Page 1

AS Series

HM-6159-11

OPERATING MANUAL

AS66, AS69, AS98, AS911

C

Table of Contents

Introduction........................................... Page 2

Safety precautions................................ Page 4

Precautions for use............................... Page 6

Preparation........................................... Page 8

Checking the product......................... Page 8

Names and functions of parts ............ Page 14

Installation ............................................ Page 16

Location for installation ...................... Page 16

Installing the motor ............................ Page 16

Installing a load.................................. Page 17

Overhung load and thrust load .......... Page 18

Installing the driver ............................ Page 19

Installing and wiring in compliance

with EMC directive ...... Page 22

Connection ........................................... Page 25

Connection example for a

standard type .... Page 25

Connection example for an

electromagnetic-brake type .... Page 25

Connecting the driver ........................ Page 26

Connecting to the power supply ........ Page 28

Connecting the motor ........................ Page 31

Grounding the motor and driver......... Page 33

Connecting control input/output ......... Page 33

About control input/output.................. Page 36

Timing chart....................................... Page 42

Setting .................................................. Page 43

Resolution ......................................... Page 43

Pulse input modes ............................. Page 44

Operating current .............................. Page 44

Speed filter ........................................ Page 45

Protective functions .............................. Page 46

Inspection ............................................. Page 47

Troubleshooting and remedial actions .. Page 48

Main specifications ............................... Page 50

Appendix .............................................. Page 61

Thank you for purchasing an Oriental Motor product.

This Operating Manual describes product handling procedures and safety precautions.

• Please read it thoroughly to ensure safe operation.

• Always keep the manual where it is readily available.

1

Page 2

Introduction

Before using the motor unit

Only qualified personnel should work with the product.

Use the product correctly after thoroughly reading the section “Safety precautions.”

The product described in this manual has been designed and manufactured for use in general industrial machinery, and

must not be used for any other purpose. Oriental Motor Co., Ltd. is not responsible for any damage caused through

failure to observe this warning.

Overview of the product

The AS series models are unit products consisting of a high-performance micro-stepping driver and a stepping

motor ( ) with built-in rotor-position sensor. The AS series models incorporating are not subject to

missteps, even when the load changes suddenly. The speed and amount of rotation are constantly monitored during

operation, so that when an overload is about to cause the motor to misstep, any delay in response is corrected and

operation continues at maximum torque. In addition to the four geared types ideal for low-speed, high-torque

operation, a model equipped with an electromagnetic brake is also available, which is suitable for holding the load in

position during up or down movement in applications involving vertical travel.

Standards and CE marking

This product is recognized by UL. The CE marking (Low Voltage Directive and EMC Directive) is affixed to the product

in accordance with EN standards.

Applicable standards

Motor

Driver

Applicable Standards

UL1004, UL2111

CSA C22.2 No. 100

CSA C22.2 No. 77

EN60950

EN60034-1

EN60034-5

UL508C

CSA C22.2 No. 14

EN60950

EN50178

∗

Certification body

UL

-

UL

-

Standards File No.

File No. E64199

-

File No. E171462

-

∗ For UL standard (UL508C), the product is recognized for the conditionof Maximum Surrounding Air Temperature 50°C

(122°F).

• The names of products certified to conform with relevant standards are represented by applicable unit model motor

and driver part numbers.

Installation conditions (EN standard)

Motor and driver are to be used as a component within other equipment.

Overvoltage category: II

Pollution degree: Class 2

Class: I

For low v olta ge directive

The product is a type with machinery incorporated, so it should be installed within an enclosure.

Install the product within the enclosure in order to avoid contact with hands.

Be sure to maintain a protective ground in case hands should make contact with the product. Securely ground the

protective grounding terminals of the motor and driver.

EMC directive

This product has received EMC measures under the conditions specified in “Example of motor and driver installation

and wiring” on page 24.

Be sure to conduct EMC measures with the product assembled in your equipment by referring to “Installing and wiring

in compliance with EMC directive” on page 22.

2

Page 3

Main features

• Low-speed operation at low vibration levels

The AS series achieves smooth, low-speed operation with extremely low vibration, thanks to its micro-stepping

drive, which enables stepping in very small angles.

• Built-in alarm function

Whenever a load greatly exceeding the motor rating is encountered, or when the motor’s output shaft is constrained

during operation, the driver outputs a warning alarm.

In a vertical-travel application, the electromagnetic brake may be triggered upon the detection of this alarm to prevent

a moving section or the work from falling.

• Preset speed filter

The filter time constant that determines motor response can be set in 16 increments.

• Preset operating current

The level of motor current during operation can be set between 6 and 100% (maximum) in 16 increments.

• Preset resolution

The motor resolution levels can be set in four increments: 0.72°/pulse, 0.36°/pulse, 0.072°/pulse and 0.036°/pulse.

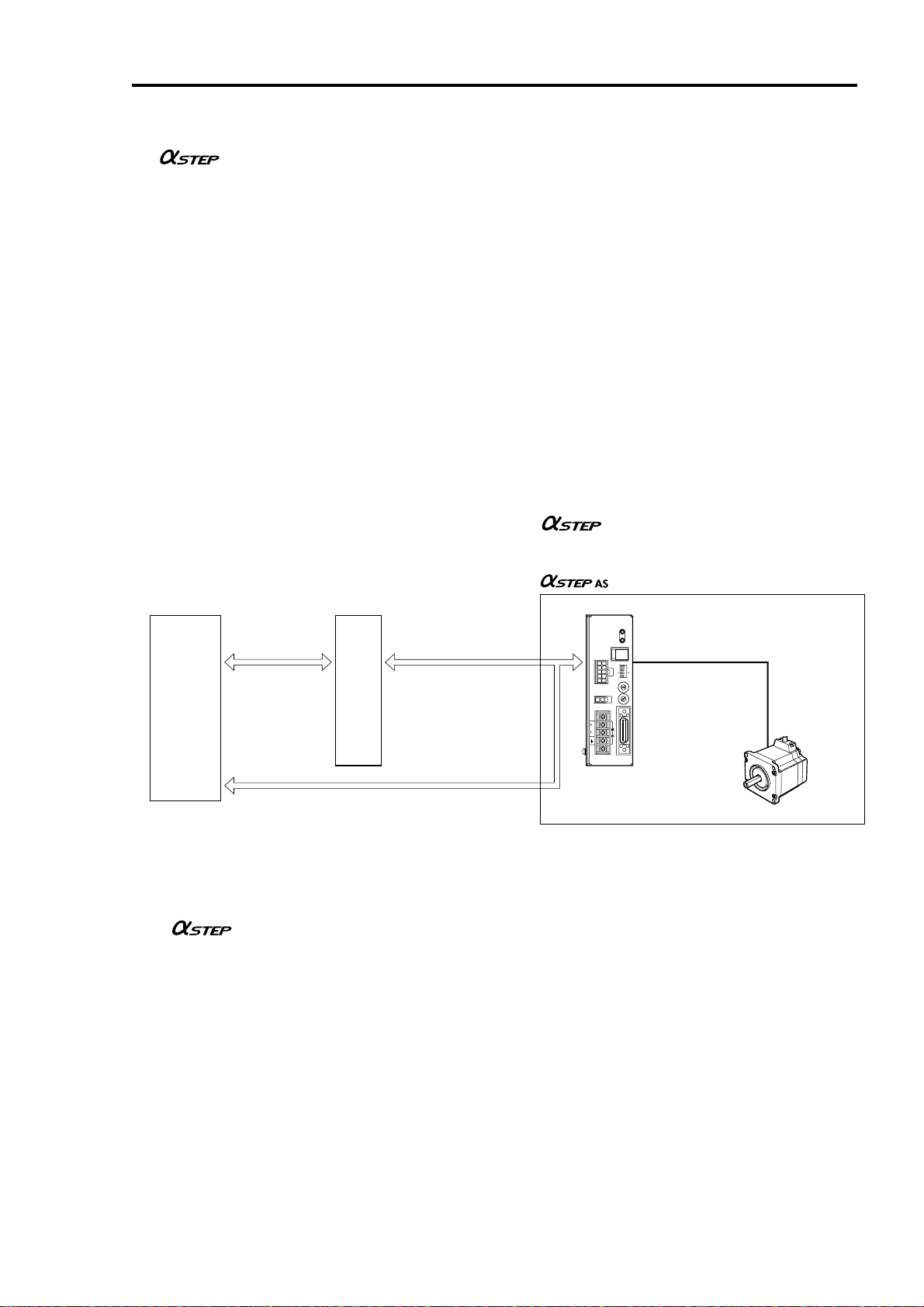

System configuration

Controllers with pulse-output functions are needed to operate the AS series.

Controller

(programmable controller

and others)

Control input

and output

Positioning controller

Pulse output and control

input/output

Shielded cable with

connectors (sold separately)

Driver

ASD24A-A

MOTOR

L

100115V

~

N

VEXTA

series

OPERATION

ALARM

CN1

Extension cable (sold separately)

500

1000

X1

X10

2P

1 2 3 4

1P

CURRENT

C

B

D

A

E

9

CN2

F

8

0

7

1

6

2

5

3

4

V.FIL

C

B

D

A

E

9

F

8

0

7

1

6

2

5

3

4

CN3

CN4

I

O

/

Motor

Control input and output

• Be sure to purchase the extension cable (for use in the model with electromagnetic brake), which is sold separately,

when using the model with the electromagnetic brake. When the motor cable is directly connected to the driver, the

electromagnetic brake will not work. Use a 24 VDC power source for the electromagnetic brake.

• The AS series is available in three input-power sources: single-phase 100-115 V, single-phase 200-230 V

and three-phase 200-230 V.

3

Page 4

Safety precautions

The precautions described below are intended to prevent danger or injury to the user and other personnel through safe,

correct use of the product. Use the product only after carefully reading and fully understanding these instructions.

Warning

Handling the product without observing the instructions that accompany a “Warning” symbol may result in serious

injury or death.

Caution

Handling the product without observing the instructions that accompany a “Caution” symbol may result in injury or

property damage.

Note

The items under this heading contain important handling instructions that the user should observe to ensure safe use

of the product.

Warning

General

• Do not use the product in explosive or corrosive environments, in the presence of flammable gases, locations

subjected to splashing water, or near combustibles. Doing so may result in fire, electric shock or injury.

• Assign qualified personnel the task of installing, wiring, operating/controlling, inspecting and troubleshooting the

product. Failure to do so may result in fire, electric shock or injury.

• Do not transport, install the product, perform connections or inspections when the power is on. Always turn the power

off before carrying out these operations. Failure to do so may result in electric shock.

• The terminals on the driver’s front panel marked with symbol indicate the presence of high voltage.

Do not touch these terminals while the power is on to avoid the risk of fire or electric shock.

• Provide a means to hold the moving parts in place for applications involving vertical travel. The motor loses holding

torque when the power is shut off, allowing the moving parts to fall and possibly cause injury or damage to

equipment.

• Do not use the motor’s built-in electromagnetic brake mechanism for stopping or for safety purposes. Using it for

purposes other than holding the moving parts and motor in position may cause injury or damage to equipment.

• When the driver-protection function is triggered, the motor will stop and lose its holding torque, possibly causing injury

or damage to equipment.

• When the driver’s protection function is triggered, first remove the cause and then clear the protection function.

Continuing the operation without removing the cause of the problem may cause malfunction of the motor, leading to

injury or damage to equipment.

Installation

• To prevent the risk of electric shock, use the motor and driver for class I equipment only.

• Install the motor and driver in their enclosures in order to prevent electric shock or injury.

• Install the motor and driver so as to avoid contact with hands, or ground them to prevent the risk of electric shock.

Connection

• Keep the driver’s input-power voltage within the specified range to avoid fire and electric shock.

• Connect the cables securely according to the wiring diagram in order to prevent fire and electric shock.

• Do not forcibly bend, pull or pinch the cable. Doing so may fire and electric shock.

• To prevent electric shock, be sure to install the terminal cover (supplied) over the driver’s power-supply terminals

after making connections.

Operation

• Turn off the driver power in the event of a power failure, or the motor may suddenly start when the power is restored

and may cause injury or damage to equipment.

• Do not turn the C.OFF (All Windings Off) input to “ON” while the motor is operating. The motor will stop and lose its

holding ability, which may result in injury or damage to equipment.

• If the driver’s OPERATION LED does not come on when the power is turned on, shut off the power immediately. The

neutral-side fuse may be burnt out while the live-side fuse is intact, posing a risk of electric shock. For repair, contact

the branch or sales office from which you purchased the product.

4

Page 5

Maintenance and inspection

• Do not touch the connection terminals of the driver immediately after the power is turned off (for a period of 10

seconds). The residual voltage may cause electric shock.

Repair , disassembly and modification

• Do not disassemble or modify the motor or driver. This may cause electric shock or injury. Refer all such internal

inspections and repairs to the branch or sales office from which you purchased the product.

Caution

General

• Do not use the motor and driver beyond their specifications, or electric shock, injury or damage to equipment may

result.

• Keep your fingers and objects out of the openings in the motor and driver, or electric shock, injury or damage to

equipment may result.

• Do not touch the motor or driver during operation or immediately after stopping. The surfaces are hot and may cause

a burn.

Transportation

• Do not hold the motor output shaft or motor cable. This may cause injury.

Installation

• Keep the area around the motor and driver free of combustible materials in order to prevent fire or a burn.

• To prevent the risk of damage to equipment, leave nothing around the motor and driver that would obstruct

ventilation.

• Provide a cover over the rotating parts (output shaft) of the motor to prevent injury.

Operation

• Use a motor and driver only in the specified combination. An incorrect combination may cause a fire.

• To avoid injury, remain alert during operation so that the motor can be stopped immediately in an emergency.

• Before supplying power to the driver, turn all control inputs to the driver to “OFF.” Otherwise, the motor may start

suddenly and cause injury or damage to equipment.

• To prevent bodily injury, do not touch the rotating parts (output shaft) of the motor during operation.

• Before moving the motor directly (as in the case of manual positioning), confirm that the driver C.OFF

(All Windings Off) input is “ON” to prevent injury.

• The motor’s surface temperature may exceed 70°C, even under normal operating conditions. If a motor is accessible

during operation, post a warning label shown in the figure in a conspicuous position to prevent the risk of burns.

Warning label

• When an abnormality is noted, stop the operation immediately, or fire, electric shock or injury may occur.

• To prevent electric shock, use only an insulated screwdriver to adjust the internal switches.

Maintenance and inspection

• To prevent the risk of electric shock, do not touch the terminals while measuring the insulation resistance or

conducting a voltage-resistance test.

Disposal

• When disposing of the motor or driver, treat them as ordinary industrial waste.

5

Page 6

Precautions for use

This section covers limitations and requirements the user should consider when using the AS series.

