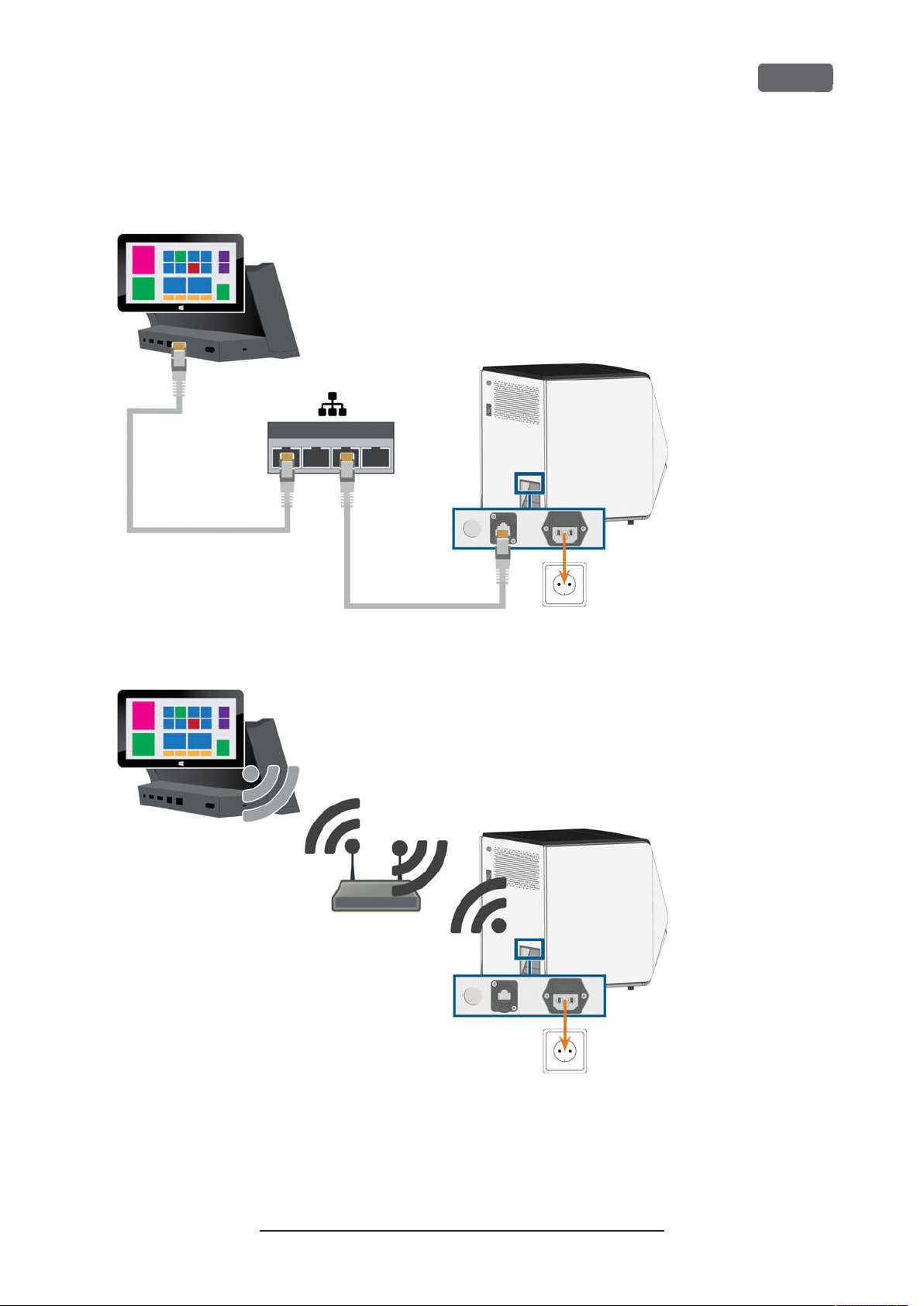

Machine installation (schema)

Wired connection

EN 17

WiFi connection

Original Operating Instructions:Z4

Version: 12/5/2018

EN 18

Z4 – Installing the machine

Establishing the electric connection

NOTICE

Damaging of the machine through heavy

voltage fluctuations

Heavy voltage fluctuations can disrupt the control unit

and can cause system failures.

Plug the machine’s power cable in a dedicated

current circuit or ensure that no devices are connected that can cause heavy voltage fluctuation

when switched on.

