Page 1

C

N

1

C

N

3

C

N

2

CN4

24V DC

TB1

E

M

P

4

0

0

POW

ER

ALARM

4

5

6

7

8

9

10

11

3

2

1

Controller for servo and stepping motors

Thank you for purchasing an Oriental Motor product.

This Operating Manual describes product handling procedures and safety precautions.

z Please read it thoroughly to ensure safe operation.

z Always keep the manual where it is readily available.

EMP400 Series

OPERATING MANUAL

HP-19036

Page 2

2

The product described in this manual has been designed and manufactured for use in general industrial

machinery, and must not be used for any other purpose. Use a DC power supply with reinforced

insulation provided on the primary and secondary sides as the power source for the controller and

input/output signals.

Oriental Motor Co., Ltd. is not responsible for any damage caused through failure to observe this

warning.

z Duplicate copies of critically important data should be stored in a separate medium in case a

mishap should occur.

z Oriental Motor shall not be liable for damage to or loss of data resulting from the use of this

product.

z Unauthorized reproduction or copying of all or part of this instruction manual is prohibited.

If a new copy is required to replace an original manual that has been damaged or lost, please

contact your nearest branch or sales office.

z This Operating Manual is subject to change without prior notice for the purpose of product

improvement or changes in specifications, or to improve its general content.

z While we make every effort to offer accurate information in the manual, we welcome your input.

Should you find unclear descriptions, errors or omissions, please contact the nearest office. Contact

information may be found at the end of this operating manual.

is a trademark of Oriental Motor Co., Ltd., and is registered in Japan and other countries.

All other product names and company names are the trademarks or registered trademarks of their

respective companies. Any reference made in this Operating Manual to the names of products

manufactured by companies other than Oriental Motor is done so for reference purposes only and is

not intended to enforce or recommend the use thereof. Oriental Motor shall not be liable in anyway

whatsoever for the performance or use of products made by other companies.

Copyright

ORIENTAL MOTOR CO., LTD. 2001

c

Page 3

3

Introduction

1.1 Main features ....................................................................1-2

1.2 System configuration ........................................................1-2

Safety precautions

2.1 Important safety instructions.............................................2-2

2.2 Precautions for use...........................................................2-4

Preparations

3.1 Checking the product........................................................3-2

3.2 Names of parts .................................................................3-3

3.3 Specifications of EMP400 series ......................................3-4

Installation

4.1 Location for installation .....................................................4-2

4.2 Orientation ........................................................................4-2

4.3 Installation method............................................................4-3

Connection

5.1 Assembling the connector ................................................5-2

5.2 Connecting to the power supply .......................................5-3

5.3 Connecting the host controller (CN1) ...............................5-4

5.3.1 Connection method .......................................................... 5-4

5.3.2 Internal input circuit .......................................................... 5-5

5.3.3 Internal output circuit........................................................ 5-6

5.3.4 Connection example for a host controller ........................ 5-7

5.4 Connecting the driver (CN3·CN4

∗EMP402 only

) ......................5-8

5.4.1 Connection method .......................................................... 5-8

5.4.2 Internal input circuit .......................................................... 5-9

5.4.3 Internal output circuit...................................................... 5-10

5.4.4 Connection example for a driver .................................... 5-11

5.5 Terminal connection (CN2).............................................5-12

5.5.1 Connection method ........................................................ 5-12

Contents

1

2

3

4

5

Page 4

4

Writing and editing a program

6.1 How to write a sequence program ....................................6-2

6.2 Additional information on program composition................6-3

6.2.1 Sequence program .......................................................... 6-3

6.2.2 Parameter settings for motor operation ........................... 6-3

6.3 Starting and exiting HyperTerminal ..................................6-4

6.3.1 Verifying the communication method .............................. 6-4

6.3.2 How to start HyperTerminal ............................................. 6-5

6.3.3 How to exit HyperTerminal............................................... 6-8

6.4 Writing a program with a line editor ..................................6-9

6.5 Writing a program with a text editor ................................6-10

6.5.1 How to write a program .................................................. 6-11

6.5.2 Downloading a program ................................................. 6-12

6.5.3 Uploading a program ..................................................... 6-14

6.6 Editing the program ........................................................6-17

6.6.1 Checking the number of steps ....................................... 6-17

6.6.2 How to edit the program................................................. 6-18

6.6.3 Quitting the program editing .......................................... 6-24

6.7 List of messages associated with program.....................6-25

Executing the program

7.1 How to execute a program................................................7-2

7.2 Program execution via the host controller ........................7-3

7.2.1 Example of program execution ........................................ 7-4

7.2.2 Emergency stop ............................................................... 7-5

7.2.3 Alarm signal input from the driver .................................... 7-6

7.3 Automatic program execution ...........................................7-7

7.4 Program execution via command .....................................7-8

Program command

8.1 Command input ................................................................8-2

8.2 Command classification....................................................8-3

8.2.1 Hardware configuration commands ................................. 8-3

8.2.2 Common commands ........................................................ 8-4

8.2.3 Operation commands....................................................... 8-5

8.2.4 Other commands ............................................................. 8-7

8.3 Special keys......................................................................8-8

8.4 List of commands..............................................................8-9

8.5 Command details............................................................8-11

ABS ............................................................................................. 8-11

ACTL ........................................................................................... 8-12

CJMP .......................................................................................... 8-13

D.................................................................................................. 8-14

DEL ............................................................................................. 8-15

DELAY ........................................................................................ 8-16

DOWEL....................................................................................... 8-17

DWNLD ....................................................................................... 8-18

EDIT ............................................................................................ 8-19

6

7

8

Page 5

5

EEN............................................................................................. 8-20

END ............................................................................................ 8-21

ENDL .......................................................................................... 8-22

ETIME ......................................................................................... 8-23

H.................................................................................................. 8-24

ID................................................................................................. 8-25

IN................................................................................................. 8-26

INC .............................................................................................. 8-27

JMP ............................................................................................. 8-28

LOOP .......................................................................................... 8-29

MHOME ...................................................................................... 8-30

MU............................................................................................... 8-32

OFS............................................................................................. 8-33

OUT............................................................................................. 8-34

PULSE ........................................................................................ 8-35

R.................................................................................................. 8-36

RAMP.......................................................................................... 8-37

RESET ........................................................................................ 8-38

RTNCR ....................................................................................... 8-39

RUN ............................................................................................ 8-40

S.................................................................................................. 8-41

SCAN .......................................................................................... 8-42

SEN............................................................................................. 8-43

T .................................................................................................. 8-44

TIM .............................................................................................. 8-45

UNIT............................................................................................ 8-46

UPLD .......................................................................................... 8-47

V.................................................................................................. 8-48

VS ............................................................................................... 8-49

Controlling with the operational unit

9.1 Installing and connecting the operational unit...................9-2

9.2 Basic operations ...............................................................9-3

9.2.1 Names of parts................................................................. 9-3

9.2.2 Switching between operation modes ............................... 9-4

9.2.3 Entering and saving numeric values................................ 9-4

9.2.4 Entering the sign .............................................................. 9-5

9.2.5 Entering a numeric value with a decimal point ................ 9-5

9.3 Monitor mode....................................................................9-6

9.4 Edit mode..........................................................................9-7

9.5 Teaching mode .................................................................9-8

9.5.1 Operation in teaching mode............................................. 9-9

9.5.2 Operation in HOME mode ............................................. 9-10

9.5.3 Operation in step execution mode ................................. 9-11

9.5.4 Operation in speed setting mode ................................... 9-13

9.6 Quick chart......................................................................9-14

9.7 Error display....................................................................9-15

9

Page 6

6

Troubleshooting

10.1 When ALARM LED illuminates....................................... 10-2

10.1.1 Main causes of an alarm................................................ 10-2

10.2 Error messages ..............................................................10-3

Sample programs

11.1 Operation by the host controller......................................11-2

11.2 Speed change operation by the host controller ..............11-3

11.3 Speed change operation at a specified time...................11-4

11.4 Repeating positioning operations ...................................11-5

11.4.1 When movement amount is set in pulses ...................... 11-5

11.4.2 When movement amount is set in degrees ................... 11-6

11.4.3 When movement amount is set in mm .......................... 11-7

11.5 Conditional jump procedure............................................11-8

10

11

Page 7

1

Introduction

Explains the items you should know before using this product.

Page 8

11

11

1

Introduction

1-2

1.1 Main features

Writing a sequence program on a personal computer

You can download the sequence program you have written on your personal computer and execute

the program by activating the START input from the host controller.

The sequence program can be written and modified using Windows HyperTerminal or a text editor.

No special software is required.

Superior expandability

The controller features eight and six general-purpose inputs and outputs points, respectively.

Motor control via multiple sources

The EMP400 Series allows motor operation either from the host controller or a personal computer.

The motor can be operated via the host controller by selecting 32 different sequence programs

through unique combinations of different states of program selection inputs connected to the host

controller and activating the START input.

The motor can also be operated via a personal computer by transmitting commands from a terminal

program via an RS-232C communication interface.

Easy teaching

The workpiece position can easily be adjusted using the optional OP300 operational unit.