• Operate the motor at a level below the maximum torqu e.

Operating the motor beyond the maximum torque or placing a continuous constraint on the output shaft may damage

the motor bearings (ball bearings). Be sure to keep the motor load below the maximum torque.

• Do not apply an overhung load in excess of the specified permissible limit.

Be sure to operate the motor within the specified permissible limit of overhung load. Operating it under an excessive

overhung load may damage the motor bearings (ball bearings).

• Operate the motor with a surface temperature not exceeding 100°C (212°F).

The driver has an overheat-protection function, but the motor has no such feature. The motor case’s surface

temperature may exceed 100°C (212°F) under certain conditions (ambient temperature, operating speed, duty cycle,

etc.). Keeping the surface temperature of the motor casing below 100°C (212°F) will also maximize the life of the motor

bearings (ball bearings).

• About maximum static torque at excitation

Maximum static torque at excitation represents a value obtained when the motor is excited using a rated current. When

combined with a dedicated driver and while the motor is stopped motor-temperature increases are suppressed due to

a current-reduction of approximately 50% by the current-cutback function. Acceleration and operation at the maximum

static torque at excitation is possible in start-up, but it has approximately 50% holding power after it has stopped. When

selecting a motor for your application, consider the fact that the holding power will be reduced to approximately 50%

after the motor has stopped.

• Use an electromagnetic-brake type for an application involving up/down travel.

When the motor is used in an application involving up/down travel, such as a lifter, use an electromagnetic-brake type

to hold the load in position. To hold the load in position, apply the electromagnetic brake only after the motor has

stopped.

Do not use the brake to bring the moving motor to a halt. Repeated braking for such a purpose will wear the brake hub

excessively, causing its holding ability to drop.

Since the electromagnetic brake is of the non-excitation type, it can also be used to hold the load in position upon the

occurrence of a power failure. However, this is not a secure means of holding the load.

Do not use the electromagnetic brake as a safety brake.

When the driver-protection function is triggered, the motor stops as the current is turned off. The user must set a

controller sequence that will cut off the power to the electromagnetic brake and hold the load in position upon detecting

an “OFF” ALARM output.

• Connecting an electromagnetic-brake type

Be sure to use a junction cable (sold separately) for connection of an electromagnetic-brake type and driver. Direct

connection of the motor cable to the driver will not provide the electromagnetic brake function.

The electromagnetic brake operates via the ON/OFF status of the DC power supply. When connecting the lead wires

of the electromagnetic brake extending from the junction cable, observe the correct polarity. Be sure to connect the

supplied varistor (non-polarized) to protect the switch contacts and prevent noise.

• Install the driver in a vertical orientation.

The driver’s heat-dissipation function is designed according to vertical orientation. Installing the driver in any other

orientation may shorten the life of electronic parts due to temperature increases within the driver.

• Preventing leakage current

Stray capacitance exists between the driver’s current-carrying line and other current-carrying lines, the earth and the

motor, respectively. A high-frequency current may leak out through such capacitance, having a detrimental effect on the

surrounding equipment. The actual leakage current depends on the driver’s switching frequency, the length of wiring

between the driver and motor, and so on.

When providing a leakage current breaker, use the following products, for instance, which have high-frequency signal

protection:

Mitsubishi Electric: NV series

Fuji Electric: EG and SG series

6

Page 7

• Preventing electrical noise

See “Installing and wiring in compliance with EMC directive” on page 22 for measures with regard to noise.

7

Page 8

Preparation

This section covers the points to be checked along with the names and functions of respective parts.

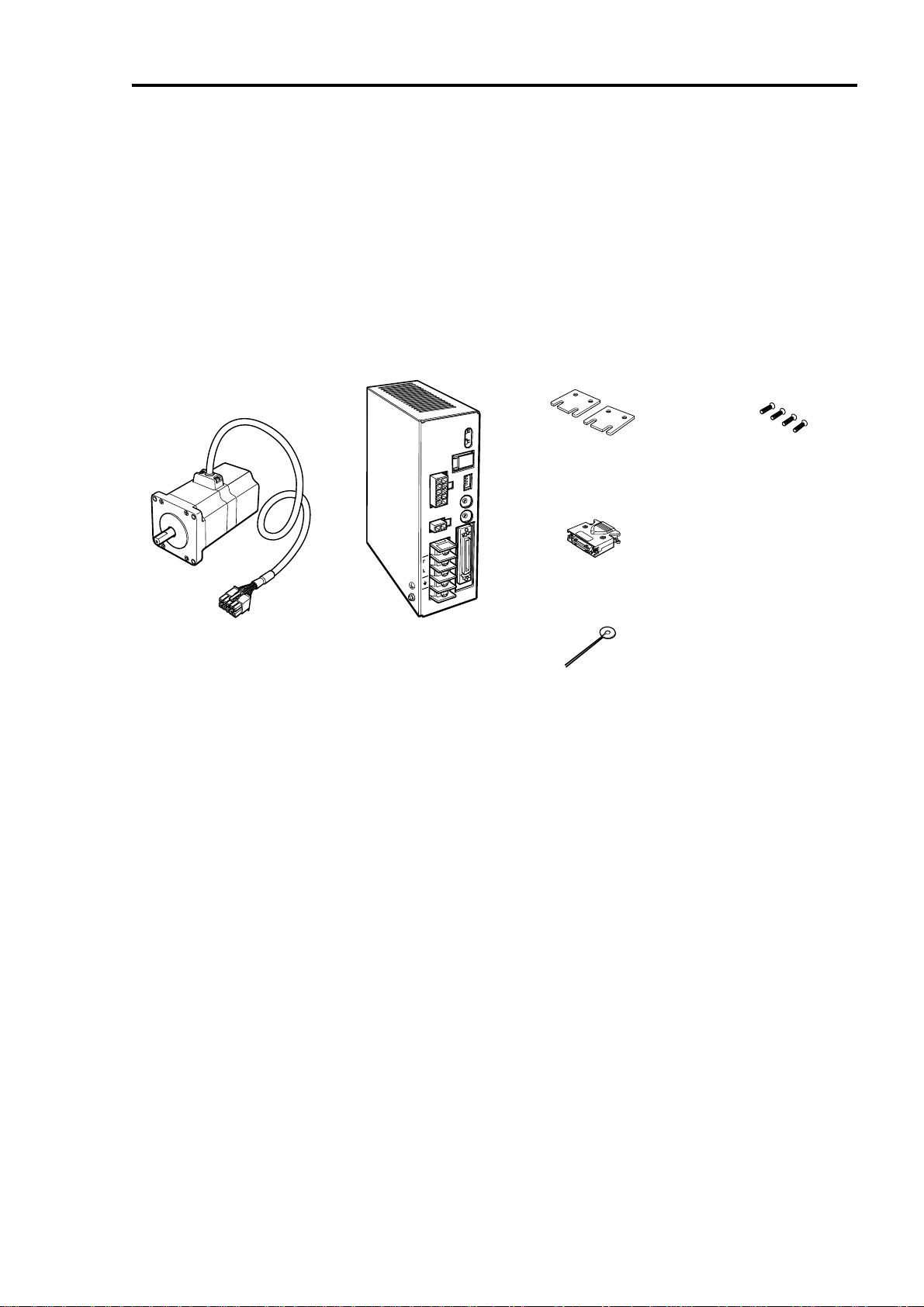

Checking the product

Upon opening the package, verify that the items listed below are included.

Report any missing or damaged items to the branch or sales office from which you purchased the product.

Verify the model number of the purchased unit against the number shown on the package label.

Check the model number of the motor and driver against the number shown on the nameplate.

The unit models and corresponding motor/driver combinations are listed on pages 10 to 13.

ASD24A-A

N

IO

T

A

R

E

P

O

∗

Illustration shows the round

shaft type with

electromagnetic brake.

∗ A parallel key (1 unit) is supplied

with all geared-type motors

(excluding the AS66 TH geared

type).

ALARM

1

N

C

1000

F/H

NORM

1P

C

B

A

9

8

7

CN2

R

C

O

T

B

O

M

A

9

8

7

3

N

C

L

00-

1

~

V

5

11

N

C

I/O

VEXTA

Driver mounting brackets

2 pieces

500

4

3

X10

2

TEST

1

N

O

2P

E

D

F

0

1

2

3

4

5

6

E

D

F

0

1

2

3

4

5

6

Control input/output connector

4

N

1 set

3

‑

A

5

8F

‑

C

5

Driver 1 UnitMotor 1 Unit

Varistor 1 piece

Varistor supplied with the motor with

an electromagnetic-brake type

Screws for driver mounting

brackets (M3) 4 pieces

Operating manual

1 copy

8

Page 9

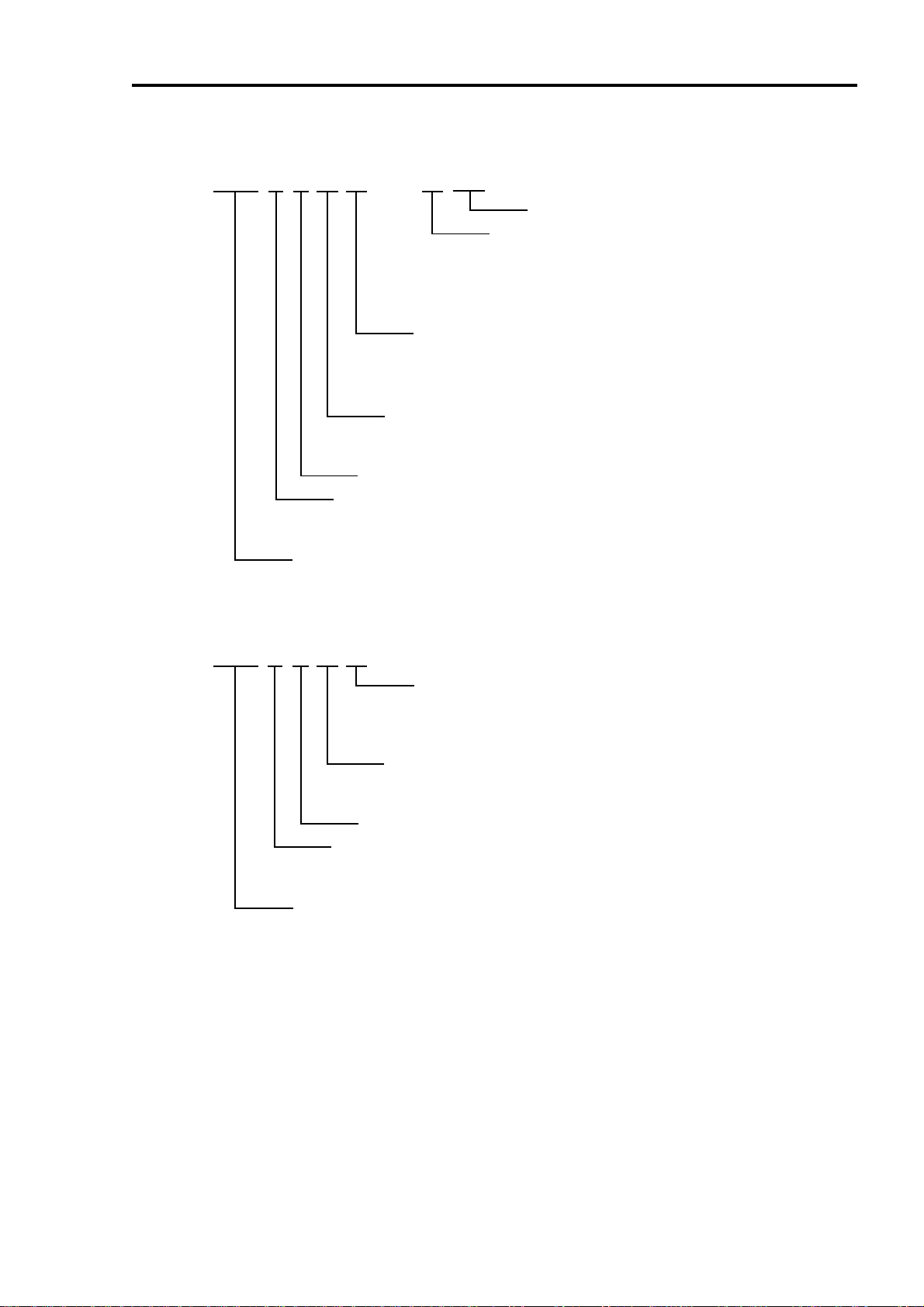

How to identify the product model

Geared type

A S 6 6 A A 2 - H 50

Motor type

A: Standard type

M: With electromagnetic brake

Motor length

Motor size

6: 60 mm (2.36 in.) square

9: 90 mm (3.54 in.) square

Series name AS series

Gear ratio

Gear type

T: TH gear

P: PL gear

N: PN gear

H: Harmonic gear

Power input

A: Single-phase 100-115 V

C: Single-phase 200-230 V

S: Three-phase 200-230 V

Round shaft type

A S 6 6 A A

Power input

A: Single-phase 100-115 V

C: Single-phase 200-230 V

S: Three-phase 200-230 V

Motor type

A: Standard type

M: With electromagnetic brake

Motor length

Motor size

6: 60 mm (2.36 in.) square

9: 85 mm (3.35 in.) square

Series name AS series

Options (sold separately)

• Extension cable Pages 31, 32 and 61

Required for extending the distance between the motor and driver.

Be sure to use the electromagnetic-brake extension cable to connect an electromagnetic-brake-type motor.

• Flexible cable Pages 32 and 61

Highly flexible extension cable.

• Shielded cable with connectors Pages 33 and 61

Cable with connectors for driver control input/output (36 pins), providing excellent noise resistance.

• DIN rail mounting plate Pages 21 and 61

Plate for mounting the driver to a DIN rail.