If heavy voltage fluctuations cannot be avoided,

install a suitable device which protects the

machine from heavy voltage fluctuations.

NOTICE

Short-circuit hazard when the machine is

too cold

If the machine is transported from a cold environment

into a warmer environment, a short circuit may occur

caused by condensate.

Before

portation, ensure the following:

n

n

n

The machine requires a continuous power supply for

proper operation.

1.

Plug the provided power cable into the power

connection at the connection panel of the

machine.

2.

If power failures occur regularly at the installation

location or if there are frequent voltage fluctuations, install an online Uninterruptible Power

Supply (UPS).

switching on the machine after trans-

The ambient air has the allowed temperature.

The machine has the same temperature as the

ambient air. This will take

The machine is completely dry.

If a power failure occurs during job execution, the tool may break and the blank

may be destroyed.

at least

48hours.

Removing the transport lock

Before operating the machine for the first time, you

must remove the transport lock. The transport lock

prevents the spindle from getting damaged during

transport.

1.

Ensure the following:

The machine is connected to the electrical

n

source.

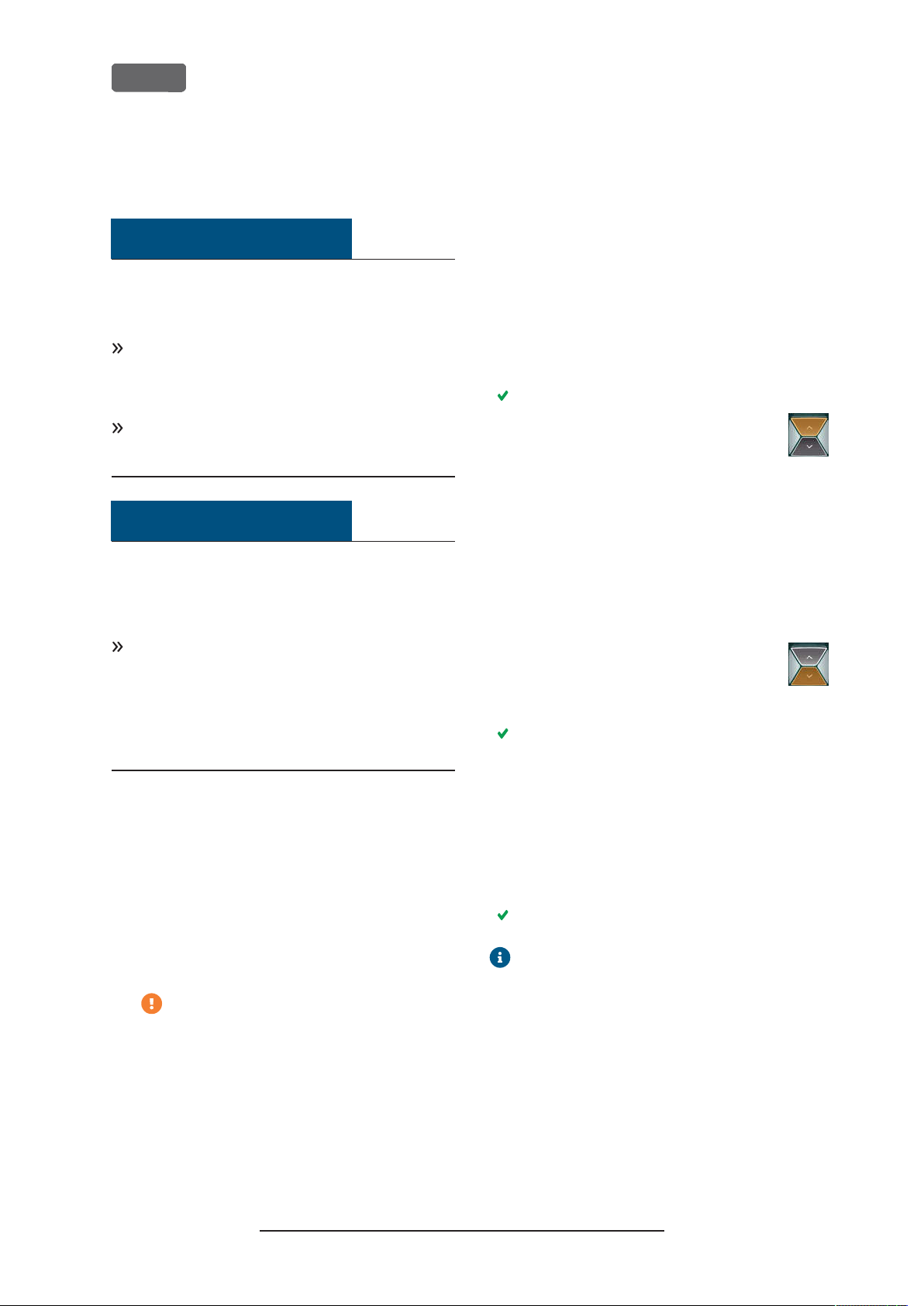

2.

