Page 1

HP-7420-4

Compact & Lightweight Stepping Motor and Driver Package

PMC Series

• Standard Type

• MG Geared Type

• Harmonic Geared Type

OPERATING MANUAL

Table of Contents

Safety precautions................................. Page 2

Product verification ................................ Page 5

Names and function of driver parts ....... Page 7

Installation.............................................. Page 9

Driver function swithces ........................ Page 15

Input/output signals ............................... Page 16

Connections........................................... Page 22

Motor current adjustment ...................... Page 24

Troubleshooting..................................... Page 27

Specifications......................................... Page 30

Installing and wiring in compliance........ Page 33

with EMC directive

Thank you for purchasing an Oriental Motor product.

This Operating Manual describes product handling procedures and safety precautions.

• Please read it thoroughly to ensure safe operation.

• Always keep the manual where it is readily available.

1

Page 2

Safety precautions

Only qualified personnel should work with the product.

Use the product correctly after thoroughly reading the section “Safety precautions.”

The precautions described below are intended to prevent danger or injury to the user and

other personnel through safe, correct use of the product. Use the product only after

carefully reading and fully understanding these instructions.

Warning

Handling the product without observing the instructions that accompany a “Warning”

symbol may result in serious injury or death.

Caution

Handling the product without observing the instructions that accompany a “Caution”

symbol may result in injury or property damage.

Note

The items under this heading contain important handling instructions that the user should

observe to ensure safe use of the product.

Warning

General

• Do not use the product in explosive or corrosive environments, in the presence of

flammable gases, locations subjected to splashing water, or near combustibles. Doing

so may result in fire or injury.

• Assign qualified personnel the task of installing, wiring, operating/controlling, inspecting

and troubleshooting the product. Failure to do so may result in fire or injury.

Installation

• Install the motor and driver in their enclosures in order to prevent injury.

Connection

• Keep the driver’s input-power voltage within the specified range to avoid fire.

• The driver power supply to be used should be a DC power supply where the primary

and secondary sides are provided with reinforced insulation. Otherwise, an electric

shock may occur.

• Connect the cables securely according to the wiring diagram in order to prevent fire.

• Do not forcibly bend, pull or pinch the cable. Doing so may fire.

2

Page 3

Operation

• Turn off the driver power in the event of a power failure, or the motor may suddenly start

when the power is restored and may cause injury or damage to equipment.

• When you want to use the motor in a vertical application, take position holding

measures. When the power is turned off, the motor will lose the holding brake force.

The movable part will drop and possibly cause injury to personal and damage to the

equipment.

• Do not turn the output current off input to “ON” while the motor is operating. The motor

will stop and lose its holding ability, which may result in injury or damage to equipment.

Repair, disassembly and modification

• Do not disassemble or modify the motor or driver. This may cause injury. Refer all such

internal inspections and repairs to the branch or sales office from which you purchased

the product.

Caution

General

• Do not use the motor and driver beyond their specifications, or injury or damage to

equipment may result.

• Do not touch the motor or driver during operation or immediately after stopping. The

surfaces are hot and may cause a burn.

Transportation

• Do not hold the motor output shaft or motor cable. This may cause injury.

Installation

• Keep the area around the motor and driver free of combustible materials in order to

prevent fire or a burn.

• To prevent the risk of damage to equipment, leave nothing around the motor and driver

that would obstruct ventilation.

• The motor and driver should be firmly secured on the metallic plate in order to prevent

personal injury or equipment damage.

• Provide a cover over the rotating parts (output shaft) of the motor to prevent injury.

3

Page 4

Operation

• Use a motor and driver only in the specified combination. An incorrect combination may

cause a fire.

• To avoid injury, remain alert during operation so that the motor can be stopped

immediately in an emergency.

• Before supplying power to the driver, turn all control inputs to the driver to “OFF.”

Otherwise, the motor may start suddenly and cause injury or damage to equipment.

• Make sure that the output power off input of the driver is turned on if you want to move

the motor shaft directly (e.g. for manual positioning). This caution is to prevent

personal injury.

• When an abnormality is noted, stop the operation immediately, or fire or injury may

occur.

Disposal

• When disposing of the motor or driver, treat them as ordinary industrial waste.

Note

Before using the product, read the content of the label carefully.

The content and stick position of the label are as follows.

ATTENTION

Please pay attention to the following

to the product work in the best

condition.

●Do not take the product out of the

protective bag until ready to use it.

●Do not touch parts and contacts to

avoid electrostatic damage.

●Do not expose the product to

vibration or shock.

●Keep the product away from dusty

and humid condition.

4

Protective bag

Driver

MNX7227

Page 5

Product verification

Equipment checklist

• Motor........................................................................ 1

• Driver ....................................................................... 1

• M2.5 Cross recessed head machine screws

with washer for mounting the motor

(for only MG geared type)........................................ 4

• Connector for signals

6-173977-4 (AMP), 6-173977-8 (AMP).................... 2

• Connector for power supply

6-173977-3 (AMP) ................................................... 1

• Connector for motor connection

6-173977-5 (AMP) ................................................... 1

• Operating manual .................................................... 1

Note

Do not take the product out of the protective bag until ready to use it. Otherwise, the driver

may be damage.

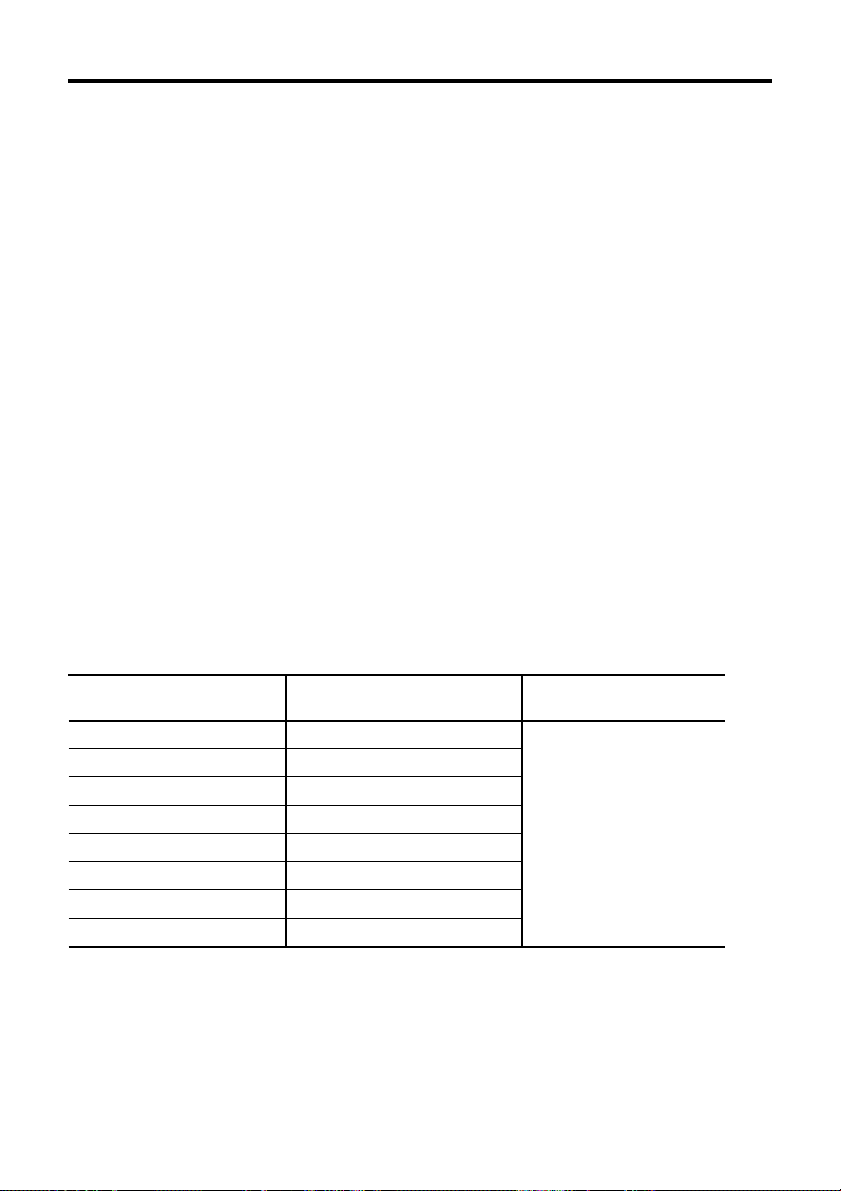

Model numbers and motor/driver combinations

The PMC series is a combined package which includes a stepping motor and driver.

This operating manual is designated for the following products.

Package model number

PMC33A3

PMC33B3

PMC35A3

PMC35B3

PMC33A1-MG∗

PMC33B1-MG∗

PMC33A1-HG∗

PMC33B1-HG∗

1

1

2

2

Motor model number

PMM33A2

PMM33B2

PMM35A2

PMM35B2

PMM33A-MG∗

PMM33B-MG∗

PMM33A-HG∗

PMM33B-HG∗

1

1

2

2

Driver model number

PMD03CA

The box (∗1) represents the desired gear ratio (3.6, 7.2, 10, 20, 30, 50).

The box (∗

2

) represents the desired gear ratio (50, 100).

Note

The motor and the driver are precision equipment and should not be dropped or subject to

any physical shocks.