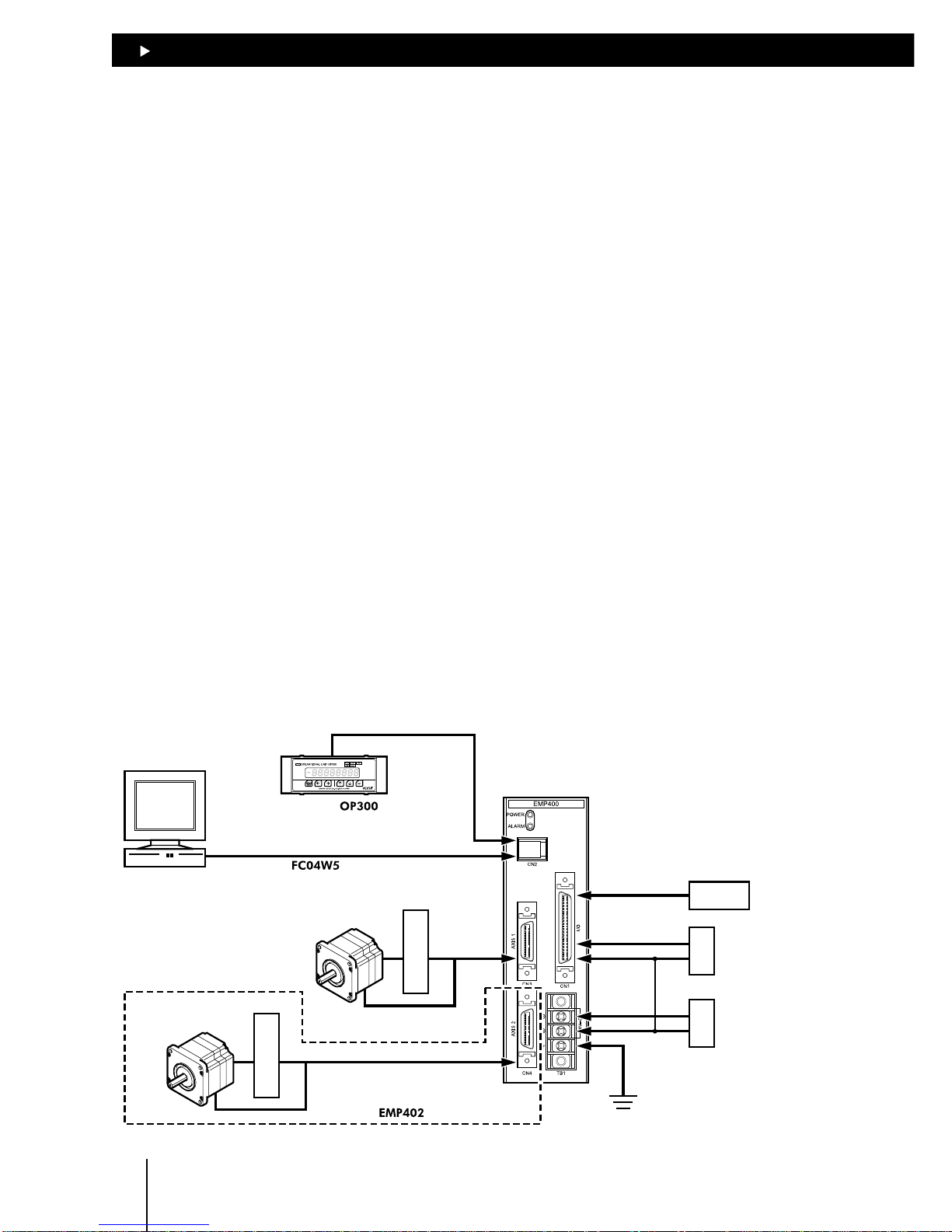

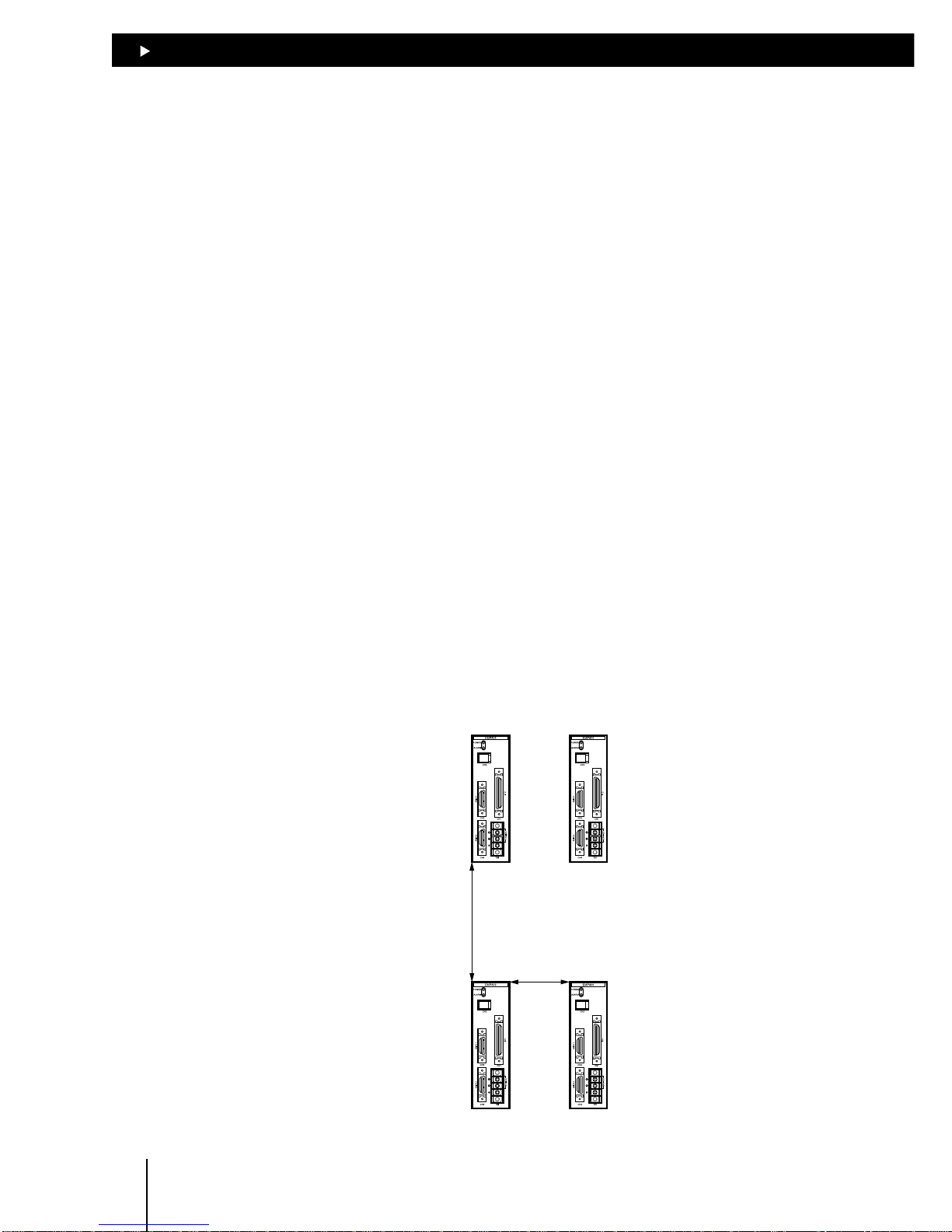

1.2 System configuration

A sample system configuration using the EMP400 series is provided below.

24 VDC power supply

(for I/O)

Host controller

24 VDC power supply

(for the main unit)

+24V

RS-232C

Modular cable

(option)

GND

+24V

GND

Personal computer

Driver

Motor or

Motorized slider

Driver

Motor or

Motorized slider

Data setter

(option)

∗ The unit cannot be used to write

a sequence program.

only

Page 9

2

Safety precautions

This section covers safety precautions to ensure safe operation of

the product.

Page 10

2

Safety precautions

2-2

2.1 Important Safety Instructions

Only qualified personnel should work with the product.

Use the product correctly after thoroughly reading the section “Safety precautions.”

The precautions described below are intended to prevent danger or injury to the user and other

personnel through safe, correct use of the product.

Use the product only after carefully reading and fully understanding these instructions.

Please read “Safety Precautions” in the Operating Manual for the motor you are using with this

product.

Warning

Handling the product without observing the instructions that accompany a “Warning” symbol may

result in serious injury or death.

Caution

Handling the product without observing the instructions that accompany a “Caution” symbol may

result in injury or property damage.

Note

The items under this heading contain important handling instructions that the user should observe to

ensure safe use of the product.

This contains information relative to the description provided in the main text.

Warning

General z Do not use the product in explosive or corrosive environments, in the presence of flammable

gases, locations subjected to splashing water, or near combustibles.

Doing so may result in fire or injury.

z Assign qualified personnel the task of installing, wiring, setting, operating/controlling, and inspecting

the product.

Failure to do so may result in fire, electric shock or injury.

Installation z Install the controller and data setter in enclosures in order to prevent injury.

Connection z Keep the controller’s input-power voltage within the specified range to avoid fire.

z For the controller’s input-power voltage within the specified range to avoid fire.

z Connect the cables securely according to the wiring example in order to prevent fire.

z Do not forcibly bend, pull or pinch the power cable.

Doing so may result in fire.

Operation z Turn off the driver power in the event of a power failure, or the motor may suddenly start when the

power is restored and may cause injury or damage to equipment.

z Stop the motor in the event the controller’s ALM (alarm) output is detected.

Failure to do so may result in fire or damaged driver.

Repair, disassembly and modification

z Do not disassemble or modify the controller.

Refer all such internal inspections and repairs to the branch or sales office from which you purchased

the product.

Page 11

2

Safety precautions

2-3

Caution

General z Do not use the controller beyond their specifications, or injury or damage to equipment may

result.

z Keep your fingers and objects out of the openings in the controller, or fire may result.

Installation z Keep the area around the controller, and data setter free of combustible materials in order to

prevent fire or a burn.

z To prevent the risk of damage to equipment, leave nothing around the controller and data setter

that would obstruct ventilation.

Operation z Use a controller and driver only in the specified combination. An incorrect combination may

cause a fire.

z To avoid injury, remain alert during operation so that the motor can be stopped immediately in an

emergency.

z Before switching on the controller, disconnect all of its output signals.

Failure to do so may cause the motor to start unexpectedly, resulting in fire or equipment damage.

z Set the speed and acceleration/deceleration rate well within the respective capacities in order to

prevent abrupt load fluctuations.

Failure to do so may cause the motor to misstep and the moving part to move in unexpected

directions, possibly resulting in injury or equipment damage.

z When an abnormality is noted, stop the operation immediately, or fire, or injury may occur.

Disposal z When disposing of the controller, treat them as ordinary industrial waste.

Page 12

2

Safety precautions

2-4

2.2 Precautions for use

This section covers limitations and requirements the user should consider when using the controller

EMP400 series and the data setter OP300.

Power capacity

For the controller, use a DC power supply capable of supplying 24VDC ±5% at 0.45A or greater, with

reinforced insulation provided on the primary and secondary sides.

Connecting the OP300 operational unit

Be sure to use the cable supplied with the OP300 operational unit when connecting it to the controller.

The cable comes with two ferrite cores intended for noise prevention. Do not remove these ferrite

cores, since doing so may diminish noise resistance and possibly cause a malfunction.

Preventing electrical noise

Take the following anti-noise measures to prevent malfunction of the controller, driver, and motor

due to external noise:

zz

zz

z Wiring the motor

Use an extension cable (sold separately) for connection between the driver and motor.

zz

zz

z Wiring the I/O cable

For I/O cables, use a shielded cables with connectors (sold separately).

Minimize the length of the I/O cable.

Wire the I/O cables by maintaining a minimum distance of 300mm (11.8in.) from the inductive loads

of electromagnetic relays, etc., as well as the power lines (the power source and motor, etc.) Do not

wire the I/O cables in the same duct or pipe in which power lines are wired.

zz

zz

z Connecting mains filter for power source line

Connect a mains filter to the AC power source input part of the driver in order to prevent externally

generated noise from being transmitted to the driver via the power-source line.

Ground the noise filter’s contact terminal using a cable of AWG16 (1.25mm

2

) or more in diameter.

The use of a cable smaller than AWG16 may cause heat generation.

Page 13

3

Preparations

This section covers the items that needs to be checked after

purchasing the product, along with the names, functions and main

specifications of components in the controller.

Page 14

33

33

3

Preparations

3-2

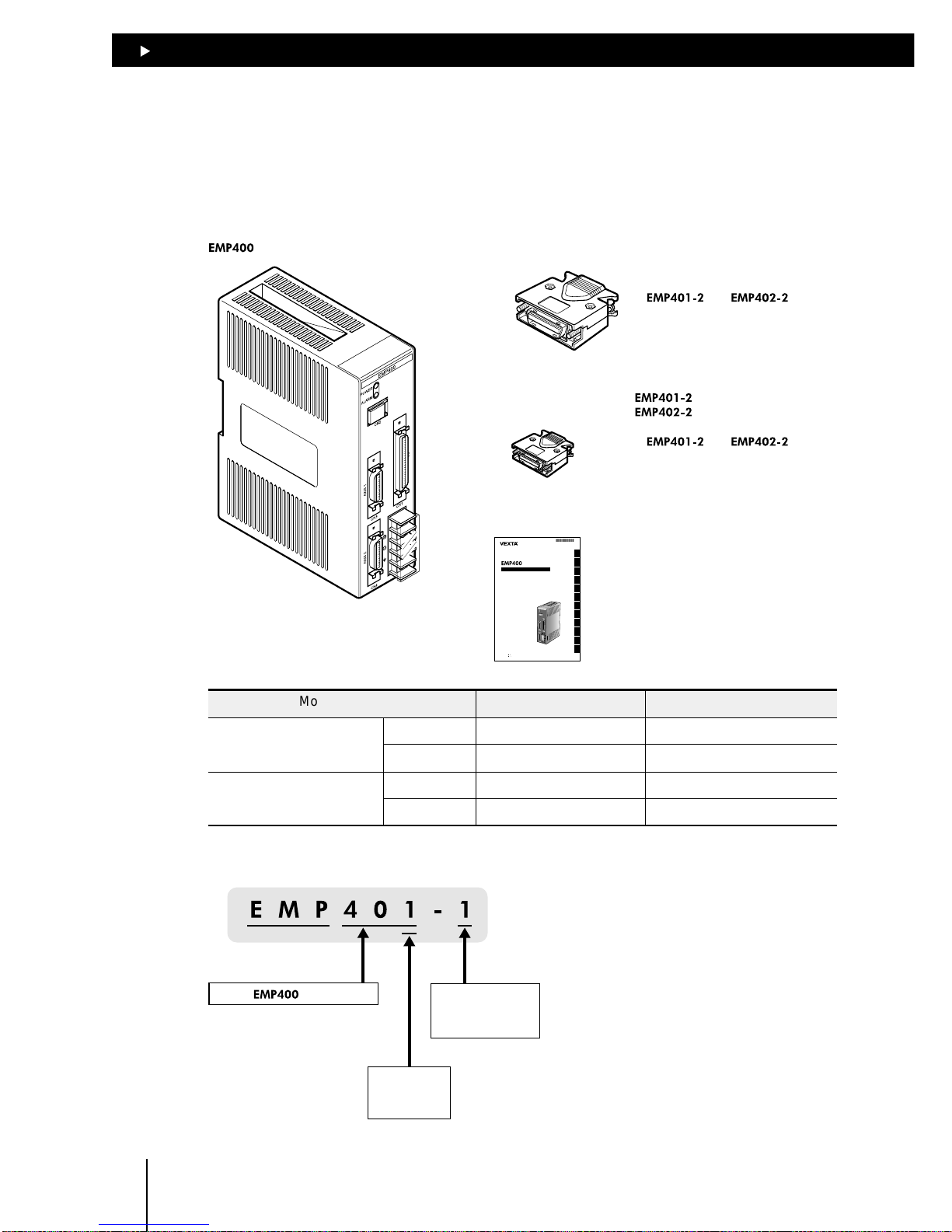

3.1 Checking the product

Upon opening the package, verify that the items listed below are included.

In case any of these items is missing or damaged, check the model number shown on the package

label and contact the branch or sales office from which you purchased the product.

C

N

1

C

N

3

C

N

2

C

N

4

24V DC

T

B

1

E

M

P

4

0

0

P

O

W

E

R

A

L

A

R

M

Series

Controller for servo motor and stepping motor

Thank you for purchasing an Oriental Motor product.

This Operating Manual describes product handling procedures and safety precautions.

l

Please read it thoroughly to ensure safe operation.

l

Always keep the manual where it is readily available.