Switch on the machine at the main power switch.

3.

Press the start button.

The machine references.

4.

Open the working chamber door by

selecting the upper arrow of the depicted icon on the touchscreen.

5.

Remove the transport lock as shown in the supplement.

Checking the tool magazines in

the drawer

After you have removed the transport lock, you should

open the multi-purpose drawer and check the tool

magazines.

1.

To unlock the multi-purpose drawer,

select the lower arrow of the depicted

icon in the

screen.

After a couple of seconds, the drawer will open.

2.

Pull the drawer open.

3.

Remove the transport protection cover from the

tool magazines.

4.

Verify that there are 5 tool magazines with different color codes in the drawer.

5.

To close the multi-purpose drawer, push it until it

locks back in place.

You will hear a clicking sound.

More information on tool magazines and

managing tools:

page41

section of the touch-

Home

Ž

Managing tools

– on

3.

Insert the plug of the cable into a socket that is

protected by a Residual Current Device/ Ground

Fault Circuit Interrupter.

Original Operating Instructions:Z4

Version: 12/5/2018

Z4 – Installing the machine

EN 19

CAD computer network integration

The CAD/ CAM integration workflow is as follows:

1.

Prepare the machine and the CAD computer (

page 19

2.

Access the CAM computer (

3.

(Optional)Set up WiFi access for the machine

(

Ž

4.

Integrate the CAD and CAM/CNC software (

page 24

)

page 23

)

Ž

page 20

)

)

Ž

NOTICE

Danger caused by default passwords and

network intrusions

The default passwords mentioned in this public document allow everyone to access the corresponding

devices via the network and/ or the internet. This can

lead to data theft, data corruption and damaging of

the machine and other devices.

Have the network integration of the machine and

other connected devices carried out by a qualified

network and IT specialist.

Have the specialist change the default passwords

after installation and secure your network against

intrusion. Ensure that passwords are recorded and

handed to you.

Ensure that the user

signed-in at Windows®startup. Otherwise, the

machine will not be operational. You must reenable the automatic sign-in when you change the

password for this user.

Ensure that the user

istrator privileges. Otherwise, the machine will not

be operational.

Be aware that changing the passwords for the predefined user accounts may require a reconfiguration of the machine’s network connection

and the CAD/CAM integration.

For remote maintenance, you can use

TeamViewer. Start the application via the icon on

the desktop of the CAM computer.