5

Page 6

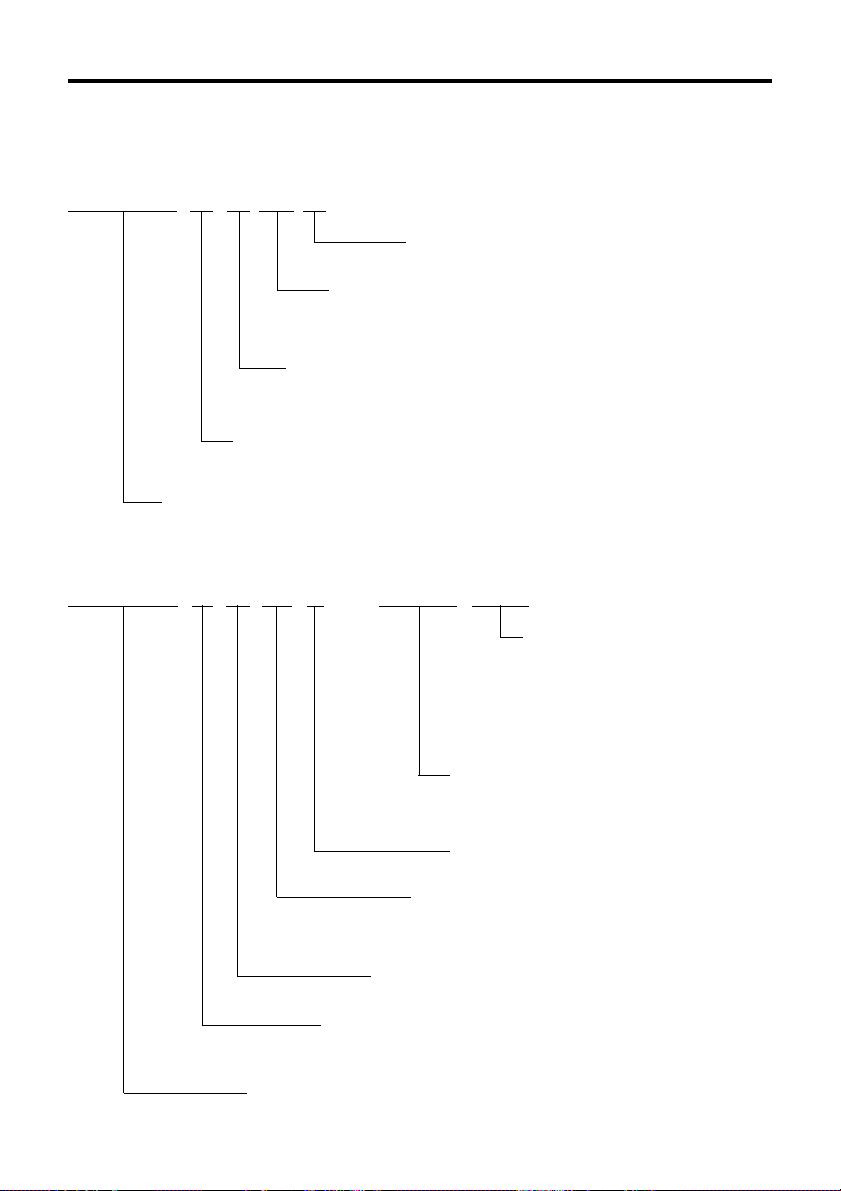

Interpreting the model number

P M C 3 3 A 3P M C 3 3 A 3

P M C 3 3 A 3

P M C 3 3 A 3P M C 3 3 A 3

Reference number

Shaft type

A:Single shaft

B:Double shaft

Motor case length

3:31mm (1.22in.)

5:50.5mm (1.99in.)

Motor frame size

3:28mm (1.1in.) sq.

Compact & lightweight stepping motor and driver package

PMC series

P M C 3 3 A 1 - M G 3.6P M C 3 3 A 1 - M G 3.6

P M C 3 3 A 1 - M G 3.6

P M C 3 3 A 1 - M G 3.6P M C 3 3 A 1 - M G 3.6

Geared type

MG : MG gear

HG : Harmonic gear

Gear ratio

MG geared type

3.6: 3.6:1 20 : 20:1

7.2: 7.2:1 30 : 30:1

10 : 10:1 50 : 50:1

Harmonic geared type

50 : 50:1 100 : 100:1

Reference number

Shaft type

A:Single shaft

B:Double shaft

Motor case length

Motor frame size

3:28mm (1.1in.) sq.

Compact & lightweight stepping motor and driver package

PMC series

6

Page 7

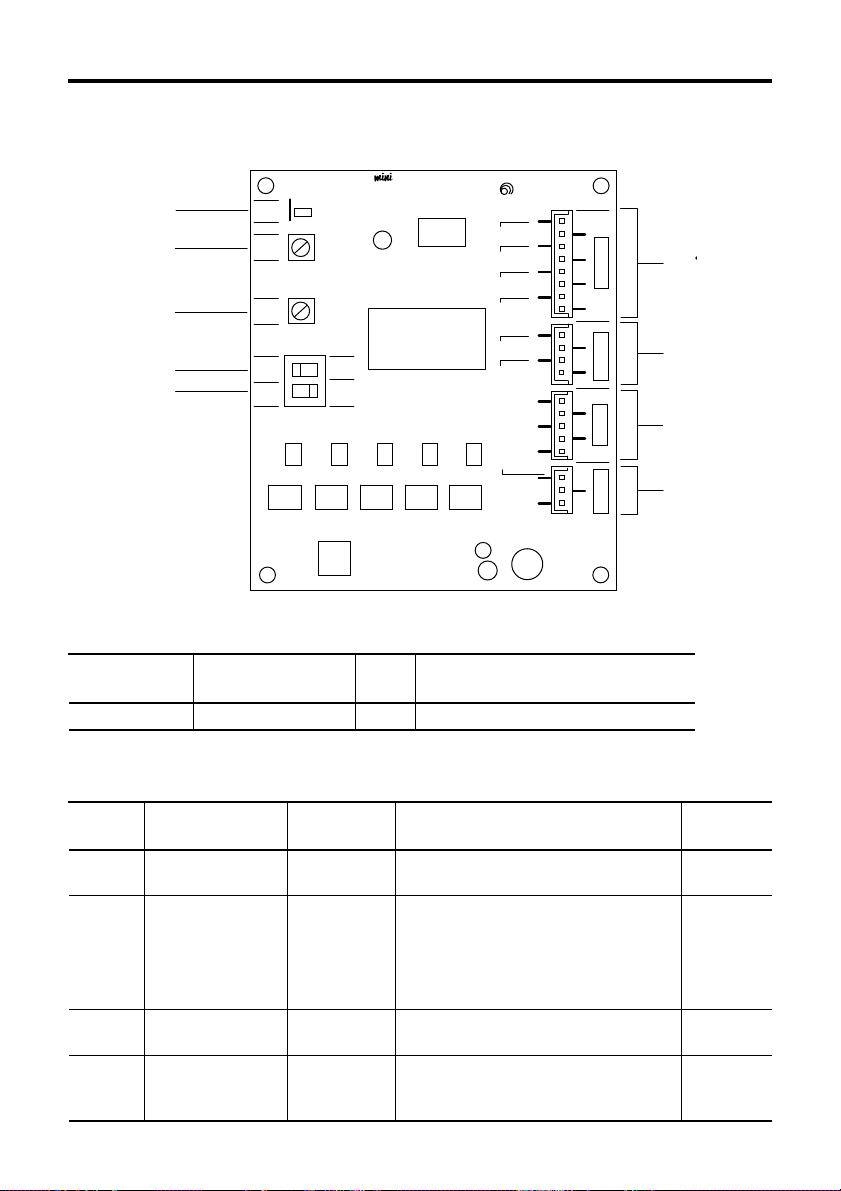

Names and functions of driver parts

Illustration shows the view from the connector side.

STEPPING DRIVER

CW/P.

CCW/D.

C.OFF

F/H

C.UP

TIM

BLU

RED

ORG

GRN

BLK

24 / 36V

GND

NC

1

+

+

CN1CN4CN3

+

+

+

+

+

1

1

1

CN2

SIGNAL 1

SIGNAL 2

MOTOR

POWER

①

②

③

④

⑤

LED indications

POWER

RUN

STOP

F

2P

VEXTA

H

1P

⑥

⑦

⑧

⑨

Indication

LED name

Color

① POWER Power input LED Green

Potentiometers and switches

Indication

② RUN

③STOP

④ F/H

⑤ 2P/1P

Name

Run potentiometer

Stop potentiometer

Step angle switch

Pulse input mode

switch

Factory

setting

0.35A/phase

0.175A/phase

F

1P

Current adjustment potentiometer used

when motor is running.

Motor standstill current adjustment

potentiometer used when current has

been cut back by the automatic current

cutback function when there is no pulse

input (motor standstill).

The motor step angle can be set to full

step or half step with this switch.

The pulse signal input mode can be set

to 1-pulse input mode or 2-pulse input

mode this switch.

Conditions when LED ON

Lights when the power is input.

Function

Page

reference

Page25

Page25, 26

Page15

Page15

7

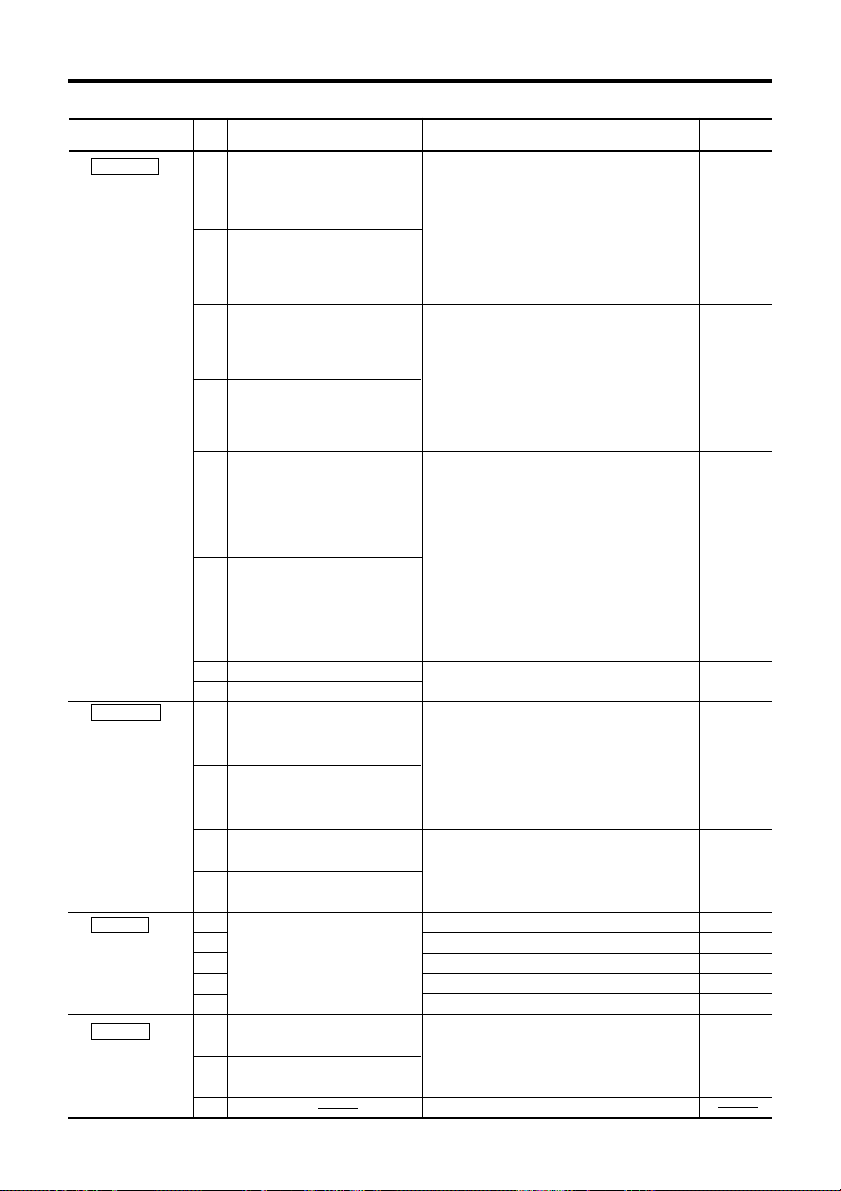

Page 8

Terminals

Indication Terminal name Function

⑥ SIGNAL 1

6-173977-8

(AMP)

∗1

The selection of

the pulse signal

input mode can

be set with the

pulse input

mode switch.