OPERATING MANUAL

1

2

3

4

5

6

7

8

9

10

11

12

HP-19036

series controller 1 unit I/O connector (50 pins) 1 set

∗

and only

∗

and only

AXIS connector (26 pins)

1 set

2 set

Operating manual 1 copy Appendix 1 copy

Series

Controller for servo motor and stepping motor

UNIT

HP-19034-2

Model number Connector included Equivalent

I/O connector (50 pins) Connector 54306-5011 (MOLEX)

10150-3000VE (SUMITOMO 3M)

Cover 54331-0501 (MOLEX)

10350-52A0-008 (SUMITOMO 3M)

AXIS connector (26 pins) Connector 54306-2611 (MOLEX)

10126-3000VE (SUMITOMO 3M)

Cover 54331-0261 (MOLEX)

10326-52A0-008 (SUMITOMO 3M)

How to identify the product model

Connector

1: No connector

2: Solder type

series

Axis number

1: 1 axis

2: 2 axes

Page 15

33

33

3

Preparations

3-3

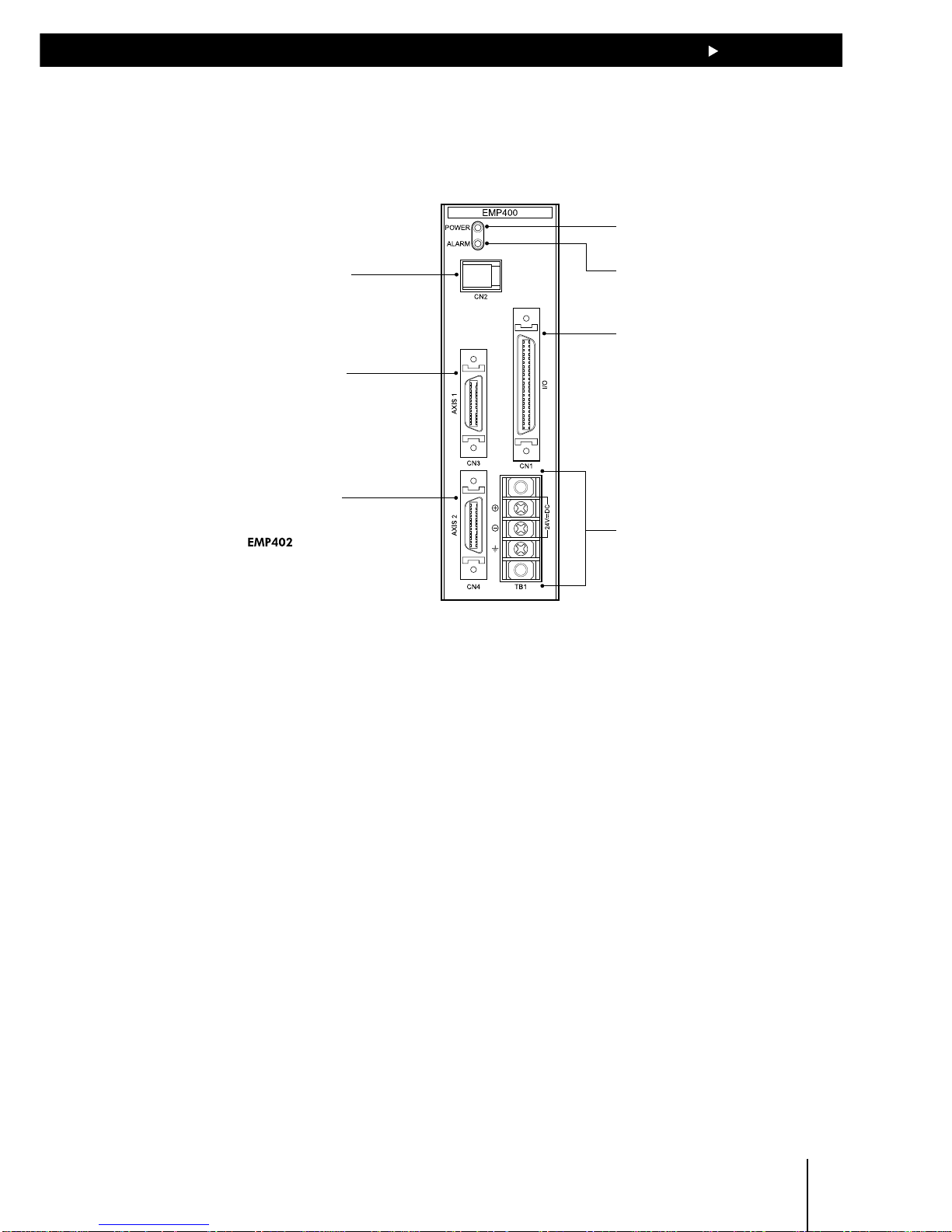

3.2 Names of parts

This section covers the names and functions of parts in the controller.

POWER LED

Lit when the power is on.

Terminal block (TB1)

Used to connect the 24VDC

power supply and frame ground.

ALARM LED

Lit when an alarm event occurs.

AXIS 1 connector (CN3)

Used to connect the first

axis I/O and sensor.

I/O connector (CN1)

Used for external-signal and

general-purpose inputs and outputs.

Modular connector (CN2)

Used to connect the cable for

communication with terminals

such as a PC and operational

unit.

AXIS 2 connector (CN4)

Used to connect the second

axis I/O and sensor.

∗Only

Page 16

33

33

3

Preparations

3-4

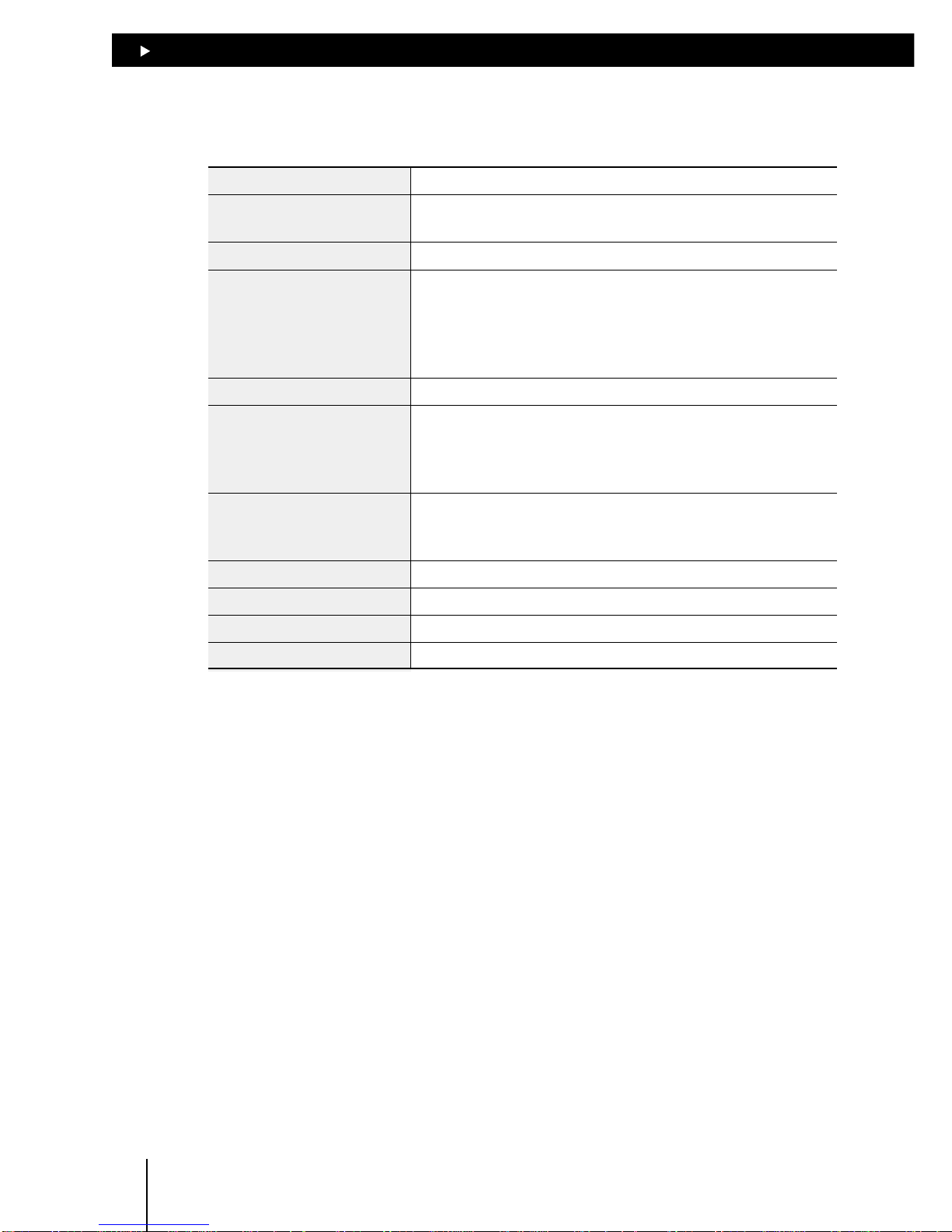

3.3 Specifications of EMP400 series

Control axis number 1 or 2

Number of sequence programs 32 (sequence programs 0 through 31)

The sequence program 99 is a CONFIG program.

Number of program lines 1,000 lines

Parameters Starting speed: 10 to 200kHz (1Hz increments)

Operating speed: 10 to 200kHz (1Hz increments)

Acceleration rate: 0.5 to 1,000ms/kHz (0.1ms/kHz increments)

Acceleration mode: Linear acceleration/deceleration, jerk limit control

Pulse count: ± 16,777,215 pulses

Pulse range -8,388,608 to 8,388,607 pulses

Operation mode Positioning operation (two-axis linear interpolation operation available

with EMP402 only)

Continuous operation

Mechanical home seeking operation

Mode for mechanical home Three-sensor mode (high-speed home seeking)

seeking Two-sensor mode (constant-speed home seeking)

Mechanical home seeking is possible via TIM or SLIT input

Data transmission format RS-232C based (3-wire)

General-purpose input 8 points, photocoupler inputs

General-purpose output 6 points, open-collector outputs, +5~24VDC, 25mA max. each

Power source 24VDC ± 5% at 0.45A min.

Page 17

4

Installation

This section covers the conditions and method for controller

installation.

Page 18

44

44

4

Installation

4-2

4.1 Location for installation

This controller is designed and manufactured for installation in equipment.

Since heat generated from the controller is dissipated via air convection, install the controller in a well

ventilated area that ensures easy maintenance.

The conditions of the installation location are as follows:

z Inside an enclosure that is installed indoors (provide vent holes)

z Operating ambient temperature 0°C to +50°C (+32°F to + 122°F) (non-freezing)

z Operating ambient humidity 20 to 85%, maximum (no condensation)

z Area that is free from an explosive nature or toxic gas (such as sulfuric gas) or liquid

z Area not exposed to direct sun

z Area free of excessive amount dust, iron particles or the like

z Area not subject to splashing water (storms, water droplets), oil (oil droplets) or other liquids

z Area free of excessive salt

z Area not subject to continuous vibration or excessive shocks

z Area free of excessive electromagnetic noise (from welders, power machinery, etc.)

z Area free of radioactive materials, magnetic fields or vacuum

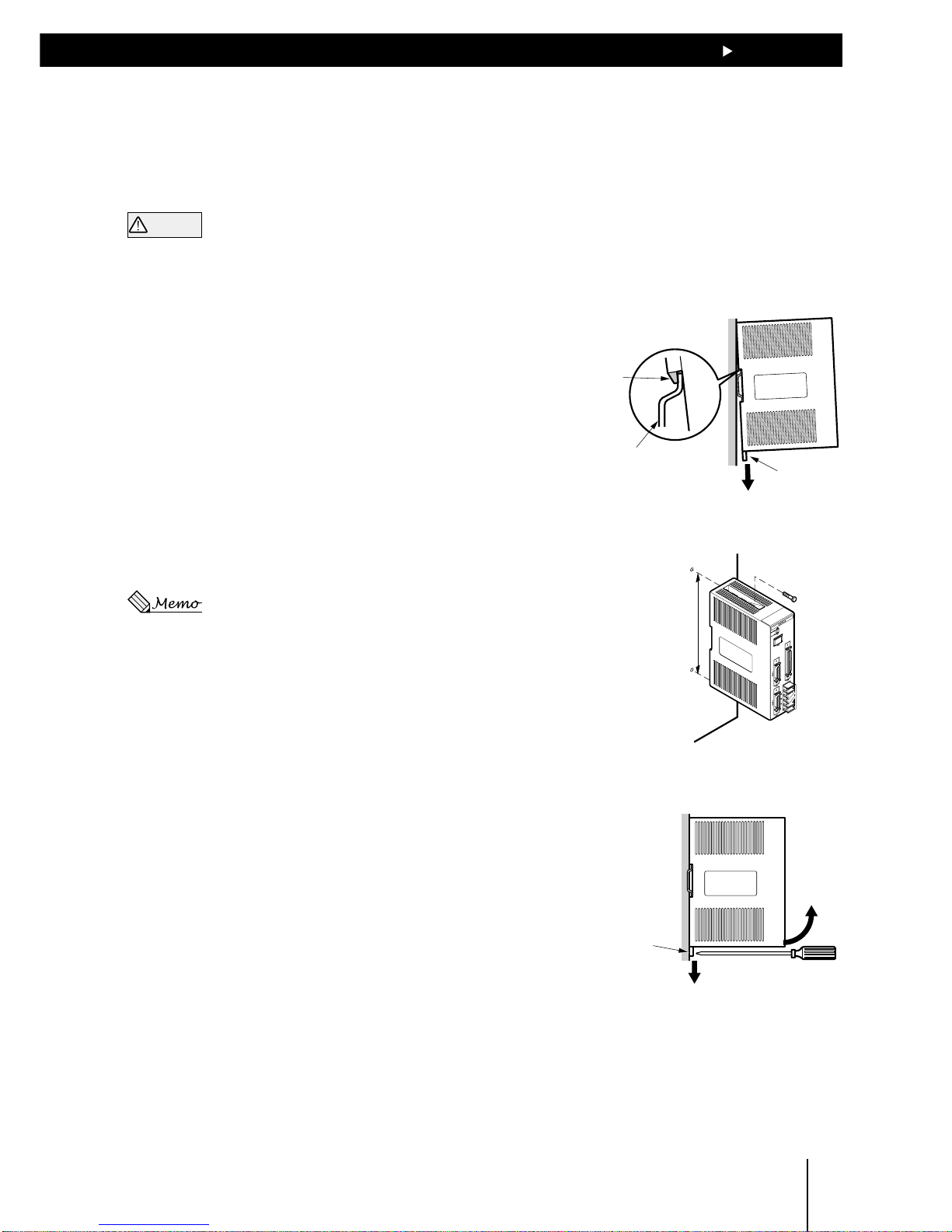

4.2 Orientation

When installing the controller inside an enclosure, place it in a vertical orientation by mounting it on

a DIN rail or securing it with screws through the two mounting holes provided on the controller.