camcomputer

camcomputer

is automatically

has admin-

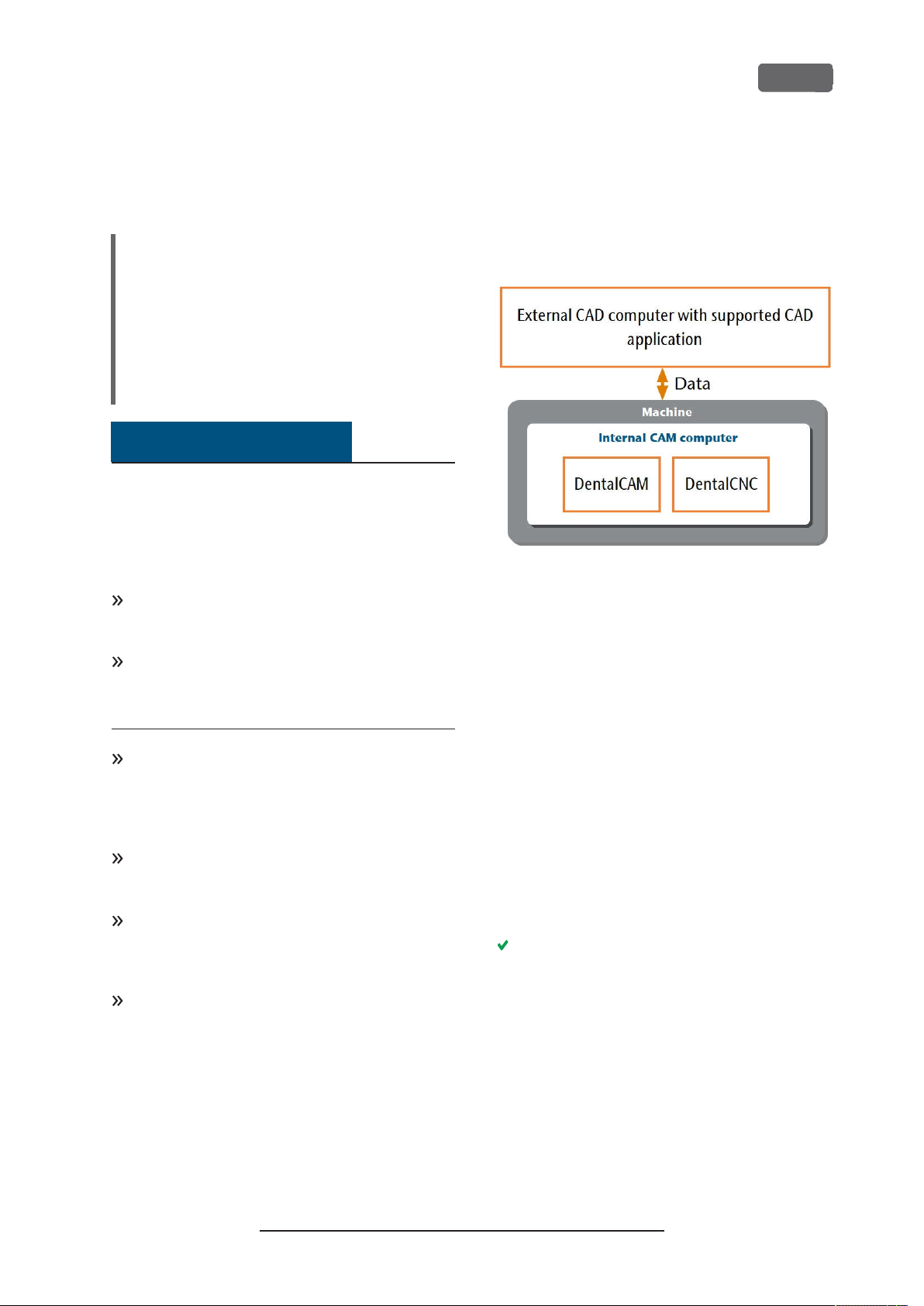

Internal CAM computer

The machine is equipped with an internal CAM

computer running the manufacturing software

DentalCAM DentalCNC. Manufacturing data is trans-

Ž

ferred as follows:

FIG. 11 – D

INTEG RATION

IAG RAM

ATA TRANSFER IN CA SE OF

: D

CAD/ CAM

Preparing the machine and CADcomputer

Before you can set up the CAD/ CAM integration, you

need to prepare all hardware and software components.

1.

Shut down the machine.

2.

Install the CAD application on the CAD computer.

Ensure that the CAD application is licensed to use

the Z4 for manufacturing.

3.

Ensure that the CAD computer is configured for

network connectivity. This includes WiFi access if

desired.

4.

To connect the machine to a wired network, connect the machine and the CAD computer to the

local network with Ethernet cables. Do not directly connect the CAD computer to the machine.

If a DHCP server is available in the local network,

the integrated CAM computer will automatically

try to obtain a valid IP address.

5.

To connect the machine to a WiFi network, prepare the machine as follows.

a.

Connect the CAD computer to the Ethernet

port of the machine with an Ethernet cable.

b.

For the moment, deactivate WiFi access on

your CAD computer.

Otherwise, the CAD computer will not find

the CAM computer.

Original Operating Instructions:Z4

Version: 12/5/2018

Access to

EN 20

6.

If a local network is not available, connect the

CAD computer to the Ethernet port of the

machine with an Ethernet cable.

7.

Ensure that the internal CAM computer of the

machine has access to the Internet.

If required, configure your network firewall

n

accordingly.

If permanent Internet access cannot be guar-

n

anteed, ensure that the machine is connected to the Internet at least once per

week.

The machine requires Internet access for

important updates.

8.

Switch on the machine at the main power switch.

Press the start button.

9.

Wait until the machine has referenced.

Z4 – Installing the machine

Accessing the CAM computer

NOTICE

Installing Microsoft®Office onto the

CAMcomputer violates the Windows

License Agreements

The CAM computer runs Windows®10 IoT Enterprise.

