Vexta SMK0A-*A Series, SMK2 Series, SMK0A-*B Series, SMK014A-A, SMK014A-B Operating Manual

...Page 1

■

Method of installation

Install the motor on a smooth metallic plate offering a high resistance to vibration and excellent

heat-conductive properties.

●

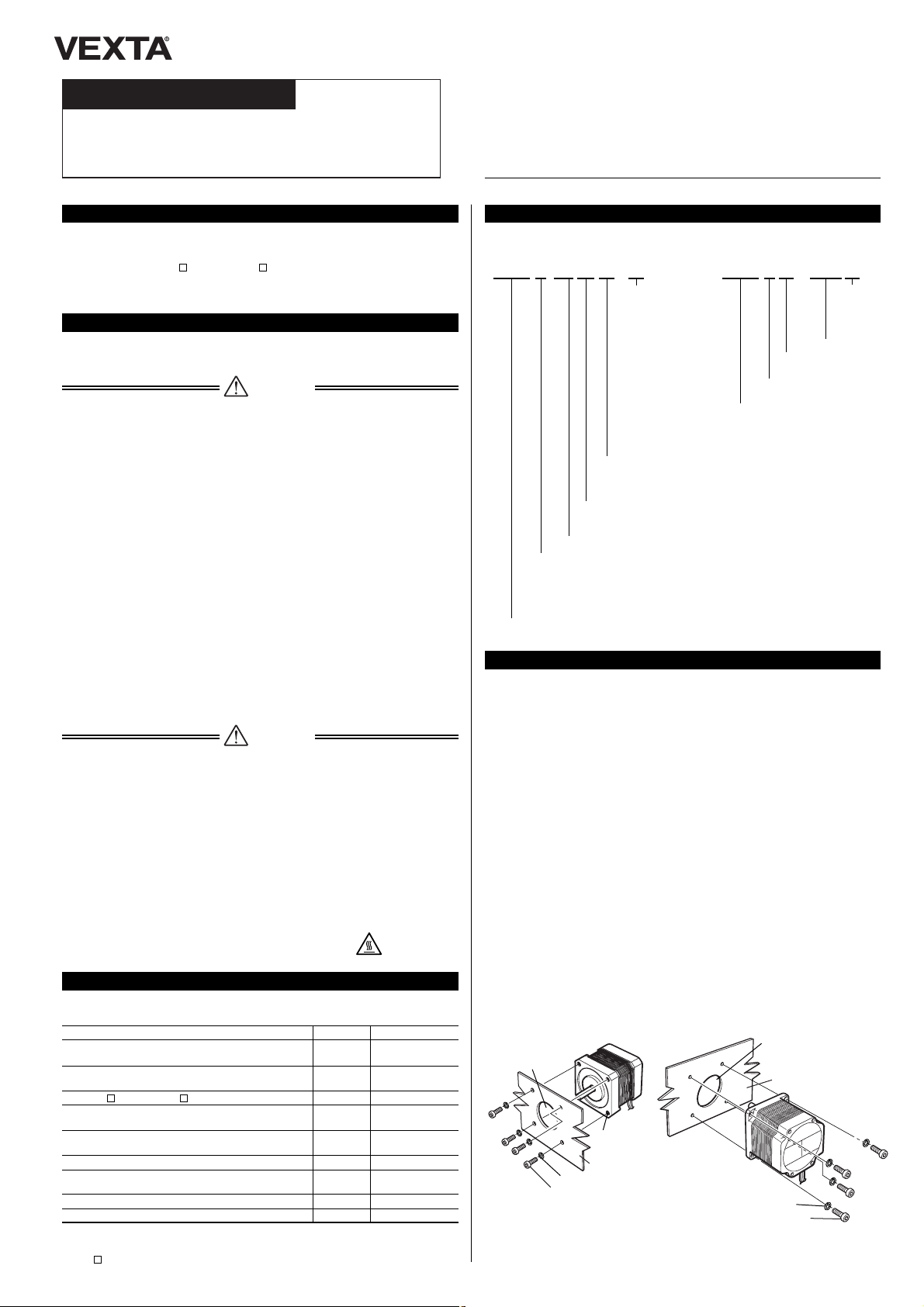

Round shaft type

Using the four installation holes (or tapped holes) located on the motor's installation surfaces,

secure the motor with four bolts (not provided).