There must be a clearance of at least 25mm (0.98in.) and 50mm (1.97in.) in the horizontal and

verticaldirections, respectively, between the controller and the enclosure or other equipment within

the enclosure.

50mm (1.97in.) minimum

25mm (0.98in.) minimum

Page 19

44

44

4

Installation

4-3

4.3 Installation method

Mount the controller on a DIN rail. In case the DIN rail produces significant vibrations, mount the

controller on an appropriate metal plate.

Warning

z

Do not place any equipment that generates excessive heat or noise in the vicinity of the controller.

z

Check and reexamine the means of ventilation if the ambient temperature of the controller exceeds

50°C (122°F).

Mounting the controller on a DIN rail

Use a DIN rail of 35mm (1.38in.) in width. Use the end

plates to secure the controller mounted on the DIN rail.

1. Engage the hook on the back of the controller over the

DIN rail by pulling down the controller’s DIN lever, and

push the controller until the DIN lever locks in place.

2. Secure each end of the controller using the end plates.

Installing the controller with screws

Install the controller on a metal plate and secure it using

two screws (M3 or M4, two pieces).

There should be no gap between the controller and plate.

The screws are not included in the package.

Removing the controller from the DIN rail

125±0.1mm

(4.92±0.004in.)

1. Use a flat-head screwdriver to pull down the DIN lever

until it locks in place.

Pull the DIN lever with a force of 10 to 20N (2.2 to

4.41lb.).

Applying excessive force may damage the DIN lever.

2. Raise the controller upward to remove from the DIN

rail.

Tab

DIN rail

DIN lever

DIN lever

Page 20

44

44

4

Installation

4-4

Page 21

5

Connection

This section covers the methods for connecting the power, driver,

host controller and other units to the EMP400 Series controller, as

well as the grounding method, input/output circuits and a

connection example.

Page 22

55

55

5

Connection

5-2

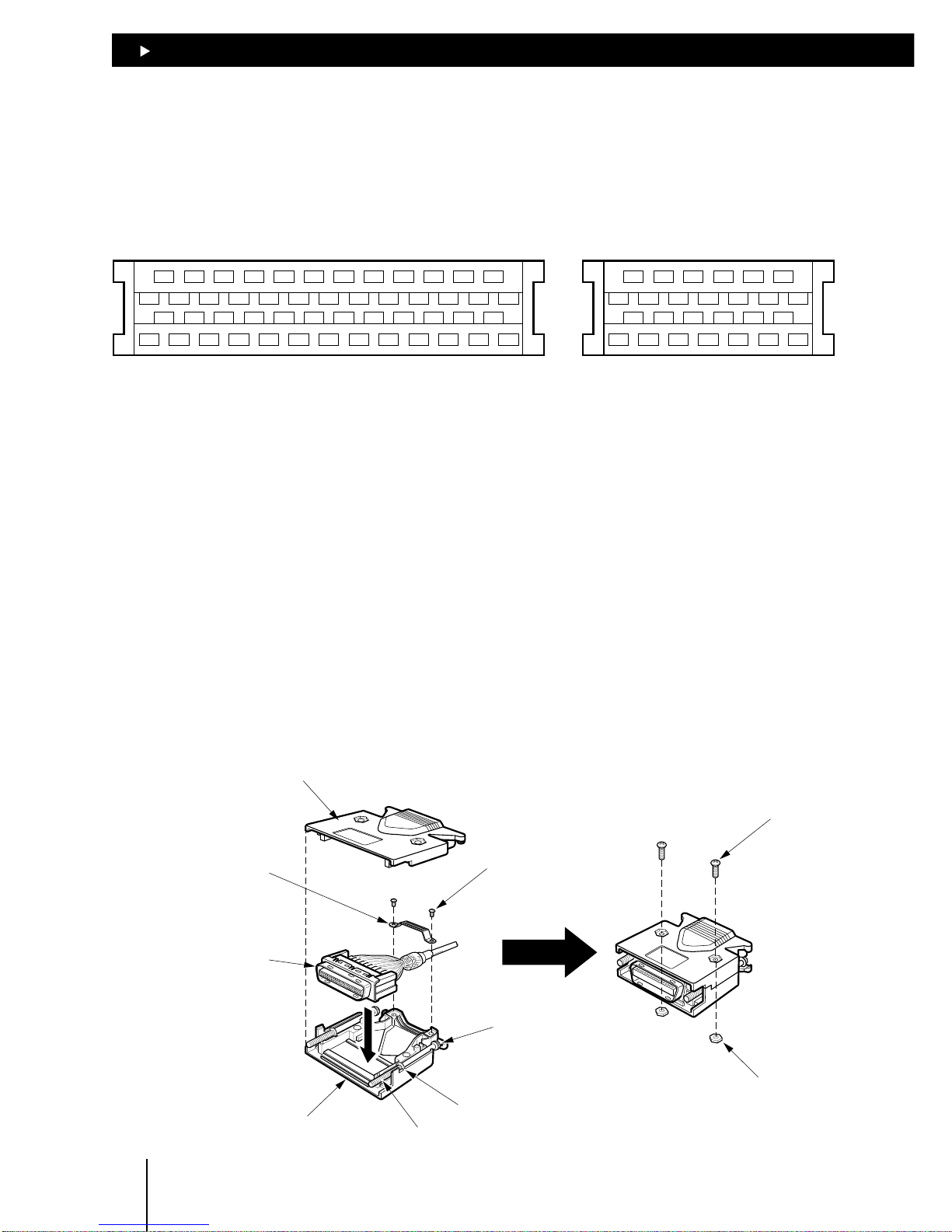

5.1 Assembling the connector

Solder-type connectors are supplied with the EMP401-2 and EMP402-2 series controllers.

Solder the host controller cable for the I/O connector and the driver cable for the AXIS connector.

The following figure shows the pin arrangement of the connector.(Viewed from the soldering side)

1

26

25

50

2

135791113151719212325

4681012141618202224

27

26283032343638404244464850

2931333537394143454749

1

14

13

26

2

135791113

4681012

15

14161820222426

1719212325

I/O connector AXIS connector

1 Solder a cable to the half-pitch connector.

The cable is not included in the package. Use a multi-core, overall-shielded, twisted-pair cable

of AWG28 (0.08mm

2

) or more in diameter.

2 Place the screws (M2.5, two pieces) supplied with the connector in the bottom connector cover.

Place the screws so that their flat washers align with the indents in the connector cover and the

spring washers sit on the outside of the connector cover.

3 Place the connector with the cable in the bottom connector cover and screw the cable mounting

bracket.

Tighten the mounting bracket screws (M2, two pieces) to the specified torque.

Torque: 0.3 to 0.35N·m (42.6 to 49.7oz-in)

4 Place the top connector cover and assemble the top and bottom connector covers using the

supplied screws (M2.5, two pieces) with hexagonal nuts.

Tighten the connector cover screws to the specified torque.

Torque: 0.5 to 0.55N·m (71 to 78.1oz-in)

Top connector cover

Bottom connector cover

Connector

Cable mounting

bracket

Screws for cable

mounting bracket

(M2, two pieces)

Screw for

connector cover

(M2.5, two pieces)

Hexagonal nut

Spring

washer

Flat washer

Screw (M2.5, two pieces)

Page 23

55

55

5

Connection

5-3

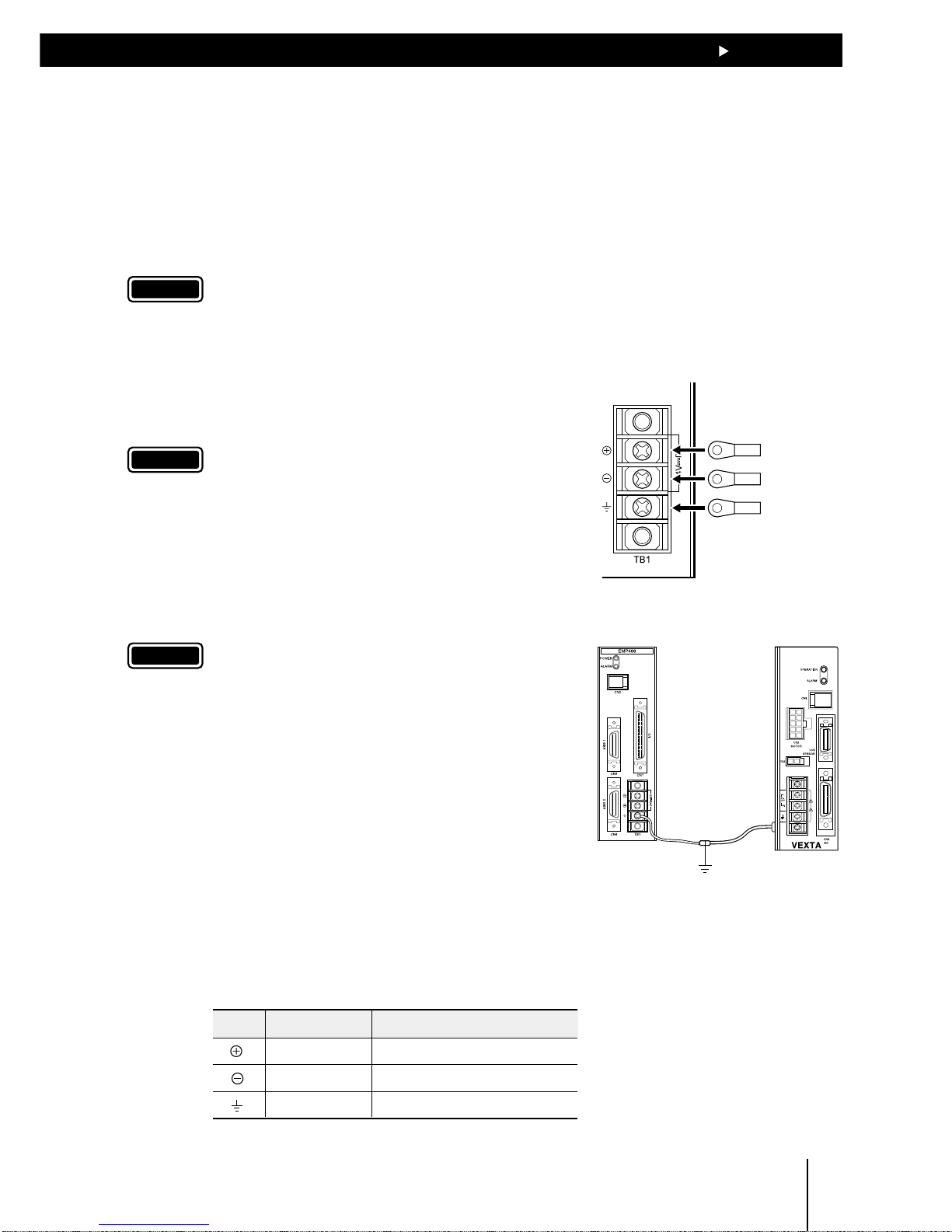

5.2 Connecting to the power supply

The controller’s power supply is connected to the TB1 terminals. In addition to the power-supply

terminals, TB1 has a frame ground (FG) terminal to prevent malfunctions caused by external noise.

The power supply provides a voltage of 24VDC ± 5% with current consumption of 0.45A max. The

current consumption level includes the current supplied to the operational unit.

Use round, insulated crimp terminals for power and grounding cables.

Note

The power supply should be designed to provide ample capacity. Insufficient power capacity may

cause an error in the controller operation.

24VDC/+ terminal

24VDC/

-

terminal

FG terminal

Grounded at

one point

Controller Driver

1. Remove the terminal cover from TB1.

2. Remove the positive and negative terminal screws, then

connect the 24VDC power cable.

Verify that the connection has the proper polarity.

Note

For the power cable, use the cable of AWG20 (0.5mm2) or

more in diameter. Any cable with a smaller diameter

may cause heat generation.

3. Tighten terminal screws at a tightening

torque of 0.5N·m (71oz-in).

4. Remove the FG terminal screws and connect the

grounding cable.

Note

For the power cable, use the cable of AWG18 (0.75mm2)

or more in diameter. Any cable with a smaller diameter

may cause heat generation.

5. Tighten terminal screws at a tightening

torque of 0.5N·m (71oz-in).

6. Secure the grounding cable connected to the FG

terminal to the ground point, using screws with an inner

clip washer.

The above grounding cable should be grounded at one

point together with the grounding cable connected to

the driver’s protective earth terminal.