If you install any version of Microsoft®Office onto the

CAM computer, you will violate the Windows®License

Agreement which may result in the following:

You may lose the right to use the pre-installed

n

Windows®on the CAM computer. Without Windows®, the machine will not work.

You may become subject to civil and criminal

n

prosecution.

Never

the CAM computer.

install any version of Microsoft®Office onto

®

Once the machine is connected to the CAD computer

and the network connection is established, the CAM

computer can be accessed in 3 ways:

Access method

Remote Desktop applic-

CAM/CNC

folder?

Yes Yes

Access to Win-

dows?

ation on the CAD

computer

Connecting hardware

Yes Yes

to the machine

Windows®Explorer on

Yes No

the CAD computer

Access via the Microsoft®Remote Desktop applic-

n

ation allows you to use Windows®/ DentalCAM

DentalCNC on the CAM computer without

additional hardware.

n

You can connect additional hardware to access

the CAM computer to use Windows®/

DentalCAM DentalCNC

Accessing the DentalCAM DentalCNC install-

n

ation folder via Windows®Explorer is usually only

required for customer service.

If you do not use an integrated CAD/ CAM workflow,

you will need to access Windows®on the CAM

computer during standard operation to directly work

with DentalCAM DentalCNC.

Original Operating Instructions:Z4

Version: 12/5/2018

Z4 – Installing the machine

EN 21

Overview CAM computer access data

Following you find the access data for the internal

CAM computer as a quick reference.

Computer name: Serial number of the machine

n

IP address: None specified, DHCP activated

n

*

Ž

Location of the identification plate serial number

on page13

Administrator user with auto sign-in at Windows

startup:

n

User:

camcomputer

n

Password:

Standard user for accessing the DentalCAM

DentalCNC installation folder, which is shared by

default:

n

User:

n

Password:

When you disconnect from the CAM

computer, never sign-out or shut down the

CAM computer. If you do, the machine will not

be operational until you restart it.

camcomputer

cnctransfer

cnctransfer

Accessing Windows®on the CAM computer

using a Remote Desktop connection

Microsoft®Remote Desktop allows you to work with

the CAM computer from another computer as if you

*

were using the CAM computer directly.