∗2

In this table, the

rotation direction

shows that of

motor output

shaft.

For harmonic

geared type and

gear ratio 10:1 of

MG geared type,

the motor rotation

direction is

opposite to the

output shaft

rotation direction.

⑦ SIGNAL 2

6-173977-4

(AMP)

⑧ MOTOR

6-173977-5

(AMP)

⑨ POWER

6-173977-3

(AMP)

8

Pin

No.

(Pulse/CW Pulse

CW/P.+

1

2

CW/P.

CCW/D.+

3

CCW/D.

4

C.OFF+

5

C.OFF

6

F/H+

7

F/H

8

C.UP+

1

2

C.UP

TIM+

3

TIM

4

1

2

Motor Connection Terminal

3

4

5

24/36V

1

GND

2

3

NC

Signal Input

Terminal)

(Pulse/CW Pulse

Signal Input

Terminal)

(Rotation Direction/

CCW Pulse Signal

Input Terminal)

(Rotation Direction/

CCW Pulse Signal

Input Terminal)

(All Windings Off

Signal Input

Terminal)

(All Windings Off

Signal Input

Terminal)

(Step Angle Signal Input Terminal)

-

(Step Angle Signal Input Terminal)

(Automatic Current

Cutback Release

Signal Input Terminal)

(Automatic Current

-

Cutback Release

Signal Input Terminal)

(Excitation Timing

Signal Output Terminal)

(Excitation Timing

Signal Output Terminal)

(Power Supply

Connection Terminal)

(Power Supply

Connection Terminal)

The pulse mode signal is input to this

terminal. The direction of the motor’s

rotation is determined by the following

rotation direction input terminal.

(When in 2-pulse input mode the CW

direction command pulse signal is input

to this terminal.)

The rotation direction signal is input to

this terminal. When a signal is input to

the terminal the motor output shaft will

rotate the counterclockwise direction.

(When in 2-pulse input mode the CCW

direction command pulse signal is input

to this terminal.)

The all windings off signal is input to this

terminal.

When a signal is input to the terminal the

driver will cut the power supply to the

motor.

The motor torque will then be reduced to

zero and the motor shaft can be rotated

freely for adjustment.

This function is used when manual

positioning etc. is required.

The motor step angle is input to this

terminal.

The automatic current cutback release

signal is input to this terminal.

Signal for deactivating the automatic

current cutback function, which cuts back

the output current to the motor when it is

standstill.

Signal indicating that the motor excitation

sequence is at step “0”.

Connect this terminal to the blue lead wire.

Connect this terminal to the red lead wire.

Connect this terminal to the orange lead wire.

Connect this terminal to the green lead wire.

Connect this terminal to the black lead wire.

Connect this terminal to a “+” side of

DC24V or DC36V and GND.

No connection.

Page

reference

Page16, 17

Page16, 17

Page18, 19

Page19

Page20

Page21

Page22, 23

Page22, 23

Page22, 23

Page22, 23

Page22, 23

Page22

Page 9

Installation

Motor installation

Motor installation location

To prevent motor damage, install in a location with the following conditions.

• Indoors (The motor is designed and manufactured to be used as an internal component

within other equipment.)

• Ambient temperature range

For harmonic geared type: 0°C~+40°C (+32°F~+104°F) (non-freezing)

• Ambient humidity below 85% (non-condensing)

• No explosive, combustible, or corrosive gases

• No direct sunlight

• No dust or conductive particles (i.e. metal chips or shavings, pins, or wire fragments

etc.)

• No water, oil, or other fluids

• Where the motor is able to dissipate heat easily

• No continuous vibration or sudden shocks

• No nearby radiation, magnetic field, or air vacuum environment

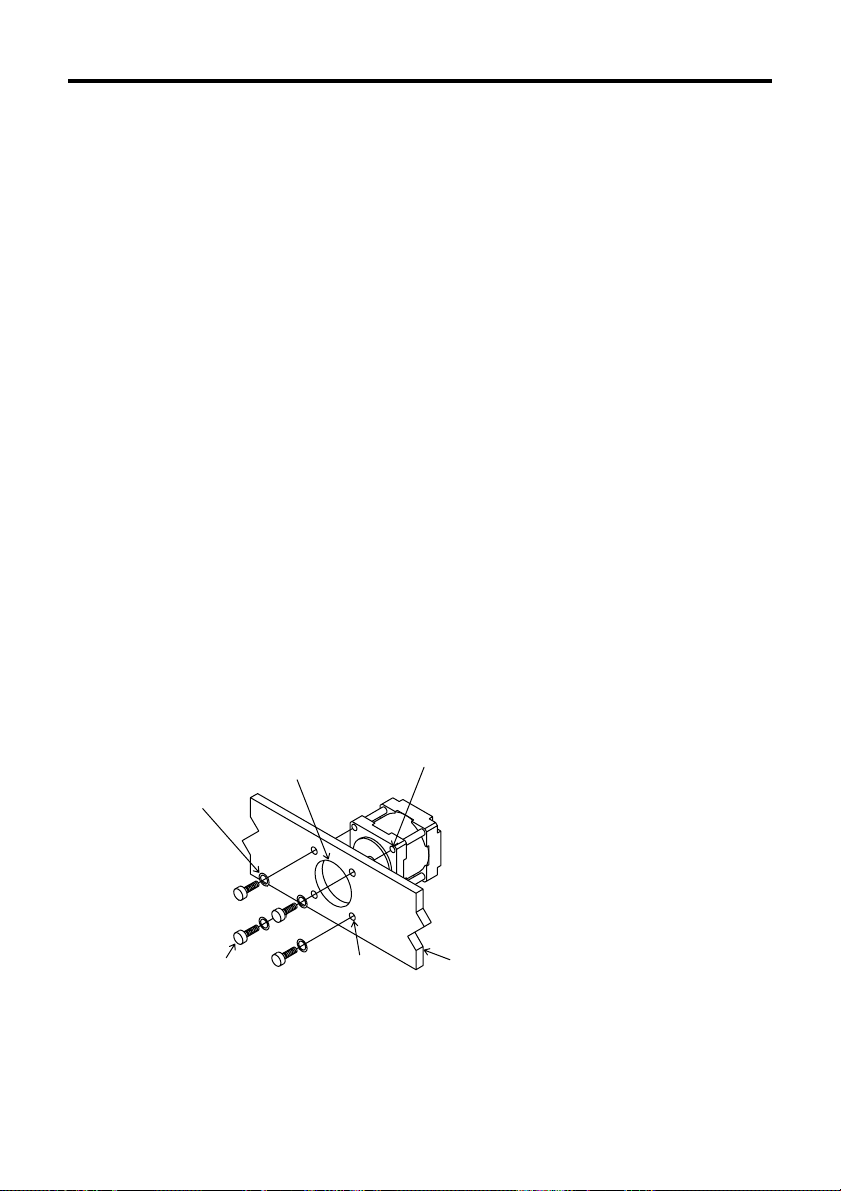

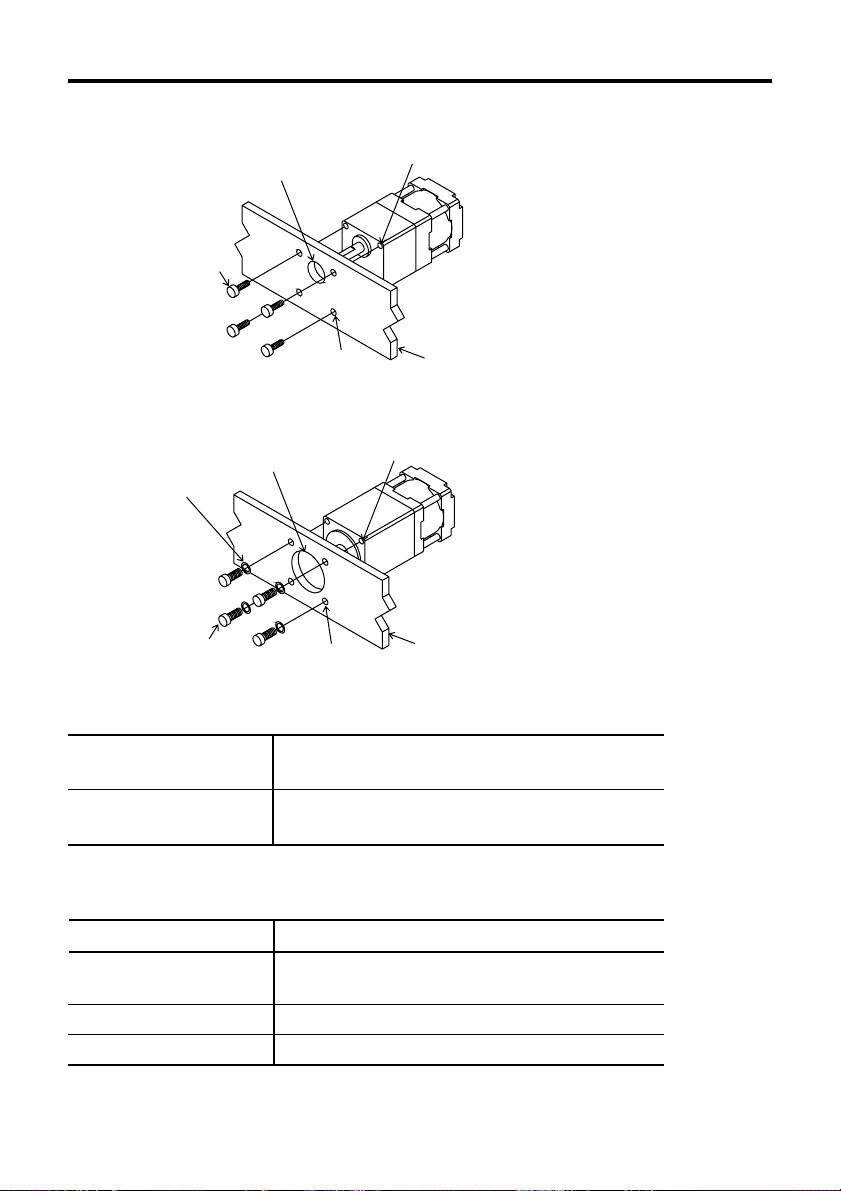

How to install the motor

To allow for heat dissipation and to prevent vibration, be sure to securely attach the motor

to solid metal surface.

The motor flange incorporates a pilot diameter. Use this pilot diameter as a guide for

alignment when mounting the motor.