9

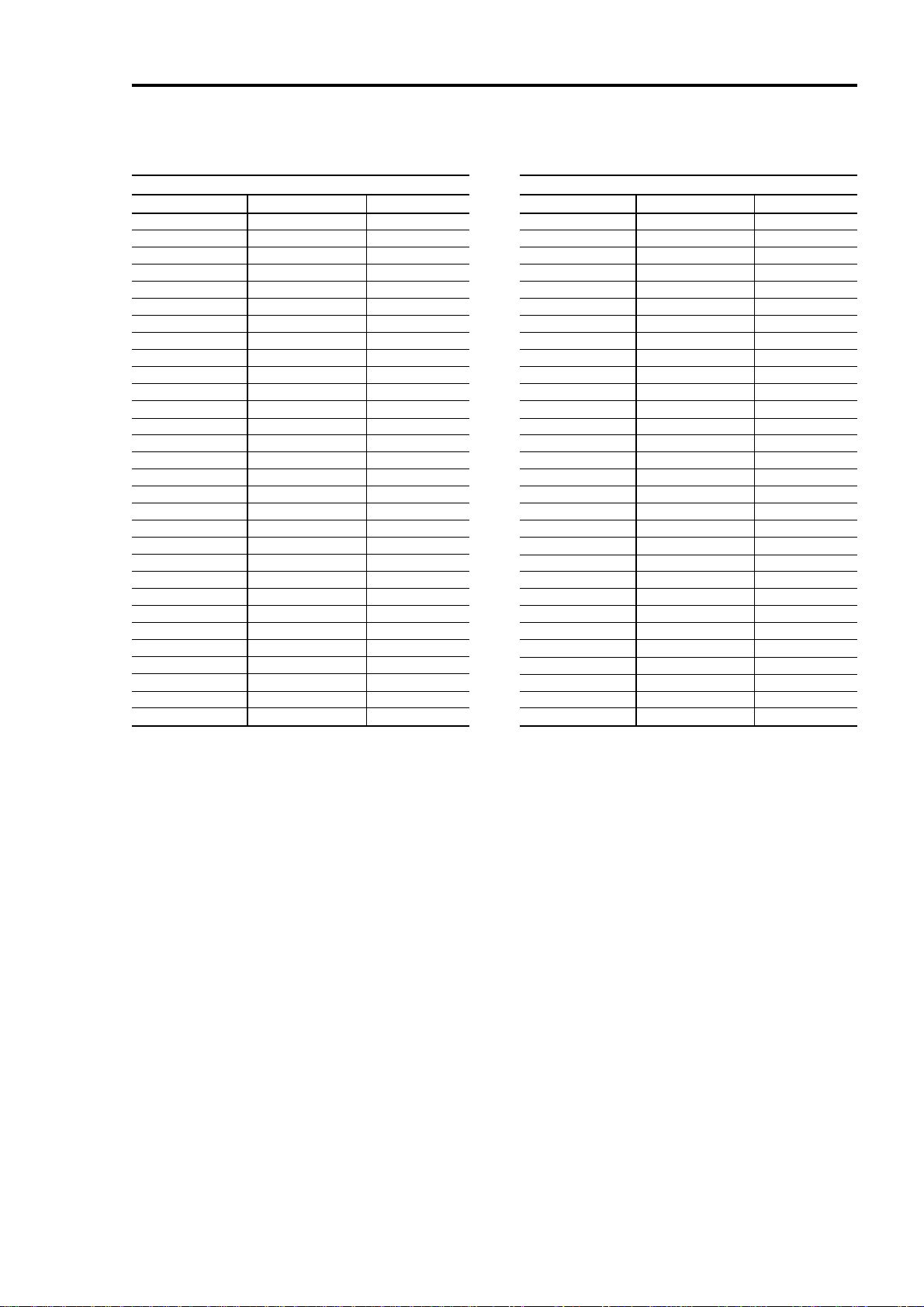

Page 10

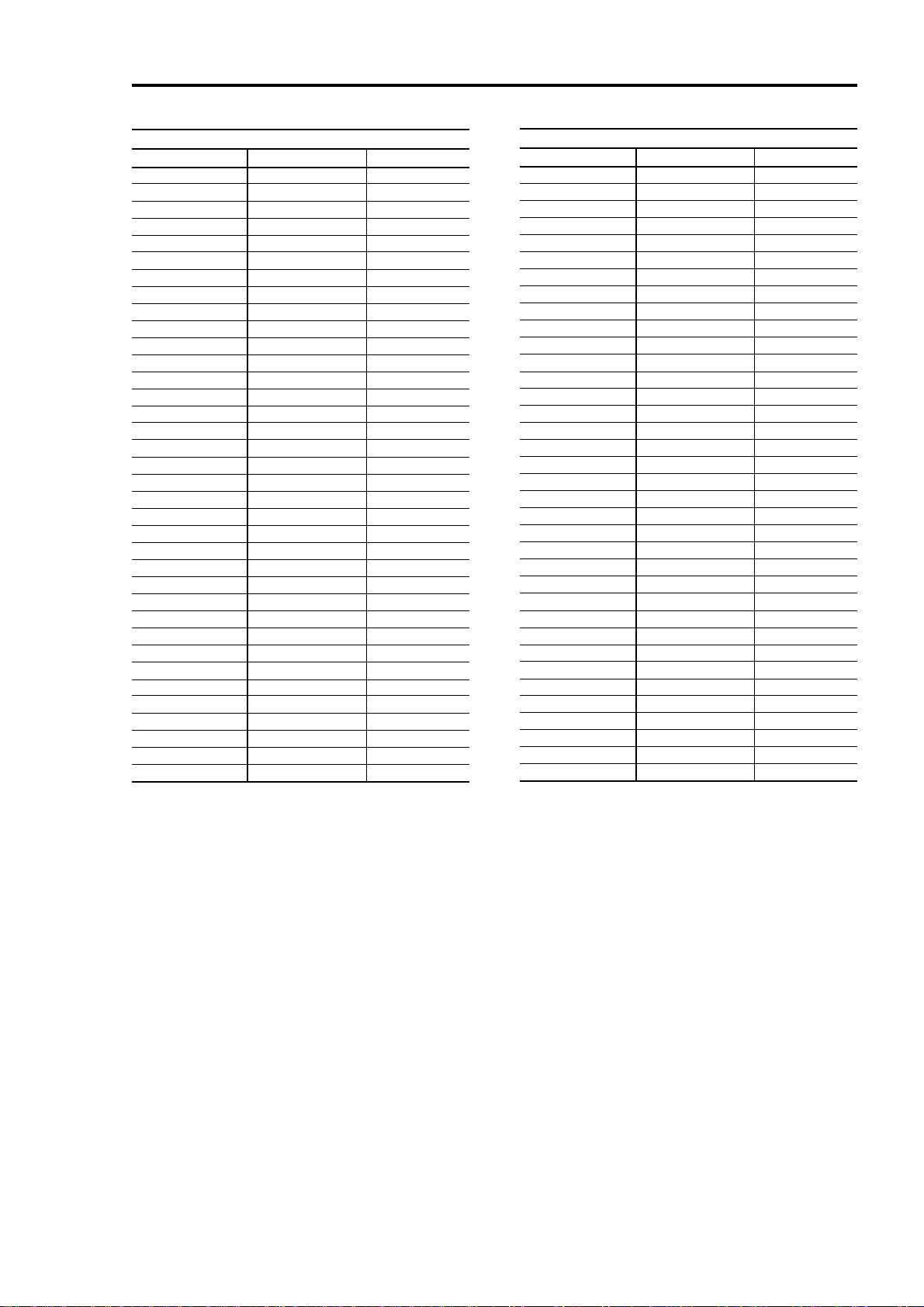

Combinations of motors and drivers

TH geared type

Standard type

Unit model

AS66AA-T3.6

AS66AA-T7.2

AS66AA-T10

AS66AA-T20

AS66AA-T30

AS66AC-T3.6

AS66AC-T7.2

AS66AC-T10

AS66AC-T20

AS66AC-T30

AS66AS-T3.6

AS66AS-T7.2

AS66AS-T10

AS66AS-T20

AS66AS-T30

AS98AA-T3.6

AS98AA-T7.2

AS98AA-T10

AS98AA-T20

AS98AA-T30

AS98AC-T3.6

AS98AC-T7.2

AS98AC-T10

AS98AC-T20

AS98AC-T30

AS98AS-T3.6

AS98AS-T7.2

AS98AS-T10

AS98AS-T20

AS98AS-T30

Motor model

ASM66AA-T3.6

ASM66AA-T7.2

ASM66AA-T10

ASM66AA-T20

ASM66AA-T30

ASM66AC-T3.6

ASM66AC-T7.2

ASM66AC-T10

ASM66AC-T20

ASM66AC-T30

ASM66AC-T3.6

ASM66AC-T7.2

ASM66AC-T10

ASM66AC-T20

ASM66AC-T30

ASM98AA-T3.6

ASM98AA-T7.2

ASM98AA-T10

ASM98AA-T20

ASM98AA-T30

ASM98AC-T3.6

ASM98AC-T7.2

ASM98AC-T10

ASM98AC-T20

ASM98AC-T30

ASM98AC-T3.6

ASM98AC-T7.2

ASM98AC-T10

ASM98AC-T20

ASM98AC-T30

Driver model

ASD24B-A

ASD24B-A

ASD24B-A

ASD24C-A

ASD24C-A

ASD12B-C

ASD12B-C

ASD12B-C

ASD12C-C

ASD12C-C

ASD12B-S

ASD12B-S

ASD12B-S

ASD12C-S

ASD12C-S

ASD30A-A

ASD30A-A

ASD30A-A

ASD30C-A

ASD30C-A

ASD16A-C

ASD16A-C

ASD16A-C

ASD16C-C

ASD16C-C

ASD16A-S

ASD16A-S

ASD16A-S

ASD16C-S

ASD16C-S

Electromagnetic-brake type

Unit model

AS66MA-T3.6

AS66MA-T7.2

AS66MA-T10

AS66MA-T20

AS66MA-T30

AS66MC-T3.6

AS66MC-T7.2

AS66MC-T10

AS66MC-T20

AS66MC-T30

AS66MS-T3.6

AS66MS-T7.2

AS66MS-T10

AS66MS-T20

AS66MS-T30

AS98MA-T3.6

AS98MA-T7.2

AS98MA-T10

AS98MA-T20

AS98MA-T30

AS98MC-T3.6

AS98MC-T7.2

AS98MC-T10

AS98MC-T20

AS98MC-T30

AS98MS-T3.6

AS98MS-T7.2

AS98MS-T10

AS98MS-T20

AS98MS-T30

Motor model

ASM66MA-T3.6

ASM66MA-T7.2

ASM66MA-T10

ASM66MA-T20

ASM66MA-T30

ASM66MC-T3.6

ASM66MC-T7.2

ASM66MC-T10

ASM66MC-T20

ASM66MC-T30

ASM66MC-T3.6

ASM66MC-T7.2

ASM66MC-T10

ASM66MC-T20

ASM66MC-T30

ASM98MA-T3.6

ASM98MA-T7.2

ASM98MA-T10

ASM98MA-T20

ASM98MA-T30

ASM98MC-T3.6

ASM98MC-T7.2

ASM98MC-T10

ASM98MC-T20

ASM98MC-T30

ASM98MC-T3.6

ASM98MC-T7.2

ASM98MC-T10

ASM98MC-T20

ASM98MC-T30

Driver model

ASD24B-A

ASD24B-A

ASD24B-A

ASD24C-A

ASD24C-A

ASD12B-C

ASD12B-C

ASD12B-C

ASD12C-C

ASD12C-C

ASD12B-S

ASD12B-S

ASD12B-S

ASD12C-S

ASD12C-S

ASD30A-A

ASD30A-A

ASD30A-A

ASD30C-A

ASD30C-A

ASD16A-C

ASD16A-C

ASD16A-C

ASD16C-C

ASD16C-C

ASD16A-S

ASD16A-S

ASD16A-S

ASD16C-S

ASD16C-S

10

Page 11

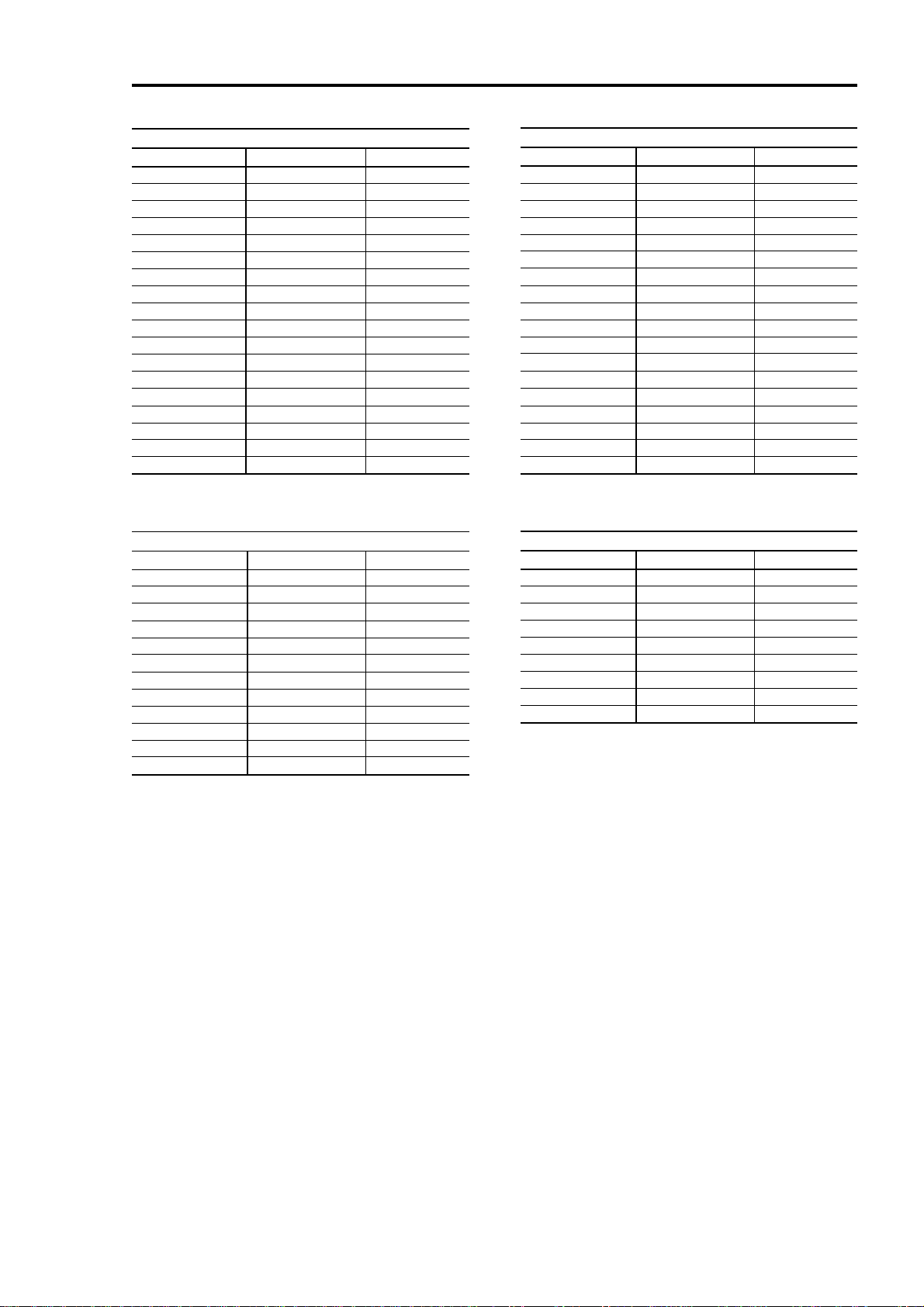

PL geared type

Unit model

AS66AA-P5

AS66AA-P7.2

AS66AA-P10

AS66AA-P25

AS66AA-P36

AS66AA-P50

AS66AC-P5

AS66AC-P7.2

AS66AC-P10

AS66AC-P25

AS66AC-P36

AS66AC-P50

AS66AS-P5

AS66AS-P7.2

AS66AS-P10

AS66AS-P25

AS66AS-P36

AS66AS-P50

AS98AA-P5

AS98AA-P7.2

AS98AA-P10

AS98AA-P25

AS98AA-P36

AS98AA-P50

AS98AC-P5

AS98AC-P7.2

AS98AC-P10

AS98AC-P25

AS98AC-P36

AS98AC-P50

AS98AS-P5

AS98AS-P7.2

AS98AS-P10

AS98AS-P25

AS98AS-P36

AS98AS-P50

Standard type

Motor model

ASM66AA-P5

ASM66AA-P7.2

ASM66AA-P10

ASM66AA-P25

ASM66AA-P36

ASM66AA-P50

ASM66AC-P5

ASM66AC-P7.2

ASM66AC-P10

ASM66AC-P25

ASM66AC-P36

ASM66AC-P50

ASM66AC-P5

ASM66AC-P7.2

ASM66AC-P10

ASM66AC-P25

ASM66AC-P36

ASM66AC-P50

ASM98AA-P5

ASM98AA-P7.2

ASM98AA-P10

ASM98AA-P25

ASM98AA-P36

ASM98AA-P50

ASM98AC-P5

ASM98AC-P7.2

ASM98AC-P10

ASM98AC-P25

ASM98AC-P36

ASM98AC-P50

ASM98AC-P5

ASM98AC-P7.2

ASM98AC-P10

ASM98AC-P25

ASM98AC-P36

ASM98AC-P50

Driver model

ASD24A-A

ASD24A-A

ASD24A-A

ASD24B-A

ASD24C-A

ASD24C-A

ASD12A-C

ASD12A-C

ASD12A-C

ASD12B-C

ASD12C-C

ASD12C-C

ASD12A-S

ASD12A-S

ASD12A-S

ASD12B-S

ASD12C-S

ASD12C-S

ASD30A-A

ASD30A-A

ASD30A-A

ASD30A-A

ASD30B-A

ASD30B-A

ASD16A-C

ASD16A-C

ASD16A-C

ASD16A-C

ASD16B-C

ASD16B-C

ASD16A-S

ASD16A-S

ASD16A-S

ASD16A-S

ASD16B-S

ASD16B-S

Electromagnetic-brake type

Unit model

AS66MA-P5

AS66MA-P7.2

AS66MA-P10

AS66MA-P25

AS66MA-P36

AS66MA-P50

AS66MC-P5

AS66MC-P7.2

AS66MC-P10

AS66MC-P25

AS66MC-P36

AS66MC-P50

AS66MS-P5

AS66MS-P7.2

AS66MS-P10

AS66MS-P25

AS66MS-P36

AS66MS-P50

AS98MA-P5

AS98MA-P7.2

AS98MA-P10

AS98MA-P25

AS98MA-P36

AS98MA-P50

AS98MC-P5

AS98MC-P7.2

AS98MC-P10

AS98MC-P25

AS98MC-P36

AS98MC-P50

AS98MS-P5

AS98MS-P7.2

AS98MS-P10

AS98MS-P25

AS98MS-P36

AS98MS-P50

Motor model

ASM66MA-P5

ASM66MA-P7.2

ASM66MA-P10

ASM66MA-P25

ASM66MA-P36

ASM66MA-P50

ASM66MC-P5

ASM66MC-P7.2

ASM66MC-P10

ASM66MC-P25

ASM66MC-P36

ASM66MC-P50

ASM66MC-P5

ASM66MC-P7.2

ASM66MC-P10

ASM66MC-P25

ASM66MC-P36

ASM66MC-P50

ASM98MA-P5

ASM98MA-P7.2

ASM98MA-P10

ASM98MA-P25

ASM98MA-P36

ASM98MA-P50

ASM98MC-P5

ASM98MC-P7.2

ASM98MC-P10

ASM98MC-P25

ASM98MC-P36

ASM98MC-P50

ASM98MC-P5

ASM98MC-P7.2

ASM98MC-P10

ASM98MC-P25

ASM98MC-P36

ASM98MC-P50

Driver model

ASD24A-A

ASD24A-A

ASD24A-A

ASD24B-A

ASD24C-A

ASD24C-A

ASD12A-C

ASD12A-C

ASD12A-C

ASD12B-C

ASD12C-C

ASD12C-C

ASD12A-S

ASD12A-S

ASD12A-S

ASD12B-S

ASD12C-S

ASD12C-S