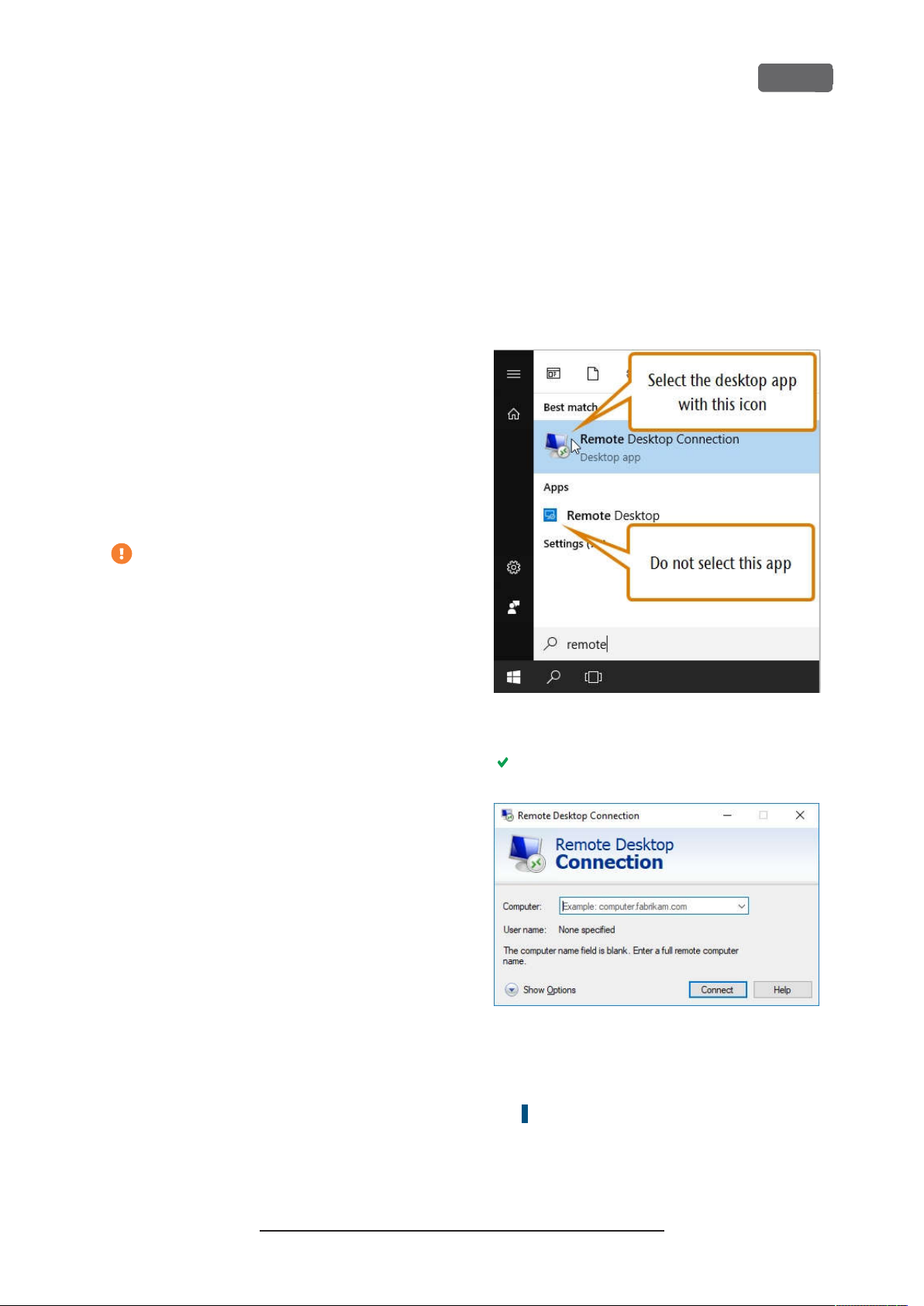

Start the

–

1.

application. Do not start the Windows®store app

Remote Desktop

®

Remote Desktop Connection

.

desktop

FIG. 12 – S

APPL ICATION

FIG. 13 – THER

2.

3.

TARTING THEREM OTEDES KTOPCONNECT ION

The

Remote Desktop Connection

EM OTEDES KTOPCONNECT ION APPLICA TION

Enter the following into the

box:

Machine serial number

Example:

Select

Z4ID212345678

[Connect]

.

window opens.

Computer

combo

Original Operating Instructions:Z4

Version: 12/5/2018

EN 22

Z4 – Installing the machine

You are prompted to enter the login credentials.

4.

Enter the following login credentials:

n

User:

camcomputer

n

Password:

If a different default user name displays that you

cannot change, do the following:

Select

a.

Additional options display.

Select

b.

You can enter the user name given above.

Select

5.

[OK]

The desktop of the CAM computer displays in

the remote desktop application window.

Through it you can access files and start applications on the CAM computer.

camcomputer

More choices

.

Use a different account

.

.