-

10°C~+50°C (+14°F~+122°F) (non-freezing)

PMC3A(B)3

M2.5

Spring washer

M2.5

Recessed cross

head screws

Spot facing or

through hole for pilot

Ø3(.12)-4holes

4-M2.5 P0.45

Mounting plate

9

Page 10

PMC33A(B)1-MG

M2.5

Cross recessed

head machine

screws with

washer (attached)

Spot facing or

through hole for pilot

4-M2.5 P0.45

Ø3(.12)-4holes

Mounting plate

PMC33A(B)1-HG

M3

Spring washer

M3

Hexagonal

socket screws

Spot facing or

through hole for pilot

Ø3.5(.14)-4holes

4-M3 P0.5

Mounting plate

The following hardware (not supplied) is needed to mount the motor.

For the installation of the MG geared type, use the supplied screws.

PMC3A(B)3

PMC33A(B)1-HG

・M2.5 Recessed cross head screws : 4

・M2.5 Spring washers : 4

・M3 Hexagonal socket screws : 4

・M3 Spring washers : 4

Select screws with a length appropriate for the thickness of the mounting plate.

(Refer to the below table.)

Model

PMC33A(B)3

PMC35A(B)3

PMC33A(B)1-MG

PMC33A(B)1-HG

Length of the screws [Unit: mm (inch)]

thickness of the mounting plate +2.5 (0.1)

thickness of the mounting plate +3.5 (0.14)

thickness of the mounting plate +5 (0.2)

10

Page 11

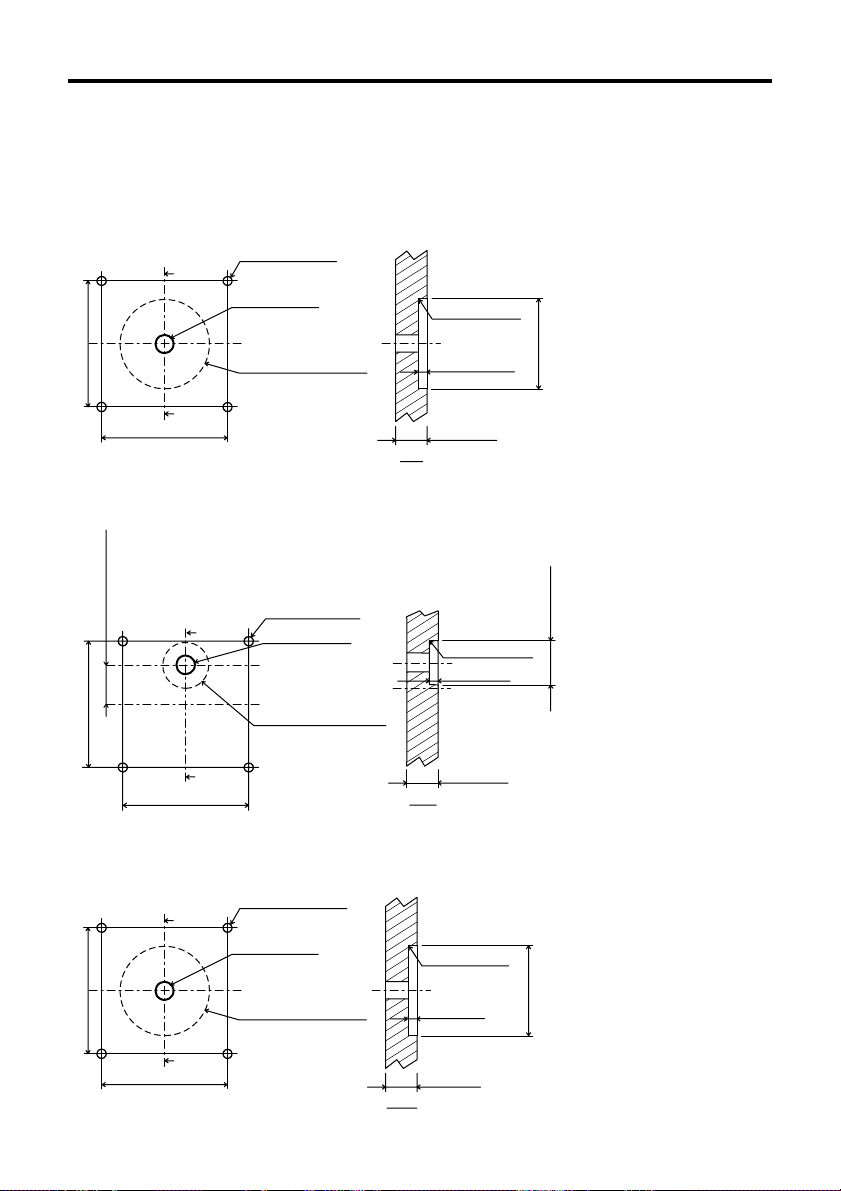

Motor mounting plate dimensions

[unit: mm (inch)]

PMC3A(B)3

Ø3(.12)-4holes

Ø5.5(.22)min.

Shaft hole

+0.033

+.0013

()

0

.87

0

Ø22

Spot facing or

through hole for pilot

23±0.2(.9±.008)

23±0.2(.9±.008)

X

X’

PMC33A(B)1-MG

Ø3(.12)-4holes

6±0.2(.2±.008)

X

Ø5.5(.22)min.

Shaft hole

R0.3(.01)max.

1.5(.059)min.

2(.08)min.

X-X’

R0.5(.02)max.

2(.08)min.

0

+.0013

.87

()

+0.033

0

Ø22

Ø11.5(.45)

23±0.2(.9±.008)

X’

23±0.2(.9±.008)

PMC33A(B)1-HG

X

23±0.2(.9±.008)

23±0.2(.9±.008)

X’

Ø11.5(.45)

Spot facing or

through hole for pilot

Ø3.5(.14)-4holes

Ø8.5(.33)min.

Shaft hole

+0.033

+.0013

()

0

.87

0

Ø22

Spot facing or

through hole for pilot

X-X’

R0.3(.01)max.

2(.08)min.

5(.2)min.

X-X’

2(.08)min.

0

+.0013

.87

()

+0.033

0

Ø22

11

Page 12

Connecting the motor to the drive mechanism (Load)

Ball screw

Stepping motor

Coupling

Proper alignment is necessary when

connecting the drive mechanism (load) to

the motor shaft. Use a flexible coupling.

Note

• Inadequate alignment may reduce the life span of the motor bearings or damage the

motor shaft.

• Exceeding the permissible overhung load or permissible thrust load will damage or shorten

the life span of the bearings and motor shaft.

Do not exceed the permissible overhung load and thrust load as indicated in the

following chart.

• For geared motor, do not separate the motor and the gearhead.

Permissible overhung load [Unit: N (lb.)]

Distance from the end

of the shaft [mm (inch)]

PMC3

A(B)3

1

PMC33A(B)1-MG

PMC33A(B)1-HG

∗

∗

2

0

25 (5.51)

9.2 (2.02)

140 (30.8)

Permissible thrust load [Unit: N (lb.)]

PMC33A(B)3

PMC35A(B)3

PMC33A(B)1-MG

PMC33A(B)1-HG

1

The box (∗

The box (∗

) represents the desired gear ratio (3.6, 7.2, 10, 20, 30, 50).

2

) represents the desired gear ratio (50, 100).

1

∗

2

∗

1 (0.22)

1.7 (0.374)

10 (2.2)

100 (22)

5 (0.2)

34 (7.49)

11.4 (2.51)

160 (35.2)

10 (0.39)

52 (11.4)

15 (3.3)

200 (44.1)

15 (0.59)

21.9 (4.82)

240 (52.8)

12

Page 13

Driver installation

Driver installation location

To prevent driver damage, install in a location with the following conditions.

• Indoors (The driver is designed and manufactured to be used as an internal component

within other equipment.)

Ambient temperature range 0°C~+40°C (+32°F~+104°F) (non-freezing).

Install a forced-air cooling fan if ambient temperatures exceed +40°C (+104°F).

• Ambient humidity below 85%(non-condensing)

• No explosive, combustible, on corrosive gases

• No direct sunlight

• No dust or conductive particles (i.e. metal chips or shavings, pins, or wire fragments

etc.)

• No water, oil, or other fluids

• Where the driver is able to dissipate heat easily

• No continuous vibration or sudden shocks

• No nearby radiation, magnetic field, or air vacuum environment

• If the driver is installed in a switch box or other enclosed area, and near a heat source,

be sure to establish ventilation holes. The heat generated by the driver will cause the

ambient temperature to rise which could consequently damage the driver.

• If the driver is installed near a source of vibration, and this vibration is transmitted to the

driver, attach a shock absorber to prevent driver damage.

• If the driver is installed near a source of noise interference (i.e. high frequency welding

machine, electromagnetic switch, etc.) install a noise filter, or connect it to a separate

power source to reduce the effect of the interference, otherwise the motor may not

operate correctly.

• Leave a space of at least 25mm (1in.). If using more than one driver, leave a space of at

least 20mm (0.8in.) between each driver. Driver heat generation will cause the ambient

temperature to rise, and if the permissible ambient operating temperature is exceeded,

driver damage may result.

How to install the driver

The driver is designed to cool naturally by convection.

Secure the driver to a metal plate made of steel, aluminium or other material having good

thermal conductivity.

The following hardware (not supplied) is needed to mount the driver.

• M3 Screws :4

• M3 Spring washers :4

• Insulation type spacers : 4

• M3 Nuts :4

13

Page 14

Driver mounting plate dimensions

Horizontal mounting Vertical mounting

Connector

Securing the driver

1. Insert spring washers and M3 screws from the surface of the connector side of the

circuit board.

2. Insert the spacer between the driver and the mounting plate, and secure by using M3

nuts.

• Spacer size: Ø9mm (0.35in.) max. 6mm (0.24in.) min. long

• Screw tightening torque: 0.5N·m (71oz-in)

[Unit: mm (inch)]

14

56(2.2)

50±0.3(1.97±.01)

3(.12)

72(2.83)

66±0.3(2.6±.01)

3(.12)

M3 Spring washer

Ø3.2(.13)-4holes

M3 Screw

Insulation

type spacer

M3 nut

Driver

6(.24)min.

Chassis

Page 15

Driver function switches

The driver has various operation functions which are set with the function switches.

ON

ON

12

H

1P

Step angle switch

Pulse input mode switch

OFF

F

2P

∗The white square section of the function switch represents the switch lever.

Step angle switch (Factory setting : F)

When the switch is set to:

ON

1

F

2

H

“F” (Full step)

Standard type: 1step = 0.72° (1 rotation = 500 pulses)

Geared type: 1step= 0.72°×

1

gear ratio

(1 rotation = 500×gear ratio pulses)

“H” (Half step)

Standard type: 1step = 0.36° (1 rotation = 1000 pulses)

Geared type: 1step = 0.36°×

1

gear ratio

(1 rotation =1000×gear ratio pulses)

Pulse input mode switch (Factory setting : 1P)

Select the appropriate pulse input mode to correspond to

your controller with this switch.