ASD30A-A

ASD30A-A

ASD30A-A

ASD30A-A

ASD30B-A

ASD30B-A

ASD16A-C

ASD16A-C

ASD16A-C

ASD16A-C

ASD16B-C

ASD16B-C

ASD16A-S

ASD16A-S

ASD16A-S

ASD16A-S

ASD16B-S

ASD16B-S

11

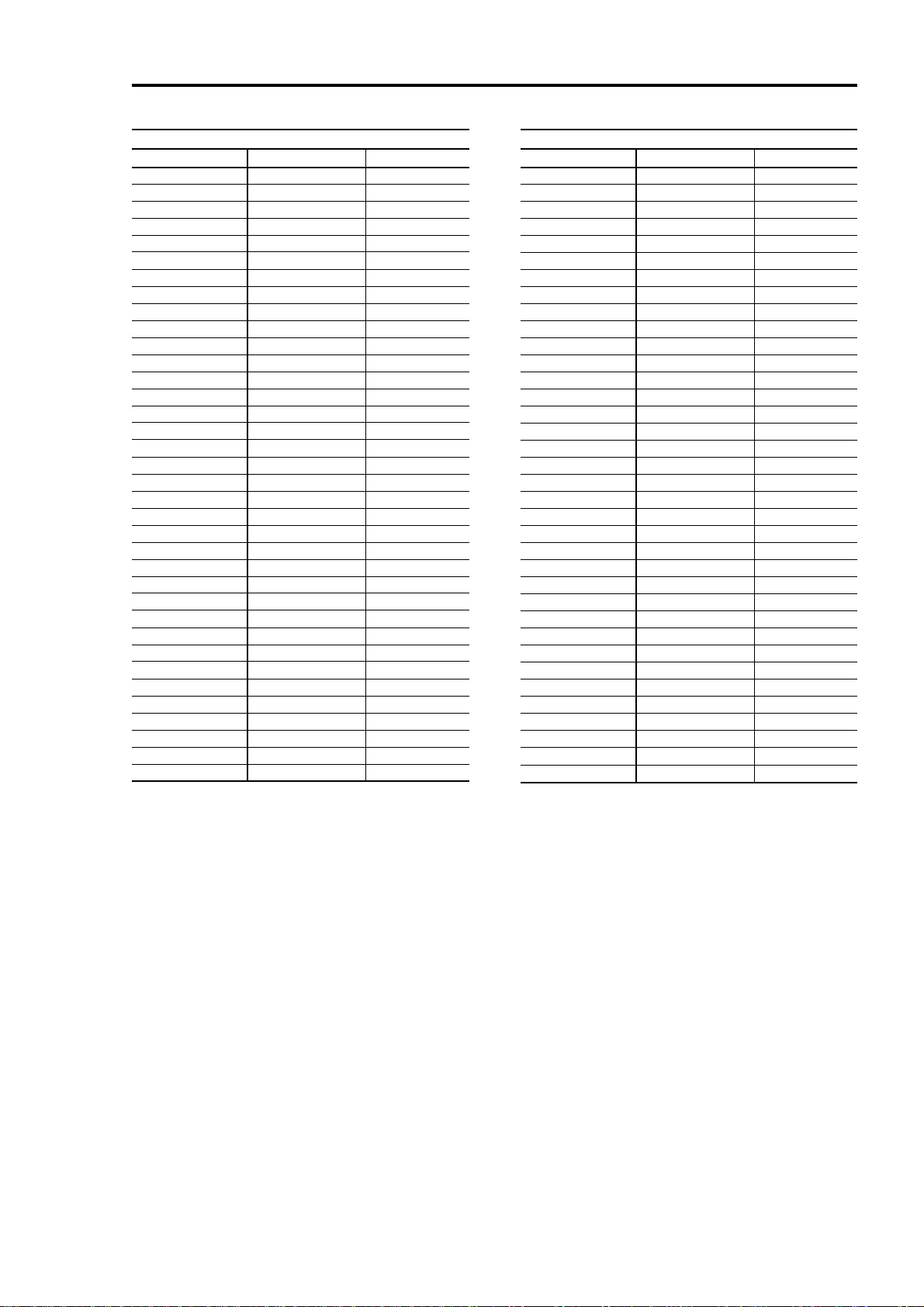

Page 12

PN geared type

Unit model

AS66AA-N5

AS66AA-N7.2

AS66AA-N10

AS66AA-N25

AS66AA-N36

AS66AA-N50

AS66AC-N5

AS66AC-N7.2

AS66AC-N10

AS66AC-N25

AS66AC-N36

AS66AC-N50

AS66AS-N5

AS66AS-N7.2

AS66AS-N10

AS66AS-N25

AS66AS-N36

AS66AS-N50

AS98AA-N5

AS98AA-N7.2

AS98AA-N10

AS98AA-N25

AS98AA-N36

AS98AA-N50

AS98AC-N5

AS98AC-N7.2

AS98AC-N10

AS98AC-N25

AS98AC-N36

AS98AC-N50

AS98AS-N5

AS98AS-N7.2

AS98AS-N10

AS98AS-N25

AS98AS-N36

AS98AS-N50

Standard type

Motor model

ASM66AA-N5

ASM66AA-N7.2

ASM66AA-N10

ASM66AA-N25

ASM66AA-N36

ASM66AA-N50

ASM66AC-N5

ASM66AC-N7.2

ASM66AC-N10

ASM66AC-N25

ASM66AC-N36

ASM66AC-N50

ASM66AC-N5

ASM66AC-N7.2

ASM66AC-N10

ASM66AC-N25

ASM66AC-N36

ASM66AC-N50

ASM98AA-N5

ASM98AA-N7.2

ASM98AA-N10

ASM98AA-N25

ASM98AA-N36

ASM98AA-N50

ASM98AC-N5

ASM98AC-N7.2

ASM98AC-N10

ASM98AC-N25

ASM98AC-N36

ASM98AC-N50

ASM98AC-N5

ASM98AC-N7.2

ASM98AC-N10

ASM98AC-N25

ASM98AC-N36

ASM98AC-N50

Driver model

ASD24A-A

ASD24A-A

ASD24A-A

ASD24B-A

ASD24C-A

ASD24C-A

ASD12A-C

ASD12A-C

ASD12A-C

ASD12B-C

ASD12C-C

ASD12C-C

ASD12A-S

ASD12A-S

ASD12A-S

ASD12B-S

ASD12C-S

ASD12C-S

ASD30A-A

ASD30A-A

ASD30A-A

ASD30A-A

ASD30B-A

ASD30B-A

ASD16A-C

ASD16A-C

ASD16A-C

ASD16A-C

ASD16B-C

ASD16B-C

ASD16A-S

ASD16A-S

ASD16A-S

ASD16A-S

ASD16B-S

ASD16B-S

Electromagnetic-brake type

Unit model

AS66MA-N5

AS66MA-N7.2

AS66MA-N10

AS66MA-N25

AS66MA-N36

AS66MA-N50

AS66MC-N5

AS66MC-N7.2

AS66MC-N10

AS66MC-N25

AS66MC-N36

AS66MC-N50

AS66MS-N5

AS66MS-N7.2

AS66MS-N10

AS66MS-N25

AS66MS-N36

AS66MS-N50

AS98MA-N5

AS98MA-N7.2

AS98MA-N10

AS98MA-N25

AS98MA-N36

AS98MA-N50

AS98MC-N5

AS98MC-N7.2

AS98MC-N10

AS98MC-N25

AS98MC-N36

AS98MC-N50

AS98MS-N5

AS98MS-N7.2

AS98MS-N10

AS98MS-N25

AS98MS-N36

AS98MS-N50

Motor model

ASM66MA-N5

ASM66MA-N7.2

ASM66MA-N10

ASM66MA-N25

ASM66MA-N36

ASM66MA-N50

ASM66MC-N5

ASM66MC-N7.2

ASM66MC-N10

ASM66MC-N25

ASM66MC-N36

ASM66MC-N50

ASM66MC-N5

ASM66MC-N7.2

ASM66MC-N10

ASM66MC-N25

ASM66MC-N36

ASM66MC-N50

ASM98MA-N5

ASM98MA-N7.2

ASM98MA-N10

ASM98MA-N25

ASM98MA-N36

ASM98MA-N50

ASM98MC-N5

ASM98MC-N7.2

ASM98MC-N10

ASM98MC-N25

ASM98MC-N36

ASM98MC-N50

ASM98MC-N5

ASM98MC-N7.2

ASM98MC-N10

ASM98MC-N25

ASM98MC-N36

ASM98MC-N50

Driver model

ASD24A-A

ASD24A-A

ASD24A-A

ASD24B-A

ASD24C-A

ASD24C-A

ASD12A-C

ASD12A-C

ASD12A-C

ASD12B-C

ASD12C-C

ASD12C-C

ASD12A-S

ASD12A-S

ASD12A-S

ASD12B-S

ASD12C-S

ASD12C-S

ASD30A-A

ASD30A-A

ASD30A-A

ASD30A-A

ASD30B-A

ASD30B-A

ASD16A-C

ASD16A-C

ASD16A-C

ASD16A-C

ASD16B-C

ASD16B-C

ASD16A-S

ASD16A-S

ASD16A-S

ASD16A-S

ASD16B-S

ASD16B-S

12

Page 13

Harmonic geared type

Standard type

Unit model

AS66AA2-H50

AS66AA2-H100

AS66AC2-H50

AS66AC2-H100

AS66AS2-H50

AS66AS2-H100

AS66AA-H50

AS66AA-H100

AS66AC-H50

AS66AC-H100

AS66AS-H50

AS66AS-H100

AS98AA-H50

AS98AA-H100

AS98AC-H50

AS98AC-H100

AS98AS-H50

AS98AS-H100

Motor model

ASM66AA2-H50

ASM66AA2-H100

ASM66AC2-H50

ASM66AC2-H100

ASM66AC2-H50

ASM66AC2-H100

ASM66AA-H50

ASM66AA-H100

ASM66AC-H50

ASM66AC-H100

ASM66AC-H50

ASM66AC-H100

ASM98AA-H50

ASM98AA-H100

ASM98AC-H50

ASM98AC-H100

ASM98AC-H50

ASM98AC-H100

Round shaft type

Standard type

Unit model

AS66AA

AS69AA

AS66AC

AS69AC

AS66AS

AS69AS

AS98AA

AS911AA

AS98AC

AS911AC

AS98AS

AS911AS

Motor model

ASM66AA

ASM69AA

ASM66AC

ASM69AC

ASM66AC

ASM69AC

ASM98AA

ASM911AA

ASM98AC

ASM911AC

ASM98AC

ASM911AC

Driver model

ASD24B-A

ASD24C-A

ASD12B-C

ASD12C-C

ASD12B-S

ASD12C-S

ASD24C-A

ASD24C-A

ASD12C-C

ASD12C-C

ASD12C-S

ASD12C-S

ASD30B-A

ASD30B-A

ASD16B-C

ASD16B-C

ASD16B-S

ASD16B-S

Driver model

ASD24A-A

ASD30D-A

ASD12A-C

ASD16D-C

ASD12A-S

ASD16D-S

ASD30A-A

ASD30E-A

ASD16A-C

ASD20A-C

ASD16A-S

ASD20A-S

Electromagnetic-brake type

Unit model

AS66MA2-H50

AS66MA2-H100

AS66MC2-H50

AS66MC2-H100

AS66MS2-H50

AS66MS2-H100

AS66MA-H50

AS66MA-H100

AS66MC-H50

AS66MC-H100

AS66MS-H50

AS66MS-H100

AS98MA-H50

AS98MA-H100

AS98MC-H50

AS98MC-H100

AS98MS-H50

AS98MS-H100

Electromagnetic-brake type

Unit model

AS66MA

AS69MA

AS66MC

AS69MC

AS66MS

AS69MS

AS98MA

AS98MC

AS98MS

Motor model

ASM66MA2-H50

ASM66MA2-H100

ASM66MC2-H50

ASM66MC2-H100

ASM66MC2-H50

ASM66MC2-H100

ASM66MA-H50

ASM66MA-H100

ASM66MC-H50

ASM66MC-H100

ASM66MC-H50

ASM66MC-H100

ASM98MA-H50

ASM98MA-H100

ASM98MC-H50

ASM98MC-H100

ASM98MC-H50

ASM98MC-H100

Motor model

ASM66MA

ASM69MA

ASM66MC

ASM69MC

ASM66MC

ASM69MC

ASM98MA

ASM98MC

ASM98MC

Driver model

ASD24B-A

ASD24C-A

ASD12B-C

ASD12C-C

ASD12B-S

ASD12C-S

ASD24C-A

ASD24C-A

ASD12C-C

ASD12C-C

ASD12C-S

ASD12C-S

ASD30B-A

ASD30B-A

ASD16B-C