The motor's mounting pilot on the motor-installation hole should be inserted into the mountingpilot holder, which is countersunk or drilled through.

Low-Speed Synchronous Motor

SMK Series

OPERATING MANUAL

Thank you for purchasing an ORIENTAL MOTOR product.

This Operating Manual describes product handling procedures and safety precautions.

●

Please read it thoroughly to ensure safe operation.

●

Always keep the manual where it is readily accessible.

Only qualified personnel should work with the product.

This product is designed for incorporation in general industrial machinery, and must not be used

for another purpose. ORIENTAL MOTOR Co., Ltd. is not responsible for any damage caused

through failure to observe this warning.

This product is UL-recognized (impedance-protected ), and has made self-declaration of the

CE marking (the Low-Voltage Directive). (This does not apply to the SMK014A-A ,

SMK014A-B, SMK014MA-A, SMK014MA-B, SMK014K-A, SMK014K-B,

SMK014K-AA , SMK0A- A and SMK0A- B.)

■

Installation conditions

Overvoltage category

II

, Pollution degree 2, Class Iequipment

Introduction

The precautions described below are intended to ensure the safe and correct use of the product, and to prevent the customer or others from exposure to the risk of injury.

Read the body of the text based on a sufficient understanding of its importance.

Safety precautions

Warning

●

SMK0 type

●

SMK2, SMK5 type

Failure to observe the warnings contained herein may result in a situation leading to serious

injury or death.

●

Do not use the product in explosive or corrosive environments, in the presence of flammable

gases, locations subjected to splashing water, or near combustibles. Doing so may result in

fire, electric shock or injury.

●

Qualified personnel are required for the installation, connection, operation and inspection of

this product. Failure to do so may result in fire, electric shock or injury.

●

Be sure to turn off the power before installing, connecting or inspecting this product. Failure

to do so may result in electric shock.

●

Install the motor in the enclosure to avoid contact with the hands, or provide sufficient grounding. Failure to do so may result in electric shock or injury.

●

Connect this product securely and accurately, according to the connection diagrams. Failure

to do so may result in fire or electric shock.

●

Be sure to insulate the connection terminals of the capacitor and external resistor. Failure to

do so may result in electric shock.

●

Do not forcibly bend, pull or pinch the motor cable. Doing so may result in fire or electric

shock.

●

In case of power failure, be sure to turn off the power. Failure to do so may cause the motor

to start suddenly when the power is restored, and could result in injury or damage to the

equipment.

●

If this product is used in an elevator application, be sure to provide a measure for the position retention of moving parts. The motor loses its retentiveness when the power is turned off.

Failure to provide such a measure may cause the moving parts to fall off, resulting in injury

or damage to the equipment.

●

Do not touch the connection terminals of the motor or capacitor immediately after the power

is turned off (for a period of 30 seconds). The residual voltage may cause electric shock.

●

Do not disassemble or modify the motor. Doing so may result in electric shock, injury or damage to the equipment.

■

Installation site

The motor is designed and manufactured for incorporation in machinery and equipment. Install

it at the site in consideration of the following to ensure effective ventilation and easy inspection:

◆

In indoor enclosure (where a ventilation port must be provided )

◆

Ambient temperature:

-

10°C~ +40°C(non-freezing)

[+14°F~ +104°F]

◆

Ambient humidity:85% or less (non-condensing)

◆

Not in an explosive atmosphere in the presence of hazardous gas (sulfide gas ) or liquid

◆

Not at a site exposed to sunlight

◆

Not at a site exposed to dust or metallic chips and particulate matter

◆

Not subject to splashing water (rainstorm and otherwise), oils or other liquids

◆

Not at a site containing excessive salt

◆

Not subjected to continuous vibration or excessive shock

◆

Not exposed to electromagnetic noise (welders and power equipment )

◆

Not in the presence of radiation, magnetic fields or a vacuum environment

◆

At an elevation not exceeding 1,000 meters

Installation

Mounting-pilot holder

(countersunk or

drilled through)

Hexagonal-socket set screw

Mounting plate

Plain spring washer

4-M3 P0.5

(4-No.4 -40UNC)

Mounting plate

Hexagonal-socket set screw

Mounting-pilot holder

(countersunk and

drilled through)

Plain spring washer

Caution

Failure to observe the following precautions may result in injury or property damage.