When the switch is set to the 1P position, 1-pulse input

mode is established and motor rotation is controlled by

pulse signals and rotation direction signals.

When the pulse input mode switch is set to the 2P position,

2-pulse input mode is established and motor rotation is

controlled by CW and CCW pulse signals.

2P

ON

12

1P

15

Page 16

Input/output signals

Input signals

The input signals to the driver and their functions are specified below.

Pulse/CW pulse signals

Rotation direction/CCW pulse signals

The diagram below shows the input circuits and an example connection to a controller.

Driver input

Controller output

Open collector

output

PLS(CW)

DIR.(CCW)

0

V

R

R

(Internal circuit)

Pulse(CW)

+

1

220Ω

CW/P.

2

‑

Rotation direction(CCW)

+

3

220Ω

CCW/D.

4

‑

20mA max.

20mA max.

1-Pulse input mode

Pulse signal

When the photocoupler state changes from “ON” to “OFF”, the motor rotates one step.

The direction of rotation is determined by the following rotation direction signals.

Rotation direction signal

The rotation direction signal is input to rotation direction/CCW pulse signal input terminal.

An input signal at “photocoupler ON” commands a clockwise direction rotation.

(For harmonic geared type and gear ratio 10:1 of MG geared type: counterclockwise)

An input signal at “photocoupler OFF” commands a counterclockwise direction rotation.

(For harmonic geared type and gear ratio 10:1 of MG geared type: clockwise)

The number within refers to the pin

number of driver connector SIGNAL 1.

The information in the brackets ( ) refers to

signals when in 2-pulse input mode.

Keep the voltage between DC5V and DC24V.

When voltage is equal to DC5V, external

resistance R is not necessary.

When voltage is above DC5V, connect

external resistance R and keep the input

current below 20mA.

2-Pulse input mode

CW∗ pulse signal

When the photocoupler state changes from “ON” to “OFF”, the motor rotates one step in

the clockwise direction.

(For harmonic geared type and gear ratio 10:1 of MG geared type: counterclockwise)

CCW∗ pulse signal

When the photocoupler state changes from “ON” to “OFF”, the motor rotates one step in

the counterclockwise direction.

(For harmonic geared type and gear ratio 10:1 of MG geared type: clockwise)

∗ CW and CCW refer to clockwise and counterclockwise directions respectively, from a

reference point of facing the motor output shaft.

16

Page 17

Relation to the pulse input mode switch

When the switch is set to the 1P position, motor rotation is controlled by pulse signals and

rotation direction signals.

When the switch is set to the 2P position, motor rotation is controlled by CW pulse signals

and CCW pulse signals.

Pulse waveform characteristics

1-Pulse input mode

5µs

min.

2µs

max.

5µs

min.

2µs

max.

Photocoupler ON

Photocoupler OFF

Photocoupler ON

Photocoupler OFF

90%

10%

10

µsmin.

10

Pulse signal

µsmin.

Rotation direction signal

2-Pulse input mode

Photocoupler ON

Photocoupler OFF

Photocoupler ON

Photocoupler OFF

• The shaded area indicates when the photocoupler diode is ON. The motor moves when

the photocoupler states changes from ON to OFF as indicated by the arrow.

• The pulse voltage is 4~5V in the “photocoupler ON” state, and 0~0.5V in the

“photocoupler OFF” state.

• Input pulse signals should have a pulse width over 5µs, pulse rise/fall below 2µs, and

a pulse duty below 50%.

• Keep the pulse signal in the “photocoupler OFF” state when no pulse is being input.

• The minimum interval time when changing rotation directions is 10µs.

• In 1-pulse input mode, leave the pulse signal at rest “photocoupler OFF” when

changing rotation directions.

• In 2-pulse input mode, do not input CW and CCW pulse signals at the same time.

Inputting a pulse signal while the other pulse signal is already in the “photocoupler

ON” state will result in erratic motor rotation.

90%

10%

2µs

max.

5µs

min.

5µs

min.

2µs

max.

10

CW pulse signal

CCW pulse signal

µsmin.

17

Page 18

All windings off signal

The diagram below shows the input circuit and an example connection to a controller.

The number within refers to the pin

number of driver connector SIGNAL 1.

Keep the voltage between DC5V and DC24V.

When voltage is equal to DC5V, external

resistance R is not necessary.

When voltage is above DC5V, connect

external resistance R, and keep the input

current below 20mA.

Controller output

Open collector

output

C.OFF

Driver input

+

C.OFF

‑

(Internal circuit)

220Ω

5

6

20mA max.

0

V

R

When the all windings off signal is in the “photocoupler ON” state, the current to the motor

is cut off and motor torque is reduced to zero. The motor output shaft can then be rotated

freely by hand.

When the all windings off signal is in the “photocoupler OFF” state, the motor holding

torque is proportional to the current set by the current adjustment rotary switches. During

motor operation be sure to keep the signal in the “photocoupler OFF” state.

This signal is used when moving the motor by external force or manual home positioning

etc. is desired. If this function is not needed, it is not necessary to connect this terminal.

Switching the all windings off signal from “photocoupler ON” to “photocoupler OFF” does

not alter the excitation sequence.

When the motor shaft is manually adjusted with the all windings off signal input, the shaft

will shift up to ±3.6°

(geared type: ±3.6°/gear ratio) from the position set after the all windings off signal is

released.

18

Page 19

Manual detection of the home position

Input the all windings off signal, set the motor to the desired position, then release the all

windings off signal.

All windings off signal input

All windings off

signal release

All windings off

signal input

Photocoupler ON

Photocoupler OFF

Home position

set

OFF OFF

ON

Note

For geared type, do not do manual detection of the home position. It may cause damage

the gearhead and may cause the following problems.

• The motor makes a strange noise.

• The motor does not rotates correctly.

Step angle signal

The diagram below shows the input circuit and an example connection to a controller.

Driver input

+

F / H

‑

(Internal circuit)

220Ω

7

8

20mA max.

Controller output

Open collector

output

F / H

0

V

R

Half Step

Standard type:

When the step angle signal is in the

“photocoupler ON” state, it is set to half-step

mode (0.36°/step, 1 rotation 1000 pulses)

Geared type:

When the step angle signal is in the

“photocoupler ON” state, it is set to half-step

mode

(0.36°× / step,

1

gear ratio

1 rotation 1000×gear ratio pulses)

The number within refers to the pin

number of driver connector SIGNAL 1.

Keep the voltage between DC5V and DC24V.

When voltage is equal to DC5V, external

resistance R is not necessary.

When voltage is above DC5V, connect

external resistance R, and keep the input

current below 20mA.

Full Step

Standard type:

When the step angle signal is in the

“photocoupler OFF” state, it is set to fullstep mode (0.72°/step, 1 rotation 500

pulses)

Geared type:

When the step angle signal is in the

“photocoupler OFF” state, it is set to fullstep mode

(0.72°× / step,

1

gear ratio

1 rotation 500×gear ratio pulses)

Note

When the step angle signal is used, the switch must be set to the F position.

19

Page 20

Automatic current cutback release signal

The diagram below shows the input circuit and an example connection to a controller.

Controller output

Open collector

output

C.UP

Driver input

+

C.UP

‑

(Internal circuit)

220Ω

1

2

20mA max.

0

V

R

The number within refers to the pin

number of driver connector SIGNAL 2.

Keep the voltage between DC5V and DC24V.

When voltage is equal to DC5V, external

resistance R is not necessary.

When voltage is above DC5V, connect

external resistance R, and keep the input

current below 20mA.

• When the automatic current cutback release signal is in the “photocoupler OFF” state,

the automatic current cutback function is activated; 0.1s. after the pulse is stopped the

motor output current is automatically cut back, reducing motor and driver heat.

(The factory setting for the current cutback is 50%. In order to change this, refer to the

instructions for adjusting the current at motor standstill on pages 25, 26)

• When the maximum holding torque is needed, input “photocoupler ON” signal. The

automatic current cutback function is deactivated.

• When the automatic current cutback release signal is in the “photocoupler ON” state,

the automatic current cutback function is deactivated.

• Because the motor’s holding power is proportional to the motor output current, the motor’s

holding power is reduced when the current is cut back. (The motor has holding power

proportional to the current at motor standstill, which is set with the STOP potentiometer.

Refer to page 24.)

Note

Generally, automatic current cutback release signal should be set to “photocoupler OFF”

to suppress heat generation in the motor and driver.

20

Page 21

Output signals

The output signals from the driver and their functions are specified below.

Excitation timing signal

The diagram below shows the output circuit and an example connection to a controller.

Controller output

Driver input

(Internal circuit)

V

0

R

TIM

+

‑

3

4

10mA max.

The number within refers to the pin

number of driver connector SIGNAL 2.

Keep the voltage between DC5V and DC24V.

Keep the current below 10mA.

If the current exceeds 10mA, connect external

resistance R.

The excitation timing signal is output to indicate when the motor excitation (current flowing

through the winding) is in the initial stage (step “0” at power up ).

The excitation timing signal can be used to increase the accuracy of home position

detection by setting mechanical home position of your equipment (photo-sensor etc.) to

coincide with the excitation sequence initial stage (step “0”).

When connected as shown in the example connection, the signal will be “photocoupler

ON” at step “0”.

The excitation timing signal is output simultaneously with a pulse input each time the

excitation sequence returns to step “0”.

The excitation sequence will complete one cycle for every 7.2° rotation of the motor output

shaft.

When the power is turned ON, the excitation sequence is reset to step “0”.

Relation to the step angle switch

When the switch is set to the F position:

Full step: signal is output once every 10 pulses

(Standard type: 0.72°/step, Geared type: 0.72°× / step)

When the switch is set to the H position:

Half step: signal is output once every 20 pulses

(Standard type: 0.36°/step, Geared type: 0.36°× / step)

1

gear ratio

1

gear ratio

Timing chart when in full step mode

123456789101112

Pulse

Rotation direction

Excitation timing

output

Step

0

123456789012

12

1

0

21

Page 22

Connections

Connecting the motor, driver and power supply

• For signal lines, use twisted pair wire of AWG28 (0.08mm2) or greater, and 1m (39.4in.)

or less in length.

• For power lines and when extending the motor lead wires use wires of AWG26 (0.14mm

or greater.

• Separate the signal lines from the power lines and motor lead wires by at least 30cm

(11.8in.). Do not band place the signal lines in the same duct as, or bind them together

with, power lines, as this makes it easier for noise to enter the signal line, which can

cause operating errors.

• Use an open collector transistor (sink type) for the controller signal output.

• If electrical noise generated by the motor lead wires or other equipment causes

operational errors, shield the signal lines with conductive tape or wire mesh etc. (not

supplied).