ASD16B-C

ASD16B-S

ASD16B-S

Driver model

ASD24A-A

ASD30D-A

ASD12A-C

ASD16D-C

ASD12A-S

ASD16D-S

ASD30A-A

ASD16A-C

ASD16A-S

13

Page 14

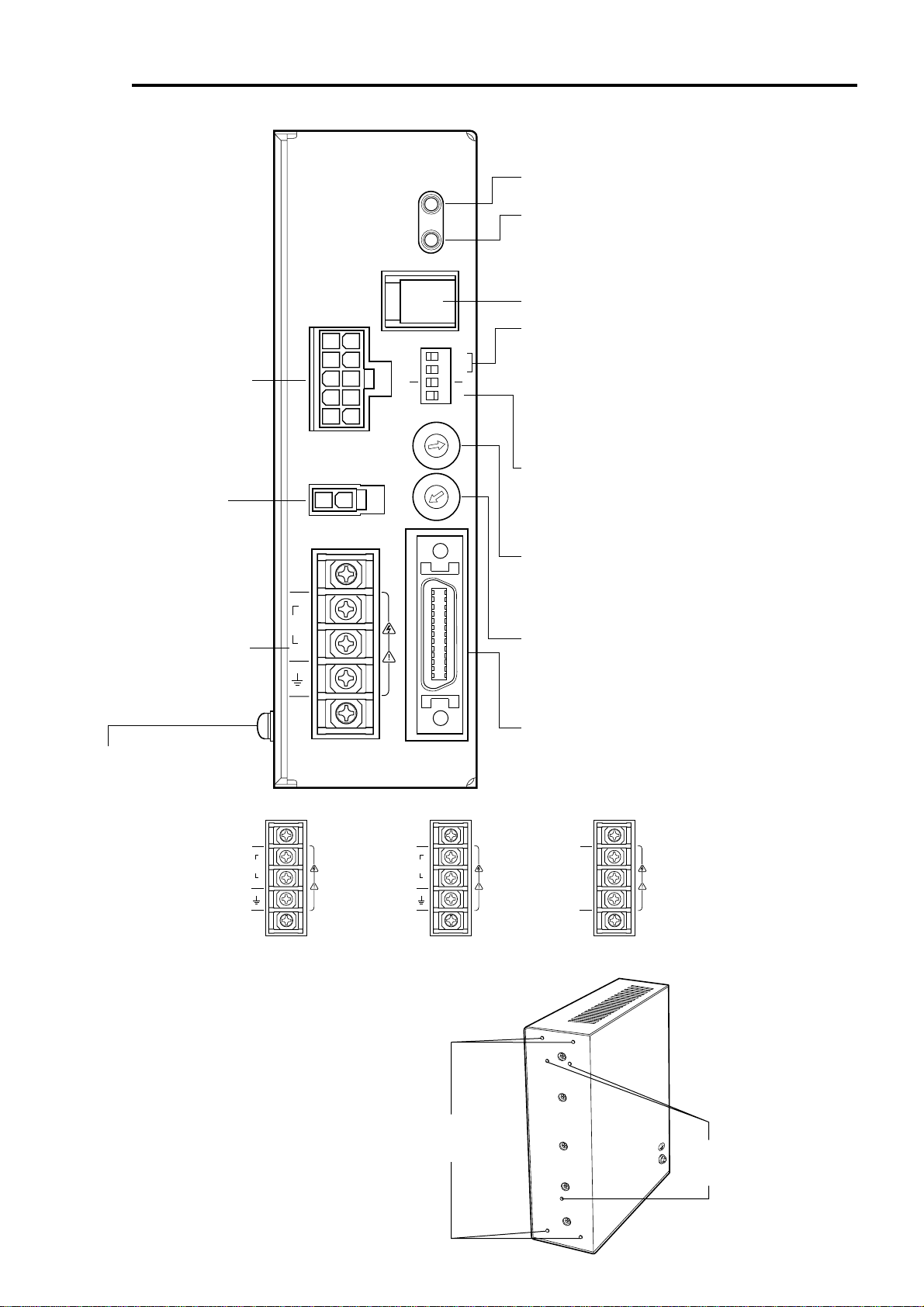

Names and functions of parts

This section covers the names and functions of parts in the motor and driver.

For further details on each part, refer to the page shown in the square bracket.

Motor

Mounting holes (four locations) [P.16]

Electromagnetic brake [motor with an electromagnetic brake] [P.32,41]

Non-excitation operation electromagnetic brake (24 VDC input)

Varistor

3

‑

A

5

8F

‑

C

5

Pilot

Motor cable [P.31,32]

Output shaft

An accessory supplied with the motor with an electromagnetic brake.

Be sure to connect the varistor when wiring the electromagnetic brake.

14

Page 15

Driver

Motor connector (CN2)

[P.31,32]

Connect the motor cable's

connector.

Regeneration unit

connector (CN3)

Power supply terminal

[P.28,29,30]

Connect the power-supply

cable.

Front side of driver

ASD24A-A

OPERATION

CN1

CN2

MOTOR

CN3

L

100115V

~

N

ALARM

1000

CURRENT

V.FIL

OPERATION (green)

Lit when the power is on.

ALARM (Red) [P.46]

This alarm blinks when a protective function is triggered and

the ALARM output turns "OFF."

Count the number of blinks to ascertain the cause of triggering

of the protective function.

Not used (CN1)

Resolution selection switches [P.43]

500

X1

X10

2P

1 2 3 4

1P

Use these two switches to select the motor resolution.

1000/500: Switches motor resolution between 1000 P/R

"0.36˚/pulse" or 500 P/R "0.72˚ //pulse."

×1/ ×10: Switches motor resolution between multipliers 1 and

10 of the value set by the 1000/500 switch.

The factory setting is "1000: 1000 P/R" and "×1: Multiplier 1."

C

D

B

E

A

F

9

8

0

7

1

6

2

5

3

4

C

D

B

E

A

F

9

8

0

7

1

6

2

5

3

4

Be sure to switch to "×1" when the resolution switching input

"CN4 Pin No. 31, 32: ×10" is used.

Pulse-input mode selection switch [P.44]

Allows for the selection of 2-pulse input mode or 1-pulse input

mode in accordance with the pulse-output mode in the

positioning controller.

The factory setting is "2P: 2-Pulse Input Mode."

Current setting switch [P.44]

Sets the motor's operating current.

If there is extra torque, the current may be set to a lower level

in order to suppress increases in motor temperature.

The factory setting is "F: Driver's maximum output-current value."

Speed-filter selection switch [P.45]

Sets the time constant for the filter that determines motor response.

A longer time constant will smooth out the motor's rotation but

render the setting time longer at motor standstill.

The factory setting is "6: 1.20 ms."

Protective earth terminal [P.33]

Used for grounding via a

grounding cable of AWG18

(0.75 mm

2

) or more.

•

Driver power-supply terminal

Single-phase 100-115 V

Control input/output connectors (CN4) [P.25,26,27,33,34,35]

CN4

I

O

/

Used to connect to the motor-positioning control and others.

VEXTA

L

100115V

~

N

Mounting holes for the driver

mounting brackets

(M3, four locations) [P.19]

L

200230V

~

N

•

Driver power-supply terminal

Single-phase 200-230 V

Rear side of driver

L1

L2

L3

•

Driver power-supply terminal

Three-phase 200-230 V

Mounting holes for the DIN rail

mounting plate

(M3, three locations) [P.21]

15

Page 16

Installation

This section covers the environment and method of installing the motor and driver, along with

load installation.

Also covered in this section are the installation and wiring methods that are in compliance with

the relevant EMC directives (89/336/EEC, 92/31/EEC).

Location for installation

The motor and driver are designed and manufactured for installation in equipment.

Install them in a well-ventilated location that provides easy access for inspection. The location

must also satisfy the following conditions:

• Inside an enclosure that is installed indoors (provide vent holes)

• Operating ambient temperature Motor: 0°C to +50°C (+32°F to +122°F) (non-freezing)

Harmonic geared type: 0°C to +40°C (+32°F to +104°F)

(non-freezing)

Driver: 0°C to +50°C (+32°F to +122°F) (non-freezing)

• Operating ambient humidity 85%, maximum (no condensation)

• Area that is free from an explosive nature or toxic gas (such as sulfuric gas) or liquid

• Area not exposed to direct sun

• Area free of excessive amount dust, iron particles or the like

• Area not subject to splashing water (storms, water droplets), oil (oil droplets) or other liquids

• Area free of excessive salt

• Area not subject to continuous vibration or excessive shocks

• Area free of excessive electromagnetic noise (from welders, power machinery, etc.)

• Area free of radioactive materials, magnetic fields or vacuum

• 1000 m or lower above sea level

Note

Insert the pilot located on the

motor’s installation surface into

the mounting plate’s countersunk

or through hole.