●

Do not use the motor beyond the specified values. Doing so may result in electric shock,

injury or damage to the equipment.

●

Do not hold the motor shaft or motor cable. Doing so may result in injury.

●

Be sure to secure the motor onto the metal plate. Failure to do so may result in injury or damage to the equipment.

●

Be sure to cover the rotating portion (motor shaft) of the motor. Failure to do so may result in

injury.

●

If any abnormality is detected, turn the power off immediately. Failure to do so may result in

fire, electric shock or injury.

●

Do not touch the motor or external resistor during operation or immediately after the equipment is stopped, since the surfaces of the motor and external resistor will be extremely hot.

Failure to do so may result in a burn.

●

The surface temperature of the motor may exceed 70°C (158°F), even during normal operation. Be sure to attach a warning label, as shown in the figure, in a clearly visible location if

it is possible for the operator to access the motor during operation.

Failure to do so may result in a burn.

●

Dispose of the motor as industrial waste.

400Ω

1500Ω

400Ω

400Ω

2000Ω

-

-

-

-

30W

30W

30W

30W

30W

Model Capacitor External resistor

SMK014A-A, SMK014A-B

SMK014MA-A, SMK014MA-B

SMK014K-A, SMK014K-B

SMK014K-AA

SMK0A- A

∗

1

, SMK0A- B

∗

1

SMK237A-A, SMK237A-B

SMK216A-GN, SMK216A-GNB

SMK5100A-A, SMK5100A-B

SMK5100A-AA, SMK5100A-BA

SMK5100C-A, SMK5100C-B

SMK5160A-A, SMK5160A-B

SMK5160A-AA, SMK5160A-BA

SMK550A-GN, SMK550A-GNB, SMK550A-GNBA

SMK550C-GN, SMK550C-GNB

0.6µF

∗

2

12µF

0.6

µ

F

∗

2

1.2µF

∗

2

2.5µF

∗

2

0.6µF

∗

2

2.5µF

∗

2

0.6µF

∗

2

0.35µF

∗

1

Mounting screws (4 pieces) are provided.

∗

2

A capacitor cap is provided.

Open the package and verify that the following items are present. If there is any shortage or

damage, contact the sales office from which you purchased the product.

Product confirmation

Speed

M : 50 Hz 30r /min, 60 Hz 36r /min

Blank : 50Hz 60r/ min, 60Hz 72 r/ min

Motor Torque

Motor Frame Size

0 :

42 mm (1.65 in.)sq.

2 :

56.4 mm (2.22 in.)sq.

[

GN type pinion shaft is 60 mm (2.36 in.)sq.]

5 :

85 mm (3.35 in.)sq.

[GN type pinion shaft is 90 mm (3.54 in.)sq.]

Low-Speed Synchronous Motor SMK Series

Voltage

A :

Single-Phase100/115 V

Motor Frame Size

0 :

42 mm (1.65 in.)sq.

Low-Speed Synchronous Motor SMK Series

Product number code

HM-4006-6

A box ( ) of the model is filled with a number to represent the gear ratio.

SMK 0 A - 120 A

●

Geared type

SMK 0 14 M A - A

●

Round shaft type

and pinion shaft type

Shaft Type

A : Single Shaft

(metric size)

B : Double Shaft

(metric size)

AA : Single Shaft

(inch size)

BA : Double Shaft

(inch size)

GN : Single GN Type

Pinion Shaft

GNB :Double GN Type

Pinion Shaft

(metric size)

GNBA:Double GN Type

Pinion Shaft

(inch size)

Voltage

K :

Single-Phase24 V

A :

Single-Phase100/115 V

C :

Single-Phase200/230 V

Gear Ratio

Shaft Type

A :

Single Shaft

(metric size)

B :

Double Shaft

(metric size)

Page 2

●

Pinion shaft type

Using the four installation holes (or tapped holes) located

on the motor’s installation surfaces, secure the motor with

four bolts attached to the gearhead.