7. Place the terminal cover on TB1.

TB1 signals

Symbol Signal Description

+24V power Input terminal of the power supply

GND Ground of the power supply

FG Frame ground

Page 24

55

55

5

Connection

5-4

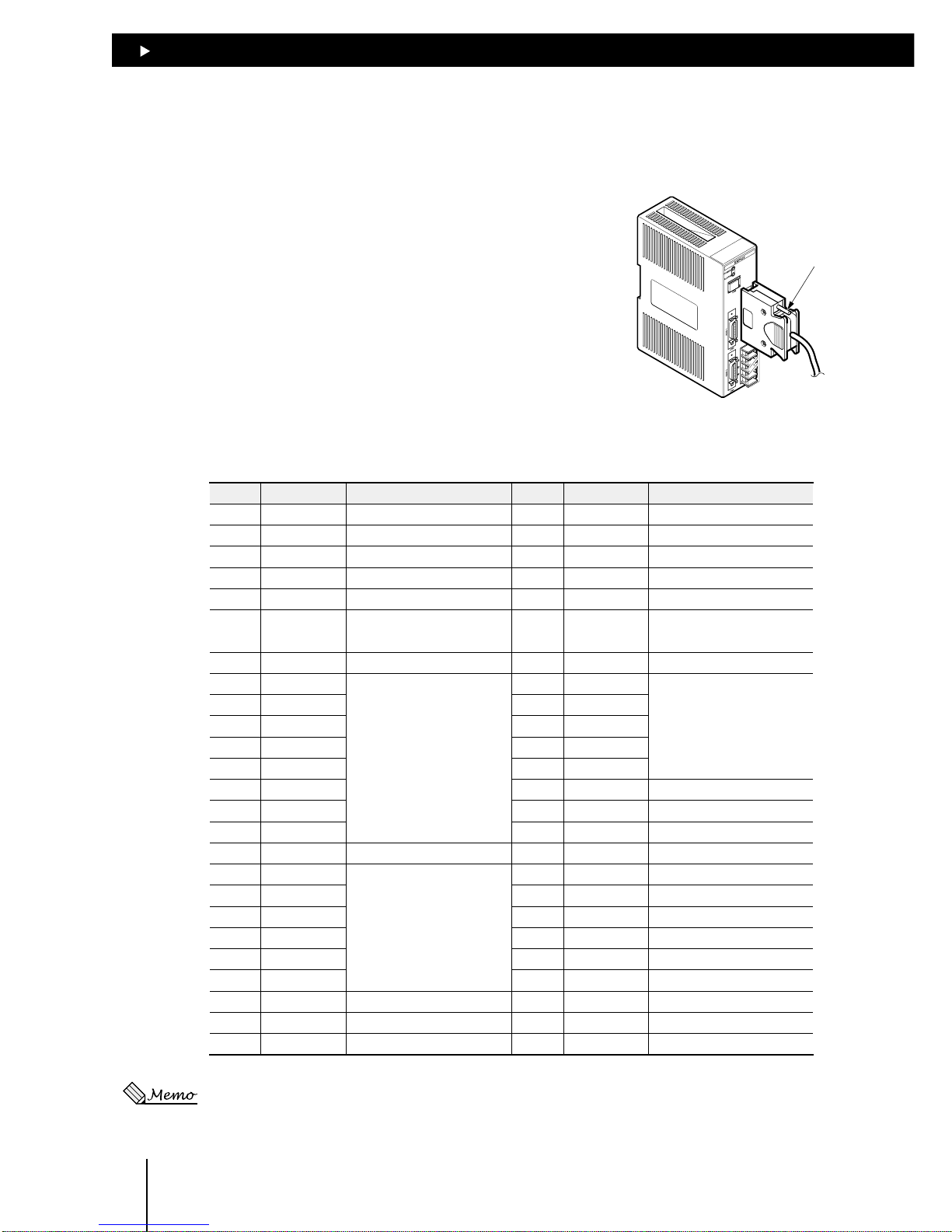

5.3 Connecting the host controller (CN1)

CN1 (I/O) signal table

Pin No. Signal Description Pin No. Signal Description

1

− No connection

26

− No connection

2

E-STOP input Emergency stop

*1

27

ALM output Alarm

3 START input Execution of a program 28

−

No connection

4 S-STOP input Interruption of a program 29 MOVE output During pulse generation

5

− No connection

30

− No connection

6

− No connection

31

READY output

Ready to accept START

input

7

+COM input

Power source for I/O (+24V)

*2

32

+COM input

Power source for I/O (+24V)

*2

8

IN1 input

General input

33

M0 input

Selection of

program number

9

IN2 input

34

M1 input

10

IN3 input

35

M2 input

11

IN4 input

36

M3 input

12

IN5 input

37

M4 input

13

IN6 input

38

− No connection

14

IN7 input

39

− No connection

15

IN8 input

40

− No connection

16

+COM input I/O (+24V)

*2

41

− No connection

17

OUT1 output

General output

42

− No connection

18

OUT2 output

43

− No connection

19

OUT3 output

44

− No connection

20

OUT4 output

45

− No connection

21

OUT5 output

46

− No connection

22

OUT6 output

47

− No connection

23

− No connection

48

− No connection

24

− No connection

49

END output Positioning complete

25

-

COM input

Power source for I/O (GND)

*2

50

-

COM input

Power source for I/O (GND)

*2

∗1:The E-STOP input is at normally closed. (The state of the contact is given when the photocoupler is turned

off.)

∗2:+COM and -COM inputs are shared internally.

5.3.1 Connection method

Use the I/O connector (50-pin) for connection with the host

controller.

Plug the I/O connector into CN1 and tighten the screw.

Screw

Page 25

55

55

5

Connection

5-5

5.3.2 Internal input circuit

The signal state represents the “ON: Carrying current” or “OFF: Not carrying current” state of the internal

photocoupler rather than the voltage level of the signal.

5.4k

820

PS2801 or

equivalent

+COM

E-STOP, START

S-STOP, IN1 to IN8

M0 to M4

zz

zz

z E-STOP input

This terminal is used to input the emergency stop signal.

The E-STOP input is a normally closed. Input is enabled when the E-STOP is turned off, immediately

stopping pulse output and stopping the motor. The program stops, also.

In the normal state, be sure to connect the E-STOP input to GND to keep it on.

zz

zz

z START input

This terminal is used to input the signal for starting the program.

The program is executed once the START input is turned on.

zz

zz

z S-STOP input

This terminal is used to input the signal for stopping the operation.

The program is stopped once the S-STOP input is turned on. If the S-STOP input is turned

on while the motor is in operation, the motor will decelerate to a stop.

Once operation resumes, the program will start over from the beginning.

zz

zz

z IN1 to IN8 inputs

General-purpose input terminals

zz

zz

z M0 to M4 inputs

Terminals for choosing the program to be used through unique combinations of the M0 to M4 input

states. For more information about the selection of programs through combinations of M0 to M4

input states, see section 7.2, “Program execution via the host controller.”

Page 26

55

55

5

Connection

5-6

5.3.3 Internal output circuit

The signal state represents the “ON: Carrying current” or “OFF: Not carrying current” state of the internal

photocoupler rather than the voltage level of the signal.

TD62004AF

or equivalent

+COM

+5〜24VDC

25mA max.

-

COM

ALM, MOVE, READY

OUT1 to OUT6, END

zz

zz

z ALM output

The ALM output is turned on when the E-STOP input is turned off, an alarm input is fed from the

driver or there is an error in the controller.

Once the problem’s cause is eliminated, the ALM output is cancelled automatically. For more

information on the causes and handling of alarms, see section 10.1, “When ALARM LED illuminates.”

The output logic may be switched between normally open and normally closed via command inputs.

(Set to “normally closed” at the time of power-on.)

z MOVE output

The MOVE output is turned on during pulse output.

z READY output

The READY output is turned on when the controller is ready to accept the START input.

The READY output is turned off while the program is being executed or modified.

z OUT1 to OUT6 outputs

General-purpose outputs

z END output

One-shot output will be performed after a positioning operation.

The amount of output time can be changed via command input. (Set to 10ms at the time of poweron.) If END input from the driver is set to “used” via command input, pulse output from the controller

will cease. When the END input from the driver turns on, END output also turns on.

Page 27

55

55

5

Connection

5-7

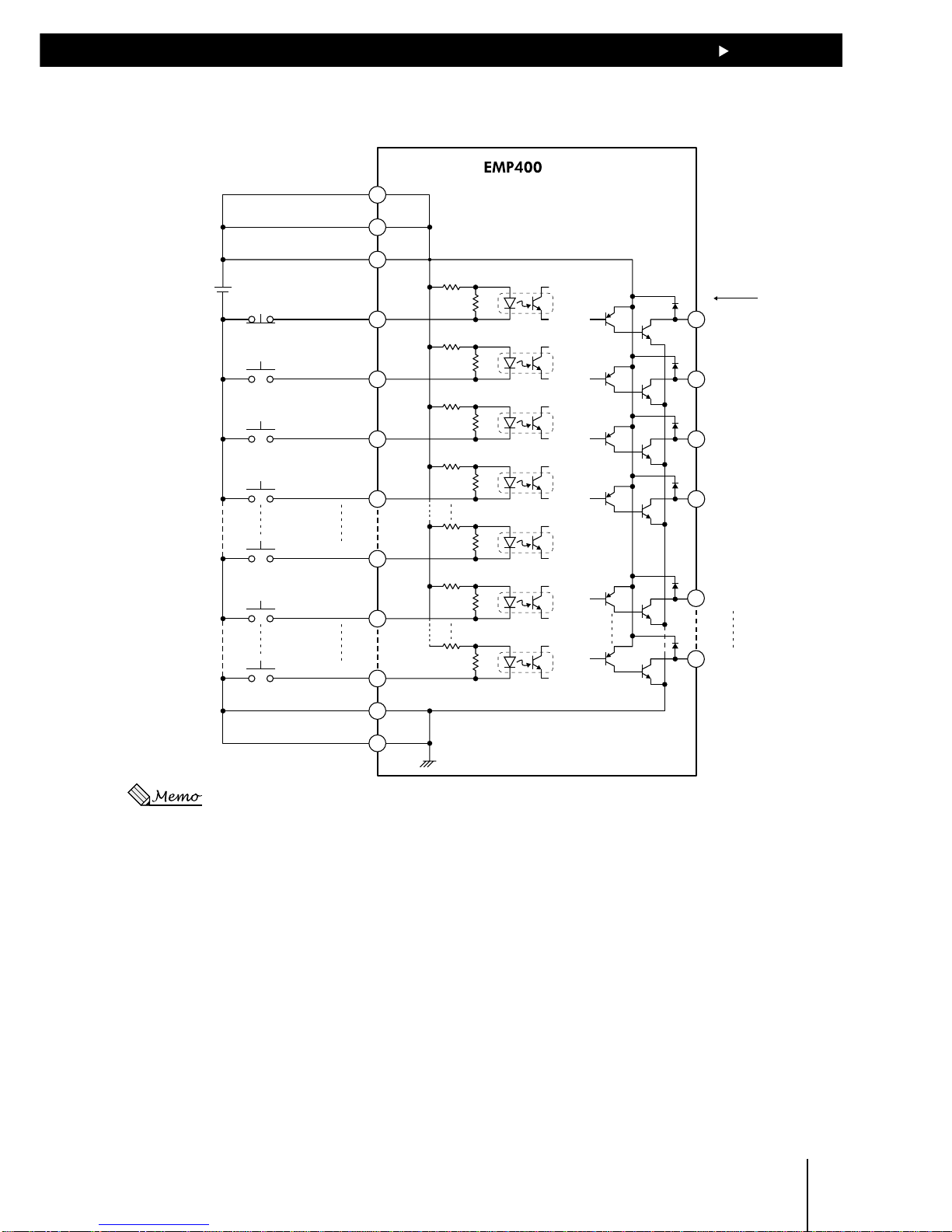

5.3.4 Connection example to a host controller

Series

CN1

7

16

32

2

3

4

33

37

8

15

25

50

27

29

31

49

17

22

ALM output

MOVE output

READY output

END output

OUT1 output

OUT6 output

E-STOP input

24VDC

+COM input

+COM input

+COM input

-

COM input

-

COM input

START input

S-STOP input

M0 input

M4 input

IN1 input

IN8 input

+5~24VDC

25mA max.

The current flow for each output signal is 25mA or less.