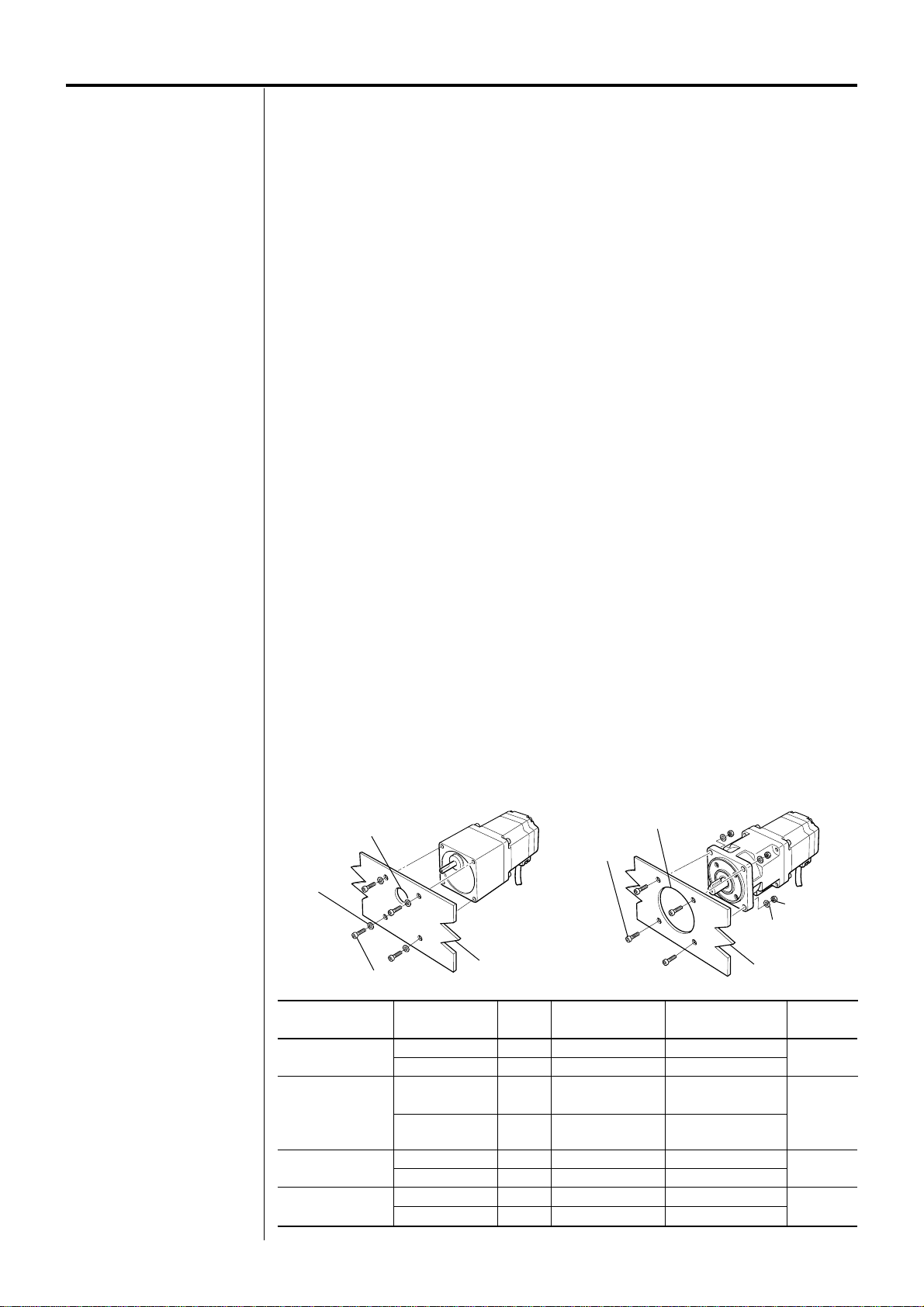

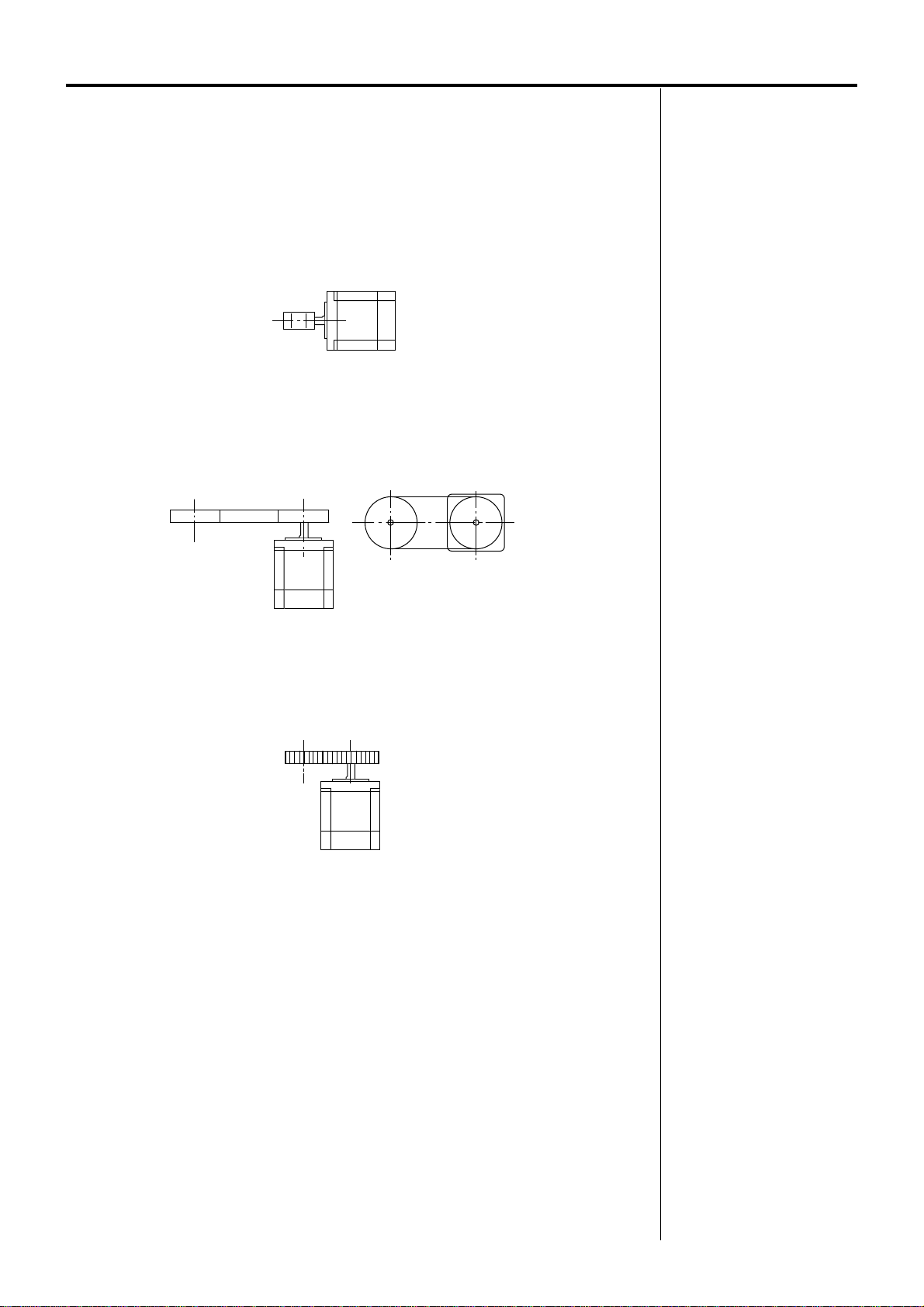

Installing the motor

How to install the motor

Install the motor onto an appropriate flat metal plate having excellent vibration resistance and

heat conductivity.

When installing the motor, secure it with four bolts (not supplied) through the four mounting

holes provided. Leave no gap between the motor and plate.

• Types of installation

A B

Spot facing or through hole for pilot

Spring washer

Hexagonal socket screw

Motor type

TH geared

PL geared

PN geared

Harmonic geared

AS66A2, AS66M2

Harmonic geared

AS66A, AS98A

Round shaft

Frame size

60 mm (2.36 in.)

90 mm (3.54 in.)

60 mm (2.36 in.)

90 mm (3.54 in.)

60 mm (2.36 in.)

90 mm (3.54 in.)

60 mm (2.36 in.)

85 mm (3.35 in.)

Mounting plate

Bolt size

M4

M8

M5

M8

M5

M8

M4

M6

Spot facing or through hole for pilot

Hexagonal socket

screw

Tightening torque

2 N·m (277 oz-in)

4 N·m (554 oz-in)

2.5 N·m (346 oz-in)

4 N·m (554 oz-in)

2.5 N·m (346 oz-in)

4 N·m (554 oz-in)

2 N·m (277 oz-in)

3 N·m (415 oz-in)

Effective depth of bolt

8 mm (0.315 in.)

15 mm (0.591 in.)

10 mm (0.394 in.)

15 mm (0.591 in.)

-

-

-

-

Hexagonal nut

Spring washer

Mounting plate

Types of

installation

A

A

B

B

16

Page 17

Installing a load

When connecting a load to the motor, align the centers of the motor’s output shaft and load

shaft.

Optional flexible couplings are available (sold separately).

Direct coupling

Align the centers of the motor’s output shaft and load shaft in a straight line.

Using a belt drive

Align the motor’s output shaft and load shaft in parallel with each other, and position both

pulleys so that the line connecting their centers is at a right angle to the shafts.

Note

• When coupling the load to the

motor, pay attention to the

centering of the shafts, belt

tension, parallelism of the

pulleys, and so on.

Securely tighten the coupling

and pulley set screws.

• Be careful not to damage the

output shaft or the bearings

when installing a coupling or

pulley to the motor’s output

shaft.

• Do not modify or machine the

motor’s output shaft. Doing so

may damage the bearings and

destroy the motor.

Using a gear drive

Align the motor’s output shaft and gear shaft in parallel with each other, and let the gears mesh

at the center of the tooth widths.

Using a geared motor

With a geared motor, to connect a load to the gear output shaft having a key groove, first

provide a key groove on the load and fix the load with the gear output shaft using the supplied

key.

17

Page 18

Note

Failure due to fatigue may occur

if the motor’s bearings and

output shaft are subject to

repeated loading by an overhung

or thrust load that is in excess of

the permissible limit.

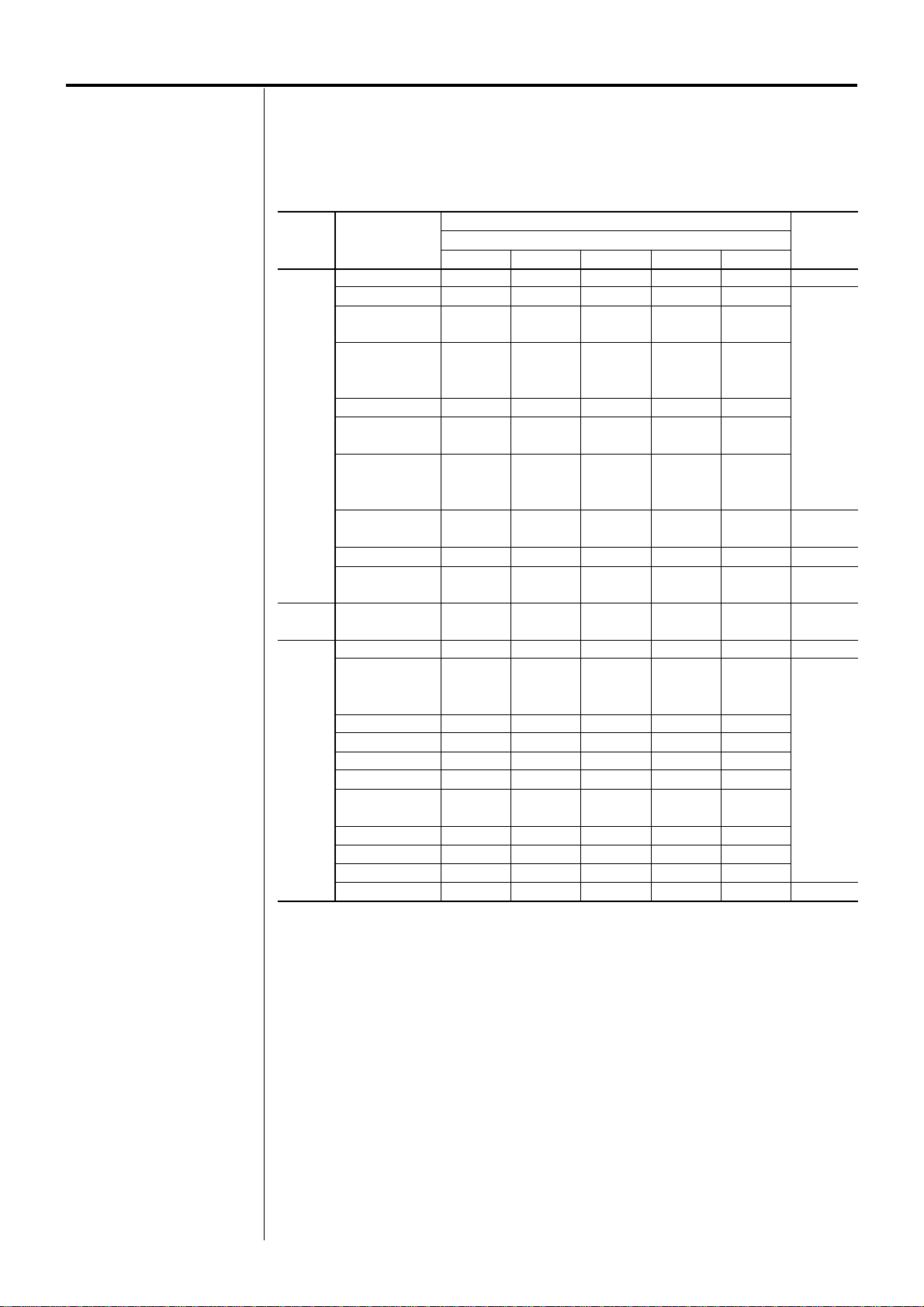

Overhung load and thrust load

The overhung load on the motor’s output shaft or gear output shaft must be kept within the

permissible values listed below.

The thrust load must not exceed the motor’s mass.

Frame

size

60 mm

(2.36 in.)

85 mm

(3.35 in.)

90 mm

(3.54 in.)

• The square box in the unit type will contain a value representing the gear ratio.

∗Calculate half the motor’s mass for this value.

Unit type

AS66-T

AS66-P5

AS66-P7.2

AS66-P10

AS66-P25

AS66-P36

AS66-P50

AS66-N5

AS66-N7.2

AS66-N10

AS66-N25

AS66-N36

AS66-N50

AS66A2-H

AS66M2-H

AS66-H

AS66

AS69

AS98

AS911

AS98-T

AS98-P5

AS98-P7.2

AS98-P10

AS98-P25

AS98-P36

AS98-P50

AS98-N5

AS98-N7.2

AS98-N10

AS98-N25

AS98-N36

AS98-N50

AS98-H

Distance from the tip of motor’s output shaft [mm (inch)]

0 (0)

70 (15.7)

200 (45)

250 (56)

330 (74)

200 (45)

250 (56)

330 (74)

320 (72)

300 (67)

63 (14.1)

260 (58)

220 (49)

480 (108)

850 (191)

930 (200)

1050 (230)

480 (108)

480 (108)

850 (191)

930 (200)

1050 (230)

1090 (240)

Overhung load [N (lb.)]

5 (0.2)

80 (18)

220 (49)

270 (60)

360 (81)

220 (49)

270 (60)

360 (81)

370 (83)

330 (74)

75 (16.8)

290 (65)

250 (56)

540 (121)

940 (210)

1030 (230)

1160 (260)

520 (117)

540 (121)

940 (210)

1030 (230)

1160 (260)

1150 (250)

10 (0.39)

100 (22)

250 (56)

300 (67)

400 (90)

250 (56)

300 (67)

400 (90)

440 (99)

370 (83)

95 (21)

340 (76)

300 (67)

600 (135)

1050 (230)

1150 (250)

1300 (290)

550 (123)

600 (135)

1050 (230)

1150 (250)

1300 (290)

1230 (270)

15 (0.59)

120 (27)

280 (63)

340 (76)

450 (101)

280 (63)

340 (76)

450 (101)

550 (123)

420 (94)

130 (29)

390 (87)

350 (78)

680 (153)

1 190 (260)

1310 (290)

1480 (330)

580 (130)

680 (153)

1110 (240)

1220 (270)

1380 (310)

1310 (290)

20 (0.79)

150 (33)

320 (72)

390 (87)

520 (117)

320 (72)

390 (87)

520 (117)

720 (162)

480 (108)

190 (42)

480 (108)

400 (90)

790 (177)

1380 (310)

1520 (340)

1710 (380)

620 (139)

790 (177)

1190 (260)

1300 (290)

1490 (330)

1410 (310)

Thrust

load

[N (lb.)]