The boss on the gearhead’s mounting surface should be

inserted into the boss holder,

which is countersunk or drilled through.

●

Geared type

When installing the motor, secure it

with four bolts (supplied) through

the four tapped holes provided.

Leave no gap between the motor

and plate.

■

Combination with gearhead

(optional)

Use the pinion shaft type in combination with the following gearhead:

2GN K

5GN K

Model

Compatible gearhead (optional)

SMK216A-GN, SMK216A-GNB

SMK550A-GN, SMK550A-GNB, SMK550A-GNBA

SMK550C-GN, SMK550C-GNB

A box ( ) of the gearhead model is filled with a number to represent the gear ratio.

Mounting plate

Screw attached

to gearhead

Hexagonal-socket

set screw

Boss holder

(countersunk or

drilled through)

Gearhead (optional)

Motor

Plain washer

Motor-mounting pilot

Pinion shaft

Boss

When mounting the gearhead on the

motor, set the pilot of the motor to

that of the gearhead and assemble

them by turning the gearhead slowly

back and forth from right to left.

Do not assemble the motor and gearhead forcibly, nor bring the pinion shaft into forcible contact with the gearhead’s side plate or gear. This precaution must be observed in order to avoid

abnormal noise or reduced service life in the gearhead.

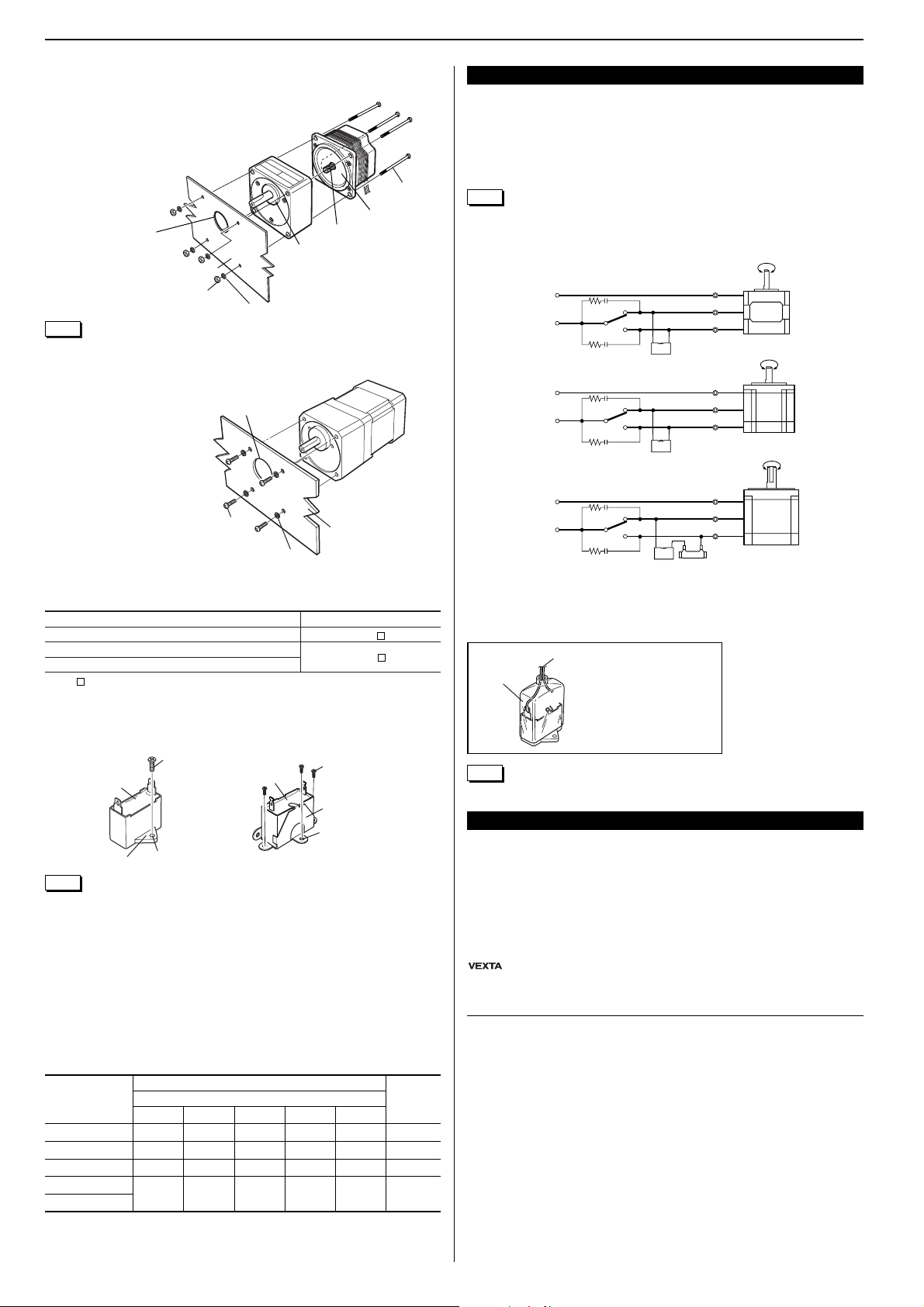

Capacitor

M4 Screw

M4 Screw

Capacitor

Mounting leg

Fixture

4.3

(.169DIA.)

5x 4.3

(5x .169DIA.)

φ