Page 28

55

55

5

Connection

5-8

5.4 Connecting the driver (CN3·CN4

∗EMP402 only

)

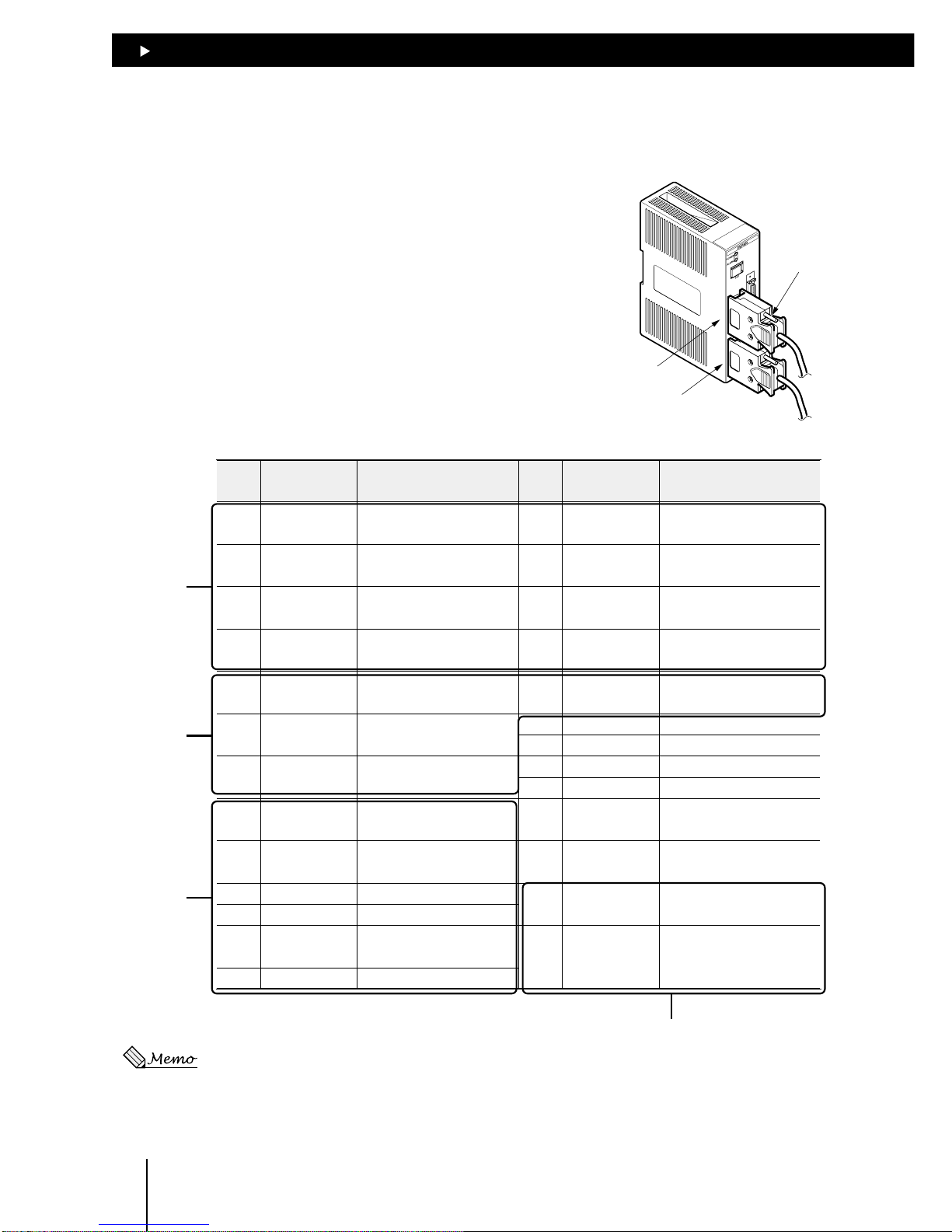

5.4.1 Connection method

Use the AXIS connector (26-pin) for connection with the

driver.

Plug the AXIS connectors for the first- and second-axis

drivers into CN3 and CN4, respectively, and tighten them

with screws.

Screw

CN3

CN4

CN3·CN4 signal table

Pin

No.

Signal Description

Pin

No.

Signal Description

1

+CW-P output

(+PULSE output)

CW pulse (pulse)

14

-

No connection

2

-

CW-P output

(-PULSE output)

CW pulse (pulse)

15

-

No connection

3

+CCW-P output

(+DIR output)

CCW pulse

(Direction of rotation)

16

+CCR output Counter-clear

4

-

CCW-P output

(-DIR output)

CCW pulse

(Direction of rotation)

17

-

CCR output Counter-clear

5

END input END signal from driver

18

GND

GND signal from driver

6

TIM input

Timing signal from driver

7

ALM input

Alarm signal from driver

8

+LS input

CW limit sensor

19

-

No connection

9

-

LS input CCW limit sensor

20

-

No connection

10

HOMELS input Home limit sensor

21

-

No connection

11

SLIT input Slit sensor

22

-

No connection

12

+12V output

Power source terminal

for sensor (35mA max.)

23

-

No connection

13

GND GND for sensor

24

-

No connection

25

+5V output

Power source terminal for

timing signal (20mA max.)

26

GND GND for timing signal

Outputs to

driver

Inputs from

driver

SENSOR

For timing signals

Shown in parentheses is the information for 1-pulse output mode.

Page 29

55

55

5

Connection

5-9

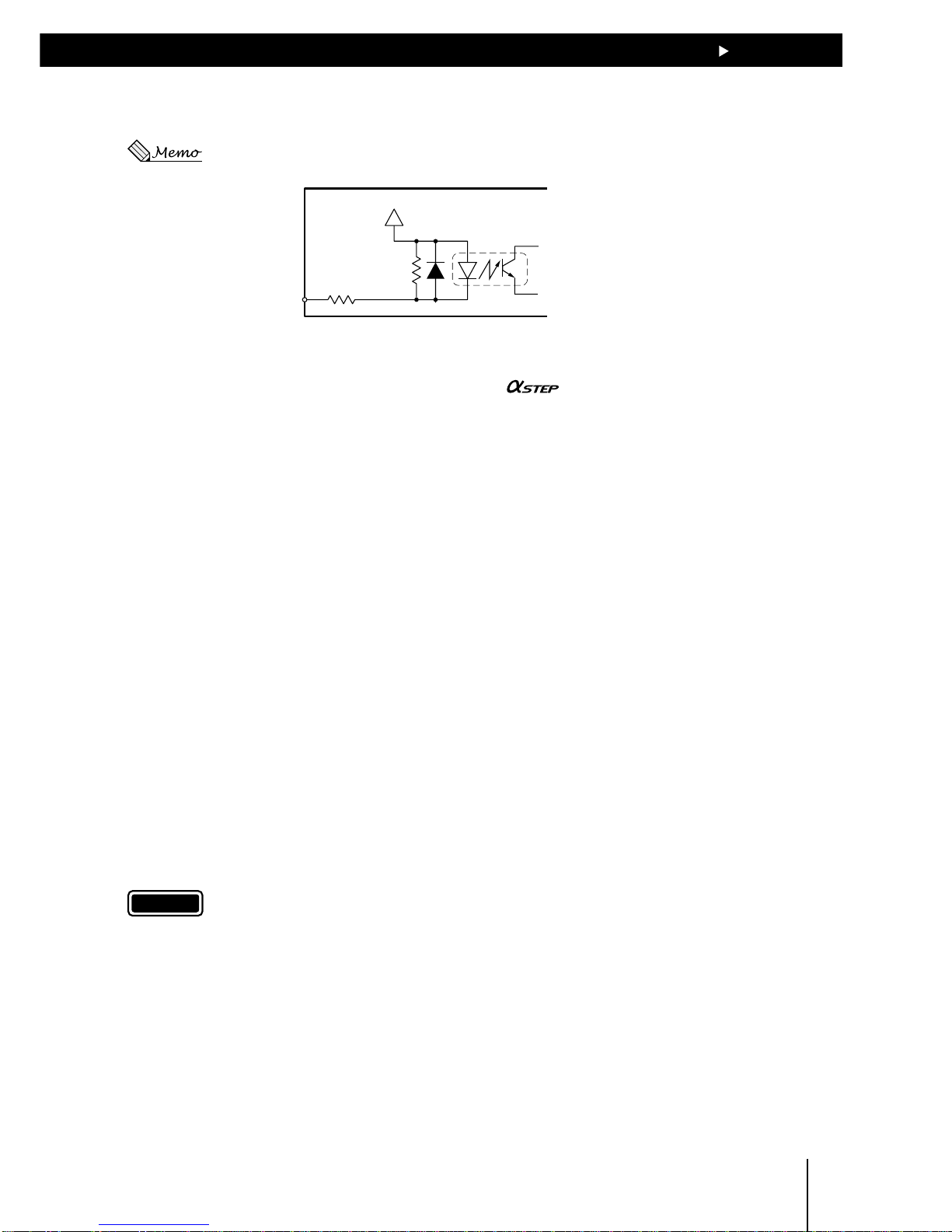

5.4.2 Internal input circuit

The signal state represents the “ON: Carrying current” or “OFF: Not carrying current” state of the internal

photocoupler rather than the voltage level of the signal.

2.7kΩ

1kΩ

PS2801 or

equivalent

+12V

END, TIM, ALM

+LS,

-

LS

HOMELS, SLIT

z END input

This terminal is used to input the END signal output from the driver at the end of operation. This

terminal should be connected when using the

or servo motor.

The END signal is enabled or disabled via command input. (Set to “enabled” at the time of poweron.)

z TIM input

This terminal is used to input the timing signal from the driver.

When mechanical home is detected in mechanical home seeking mode, an accurate home position

can be found by using this signal with the HOMELS input or the HOMELS input/TIM input by

connecting them with an AND logic operator.

z ALM input

This terminal is used to input the alarm signal from the driver. (The driver’s alarm outputs may either

be at normally open or normally closed, depending on the model.)

If an alarm-signal input is fed while the motor is in operation, the motor will decelerate to a stop and

the program will stop also.

No pulse can be output while alarm signal inputs are being fed, although any command not associated

with pulse output can be executed.

The input logic may be switched between normally open and normally closed via command inputs.

(Set to “normally closed” at the time of power-on.)

z +LS and –LS inputs

This terminal is used to input signals from +LS and –LS.

If the LS input is turned on during pulse output, the motor will stop immediately. However, mechanical

home seeking will continue even if the LS input is turned on.

The input logic may be switched between normally open and normally closed via command inputs.

(Set to “normally open” at the time of power-on.)

Note

Note that two different input logics cannot be set for the +LS and –LS inputs, respectively.

z HOMELS input

This terminal is used to input signals from HOMELS when performing high-speed home seeking

using three sensors.

The input logic may be switched between normally open and normally closed via command inputs.

(Set to “normally open” at the time of power-on.)

z SLIT input

This terminal is connected when using a motorized slider with a slit sensor.

An accurate home position can be found by using this signal with the HOMELS input or the HOMELS

input/TIM input by connecting them with an AND logic operator.

The input logic may be switched between normally open and normally closed via command inputs.

(Set to “normally open” at the time of power-on.)