40 (9)

100 (22)

470 (105)

400 (90)

∗

∗

100 (22)

300 (67)

1300 (290)

18

Page 19

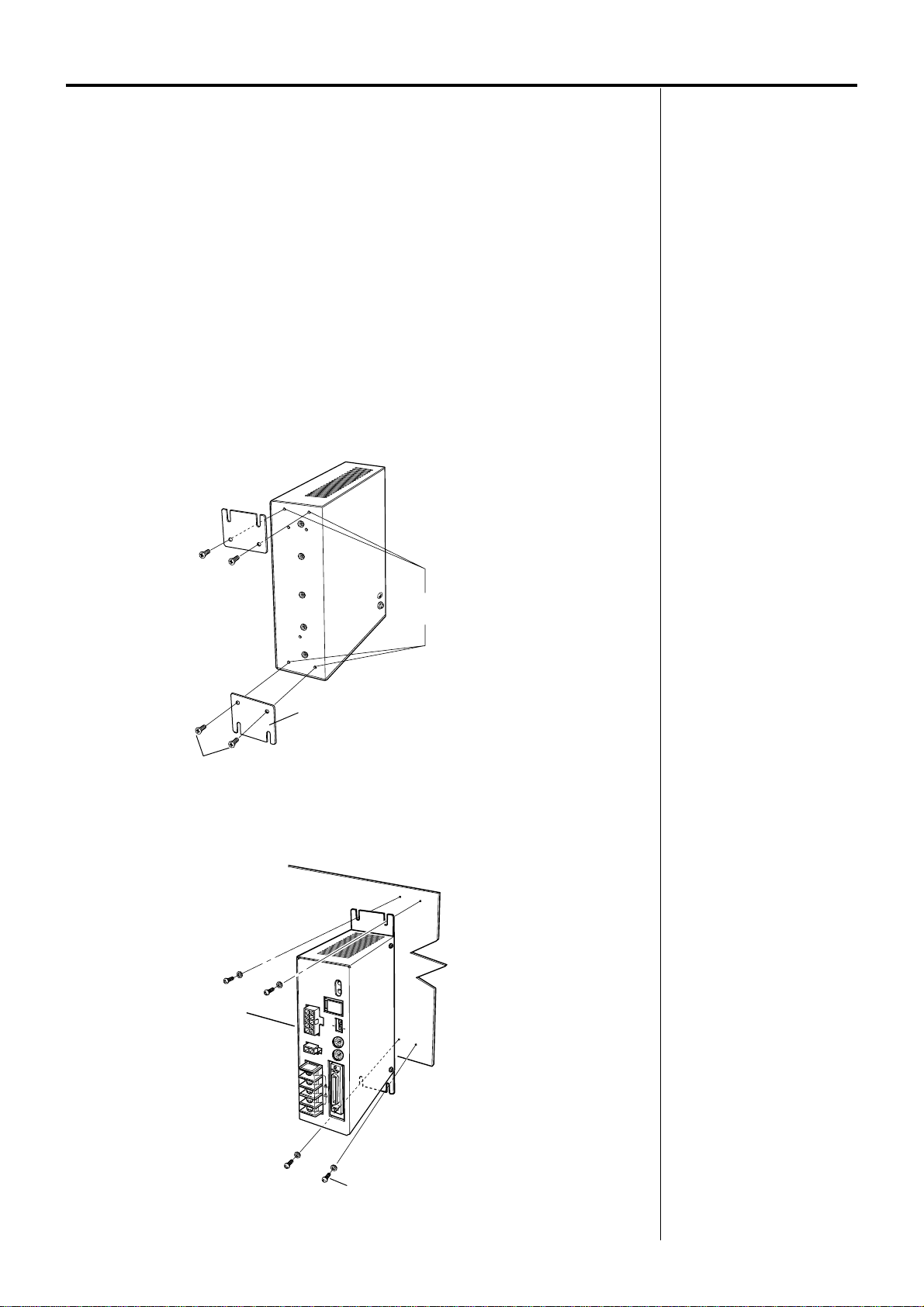

Installing the driver

Orientation

The driver is designed so that heat is dissipated via air convection and conduction through the

enclosure.

When installing the driver in an enclosure, it must be placed in perpendicular (vertical)

orientation using a DIN rail or driver mounting brackets.

How to install the driver

Install the driver on a flat metal plate having excellent vibration resistance and heat

conductivity.

In the presence of a great amount of vibration, do not use a DIN rail. Screw down the driver

directly through the use of driver mounting brackets.

If a DIN rail is to be used, use a DIN rail mounting plate (sold separately).

Using driver mounting brackets

1.Attaching the driver mounting brackets

Mounting holes for the driver

mounting brackets (M3, four locations)

Note

• Install the driver in an enclosure.

• Do not install any equipment

that generates a large amount

of heat near the driver.

• Check ventilation if the ambient

temperature of the driver

exceeds 50°C (122°F).

Note

• Do not use the mounting holes

(M3, four locations) for the driver

mounting brackets provided on

the back of the driver for any

purpose other than securing the

driver mounting brackets.

• Be sure to use the supplied

screws when securing the driver

mounting brackets.

Mounting brackets (two pieces)

Screws for driver mounting brackets M3 (provided)

Attach the driver mounting brackets to the four mounting holes provided in the back of the

driver, using optional screws for the driver mounting brackets (M3, four pieces).

2.Installing the driver

ASD24A-A

O

PER

ATIO

N

ALA

R

M

CN1

1000

500

X1

X

1

0

1P

2P

CURRENT

CN

2

M

O

TO

R

V.FIL

C

N

3

VEXTA

C

N

4

I/O

M4 (not supplied)

Install the driver by securing it with four bolts (M4, not supplied) through the four mounting holes

provided. Leave no gap between the driver and plate.

19

Page 20

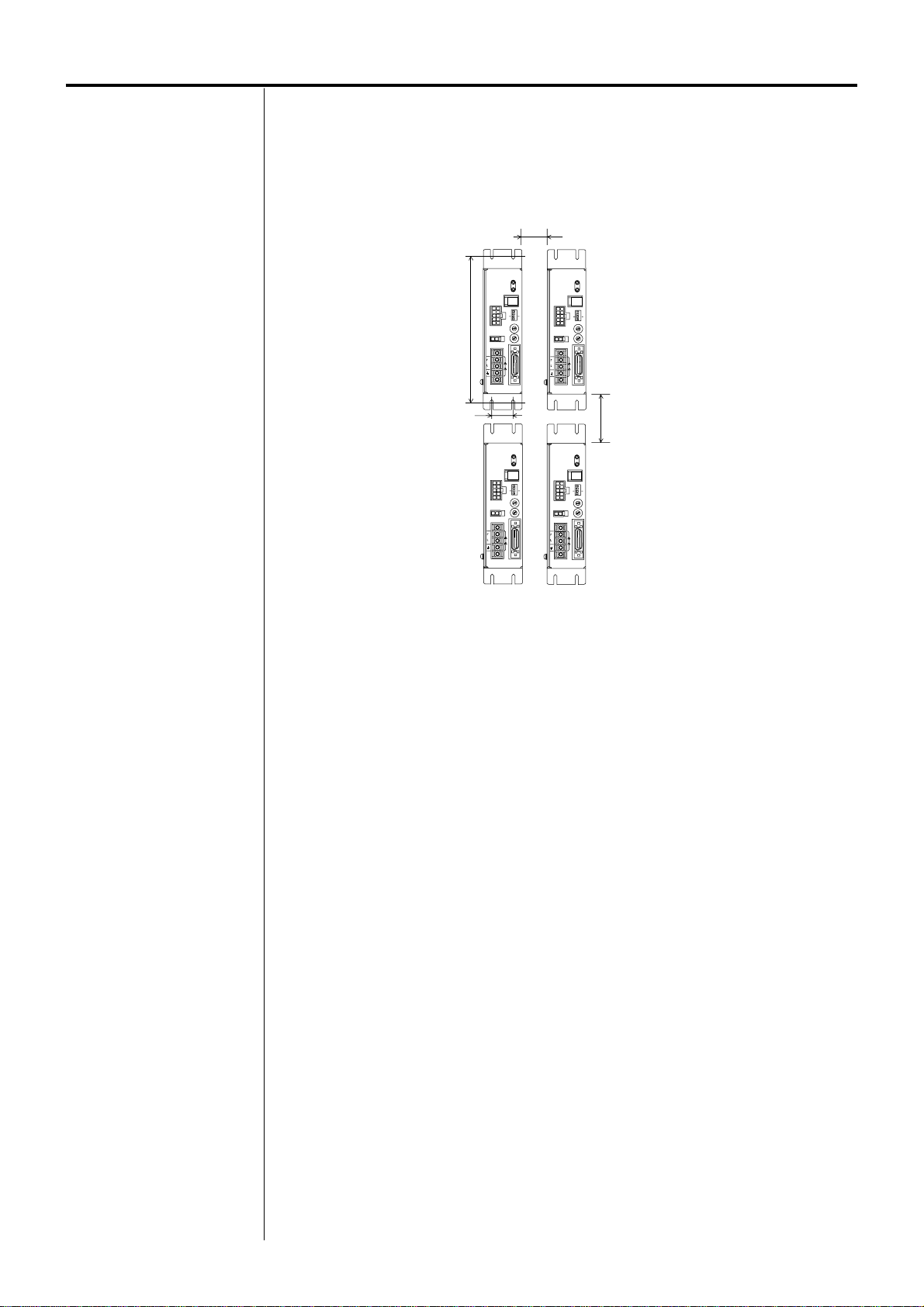

There must be a clearance of at least 25 mm (0.98 in.) in the horizontal and vertical directions,

respectively, between the driver and enclosure or other equipment within the enclosure.

When two or more drivers are to be installed side by side, provide 20 mm (0.79 in.) and 25 mm

(0.98 in.) clearances in the horizontal and vertical directions, respectively.

20 mm (0.79 in.) minimum

25 mm

(0.98 in.)

ASD24A-A

OPERATION

CN1

CN2

MOTOR

(7.09 in.)

CN3

L

100115V

~

N

180 mm

VEXTA

ASD24A-A

OPERATION

CN2

MOTOR

CN3

L

100115V

~

N

VEXTA

ASD24A-A

ALARM

500

1000

X1

X10

2P

1 2 3 4

1P

CURRENT

B

C

A

D

9

E

8

F

0

7

1

6

2

5

3

4

V.FIL

B

C

A

D

9

E

8

F

0

7

1

6

2

5

3

4

CN4

I

O

/

OPERATION

ALARM

CN1

500

1000

X1

X10

2P

1 2 3 4

1P

CURRENT

B

C

A

D

9

E

CN2

8

F

0

7

1

MOTOR

6

2

5

3

4

V.FIL

B

C

A

D

9

E

8

F

0

7

1

6

2

5

3

4

CN3

L

100115V

~

N

CN4

I

O

/

VEXTA

25 mm (0.98 in.) minimum

ASD24A-A

ALARM

CN1

1000

X1

1 2 3 4

1P

CURRENT

B

C

A

D

9

8

7

6

2

5

3

4

V.FIL

B

C

A

D

9

8

7

6

2

5

3

4

CN4

I

O

/

OPERATION

ALARM

CN1

500

X10

2P

E

F

0

1

E

F

0

1

500

1000

X1

X10

2P

1 2 3 4

1P

CURRENT

B

C

A

D

9

E

CN2

8

F

0

7

1

MOTOR

6

2

5

3

4

V.FIL

B

C

A

D

9

E

8

F

0

7

1

6

2

5

3

4

CN3

L

100115V

~

N

CN4

I

O

/

VEXTA

20

Page 21

Mounting to DIN rail

Use a DIN rail 35 mm (1.38 in.) wide to mount the driver.

1.Attach the DIN rail mounting plate (model number: PADP01) to the back of the driver using

the screws supplied with the plate.

DIN rail mounting plate

Mounting holes for the DIN rail

mounting plate (M3, three locations)

Mounting screws (M3)

2.Pull the DIN lever down, engage the upper hooks of the DIN rail mounting plate over the DIN

rail, and push the DIN lever until it locks in place.

DIN rail

Note

• Do not use the mounting holes

(M3, three locations) for the DIN

rail mounting plate provided in

the back of the driver for any

purpose other than securing the

DIN rail mounting plate.

• Be sure to use the supplied

screws when securing the DIN

rail mounting plate. The use of

screws that would penetrate

3 mm (0.12 in.) or more through

the surface of the driver may

cause damage to the driver.

DIN lever

3.Removing from DIN rail

Pull the DIN lever down until it locks using a flat blade-parallel tip type screwdriver, and lift

the bottom of the driver to remove it from the rail.

ASD24A-A

OPERATION

ALARM

CN1

500

1000

X1

X10

2P

1 2 3 4

1P

CURRENT

C

B

D

A

E

9

CN2

F

8

0

7

1

MOTOR

6

2

5

3

4

V.FIL

C

B

D

A

E

9

F

8

0

7

1

6

2

5

3

4

CN3

L

100115V

~

N

VEXTA

CN4

I

O

/

End plate

Note

• Use force of about 10 to 20 N

(2.2 to 4.41 lb.) to pull the DIN

lever to lock it. Excessive force

may damage the DIN lever.

• Use an end plate (not supplied)

to secure the driver.

21

Page 22

Installing and wiring in compliance with EMC directive

General

EMC directive (89/336/EEC, 92/31/EEC)

The AS series has been designed and manufactured for incorporation in general

industrial machinery. The EMC directive requires that the equipment incorporating this product

comply with these directives.

The installation and wiring method for the motor and driver are the basic methods that would

effectively allow the customer’s equipment to be compliant with the EMC directive.

The compliance of the final machinery with the EMC directive will depend on such factors as

the configuration, wiring, layout and risk involved in the control-system equipment and

electrical parts. It therefore must be verified through EMC measures by the customer of the

machinery.

Applicable standards

EMI

Emission Tests EN50081-2

Radiated Emission Test EN55011

Conducted Emission Test EN55011

EMS

Immunity Tests EN61000-6-2

Radiation Field Immunity Test IEC61000-4-3

Electrostatic Discharge Immunity Test IEC61000-4-2

Fast Transient/Burst Immunity Test IEC61000-4-4

Conductive Noise Immunity Test IEC61000-4-6

Surge Immunity Test IEC61000-4-5

Voltage Dip Immunity Test IEC61000-4-11

Voltage Interruption Immunity Test IEC61000-4-11

Note

When measuring dielectric

strength of the equipment, be

sure to remove the surge

arrester, or the surge arrester

may be damaged.

22

Installing and wiring

Effective measures must be taken against the EMI that the AS series may give to

adjacent control-system equipment, as well as the EMS of the AS series itself, in

order to prevent a serious functional impediment in the machinery.

The use of the following installation and wiring methods will enable the AS series

to be compliant with the EMC directive (the aforementioned compliance standards).

Connecting mains filter for power source line

Connect a mains filter in the AC input line to prevent the noise generated in the driver from

propagating externally through the power-source line.

Use a mains filter or equivalent as below table.

Manufacturer

Schaffner Electronik AG

EPCOS

Install the mains filter as close to the driver as possible, and use cable clamps and other means

to secure the input and output cables firmly to the surface of the enclosure. Connect the ground

terminal of the mains filter to the grounding point, using as thick and short a wire as possible.

Do not place the AC input cable (AWG18: 0.75 mm

cable (AWG18: 0.75 mm

the enclosure’s internal noise is directly coupled to the power-supply cable by means of stray

capacitance.

Connecting surge arrester

Use a surge arrester or equivalent as below table.

Manufacturer

OKAYA ELECTRIC INDUSTRIES CO., L TD

PHOENIX CONTACT GmbH & Co. KG

Power supply for electromagnetic brake (for electromagnetic-brake motor only)

If an external DC power source is required for the use of the electromagnetic brake, use a DC

power source that complies with the EMC directive.