φ

■

How to install the capacitor

Secure the capacitor in place using screws (not supplied), as shown in the figure.

NOTE

〈

A type with Mounting leg

〉〈

A type with Fixture

〉

●

The tightening torque of the capacitor’s mounting screws having mounting legs should be

1 N·m (142 oz-in) or more in order to prevent the legs from being damaged.

●

Install the capacitor at a distance of 100 mm (4 inch) or more from the motor. Otherwise, the

life of the capacitor may be reduced due to the heat of the motor.

NOTE

[Unit:mm(inch)]

ORIENTAL MOTOR U.S.A. CORP.

Technical Support Line Tel :(800)468- 3982

Available from 7:30 AM to 5: 00 PM, P.S.T.

E-mail: techsupport@orientalmotor.com

www.orientalmotor.com

ORIENTAL MOTOR (EUROPA) GmbH

Headquarters and Düsseldorf Office

Tel:0211-5206700 Fax: 0211-52067099

Munich Office

Tel:08131- 59880 Fax: 08131-598888

Hamburg Office

Tel:040 -76910443 Fax: 040-76910445

ORIENTAL MOTOR (UK) LTD.

Tel:01252 -519809 Fax: 01252-547086

ORIENTAL MOTOR (FRANCE) SARL

Tel:01 47 86 97 50 Fax: 01 47 82 45 16

ORIENTAL MOTOR ITALIA s.r.l.

Tel:02 -3390541 Fax: 02-33910033

TAIWAN ORIENTAL MOTOR CO., LTD.

Tel:(02)8228 -0707 Fax: (02)8228-0708

SINGAPORE ORIENTAL MOTOR PTE LTD.

Tel:(6745)7344 Fax: (6745)9405

ORIENTAL MOTOR (MALAYSIA) SDN BHD

Tel:(03)79545778 Fax: (03)79541528

INA OM LTD.

KOREA

Tel:(032)822 -2042~3 Fax: (032)819-8745

ORIENTAL MOTOR CO., LTD.