2

)

Pressure welding of the connectors

• The suitable wire size of AWG28 (0.08mm

having an outside diameter of 0.85mm (0.03in.)~1.05mm (0.04in.).

Use a wire rated at AWG26 (0.14mm

• Use the tool specified by the connector manufacturer (AMP 911790-1) for pressure

welding of the terminals.

Note

When pulling and inserting the connector to the driver, hold the connector itself.

Otherwise, the motor and the driver may be damaged.

2

) to AWG26 (0.14mm2) with a sheathing

2

) for the power line.

Driver power supply

The input power voltage should come from a DC24V or DC36V power supply which is

reinforced insulation.

The input current of the power supply is 0.7A or less.

Use a power supply which will supply sufficient input current.

(The current value for input power is a maximum value when connecting the drive

mechanism (load) to the motor shaft.)

Note

If the current from the power supply is insufficient the motor torque will be reduced and the

transformer may be damaged. The following abnormalities may also occur.

• Erratic motor rotation during high speeds

• Delayed motor start-up and stopping

22

Page 23

Example connections

Connection to user’s controller

Driver( )

①

+

CW / P.

+

CCW / D.

+

C.OFF

+

F / H

+

C.UP

+

TIM

BLU

RED

ORG

GRN

BLK

24 / 36V

+

GND

NC

②

③

④

⑤

SIGNAL1SIGNAL2MOTORPOWER

⑥

⑦

⑧

①

②

③

④

①

②

③

④

⑤

①

②

③

Pulse/CW pulse signal input

Rotation direction/

CCW pulse signal input

All windings off signal input

Step angle signal input

Automatic current cutback

release signal input

Excitation timing

Signal output

Blue

Red

Orange

Green

Black

+24 / 36V

GND

N.C (power supply which is reinforced insulation)

Stepping motor

+

DC24V or DC36V

Power supply

-

User’s controller

V0(+5V〜24V)

R

1

R

1

R

1

R

1

R

1

R

2

R

0

GND

Note: For operations involving sudden

deceleration or the driving of large

inertial loads, connect a capacitor

of 1000µF or more to suppress

the motor’s regenerative voltage.

+24V±10%

GND

DC POWER

+

SUPPLY

‑

Input signal connections

Keep the voltage between DC5V and DC24V.

When voltage is equal to DC5V, external resistance R

When voltage is above DC5V, connect external resistance R

is not necessary.

1

and keep the input

1

current below 20mA.

Output signal connections

Keep the voltage between DC5V and DC24V.

Keep the current below 10mA.

If the current exceeds 10mA, connect external resistance R2.

Turning on the power

Before turning the power ON, be sure that the signal lines, motor lead wires, power line,

and earth line are all properly connected.

The power LED lights when turning on the power (The power LED keeps lighting during

turning on the power.).

23

Page 24

Motor current adjustment

)

The PMC driver is shipped with the motor rated current set to 0.35A/phase (and the

standstill current reduction (current cutback) ratio set to approximately 50%).

It is not necessary to adjust the current under normal operating conditions. However,

readjust the current setting in the following cases.

To reduce motor vibration Æ Reduce the motor running current

To reduce temperature rise of the motor and driverÆReduce the motor running current and the motor

To increase the motor’s standstill holding torqueÆ Raise the motor’s standstill current

Holding torque can be calculated using the following formulas

(Holding torque is proportional to output current.)

Current cutback ratio (%)=

× 100

Running current setting

Maximum holding torque [N·m (oz-in)]×Current cutback ratio (%)

Holding torque [N·m (oz-in)]=

100

Relationship between the potentiometers and the current

The relationship between the potentiometers and the current is shown below.

Standstill current setting

Motor running current

(Representative values)

0.4

0.3

0.2

0.1

Output current A/phase

0

0

RUN potentiometer scale

2 3

Factory setting

(0.35A/phase

2

3

1

41

Motor standstill current

(Representative values)

100

Factory setting

75

(50%)

50

25

Down ratio %

0

01 23

STOP potentiometer scale

2

1

4

3

24

Page 25

Adjusting the current using an ammeter

When more precise current adjustment are necessary, make them by connecting an

ammeter between the driver and motor, as shown below.

RUN potentiometer

Used to adjust the

motor’s running current

STOP potentiometer

Used to adjust the

current cutback ratio

at motor standstill

Step angle switch

Set to F

Custom driver ( )

RUN

STOP

FH

2P

1P

C.UP

BLU

RED

ORG

GRN

BLK

24/36V

+

GND

NC

+

1

2

3

4

5

6

SIGNAL 1

7

8

1

2

3

4

SIGNAL 2

1

2

3

4

MOTOR

5

1

2

3

POWER

(This power supply is not

needed when setting only the

5V

standstill current.)

Automatic current cutback

release input

SW1

Set according to the

explanation below.

DC ammeter

Blue

Red

Orange

Green

Black

Stepping motor

DC24V or DC36V+

-

power supply

-

+

+24 / 36V

GND

NC

Note

With the connections shown here, the current flowing to the ammeter is twice that of

a single phase.

Therefore, the current setting (per single phase) is equivalent to half the value indicated

on the ammeter.

For example, when the ammeter indicates 0.5A, the setting is 0.25A/phase.

Setting the motor running current

1. Confirm that the step angle switch set to F.

ON

1

F

2

H

2. Turn on SW1 for the C.UP automatic current cutback release input. (Do not input any

other signals)

3. After connecting the motor and DC ammeter, turn the power on.

4. Set the current using the RUN potentiometer.

∗Set the value indicated on the ammeter to twice the desired current setting (per phase).

5. Turn the power off.

6. Turn off SW1 for the C.UP automatic current cutback release input.

25

Page 26

Setting the motor standstill current

1. Confirm that the step angle switch set to F.

ON

1

F

2

2. Check that nothing is connected or input to the C.UP terminal, and that the SW1 switch

is turned off when using the connection shown above.

3. After connecting the motor and DC ammeter, turn the power on.

4. Set using the STOP potentiometer.

∗Set the value indicated on the ammeter to twice the desired current setting (per phase).

5. Turn the power off.

H

26

Page 27

Troubleshooting

Consult the following chart if the motor is not functioning properly. If the motor is still not

functioning properly after confirming the checkpoints below, contact your nearest sales

office as listed at the back of this manual.

Problem

No excitation in the

motor.

(The motor has no

holding torque and the

shaft can be turned

freely by hand.)

The motor does not

rotate.

The motor does not

rotate when a pulse

signal is input.

Check points

1. Is the driver POWER

LED On?

(If On, condition is normal)

2. Is the all windings off signal

being input to the driver?

3. Are the driver and motor

correctly connected?

4. Are the current adjustment

potentiometers (RUN or

STOP) set too low?

Note: If the motor still has no torque after checking the above conditions, the

driver is probably defective.

After reconfirming that the current voltage and connections are correct,

contact your nearest sales office for service.

First check the 4 items above.

5. In 2-pulse input mode

(pulse input mode

switch in the 2P position) is

either the pulse/CW pulse

or rotation direction/CCW

pulse signal input terminal

already in the “photocoupler

ON” state?

6. In 1-pulse input mode

(pulse input mode

switch in the 1P position) is

the pulse signal connected

to the rotation direction/

CCW pulse signal input

terminal?

If the POWER LED is not On, check if the

power supply is properly connected.

When the all windings off signal is input the

motor will lose all excitation (no holding

torque). Return the all windings off signal to

“photocoupler OFF”.

Check the wiring configuration and continuity

of the connector pressure weld. If the lead

wires have been extended, check the

extension connection.

These potentiometers control the output

current to the motor (refer to pages 24, 25,

26). If they are set too low return them to the

factory set positions.

The motor will not rotate if a pulse signal is

input when the other pulse signal input

terminal is already in the “photocoupler ON”

state.

Be sure to keep the pulse signal in the

“photocoupler OFF” state.

Connect the pulse signal to the pulse/CW

pulse signal input terminal.

Measures

27

Page 28

Problem

The motor rotates in

the wrong direction.

Motor rotation is

erratic.

Motor start up is

unstable.

Check points

7. In 2-pulse input mode

(pulse input mode switch

in the 2P position) are the

CW and CCW pulse signal

lines connected

backwards?

8. In 1-pulse input mode

(pulse input mode switch

in the 1P position) leave

the rotation direction/CCW

pulse signal input terminal

unconnected and try

inputting a pulse signal to

the pulse/CW pulse signal

input terminal.

9. Is harmonic geared type or

gear ratio of 10:1 of MG

geared type used?

First check items 5, 6, 7 and 8.

10. While in 2-pulse input

mode (pulse input mode

switch in the 2P position)

are the both of pulse/CW

pulse and rotation

direction CCW pulse

signal input at the same

time?

11. Are the motor shaft and

load properly aligned? Is

the load too heavy for the

motor?

Measures

Connect the CW pulse signal line to the

pulse/CW pulse signal input terminal, and

connect the CCW pulse signal line to the

rotation direction/CCW pulse signal input

terminal.

If the motor rotates in a counterclockwise

direction the motor and driver are normal.

Recheck the rotation direction signal levels.

(“photocoupler ON” = clockwise,

“photocoupler OFF” = counterclockwise)

For harmonic geared type and 10:1 of MG

geared type, due to the gear’s construction,

the direction of rotation of the output shaft is

opposite to the direction of rotation of the

motor itself as commanded by pulse input

(Refer to page 16).

Connect the CW pulse signal line to the

rotation direction/CCW pulse signal input

terminal, and connect the CCW pulse signal

line to the pulse/CW pulse signal input

terminal.

The motor will run irregularly if two pulses are

input at the same time.

Make sure the motor shaft and load are

securely attached and properly aligned.

Recheck the operating conditions, and if

necessary lighten the load.

28

Page 29

Problem

The motor rotates too

far or not far enough.

The motor loses

synchronization during

acceleration or while

running.

Motor vibration is very

high.

Motor temperature is

very high.

[The temperature of

the motor case should

be less than 100°C

(212°F). For harmonic

geared type: less than

70°C (158°F). ]

The automatic current

cutback function does

not work.

Check points

12.Does the step angle

required by your

equipment match the step

angle of the stepping

motor?

13.Is the number of pulses set

to match the amount of

motor rotation?

14.Is the starting pulse

frequency too high?

15.Is the acceleration/

deceleration time too

short?

16.Is the motor being affected

by noise interference?

17.Is the output torque too

high?

18.Try changing the pulse

frequency.

19.Is the motor running time

too long?

20.Is the automatic current

cutback release function

input?

21.Try changing the pulse

rate.

22.Is the pulse/CW pulse or

rotation direction/CCW

pulse signal input

“photocoupler ON”

after the completion of the

pulse signal?

23.Is automatic current

cutback release

function being input?

Measures

Check the setting of the step angle switch

located on the driver.

Check the controller pulse setting.

Check this by decreasing the frequency.

Check this by increasing the acceleration/

deceleration time.