Use a shielded cable for wiring, and keep the wiring and grounding as short as possible. Refer

to “Wiring the signal cable” for details on how to ground the shielded cable.

Single-phase 100-115 V

Single-phase 200-230 V

FN2070-10-06

B84113-C-B110

2

2

or more). Parallel placement will reduce mains-filter effectiveness if

or more) parallel with the mains-filter output

Single-phase 100-115 V

PT2-PE/S120AC-ST

Three-phase 200-230 V

FN251-8-07

-

Single-phase 200-230 V

R·A·V-781BWZ-2A

PT2-PE/S230AC-ST

VAL-MS 230 VF ST

Page 23

How to ground

The cable used to ground the driver, motor and mains filter must be as thick and short to the

grounding point as possible so that no potential difference is generated. Choose a large, thick

and uniformly conductive surface for the grounding point.

How to ground the driver

Single-phase 100/200 V input

Three-phase 200 V input

Ground the power-supply

terminal using its ground

terminal.

ASD24A-A

CN2

MOTOR

C

L

-

100

V

115

~

N

VEXTA

OPERATION

ALARM

CN1

0

0

5

4

3

0

0

1

0

X

0

1

2

1

1

X

ON

P

2

P

1

D

E

C

F

0

B

1

A

2

CURRENT

9

3

8

4

7

5

6

D

E

C

F

0

B

1

V.FIL

A

2

9

3

8

4

7

5

6

3

N

Use the protective earth

terminal located on the side

4

CN

I/O

of the driver.

ASD12A-S

CN2

MOTOR

3

N

C

L1

L2

L3

VEXTA

CN1

OPERATION

CURRENT

ALARM

0

0

5

4

3

0

0

1

0

X

0

1

2

1

1

X

ON

P

2

P

1

D

E

C

F

0

B

1

A

2

9

3

8

4

7

5

6

D

E

C

F

0

B

1

V.FIL

A

2

9

3

8

4

7

5

6

4

CN

I/O

How to ground the motor

Scrape the paint away from the mounting flange and connect the grounding cable along with a

set screw to the grounding point, using an inner-clip washer.

Wiring the signal cable

Use a shielded cable of AWG24 (0.2 mm

keep it as short as possible. Contact the nearest sales office for a shielded cable (sold separately).

To ground a shielded cable, use a metal clamp or similar device that will maintain contact with

the entire circumference of the shielded cable. Attach a cable clamp as close to the end of the

cable as possible, and connect it to an appropriate grounding point as shown in the figure.

2

) or more in diameter for the driver signal cable, and

Shielded cable

Cable clamp

Others

• Connect the motor, driver and other peripheral control equipment directly to the grounding

point so as to prevent a potential difference from developing between grounds.

• When relays or electromagnetic switches are used together with the system, use mains filters

and CR circuits to suppress surges generated by them.

• Keep cables as short as possible without coiling and bundling extra lengths.

• Place the power cables such as the motor and power-supply cables as far apart [100 to

200 mm (3.94 to 7.87 in.)] as possible from the signal cables. If they have to cross, cross

them at a right angle.

Place the AC input cable and output cable of a mains filter separately from each other.

• If an extension cable is required between the motor and driver, it is recommended that an

optional extension cable (sold separately) be used, since the EMC measures are conducted

using the Oriental Motor extension cable.

23

Page 24

Example of motor and driver installation and wiring

Power input

L

N

Motor

F

D

A

G

B

F

F

Driver

ASD24A-A

OPERATION

C

C

ALARM

CN1

500

1000

X1

X1

TEST

NORM.

2P

1 2 3 4

1P

CURRENT

C

D

B

A

E

9

F

CN2

8

0

7

1

MOTOR

6

2

5

3

4

V.FIL

C

D

B

A

E

9

F

8

0

7

1

6

2

5

3

4

CN3

L

100-

~

115V

N

CN4

I

O

/

VEXTA

E

C

D

A: Motor cable

B: Mains filter

C: Cable clamp

D: Protective earth cable

E: Signal cable

F: Power cable

G: Surge arrester

Note

Do not come close to or touch

the driver while the power is on.

24

Precautions about static electricity

Static electricity may cause the driver to malfunction or suffer damage. Be careful when

handling the driver with the power on.

Always use an insulated screwdriver to adjust the driver’s built-in motor current switch.

Page 25

Connection

This section covers the methods and examples of connecting and grounding the driver, motor,

power and controller, as well as the control input/output.

Connection example for a standard type

Motor cable or extension cable (sold separately)

Motor

Connect to

CN2

Single-phase

100-115 V

50/60 Hz

+

10%

−

15%

Power input

Driver

OPERATION

ALARM

CN1

1000

X1

1P

CURRENT

CN2

MOTOR

V.FIL

CN3

L

100115V

~

N

VEXTA

Protective earth

500

X10

2P

1 2 3 4

C

D

B

E

A

9

F

8

0

7

1

6

2

5

3

4

C

D

B

E

A

9

F

8

0

7

1

6

2

5

3

4

CN4

I

O

/

Control input/output

Controller

Connect to CN4

Connection example for an electromagnetic-brake type

Power supply for an electromagnetic brake

+

24 VDC±5%

0.3 A or more

Control input/output

Controller

Connect to CN4

Extension cable, electromagnetic-brake type

(sold separately)

Motor

Connect to CN2

Single-phase

100-115 V

50/60 Hz

+

10%

−

15%

Power input

Orange/black

Gray

Varistor (supplied)

Driver

OPERATION

ALARM

CN1

1000

X1

1P

CURRENT

CN2

MOTOR

V.FIL

CN3

L

100115V

~

N

VEXTA

Protective earth

C

B

A

9

8

7

6

5

4

C

B

A

9

8

7

6

5

4

CN4

I

/

D

3

D

3

O

500

X10

2P

1 2 3 4

E

F

0

1

2

E

F

0

1

2

Switch

Note

Be sure to use the extension

cable for the electromagneticbrake type (sold separately) to

connect the motor with an

electromagnetic brake.

25

Page 26

Note

Be sure to use the same voltage

for C.OFF, ×10 and ACL inputs

and TIM1/TIM2, ASG1/ASG2

and BSG1/BSG2 outputs.

Connecting both 5 and 24 VDC

power supplies may damage the

driver and power supplies.

Connecting the driver

• Either 5 or 24 VDC is selected as a signal voltage for the C.OFF input, ×10 input and ACL input.

• The TIM1/TIM2 outputs, ASG1/ASG2 outputs and BSG1/BSG2 outputs require a 5 or 24 VDC power.

In case of current sourcing inputs and current sinking outputs

When ACL, resolution select, C.OFF controller power supply is 5 VDC.

Controller

+30 V maximum

+5 V

Twisted pair cable

or shielded cable

Vcc+5 V input

CN4

CW input

CW input

CCW input

CCW input

ACL input

ACL input

×10 input

×10 input

C.OFF input

C.OFF input

GND

ALARM output

ALARM output

END output

END output

TIM1 output

GND

ASG1 output

GND

BSG1 output

GND

Driver

11

12

9

10

21

22

31

32

33

34

1

2

25

26

29

30

23

24

15

16

13

14

Photocoupler input

5 VDC Input current 7~20 mA

Photocoupler input

5 VDC Input current 16 mA

Photocoupler/open-collector output

30 VDC, maximum

Output current 15 mA, maximum

Transistor/open-collector output

30 VDC, maximum

Output current 15 mA, maximum

TIM2 output

TIM2 output

ASG2 output

ASG2 output

BSG2 output

BSG2 output

27

28

19

20

17

18

Line-driver output

26C31 or equivalent

When ACL, resolution select, C.OFF controller power supply is 24 VDC.

CN4

11

12

10

22

32

34

25

26

29

30

23

24

15

16

13

14

Driver

9

3

2

Photocoupler input

5 VDC Input current 7~20 mA

Photocoupler input

24 VDC Input current 5 mA

Photocoupler/open-collector output

30 VDC, maximum

Output current 15 mA, maximum

Transistor/open-collector output

30 VDC, maximum

Output current 15 mA, maximum

Controller

+24 V

+30 V maximum

+5 V

Twisted pair cable

or shielded cable

Vcc+24 V input

ALARM output

ALARM output

CW input

CW input

CCW input

CCW input

ACL input

×10 input

C.OFF input

GND

END output

END output

TIM1 output

GND

ASG1 output

GND

BSG1 output

GND

26

TIM2 output

TIM2 output

ASG2 output

ASG2 output

BSG2 output

BSG2 output

27

28

19

20

17

18

Line-driver output

26C31 or equivalent

Page 27

In case of current sinking inputs and current sourcing outputs

Controller

+5 V

Twisted pair cable

or shielded cable

Vcc+5 V input

CW input

CW input

CCW input

CCW input

ACL input

ACL input

×10 input

×10 input

C.OFF input

C.OFF input

GND

CN4

Driver

11

12

9

10

21

22

31

32

33

34

1

2

Photocoupler input

5 VDC Input current 7~20 mA

Photocoupler input

5 VDC Input current 16 mA

Note

Be sure to use the same voltage

for C.OFF, ×10 and ACL inputs

and TIM1/TIM2, ASG1/ASG2

and BSG1/BSG2 outputs.

Connecting both 5 and 24 VDC

power supplies may damage the

driver and power supplies.

∗ GND of TIM1, ASG1, BSG1

is common.

The output type of these signals

is current sinking outputs.

See page 39 for the wiring.

ALARM output

ALARM output

END output

END output

TIM1 output

GND

ASG1 output

GND

BSG1 output

GND

TIM2 output

TIM2 output

ASG2 output

ASG2 output

BSG2 output

BSG2 output

25

26

29

30

23

24

15

16

13

14

27

28

19

20

17

18

Photocoupler/open-collector output

30 VDC, maximum

Output current 15 mA, maximum

Transistor/open-collector output

30 VDC, maximum

Output current 15 mA, maximum

Line-driver output

26C31 or equivalent

27

Page 28

Note

• Furnish a power supply capable

of supplying adequate driver

input current.

If the current capacity is

insufficient, the transformer may

be damaged, or the motor may

run erratically due to a drop in

torque.

• Do not run the driver’s power

cable through a conduit

containing other power lines or

motor cables.

• After shutting down the power,

wait at least 10 seconds before

turning it back on, unplugging,

or plugging in the motor’s cable

connector.

Connecting to the power supply

Connect the power cable to the L and N terminals or the L1, L2 and L3 terminals of the

power-supply terminals located on the driver.

For single-phase 100-115 V unit

Connect the live side of the single-phase 100-115 V power cable to the L terminal and the

neutral side to the N terminal.

Connect the terminal to the grounding point of the power source.

L

Single-phase

100-115 V

50/60 Hz

Use a power supply capable of supplying the power/current capacity as shown below.

Unit name

Power/current capacity

AS66AA-T

AS66MA-T

AS66AA-P

AS66MA-P

AS66AA-N

AS66MA-N

AS66AA2-H

Single-phase 100-1 15 V

+10%

-

15%

AS66MA2-H

AS66AA-H

AS66MA-H

AS66AA

AS66MA

AS69AA

AS69MA

Single-phase 100-115 V

+10%

-

15%

AS98AA-T

AS98MA-T

AS98AA-P

AS98MA-P

AS98AA-N

AS98MA-N

Single-phase 100-1 15 V

+10%

-

15%

AS98AA-H

AS98MA-H

AS98AA

AS98MA

AS911AA

The square box in the unit model will contain a value representing the gear ratio.

Single-phase 100-115 V

+10%

-

15%

100115V

~

N

5 A or more

6.4 A or more

6 A or more

6.5 A or more

28

Page 29

For single-phase 200-230 V unit

Connect the live side of the single-phase 200-230 V power cable to the L terminal and the

neutral side to the N terminal.

Connect the terminal to the grounding point of the power source.

L

Single-phase

200-230 V

50/60 Hz

200230V

~

N

Use a power supply capable of supplying the power/current capacity as shown below.

Unit name

Power/current capacity

AS66AC-T

AS66MC-T

AS66AC-P

AS66MC-P

AS66AC-N

AS66MC-N

AS66AC2-H

Single-phase 200-230 V

+10%

3 A or more

-

15%

AS66MC2-H

AS66AC-H

AS66MC-H

AS66AC

AS66MC

AS69AC

AS69MC

Single-phase 200-230 V

+10%

3.9 A or more

-

15%

AS98AC-T

AS98MC-T

AS98AC-P

AS98MC-P

AS98AC-N

AS98MC-N

Single-phase 200-230 V

+10%

3.5 A or more

-

15%

AS98AC-H

AS98MC-H

AS98AC

AS98MC

AS911AC

Single-phase 200-230 V

The square box in the unit model will contain a value representing the gear ratio.

+10%

4.5 A or more

-

15%

29

Page 30

For three-phase 200-230 V unit

Connect the U, V and W phase lines of the three-phase 200-230 V power cable to the L1, L2

and L3 terminals, respectively.

Three-phase

200-230 V

50/60 Hz

L1

L2

L3

Use a power supply capable of supplying the power/current capacity as shown below.

Unit name

Power/current capacity

AS66AS-T

AS66MS-T

AS66AS-P

AS66MS-P

AS66AS-N

AS66MS-N

AS66AS2-H

Single-phase 200-230 V

+10%

1.5 A or more

-

15%

AS66MS2-H

AS66AS-H

AS66MS-H

AS66AS

AS66MS

AS69AS

AS69MS

Single-phase 200-230 V

+10%

2.2 A or more

-

15%

AS98AS-T

AS98MS-T

AS98AS-P

AS98MS-P

AS98AS-N

AS98MS-N

Single-phase 200-230 V

+10%

1.9 A or more

-

15%

AS98AS-H

AS98MS-H

AS98AS

AS98MS

AS911AS

The square box in the unit model will contain a value representing the gear ratio.

Single-phase 200-230 V

+10%

2.4 A or more

-

15%

30

T erminal screw size and cable size for power connection

Screw size: M3

Tightening torque: 0.8 to 1.0 N·m (113 to 141 oz-in)

Cable size capacity: AWG18 (0.75 mm

2

)

Use round, insulated crimp terminals for connection.

[Unit: mm (inch)]

Ø3.2 (0.13 DIA.) minimum

9 (0.35) minimum

6.2 (0.24) maximum

Page 31

Connecting the motor

Standard type

Plug the connector of the motor cable or the extension cable into the driver’s motor connector

(CN2).

Push the plug until it clicks to ensure a solid connection.

ASD24A-A

OPERATION

M

LAR

A

1

CN

500

4

3

X10

1000

2

1

X1

N

O

2P

1P

D

E

C

F

0

B

1

A

2

CURRENT

9

3

8

4

7

5

6

CN2

D

E

C

F

0

B

1

V.FIL

MOTOR

A

2

9

3