Page 30

55

55

5

Connection

5-10

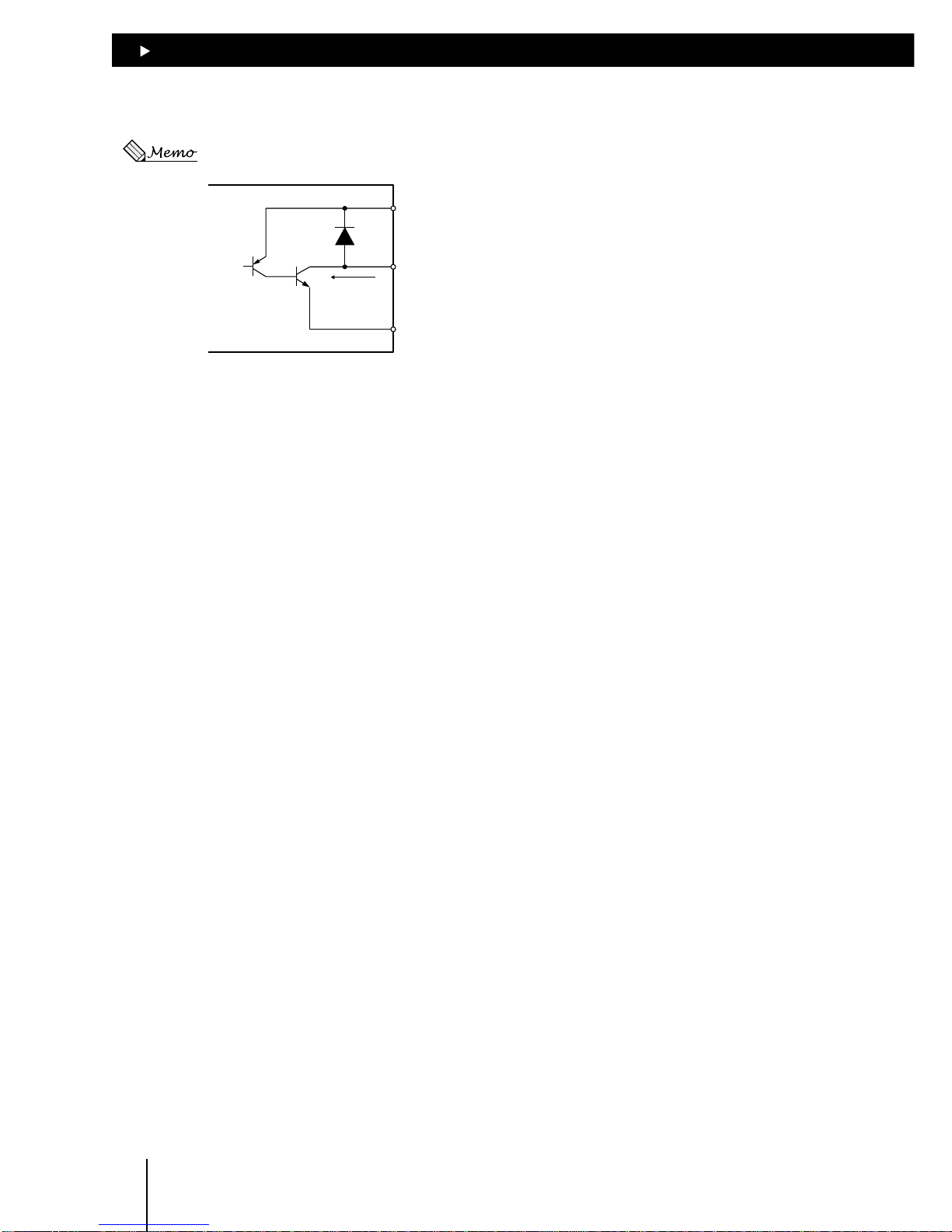

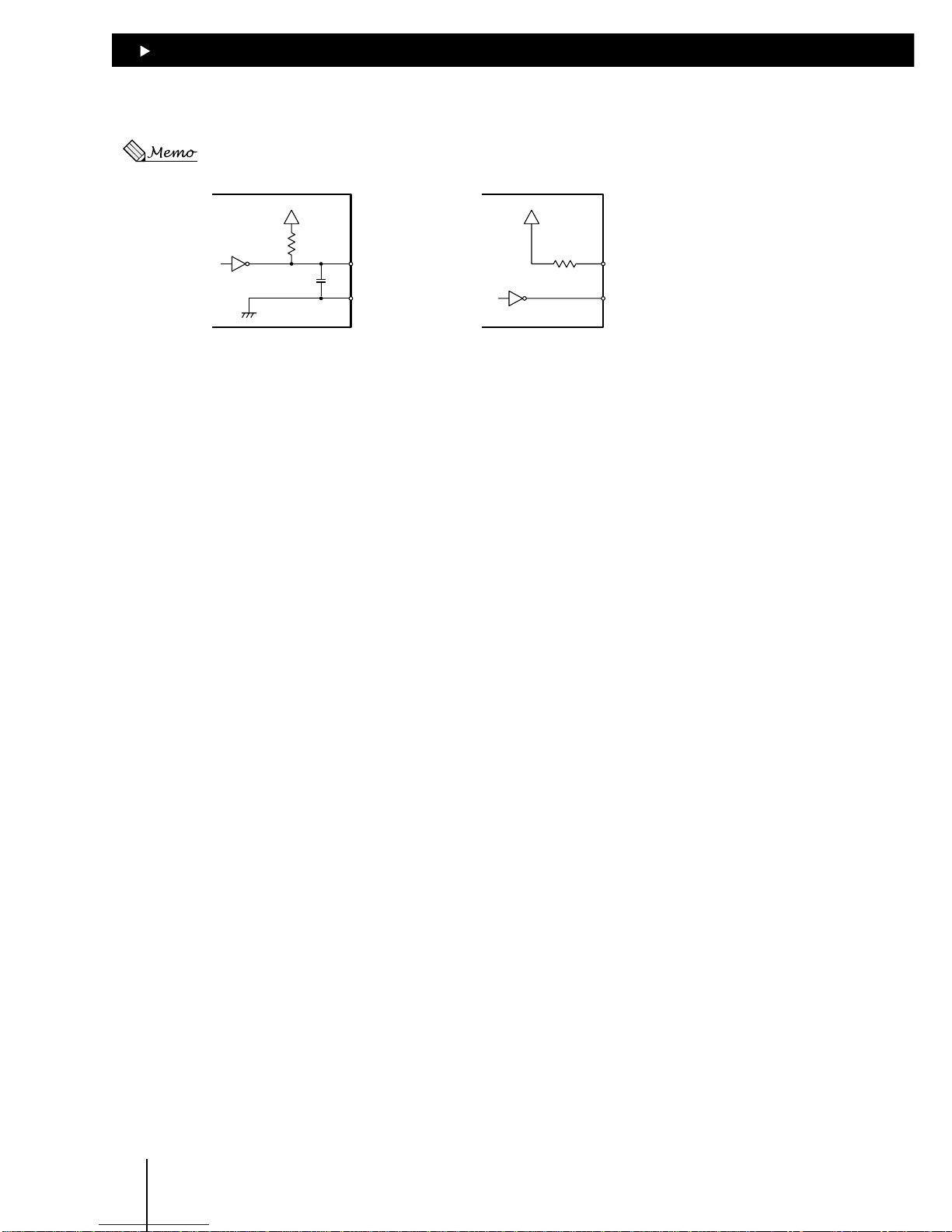

5.4.3 Internal output circuit

The signal state represents the “ON: Carrying current” or “OFF: Not carrying current” state of the internal

photocoupler rather than the voltage level of the signal.

+12V +12V

560Ω

74LS06 or

equivalent

1000pF

+CW-P (+PULSE)

+CCW-P (+DIR)

-

CW-P (-PULSE)

-

CCW-P (-DIR)

560Ω

74LS06 or equivalent

+CCR

-

CCR

z±CW-P (±PULSE) output, ±CCW-P (±DIR) output

These terminals are used to output pulses.

Information in parentheses is for 1-pulse output mode. In the 1-pulse output mode, the motor will

rotate in the CW direction with the DIR output turned on and in the CCW direction with the DIR output

turned off.

The output mode may be switched between 1-pulse and 2-pulse modes via the PULSE command.

(Set to “2-pulse mode” at the time of power-on.)

z ±CCR output

These terminals are used to output counter clear signals for resetting the counter in the driver.

These terminals should be connected when a servo motor is used.

The circuit will generate CCR outputs in any of the following situations (output width 500µs):

• The E-STOP input is turned off while the motor is in operation

• While mechanical home seeking is in progress

• When the motor has pulled out from the limit sensor during continuous operation

• When an alarm event has caused the operation to stop immediately

• When the power is turned on or the RESET command is input

Page 31

55

55

5

Connection

5-11

5.4.4 Connection example to a driver

series

CN3・CN4

Driver

15

6

7

8

9

10

11

2

3

4

16

17

25

26

12

13

18

+5V output/Power source f or TIM

∗

5

(20mA max.)

GND∗5

+12V output

GND

GND

+CCR output∗4

-

CCR output∗4

+CCW-P output

-

CCW-P output

+CW-P output

-

CW-P output

Power source

for sensor

(140mA max.)

SLIT input∗3

END input*1

+12V

+12V

+12V

+5V

+12V

TIM input*2

ALM input

+LS input

-

LS input

HOMELS input

+CW-P input

-

CW-P input

+CCW-P input

END output

TIM output

ALM output

COM

-

CCW-P input

+CCR input

-

CCR input

Power source

for TIM

Vcc+5V

GND

∗1: Connect the END input (5-pin) when using an or servo motor.

∗2: Do not connect the TIM input (6-pin) when using a servo motor.

∗3: Connect the SLIT input (11-pin) when using a motorized slider with a slit sensor.

∗4: Connect the CCR output (16/17-pin) when using a servo motor.

∗5: Connect the timing-signal power supply (25/26-pin) to the driver when using the TIM output with an

motor.

Page 32

55

55

5

Connection

5-12

CN2

5.5 Terminal connection (CN2)

5.5.1 Connection method

Modular cables are used to connect a PC and the

operational unit.

Plug the modular cable connector into CN2.

Page 33

6

Writing and editing

a program

This section covers how to write a sequence program and edit an

existing sequence program.

Page 34

6 Writing and editing a program

6-2

6.1 How to write a program

The program contains the method of motor operation as well as speed settings and other

parameters.

Once the program is started, the motor will execute the commands contained in the program

according to a specified order.

The program is stored in the controller memory.

A program can be written using one of the following two methods:

Using a line editor

Input commands

using a line editor.

Send a command at

each press of the key.

[Procedure]

1. Connect the controller with a PC.

(See section 6.3, “Starting and exiting HyperTerminal.”)

2. Use a line editor to save commands to the controller in real time.

Each time the Enter key is pressed following command input, the command is sent to the controller.

(See section 6.4, “Writing a program with a line editor.”)

Using a text editor

Write a program

using a text editor.

Download the program.

[Procedure]

1. Write a program using a text editor, then save it in text format.

(See section 6.5, “Writing a program with a text editor.”)

2. Connect the controller with a PC.

(See section 6.3, “Starting and exiting HyperTerminal.”)

3. Download the program in the text-format file to the controller.

(See section 6.5.2, “Downloading a program.”)

Page 35

6 Writing and editing a program

6-3

6.2 Additional information on program

composition

6.2.1 Program

• A program is composed of commands to the controller and parameters.

• Type in alphanumeric characters (case-insensitive) to define commands and parameters for the

program.

• The character string containing a command and parameters is called “line.” One line can only

contain one command.

T I M 2

,

1

,

0

Axis set parameter

No space is necessary between an

axis set parameter and a command.

(Separating them with a space will result in an error.)

Parameter

Space or comma

A space or comma should be used to

delimit parameters or a command

and a parameter.

Command

A maximum of 32 sequence programs can be created, from program numbers 0 through 31.

Additionally, program number 99 can be written as an automatically executable program. (See

section 7.3, “Automatic program execution.”)

A total of 1000 lines can be configured for these 33 programs.

Example 1: 125 lines x 8 programs = 1,000 lines

Example 2: 500 lines x 2 programs = 1,000 lines

6.2.2 Parameter settings for motor operation

Correct settings for sensors and drivers should be defined before operating the motor.

Settings are required for the following parameters. For further details, see 8.2.1, “Hardware

configuration commands.”

• Pulse output mode setting............................................................... PULSE command

• ID setting ......................................................................................... ID command

• Setting for +/

-

LS input, HOMELS input or SLIT input logic............ ACTL command

• Input logic setting for alarm input from the driver ............................ ACTL command

• Setting for alarm output logic...........................................................ACTL command

• Home detection method setting ...................................................... SEN command

• END input usage .............................................................................EEN command

• TIM input usage............................................................................... TIM command

• SLIT input usage .............................................................................TIM command

• Unit-value setting............................................................................. UNIT command

Page 36

6 Writing and editing a program

6-4

6.3 Starting and exiting HyperTerminal

6.3.1 Verifying the communication method

1. Start the PC and open “System” in the control panel.

The System window then appears.

2. Select the “Device Manager” tab.

The Device window then appears.

3. Verify that there is “Communication Port (COM∗)” under “Port.”

If there is no “Communication Port (COM∗),” read the operating manual for your computer and

set up a serial communication function.

Page 37

6 Writing and editing a program

6-5

6.3.2 How to start HyperTerminal

1. Switch off the power to the controller.

2. Connect the controller’s CN2 with your computer using the optional FC04W5 modular cable

(purchased separately).

3. Start the computer.

4. Click on the “Start,” “Program,” “Accessories,” “Communication” and “HyperTerminal” icons to

start Hyper Treminal.

A window appears with a slot, where a name can be typed in for the new connection.

Page 38

6 Writing and editing a program

6-6

5. Type in a name for the connection (e.g. EMP400), then select an icon and click “OK.”

A window appears, asking you to enter information regarding the telephone number.

6. In a typical connection method you may select the communication port you have previously

verified as described in section 6.3.1, “Verifying the communication method,” and click “OK.”

A window appears in which to set properties.

Note

The connection method may vary, depending on the computer.

For details, see the operating manual for your computer.

7. Set properties as follows:

• Bits per second: 9600 bps

• Data bit: 8

• Parity: None

• Stop bit: 1

• Flow control: None

Page 39

6 Writing and editing a program

6-7

8. Click “OK.”

The selected connection is saved and the HyperTerminal screen appears.

9. Power on the controller.

The HyperTerminal screen indicates that the controller has started up.

The connection settings are required only before the initial connection.

Page 40

6 Writing and editing a program

6-8

6.3.3 How to exit HyperTerminal

1. Exit HyperTerminal.

A message appears, asking if you want to disconnect.

2. Click “Yes.”

A message appears, asking if you want to save the settings.

3. Click “Yes.”

The settings are saved and an icon is created.

Saving of the settings is required only after the initial connection.

For subsequent connections, you may start HyperTerminal simply by double-clicking the icon.

EMP400

Page 41

6 Writing and editing a program

6-9

6.4 Writing a program with a line editor

HyperTerminal (Windows application) can be used as a line editor to write a program.

While using HyperTerminal, command inputs to HyperTerminal are saved to the controller in real

time.

1. See section 6.3, “Starting and exiting HyperTerminal,” to connect the controller with your computer

and start HyperTerminal.

2. Type in “EDIT∗” (∗ represents a program).

Insert a space between “EDIT” and the program number.

Once the entry is made, a message “Empty... Direct Insert Mode” appears, indicating that the

program is empty. You can now write a new program.

3. See section 8, “Communication command,” to enter commands and parameters in order to write

a program.

The example program below shows the program number 1 specifying astarting speed of 100Hz,

operating speed of 3,000Hz, distance of 6,000 pulses and + (CW) direction.

To complete the writing of a program, type in “Q” or press the ESC key.

Page 42

6 Writing and editing a program

6-10

When an error message appears

An error message is displayed if any invalid command or parameter is entered while the sequence

program is being created.

If an error message appears, see section 6.7, “List of messages associated with programs,” for the

appropriate corrective action.

6.5 Writing a program with a text editor

A program may be written using a text editor on your PC.

The program should then be saved in text format for downloading to the controller via HyperTerminal’s

transmission function.

The downloaded program will be saved in the controller memory.

The program saved in the controller may also be uploaded to a PC via HyperTerminal’s transmission

function and saved in text format.

Controller

PC

Downloading

Uploading

Page 43

6 Writing and editing a program

6-11

6.5.1 How to write a program

There is a set of requirements that must be satisfied when writing a program using a text editor.

These requirements are explained in the following example of program composition.

1. Start a text editor.

2. Write a program by meeting the requirements explained below.

Type in alphanumeric characters.

Up to 80 characters may be entered for each line.

[Requirements]

∗1. The program should start with “Seq∗” (∗ represents

a program number). Enter a space between

“Seq” and the program number.

∗2. Enter the line number in brackets “[ ].”

∗3. No more than one command can be entered into a

single line.

∗4. Following the last line of the program, be sure to

press the Enter key at least once.

∗5. One text file can contain more than one program.

∗6. The line number may be omitted. A space may be

entered.

∗7. Any character string entered following “ ; ” will be a

comment. The comment will not be saved in the

controller.

3. Save the created program in text format.

Always add the “.txt” extension to the text file name.

Downloading the file you created and saved in text

format in Step 2 to the controller and then uploading it

to a PC will result in the following:

[Results]

∗3. An error has occurred, since more than one

command was entered into one step.

∗4. Blank steps have been deleted.

∗6. An [n] representing the line number has been

added. A space has been deleted.