Check this by running the motor while the

machine suspected of producing the noise

interference is off.

Try reducing the motor running current with

the current adjustment potentiometer “RUN”.

If the vibration decreases after the pulse

frequency has been adjusted, this means the

motor is resonating. Either adjust the

frequency or change the step angle.

Also try installing the optional (sold

separately) clean damper (for double shaft

model only).

Shorten the running time or increase the

resting time.

Turn off the automatic current cutback

release input.

The temperature of the motor rise varies

depending on the pulse rate. Refer to the

speed-torque characteristics in the catalog,

and operate at a lower input speed.

This function does not work, and the motor

current is not reduced, when the pulse signal

is held at “photocoupler ON”. Always return it

to “photocoupler OFF”.

Turn off the automatic current cutback

release input.

29

Page 30

Specifications

Package Model

Maximum Holding Torque

Rotor Inertia

Rated Current

Basic Step Angle

Shaft Runout

Perpendicularity

Concentrictly

Insulation Class

Power Source

Output Current

Excitation Mode

Input Signal

• Pulse Signal

(CW Pulse Signal)

• Rotation Direction Signal

(CCW Pulse Signal)

• Step Angle Signal

Input Signals

• All Windings Off Signal

•

Automatic Current Cutback

Release Signal

Output Signal Circuit

• Excitation Timing Signal

Output Signals

Functions

Indication (LED)

Driver Cooling Method

Mass

Insulation Resistance

Dielectric Strength

Ambient Temperature Range

• Maximum holding torque refers to the holding torque at motor standstill when the rated current is supplied to the

motor (5-phase excitation). Use this value to compare motor torque performance. When using the motor with the

included driver, the driver’s “Automatic Current Cutback” function at motor standstill reduces maximum holding

torque by approximately 50%.

• The power source input current value represents the maximum current. (The input current varies according to the

pulse frequency.)

Single Shaft

Double Shaft

N·m (oz-in)

kg·m2 (oz-in2)

A/phase

mm (inch)

mm (inch)

mm (inch)

•Full step (4 phase excitation): 0.72°/step

•Half step (4-5 phase excitation): 0.36°/step

Photocoupler input, Input resistance 220Ω, Input current 20mA maximum

Signal voltage Photocoupler ON: +4~+5V, Photocoupler OFF: 0~+0.5V

Step command pulse signal (CW step command signal at 2-pulse input mode)

Pulse width: 5µs minimum, Pulse rise/fall: 2µs maximum

Motor moves when the photocoupler state changes from ON to OFF.

Rotation direction signal Photocoupler ON: CW, Photocoupler OFF: CCW

(CCW step command signal at 2-pulse input mode

Pulse width: 5µs minimum, Pulse rise/fall: 2µs maximum

Motor moves when the photocoupler state changes from ON to OFF.)

Full Step (0.72°) at “photocoupler OFF”

Half Step (0.36°) at “photocoupler ON”

When in the “photocoupler ON” state, the current to the motor is cut off and the motor shaft can be rotated manually.

When in the “photocoupler OFF” state, the current level set by the RUN switch is supplied to the motor.

When in the “photocoupler ON” state, the “Automatic Current Cutback” function at motor standstill is disabled.

When in the “photocoupler OFF” state, the “Automatic Current Cutback” function at motor standstill is activated.

(approximately 100ms after motor stops)

Photocoupler, Open-Collector Output

External use condition : 24VDC maximum, 10mA maximum

Signal is output every time the excitation sequence returns to the initial “0”. (Photocoupler: ON)

Full step: Signal is output every 10 pulses, Half step: Signal is output every 20 pulses

Automatic current cutback, All windings off, Pulse input mode switch

Motor kg (lb.)

Driver kg (lb.)

100MΩ minimum under normal temperature and humidity, when measured by a

DC500V megger between the motor coils and the motor casing.

Sufficient to withstand 0.5kV, 60Hz applied between the motor coils and

casing for one minute, under normal temperature and humidity.

Motor

Driver

Note

•

Do not measure insulation resistance or perform the dielectric withstand test while the motor and driver are connected.

30

PMC33A3

PMC33B3

0.033 (4.58)

-7

9×10

(0.05)

0.35

0.05 (0.002) T.I.R. at top of output shaft

Class B [130°C (266°F)]

0.1 (0.22) 0.17 (0.38)

-10°C~+50°C (+14°F~+122°F)

0°C~+40°C (+32°F~+104°F)

0.72°

0.075 (0.003) T.I.R.

0.075 (0.003) T.I.R.

DC24V±10% 0.7A or

DC36V±10% 0.7A

0.35

Power Input

Natural Ventilation

0.025 (0.06)

PMC35A3

PMC35B3

0.06 (8.33)

18×10

-7

(0.099)

Page 31

Package Model

Maximum Holding Torque

Rotor Inertia

Rated Current

Basic Step Angle

Gear Ratio

Permissible Torque

Permissible Thrust Load

Permissible Overhung Load

Permissible of Gear Shaft Rotation

Permissible Speed Range

(Gear Output Shaft Speed)

Insulation Class

Power Source

Output Current

Excitation Mode

Input Signal Circuit

• Pulse Signal

(CW Pulse Signal)

• Rotation Direction Signal

(CCW Pulse Signal)

• Step Angle Signal

Input Signals

• All Windings Off Signal

•

Automatic Current Cutback

Release Signal

Output Signal Circuit

• Excitation Timing Signal

Output Signals

Functions

Indication (LED)

Driver Cooling Method

Mass

Insulation Resistance

Dielectric Strength

Ambient Temperature Range

• Maximum holding torque refers to the holding torque at motor standstill when the rated current is supplied to the

motor (5-phase excitation), with consideration given to the permissible strength of the gear. Use this value to

compare motor torque performance. When using the motor with the dedicated driver, the driver’s “Automatic

current cutback” function at motor standstill reduces maximum holding torque by approximately 50%.

• The power source input current value represents the maximum current. (The input current varies according to the

pulse frequency.)

• Permissible torque is the marginal value of the mechanical strength of the gear unit. Use the product with a total

torque (load and acceleration) less than the permissible torque.

• Maximum overhung load indicates the value measured at 10mm (0.39in.) from the tip of the gear output shaft.

Single Shaft

Double Shaft

kg·m2 (oz-in2)

N·m (oz-in)

Full Step

Half Step

A/phase

Full Step

Half Step

Motor kg (lb.)

Driver kg (lb.)

PMC33A1-MG3.6

PMC33B1-MG3.6

N·m (oz-in)

A/phase

0.08 (11.1)

0.08 (11.1)

N (lb.)

N (lb.)

0~833r/min 0~416r/min

0.2°/step 0.1°/step 0.072°/step 0.036°/step 0.024°/step 0.0144°/step

0.1°/step 0.05°/step 0.036°/step 0.018°/step 0.012°/step 0.0072°/step

Photocoupler input, Input resistance 220Ω, Input current 20mA maximum

Signal voltage Photocoupler ON: +4~+5V, Photocoupler OFF: 0~+0.5V

Step command pulse signal (CW step command signal at 2-pulse input mode)

Pulse width: 5µs minimum, Pulse rise/fall: 2µs maximum

Motor moves when the photocoupler state changes from ON to OFF.

Rotation direction signal Photocoupler ON: CW, Photocoupler OFF: CCW

(CCW step command signal at 2-pulse input mode Pulse width: 5µs minimum, Pulse rise/fall: 2µs maximum

Motor moves when the photocoupler state changes from ON to OFF.)

Full Step at “photocoupler OFF” Half Step at “photocoupler ON”

When in the “photocoupler ON” state, the current to the motor is cut off and the motor shaft can be rotated manually.

When in the “photocoupler OFF” state, the current level set by the RUN switch is supplied to the motor.

When in the “photocoupler ON” state, the “Automatic Current Cutback” function at motor standstill is disabled.

When in the “photocoupler OFF” state, the “Automatic Current Cutback” function at motor standstill is activated.

(approximately 100ms after motor stops)

Photocoupler, Open-Collector Output External use condition: 24VDC maximum, 10mA maximum

Signal is output every time the excitation sequence returns to the initial “0”. (Photocoupler: ON)

Full step: Signal is output every 10 pulses, Half step: Signal is output every 20 pulses

Automatic current cutback, All windings off, Pulse input mode switch

100MΩ minimum under normal temperature and humidity, when measured by

a DC500V megger between the motor coils and the motor casing.

Sufficient to withstand 0.5kV, 60Hz applied between the motor coils and

casing for one minute, under normal temperature and humidity.

Motor

Driver

PMC33A1-MG7.2

PMC33B1-MG7.2

0.16 (22.2)

0.2°

3.6:1

0.16 (22.2)

Same as motor

PMC33A1-MG10

PMC33B1-MG10

0.21 (29.1)

0.1°

7.2:1

DC24V±10% 0.7A or DC36V±10% 0.7A

0.072°

10:1

0.21 (29.1)

Opposite to motor

0~300r/min

Class B [130°C (266°F)]

Natural Ventilation

-10°C~+50°C (+14°F~+122°F)

0°C~+40°C (+32°F~+104°F)

PMC33A1-MG20

PMC33B1-MG20

0.34 (47.2)

-7

9×10

(0.05)

0.35

0.036°

20:1

0.34 (47.2)

10 (2.2)

15 (3.3)

0~150r/min 0~100r/min 0~60r/min

0.35

Power Input

0.16 (0.36)

0.025 (0.06)

Same as motor

PMC33A1-MG30

PMC33B1-MG30

0.51 (70.8)

0.024°

30:1

0.51 (70.8)

PMC33A1-MG50

PMC33B1-MG50

0.0144°

50:1

Note

•

Do not measure insulation resistance or perform the dielectric withstand test while the motor and driver are connected.

31

Page 32

Package Model

Maximum Holding Torque

Rotor Inertia

Rated Current

Basic Step Angle

Gear Ratio

Permissible Torque

Maximum Torque

Permissible Thrust Load

Permissible Overhung Load N (lb.)

Direction of Gear Shaft Rotation

Permissible Speed Range

(Gear Output Shaft Speed)

Insulation Class

Power Source

Output Current

Excitation Mode

Input Signal Circuit

• Pulse Signal

(CW Pulse Signal)

• Rotation Direction Signal

(CCW Pulse Signal)

• Step Angle Signal

Input Signals

• All Windings Off Signal

Automatic Current Cutback

•

Release Signal

Output Signal Circuit

• Excitation Timing Signal

Output Signals

Functions

Indication (LED)

Driver Cooling Method

Mass

Insulation Resistance

Dielectric Strength

Ambient Temperature Range

• Maximum holding torque refers to the holding torque at motor standstill when the rated current is supplied to the

motor (5-phase excitation), with consideration given to the permissible strength of the gear. Use this value to

compare motor torque performance. When using the motor with the dedicated driver, the driver’s “Automatic

current cutback” function at motor standstill reduces maximum holding torque by approximately 50%.

