Page 1

VEXILAR FL SERIES BRUSH REPLACEMENT KIT

Things Included Tools Needed Requirement

1 - Brush Assembly

3 - Slip Rings

1 – 1.5mm Allen Driver

INSTRUCTIONS

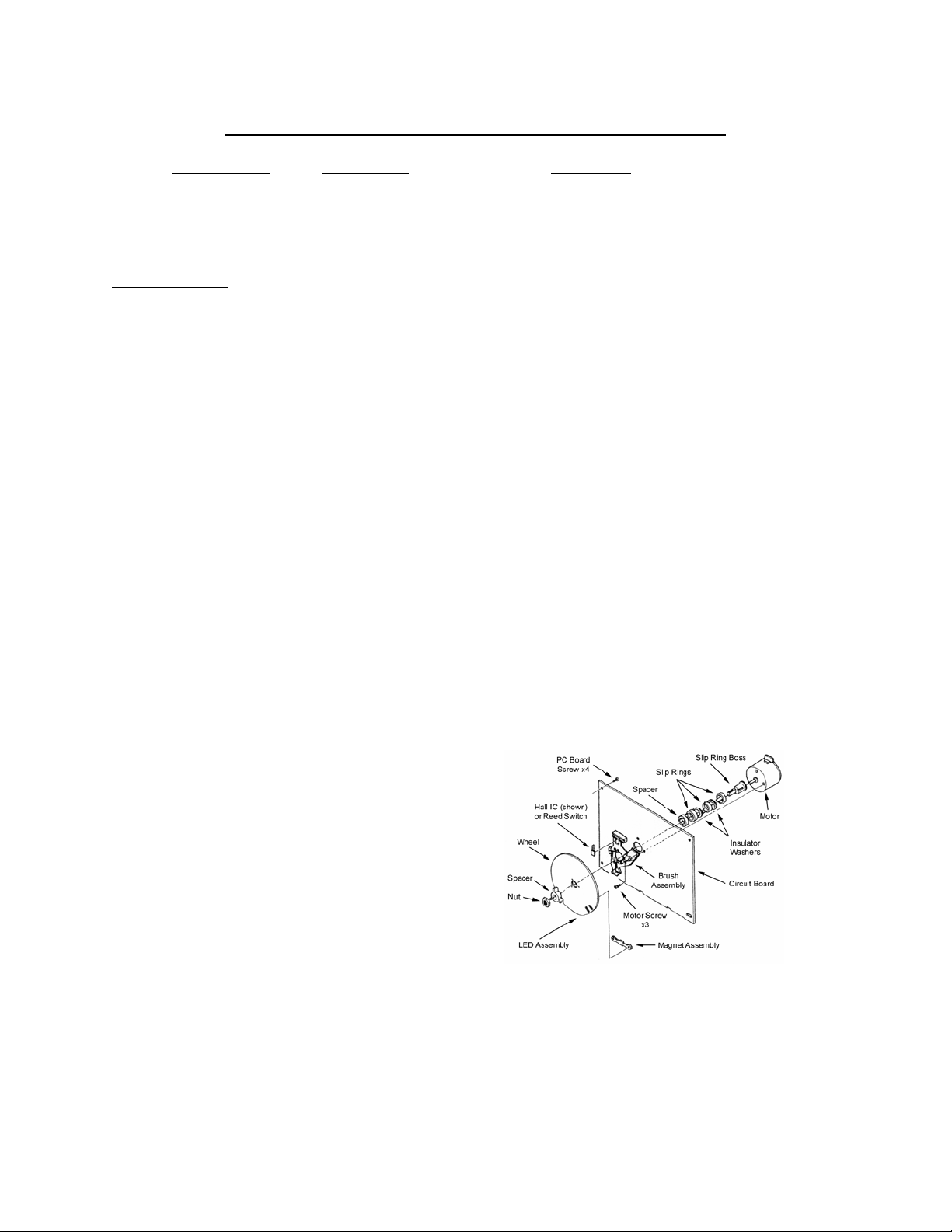

1. Remove both screws from the rear case.

2. Remove the rear case by unplugging the power jack, transducer jack, and alarm jack (if applicable).

3. Remove the control knobs using the 1.5mm allen driver.

4. Remove the four phillips screws from the control board corners. Remove the control board from the front

case.

5. Clean the excess brush dust from the front case. Wash it, inside and out, with water, common dish detergent

and a soft brush. Wipe or blow it dry.

6. Remove the 9mm nut that is holding on the wheel, unsolder the three slip ring tabs from the wheel. Remove

the wheel and set it aside.

7. Unsolder the wires from the motor. Be sure to mark the wires so they go back on the same way. Unscrew

the three small philip screws holding the motor.

8. Notice the component sitting on top of the assembly. This is either a Reed Switch or a Hall IC. If it’s a Reed

Switch, it must be moved out of the way prior to removing the old brush assembly. Heat one of the two

solder joints and lift the Reed Switch up far enough so the brush assembly can be pulled out from

underneath it. If you have the Hall IC, they are glued onto the brush assembly. Simply break it free from the

brush assembly and bend it up slightly.

9. Remove the old brush assembly by heating each point where the assembly is soldered to the circuit board

and pulling up on the assembly while the joint is still hot.

10. You can now wipe down or blow off the control board to remove brush dust. Clean the wheel also. Do not

wash with water.

11. Bend and cut the tabs on your new brush assembly to make it look like your old brush assembly.

12. Remove the old slip rings and insulators from the slip ring boss. Take a new slip ring and install it into the

longest slot, then place an insulator washer on top. Do same for the next longest slot and again for the

shortest slot. Place the spacer collar on top. Cut the tallest two slip ring tabs down to the level of the shortest

one.

13. Set the new brush assembly into position and solder it down. Reinstall the motor making sure you move

each brush out of the way as you insert the motor into place. Tighten it and the brush assembly down with

the three small philips screws. Reheat each solder connection to insure there is no excess pressure on the

solder joints.

14. Put the Reed Switch or Hall IC back into position.

15. Reinstall the wheel onto the slip ring boss shaft.

Make sure that the flat spot on the shaft is facing to

the left of the wheel, at the 8 O’clock position, and

the LED assembly on the wheel is at the 12 O’clock

position.

16. Bend down the tabs, install the spacer, and then

the nut. Make sure the three bumps on the bottom

of the spacer fit into the three holes on the wheel.

Tighten the nut down securely, but do not over

tighten so that the spacer becomes compressed.

Solder the slip ring tabs to the wheel and solder the

wires back onto the motor. Rotate the wheel slowly

by hand and observe the clearance between the magnet assembly on the underside of the wheel and the

Reed Switch or Hall IC. Ideally, they should come as close to each other as possible without making contact.

17. Reinstall the control board into the front case with the four philips screws. Put the rear case back on, install

the power jack, transducer jack, and alarm jack (if applicable). Secure the rear case using the two remaining

screws. Put the control knobs back on making sure the white line is pointing to the correct position.

18. Connect the unit to power and turn it on. No transducer needs to be connected. Make sure you have all

three colors at the zero position. Let the unit run for about 30 minutes at room temperature to let the new

brushes seat properly.

Philips Screw Driver

Soldering Iron and Electrical Solder

9mm Wrench or Socket

Desoldering Tool

If you have any questions about this procedure, please contact us

by telephone at 952-884-5291 or email at service@vexilar.com.

In order to perform this brush

replacement, you need to have basic

soldering skills. If you are not sure you

can complete the replacement, send

your unit and this kit to the Vexilar

Service Department.

Loading...

Loading...