∗7. A comment has been deleted.

Seq 1

[1] LOOP 10

[2] VS 100

[3] V 3000, TR 30

[4] D 1000

[5] INC

[6] ENDL

Seq 2

LOOP 10

VS 100

V 3000

D 1000

inc

;comment

ENDL

Seq 1

[1] LOOP 10

[2] VS1 100

[3] syntax error

[4] D1 1000

[5] INC1

[6] ENDL

Seq 2

[1] LOOP 10

[2] VS1 100

[3] V1 3000

[4] D1 1000

[5] INC1

[6] ENDL

∗2

∗1

∗4

∗5

∗7

∗3

∗6

∗4

∗3

∗7

∗6

Page 44

6 Writing and editing a program

6-12

6.5.2 Downloading a program

The program saved in a PC can be downloaded to the controller using HyperTerminal.

Only programs in text format are downloadable.

Note

To download a program, exit all applications other than HyperTerminal. If you attempt to download

the program while running other applications, the motor may move abruptly.

1. See section 6.3, “Starting and exiting HyperTerminal,” to connect the controller with a PC and

start HyperTerminal.

2. Type in the download command “DWNLD” and press the Enter key.

It’s now ready to download.

3. Select “Send text file” from the “Transfer” menu of HyperTerminal.

A window appears with a slot to specify the file to be downloaded to the controller.

Only text files are downloadable.

Page 45

6 Writing and editing a program

6-13

4. Enter the name of the file you want to download, then click on “Open.”

Downloading of the program begins.

Once downloading is complete, the “Completed” message appears.

Note

Do not use the keyboard while the sequence program is being downloaded. Doing so may result in

a download error.

The numbers of the program and line in which the first downloading error was detected will be

displayed. (The figure below shows an example in which the first error was detected in Line

5 of Program 1.)

The command and parameters of the error line will be cancelled, and subsequent lines will be

correctly received by the controller. Since no command exists in the cancelled line, the error

program, if executed, will be halted at the cancelled line. Correct any error program and repeat

the download.

Note

You cannot overwrite an existing program. To replace the existing program with a new one, first

delete the applicable program saved in the controller and assign the same program number to the

new program before downloading it to the controller.

z You can download several sequence programs at once by writing and saving them in a single text file.

z If the same program number is assigned for more than one program within a single text file, the first program

downloaded will be enabled with the remaining programs cancelled.

Page 46

6 Writing and editing a program

6-14

6.5.3 Uploading a program

The program saved in the controller may be uploaded to a PC via HyperTerminal’stransmission

function.

The uploaded program will then be saved to a specified file in text format.

Either one or all of the programs can be uploaded at once.

1. See section 6.3, “Starting and exiting HyperTerminal,” to connect the controller with a PC and

start HyperTerminal.

2. Start a text editor.

3. Create and save a new text file.

Add the “.txt” extension to the text file name. Do not make any entry to the file.

4. Switch on the power to the controller.

The HyperTerminal screen will indicate that the controller has been started.

5. Type in the upload command “UPLD” and press the Enter key.

A message appears, prompting you to select a sequence program (Select upload Sequence No.

0-31, 99, ALL).

Page 47

6 Writing and editing a program

6-15

6. Select a program for uploading to the PC.

Type in a desired number from among “0” through “31” and “99” to specify one sequence program

number, or type in “A” to upload all of the sequence programs. Then, press the Enter key.

A message appears, prompting you to select text capture (Start “TEXT CAPTURE”).

7. Select “Capture Text” from the “Transfer” menu of HyperTerminal.

The Text Capture window appears.

8. Click on “Browse.”

A window appears to specify the file name and the folder under which to save the file.

9. Specify the text file saved in step 3 and click on “Save.”

The Text Capture window appears.

Page 48

6 Writing and editing a program

6-16

10. Click on “Start.”

The HyperTerminal screen appears.

11. Press the Enter key.

The controller begins uploading the program.

Once uploading is complete, a message (End “TEXT CAPTURE”) appears.

Note

Do not use the keyboard while the program is being uploaded.

Doing so may result in an upload error.

12. Select “Capture Text” from the “Transfer” menu of HyperTerminal, then select “Stop.”

This ends the Text Capture function.

13. Press the Enter key.

The “0>” command prompt is displayed.

14. Open the text file you saved and check to see that the program has been uploaded correctly.

If you try to save a new program to an existing text file, the program will be added and saved at the end of that text

file.

If you try to save a program under an existing program

number within the same text file, the new program will be

added and saved at the end of the existing program.

However, if you download this text file to the controller, the

first program will be enabled and the latter program will be

deleted.

The same program

numbers are written.

The leading program is downloaded

(the remaining programs are deleted).

Page 49

6 Writing and editing a program

6-17

6.6 Editing the program

An existing program can be modified by changing, inserting or deleting a command.

The command may be entered in the same manner as when writing a new program.

6.6.1 Checking the number of steps

Start HyperTerminal, type in “EDIT” and press the Enter key. You will get a list of program numbers

and the line numbers, along with a message indicating the number of remaining lines.

Check the already existing program numbers and the number of available lines.

Page 50

6 Writing and editing a program

6-18

6.6.2 How to edit the program

1. Enter the edit command “EDIT∗” (∗ represents the program number).

Insert a space between “EDIT” and the program number.

The content of the selected program is displayed for editing.

2. Enter the command and line number according to the intended editing.

A 5

Space

Edit command Line number to be edited

Command Description

A Alter

I Insert

D Delete

Q Quit

Page 51

6 Writing and editing a program

6-19

Example of editing a program

The example below provides a step-by-step description of how program 1 is edited under the following

conditions:

Seq 1

[1] LOOP 5

[2] V1 20000

[3] D1 1200

[4] INC1

[5] ENDL

[6] MHOME1

Seq 1

[1] LOOP 5

[2] V1 20000

[3] D1 1200

[4] ABS1

[5] DELAY 1

[6] ENDL

[Before edit] [After edit]

Add the DELAY command between the

fourth and fifth lines.

Change the fourth line from INC 1 to ABS 1.

Delete MHOME1.

1. Type in “EDIT 1” and press the Enter key.

The contents of program 1 is displayed for editing.

2. Follow the lines below to change the fourth line from “INC 1” to “ABS 1.”

a. Type in “A 4” and press the Enter key.

The fourth line is now ready for editing.

Page 52

6 Writing and editing a program

6-20

b. Type in “ABS1.”

c. Press the Enter key.

The fourth line of program 1 is changed to “ABS 1,” and you can now enter another

command for editing.

Page 53

6 Writing and editing a program

6-21

3. Follow the steps below to insert “DELAY 1” between the fourth and fifth lines.

a. Type in “I 5” and press the Enter key.

The fifth line is added and now ready for command entry.

b. Type in “DELAY 1.”

Page 54

6 Writing and editing a program

6-22

c. Press the Enter key.

“DELAY 1” is added to the fifth line of program 1, and the subsequent line number is

changed. You can now enter another command for editing.

4. Follow the steps below to delete “MHOME 1” from the seventh line.

a. Type in “D 7” and press the Enter key.

A message appears, asking if you want to delete (Delete line 7 (Y/N)?).

Page 55

6 Writing and editing a program

6-23

b. Type in “Y.”

c. Press the Enter key.

The seventh line of program 1 is deleted, and you can now enter another commandfor

editing.

Page 56

6 Writing and editing a program

6-24

6.6.3 Quitting the program editing

1. Type in the “Q” command to quit the program editing.

2. Press the Enter key.

This completes the program editing, and the “0>” command prompt is displayed.

Page 57

6 Writing and editing a program

6-25

6.7 List of messages associated with

programming

The messages listed below may be displayed while writing, editing, downloading or uploading a

program.

An error message will appear if any invalid command or parameter is entered while editing a

program.

If an error message is displayed, go back to enter the A, I or D command again.

Message Description

Can not Overwrite You cannot overwrite an existing program.

>> Command: Enter a command.

Completed. Downloading/uploading has been completed.

Delete line n (Y/N)? The nth line will be deleted.

Empty...Direct Insert Mode. (ESC/Q = exit) The program is empty. A new program may be written.

End TEXT CAPTURE Stop Text Capture of HyperTerminal.

Insert line n The nth line will be inserted.

Invalid value. An invalid parameter has been entered for the command

you want to change or insert.

Line does not exist. The line you want to change/insert/delete does not exist.

Press ENTER key. Press the Enter key.

Select: Ax, Ix, or Dx (Alt/Ins/Del/Q = exit) Select the command for editing.

Select upload Sequence No. 0-31, 99, A Select the program you want to upload.

(0-31, 99, ALL)?

Start DOWNLOAD Start sending the text file via HyperTerminal.

Start TEXT CAPTURE Start Text Capture of HyperTerminal.

Syntax error. The command you want to change or insert is invalid.

Page 58

6 Writing and editing a program

6-26

Page 59

7

Executing the

program

This section covers how to execute the program you have written.

Page 60

77

77

7

Executing the program

7-2

7.1 How to execute a program

The program saved in the controller memory may be executed in one of the following three methods:

zz

zz

z Executing via the host controller

You can select and execute a program via the host controller.

See section 7.2, “Program execution via the host controller.”

zz

zz

z Automatic program execution

The program you have written under program number 99 is automatically executed upon power

on or RESET command input.

See section 7.3, “Automatic program execution.”

zz

zz

z Program execution via command

The program may be executed by inputting an execution command to HyperTerminal.

See section 7.4, “Program execution via command.”

Page 61

77

77

7

Executing the program

7-3

7.2 Program execution via the host controller

CN1, which is connected to the host controller connector, has M0 through M4 inputs for selecting the

program number and START input for execution of the program.

You can select a program number through a unique combination of M0 through M4 input conditions

and execute the program by activating the START input.

1. Use the host controller to select a program you’d like to execute through a unique combination of

M0 through M4 input conditions (CN1: 33- to 37-pin).

Input signal

Sequence

program No

M0M1M2M3M4

OFFOFF0

OFFOFF1

OFFOFF2

OFFOFF3

OFFOFF4

OFFOFF5

OFFOFF6

OFFOFF7

OFF8

OFF9

OFF10

OFF11

OFF12

OFF13

OFF14

OFF15

ON

ON

ON

ON

ON

ON

ON

ON

OFF

OFF

OFF

OFF

ON

ON

ON

ON

OFF

OFF

OFF

OFF

ON

ON

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

Input signal

Sequence

program No

M0M1M2M3M4

OFF16

OFF17

OFF18

OFF19

OFF20

OFF21

OFF22

OFF23

24

25

26

27

28

29

30

31

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

OFF

OFF

OFF

OFF

ON

ON

ON

ON

OFF

OFF

OFF

OFF

ON

ON

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

2. Turn the START input (CN1: 3-pin) to on via the host controller.

This will start the program you have selected.

Page 62

77

77

7

Executing the program

7-4

7.2.1 Example of program execution

The timing chart below shows the status of operation with program 1 when an S-STOP input is

turned on during continuous operation as specified by program 1 and program 3 is executed

subsequently.

Seq 1

[1] D 10000

[2] INC

[3] IN 1,1

[4] H

-

[5] SCAN

Motor

M0 to M4 inputs

START input

IN input

S-STOP input

READY output

END output

MOVE output

CW-P output

CCW-P output

ON

OFF

ON

OFF

ON

OFF

OFF

ON

OFF

ON

OFF

ON

ON

OFF

ON

OFF

ON

OFF

INC

Seq.1 Seq.3

SCAN

1ms maximum

1ms minimum

*1

1ms maximum

0ms minimum

0ms minimum

1ms minimum

1ms

minimum

1ms minimum

1ms maximum

*3

1ms to 100ms

*2

1ms maximum

1ms maximum

1ms

maximum

∗1: To use a general-purpose input, set the duration of input’s “On” or “Off” status to 1 ms or longer.

∗2: The duration of END output can be set via the ETIME command. (The factory setting is 10 ms.)

∗3: When the END input is enabled via the EEN command, the END output is produced following an END input

through the driver.

Page 63

77

77

7

Executing the program

7-5

7.2.2 Emergency stop

The timing chart below shows the status of operation when an emergency stop signal (E-STOP

input) is fed and the operation then resumes.

Motor

E-STOP input

M0 to M4 inputs

READY output

ALM output

MOVE output

CW-P output

CCR output

START input

ON

OFF

ON

OFF

ON

OFF

OFF

ON

OFF

ON

OFF

ON

ON

OFF

ON

OFF

1ms maximum

1ms maximum

1ms

maximum

1ms maximum

3ms minimum

3ms

maximum

3ms

maximum

1ms minimum

500μs

1ms minimum

Page 64

77

77

7

Executing the program

7-6

7.2.3 Alarm signal input from the driver

The timing chart below shows the status of operation when an alarm signal (ALM input) is fed from

the driver during operation and the operation then resumes.

Motor

ALM input

M0 to M4 inputs

READY output

ALM output

MOVE output

CW-P output

START input

ON

OFF

ON

OFF

ON

OFF

OFF

ON

OFF

ON

ON

OFF

ON

OFF

1ms maximum

1ms maximum3ms maximum

1ms minimum

1ms maximum

Page 65

77

77

7

Executing the program

7-7

7.3 Automatic program execution

If a program is written under program number 99 (CONFIG program), program 99 will be automatically

executed upon power on or RESET command input.

Note

Inputting the operation command to sequence program 99 will cause the equipment to move abruptly

upon power on or RESET command input. Take safety considerations when writing a program for

program number 99.