Headquarters Tokyo, Japan

Tel:(03)3835 -0684 Fax: (03)3835-1890

0

20( 4.4)

10( 2.2)

54( 11.9)

260( 57)

5 (0.2 )

25( 5.5)

15( 3.3)

67( 14.7)

290( 63)

10 (0.39 )

34( 7.4)

20( 4.5)

89( 19.6)

340( 74)

15 (0.59 )

52( 11.4)

30( 6.7)

130( 28)

390( 85)

20 (0.79 )

-

-

-

480( 105)

Printed on Recycled Paper

●

Please contact your nearest ORIENTAL MOTOR office for further information.

■

Load installation

When installing the load on the motor, align the centerline between the motor shaft and the load

shaft.

When installing the coupling or pulley on the motor shaft, take care not to damage the motor

shaft or bearing.

■

Overhang and thrust loads

Make sure that the overhang load and thrust load applied to the motor shaft does not exceed

the following tolerance:

Motor type

Overhung load

[N(lb.)]

Distance from tip of output shaft

[mm (inch )]

Thrust load

[N(lb.)]

SMK014

SMK0A

∗

1

SMK237

SMK5100

SMK5160

∗

2

15( 3.3)

∗

2

∗

2

When overhang and thrust loads have exceeded the tolerance, the motor bearing and motor

shaft will result in breakdown due to fatigue caused by repeated loads.

■

Operation

Be sure to connect the supplied capacitor and external resistor (for the SMK5 type only), as

shown in the figures.

Flip the switch to CW to rotate the motor in the clockwise direction and to CCW for rotate the

motor in the counterclockwise direction. When the power is turned off, the motor stops within

±

3.6˚. (The direction of rotation indicates the rotational direction of the motor shaft when viewed

from the motor shaft side.)

Connection

◆

Do not give any constraint to the motor shaft.

If the motor shaft is constrained with a load torque exceeding the motor torque, the motor cannot be started and a vibrating condition will occur, resulting in a significant decrease in motor

life. Be sure to use a load torque that is less than the motor torque.

◆

Use a gearhead that is below the permissible torque.

The load torque of the gearhead must be below the permissible gearhead torque. If a load

torque exceeding the permissible gearhead torque is used, it may damage the gearhead.

Precautions for use

●

SMK0 type

●

SMK2 type

●

SMK5 type

This Operating Manual may be revised without prior notice due to product improvement,

changes in specifications or other revisions.

is a registered trademark of ORIENTAL MOTOR CO., LTD., in Japan and other coun-

tries.

© Copyright ORIENTAL MOTOR CO., LTD. 2002

SW

CW

CCW

CCW CW

Red

White

Blue

Capacitor

Motor

R0 C0

R0 C0

Single-Phase

24 V

or

Single-Phase

100/ 115 V

Single-Phase

100/ 115 V

SW

CW

CCW

CCW CW

Red

Gray

Blue

Capacitor

Motor

R0 C0

R0 C0

External resistance

Single-Phase

100/ 115 V

or

Single-Phase

200/ 230 V

SW

CW

CCW

CCW CW

Red

Gray

Blue

Capacitor

Motor

R0 C0

R0 C0

After connecting a lead wire to

the Capacitor terminal, cover

it with the Capacitor cap.

CHC3115AUL

E56078 TP-31

CHC3115AULCHC3115AUL

E56078 TP-31E56078 TP-31

Capacitor cap

Lead wire

[How to install the capacitor cap]

SMK014K-A, SMK014K-AA, SMK014K-B, SMK550C-GN and SMK550C-GNB are

not supplied.

To protect the switch and relay contacts, be sure to connect a surge suppresser circuit.

NOTE

Refer to the catalog for

DC excitation.

Hexagon socket screw

or

Cross recessed screw

Spot facing or through

hole for pilot

Spring washer

Mounting plate

∗

1

This table indicates the overhung load and thrust load of the gearhead.

∗

2

Set to the dead mass of the motor or less where denoted by an asterisk 2 (

∗

2

).

When the pinion shaft type motor is used, the direction of rotation of the gearhead (sold separately) output shaft is opposite to that of the motor when the gear ratio is

25, 30

and 36.

For the geared motor, the direction of rotation of the gear output shaft is opposite when the

gear ratio is

15, 18, 100

and

120

.

NOTE

Loading...

Loading...