• The power source input current value represents the maximum current. (The input current varies according to the

pulse frequency.)

• Permissible torque is the marginal value of the mechanical strength of the gear unit. Use the product with a total

torque (load and acceleration) less than the permissible torque.

• Maximum overhung load indicates the value measured at 10mm (0.39in.) from the tip of the gear output shaft.

Single Shaft

Double Shaft

N·m (oz-in)

kg·m2 (oz-in2)

A/phase

N·m (oz-in)

N·m (oz-in)

N (lb.)

Full Step

Half Step

A/phase

Full Step

Half Step

Photocoupler input, Input resistance 220Ω, Input current 20mA maximum

Signal voltage Photocoupler ON: +4~+5V, Photocoupler OFF: 0~+0.5V

Step command pulse signal (CW step command signal at 2-pulse input mode)

Pulse width: 5µs minimum, Pulse rise/fall: 2µs maximum

Motor moves when the photocoupler state changes from ON to OFF.

Rotation direction signal Photocoupler ON: CW, Photocoupler OFF: CCW

(CCW step command signal at 2-pulse input mode Pulse width: 5µs minimum, Pulse rise/fall: 2µs maximum

Motor moves when the photocoupler state changes from ON to OFF.)

Full Step at “photocoupler OFF” Half Step at “photocoupler ON”

When in the “photocoupler ON” state, the current to the motor is cut off and the motor shaft can be rotated manually.

When in the “photocoupler OFF” state, the current level set by the RUN switch is supplied to the motor.

When in the “photocoupler ON” state, the “Automatic Current Cutback” function at motor standstill is disabled.

When in the “photocoupler OFF” state, the “Automatic Current Cutback” function at motor standstill is activated.

(approximately 100ms after motor stops)

Photocoupler, Open-Collector Output External use condition: 24VDC maximum, 10mA maximum

Signal is output every time the excitation sequence returns to the initial “0”. (Photocoupler: ON)

Full step: Signal is output every 10 pulses, Half step: Signal is output every 20 pulses

Automatic current cutback, All windings off, Pulse input mode switch

Motor kg (lb.)

Driver kg (lb.)

100MΩ minimum under normal temperature and humidity, when measured by

a DC500V megger between the motor coils and the motor casing.

Sufficient to withstand 0.5kV, 60Hz applied between the motor coils and

casing for one minute, under normal temperature and humidity.

Motor

Driver

PMC33A1-HG50

PMC33B1-HG50

1.5 (213)

0.0144°

50:1

1.5 (213)

2.0 (284)

0~70r/min

Class B [130°C (266°F)]

DC24V±10% 0.7A or DC36V±10% 0.7A

0.0144°/step

0.0072°/step

0°C~+40°C (+32°F~+104°F)

0°C~+40°C (+32°F~+104°F)

-7

12×10

0.35

100 (22)

200 (45)

Opposite to motor

0.35

Power Input

Natural Ventilation

0.21 (0.47)

0.025 (0.06)

PMC33A1-HG100

PMC33B1-HG100

2.0 (284)

(0.066)

0.0072°

100:1

2.0 (284)

2.8 (397)

0~35r/min

0.0072°/step

0.0036°/step

Note

•

Do not measure insulation resistance or perform the dielectric withstand test while the motor and driver are connected.

32

Page 33

Installing and wiring in compliance

with EMC directive

Introduction

The EMC directive (89/336EEC and 92/31/EEC)

Stepping motors from ORIENTAL MOTOR are designed to be a built in component. The

EMC directive requires that the customer’s equipment incorporated with this product

should comply with the EMC directive.

The installation and wiring method for the motor and driver are the basic methods that

would effectively allow the customer’s equipment to be compliant with the EMC directive.

Final compliance of the equipment to the EMC directive varies according to the

configuration, wiring, layout, and level of hazard of other control systems and electrical

components used with the motor and driver.

This requires the customers to conduct the EMC measures of their equipment for

verification.

Applicable standards

EMI Emission Tests EN50081-2: 1993

Radiated Emission Test EN55011: 1998

EMS Immunity Tests EN50082-2: 1995

Radiation Field Immunity Test EN61000-4-3: 1996

ENV50204: 1995

Fast Transient/Burst Immunity Test EN61000-4-4: 1995

Conductive Noise Immunity Test EN61000-4-6: 1996

Installation and wiring procedures according to the EMC directive

It is essential to take effective measures against the EMI from this product to the

peripheral control systems and the EMS of this product. Otherwise, a serious adverse

effect may be given to the equipment functions.

The following installation and wiring procedures ensure compliance of this product to

the EMC directive (applicable standards as specified on this page).

Power supply

These products use the DC power supply input specifications.

Use the optimum DC power supply (switched power supply or the like) that conforms

with the EMC directive.

Also, when using a transformer for the power supply, always connect a mains filter on

the input side of the transformer.

33

Page 34

Connection of mains filter for power line

To prevent the noise generated from the driver being transferred to the outside through

the power supply transformer, connect a mains filter to the AC input line of the power

supply transformer.

Use FN250-12/07 by Schaffner Electronik AG, 10ESK1 by CORCOM, ZAG2210-11S by

TDK or their equivalent as the mains filter.

Install the mains filter as close as possible to the driver. Use cable clamps or similar tools

to fix the input cable and output cable. The input cables and output cables to be firmly

ensured that they will not be separated from the surface of the enclosure. Connect

the grounding terminal of the mains filter to the grounding point in the shorter distance.

Do not connect the AC input cable (AWG18: 0.75mm

cables in parallel to each other. Otherwise, the noise in the enclosure may be connected

directly with the power cable through the floating capacity. This may result in the effects

reduced of the mains filter.

Mains filter

FN250-12/07 by Schaffer Electronik 10ESK1 by CORCOM ZAG2210-11S by TDK

Grounding method

To ensure that potential difference will not occur, connect the driver, motor and mains

filter to the grounding point in the shorter distance by the use of a larger grounding cable.

Use a large uniform conductive surface for the grounding point.

2

or more) and mains filter output

Connection of signal cable

High quality braided-screen cable of AWG24 (0.2mm2) or more should be used for signal

cabling, and connect it to a controller in the shorter distance.

For some products, such braided-screen cable is available as an option. Please inquire

at your nearest Oriental Motor sales office.

To earth the braided-screen, use such clamps as metallic cable clamps which can be in

contact with the circumference of the braided-screen cable. Cable clamps on the

braided-screen cable should be installed as close to the cable end as possible as per

illustrated. On of the braided-screen cable, as illustrated. Connect the earth wire to the

adequate grounding point.

Cable clamp

34

Page 35

Others

• To ensure that potential difference will not occur between the motor/driver and

peripheral control system equipment, earth the cable directly to the grounding point.

• When the relay and magnetic switch are used together, make sure that the surge is

absorbed by the mains filter and CR circuit.

• The length of the cables should be as short as possible; do not use long cables with the

excess portion wound in a bundle.

• Keep the power cables such as the motor cable and power cable away from the signal

cables and connect them separately from each other as far as possible [For example,

keep them 100 to 200mm (3.94 to 7.87in.) apart from each other]. Signal cables should

only cross the path of motor or power cables at right angle. The AC input cable and

output cable of the mains filter should be kept away from each other.

Example of motor and driver installation and wiring

Motor

The standard length of the motor cable is 23.6in. (600mm).

The length of the cable between the driver and controller is 78in. (2,000mm).

Grounded panel

Driver Controller

FG

BC

P.E.

P.E.

AA

FG FG

AA

Braided-screen

cable

FG FG

A: Cable clamp

B: Mains filter

FG

C: DC power supply

Precautions concerning static electricity

Static electricity can make the driver malfunction or destroy it. Handle the driver carefully

when its power is on.

Always use an insulated screwdriver when adjusting the motor current with the driver’s

internal control (VR) or switch.

When using a driver mounted on the current check terminals, adjust the current in the

following manner.

1.Switch off the driver power supply.

2.Insert the tester into the current check terminals.

3.Switch on the driver power supply.

4.Adjust the current by adjusting the internal control (VR) with an insulated screwdriver.

5.Switch off the driver power supply, then remove the tester.

Note: Do not approach or touch the driver with the power on.

35

Page 36

• Unauthorized reproduction or copying of all or part of this operating manual is prohibited.

If a new copy is required to replace an original manual that has been damaged or lost,

please contact your nearest branch or sales office.

• This Operating Manual is subject to change without prior notice for the purpose of

product improvement or changes in specifications, or to improve its general content.

• While we make ev ery effort to offer accurate inf ormation in the manual, we welcome y our

input. Should you find unclear descriptions, errors or omissions, please contact the

nearest office.

• is a trademark of Oriental Motor Co., Ltd., and is registered in Japan and other

countries.

All other product names and company names are the trademarks or registered

trademarks of their respective companies. Any reference made in this oper ating man ual

to the names of products manufactured by companies other than Oriental Motor is done

so for reference purposes only and is not intended to enforce or recommend the use

thereof. Oriental Motor shall not be liable in anyway whatsoever for the performance or

use of products made by other companies.

Copyright

ORIENTAL MOTOR CO., LTD. 2001

• Please contact your nearest ORIENTAL MOTOR office for further information.

ORIENTAL MOTOR U.S.A. CORP.

Technical Support Line Tel:(800)468-3982

Available from 7:30 AM to 5:00 PM, P.S.T.

E-mail: techsupport@orientalmotor.com

www.orientalmotor.com

ORIENTAL MOTOR (EUROPA) GmbH

Headquarters and Düsseldorf Office

Tel:0211-5206700 Fax:0211-52067099

Munich Office

Tel:08131-59880 Fax:08131-598888

Hamburg Office

Tel:040-76910443 Fax:040-76910445

ORIENTAL MOTOR (UK) LTD.

Tel:01252-519809 Fax:01252-547086

ORIENTAL MOTOR (FRANCE) SARL

Tel:01 47 86 97 50 Fax:01 47 82 45 16

ORIENTAL MOTOR ITALIA s.r.l.

Tel:02-3390541 Fax:02-33910033

36

TAIWAN ORIENTAL MOTOR CO., LTD.

Tel:(02)8228-0707 Fax:(02)8228-0708

SINGAPORE ORIENTAL MOTOR PTE LTD.

Tel:(6745)7344 Fax:(6745)9405

ORIENTAL MOTOR (MALAYSIA) SDN BHD

Tel:(03)79545778 Fax:(03)79541528

INA OM LTD.

KOREA

Tel:(032)822-2042~3 Fax:(032)819-8745

ORIENTAL MOTOR CO., LTD.

Headquarters Tokyo, Japan

Tel:(03)3835-0684 Fax:(03)3835-1890

Printed on Recycled Paper

Loading...

Loading...