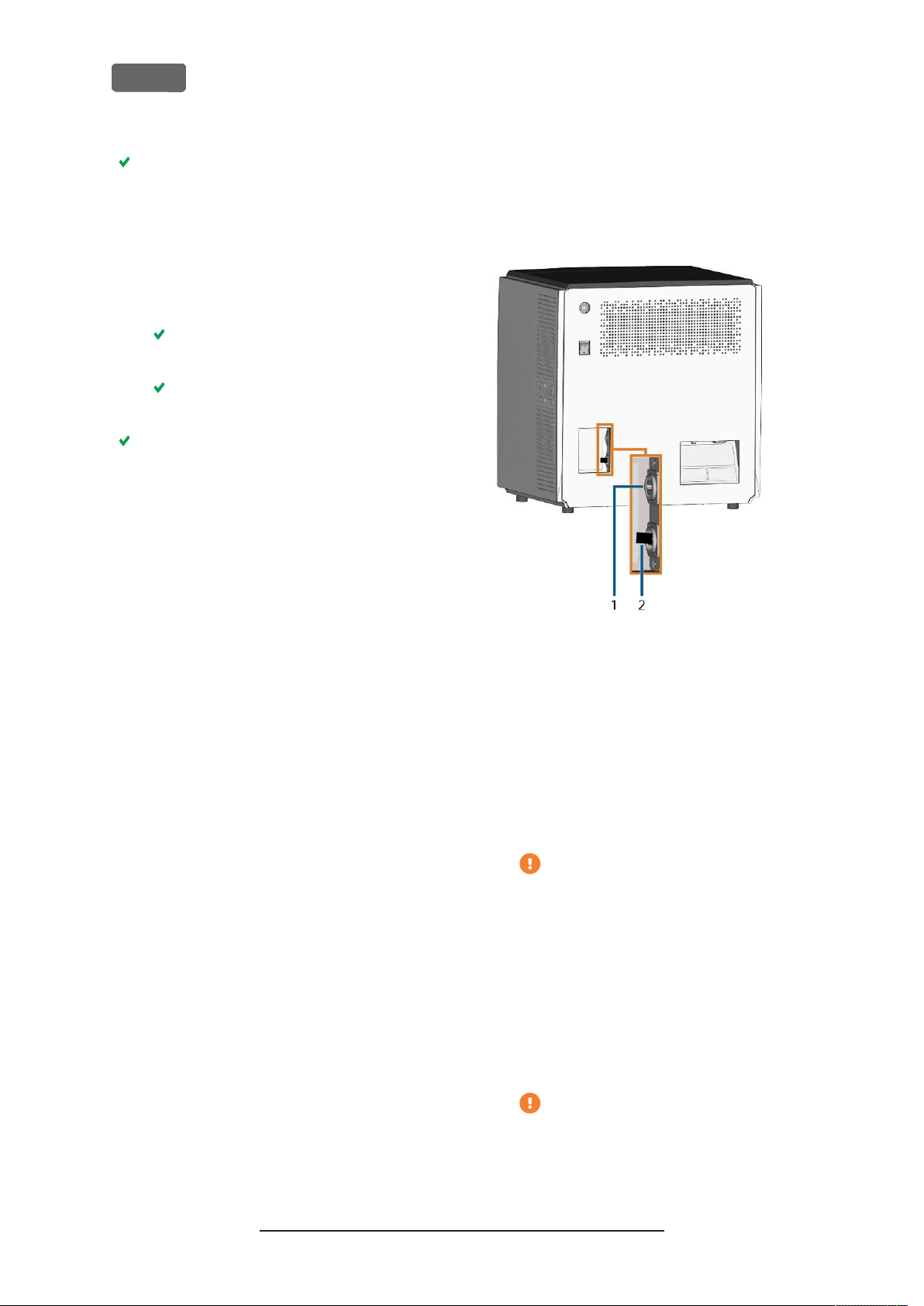

Accessing the CAM computer via hardware

You can directly connect a monitor and/ or USB

devices to the CAM computer.

Use the ports of the CAM computer panel for this:

FIG. 14 – CAM

1.

2.

You can connect hardware to the internal CAM

computer as follows:

1.

Connect the monitor to the HDMI connectorof

the machine. If your monitor isnt equipped with

an HDMI cable, use an adapter.

2.

If you want to install USB devices to the CAM computer, do as follows:

COMPUTER PANEL

HDMI 1.4b port

USB 2.0 port with WiFi device

Do not connect a laptop/ tablet or similar

to the HDMI port; only connect a monitor

to the port.

a.

Remove the WiFi device from the USB port.

b.

(Optional)Connect a USB hub to the USB

port.

c.

Connect the desired USB devices to the

USB port or USB hub.

You must reconnect the WiFi device to the

USB port after removing the other

devices.

Original Operating Instructions:Z4

Version: 12/5/2018

Z4 – Installing the machine

3.

Activate the interface of the CAM computer with

the connected input device (e.g. mouse, keyboard, touch display).

You are prompted to enter the login credentials.

4.

Enter the following login credentials:

n

User:

camcomputer

n

Password:

Press .

5.

The desktop of the CAM computer displays on

the connected display. You can access files and

start applications on the CAM computer.

camcomputer

EN 23

Accessing the DentalCAM DentalCNC

installation folder

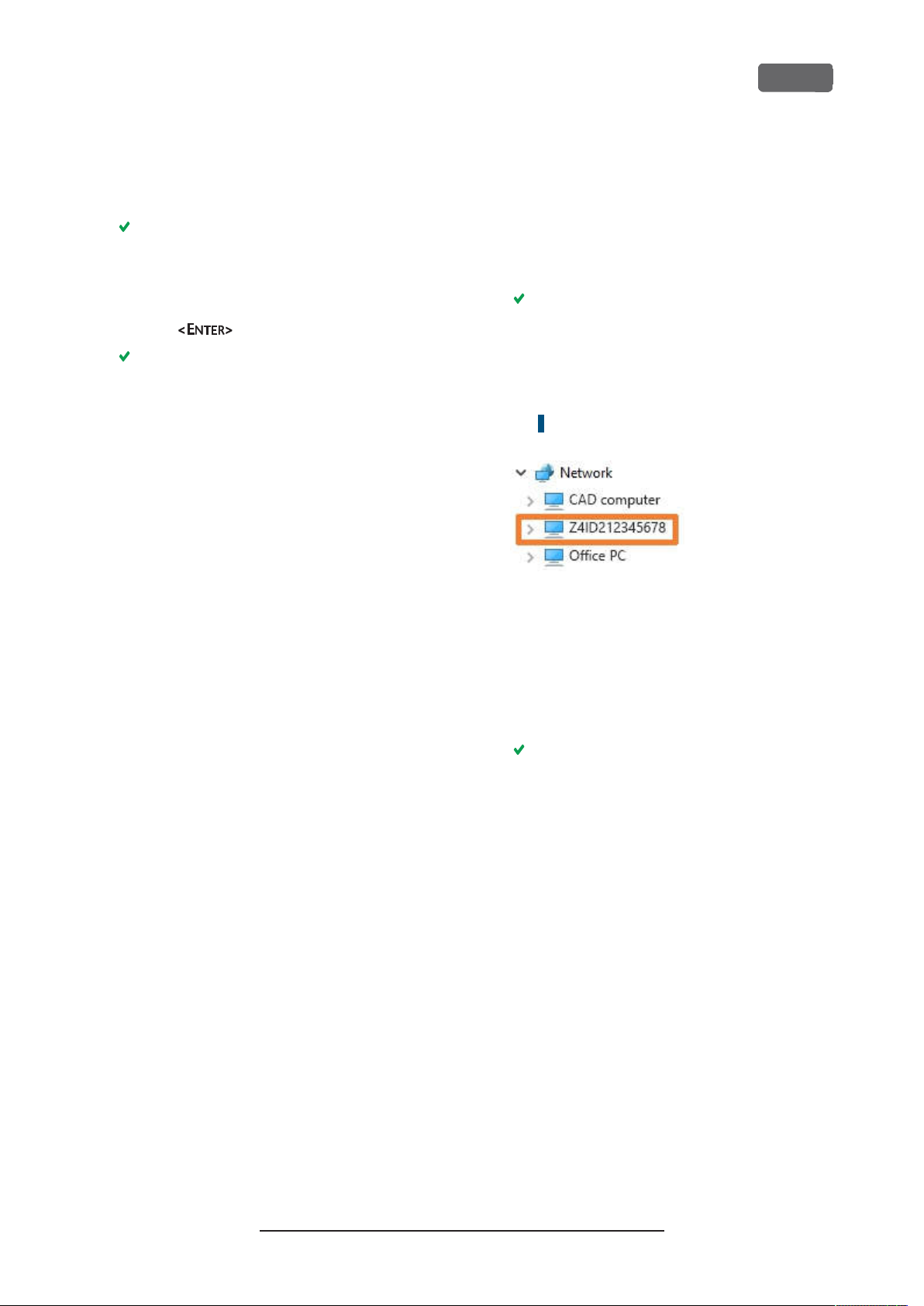

You can access the DentalCAM DentalCNC installation folder via Windows®Explorer as follows:

1.

Start Windows®Explorer on the CAD computer.

In the folder and device list in the left column,

the CAM computer name displays under the

Network

serial number of the machine (

the identification plate serial number

page13

node. The name is identical to the

).

Example:Z4ID212345678

Ž

Location of

– on

FIG. 15 – THECAM

XPL ORER

E

2.

If there is no entry for the CAM computer,

COMPUTER NAME D ISPL AYS INWINDO WS

check whether the CAD computer is correctly

integrated into the same network as the CAM

computer.

3.

Select the entry for the CAM computer.

You are prompted to enter the login credentials.

4.

Enter the following login credentials:

n

User:

cnctransfer

n

Password:

Activate the

5.

6.

Access the files on the CAM computer as you

cnctransfer

Save login credentials

option.

would with any other device.

Configuring the WiFi connection

The machine uses a pre-installed WiFi device to

connect to your access point.

1.

Ensure the following:

Your WiFi access point is operational.

n

You have fully prepared your CAD com-

n

puter and the machine as described above

(

Ž

Preparing the machine and CADcomputer

– on page19

).

®

Original Operating Instructions:Z4

Version: 12/5/2018

Loading...

Loading...